#Industrial Valves Manufacturer in India

Explore tagged Tumblr posts

Text

Globe Valve Manufacturer & Exporter

Flow Marshal Valves stands as a beacon of excellence in the realm of valve manufacturing, renowned for our exceptional quality globe valves. As a premier globe valve manufacturer in India, we pride ourselves on our unwavering commitment to innovation, precision engineering, and customer satisfaction. With a steadfast focus on delivering products of the highest caliber, we have earned a distinguished reputation as a trusted provider of industrial valve solutions.

Our extensive range of globe valves caters to a diverse array of industrial applications, including oil and gas, petrochemical, power generation, water treatment, and more. Whether you require globe valves for high-pressure environments or corrosive fluids, Flow Marshal Valves offers solutions tailored to meet your specific needs and operational requirements. At Flow Marshal Valves, we understand the critical role that reliability and durability play in industrial operations.

As a globe valve exporter in India, we take great pride in our ability to deliver superior products to customers around the globe. Our commitment to quality, timely delivery, and competitive pricing has positioned us as the preferred choice for businesses seeking reliable valve solutions for their operations. In addition to standard globe valves, Flow Marshal Valves also specializes in providing customized valve solutions to address unique project requirements. Quality assurance is at the heart of our operations at Flow Marshal Valves.

#Best Globe Valve Manufacturers in India#Globe Valve Exporter in India#Top Industrial Globe Valve Exporters in Bahrain

0 notes

Text

Top Industrial Valve Manufacturers in India

We are trusted and leading industrial valve manufacturers in India and global exporters of industrial applications. Headquartered in Coimbatore, India, and established in 2013 by an industry specialist, our company has achieved a higher position as a top valve manufacturer in India with high quality, durability, and versatility apart from buying the finest industrial valves at the global level.

1. Control Valve - We are one of the top control valve manufacturers in India. It fluid flow or pressure by varying the size of the flow passage based on signals from a controller. It is essential in maintaining the desired process conditions in industries like chemical and oil & gas.

We provide valves in the following description

1. Available Materials: Ductile Iron, Cast iron (WCB, WCC, WC6), LCC, LCB, Stainless Steel (SS316, SS304), Super Duplex (F51, F53, F55).

2. Class: 150 to 2500.

3. Nominal Pressure: PN10 to PN450.

4. Medium: Air, Water, Chemical, Steam, Oil.

5. Operations: Electric Actuated and Pneumatic Operated.

6. Size: 1/2”- 24”.

7. Ends: Flanged, butt weld, socket weld, threaded.

Electric Actuator Details:

1. Torque: 3 – 9 nm.

2. Operating pressure: 8 Bar.

3. Port Connection: NPT1.4”.

4. Mounting Base: ISO5211.

5.Temperature: -20°C to +80°C.

Pneumatic Actuator Configuration:

1.4-20 amp.

2. Pneumatic single-acting actuators.

3. Pneumatic double-acting actuators.

4. Pneumatic rotary actuators.

5. Pneumatic Scotch and Yoke actuators.

6. Pressure: 228 bar.

Temperature Ranges:

1.Standard: -4°F to 200°F (-20°C to 93°C).

2.Low: -40°F to 176°F (-40°C to 80°C).

3.High: 0°F to 300°F (-18°C to 149°C).

2. Cryogenic Valve - We are famous for our design and the best cryogenic valve manufacturers in India. It is designed to operate at extremely low temperatures and is used in the transport and storage of liquefied gases like nitrogen, oxygen, and LNG. They ensure safe control and isolation in cryogenic systems.

We supply valves in the following description:

1.Materials: SS304, SS316, CF8M, CF8, F51, F55, F53, WCB, WC6, WCC, LCB, LCC.

