#gate valve manufacturers in india

Explore tagged Tumblr posts

Text

Best Gate Valve Manufacturers in India

Specialty Valve offers high-performance gate valves used across various sectors like water treatment, oil & gas, and chemicals. These valves are designed for precise flow control and come in materials like stainless steel, cast iron, and alloy steel to ensure durability and resistance to corrosion. With cutting-edge technology and customized solutions, these gate valve manufacturers in India cater to specific industry requirements. For reliable, long-lasting gate valves, trust the leading names in India. Contact us today to explore our wide range of specialty valves and find the perfect solution for your needs!

#industrial valve manufacturer#manufacturer#valves manufacture#valve company in india#valve companies#gate valve manufacturers#gate valve manufacturers in india

0 notes

Text

Trust the leading control valve manufacturers in India

When it comes to manufacturing, the quality of industrial valves plays a critical role in ensuring safety, efficiency, and productivity. SAP Industries Ltd is a leading industrial valves manufacturers in India, including gate valves, control valves, and butterfly valves. We're proud to say that our valves are manufactured with the latest technology and engineering practices to deliver unmatched performance, durability, and reliability.

At control valve manufacturers, we're committed to meeting the needs and expectations of our customers. Whether you're looking for gate valves, control valves, butterfly valves, or any other type of industrial valves, we have the expertise and resources to deliver the best products. Our valves are designed for various applications, from general industrial use to critical applications in oil and gas, chemical, and other industries.

Get unmatched reliability and longevity with our industrial valves

As one of the top gate valve manufacturers in India, we understand the importance of using high-quality materials and precision manufacturing techniques. All our valves are made from premium-grade raw materials, such as cast iron, stainless steel, and bronze, using advanced casting, machining, and assembly processes. This ensures that our valves meet or exceed industry standards for performance and reliability.Gate valves are essential for controlling the flow of liquids, gases, and other substances in pipeline systems. Our gate valves come in several sizes, types, and materials, including cast iron gate valves, stainless steel gate valves, and bronze gate valves. We also offer customized valves to meet specific customer requirements.

Control valves are used to regulate the flow, pressure, and temperature of fluids in process systems. Our control valves are engineered to deliver precise control, high efficiency, and long-lasting performance. We offer a wide range of control valves, including globe valves, angle valves, and ball valves, among others. Butterfly valves are ideal for applications where reliable and fast-flow control is required. Our butterfly valves come in various sizes, materials, and types, such as wafer-type, lug-type, and double-flanged butterfly valves. As butterfly valve manufacturer, we also offer triple offset and high-performance butterfly valves for demanding applications.

#industrial valves manufacturers in India#control valve manufacturers#gate valve manufacturers in India#butterfly valve manufacturer

0 notes

Text

Reducing Operational Costs with Bellow Sealed Valves

Traditional valves often fall short in preventing leaks, necessitating frequent repairs and replacements that can strain budgets and resources. In contrast, Bellow sealed valves offer a robust solution to these challenges, providing a long-term strategy for leak prevention and operational efficiency. In industrial settings, valve leakage is a significant concern that can lead to hidden costs, including downtime, product loss, safety incidents, and increased maintenance expenses.

The Hidden Costs of Valve Leakage

Valve leakage can have far-reaching implications for businesses. When a valve fails, it can lead to unplanned downtime, disrupting production schedules and delaying deliveries. This downtime translates to lost revenue and can damage relationships with clients. Additionally, product loss due to leaks not only affects the bottom line but can also lead to environmental compliance issues, especially in industries like oil and gas, where spills can have severe consequences.

Safety incidents are another critical concern. Leaking valves can create hazardous conditions, putting employees at risk and potentially leading to costly accidents. Furthermore, the maintenance expenses associated with traditional valves can add up quickly. Frequent repairs and replacements require skilled labor and can divert resources from other essential operations.

