#Smart Food Packaging Market Report

Explore tagged Tumblr posts

Text

The smart food packaging market is estimated at USD 26.42 billion in 2024 and is projected to reach USD 35.69 billion by 2029, at a CAGR of 6.2% from 2024 to 2029, fueled by increased R&D investment, rising consumer awareness, and the expansion of e-commerce.

#Smart Food Packaging Market#Smart Food Packaging#Smart Food Packaging Market Size#Smart Food Packaging Market Share#Smart Food Packaging Market Growth#Smart Food Packaging Market Trends#Smart Food Packaging Market Forecast#Smart Food Packaging Market Analysis#Smart Food Packaging Market Report#Smart Food Packaging Market Scope#Smart Food Packaging Market Overview#Smart Food Packaging Market Outlook#Smart Food Packaging Market Drivers#Smart Food Packaging Industry#Smart Food Packaging Companies

0 notes

Text

How Much Does Cannabis Oil Cost?

Whether you’re a new or experienced cannabis consumer, you’ve likely wondered, “how much does cannabis oil cost?” This new therapeutic product has earned high praise from medical and recreational users. Each bottle of cannabis oil, also known as a tincture, comes with varying ratios of cannabinoids at relatively steep prices compared to other health- and wellness-related products. Despite the high markup for cannabis oil, many consumers regularly use this delivery method to reap all of the mental and physical benefits of two major cannabinoids: cannabidiol (CBD) and delta-9-tetrahydrocannabinol (THC). A number of factors affect the price of the oil. You can expect to pay anywhere from $30 to up to $200 for a single bottle. Here’s what you need to know about shopping smart for cannabis oil.

How Much Does CBD Oil Cost?

CBD oil has become widely accessible to the entire nation. It’s revered for its non-psychoactive and therapeutic effects on pain, anxiety, inflammation, seizures, and other debilitating symptoms. The health and wellness aspect of CBD oil commands a premium price for its symptomatic relief. Apart from its medical applications, there are plenty of other factors that determine how much consumers pay for cannabis oil in general. Katie Stem of Peak Extracts told Weedmaps, “When examining a cost analysis from a production perspective, you look at labor, materials, packaging, labels, potency/purity testing, marketing, and shipping distribution.” For manufacturers, bulk CBD can range from $3 to $15 per gram, which works out to be less than one cent to 1.5 cents per milligram. Consumers end up paying about $50 to $60 per 1,000 mg bottle, or about 5 to 20 cents per milligram.

Why Are People Paying Premium Prices for CBD Oil?

CBD oil products, in particular, offer many potential health benefits for medical and recreational consumers. People generally buy CBD oil to help them with inflammation, pain, anxiety, stress, depression, muscle spasms, fatigue, sleep disorders, and plenty of other symptoms. Furthermore, CBD doesn’t produce the negative side effects, especially if you take the appropriate dosage. Despite the popularity of CBD oil products, their efficacy has not been approved by the Food and Drug Administration. Only the CBD-based drug, Epidiolex, has been approved for medical use. In fact, many hemp companies have received warning letters from the FDA for claiming unproven health benefits on its packaging and advertising. While CBD oil can help supplement a conventional treatment plan, it’s important to consult with your physician before starting a cannabis oil regimen.

How Much Does Cannabis Oil Cost?

Cannabis oil varies in price based on cannabinoid content, as well as the region where it’s sold. Seattle-based Headset published a report detailing pricing data for a variety of marijuana products in Washington State, California, Nevada, and Colorado. The price of THC oil varied by state. For example, Colorado had the highest price at 41 cents per milligram, which was 64 percent higher than Nevada’s 25 cents per milligram. California and Washington both had a 30 cent per milligram average price for THC oil. Here are just a few examples of THC oil prices in the Southern California market: - Mary’s Medicinals The Remedy THC has 1,000 mg of THC priced at $56, about 6 cents per milligram. - Raw 1:20 THC:CBD Focus tincture has 1,000 mg priced at $87, about 9 cents per milligram. - Select 1:1 Peppermint oil has 1,000 mg priced at $68, about 7 cents per milligram. - Care by Design 8:1 CBD-rich sublingual drops has about 240 mg priced at $40, about 16 cents per milligram. - Humboldt Apothecary Relax CBD 3:1 tincture has 250 mg priced at $65, about 26 cents per milligram. - Releaf 1:1 CBD:THCa tincture has 900 mg priced at $99.62, about 11 cents per milligram.

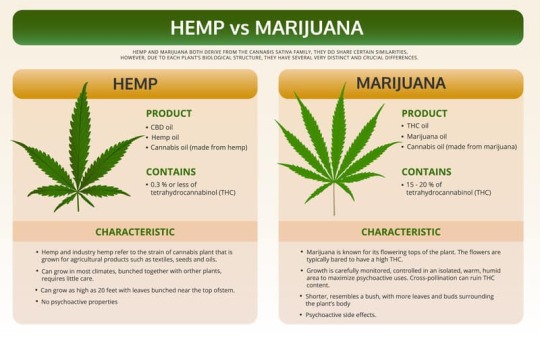

Marijuana vs. Hemp-Derived Cannabis Oil

Cannabis oil products can be derived from either marijuana or hemp plants. Both belong to the same Cannabis sativaplant species. Marijuana plants are primarily bred for a THC-rich resin, while hemp plants produce high-CBD resin with only trace amounts of THC. Hemp-derived oil tends to be more affordable than marijuana-derived oil. When shopping for cannabis oil, consumers may run across terms such as full-spectrum, broad-spectrum, or distillate. Each comes with varying price points depending on many factors, including its source. Full-spectrum products contain the original chemical profile of a strain, including THC, CBD, and terpenes. Broad-spectrum contains everything in the plant but the THC, for a non-intoxicating experience. Distillates only contain one cannabinoid, either CBDA or THCA. The compounds in full-spectrum and broad-spectrum cannabis oil not only add to the aroma, but also the effects and the price. Research into cannabinoids indicate that the interaction between different cannabinoids and terpenes produces an “entourage effect.” This synergistic effect of the plant’s compounds is thought to enhance the therapeutic benefits of a cannabis product. For this reason, many medical consumers look for full- or broad-spectrum cannabis oil. However, someone who doesn’t want the aroma of intoxication of cannabis, may stick with a CBD isolate. Hemp-derived CBD oil is more widely available than cannabis-derived tinctures. Ever since the 2018 Farm Bill passed, hemp-derived CBD is legal all over the country. If you’re hoping to buy cannabis-derived tinctures, you must live in a state that allows medical cannabis (at the very least). In these states, cannabis-derived tinctures tend to be pricier because hemp isn’t as expensive to produce.