2. Class: 150 to 800.

3. Nominal Pressure: PN25 to PN100.

4. Size: 1/2” to 24”.

5. Operations: Lever Operated, Gear Operated, Handwheel Operated, Electric Actuated, and Pneumatic Actuated.

6. End Connection: Buttweld, Threaded or welded, lug, and wafer

3. Pressure Reducing Valve - It is one of the largest pressure-reducing valve manufacturers in India. It automatically lowers incoming pressure to a desired downstream level, ensuring safe and consistent pressure for sensitive equipment. It is widely used in water distribution and gas systems

Description:

1. Materials: Ductile Iron, WCB, WCC, WC6, LCB, LCC, SS304, SS316, Cast iron

2. Size: 1/2″ to 24″.

3. Nominal Pressure: PN10 to PN100.

4. Class: 150 to 600.

5. Ends: Threaded, Buttweld, Socket weld, Flanged

4. Safety Valve - The leading Safety Valve Manufacturers in India. It opens to release pressure when it exceeds a preset limit, protecting equipment from overpressure damage. It is commonly used in steam boilers, pressure vessels, and pipelines.

Description:

1. Body Material: Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] , WCB, WC6, SS304, SS316, DUPLEX STEEL.

2. Class – 150 – 2500

3. PN 10 – PN 450

4. Size – �� – 24”

5. Ends- Butt welded, Socket welded, Flanged, Threaded

5. Check Valve - We are the largest check valve manufacturers in India that allow liquid to flow in one direction and prevent backflow, protecting systems from damage caused by reverse flow. It is used in applications like water systems, oil pipelines, and pumps.

Description:

1. Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), Duplex and Super duplex steel [F51, F53, F55] Forged Steel A105, A105N, F11, F22, F304, F316, F91] Alloy20, Hastelloy, ALBR.

2. Size- ½” – 80”

3. Class-150 – 2500; PN10 – PN-450

4. Ends-threaded, socket weld, butt weld, flanged, lug, wafer

#industrial valve manufacturer#gate valve manufacturers#control valve manufacturers in India#cryogenic valve manufacturers in India#pressure-reducing valve manufacturers in India#Safety Valve Manufacturers in India#check valve manufacturers in India

0 notes

Text

Winging It: Best Butterfly Valve Manufacturers in Ahmedabad

Butterfly Valve Manufacturers in Ahmedabad – Explore Ahmedabad’s leading Butterfly Valve manufacturers & suppliers. Get quality valves for industrial applications from Gold Techno Casting.

Google Map:--> https://maps.app.goo.gl/HPDJtfx5r7s11pun7

Butterfly Valve Manufacturers in Ahmedabad, Butterfly Valve Manufacturer & Supplier in Ahmedabad, Butterfly Valves in Ahmedabad, Cast Iron Butterfly Valve Manufacturer From Ahmedabad, Butterfly Valve, Butterfly Valve Manufacturer in Ahmedabad, Top Butterfly Valve Manufacturers in Ahmedabad, Cast Iron Teflon Seated Butterfly Valve in Ahmedabad, Pneumatic Actuator Wafer Type Butterfly Valve, Butterfly Valve Manufacturer & Supplier in Ahmedabad, India, Industrial Butterfly Valves Manufacturer in Ahmedabad, India, Top Damper Butterfly Valve Manufacturers in Ahmedabad, PP Butterfly Valve Manufacturer from Ahmedabad, Cast Iron Butterfly Valve Manufacturer from Ahmedabad, Ahmedabad, Gujarat, India, www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Butterfly Valve Manufacturers in Ahmedabad#Butterfly Valve Manufacturer & Supplier in Ahmedabad#Butterfly Valves in Ahmedabad#Cast Iron Butterfly Valve Manufacturer From Ahmedabad#Butterfly Valve#Butterfly Valve Manufacturer in Ahmedabad#Top Butterfly Valve Manufacturers in Ahmedabad#Cast Iron Teflon Seated Butterfly Valve in Ahmedabad#Pneumatic Actuator Wafer Type Butterfly Valve#India#Industrial Butterfly Valves Manufacturer in Ahmedabad#Top Damper Butterfly Valve Manufacturers in Ahmedabad#PP Butterfly Valve Manufacturer from Ahmedabad#Cast Iron Butterfly Valve Manufacturer from Ahmedabad#Ahmedabad#Gujarat#www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

The Essential Role of Valves in the Oil and Gas Industry

In the oil and gas industry, efficiency, reliability, and safety are paramount. Valves are essential components that play a critical role in various processes throughout the industry. From controlling flow rates to regulating pressure, valves are indispensable in extracting, transporting, and refining oil and gas. In this article, we’ll explore the different types of valves commonly used in the industry, their functions, and their importance in maintaining operational efficiency.