Cost-Benefit Analysis

When considering the financial implications of valve choices, a cost-benefit analysis reveals the advantages of investing in this valves. While the initial purchase price may be higher than that of traditional valves, the long-term savings can be substantial. They are designed with a unique sealing mechanism that provides a 100% leak-proof solution, significantly reducing the risk of leaks and their associated costs.

By minimizing downtime and maintenance requirements, these valves can lead to a more stable operational environment. Industries that have adopted this valves report fewer incidents of leakage, translating to lower overall maintenance costs. This reduction in repairs and replacements not only enhances productivity but also improves the return on investment (ROI) for companies that prioritize long-term solutions over short-term fixes.

Low-Maintenance, Long-Life This Valves Improve ROI

They are engineered for durability and reliability, making them a low-maintenance option for industrial applications. Their advanced bellows technology creates a flexible yet robust seal that withstands pressure and temperature fluctuations, reducing wear and tear. This longevity translates to fewer replacements and less frequent maintenance, allowing companies to allocate resources more effectively.

Real-world case studies demonstrate the effectiveness of this valves in various industries. For instance, in the oil and gas sector, companies have reported a significant decrease in operational downtime after switching to this valves. Similarly, in chemical processing plants, these valves have contributed to enhanced safety and compliance by minimizing the risk of leaks. Pharmaceutical companies also benefit from the precise control and reliability that this valves provide, ensuring that sensitive processes remain uninterrupted.

Best Practices for Selecting and Maintaining

To maximize the benefits of this valves, companies should follow best practices for selection and maintenance. First, it’s essential to choose valves that are specifically designed for the application in question. Consider factors such as pressure, temperature, and the nature of the fluids being handled. Consulting with manufacturers like Freture Techno Pvt. Ltd., known for their expertise in high-performance valve solutions, can provide valuable insights.

Regular inspection and maintenance are also crucial. While this valves require less frequent servicing than traditional valves, routine checks can help identify potential issues before they escalate. Keeping detailed records of maintenance activities can further enhance the reliability of these valves.

Training staff on the proper operation and maintenance of this valves is another key aspect. Ensuring that employees understand the importance of these valves and how to care for them can lead to improved performance and longevity.

Conclusion

Freture Techno Pvt. Ltd. stands out as a leader in providing cost-effective and reliable valve solutions, offering high-performance this valves that meet the demands of various industries. Investing in these advanced valves not only prevents leaks but also paves the way for a more efficient and profitable future.In conclusion, the shift towards Bellow sealed valves represents a strategic move for industries seeking to reduce operational costs and enhance safety. By addressing the hidden costs associated with valve leakage, companies can improve their bottom line while ensuring a safer working environment.

#Bellow Valves#Bellow Sealed Valves#Bellow Sealed Gate Valve#Bellow Sealed Globe Valve#manufacturers#India#Freture Techno

0 notes

Text

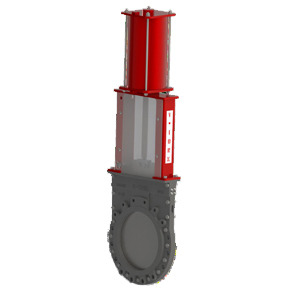

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

#Knife Gate Valve#Knife Gate Valve Manufacturers in India#Knife Gate Valve Suppliers in India#Knife Gate Valve Exporters in India#Knife Gate Valves in India

0 notes

Text

SS Flange End Ball Valve Manufacturer from Ahmedabad - Gold Techno Casting

Gold Techno Casting Company is a leading manufacturer of high-quality ball valves in Ahmedabad, Gujarat. Our range includes SS flange end ball valves, stainless steel ball valves, and SS gate valves, perfect for various industrial applications. Contact us today!