Factors Affecting Cannabis Oil Costs

A bottle of cannabis oil can vary in price based on an assortment of factors from production to marketing costs. For example, cannabis oil made from organically grown hemp from Colorado will have a higher price than oil made from a plant grown in a state with a newer market. Besides quality, potency also affects the price of a product. Cannabis oil with 1,000 mg of cannabinoids will be more expensive than oil with fewer cannabinoids per milliliter. The cannabis industry has unique costs and challenges that can drive up the price of cannabis oil. For example, lab testing requirements can force companies to spend hundreds of thousands of dollars testing their oil for contaminants. Lab testing can range from $100 to $400 per sample tested. In many cases, cannabis must be tested various times throughout the supply-chain process. Furthermore, the cannabis industry can’t write off business expenses because according to the US federal government, the marijuana plant is a Schedule I drug with no medicinal value. Dispensaries and producers may hike up their prices to offset some of these overhead costs. Industry experts believe that full legalization will help build a stronger regulatory framework for the industry to benefit both companies and consumers.

Is Cannabis Oil Lab Tested?

Certified laboratories can provide a complete analysis of licensed cannabis product samples. Third-party labs can test for potency including its cannabinoid and terpene profile. Labs also test for pesticides, microbial contamination, residual solvents, and other harmful chemicals that can remain after the extraction process. Essentially, lab testing ensures the product you are buying has the potency listed on the label. More importantly, lab testing ensures the product you are consuming has no harmful contaminants that can offset its therapeutic effects. Lab testing can significantly increase the price of cannabis oil products. However, it’s up to you to make sure your product is actually lab tested. Most companies who lab test provide a certificate of analysis (COA) on its website. Simply type in the batch number found on the packaging into their lab results page. Buying from a licensed cannabis retailer is one of the only ways to ensure you are getting a product tested by a third-party lab. While buying hemp-derived CBD oil online without lab testing may be cheaper, we recommend you spring the extra few bucks for peace of mind and security.

How to Find Reliable and Cost-Effective Cannabis Oil

Finding the right cannabis oil at the right price point can seem like an impossible task. Luckily, there are a few ways you make sure you get the most for your dollar based on your desired results. It can take a few hours, days, or weeks of research to find the right cannabis oil. While price matters, some affordable cannabis oils can be just as effective as the most expensive cannabis oils. Here are a few ways to save money on cannabis oil. - Buy cannabis oil in bulk. Larger quantities mean more upfront costs, but the product often comes with considerable savings of up to 40 percent per milligram. Manufacturers pass their savings on packaging onto you. Buying in bulk can also earn you free shipping with most hemp-derived oil companies. - Follow your favorite cannabis oil companies or retailers on their social media channels to scope out special discounts, promotions, and giveaways. - Sign up for low-income, veteran, or other financial assistance programs if you qualify. Not every company offers this perk, but the ones that do may give you a discount of more than half off if you can send qualifying proof or apply for a spot in their program. - Buy based on price-per-milligram. In order to calculate the price per milligram of a cannabis oil bottle, divide the total price of the product by the milligrams of cannabinoids in the product. - When searching for bargains, always make sure you buy cannabis oil that has a certificate of analysis (COA) from an accredited third-party laboratory ensuring you have a safe and pure products.

Will CBD Prices Ever Come Down?

Industry insiders believe the price of cannabis oil will eventually go down, but not anytime soon. The industry’s strict regulations place an enormous burden on cannabis companies in terms of testing, taxes, and other rules on the plant’s production. A variety of factors serve to limit the amount of cannabis production possible. Whether it’s commercial cannabis bans in your town or excessive licensing costs, it takes a lot of money to start up a cannabis company. Cannabis oil may never be the most affordable natural medicine available, at least compared to pharmaceutical or herbal supplement products. However, prices are expected to go down as lawmakers become more supportive of the industry. Once they remove the harsh limits imposed on weed companies, maybe then will the prices become accessible for those who truly need it. As you can see, the price of cannabis oil varies widely based on the source, quality, potency, location, size, and other manufacturing and marketing costs associated with the product. The novelty of the industry and a lack of regulation have contributed to cannabis oil’s high prices, but consumers are hopeful that one-day cannabis oil can reach an accessible price point for everyone that needs it. Stay tuned to the Cannabis Training University blog for updates on: - price of cannabis oil - THC oil cost - how much does CBD oil cost - Colorado cannabis oil cost - THC oil price per gram - how to ingest cannabis oil - cost of CBD oil products - cheapest full-spectrum CBD oil

Learn to Grow High CBD Cannabis

There's never been a better time to learn to grow with legalization efforts ramping up worldwide! Enroll in Cannabis Training University to learn how to grow your own medicine so you can control your budget. Become the next great cannabis grower with online cannabis training from the #1 rated marijuana school.

Read the full article

9 notes

·

View notes

Text

Global Corrugated Carton Market Outlook: Growth Trends and Forecast 2025-2032

Global Corrugated Carton Market Analysis and Forecast (2025–2032)

Introduction

The Global Corrugated Carton Market is expected to witness steady growth, driven by rising demand across industries such as food and beverages, e-commerce, pharmaceuticals, and consumer goods. The increasing need for sustainable and cost-effective packaging solutions, along with the rapid expansion of e-commerce platforms, is fueling the demand for corrugated cartons worldwide.

In 2023, the market was valued at approximately USD 250 billion, and it is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.6% from 2025 to 2032. This growth is attributed to increasing consumer awareness of eco-friendly packaging solutions, rising urbanization, and the expanding logistics and transportation industry.

Corrugated cartons are widely preferred due to their strength, durability, and recyclability, making them essential for shipping and logistics. As global supply chains become more complex, the role of corrugated packaging in ensuring safe product transportation is more important than ever. Additionally, the rising demand for lightweight and recyclable packaging materials is pushing manufacturers toward innovative and sustainable packaging solutions.

Get free sample copy @ https://www.statsandresearch.com/request-sample/40587-global-corrugated-carton-market-report

Regional Growth Trends:

North America and Europe remain dominant consumers of corrugated packaging due to their strong industrial and retail sectors, along with stringent environmental regulations promoting sustainable packaging.

The Asia-Pacific region is expected to experience the highest growth rate, fueled by rapid industrialization, urbanization, and increasing demand for packaged goods. Countries such as China, India, and Indonesia are emerging as major players due to their booming e-commerce and retail industries.

Additionally, regulatory frameworks promoting sustainable packaging solutions and technological advancements in digital printing and lightweight packaging are further enhancing market prospects.

Market Dynamics

1. Growing Demand for Sustainable and Eco-Friendly Packaging

The demand for environmentally friendly and recyclable packaging solutions is one of the most significant drivers of the corrugated carton market. Companies across various industries are reducing their carbon footprint and adopting biodegradable packaging materials to comply with strict government regulations and environmental policies.

Corrugated cartons, being 100% recyclable and biodegradable, are increasingly replacing traditional plastic and non-recyclable packaging solutions. Major industries such as food & beverage, consumer goods, and pharmaceuticals are prioritizing sustainable packaging alternatives, further propelling market growth.

2. E-commerce Boom Fueling Market Expansion

The surge in online shopping and e-commerce platforms has significantly increased the demand for corrugated cartons. With consumers purchasing products online more frequently, secure and lightweight packaging solutions have become essential for safe transportation and product protection.

Leading e-commerce giants such as Amazon, Alibaba, and Flipkart heavily rely on corrugated packaging for shipping goods, contributing to the rapid expansion of the market. The need for customized packaging solutions, enhanced branding, and sustainable shipping materials is also driving innovation in corrugated carton designs.