What are Valves?

A valve is a mechanical device that regulates the flow of liquids, gases, or slurries by opening, closing, or partially obstructing passageways. Various types of valves are utilized in oil and gas operations, including:

Globe Valves: Best for throttling flow.

Ball Valves: Ideal for quick shut-off applications.

Gate Valves: Primarily used for on/off control.

Check Valves: Prevent backflow.

Importance of Valves in Oil and Gas

Valves control and regulate flow and pressure, impacting overall system performance. They ensure:

Safety: By preventing leaks and controlling the release of dangerous substances.

Efficiency: By optimizing flow rates and minimizing energy costs.

Process Control: By enabling precise manipulation of flow conditions.

In the oil and gas industry, where environmental incidents can have dire consequences, reliable valve operation is crucial.

Types of Valves Used in the Industry

Ball Valves: Known for their durability and the ability to provide a tight seal. Ball valves are versatile and can handle high-pressure applications, making them a popular choice in both upstream (extraction) and downstream (refining) operations.

Gate Valves: Suitable for applications where minimal pressure drop is necessary. They are primarily used for on/off control rather than throttling, making them ideal for high-flow environments.

Check Valves: These valves allow flow in one direction only, preventing backflow. They are vital in protection against reverse flow situations that can cause significant damage to equipment.

Control Valves: Essential for regulating flow and ensuring optimal performance. Control valves adjust flow rates based on varying process conditions, maintaining desired operational parameters.

Innovations and Technologies in Valve Manufacturing

The oil and gas industry continually seeks advancements to enhance efficiency and safety. Innovations in valve manufacturing include smart valves equipped with sensors and IoT technology, allowing for real-time monitoring and diagnostics. These valves can transmit data regarding pressure, temperature, and flow rates, enabling predictive maintenance and reducing unexpected downtime.

New materials and designs are also emerging, such as corrosion-resistant alloys and composite materials that significantly improve the longevity and reliability of valves in harsh environments.

Conclusion

Valves are critical components in the oil and gas industry, influencing safety, efficiency, and operational effectiveness. With ongoing advancements in technology and design, the future looks promising for these essential devices. Ensuring the right valve type for each application and embracing innovation will be key to maintaining operational success within the industry.

0 notes

Text

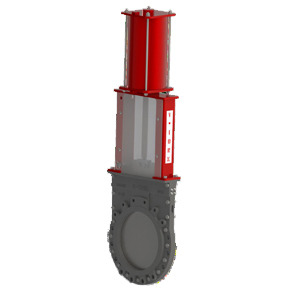

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

Leading Valves and Fittings Manufacturers, Suppliers, and Exporters in India - Mcneil Instrument

Mcneil Instruments Inc. is a top-tier manufacturer, supplier, and exporter of an extensive range of industrial valves and fittings, meeting diverse industrial needs. Our product line includes manifold valves, needle valves, ball valves, check valves, globe valves, gate valves, gauge cock valves, block and bleed valves, and a comprehensive selection of high-quality tube fittings, pipe fittings, and adapters. Designed for precision, durability, and high resistance to pressure and temperature, our valves and fittings ensure leakproof performance across industries such as oil and gas, construction, petrochemicals, and more. Committed to industry standards and customization options, Mcneil Instruments delivers reliable solutions for all your flow control needs, reinforcing our status as a trusted name in India’s industrial valve sector.