Google Map:--> https://maps.app.goo.gl/LUnHirgkXMPNPJ1V7

SS Flange End Ball Valve Manufacture in Ahmedabad, Ball Valve, SS Flange End Ball Valve, Ball Valve Manufacture in Ahmedabad, SS Ball Valve, Stainless Steel Flanged Valve, SS Gate Valves, Stainless Steel Globe Valve, Kheda, Ahmedabad, Gujarat, India, Gold Techno Casting

#SS Flange End Ball Valve Manufacture in Ahmedabad#Ball Valve#SS Flange End Ball Valve#Ball Valve Manufacture in Ahmedabad#SS Ball Valve#Stainless Steel Flanged Valve#SS Gate Valves#Stainless Steel Globe Valve#Kheda#Ahmedabad#Gujarat#India#Gold Techno Casting

0 notes

Text

Trusted Gate Valve Manufacturing in India: Combining Tradition with Modern Technology

India has a rich heritage of engineering and manufacturing, with a legacy that spans centuries. In today's rapidly advancing industrial landscape, Indian manufacturers are blending this traditional expertise with cutting-edge technology to produce world-class products. Cair Euromation, a leading gate valve manufacturer in India, exemplifies this fusion of tradition and modernity, delivering high-quality gate valves that meet the demanding needs of various industries.

The Importance of Gate Valves in Industrial Applications

Gate valves are critical components in numerous industrial applications, including oil and gas, water treatment, power generation, and chemical processing. They are designed to control the flow of liquids and gases by providing a tight seal when closed and minimal resistance when open. This precise control over fluid flow is essential for maintaining the efficiency and safety of industrial processes.

Cair Euromation recognizes the vital role that gate valves play in these industries. Our commitment to manufacturing top-quality gate valves ensures that our clients can rely on our products for their most demanding applications.

Combining Tradition with Modern Technology

As a leading gate valve manufacturer in India, Cair Euromation leverages the country's rich engineering heritage while incorporating the latest technological advancements. This unique approach allows us to produce gate valves that are not only reliable and durable but also innovative and efficient.

Commitment to Quality and Precision

At Cair Euromation, quality and precision are at the core of our manufacturing process. We adhere to stringent quality standards to ensure that every gate valve we produce meets the highest levels of performance and reliability. Our state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, allowing us to achieve precise engineering and consistent quality.

Our commitment to quality extends to the materials we use. We source high-grade raw materials that can withstand the harsh conditions often encountered in industrial environments. Whether it's extreme temperatures, high pressures, or corrosive substances, our gate valves are built to perform reliably under the most challenging conditions.

Innovation and Technological Advancements

Innovation is a key driver of Cair Euromation's success. We continuously invest in research and development to stay at the forefront of technological advancements in the gate valve industry. Our team of skilled engineers and technicians works tirelessly to design and develop innovative solutions that meet the evolving needs of our clients.

One of the key areas of innovation is our use of advanced materials and coatings. These enhancements not only improve the durability and longevity of our gate valves but also enhance their performance in specific applications. For example, our corrosion-resistant coatings ensure that our valves remain operational even in highly corrosive environments, reducing maintenance costs and downtime for our clients.

Customization for Specific Requirements

At Cair Euromation, we understand that every industrial application is unique. That's why we offer customization options for our gate valves to meet the specific requirements of our clients. Our team works closely with clients to understand their needs and provide tailored solutions that deliver optimal performance.

Whether it's a specific size, material, or design feature, we have the expertise to customize our gate valves to suit various applications. This flexibility sets us apart as a gate valve manufacturer in India that truly understands and caters to the diverse needs of the industry.

Stringent Quality Control Measures

Quality control is a cornerstone of our manufacturing process at Cair Euromation. We have implemented rigorous quality control measures at every stage of production to ensure that our gate valves meet the highest standards. From material inspection to final testing, our quality control team meticulously checks each valve to guarantee its reliability and performance.

Our state-of-the-art testing facilities are equipped with advanced equipment to simulate real-world conditions. This allows us to verify the performance of our gate valves under various operating scenarios, ensuring that they deliver consistent and reliable performance in the field.