3. Advancements in Printing and Packaging Technologies

Technological advancements in digital printing, flexographic printing, and smart packaging solutions are further transforming the corrugated carton industry. Companies are investing in high-quality and cost-effective printing solutions to enhance product visibility and brand recognition.

Additionally, the adoption of AI-powered logistics management and smart packaging solutions is optimizing supply chain efficiency and reducing packaging waste, making corrugated cartons more attractive to manufacturers and retailers.

4. Challenges in Raw Material Prices and Supply Chain Disruptions

Despite strong growth prospects, the corrugated carton market faces challenges related to fluctuating raw material prices, supply chain disruptions, and rising energy costs. The cost of paperboard and wood pulp, key raw materials for corrugated cartons, can significantly impact profit margins for manufacturers.

Additionally, global supply chain disruptions and rising transportation costs have increased logistics expenses, posing challenges for market players. However, the growing adoption of recycled materials and advancements in lightweight packaging are expected to mitigate some of these challenges in the long run.

Get full report @ https://www.statsandresearch.com/report/40587-global-corrugated-carton-market-report/

Segmental Analysis

The corrugated carton market is segmented based on type, flute type, printing technology, end-user industry, and region.

1. By Type

Single-Wall Corrugated Cartons

Double-Wall Corrugated Cartons

Triple-Wall Corrugated Cartons

Rigid Corrugated Boxes

Folding Corrugated Boxes

Single-wall corrugated cartons dominated the market in 2023, accounting for the largest share due to their cost-effectiveness and widespread application in industries such as e-commerce, food & beverage, and consumer electronics. These cartons provide adequate protection while being lightweight, making them ideal for retail and shipping applications.

2. By Flute Type

A-Flute

B-Flute

C-Flute

E-Flute

F-Flute

BC-Flute & EB-Flute

Among these, C-Flute corrugated cartons held the largest market share in 2023, as they offer an ideal balance of strength, cushioning, and cost-efficiency. These cartons are widely used for shipping, retail packaging, and logistics applications, making them the most preferred option in the industry.

3. By Printing Technology

Flexographic Printing

Lithographic Printing

Digital Printing

Screen Printing

Flexographic printing was the dominant segment in 2023, accounting for the highest market share due to its cost-effectiveness and ability to print in large volumes. This technology is extensively used in the food, beverage, and consumer electronics industries, which require high-quality, visually appealing packaging solutions.

4. By End-User Industry

Food & Beverage

Consumer Electronics

E-commerce & Retail

Pharmaceuticals & Healthcare

Personal Care & Cosmetics

Automotive & Industrial Goods

Textile & Apparel

Logistics & Transportation

Others

The food & beverage segment led the market in 2023, driven by the increasing demand for protective, sustainable, and cost-effective packaging solutions. The rising trend of ready-to-eat meals, online food delivery, and packaged food consumption has further contributed to this sector's dominance in the market.

Competitive Landscape

The global corrugated carton market is characterized by the presence of key players who dominate the industry through strategic acquisitions, product innovations, and expansion efforts.

Key Market Players:

International Paper Company

WestRock Company

Smurfit Kappa Group

DS Smith Plc

Mondi Group

Oji Holdings Corporation

Nine Dragons Paper Holdings Limited

Rengo Co., Ltd.

Recent Developments:

International Paper Company (2023): Focused on expanding sustainable packaging solutions and launched new fiber-based products to replace plastics, reducing its carbon footprint.

WestRock Company (2023): Acquired Recycled Paperboard Mill to enhance recycling capabilities and invested in digital printing solutions for customized corrugated packaging.

Pratt Industries, Inc. & Georgia-Pacific LLC: Leading contributors in North America, specializing in recycled corrugated packaging solutions.

Request Discount @ https://www.statsandresearch.com/check-discount/40587-global-corrugated-carton-market-report

0 notes

Text

Global Paper-Based Self-Adhesive Labels Market Poised for Growth Amid Rising Demand for Sustainable Packaging

Global Paper-Based Self-Adhesive Labels Market Poised for Growth Amid Rising Demand for Sustainable Packaging

Market Overview

The Global Paper-Based Self-Adhesive Labels Market is witnessing significant growth, driven by the increasing demand for eco-friendly and sustainable labeling solutions. With industries such as food & beverages, pharmaceuticals, logistics, and retail shifting toward environmentally responsible packaging, paper-based self-adhesive labels have emerged as a preferred alternative to plastic-based labels.

These labels offer high-quality printability, recyclability, and ease of application, making them ideal for product branding, regulatory compliance, and supply chain management. Additionally, the global push for reducing plastic waste and adopting biodegradable materials has accelerated the demand for paper-based self-adhesive labels across various sectors.

Free Sample Report:- Sample Request | Global Paper Based Self Ahesive Labels Market, Global Market Insights 2023, Analysis And Forecast To 2030, By Type & Application

Market Insights & Trends

Growing Focus on Sustainability: With increasing regulatory pressure and consumer awareness, industries are adopting biodegradable and recyclable label solutions to meet their sustainability goals.

Advancements in Adhesive Technology: Innovations in water-based, biodegradable, and pressure-sensitive adhesives are enhancing the efficiency and eco-friendliness of labels.

Rising Demand from E-Commerce & Logistics: The boom in online retail and global trade is driving demand for barcode labels, tracking labels, and tamper-proof packaging solutions.

Customization & Digital Printing Advancements: Brands are focusing on personalized, high-resolution, and digitally printed labels to enhance brand visibility and consumer engagement.

Stringent Regulatory Compliance: Governments worldwide are enforcing strict packaging and labeling regulations for industries like food, pharmaceuticals, and chemicals, boosting the demand for compliant, paper-based self-adhesive labels.

Key Players in the Market

The Global Paper-Based Self-Adhesive Labels Market is highly competitive, with major companies focusing on product innovation, eco-friendly materials, and advanced printing technologies. Leading players include:

Avery Dennison Corporation

UPM Raflatac

Mondi Group

3M Company

CCL Industries Inc.

Coveris Holdings S.A.

Huhtamaki Oyj

Sato Holdings Corporation

Fuji Seal International, Inc.

Constantia Flexibles

These companies are investing in sustainable label materials, high-performance adhesives, and smart labeling technologies to cater to the evolving needs of industries worldwide.

Full Report:- Global Paper Based Self Ahesive Labels Market, Global Market Insights 2023, Analysis And Forecast To 2030, By Type & Application

Regional Insights

North America: The United States and Canada are leading markets due to stringent environmental regulations, high demand from the food and beverage sector, and the rise of sustainable packaging trends.

Europe: Countries like Germany, the UK, and France are at the forefront of eco-friendly labeling initiatives, driven by strict EU policies on packaging waste reduction.

Asia-Pacific: The fastest-growing region, with China, India, and Japan leading in manufacturing, retail, and logistics expansion, boosting demand for self-adhesive labeling solutions.

South America, Middle East & Africa: These regions are experiencing steady growth due to rising industrialization, urbanization, and increasing consumer awareness of sustainable packaging.

