#Industrial Packaging Market Trends

Explore tagged Tumblr posts

Text

Exploring Emerging Materials: Industrial Packaging Market Dynamics

Industrial Packaging: Enabling Efficient Transportation and Storage of Manufactured Goods Importance of Effective Packaging for Manufactured Products Industrial packaging plays a vital role in effectively protecting manufactured goods from damage during transportation and storage. The packaging is designed to prevent breakage and ensure products reach customers inmint condition. Whether it's heavy machinery or fragile electronics, appropriate packaging is essential to minimize losses from product damage. Manufacturers rely on high-quality, robust packaging solutions to ship products safely and maximize revenue. Design and Material Selection based on Product Attributes The type of packaging used depends on the nature and specifications of the product. Factors like product weight, fragility, intended transport mode etc. are considered to design packaging suitable for the goods. Lightweight products may use corrugated boxes or paper wraps while heavy equipment requires wooden crates or customized load bearers. Materials used can range from cardboard, wood, plastics to composites depending on required strength, cost and sustainability objectives. Functional designs enable efficient handling, stacking and unitization for transport. Quality Assurance through Testing and Certification Rigorous testing simulating real-world distribution environments help ensure industrial packaging solutions meet international quality and durability standards. Certification helps manufacturing facilities and logistics companies certify that the packaging conforms to industrial and safety regulations. Packaging is subjected to vibration, compression, temperature and humidity cycling tests to confirm its ability to protect contents under typical shipping conditions by road, sea or air. This quality validation provides assurance of intact deliveries. Sustainable Practices for Environmental Stewardship With growing emphasis on sustainability, industry is focusing on reuse, recycling and reduced environmental impact of packaging materials. Use of recycled content and recyclable/biodegradable materials features prominently in packaging designs. Standardization encourages efficient utilization of transport and storage space. Collaborative efforts between manufacturers, suppliers and logistics firms encourage responsible packaging practices meeting global commitments. Harmonizing performance needs with eco-friendly attributes will factor strongly in the evolution of industrial packaging. Digital Transformation Enhances Supply Chain Visibility Adoption of Industry 4.0 technologies is driving digitization across supply chain networks. Intelligent packaging solutions are enhancing visibility and optimization. Technologies like RFID tags, sensors and IoT enable real-time tracking of shipment conditions and location updates. Analytics helps identify inefficiencies, improve route planning and reduce transit time. Integrating packaging data with digital supply chain twin simulations helps achieve continuous performance enhancement matching demand profile changes. The digital transformation will make industrial packaging an increasingly connected and intelligent asset. In conclusion, well-engineered industrial packaging plays a pivotal role in commercial success through reliable transportation and storage of manufactured goods. Continual innovation integrating material advancements, digital technologies and sustainability will future-proof the sector's contributions to seamless supply chain operations.

0 notes

Text

Navigating Regulatory Landscape in the Industrial Packaging Market: A Global Perspective

Industrial packaging products such as pallets, crates, barrels, drums & Intermediate Bulk Containers (IBC) are extensively used for shipping & storing industrial goods. They provide protection to goods from damage and ensure safe delivery from producers to end-users. With growing global trade, the need for safe and efficient packaging solutions has increased. The global Industrial Packaging Market is estimated to be valued at US$ 68,677.9 Mn in 2023 and is expected to exhibit a CAGR of 5.4% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity:

The opportunity in reducing wastage has been a major market driver. Industrial packaging helps decrease wastage at various stages of transportation and storage through effective protection of goods. Damage to goods can lead to wastage and loss of products. Use of proper industrial packaging plays a key role in avoiding wastage through breaks, leaks and other forms of damage. It is estimated that over 5% of goods transported globally get wasted every year mainly due to inadequate or improper packaging. Adopting standardized and reusable industrial packaging solutions can significantly reduce this wastage, thereby boosting supply chain efficiency for industries. This presents a major market opportunity for manufacturers of industrial packaging products. Porter’s Analysis Threat of new entrants: The industrial packaging market requires large capital investment to construct manufacturing plants and acquire high quality packaging material and machinery. Thus, threat from new entrants is low to moderate. Bargaining power of buyers: The presence of numerous industrial packaging manufacturers allows buyers to compare products and prices. Thus, the bargaining power of buyers is moderate to high. Bargaining power of suppliers: The industrial packaging market is fragmented with multiple raw material suppliers. Thus, dependence on key material suppliers is low and bargaining power of suppliers is moderate. Threat of new substitutes: Alternatives to conventional packaging include returnable transport items which pose low to moderate threat due to sustainability focus. Competitive rivalry: The market has few global players operating internationally while regional players cater to local demands. Competition is intense based on product innovation, quality, and pricing. SWOT Analysis Strengths: Established distribution network, product innovation, and economies of scale allow creation of value added packaging solutions. Weaknesses: Heavy reliance on cyclical industries, fluctuations in raw material prices, and rising labor costs impact profitability. Opportunities: Growth in e-commerce, food processing, and construction industries drive demand. Sustainable packaging presents new revenue streams. Threats: Volatility in disposable income affects consumer spending. Stricter regulations around plastic use may impact certain product segments. Key Takeaways The global Industrial Packaging market is expected to witness high growth over the forecast period supported by expansion in core end use industries. The market size for 2024 is projected to reach US$ 68,677.9 Mn representing a CAGR of 5.4% between 2023 to 2030. Regional analysis indicates North America currently accounts for the largest share supported by well-established food processing and manufacturing industries. However, Asia Pacific is identified as the fastest growing regional market with strong growth anticipated across China, India, and ASEAN countries. Key players operating in the Industrial Packaging market are Smurfit Kappa Group, Cascades Inc., Mauser Group B.V., Grief Inc., International Paper, Nefab Group, Schutz, Sonoco, AmeriGlobe, and B.A.G. Corp. Global leaders are focused on strategic acquisitions and partnerships to expand their geographic footprint and product portfolios.