Customer-Centric Approach

At Cair Euromation, we believe that our success is closely tied to the success of our clients. That's why we adopt a customer-centric approach in everything we do. From the initial consultation to after-sales support, we are committed to providing exceptional service to our clients.

Our team of experts is always available to provide technical assistance and guidance, helping clients select the right gate valve for their specific application. We also offer comprehensive after-sales support, including maintenance and repair services, to ensure that our clients' operations run smoothly without any interruptions.

Sustainable and Environmentally Friendly Practices

In addition to our focus on quality and innovation, Cair Euromation is also committed to sustainability and environmentally friendly practices. We recognize the importance of reducing our environmental footprint and strive to implement sustainable practices in our manufacturing process.

From energy-efficient production techniques to recycling and waste reduction initiatives, we are dedicated to minimizing our impact on the environment. Our sustainable practices not only benefit the planet but also contribute to the long-term success of our business by promoting efficiency and cost savings.

Conclusion

As a trusted gate valve manufacturer in India, Cair Euromation has earned a reputation for excellence in the industry. Our commitment to quality, innovation, and customer satisfaction sets us apart as a leader in gate valve manufacturing. By combining India's rich engineering tradition with modern technology, we continue to provide reliable and high-performance gate valves that meet the diverse needs of our clients.

Whether you're in the oil and gas industry, water treatment, power generation, or any other sector that requires precise flow control, you can trust Cair Euromation to deliver gate valves that exceed your expectations. Our dedication to quality and customer satisfaction ensures that you receive products that you can rely on for years to come.

0 notes

Text

knife edge gate valve manufacturer

We are leading Knife Edge Gate Valve manufacturer in Ahmedabad, India. sharp-edged gate that can slice through any particulates. This valve is commonly used in industries such as oil and gas, chemical processing and wastewater treatment

#knife edge gate valve#knife edge gate valve manufacurer#knife edge gate valve manufacturer in ahmedabad#knife edge gate valve in india#knife edge gate valve supplier in india#knife edge gate valve in ahmedabad

0 notes

Text

Forged Steel Gate Valve Manufacturer in India

Speciality Valve, renowned for its precision engineering, is Forged Steel Gate Valve manufacturer in India, crafted to meet rigorous industry standards. With a commitment to excellence, we ensure reliable performance and durability in every valve supplied to Maharashtra, Gujarat, and Tamil Nadu.

What are Forged Steel gate Valves?

Forged steel gate valves are industrial valves designed to control the flow of fluids in pipelines by either fully opening or fully closing the passage. They are manufactured through forging, a process that involves shaping metal using compressive forces, resulting in a stronger and more durable valve compared to those made by casting. These valves consist of a gate or wedge that moves perpendicular to the flow of the fluid to either block or allow passage, providing efficient shut-off capability in high-pressure and high-temperature applications.

What does Forged means? Forged refers to a manufacturing process in which metal is shaped using compressive forces, typically under high pressure and heat. In forging, the metal is heated to a high temperature to make it more malleable, then subjected to mechanical force, often applied using a hammer or press, to deform it into the desired shape.

Advantages:

Strength and Durability

Resistance to Corrosion

Reliability

High-Pressure and High-Temperature Capability

They are available in various designs

Long Service Life

Safety

Easy to Maintain

Wide Range of Applications

Industry:

Oil and Gas Industry: Forged steel gate valve are vital components in oil and gas operations, ensuring reliable flow control in pipelines and refineries.

Petrochemical Industry: These valves play a crucial role in petrochemical plants, facilitating safe and efficient fluid handling in various processes such as refining and chemical production.

Power Generation Industry: In power plants, forged steel gate valves help regulate the flow of steam and other fluids in high-pressure and high-temperature environments, ensuring smooth operation of turbines and boilers.