0 notes

Text

ENGINE VALVES Manufacturer and Supplier in India - Dasset Engineering

Dasset Engineering is a leading manufacturer and supplier of high-quality engine valves in India. With a focus on producing a wide range of aftermarket and OEM (Original Equipment Manufacturer) quality engine valves, Dasset Engineering has established itself as a trusted name in the automotive industry, catering to various engine types, from light vehicles to heavy-duty machinery.

Wide Range of Engine Valves

At Dasset Engineering, the product lineup includes engine valves made from premium materials like stainless steel, Inconel, and titanium alloys. These materials ensure durability, resistance to high temperatures, and excellent corrosion resistance, which are critical factors for engine performance. Dasset Engineering's valves are designed to meet the needs of different industries, including:

Automotive

Agricultural

Construction Machinery

Marine Engines

Industrial Engines

The company’s valves are meticulously crafted to ensure precision in dimensions, material integrity, and functionality. This attention to detail allows Dasset Engineering to deliver valves that optimize engine performance, enhance fuel efficiency, and reduce emissions.

Aftermarket and OEM Quality

Dasset Engineering is renowned for producing both aftermarket and OEM engine valves. The aftermarket valves are designed to replace worn or damaged valves, extending the lifespan of the engine. These valves meet the same specifications as the original, ensuring reliability and efficiency.

For OEM valves, Dasset Engineering partners with leading automakers and engine manufacturers, adhering to stringent standards of production. These OEM-quality valves are engineered for optimal performance and are manufactured in compliance with global standards like ISO, TS, and ASME.

Why Choose Dasset Engineering?

Unmatched Expertise: Dasset Engineering brings decades of experience in the manufacturing of engine valves, focusing on innovation, precision, and performance.

Advanced Technology: The company utilizes state-of-the-art technology and advanced manufacturing processes to produce valves that meet international standards and customer specifications.

Quality Control: Every engine valve undergoes rigorous testing, including hardness, dimensional accuracy, and material analysis, ensuring that only the highest-quality valves reach customers.

Customization: Dasset Engineering offers customized solutions for engine valves, catering to specific engine designs and customer requirements.

Competitive Pricing: Despite the high quality of their products, Dasset Engineering provides engine valves at competitive prices, making them accessible for both domestic and international markets.

Applications

The engine valves manufactured by Dasset Engineering are suitable for a broad range of applications. From small engines used in motorcycles to large engines in marine and industrial machines, Dasset Engineering caters to a variety of markets. Their valves ensure high performance and longevity in extreme operating conditions, making them the preferred choice for industries across India and globally.

Global Reach

Dasset Engineering exports its high-quality engine valves to several countries, reinforcing its position as a leading supplier in the global market. The company’s strong distribution network ensures timely deliveries and excellent customer service.

In conclusion, Dasset Engineering stands out as a premier manufacturer and supplier of engine valves in India, offering a wide range of aftermarket and OEM quality valves. With a commitment to quality, technology, and customer satisfaction, Dasset Engineering continues to be the trusted partner for engine valve solutions.

#Engine valve manufacturer in India#Engine valve supplier in India#Aftermarket engine valves India#OEM quality engine valves#Dasset Engineering engine valves#Best engine valve manufacturers India#Leading engine valve suppliers India#Automotive engine valves manufacturer#Industrial engine valve suppliers India#Marine engine valve manufacturers

0 notes

Text

Chemical Industry: Supporting Agrochemicals, Polymer Consumption, and Emerging Market Growth

India is currently 3rd in agrochemicals production & polymer consumption and an emerging player in specialty chemicals. Idex provides services for Chemical industry in India. Check out our products here. IDEX India offers innovative products tailored to the chemical industry, including solutions for agrochemicals and polymer consumption. As an emerging player in the market, IDEX India provides cutting-edge equipment that enhances production efficiency, safety, and sustainability, helping businesses stay competitive and compliant with industry standards.