Market Outlook & Growth Prospects

The Global Paper-Based Self-Adhesive Labels Market is projected to grow at a CAGR of over 6% through 2030, fueled by:

The shift toward biodegradable and recyclable packaging materials

Technological advancements in label printing and adhesives

Growing applications in food, pharmaceuticals, and logistics sectors

Regulatory mandates promoting sustainable labeling practices

Increased demand for smart labels and RFID-enabled tracking solutions

With sustainability becoming a core focus for industries worldwide, paper-based self-adhesive labels are set to play a crucial role in future packaging innovations.

Enquire Before Buy:- Enquire Before Buy | Global Paper Based Self Ahesive Labels Market, Global Market Insights 2023, Analysis And Forecast To 2030, By Type & Application

Conclusion

The Global Paper-Based Self-Adhesive Labels Market is evolving rapidly as businesses, regulators, and consumers push for sustainable, high-performance labeling solutions. With ongoing innovations in adhesives, printing, and recyclable materials, the market is poised for significant expansion in the coming years.

Top Trending Reports

Global More Electric Aircraft Market

Nigeria Oil and Gas Upstream Activities Market

Global Industrial Plastic Bags Market

Global Palladium Market

0 notes

Text

Polyurethane Foam Market Trends, Drivers & Outlook 2025-2032

The polyurethane (PU) foam market is experiencing robust growth, driven by increasing demand across diverse industries such as construction, automotive, furniture, packaging, and electronics. Known for its lightweight, durability, and excellent insulation properties, polyurethane foam is a preferred material for manufacturers looking to enhance performance and energy efficiency in their products. According to a recent report by SkyQuest, the polyurethane foam market is poised to grow at a CAGR of 6.50% by 2032, thanks to technological advancements and rising awareness about energy-efficient materials.

Polyurethane foam is a versatile polymer widely used in various applications due to its superior thermal insulation, cushioning, and soundproofing properties. It is produced by reacting polyols and diisocyanates in the presence of catalysts and additives. Based on its structure and application, polyurethane foam is classified into flexible foam, rigid foam, and spray foam.

Flexible Foam: Primarily used in furniture, bedding, and automotive seats, flexible foam offers high comfort and durability.

Rigid Foam: Known for its excellent insulation properties, rigid foam is used in construction for thermal insulation in walls, roofs, and refrigerators.

Spray Foam: Commonly used for sealing and insulating buildings, spray foam expands on application to fill gaps and cracks, offering superior air sealing and moisture resistance.

Request Sample of the Report - https://www.skyquestt.com/sample-request/polyurethane-foam-market

Emerging Trends in the Polyurethane Foam Market

Sustainable and Bio-Based PU Foams The growing focus on sustainability has led to the development of bio-based polyurethane foams derived from renewable sources such as soy, castor oil, and other plant-based materials. These eco-friendly alternatives are gaining traction in various industries as companies strive to reduce their environmental footprint.

Increasing Use of PU Foam in Cold Chain Logistics With the rapid growth of the food and pharmaceutical industries, the demand for cold chain logistics is rising. Rigid polyurethane foam plays a critical role in maintaining temperature control and ensuring the safety of temperature-sensitive products during storage and transportation.

Smart Foams for Advanced Applications Smart polyurethane foams with enhanced properties, such as shape memory, self-healing, and fire resistance, are being developed for high-performance applications. These innovations open up new opportunities in industries like aerospace, electronics, and healthcare.

Want to customize this report? https://www.skyquestt.com/speak-with-analyst/polyurethane-foam-market

Regional Insights

The polyurethane foam market is geographically diverse, with significant growth observed in several regions:

North America: North America is one of the leading markets for polyurethane foam, driven by the demand for energy-efficient insulation solutions in the construction sector. The region is also witnessing increased adoption of PU foam in automotive and packaging applications.

Europe: Europe’s focus on sustainability and stringent regulations regarding energy efficiency and environmental impact have spurred the demand for eco-friendly polyurethane foams. The construction and automotive sectors remain key contributors to market growth in the region.

Asia-Pacific: The Asia-Pacific region is expected to witness the fastest growth in the polyurethane foam market, driven by rapid industrialization, urbanization, and infrastructure development. Countries like China and India are major contributors to this growth, with expanding automotive, construction, and packaging industries.

Latin America and the Middle East: These regions are experiencing steady growth due to increased construction activities and growing demand for advanced materials in various industries.

Key Drivers of the Polyurethane Foam Market

Growing Demand for Energy-Efficient Buildings The global push for energy-efficient and sustainable buildings has significantly boosted the demand for polyurethane foam in the construction industry. Rigid polyurethane foam is widely used as insulation material due to its high thermal resistance and ability to reduce energy consumption in residential and commercial buildings.

Automotive Industry Growth The automotive industry is another major driver of the polyurethane foam market. Flexible PU foam is used extensively in vehicle seats, headrests, armrests, and interior trims due to its lightweight and cushioning properties. Moreover, the increasing demand for electric vehicles (EVs) has opened new growth opportunities for innovative PU foam solutions that improve energy efficiency and reduce vehicle weight.

Expansion of the Furniture and Bedding Sector The growing population, rising urbanization, and changing consumer lifestyles have driven the demand for high-quality furniture and bedding products. Flexible polyurethane foam is a key component in cushions, mattresses, and upholstered furniture, offering comfort and durability.

Rising Demand in Packaging The packaging industry is increasingly adopting polyurethane foam for protective packaging solutions. Its shock-absorbing and lightweight properties make it ideal for protecting delicate and valuable items during transportation. With the rapid growth of e-commerce, the demand for polyurethane foam in packaging is expected to rise significantly.

Technological Advancements Continuous innovation in polyurethane foam formulations and production techniques is driving market growth. Manufacturers are developing eco-friendly and bio-based polyurethane foams to address environmental concerns and meet stringent regulations.

Get insights into Trends, Challenges and Companies @ https://www.skyquestt.com/report/polyurethane-foam-market

Challenges in the Polyurethane Foam Market

Environmental Concerns Despite its widespread use, polyurethane foam production and disposal raise environmental concerns due to the release of volatile organic compounds (VOCs) and the use of non-renewable resources. Regulatory restrictions and growing consumer demand for sustainable products are pushing manufacturers to develop greener alternatives.

Raw Material Price Volatility The prices of raw materials used in polyurethane foam production, such as polyols and isocyanates, are subject to fluctuations, which can affect production costs and profit margins.

Health and Safety Issues Exposure to certain chemicals used in polyurethane foam production can pose health risks to workers, prompting the need for proper safety measures and adherence to regulations.

Future Outlook

The polyurethane foam market is set to witness significant growth as industries continue to adopt lightweight, durable, and energy-efficient materials. The increasing focus on sustainability and the development of bio-based alternatives will shape the future of the market. Innovations in smart foams and advanced manufacturing techniques will further expand the application scope of polyurethane foam, creating new opportunities for market players.In conclusion, the polyurethane foam market is a dynamic and rapidly evolving industry that reflects broader trends in construction, automotive, and sustainable manufacturing. As technology advances and consumer demands shift, polyurethane foam will remain a key material in driving innovation and improving product performance across sectors.