Chemical Processing Industry: Forged steel gate valves are used in chemical plants to control the flow of corrosive chemicals and other fluids, offering durability and resistance to harsh operating conditions.

Refining Industry: Refineries rely on forged steel gate valves to manage the flow of crude oil and refined products, ensuring optimal performance and safety in refining processes.

Water and Wastewater Treatment Plants: These valves are employed in water treatment facilities to regulate the flow of water and chemicals, contributing to efficient treatment processes and maintaining water quality standards.

Pulp and Paper Industry: Forged steel gate valves are utilized in pulp and paper mills to control the flow of various liquids, including chemicals and pulp slurries, supporting the production of paper products.

Mining Industry: In mining operations, these valves are used to control the flow of water, chemicals, and slurries in processing plants, providing reliable performance in demanding mining environments.

Marine Industry: These valves find applications in marine systems and vessels for controlling the flow of seawater, fuels, and other fluids, ensuring safe and efficient operation at sea.

We are Forged Steel Gate Valve manufacturer in India supplying valve in following Description:

Available materials: F55, F51, F53, F11, F22, A105, A105, F304 F316, F316L, F91, F904, F44

Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Lever Operated, gear operated, Electric Actuated and Pneumatic Actuated.

End Connection: Threaded, Buttweld, Socketweld, Flanged, Wafer, Lug

To explore our range of valves, visit our website at: https://www.specialityvalve.com/product-category/forged-steel-gate-valve/

0 notes

Text

When searching for water meter suppliers in Kuwait, you invest in technology that ensures equitable distribution and efficient use of water resources. These meters come in various forms, including mechanical and digital, offering precise readings that benefit water utilities, property owners, and industries alike. In the world of industrial processes, precision and reliability are non-negotiable. The instruments we’ve explored in this blog — pressure gauges, level gauges, level transmitters, tube fittings, and water meters — are the unsung heroes that ensure everything runs smoothly. They provide vital data and control, making them indispensable in various industries.

#thermocouple manufacturers in dubai#check valves suppliers in india#tube fittings manufacturers in dubai#gate valves suppliers in qatar#ball valves suppliers in bahrain

0 notes

Text

Top Industrial Valve Manufacturers in India

We are trusted and leading industrial valve manufacturers in India and global exporters of industrial applications. Headquartered in Coimbatore, India, and established in 2013 by an industry specialist, our company has achieved a higher position as a top valve manufacturer in India with high quality, durability, and versatility apart from buying the finest industrial valves at the global level.

1. Control Valve - We are one of the top control valve manufacturers in India. It fluid flow or pressure by varying the size of the flow passage based on signals from a controller. It is essential in maintaining the desired process conditions in industries like chemical and oil & gas.

We provide valves in the following description

1. Available Materials: Ductile Iron, Cast iron (WCB, WCC, WC6), LCC, LCB, Stainless Steel (SS316, SS304), Super Duplex (F51, F53, F55).

2. Class: 150 to 2500.

3. Nominal Pressure: PN10 to PN450.

4. Medium: Air, Water, Chemical, Steam, Oil.

5. Operations: Electric Actuated and Pneumatic Operated.

6. Size: 1/2”- 24”.

7. Ends: Flanged, butt weld, socket weld, threaded.

Electric Actuator Details:

1. Torque: 3 – 9 nm.

2. Operating pressure: 8 Bar.

3. Port Connection: NPT1.4”.

4. Mounting Base: ISO5211.

5.Temperature: -20°C to +80°C.

Pneumatic Actuator Configuration:

1.4-20 amp.

2. Pneumatic single-acting actuators.

3. Pneumatic double-acting actuators.

4. Pneumatic rotary actuators.

5. Pneumatic Scotch and Yoke actuators.

6. Pressure: 228 bar.

Temperature Ranges:

1.Standard: -4°F to 200°F (-20°C to 93°C).

2.Low: -40°F to 176°F (-40°C to 80°C).