#Chemical Process Equipment#leading valves manufacturer#Industrial Compressor#Industrial Fire Fighting#Pump and Valves#IDEX India

0 notes

Text

Safety Valve Manufacturer in India Ensuring Industrial Safety

In the dynamic landscape of industrial manufacturing, safety remains a paramount concern. Industries spanning from oil and gas to pharmaceuticals rely heavily on high-quality safety mechanisms to protect their operations and workforce. Among the critical components ensuring operational safety are safety valves. Pedlock provides a safety valve manufacturer in Mumbai, Chennai, Ahmedabad, Gujarat, Vadodara, Rajasthan, Ghaziabad, Bangalore and Delhi in India that stands out as a trusted provider of these essential devices.

The Role of Safety Valve

Safety valves are critical components in various industrial systems. They are designed to automatically release pressure from boilers, pressure vessels, and other equipment when the pressure exceeds safe limits. This function prevents potential system failures, explosions, and catastrophic accidents, ensuring the safety of both personnel and equipment.

In industries such as chemical processing, oil and gas, power generation, and manufacturing, the reliability of safety valves can make the difference between smooth operation and disaster. Hence, choosing the right manufacturer is crucial.

Pedlock: A Trusted Name in Safety Valves Manufacturer in India

Pedlock Valves has carved a niche for itself as a leading safety valve manufacturer in Chennai, Ahmedabad, Mumbai, Vadodara, Gujarat, Delhi, Bangalore, Ghaziabad, Delhi, and Rajasthan in India. With years of expertise and a commitment to excellence, Pedlock offers a comprehensive range of safety valves that meet stringent international standards.

Commitment to Quality

At Pedlock, quality is not just a buzzword but a foundational principle. Each safety valve is meticulously engineered and rigorously tested to ensure it performs flawlessly under pressure. The company adheres to globally recognized standards such as ASME, API, and ISO, guaranteeing that every valve meets or exceeds industry benchmarks.

State of the Art Manufacturing Facilities

Pedlock’s manufacturing facilities are equipped with cutting-edge technology and modern machinery. The integration of advanced CNC machines, automated assembly lines, and precision testing equipment ensures that every safety valve produced is of the highest quality. These facilities are manned by a team of skilled engineers and technicians who bring years of experience to the table, ensuring that every product is crafted to perfection.

Diverse Product Range

Our company offers a diverse range of safety valves tailored to various industrial applications. Their product line includes:

- Pressure Relief Valves: Designed to release excess pressure and protect systems from overpressure conditions.

- Thermal Relief Valves: Ideal for applications where temperature-induced pressure changes are a concern.

- Vacuum Relief Valves: Prevent vacuum conditions that could damage equipment or impede operations.

Each of these valves is available in various materials, sizes, and pressure ratings, ensuring that Pedlock can meet the unique needs of any industry.

Innovation and R&D

Innovation is at the heart of Pedlock’s operations. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This commitment to innovation enables Pedlock to continuously improve its product offerings, enhancing safety, reliability, and efficiency.

Global Reach with Local Expertise

While Pedlock is headquartered in India, its reach extends far beyond national borders. The company exports its high quality safety valves to various countries, catering to a global clientele. Despite its international presence, Pedlock remains deeply rooted in local expertise, understanding the unique challenges and requirements of the Indian market.

Sustainability and Compliance

Pedlock is committed to sustainable manufacturing practices. The company follows environmentally friendly processes and strives to minimize its carbon footprint. Additionally, Pedlock ensures compliance with all relevant environmental regulations, demonstrating its commitment to responsible manufacturing.

Conclusion

In an industry where safety cannot be compromised, Pedlock stands as a beacon of reliability and excellence. As a Safety valves manufacturer in Bangalore, Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Delhi, Rajasthan and Ghaziabad in India. We offer high quality, innovative solutions that ensure the safety and efficiency of industrial operations. With a commitment to quality, a customer centric approach, and a focus on innovation, Pedlock is poised to lead the safety valve manufacturing sector for years to come. Whether you are in the oil and gas, chemical, or power generation industry, Pedlock’s safety valves are your trusted partner in safeguarding your operations.