#Asia Polyurethane Foam Market#Europe Polyurethane Foam Market#Middle East Polyurethane Foam Market Size#North America Polyurethane Foam Market

0 notes

Text

The Future of Edible Food Packaging: From $3.9B to $7.5B by 2034 🍴💚

Edible Food Packaging Solutions Market is set to expand from $3.9 billion in 2024 to $7.5 billion by 2034, with a CAGR of 6.5%. This innovative market focuses on developing consumable packaging materials from natural ingredients like seaweed, starch, and proteins, addressing growing environmental concerns and reducing plastic waste.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10948 &utm_source=SnehaPatil&utm_medium=Article

Driven by sustainability trends and shifting consumer preferences, the starch-based packaging segment leads the market due to its biodegradability and wide applications. Seaweed-based packaging is gaining momentum, valued for its renewable properties and low environmental impact.

North America dominates the market, fueled by strict environmental regulations and eco-conscious practices. Europe ranks as the second-highest region, supported by robust eco-friendly packaging infrastructure and rising consumer awareness. The United States and Germany are key players, advancing through technological innovations and increased R&D investments.

In 2023, the market volume reached 320 million metric tons, projected to hit 500 million metric tons by 2033. The film segment holds a dominant 45% market share, driven by its versatility and rising demand for sustainable alternatives. Companies like WikiCell Designs Inc., Lactips, and Notpla are leading with cutting-edge innovations in biodegradable and water-soluble packaging.

Despite promising growth, challenges such as stringent regulations and competition from conventional packaging remain. Regulatory frameworks like the European Green Deal significantly impact market dynamics. However, the integration of advanced technologies such as nanotechnology and smart packaging is expected to unlock new opportunities.

#SustainablePackaging #EdiblePackaging #EcoFriendlyLiving #PlasticFreeFuture #GreenInnovation #BiodegradableTech #SeaweedPackaging #ZeroWasteLifestyle #StarchBasedSolutions #SmartPackaging #FoodTech #EcoConscious #GreenPackaging #CircularEconomy #PackagingInnovation

0 notes

Text

The Direct Thermal Printing Films Market is projected to grow from USD 234.76 million in 2024 to USD 336.41 million by 2032, reflecting a compound annual growth rate (CAGR) of 4.6%.The global Direct Thermal Printing Films Market is experiencing significant growth as industries increasingly rely on efficient and cost-effective printing solutions. Direct thermal printing films are widely used for printing labels, tags, and receipts without the need for ink, toner, or ribbons. This makes them an attractive choice for industries such as retail, logistics, healthcare, and food & beverage.

Browse the full report at https://www.credenceresearch.com/report/direct-thermal-printing-films-market

Understanding Direct Thermal Printing Films

Direct thermal printing films are coated with a heat-sensitive layer that changes color when exposed to a heated printhead. This process eliminates the need for additional printing supplies, making it a cost-effective and environmentally friendly option. These films are primarily used for short-term applications, such as barcode labels, shipping tags, and receipts, where high-quality printing and durability are essential.

Market Trends and Growth Drivers

Surge in E-commerce and Logistics The explosive growth of e-commerce has significantly boosted demand for direct thermal printing films. With a rise in online shopping, there is an increasing need for shipping labels and tags that can be produced quickly and cost-effectively. Logistics companies also rely on these films for tracking and inventory management.

Adoption of Eco-friendly Solutions As sustainability becomes a key priority for businesses, direct thermal printing films are gaining traction due to their eco-friendly nature. Unlike traditional printing methods, they do not require ink or toner, resulting in reduced waste and lower carbon emissions.

Technological Advancements Innovations in thermal printing technology are driving the market forward. Manufacturers are focusing on improving the durability, water resistance, and heat resistance of these films, making them suitable for a wider range of applications.

Growth in Retail and Food & Beverage Sectors Retailers and food manufacturers are increasingly using direct thermal printing films for labeling products and packaging. These films provide clear, high-resolution prints that are essential for product identification, pricing, and regulatory compliance.

Challenges in the Market

Limited Durability While direct thermal printing films are cost-effective, they are prone to fading when exposed to heat, light, or friction. This limits their use in long-term applications, creating a challenge for manufacturers to enhance their durability.

Competition from Thermal Transfer Printing Thermal transfer printing, which offers superior durability and resistance to environmental factors, poses a competitive threat. Businesses with long-term labeling requirements often prefer this method, creating a challenge for the direct thermal printing films market.

Cost Sensitivity Although direct thermal printing is economical, fluctuations in the cost of raw materials, such as specialty paper and chemicals, can affect the overall pricing and profitability of manufacturers.

Future Prospects

The future of the direct thermal printing films market looks promising, driven by advancements in technology and increasing adoption across diverse industries. Manufacturers are likely to focus on developing films with enhanced durability and resistance to environmental factors. Additionally, the growing emphasis on sustainability will further drive demand for eco-friendly printing solutions.

With the rise of automation and smart logistics systems, direct thermal printing films are expected to play a crucial role in enabling efficient supply chain management. The integration of IoT and RFID technologies with thermal printing solutions could unlock new opportunities, further propelling market growth.

Key Player Analysis:

Avery Dennison Corporation

Mondi Group

Cosmo Films Ltd.

Lintec

Smith & McLaurin

Daelim Industrial Co. Ltd.

Jindal Poly Films Ltd.

Bizerba SE & Co. KG

Italnastri S.p.A.

Green Bay Packaging

Segments:

Based on Material Type:

Paper Printing Films

Plastic Printing Films

Polypropylene (PP)

Polyethylene (PE)

Polystyrene (PS)

Others

Based on End Use:

Food & Beverages

Pharmaceuticals

Personal Care & Cosmetics

Industrial Goods

Retail

Other End Uses

Based on the Geography:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/direct-thermal-printing-films-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Smart Food Packaging Market Segmentation: Key Technologies and Regional Growth Insights

The global smart food packaging market is estimated at USD 26.42 billion in 2024 and is projected to reach USD 35.69 billion by 2029, at a CAGR of 6.2% from 2024 to 2029. The study "Active Packaging in the Food Industry", published in October 2024, explores the growing significance of active packaging in response to changing consumer demands and market trends. Unlike traditional packaging, which is designed to be inert, active packaging interacts with the product and its environment to extend shelf life and maintain food quality. This can involve incorporating additives into packaging systems, such as oxygen and ethylene scavengers, antimicrobial agents, antioxidants, and flavor-absorbing or releasing compounds. Intelligent packaging systems, like time-temperature indicators and gas detectors, are also discussed, emphasizing the importance of consumer acceptance for the commercial success of these technologies. The study reviews key mechanisms used in active packaging, including oxygen scavengers, which reduce the presence of oxygen in food packaging by using iron-based or ascorbic acid-based systems. These methods help maintain product freshness by limiting oxidative damage. Carbon dioxide-generating systems are also used to suppress microbial growth, particularly in meat, poultry, fish, and cheese packaging. Furthermore, ethylene scavengers are vital for extending the shelf life of fruits and vegetables by controlling ripening processes.