0 notes

Text

The smart food packaging market is estimated at USD 26.42 billion in 2024 and is projected to reach USD 35.69 billion by 2029, at a CAGR of 6.2% from 2024 to 2029, fueled by increased R&D investment, rising consumer awareness, and the expansion of e-commerce.

#Smart Food Packaging Market#Smart Food Packaging#Smart Food Packaging Market Size#Smart Food Packaging Market Share#Smart Food Packaging Market Growth#Smart Food Packaging Market Trends#Smart Food Packaging Market Forecast#Smart Food Packaging Market Analysis#Smart Food Packaging Market Report#Smart Food Packaging Market Scope#Smart Food Packaging Market Overview#Smart Food Packaging Market Outlook#Smart Food Packaging Market Drivers#Smart Food Packaging Industry#Smart Food Packaging Companies

0 notes

Text

An Overview of Cosmetic Regulations in Singapore Discover key regulations for cosmetics in Singapore. Learn about HSA guidelines, ASEAN Cosmetic Directive, and product registration to ensure compliance Cosmetic safety Singapore, Singapore cosmetic packaging, Singapore market entry, Singapore cosmetic trends, Singapore cosmetic approvals, Singapore cosmetic industry growth, Cosmetic documentation Singapore

#Cosmetic safety Singapore#Singapore cosmetic packaging#Singapore market entry#Singapore cosmetic trends#Singapore cosmetic approvals#Singapore cosmetic industry growth#Cosmetic documentation Singapore

0 notes

Text

#Global Blister Packaging Market#Global Blister Packaging Industry#Global Blister Packaging Market Size#Global Blister Packaging Market Analysis#Global Blister Packaging Market Share#Global Blister Packaging Market Growth#Global Blister Packaging Market Demand#Global Blister Packaging Market Trends#Global Blister Packaging Market Forecast

0 notes

Text

Food Packaging Industry 2030 Forecast, Future Outlook, Share, Trends, Application

The global food packaging market size is expected to reach USD 562.38 billion in 2030 and is expected to grow at a CAGR of 5.9% from 2025 to 2030 Increased diverse eating habits and lifestyle changes have driven the demand for convenience food products which is expected to bolster the growth of the global food packaging industry. The food packaging industry exhibits rapid growth for portable and…

0 notes

Text

Meat Packaging Market Trends and Innovations: Adapting to Changing Consumer Demands

Meat Packaging Market Trends and Innovations: Adapting to Changing Consumer Demands

Meat Packaging Market Information:

Market Overview

According to Straits Research, the global Meat Packaging market size was valued at USD 15.3 billion in 2023. It is projected to reach from USD 16.0 billion in 2024 to USD 22.9 billion by 2032, growing at a CAGR of 4.6% during the forecast period (2024–2032).

This market research report on Meat Packaging Market offers invaluable insights and guidance for businesses across diverse sectors. It delivers a thorough overview of the Meat Packaging Market, detailing aspects such as market size, trends, key players, consumer behavior, and competitive dynamics. By analyzing and interpreting the data collected through extensive research, this report enables businesses to make informed decisions and devise effective strategies.

The report provides in-depth market intelligence, highlighting opportunities and potential challenges. It helps companies identify their target audiences, understand their needs and preferences, and adjust their products or services accordingly. Additionally, the report assists in evaluating the feasibility of new product launches, assessing market demand, and setting pricing strategies.

Competitive Players in Meat Packaging Market

Some of the key players operating in the Meat Packaging market are

Bemis Company, Inc

Winpak Ltd

Sealed Air Corporation

Berry Plastic Group

Coveris Holdings S.A

Amcor Limited

XtraPlast Packaging Materials

Silgan Holdings Inc.

DuPont De Nemours, Inc

Crown Holdings, Inc

Pactiv Optimum Plastics

Get a free sample of the Meat Packaging Market @ https://straitsresearch.com/report/meat-packaging-market/request-sample

The Meat Packaging market report helps a wide range of businesses figure out what their consumers truly want by conducting extensive market research. When it comes to new products, every company owner wants to understand the demand, and this report is a great resource. Additional benefits include ensuring that the most recent market developments are covered. You may keep a close check on key rivals and their growth strategies by reading the Meat Packaging market research. It also provides in-depth analysis for the years 2022-2030, offering business owners new opportunities.

This research also provides a dashboard view of prominent organizations, highlighting their effective marketing tactics, market share, and recent advances in both historical and current settings.