3.High: 0°F to 300°F (-18°C to 149°C).

2. Cryogenic Valve - We are famous for our design and the best cryogenic valve manufacturers in India. It is designed to operate at extremely low temperatures and is used in the transport and storage of liquefied gases like nitrogen, oxygen, and LNG. They ensure safe control and isolation in cryogenic systems.

We supply valves in the following description:

1.Materials: SS304, SS316, CF8M, CF8, F51, F55, F53, WCB, WC6, WCC, LCB, LCC.

2. Class: 150 to 800.

3. Nominal Pressure: PN25 to PN100.

4. Size: 1/2” to 24”.

5. Operations: Lever Operated, Gear Operated, Handwheel Operated, Electric Actuated, and Pneumatic Actuated.

6. End Connection: Buttweld, Threaded or welded, lug, and wafer

3. Pressure Reducing Valve - It is one of the largest pressure-reducing valve manufacturers in India. It automatically lowers incoming pressure to a desired downstream level, ensuring safe and consistent pressure for sensitive equipment. It is widely used in water distribution and gas systems

Description:

1. Materials: Ductile Iron, WCB, WCC, WC6, LCB, LCC, SS304, SS316, Cast iron

2. Size: 1/2″ to 24″.

3. Nominal Pressure: PN10 to PN100.

4. Class: 150 to 600.

5. Ends: Threaded, Buttweld, Socket weld, Flanged

4. Safety Valve - The leading Safety Valve Manufacturers in India. It opens to release pressure when it exceeds a preset limit, protecting equipment from overpressure damage. It is commonly used in steam boilers, pressure vessels, and pipelines.

Description:

1. Body Material: Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] , WCB, WC6, SS304, SS316, DUPLEX STEEL.

2. Class – 150 – 2500

3. PN 10 – PN 450

4. Size – ½ – 24”

5. Ends- Butt welded, Socket welded, Flanged, Threaded

5. Check Valve - We are the largest check valve manufacturers in India that allow liquid to flow in one direction and prevent backflow, protecting systems from damage caused by reverse flow. It is used in applications like water systems, oil pipelines, and pumps.

Description:

1. Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), Duplex and Super duplex steel [F51, F53, F55] Forged Steel A105, A105N, F11, F22, F304, F316, F91] Alloy20, Hastelloy, ALBR.

2. Size- ½” – 80”

3. Class-150 – 2500; PN10 – PN-450

4. Ends-threaded, socket weld, butt weld, flanged, lug, wafer

#industrial valve manufacturer#gate valve manufacturers#control valve manufacturers in India#cryogenic valve manufacturers in India#pressure-reducing valve manufacturers in India#Safety Valve Manufacturers in India#check valve manufacturers in India

0 notes

Text

Get Quality Industrial Valves from India's Leading Manufacturer

Sap Industries Ltd is the one-stop destination for quality industrial valves manufacturers in India. With a highly skilled team and advanced manufacturing facilities, the company has been a pioneer in the industry for more than two decades. If you're looking for reliable and efficient valves for your industrial needs, Sap Industries Ltd is the right choice for you. Here, we will explore the products and services offered by Sap Industries Ltd and understand why it is the leading manufacturer of industrial valves in India.

1. Quality Products:

At gate valve manufacturers in India, we understand the importance of high-quality valves for the smooth functioning of industrial processes. We offer a wide range of valves, including gate valves, control valves, and butterfly valves, which are manufactured to cater to the diverse needs of clients. Our valves are made with advanced technology that ensures durability, efficiency, and reliability. Additionally, we offer customization options to meet specific requirements of customers.

2. Manufacturing Facilities:

Our state-of-the-art manufacturing facilities are equipped with the latest machinery and equipment that help us deliver high-quality valves. We have a team of highly skilled professionals who are trained in advanced manufacturing techniques. As reputed control valve manufacturers, we adhere to strict quality checks at every stage of production to ensure that the valves meet international standards.