0 notes

Text

Industrial dampers manufacturer in Pune

Pune, a bustling hub of industrial activity in India, is home to numerous manufacturing companies, including Parth Valve & Hoses Pvt. Ltd, a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation, quality, and customer satisfaction, Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs

A Legacy of Excellence

Founded with a vision to deliver top-notch industrial solutions, Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a reputation for producing some of the best Industrial Dampers manufacturer in Pune market. The company’s dedication to maintaining high standards is evident in every product they manufacture.

Industrial Dampers

Cutting-Edge Technology and Innovation

Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize state-of-the-art machinery and employ advanced manufacturing techniques to ensure their products meet the highest quality standards. By continuously investing in research and development, Parth Valve stays ahead of the curve, delivering innovative solutions that cater to the evolving needs of their clients.

Industrial Dampers

Comprehensive Product Range

Parth Valve, the Industrial Dampers manufacturer in Pune, offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:

Butterfly Dampers: Known for their compact design and efficient operation, butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.

Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment, providing a reliable seal even in high-temperature environments.

Louver Dampers: Designed for precise airflow regulation, louver dampers are used in various industrial applications to control ventilation and exhaust systems.

Multi-Louver Dampers: These dampers offer superior control over airflow, making them suitable for complex ventilation systems in industrial settings.

Quality Assurance

Quality is at the core of Parth Valve’s manufacturing process. Each product undergoes rigorous testing and quality checks to ensure it meets the stringent industry standards. The company is ISO certified, which reflects its commitment to delivering products that are not only reliable but also durable and efficient.

Customer-Centric Approach

Parth Valve’s success can be attributed to their customer-centric approach. They work closely with clients to understand their specific needs and provide customized solutions that best fit their requirements. Their dedicated customer support team ensures that clients receive prompt assistance and support throughout their engagement with the company.

Sustainability and Environmental Responsibility

In addition to their focus on quality and innovation, Parth Valve is committed to sustainability and environmental responsibility. They implement eco-friendly manufacturing practices and strive to minimize their environmental footprint. By doing so, they contribute to a greener future while maintaining their competitive edge in the industry.

Conclusion

Parth Valve & Manufacturing Co. is the best choice for Industrial Dampers manufacturer in Pune. Their unwavering commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation. As industries continue to evolve, Parth Valve is well-equipped to meet the challenges of the future, providing top-tier solutions that drive efficiency and reliability in industrial operations.

For more information on Parth Valve’s products and services, visit their website or contact their customer support team. With Parth Valve, you can be assured of the best in Industrial Dampers technology and unparalleled service.

#Industrial Dampers in Pune#Industrial Dampers#Importance of industrial dampers#Pune#a bustling hub of industrial activity in India#is home to numerous manufacturing companies#including Parth Valve & Hoses Pvt. Ltd#a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation#quality#and customer satisfaction#Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs#A Legacy of Excellence#Founded with a vision to deliver top-notch industrial solutions#Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a r#Cutting-Edge Technology and Innovation#Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize s#Parth Valve stays ahead of the curve#delivering innovative solutions that cater to the evolving needs of their clients.#Comprehensive Product Range#Parth Valve#the Industrial Dampers manufacturer in Pune#offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:#Butterfly Dampers:#Known for their compact design and efficient operation#butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.#Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment#providing a reliable seal even in high-temperature environments.#Louver Dampers: Designed for precise airflow regulation#louver dampers are used in various industrial applications to control ventilation and exhaust systems.#Multi-Louver Dampers: These dampers offer superior control over airflow

0 notes

Text

Industrial Valve Exporter - MVS Valves

Looking for a trusted Industrial Valve Exporter? MVS Valves, established in 1978, is a leading manufacturer and exporter of industrial valves from Gujarat, India. Our company specializes in providing high-quality valves for various industrial applications. Leading the global market, Our company is proudly a known industrial valve exporter, offering high quality and reliability. With precision engineering and cutting-edge technology, We offer a wide range of valves used for various industries. Explore our valve selection for superior efficiency and dependability. Contact MVS Valves today to discuss your specific industrial valve requirements- https://mvsvalves.com/ or call at- +91 9898563969