Global Meat Packaging Market: Segmentation

By Type

Poultry

Beef

Pork

Seafood

By Material Type

Polyethylene (PE)

Polyamide (PA)

Polyvinyl Chloride (PVC)

Ethylene Vinyl Alcohol (EVOH)

Biaxially Oriented Polypropylene Films (BOPP)

By Technology

Modified Atmosphere Packaging (MAP)

Vacuum Skin Packaging (VSP)

Vacuum Thermoformed Packaging (VTP)

The report forecasts revenue growth at all geographic levels and provides an in-depth analysis of the latest industry trends and development patterns in each of the segments and sub-segments. Some of the major geographies included in the market are given below:

North America (U.S., Canada)

Europe (U.K., Germany, France, Italy)

Asia Pacific (China, India, Japan, Singapore, Malaysia)

Latin America (Brazil, Mexico)

Middle East & Africa

Buy Full Meat Packaging Market Report @ https://straitsresearch.com/buy-now/meat-packaging-market

Key Highlights

The purpose of this study is to examine the manufacturers of Meat Packaging, including profiles, primary business activities, news, sales and price, revenue, and market share.

The study provides an overview of the competitive landscape among leading manufacturers worldwide, including sales, revenue, and market share of Meat Packaging percent.

It illustrates the market subdivided by type and application, with details on sales, price, revenue, market share, and growth rate broken down by type and application.

The research covers key regions by manufacturers, categories, and applications, including North America, Europe, Asia Pacific, the Middle East, and South America, with sales, revenue, and market share segmented by manufacturers, types, and applications.

It also investigates production costs, essential raw materials, and production methods.

Principal Motives Behind the Purchase:

To gain deep analyses of the industry and understand the commercial landscape of the global market.

To analyze production processes, key problems, and potential solutions to mitigate future issues.

To understand the most influential driving and restraining factors in the Meat Packaging industry and their global market impact.

To gain insights into the market strategies employed by the most successful firms.

To understand the market's future and potential.

About Us:

StraitsResearch.com is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us:

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: +1 6464807505, +44 203 318 2846

Meat Packaging Market, Meat Packaging Industry, Meat Packaging Market Share, Meat Packaging Market Size, Meat Packaging Market Trends, Meat Packaging Market Regional Analysis, Meat Packaging Market Growth Rate, Meat Packaging Market Analysis, Meat Packaging Market Forecast

#Meat Packaging Market#Meat Packaging Industry#Meat Packaging Market Share#Meat Packaging Market Size#Meat Packaging Market Trends#Meat Packaging Market Regional Analysis#122 Market Growth Rate

0 notes

Text

Pharmaceutical Packaging Market Analysis Report - Industry Trends, Growth and Segmentation 2030

In 2023, the global pharmaceutical packaging market reached a valuation of USD 139.37 billion and is projected to grow at a compound annual growth rate (CAGR) of 9.7% from 2024 through 2030. This growth is largely driven by the rapid expansion of the pharmaceutical industry, which has seen significant advancements in science and technology in recent years. These advancements are anticipated to continue driving demand, especially in emerging markets like China, India, Saudi Arabia, and Brazil, where pharmaceutical production and healthcare services are expanding rapidly.

The United States holds the largest pharmaceutical market share worldwide. Key factors behind this include the nation’s extensive healthcare infrastructure, high per capita income, and significant investments in drug research and development. The rise in generic drugs and improved access to healthcare services in the U.S. are also expected to create promising opportunities for pharmaceutical packaging over the coming years. Additionally, the 21st Century Cures Act (Cures Act), signed into law on December 13, 2016, was enacted to accelerate the development and approval of medical products, encouraging innovations that are anticipated to drive demand for pharmaceutical packaging in the U.S.

Gather more insights about the market drivers, restrains and growth of the Pharmaceutical Packaging Market

In Europe, the pharmaceutical industry is a crucial component of the economy and is one of the region's most high-performing and technologically advanced sectors. Recent years have seen a significant shift toward the development of biopharmaceutical drugs, a focus that has grown substantially. Biopharmaceuticals often require specialized packaging, as many biotechnology-derived drug therapies are unstable in liquid form and are instead offered as lyophilized (freeze-dried) or dry powder formulations. These specialized dosage forms demand advanced packaging solutions to maintain the drugs' stability and efficacy, creating new opportunities for packaging manufacturers to innovate.

The pharmaceutical packaging market is diverse and fragmented, featuring large and medium-sized international companies alongside smaller domestic players. Key players in this market include Amcor plc, Becton, Dickinson and Company, AptarGroup, Inc., Drug Plastics Group, Gerresheimer AG, Schott AG, O-I Glass, Inc., SGD Pharma, West Pharmaceutical Services, Inc., Berry Global Group, Inc., WestRock Company, International Paper, Comar, LLC, CCL Industries, and Vetter Pharma International.

Product Segmentation Insights:

Pharmaceutical packaging is categorized into three main types: primary, secondary, and tertiary packaging. In 2023, primary packaging accounted for the largest share of the market. Primary packaging refers to materials such as bottles, tubes, and blister packs that come into direct contact with the drug, protecting it from contamination and aiding in safe storage. Primary packaging often also plays a role in dispensing and dosing, and manufacturers are focusing on user-friendly designs, including easy-open closures and dispensing systems that ensure the correct dose is given at the appropriate time. These advancements are especially beneficial for elderly populations, who may need additional support in handling medication.

Secondary pharmaceutical packaging is the next layer of protection, grouping multiple primary packages to safeguard them from external impacts. This packaging is critical for both branding and logistics. It not only helps protect the drug but also serves as a marketing tool by displaying the product in an attractive way. Secondary packaging also makes it easier to handle and transport multiple units, which is important for distribution efficiency.