3. Customer Satisfaction:

At Sap Industries Ltd, customer satisfaction is our top priority. We ensure a transparent and hassle-free experience for our clients. From the initial consultation to after-sale services, we provide excellent customer support. Our team of experts is always ready to assist clients with any queries or issues they might face.

4. Reputation:

With over two decades of experience in the industry, Sap Industries Ltd has established itself as a reliable and trustworthy butterfly valve manufacturer in India. Our products have been used in various industrial applications in the country and abroad. Our satisfied clients are a testament to our commitment to quality and customer satisfaction.

5. Competitive Pricing:

We offer our products at competitive prices without compromising on quality. Our aim is to make our valves accessible to all types of industries, and we strive to provide value for money. We also offer timely delivery services, ensuring that our clients receive their orders on time.

#industrial valves manufacturers in India#gate valve manufacturers in India#control valve manufacturers#butterfly valve manufacturer in India

0 notes

Text

The Essential Guide to Gate Valves: Key Benefits and Applications Across Industries

Gate valves are crucial components in many industrial systems, providing control over fluid flow and ensuring operational efficiency. These valves are used in a variety of sectors, including oil and gas, pharmaceuticals, petrochemicals, power generation, water treatment, refineries, and HVAC systems. Understanding the benefits and applications of gate valves can help businesses select the right solution for their needs. This guide explores the key advantages of gate valves and their specific applications in different industries.

Oil and Gas Industry: Reliability Under Pressure

Maximizing Performance in Harsh Conditions

In the oil and gas industry, gate valves are designed to handle extreme pressures and temperatures. These valves are essential for managing the flow of crude oil and natural gas, often in challenging environments. The primary concern for industry professionals is ensuring that the valves can perform reliably without leaks or failures. Gate valves provide a robust solution by offering durability and precise control, essential for maintaining the efficiency and safety of oil and gas operations.

Pharmaceutical Industry: Ensuring Sterility and Compliance

Maintaining High Standards of Cleanliness

Pharmaceutical manufacturing demands strict adherence to cleanliness and regulatory standards. Gate valves are used in processes such as water purification and chemical handling. The challenge in this sector is ensuring that valves do not introduce contaminants into the system. High-quality gate valves are engineered to prevent leakage and contamination, thereby ensuring that the pharmaceutical products meet safety and quality requirements.

Petrochemical Industry: Handling Corrosive Substances

Enhancing Longevity and Performance

Petrochemical facilities process highly corrosive chemicals, which can impact the performance of standard valves. Gate valves used in this industry must be constructed from materials resistant to corrosion and wear. This is crucial for maintaining the integrity and longevity of the valves. Advanced gate valves with specialized coatings and materials provide a solution, ensuring reliable operation and reducing the need for frequent replacements.

Power Generation: Efficient Flow Control

Withstanding High-Pressure Environments

In power generation, gate valves control the flow of steam and other fluids under high pressure and temperature. These valves are vital for the efficient operation of boilers and turbines. The main concern is the valve's ability to withstand harsh conditions while providing consistent performance. Gate valves designed for high-pressure applications ensure that power generation systems operate smoothly and efficiently, contributing to overall energy production.

Water Treatment: Ensuring System Integrity

Reliable Performance for Clean Water

Water treatment facilities rely on gate valves to manage the flow of water and maintain system integrity. These valves are used for isolating parts of the system during maintenance or emergencies. The key challenge is ensuring that valves can handle various water conditions without compromising their sealing capabilities. Gate valves designed for water treatment provide reliable performance, ensuring the delivery of clean and safe water.

Refineries: Managing Extreme Conditions

Durability in High-Temperature Environments

Refineries require gate valves that can operate efficiently under high temperatures and pressures. These valves are used to control the flow of fluids in refining processes, where durability and precision are critical. The challenge for refinery operators is finding valves that can withstand these extreme conditions while providing accurate control. Gate valves designed for such applications offer the robustness needed to improve operational efficiency and reduce downtime.