Other applications discussed include the use of flavor and odor absorbers/releasers, which enhance the sensory properties of packaged food, and antimicrobial packaging that inhibits microbial growth to ensure food safety. The potential of nanotechnology to develop new and more effective active and intelligent packaging solutions is highlighted, paving the way for further innovations in the food packaging industry. This study underscores the need for advanced packaging technologies to meet consumer demand for fresh, safe, and high-quality food products and their critical role in prolonging shelf life and improving food safety.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=103797679

The Meat, Poultry & Seafood is the having a largest share within the application sector of the smart food packaging market.

Due to growing global demand, meat, poultry, and seafood accounts for the highest market share of application in the smart food packaging market. Its needs lie in extending shelf life, safety, and traceability. As per data provided by the USDA from October 2024, Brazil dominates global chicken meat exports during 2025 as the production will be 11.8 million tons. Australia's poultry production will increase by 2 percent to 2.6 million tons, as high global demand is expected. Beef exports from Australia will also reach a record 1.9 million tons in the year, as its demand increases in the US. These trends point towards the increasing international meat trade and export opportunities.

Increased production and exports require more advanced smart packaging technologies, such as modified atmosphere packaging and active packaging, for freshness, less food waste, and greater safety. This will fuel innovation and adoption of smart packaging solutions, especially in global markets like East Asia and North America.

The active packaging segment holds significant market share in the smart food packaging market during the forecasted period 2024-2029.

Active food packaging accounts for a major market share in the smart food packaging industry, which is mainly attributed to the quality improvement, safety, and shelf life that active packaging can offer. Technologies, including oxygen scavengers, moisture absorbers, and antimicrobial agents, respond to some of the most important consumer needs related to freshness and reduction of food waste.

It is primarily gaining adoption across key industries, including meat, poultry, seafood, and dairy, where growing concerns about global food safety and sustainability are driving growth. Additionally, increasing export of perishable food products, particularly in North America, Europe, and Asia-Pacific, further supports the increasing demand for active packaging. As manufacturers look for more innovative ways to meet their regulatory requirements and consumer demands, active packaging will maintain its position in the market.

Make an Inquiry: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=103797679

Based on region, Europe has a significant share in the smart food packaging market.

The growth of the food and beverage industry in Europe is a major driving force for the smart food packaging market, which is motivated by the increasing demand for advanced packaging solutions that would ensure food safety, traceability, and extended shelf life. According to European Commission data (March 2024), the food and drinks industry generates ~USD 245 billion (€227 billion) in added value and employs 4.6 million people, making it the EU's largest manufacturing sector in terms of jobs and value. SMEs are over 99% of businesses in this ecosystem. The sector has also recorded a food trade surplus, with exports doubled over the last decade to exceed ~USD 196 billion (€182 billion), contributing a positive balance of nearly ~USD 32 billion (€30 billion). These strong figures, combined with growing trade opportunities and EU Single Market benefits, are driving demand for smart food packaging technologies to support efficient, sustainable, and competitive food supply chains.

Leading Smart Food Packaging Manufacturers:

The report profiles key players such as Amcor plc (Switzerland), Mondi (UK), Sealed Air (US), Berry Global Inc. (US), Toyo Seikan Group Holdings, Ltd. (Japan), THE TETRA LAVAL GROUP (Switzerland), Crown (US), 3M (US), MITSUBISHI GAS CHEMICAL COMPANY, INC. (Japan), Multisorb (US), Huhtamäki Oyj (Finland), Timestrip UK LTD (UK), Stepac (Israel), Checkpoint Systems, Inc. (US), and Novipax Buyer, LLC (US).

#Smart Food Packaging Market#Smart Food Packaging#Smart Food Packaging Market Size#Smart Food Packaging Market Share#Smart Food Packaging Market Growth#Smart Food Packaging Market Trends#Smart Food Packaging Market Forecast#Smart Food Packaging Market Analysis#Smart Food Packaging Market Report#Smart Food Packaging Market Scope#Smart Food Packaging Market Overview#Smart Food Packaging Market Outlook#Smart Food Packaging Market Drivers#Smart Food Packaging Industry#Smart Food Packaging Companies

0 notes

Text

Global Cold Chain Packaging: Growth Drivers and Opportunities in 2025

The global cold chain packaging market size is estimated at USD 59.95 billion in 2030 and is expected to grow at a CAGR of 12.6% from 2024 to 2030. The key drivers attributing to the market expansion include a significant boost in demand for cold chain packaging solutions from the pharmaceutical industry. Amidst the coronavirus pandemic, the trade and transit of temperature-sensitive drugs, medicines, and test samples are drastically increasing. Along with the pharmaceuticals market, the packaging market is anticipated to witness significant growth. The overall market growth is profoundly influenced by the high demand for perishable goods worldwide and the availability of fresh food and frozen food supplies.

The growing popularity of e-commerce as a channel for purchasing fresh goods drives the market growth. The increasing usage of e-commerce websites and mobile apps has enabled customers to order preserved food, fresh vegetables, dairy products, and daily meals. Digital retailing has given enabled consumers to purchase products from anywhere they want. The rising trend of online purchases for perishable products has led to new opportunities and challenges. These include the need for innovative solutions to provide the critical service of last-mile delivery, automated warehouse facilities to manage inventories and to reduce per-item costs, and advanced cold chain packaging solutions that would maintain the safety of fresh food products.

North America dominated the market for cold chain packaging in 2019 and is estimated to continue leading over the forecast period leveraging the high consumption rate of meat, processed food, and dairy products. Additionally, the regional market is highly fragmented with numerous market players, which has increased the regional market share. However, the current economic and political scenario has impacted industry growth. The trade conflict between the U.S. and China is expected to negatively impact the growth of the cold chain market in the U.S. In early 2018, China announced a 15% to 25% tariff on products imported from the U.S., including pork, fruits, wine, nuts, and vegetables. This high tariff imposed on food and agriculture products is expected to hinder the regional market growth.

The Middle East and Africa market for cold chain packaging is anticipated to register the highest CAGR over the forecast period on account of significant improvements in material handling, warehousing, intralogistics, and supply chain solutions. The Asia Pacific regional market is estimated to witness a significant CAGR of more than 21% from 2020 to 2027. The growth is attributed to the ever-increasing population, rapid industrialization, continued rollout of transportation and warehousing networks, and the rise in demand for processed and canned food items.

Cold Chain Packaging Market Report Highlights

Amid the COVID-19 pandemic, governments across the globe are emphasizing on providing ample medicinal supply to the healthcare facilities. With the increasing tests per day, the transit of blood samples is also increasing, thereby increasing the need for reliable temperature-controlled packaging solutions in the pharmaceutical and healthcare industry.

The evolution of the smart technologies, such as smart boxes or smart temperature-controlled packaging solutions that provide real-time data on variations in temperature, humidity, and air pressure, is expected to drive the future growth of the market.

The increasing emphasis on low ozone depletion potential (ODP) and low global warming potential (GWP) gases is expected to boost demand for natural and inorganic refrigerants such as ammonia and carbon dioxide.

The fruits & vegetable segment is expected to grow at a significant compound annual growth rate (CAGR) of more than 20% from 2020 to 2027 owing to the increasing demand for fresh vegetables and fruits from end consumers across the globe.