Tertiary packaging, on the other hand, is used to wrap or bundle large groups of products, facilitating safe handling and transportation of goods across long distances. Examples of tertiary packaging include brown cardboard boxes, shrink wraps, and plastic bags. The growth of e-pharmacy (online pharmaceutical sales) has contributed to the increased need for tertiary packaging, as it ensures the safe and efficient transport of pharmaceutical products directly to consumers. This trend is expected to further drive demand for tertiary packaging over the forecast period.

Order a free sample PDF of the Pharmaceutical Packaging Market Intelligence Study, published by Grand View Research.

#Pharmaceutical Packaging Industry#Pharmaceutical Packaging Market Share#Pharmaceutical Packaging Market Analysis#Pharmaceutical Packaging Market Trends

0 notes

Text

Pharmaceutical Packaging Market Overview, Challenges and Growth Opportunities Analysis till 2030

In 2023, the global pharmaceutical packaging market reached a valuation of USD 139.37 billion and is projected to grow at a compound annual growth rate (CAGR) of 9.7% from 2024 through 2030. This growth is largely driven by the rapid expansion of the pharmaceutical industry, which has seen significant advancements in science and technology in recent years. These advancements are anticipated to continue driving demand, especially in emerging markets like China, India, Saudi Arabia, and Brazil, where pharmaceutical production and healthcare services are expanding rapidly.

The United States holds the largest pharmaceutical market share worldwide. Key factors behind this include the nation’s extensive healthcare infrastructure, high per capita income, and significant investments in drug research and development. The rise in generic drugs and improved access to healthcare services in the U.S. are also expected to create promising opportunities for pharmaceutical packaging over the coming years. Additionally, the 21st Century Cures Act (Cures Act), signed into law on December 13, 2016, was enacted to accelerate the development and approval of medical products, encouraging innovations that are anticipated to drive demand for pharmaceutical packaging in the U.S.

Gather more insights about the market drivers, restrains and growth of the Pharmaceutical Packaging Market

In Europe, the pharmaceutical industry is a crucial component of the economy and is one of the region's most high-performing and technologically advanced sectors. Recent years have seen a significant shift toward the development of biopharmaceutical drugs, a focus that has grown substantially. Biopharmaceuticals often require specialized packaging, as many biotechnology-derived drug therapies are unstable in liquid form and are instead offered as lyophilized (freeze-dried) or dry powder formulations. These specialized dosage forms demand advanced packaging solutions to maintain the drugs' stability and efficacy, creating new opportunities for packaging manufacturers to innovate.

The pharmaceutical packaging market is diverse and fragmented, featuring large and medium-sized international companies alongside smaller domestic players. Key players in this market include Amcor plc, Becton, Dickinson and Company, AptarGroup, Inc., Drug Plastics Group, Gerresheimer AG, Schott AG, O-I Glass, Inc., SGD Pharma, West Pharmaceutical Services, Inc., Berry Global Group, Inc., WestRock Company, International Paper, Comar, LLC, CCL Industries, and Vetter Pharma International.

Product Segmentation Insights:

Pharmaceutical packaging is categorized into three main types: primary, secondary, and tertiary packaging. In 2023, primary packaging accounted for the largest share of the market. Primary packaging refers to materials such as bottles, tubes, and blister packs that come into direct contact with the drug, protecting it from contamination and aiding in safe storage. Primary packaging often also plays a role in dispensing and dosing, and manufacturers are focusing on user-friendly designs, including easy-open closures and dispensing systems that ensure the correct dose is given at the appropriate time. These advancements are especially beneficial for elderly populations, who may need additional support in handling medication.

Secondary pharmaceutical packaging is the next layer of protection, grouping multiple primary packages to safeguard them from external impacts. This packaging is critical for both branding and logistics. It not only helps protect the drug but also serves as a marketing tool by displaying the product in an attractive way. Secondary packaging also makes it easier to handle and transport multiple units, which is important for distribution efficiency.

Tertiary packaging, on the other hand, is used to wrap or bundle large groups of products, facilitating safe handling and transportation of goods across long distances. Examples of tertiary packaging include brown cardboard boxes, shrink wraps, and plastic bags. The growth of e-pharmacy (online pharmaceutical sales) has contributed to the increased need for tertiary packaging, as it ensures the safe and efficient transport of pharmaceutical products directly to consumers. This trend is expected to further drive demand for tertiary packaging over the forecast period.

Order a free sample PDF of the Pharmaceutical Packaging Market Intelligence Study, published by Grand View Research.

#Pharmaceutical Packaging Industry#Pharmaceutical Packaging Market Share#Pharmaceutical Packaging Market Analysis#Pharmaceutical Packaging Market Trends

0 notes

Text

#Pharmaceuticals Temperature Controlled Packaging Solutions Market Size#Pharmaceuticals Temperature Controlled Packaging Solutions Market Share#Pharmaceuticals Temperature Controlled Packaging Solutions Market Growth#Pharmaceuticals Temperature Controlled Packaging Solutions Market Trends#Pharmaceuticals Temperature Controlled Packaging Solutions Market Forecast Analysis#Pharmaceuticals Temperature Controlled Packaging Solutions Market Segmentation#Pharmaceuticals Temperature Controlled Packaging Solutions Market 2024#Pharmaceuticals Temperature Controlled Packaging Solutions Market CAGR#Pharmaceuticals Temperature Controlled Packaging Solutions Market Analyzer Industry

0 notes

Text

The Paper Packaging Industry: Trends, Insights, and Future Prospects

Introduction

The paper packaging industry has emerged as a critical segment within the broader packaging market, driven by increasing consumer demand for sustainable alternatives to plastic. With environmental concerns at the forefront of global discourse, businesses are seeking innovative ways to reduce their carbon footprint. This blog explores current trends, market dynamics, and future opportunities within the paper packaging industry.