HVAC Systems: Optimizing Flow Control

Ensuring Consistent System Operation

In HVAC systems, gate valves regulate the flow of air and fluids, contributing to the system's overall performance. The main concern for HVAC professionals is maintaining consistent and efficient operation. Gate valves that offer precise control and reliable performance help optimize the functioning of HVAC systems, ensuring a comfortable and controlled environment.

Conclusion

Gate valves are indispensable across various industries, providing essential control and reliability in demanding applications. Whether for oil and gas, pharmaceuticals, petrochemicals, power generation, water treatment, refineries, or HVAC systems, gate valves address key challenges such as durability, performance, and compliance. For high-quality gate valves that meet industry-specific needs, consider purchasing from Freture Techno Pvt. Ltd., a leading Gate Valve manufacturers in Mumbai, India. We known for delivering superior valve solutions.

0 notes

Text

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

Knife Gate Valve Manufacturers, Suppliers, Exporters in India | Knife Gate Valves in Mumbai, Nagpur, Aurangabad, Chennai, Bangalore, Tamil Nadu

#Knife Gate Valve#Knife Gate Valve Manufacturers in India#Knife Gate Valve Suppliers in India#Knife Gate Valve Exporters in India#Knife Gate Valves in India#Pneumatic Cylinder Knife Edge Gate Valve#Pneumatic Cylinder Knife Edge Gate Valve Manufacturers in India#Pneumatic Cylinder Knife Edge Gate Valve Suppliers in India#Pneumatic Cylinder Knife Edge Gate Valve Exporters in India#Pneumatic Cylinder Knife Edge Gate Valve in India#Knife Gate Valve Manufacturers in Pune#Knife Gate Valve Suppliers in Pune#Knife Gate Valve Exporters in Pune#Knife Gate Valves in Pune#Pneumatic Cylinder Knife Edge Gate Valve Manufacturers in Pune#Pneumatic Cylinder Knife Edge Gate Valve Suppliers in Pune#Pneumatic Cylinder Knife Edge Gate Valve Exporters in Pune#Pneumatic Cylinder Knife Edge Gate Valve in Pune

0 notes

Text

Gujarat's Leading Gate Valve Manufacturers - Gold Techno Casting

Gate Valve Manufacturers in Gujarat – Gujarat is a state in western India that is known for its industrial development.

Gate Valve Manufacturers in Gujarat – Gold Techno Casting is a leading manufacturer of gate valves in Gujarat. our gate vales range are flanged gate valves, wafer gate valves, and knife gate valves.

Google Map:--> https://maps.app.goo.gl/2C8UcGmhNAEgZBdV7

Gate Valve Manufacturers in Gujarat, Best Gate Valve Manufacturers In Gujarat, Gate Valve Exporters In Gujarat, Gate & Sluice Valves in Gujarat, Top Valve Manufacturer in Gujarat, Gate Valve Manufacturer in Gujarat, India, Gate Valves Manufacturer, Supplier from Gujarat, Gate Valve Manufacturers, Suppliers in Gujarat, Flanged Gate Valve in Gujarat, Gujarat, India, www.goldtechnocasting.com/valve-manufacturer-in-gujarat.php, Gold Techno Casting

#Gate Valve Manufacturers in Gujarat#Best Gate Valve Manufacturers In Gujarat#Gate Valve Exporters In Gujarat#Gate & Sluice Valves in Gujarat#Top Valve Manufacturer in Gujarat#Gate Valve Manufacturer in Gujarat#India#Gate Valves Manufacturer#Supplier from Gujarat#Gate Valve Manufacturers#Suppliers in Gujarat#Flanged Gate Valve in Gujarat#Gujarat#www.goldtechnocasting.com/valve-manufacturer-in-gujarat.php#Gold Techno Casting

0 notes