Market players are expanding their regional presence through mergers, acquisitions, and partnerships by establishing a network of distributors located in different regions. For instance, Pelican Products, Inc. has a network of dealers located in South America (NatBio), Asia Pacific (Giddi Pharma, Pharmaserv Express, and others), and Europe (DS Smith).

Some of the key industry participants are Cold Chain Technologies, Cryopak A TCP Company, Pelican Products, Inc., Sofrigam, and Sonoco ThermoSafe.

Cold Chain Packaging Market Segmentation

Grand View Research has segmented the global cold chain packaging market report based on material, product, end use, and region

Cold Chain Packaging Material Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

Expanded Polystyrene (EPS)

Polyurethane Rigid Foam (PUR)

Paper & Paperboard

Others

Cold Chain Packaging Product Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

Insulated Pallet Shippers

Insulated Containers

Vacuum Insulated Panels

Gel Packs

Others

Cold Chain Packaging End Use Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

Fruits & Vegetables

Fruit & Pulp Concentrates

Dairy Products

Milk

Butter

Cheese

Ice Cream

Fish, Meat & Seafood

Processed Food

Pharmaceuticals

Vaccines

Blood Banking

Bakery & Confectionaries

Others

Cold Chain Packaging Regional Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Asia Pacific

China

India

Japan

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

List of Key Players

Cold chain Technologies

Cryopak

Sonoco Thermosafe

SOFRIGAM

Softbox Systems Ltd

Pelican Products, Inc.

CSafe

TOWER Cold Chain Solutions

Sealed Air Corporation

CoolPac

Nordic Cold Chain Solutions

Global Cooling Inc.

Inmark LLC

Envirotainer AB

DGP Intelsius LLC

Vericool, Inc.

Emballages Cre-O-Pack Intl

TemperPack Technologies, Inc.

Order a free sample PDF of the Cold Chain Packaging Market Intelligence Study, published by Grand View Research.

0 notes

Text

"Edible Food Packaging: Changing the Game for Sustainable Consumption 🍴🌿"

Edible Food Packaging Solutions Market is redefining packaging by introducing materials that can be safely consumed along with food products. This market addresses sustainability challenges, offering biodegradable alternatives to reduce plastic waste. It includes edible films, coatings, and wraps made from natural ingredients like seaweed, starch, and proteins, appealing to eco-conscious consumers and industries aiming for greener packaging solutions.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10948 &utm_source=SnehaPatil&utm_medium=Article

This market is experiencing significant growth, fueled by sustainability concerns and shifting consumer preferences. Starch-based packaging leads the segments due to its biodegradability and versatility. Seaweed-based packaging is also gaining traction for its renewable nature and minimal environmental impact. North America dominates the regional market, driven by stringent environmental regulations and a strong focus on sustainable practices. Europe follows closely, supported by a robust eco-friendly packaging infrastructure and high consumer awareness. The United States and Germany are standout performers in these regions, benefiting from advanced technological capabilities and substantial investments in research and development.

Market Segmentation:

Type: Films, Coatings, Sprays, Sheets, Capsules

Material Type: Proteins, Polysaccharides, Lipids, Composites, Algae

Technology: Antimicrobial, Nanotechnology, Biodegradable, Active, Intelligent Packaging

Application: Food and Beverage, Pharmaceuticals, Nutraceuticals, Personal Care, Agriculture

End Users: Food Manufacturers, Beverage Manufacturers, Retailers, Food Service Providers, Pharmaceutical Companies

Form: Solid, Liquid, Gel, Powder

Functionality: Barrier Properties, Mechanical Properties, Biodegradability, Edibility

Process: Extrusion, Coating, Molding, Casting

Solutions: Customized, Standard Packaging Solutions

In 2023, the market volume was estimated at 320 million metric tons, expected to reach 500 million metric tons by 2033. The film segment holds the largest market share at 45%, followed by coatings at 30%, and bags at 25%. The dominance of films is driven by their versatility and rising demand for sustainable solutions. Key players such as WikiCell Designs Inc., Lactips, and Notpla are pioneering in biodegradable packaging. The competitive landscape is shaped by these companies’ innovative strategies, with WikiCell Designs Inc. leading in biodegradable packaging and Lactips expanding its water-soluble films range.

Regulatory frameworks, such as the European Green Deal, play a significant role in market dynamics, influencing compliance costs and eco-friendly initiatives. The market is poised for further growth, with a projected 15% increase in capital expenditure by 2033. This optimistic outlook is driven by opportunities in biodegradable films and coatings, despite challenges like stringent regulations and competition from conventional packaging alternatives. The integration of nanotechnology and smart packaging is expected to unveil new growth prospects.

#EdiblePackaging #SustainablePackaging #EcoFriendly #Biodegradable #ZeroWaste #FoodInnovation #GreenPackaging #EcoConscious #PlasticFree #CleanLabel #SustainableLiving #NaturalIngredients #FuturePackaging #EdibleInnovation #EcoTech #SustainableSolutions #SmartPackaging #FoodSustainability #GreenFuture #InnovativePackaging

0 notes

Text

Automated Guided Vehicles Key to Logistics Automation

The Automated Guided Vehicle (AGV) market has witnessed significant growth over the past few years, driven by advancements in automation technologies and increasing demand for streamlined logistics and material handling processes across various industries. These self-guided, computer-controlled vehicles are extensively used in manufacturing facilities, warehouses, and distribution centers to enhance operational efficiency, reduce human intervention, and minimize errors.

Market Drivers and Trends

One of the key drivers for the AGV market is the growing adoption of Industry 4.0 and smart manufacturing practices. With the surge in e-commerce, businesses are focusing on optimizing supply chain operations, which has fueled the demand for AGVs. These vehicles play a critical role in automating repetitive tasks like material transportation, loading, and sorting.

Market Segmentation

The AGV market can be segmented based on type, application, industry vertical, and region.

By Type: Tow vehicles, unit load carriers, pallet trucks, and hybrid AGVs dominate the market. Tow vehicles are particularly popular due to their efficiency in moving heavy loads.

By Application: The primary applications include transportation, assembly, packaging, and warehouse operations. AGVs are becoming a backbone for warehouse automation in the retail and e-commerce sectors.

By Industry Vertical: Industries such as automotive, food & beverage, healthcare, and electronics are prominent adopters of AGVs.

By Region: North America and Europe are leading markets due to their early adoption of automation technologies. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization and the expansion of the manufacturing sector.

Challenges

Despite its potential, the AGV market faces challenges such as high initial investment costs and technical complexities in implementation. Small and medium-sized enterprises (SMEs) often hesitate to adopt AGVs due to budget constraints. Moreover, a lack of standardization and interoperability between AGVs and existing systems can hinder seamless integration.

Future Outlook

The AGV market is poised for robust growth, with innovations such as autonomous mobile robots (AMRs) and advanced fleet management systems taking center stage. As industries increasingly prioritize sustainability, AGVs are expected to incorporate energy-efficient designs and renewable energy sources.