Market Overview

As of recent market research, the Paper Packaging Market is projected to reach approximately USD 398.65 billion in 2024 and is anticipated to grow to USD 501.08 billion by 2029, with a CAGR of 4.68% during the forecast period from 2024 to 2029. This growth is fueled by the rising demand for eco-friendly packaging solutions across various sectors, including food and beverage, pharmaceuticals, electronics, and personal care.

Key Drivers of Growth

Sustainability Concerns: Increasing awareness of environmental issues has led consumers and businesses to seek sustainable packaging solutions. Paper packaging is biodegradable, recyclable, and often made from renewable resources, making it an attractive alternative to plastic.

Government Regulations: Many countries are implementing stricter regulations on plastic usage, prompting companies to shift towards paper packaging. Initiatives aimed at reducing plastic waste are pushing industries to adopt eco-friendly materials.

E-commerce Boom: The rapid growth of e-commerce has resulted in an increased need for packaging solutions that can protect products during transit. Paper packaging offers versatility, strength, and a premium feel that enhances customer experience.

Innovative Designs: Advances in technology have led to the development of innovative paper packaging designs that not only offer functionality but also aesthetic appeal. Businesses are investing in creative packaging to differentiate their products in a competitive market.

Challenges Facing the Industry

While the paper packaging industry is on an upward trajectory, it faces several challenges:

Raw Material Costs: Fluctuations in the price of wood pulp and recycled paper can affect production costs, impacting profitability.

Competition from Alternatives: Plastic packaging still holds a significant market share due to its cost-effectiveness and durability. Convincing consumers to switch to paper alternatives remains a challenge.

Environmental Concerns: Despite being more sustainable, the paper industry must address its own environmental impact, particularly related to deforestation and water usage.

Future Trends

Technological Advancements: The integration of smart technology in packaging, such as QR codes and augmented reality, can enhance customer engagement and provide additional product information.

Biodegradable and Compostable Solutions: The push for more sustainable materials will lead to innovations in biodegradable coatings and compostable paper products, further reducing environmental impact.

Increased Recycling Initiatives: Companies are investing in recycling technologies and infrastructure to create a circular economy within the paper packaging industry.

Customization and Personalization: Brands are focusing on customized packaging to improve brand loyalty and customer satisfaction, making unique packaging solutions more prevalent.

Conclusion

The paper packaging industry is poised for significant growth as it adapts to changing consumer preferences and regulatory landscapes. With sustainability at its core, the sector not only addresses environmental concerns but also meets the evolving needs of modern businesses. Companies that innovate and invest in eco-friendly practices will likely find themselves leading the charge in this promising market. As the demand for sustainable packaging continues to rise, the future of paper packaging looks bright. For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/paper-packaging-market

#Paper Packaging Industry#Paper Packaging Market#Paper Packaging Market Size#Paper Packaging Market Share#Paper Packaging Market Report#Paper Packaging Market Analysis#Paper Packaging Market Trends

0 notes

Text

Smart Food Packaging Market Segmentation: Key Technologies and Regional Growth Insights

The global smart food packaging market is estimated at USD 26.42 billion in 2024 and is projected to reach USD 35.69 billion by 2029, at a CAGR of 6.2% from 2024 to 2029. The study "Active Packaging in the Food Industry", published in October 2024, explores the growing significance of active packaging in response to changing consumer demands and market trends. Unlike traditional packaging, which is designed to be inert, active packaging interacts with the product and its environment to extend shelf life and maintain food quality. This can involve incorporating additives into packaging systems, such as oxygen and ethylene scavengers, antimicrobial agents, antioxidants, and flavor-absorbing or releasing compounds. Intelligent packaging systems, like time-temperature indicators and gas detectors, are also discussed, emphasizing the importance of consumer acceptance for the commercial success of these technologies. The study reviews key mechanisms used in active packaging, including oxygen scavengers, which reduce the presence of oxygen in food packaging by using iron-based or ascorbic acid-based systems. These methods help maintain product freshness by limiting oxidative damage. Carbon dioxide-generating systems are also used to suppress microbial growth, particularly in meat, poultry, fish, and cheese packaging. Furthermore, ethylene scavengers are vital for extending the shelf life of fruits and vegetables by controlling ripening processes.

Other applications discussed include the use of flavor and odor absorbers/releasers, which enhance the sensory properties of packaged food, and antimicrobial packaging that inhibits microbial growth to ensure food safety. The potential of nanotechnology to develop new and more effective active and intelligent packaging solutions is highlighted, paving the way for further innovations in the food packaging industry. This study underscores the need for advanced packaging technologies to meet consumer demand for fresh, safe, and high-quality food products and their critical role in prolonging shelf life and improving food safety.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=103797679

The Meat, Poultry & Seafood is the having a largest share within the application sector of the smart food packaging market.