#Industrial Valve#Industrial Valves#Industrial Valve Exporter#valve manufacturers#industrial valve manufacturers#Industrial Valve in india

0 notes

Text

Best Gate Valve Manufacturers in India

Specialty Valve offers high-performance gate valves used across various sectors like water treatment, oil & gas, and chemicals. These valves are designed for precise flow control and come in materials like stainless steel, cast iron, and alloy steel to ensure durability and resistance to corrosion. With cutting-edge technology and customized solutions, these gate valve manufacturers in India cater to specific industry requirements. For reliable, long-lasting gate valves, trust the leading names in India. Contact us today to explore our wide range of specialty valves and find the perfect solution for your needs!

#industrial valve manufacturer#manufacturer#valves manufacture#valve company in india#valve companies#gate valve manufacturers#gate valve manufacturers in india

0 notes

Text

Butterfly Valve Manufacturers in Ahmedabad - Top Quality

Discover leading Butterfly Valve Manufacturers in Ahmedabad. Get high-quality products and competitive prices. Your trusted source for valve solutions.

Google Map:--> https://maps.app.goo.gl/pmF6ogWW6EPkpfYq7

Butterfly Valve Manufacturers in Ahmedabad, Butterfly Valve Manufacturer & Supplier in Ahmedabad, Butterfly Valves in Ahmedabad, Cast Iron Butterfly Valve Manufacturer From Ahmedabad, Butterfly Valve, Butterfly Valve Manufacturer in Ahmedabad, Top Butterfly Valve Manufacturers in Ahmedabad, Cast Iron Teflon Seated Butterfly Valve in Ahmedabad, Pneumatic Actuator Wafer Type Butterfly Valve, Butterfly Valve Manufacturer & Supplier in Ahmedabad, India, Industrial Butterfly Valves Manufacturer in Ahmedabad, India, Top Damper Butterfly Valve Manufacturers in Ahmedabad, PP Butterfly Valve Manufacturer from Ahmedabad, Cast Iron Butterfly Valve Manufacturer from Ahmedabad, Ahmedabad, Gujarat, India, www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Butterfly Valve Manufacturers in Ahmedabad#Butterfly Valve Manufacturer & Supplier in Ahmedabad#Butterfly Valves in Ahmedabad#Cast Iron Butterfly Valve Manufacturer From Ahmedabad#Butterfly Valve#Butterfly Valve Manufacturer in Ahmedabad#Top Butterfly Valve Manufacturers in Ahmedabad#Cast Iron Teflon Seated Butterfly Valve in Ahmedabad#Pneumatic Actuator Wafer Type Butterfly Valve#India#Industrial Butterfly Valves Manufacturer in Ahmedabad#Top Damper Butterfly Valve Manufacturers in Ahmedabad#PP Butterfly Valve Manufacturer from Ahmedabad#Cast Iron Butterfly Valve Manufacturer from Ahmedabad#Ahmedabad#Gujarat#www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

Selecting the Right Control Valve for Fluid Handling in the Oil and Gas Industry

Control valves are critical components in the oil and gas sector, playing a vital role in regulating the flow, pressure, and temperature of fluids. These valves are essential for ensuring operational efficiency, safety, and environmental compliance. Selecting the right control valve requires a thorough understanding of the application requirements and the challenges specific to the oil and gas industry.

Challenges in Fluid Handling in the Oil and Gas Sector

The oil and gas industry presents unique challenges due to the demanding conditions under which equipment must operate. From handling high-pressure crude oil and gas to managing corrosive fluids, control valves must be robust and reliable. Some key challenges include:

High Pressure and Temperature Many oil and gas processes involve extreme pressure and temperature conditions. Equipment must be capable of withstanding these stresses without compromising performance or safety.

Corrosive and Abrasive Fluids The fluids in oil and gas operations can be highly corrosive and abrasive. Valves must resist corrosion and wear caused by contaminants, chemicals, and sand particles present in crude oil and gas streams.

Strict Regulatory Standards The industry operates under stringent safety and environmental regulations. Control valves must adhere to standards like API, ISO, and ASME to ensure compliance and prevent environmental damage.