Due to growing global demand, meat, poultry, and seafood accounts for the highest market share of application in the smart food packaging market. Its needs lie in extending shelf life, safety, and traceability. As per data provided by the USDA from October 2024, Brazil dominates global chicken meat exports during 2025 as the production will be 11.8 million tons. Australia's poultry production will increase by 2 percent to 2.6 million tons, as high global demand is expected. Beef exports from Australia will also reach a record 1.9 million tons in the year, as its demand increases in the US. These trends point towards the increasing international meat trade and export opportunities.

Increased production and exports require more advanced smart packaging technologies, such as modified atmosphere packaging and active packaging, for freshness, less food waste, and greater safety. This will fuel innovation and adoption of smart packaging solutions, especially in global markets like East Asia and North America.

The active packaging segment holds significant market share in the smart food packaging market during the forecasted period 2024-2029.

Active food packaging accounts for a major market share in the smart food packaging industry, which is mainly attributed to the quality improvement, safety, and shelf life that active packaging can offer. Technologies, including oxygen scavengers, moisture absorbers, and antimicrobial agents, respond to some of the most important consumer needs related to freshness and reduction of food waste.

It is primarily gaining adoption across key industries, including meat, poultry, seafood, and dairy, where growing concerns about global food safety and sustainability are driving growth. Additionally, increasing export of perishable food products, particularly in North America, Europe, and Asia-Pacific, further supports the increasing demand for active packaging. As manufacturers look for more innovative ways to meet their regulatory requirements and consumer demands, active packaging will maintain its position in the market.

Make an Inquiry: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=103797679

Based on region, Europe has a significant share in the smart food packaging market.

The growth of the food and beverage industry in Europe is a major driving force for the smart food packaging market, which is motivated by the increasing demand for advanced packaging solutions that would ensure food safety, traceability, and extended shelf life. According to European Commission data (March 2024), the food and drinks industry generates ~USD 245 billion (€227 billion) in added value and employs 4.6 million people, making it the EU's largest manufacturing sector in terms of jobs and value. SMEs are over 99% of businesses in this ecosystem. The sector has also recorded a food trade surplus, with exports doubled over the last decade to exceed ~USD 196 billion (€182 billion), contributing a positive balance of nearly ~USD 32 billion (€30 billion). These strong figures, combined with growing trade opportunities and EU Single Market benefits, are driving demand for smart food packaging technologies to support efficient, sustainable, and competitive food supply chains.

Leading Smart Food Packaging Manufacturers:

The report profiles key players such as Amcor plc (Switzerland), Mondi (UK), Sealed Air (US), Berry Global Inc. (US), Toyo Seikan Group Holdings, Ltd. (Japan), THE TETRA LAVAL GROUP (Switzerland), Crown (US), 3M (US), MITSUBISHI GAS CHEMICAL COMPANY, INC. (Japan), Multisorb (US), Huhtamäki Oyj (Finland), Timestrip UK LTD (UK), Stepac (Israel), Checkpoint Systems, Inc. (US), and Novipax Buyer, LLC (US).

#Smart Food Packaging Market#Smart Food Packaging#Smart Food Packaging Market Size#Smart Food Packaging Market Share#Smart Food Packaging Market Growth#Smart Food Packaging Market Trends#Smart Food Packaging Market Forecast#Smart Food Packaging Market Analysis#Smart Food Packaging Market Report#Smart Food Packaging Market Scope#Smart Food Packaging Market Overview#Smart Food Packaging Market Outlook#Smart Food Packaging Market Drivers#Smart Food Packaging Industry#Smart Food Packaging Companies

0 notes

Text

0 notes

Text

Packaging tape printing involves the customization of adhesive tapes with logos, branding, or messages. This practice enhances brand visibility, improves security, and provides tamper-evidence for shipments. It's widely used across industries like logistics, retail, and e-commerce to promote brands and ensure the integrity and authenticity of packaged goods, reflecting a trend toward personalized and secure packaging solutions.

The report "North American Packaging Tape Printing Market by Product Type (Hot Melt, Acrylic Based), Material (Polypropylene, PVC), Printing Ink (Water Based, UV-Curable), Mechanism (Digital, Flexography), End-user (Food & Beverages, Consumer Durables) - Forecast ", the packaging tape printing market size was estimated to grow from USD 5.4 Billion in 2015 to reach USD 7.0 Billion by 2020, at an estimated CAGR of 5.4% from 2015 to 2020.

#North American Packaging Tape Printing Market#North American Packaging Tape Printing#Packaging Tape Printing Market Size#Packaging Tape Printing Market Share#Packaging Tape Printing Market Forecast#Packaging Tape Printing Market Analysis#Packaging Tape Printing Market Trends#Packaging Tape Printing Market Opportunities#Packaging Tape Printing Market Overview#Packaging Tape Printing Market Insights#Packaging Tape Printing Market Regional Analysis#Packaging Tape Printing Companies#Packaging Tape Printing Manufacturers#Packaging Tape Printing Producers#Packaging Tape Printing Suppliers#Packaging Tape Printing Trends#Packaging Tape Printing Technology#Packaging Tape Printing Ecosystem#Packaging Tape Printing Applications#Packaging Tape Printing Products#Packaging Tape Printing Industry#Packaging Tape Printing Industry Trends#Packaging Tape Printing Industry Share#Packaging Tape Printing Industry Forecast#Packaging Tape Printing Industry Size#Packaging Tape Printing Industry Opportunities#Global Packaging Tape Printing Market#Global Packaging Tape Printing Industry#Packaging Tape Printing Market Segments#Packaging Tape Printing Market Segmentation

0 notes

Text

Revolutionizing Healthcare with Smart Medical Packaging Market Solutions

In the rapidly evolving landscape of healthcare, technological advancements are driving innovation across every aspect of patient care, including medication management, patient monitoring, and supply chain logistics. One of the most promising developments in this regard is the emergence of smart packaging technologies, which are transforming traditional healthcare packaging into intelligent systems capable of real-time tracking, monitoring, and data analytics. In this article, we delve into the world of smart packaging for healthcare and explore its potential to revolutionize the industry.