Flow Variability Fluctuating flow rates in pipelines and processing systems demand valves that can adapt to varying conditions without impacting efficiency or safety.

Key Features of Control Valves for Oil and Gas Applications

When selecting control valves for the oil and gas industry, the following features should be considered:

Material Compatibility Valves should be constructed from materials that can withstand exposure to corrosive and abrasive substances. Common materials include stainless steel, Hastelloy, and other high-strength alloys. Coatings and linings may also be used to enhance resistance to corrosion and erosion.

Pressure and Temperature Ratings Valves must be rated for the maximum pressure and temperature conditions they will encounter. Failing to meet these specifications can result in leaks, equipment failure, or safety hazards.

Seal Integrity Leak-tight sealing is crucial to preventing fluid loss and ensuring safety. Valves with advanced sealing technologies, such as metal-to-metal seals or polymer-based seals, provide enhanced reliability under high-pressure conditions.

Flow Control Precision Valves must deliver precise control to maintain stable flow rates and pressure levels. Actuation options, such as pneumatic or electric actuators, can improve accuracy and responsiveness in critical applications.

Ease of Maintenance Given the remote and hazardous locations of many oil and gas facilities, control valves should be easy to maintain and repair. Modular designs and readily available spare parts simplify servicing and reduce downtime.

Applications of Control Valves in Oil and Gas

Control valves are used across various stages of oil and gas production, processing, and distribution. Common applications include:

Upstream Operations In drilling and extraction, control valves regulate the flow of crude oil and gas from wells. They manage pressures to prevent blowouts and ensure steady production.

Midstream Processes During transportation and storage, valves maintain pressure and flow within pipelines, preventing leaks and ensuring safe delivery of hydrocarbons.

Downstream Applications In refining and petrochemical processes, control valves regulate temperature, pressure, and chemical reactions to produce refined products like gasoline, diesel, and plastics.

Ensuring Optimal Performance Through Proper Maintenance

The harsh environments of oil and gas facilities make regular maintenance essential to extend the life of control valves and prevent unplanned downtime. Key maintenance practices include:

Routine Inspections Inspect valves regularly for signs of wear, corrosion, or damage. Seals and actuators should be checked for proper functioning.

Cleaning and Lubrication Remove debris and contaminants to maintain smooth valve operation. Lubricate moving parts to reduce friction and wear.

Testing and Calibration Periodically test valve performance, including pressure containment and flow control accuracy. Calibration ensures the valve continues to meet operational requirements.

Replacement of Worn Components Replace seals, seats, and other worn components promptly to prevent leaks or operational failures.

Documentation Maintain detailed records of valve maintenance, repairs, and testing. This information helps track performance trends and plan future maintenance activities.

Conclusion

The oil and gas industry relies heavily on control valves to ensure the efficient, safe, and environmentally responsible handling of fluids. Choosing the right valve with appropriate materials, precise control capabilities, and robust construction is crucial for overcoming the sector's challenges. Regular maintenance further ensures reliability and prolongs the lifespan of the valves.

By prioritizing the selection and upkeep of high-quality control valves, oil and gas operators can enhance safety, improve operational efficiency, and meet regulatory standards. As technology advances, modern control valves equipped with smart features will continue to play a pivotal role in optimizing oil and gas processes.

0 notes

Text

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

Leading Instrumentation Pipe Fittings Manufacturer, Supplier, and Exporter in India - Mcneil Instruments Inc.

Mcneil Instruments Inc. is a leading manufacturer, supplier, and exporter of high-quality instrumentation pipe fittings in India. Our extensive product range includes Female Run Tee, Male Run Tee, Female Elbow, Female Branch Tee, Cap Pipe Fitting, Plug & Union, and Coupling Pipe Fitting. Designed to meet rigorous industrial standards, our fittings ensure precision, durability, and reliable performance for various applications. With a commitment to quality and customer satisfaction, Mcneil Instruments is your trusted partner for superior instrumentation solutions.

1 note

·

View note