According to Next Move Strategy Consulting, the global Advanced Packaging Market for Medical is predicted to reach USD 9.61 billion by 2030, with a CAGR of 13.6% from 2024 to 2030.

Download FREE Sample: https://www.nextmsc.com/advanced-packaging-market/request-sample

Understanding Smart Packaging for Healthcare:

Smart packaging refers to the integration of advanced technologies such as sensors, RFID (Radio Frequency Identification) tags, and IoT (Internet of Things) devices into packaging materials and containers. These technologies enable packaging to capture, store, and transmit data about the contents, environment, and usage of the packaged products. In the healthcare sector, smart packaging solutions are designed to enhance medication safety, improve patient outcomes, and optimize supply chain efficiency.

Revolutionizing Medication Management:

One of the primary applications of smart packaging in healthcare is medication management. Smart packaging solutions equipped with RFID tags or NFC (Near Field Communication) sensors can provide real-time information about medication usage, dosage schedules, and patient adherence. This data can be transmitted to healthcare providers or caregivers, allowing them to monitor patient compliance, intervene in case of missed doses, and adjust treatment plans as needed. By promoting medication adherence and reducing medication errors, smart packaging contributes to improved patient outcomes and reduced healthcare costs.

Inquire before buying: https://www.nextmsc.com/advanced-packaging-market/inquire-before-buying

Enhancing Patient Monitoring:

Smart packaging technologies also play a crucial role in patient monitoring and remote healthcare delivery. By embedding sensors or biosensors into packaging materials, healthcare providers can collect vital health data such as temperature, humidity, and pH levels in real-time. This data can be transmitted wirelessly to medical professionals, enabling remote monitoring of patients' health status and early detection of potential health issues. Smart packaging solutions also facilitate the integration of telemedicine platforms and virtual care services, enabling patients to receive personalized care and support from the comfort of their homes.

Optimizing Supply Chain Visibility:

In addition to improving patient care, smart packaging solutions offer significant benefits for supply chain management in the healthcare industry. By incorporating RFID tags or IoT devices into packaging containers, pharmaceutical companies, distributors, and healthcare facilities can track the movement of products throughout the supply chain in real-time. This enhanced visibility enables better inventory management, reduces the risk of stockouts or expired products, and improves overall operational efficiency. Smart packaging also provides tamper-evident features and authentication mechanisms, ensuring the integrity and safety of pharmaceutical products during transit and storage.

Geographical Analysis

North America region holds the lion's share of the advanced packaging market for medical applications at present and is expected to continue dominating the market during the forecast period. The growing liver diseases in the region due to the high consumption of alcohol and flour-based products increases the demand for robotic surgery equipment, which in turn drives the growth of the market. For instance, in 2021, Centres for Disease Control and Prevention (CDC) announced that 4.5 million adults were diagnosed with chronic liver disease in the U.S. contributing to 1.8% of the country’s total adult population diagnosed with liver disease.

Benefits of Smart Packaging:

1.Real-Time Tracking: Smart packaging enables real-time tracking of pharmaceutical products throughout the supply chain, from manufacturing facilities to end-users, improving traceability and transparency.

2.Temperature Monitoring: Smart packaging solutions equipped with temperature sensors ensure that temperature-sensitive medications and vaccines are stored and transported under optimal conditions, reducing the risk of spoilage and ensuring product efficacy.

3.Tamper-Evident Features: Smart packaging includes tamper-evident seals and authentication mechanisms to prevent tampering and unauthorized access to pharmaceutical products, enhancing product safety and security.

4.Improved Patient Safety: By promoting medication adherence, enabling remote patient monitoring, and ensuring product authenticity, smart packaging contributes to improved patient safety and outcomes.

5.Personalized Medicine: Smart packaging solutions can facilitate the delivery of personalized medicine by incorporating patient-specific information, such as dosage instructions, allergy alerts, and treatment schedules. By tailoring medication packaging to individual patient needs, healthcare providers can optimize treatment outcomes and minimize the risk of adverse reactions or medication errors.

6.Data Analytics and Predictive Insights: Smart packaging technologies enable the collection and analysis of vast amounts of data related to medication usage, patient health metrics, and supply chain logistics. By leveraging advanced analytics and predictive algorithms, healthcare providers can gain valuable insights into patient behavior, treatment efficacy, and supply chain performance, allowing for proactive interventions and informed decision-making.

7.Regulatory Compliance: Smart packaging solutions help pharmaceutical companies and healthcare facilities comply with regulatory requirements and quality standards, such as FDA regulations and Good Manufacturing Practices (GMP). By ensuring accurate labeling, traceability, and documentation, smart packaging helps streamline regulatory compliance processes and reduce the risk of non-compliance-related penalties or recalls.

Competitive Landscape

Various market players operating in the global advanced packaging industry for medical include Dupont, 3M, Amcor, Advanced Semiconductor Engineering, Inc., West Pharmaceutical Services, Oliver Healthcare Packaging LLC, Amkor Technology, UTAC Group, Orient Semiconductor Electronics Ltd, and Medical Packaging Inc., LLC.

For instance, in September 2022, DuPont launched a new brand, Micromax, that will encompass the products formerly under the Microcircuit and Component Materials brand. Micromax brand products are utilized for circuitry, interconnection, and packaging of electronic devices in automotive, passive components, telecom, consumer electronics, and healthcare industries.

Conclusion:

Smart packaging technologies are revolutionizing the healthcare industry by providing innovative solutions for medication management, patient monitoring, and supply chain optimization. With their ability to capture, store, and transmit real-time data, smart packaging solutions offer unprecedented visibility, control, and security throughout the pharmaceutical supply chain. As the adoption of smart packaging continues to grow, we can expect to see further advancements in healthcare delivery, improved patient outcomes, and enhanced operational efficiency across the entire healthcare ecosystem.

0 notes

Text

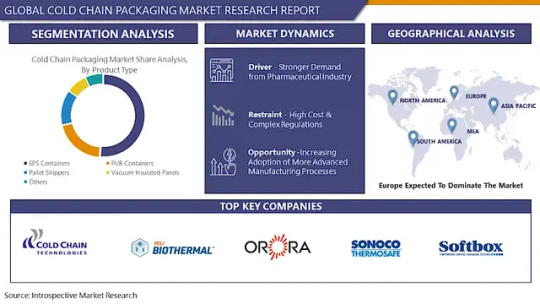

Cold Chain Packaging Market: Global Industry Analysis and Forecast 2023 – 2030

The Global Market for Cold Chain Packaging Estimated at USD 27130 Million In the Year 2022, Is Projected To Reach A Revised Size Of USD 115100 Million By 2030, Growing At A CAGR Of 19.90% Over The Forecast Period 2022-2030.

The Cold Chain Packaging Market is a critical segment within the broader packaging industry, primarily focused on preserving and maintaining the integrity of temperature-sensitive products during transportation and storage. This market plays a pivotal role in supporting industries such as pharmaceuticals, food and beverages, and healthcare, where the maintenance of specific temperature conditions is essential for product efficacy and safety. With the increasing globalization of supply chains and the growing demand for perishable goods, the cold chain packaging market has witnessed significant growth in recent years.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16601

Leading players involved in the Cold Chain Packaging Market include:

Cold Chain Technologies (U.S.), Peli BioThermal (U.S.), Orora Group (Australia), Sonoco ThermoSafe (U.S.), CREOPACK (Canada), Sofrigam (France), Intelsius (U.K.), Nordic Cold Chain Solutions (U.S.), Tempack (Spain), Cryopak (U.S.), Softbox Systems (U.K.), Sealed Air Corporation (U.S.) And Other Major Players

Market Driver:

One of the key drivers propelling the Cold Chain Packaging Market is the surge in demand for biopharmaceuticals and specialty drugs. As pharmaceutical companies continue to develop advanced and temperature-sensitive medications, the need for reliable and efficient cold chain packaging solutions becomes paramount. These intricate drugs often require strict temperature control to ensure their effectiveness and safety, creating a demand for innovative packaging solutions equipped with temperature-monitoring technologies. The increasing prevalence of chronic diseases and the expansion of the pharmaceutical sector further accentuate the importance of a robust cold chain packaging infrastructure.

Market Opportunity:

An emerging opportunity in the Cold Chain Packaging Market lies in the integration of sustainable and eco-friendly packaging materials and practices. As environmental concerns gain prominence across industries, there is a growing demand for packaging solutions that minimize carbon footprint and reduce waste. Manufacturers in the cold chain packaging sector have the chance to capitalize on this trend by developing and promoting packaging solutions that are not only effective in temperature control but also environmentally friendly. Innovations in recyclable materials and energy-efficient packaging technologies represent a significant market opportunity, aligning with the broader global shift towards sustainable practices.

The latest research on the Cold Chain Packaging market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Cold Chain Packaging industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Cold Chain Packaging market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

If You Have Any Query Cold Chain Packaging Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16601

Segmentation of Cold Chain Packaging Market:

By Product Type

EPS Containers

PUR Containers

Pallet Shippers

Vacuum Insulated Panels

Others

By Application

Food

Dairy

Pharmaceutical

Others

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Cold Chain Packaging market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Cold Chain Packaging market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Cold Chain Packaging market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Cold Chain Packaging market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Cold Chain Packaging Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16601

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email:[email protected]

#Cold Chain Packaging#Cold Chain Packaging Market#Cold Chain Packaging Market Size#Cold Chain Packaging Market Share#Cold Chain Packaging Market Growth#Cold Chain Packaging Market Trend#Cold Chain Packaging Market segment#Cold Chain Packaging Market Opportunity#Cold Chain Packaging Market Analysis 2023#US Cold Chain Packaging Market#Cold Chain Packaging Market Forecast#Cold Chain Packaging Industry#Cold Chain Packaging Industry Size#china Cold Chain Packaging Market#UK Cold Chain Packaging Market

0 notes