According to market research, the global AGV market is projected to grow at a compound annual growth rate (CAGR) of over 10% from 2023 to 2030, reaching a value of billions of dollars. The ongoing digital transformation across industries will continue to drive this growth trajectory.

Conclusion

The Automated Guided Vehicle market is at the forefront of the automation revolution, transforming traditional logistics and manufacturing processes. With continuous innovation and adoption, AGVs are set to redefine industrial operations, offering unparalleled efficiency and reliability.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NzEx&RD=Automated-Guided-Vehicle-(AGV)-Market-Report

0 notes

Text

Pet Health and Wellness Products Market Size, Trends, and Growth Forecast 2025–2032

Global Pet Health and Wellness Products Market: Industry Analysis, Trends, and Forecast (2024-2031)

Introduction

The Global Pet Health and Wellness Products Market is experiencing strong growth, driven by rising pet ownership, increasing awareness of pet health, and a shift toward premium, natural, and holistic pet care solutions. Consumers are prioritizing pet nutrition, hygiene, preventive healthcare, and technology-driven pet care solutions, fueling demand for high-quality pet foods, supplements, grooming products, and healthcare items.

In 2023, the market was valued at USD 246,660 million and is projected to reach USD 427,750 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.45% during the forecast period. The market’s growth is driven by:

The humanization of pets: Pet owners view pets as family members, leading to increased spending on premium, functional, and organic pet products.

Advancements in veterinary healthcare: Telemedicine, smart pet care devices, and AI-driven monitoring systems are revolutionizing the industry.

Growing concerns about pet health: Rising cases of obesity, diabetes, and skin issues among pets have increased the demand for specialized diets and preventive healthcare.

Sustainability in pet care: Consumers prefer eco-friendly, ethically sourced pet products, leading to growth in organic and biodegradable pet care solutions.

As urbanization and disposable income increase, pet owners are seeking convenient, innovative, and customized pet wellness solutions, contributing to market expansion across various regions.

Get free sample copy @ https://www.statsandresearch.com/request-sample/40552-global-pet-health-and-wellness-products-market

Market Dynamics

Market Drivers

Increase in Pet Ownership and Humanization of Pets

Pet adoption rates are rising globally, particularly in urban areas.

Pet parents are investing in high-quality pet foods, dietary supplements, and luxury pet care services.

The demand for personalized and breed-specific products is increasing.

Growing Awareness of Pet Nutrition and Health

Pet owners are focusing on balanced diets, functional foods, and health supplements.

There is a surge in demand for probiotics, joint support supplements, and immunity boosters for pets.

Rising Demand for Premium and Organic Pet Products

Consumers prefer organic and natural pet food, treats, and grooming products.

The shift toward chemical-free, sustainable pet care solutions is influencing buying behavior.

Technological Innovations in Pet Healthcare and Monitoring

AI-powered wearable pet trackers, smart feeding systems, and remote monitoring devices are gaining popularity.

Telehealth services for pets are improving access to veterinary care.

Increased Spending on Preventive Healthcare for Pets

Pet owners are investing in preventive care, flea and tick treatments, dental hygiene, and regular vet check-ups.

Veterinary advancements are improving early disease detection and treatment options.

Sustainability and Ethical Consumerism

Consumers are opting for eco-friendly packaging, plant-based pet foods, and cruelty-free grooming products.

The demand for biodegradable pet waste bags, recyclable pet toys, and non-toxic pet care solutions is increasing.

Market Challenges

High Cost of Premium and Organic Pet Products

Natural and organic pet products are often more expensive, limiting adoption in price-sensitive markets.

Regulatory Challenges in Pet Healthcare

Strict regulations on pet food ingredients, supplements, and animal health products can impact market expansion.

Supply Chain Disruptions and Rising Raw Material Costs

Fluctuations in ingredient prices and supply chain disruptions can impact product availability and pricing.

Limited Awareness in Developing Markets

In some regions, pet care spending remains low due to lack of awareness and financial constraints.

Get full report @ https://www.statsandresearch.com/report/40552-global-pet-health-and-wellness-products-market/

Market Segmentation

The Global Pet Health and Wellness Products Market is segmented by type, material, and end-user application.

By Type:

1. Food & Nutrition Products

Largest market segment, including dry food, wet food, treats, and dietary supplements.

Increasing demand for grain-free, raw, organic, and prescription-based pet foods.

Growth in functional foods targeting joint health, digestion, and immune support.

2. Grooming & Hygiene Products

Includes shampoos, conditioners, brushes, dental care products, and flea control solutions.

Rising demand for hypoallergenic, organic, and medicated grooming products.

3. Behavioral and Training Aids

Includes calming chews, anxiety relief sprays, training pads, and anti-bark collars.

Demand is increasing due to urban living and behavioral issues in pets.

4. Accessories

Includes collars, leashes, beds, pet carriers, and interactive toys.

Growth in smart pet accessories, such as GPS trackers and smart feeding systems.

5. Others

Includes first aid kits, wound care products, and pet mobility aids.

By Material:

1. Organic & Natural Products

Growing demand for organic pet food, biodegradable grooming products, and plant-based supplements.

2. Synthetic Products

Used in durable pet accessories, synthetic food formulations, and medicated pet care products.

3. Hybrid Materials

Combination of natural and synthetic materials to enhance product performance.

4. Others

Includes biodegradable packaging, recyclable pet toys, and eco-friendly pet waste solutions.

By End-User:

1. Pet Parents

Largest consumer segment, with increasing demand for high-quality food, supplements, and pet healthcare services.

2. Zoos & Animal Shelters

Require bulk pet food, veterinary healthcare products, and enrichment tools.

3. Animal Hospitals & Veterinary Clinics

Use clinical-grade pet medicines, nutritional supplements, and diagnostic tools.

4. NGOs and Pet Rescue Organizations

Demand affordable pet care products and bulk donations for rescued animals.

Regional Analysis

1. North America

Largest market, driven by high pet ownership rates and premium pet care spending.

Growth in organic pet food, telemedicine, and smart pet care devices.

2. Europe

Increasing demand for sustainable and eco-friendly pet care solutions.

Germany, France, and the UK lead in premium pet food and supplements adoption.

3. Asia-Pacific

Fastest-growing market, with rising urban pet adoption rates in China, India, and Japan.

Growth in pet wellness startups, veterinary healthcare investments, and premium pet foods.

4. Middle East & Africa

Emerging market for luxury pet grooming and high-end pet foods.

5. South America

Brazil and Argentina lead in pet healthcare product sales.

Increasing awareness of pet nutrition and preventive care.

Competitive Landscape

Key Players in the Global Pet Health and Wellness Products Market:

Mars Petcare (Pedigree, Royal Canin)

Nestlé Purina PetCare (Pro Plan, Fancy Feast)

Petco Animal Supplies (Retail and e-commerce pet care solutions)

Hill's Pet Nutrition (Veterinary diet pet food)

Zoetis (Pet pharmaceuticals and vaccines)

Elanco Animal Health (Pet health products and supplements)

Boehringer Ingelheim Animal Health (Veterinary diagnostics and medications)

The J.M. Smucker Company (Meow Mix, Milk-Bone)

Spectrum Brands Holdings (FURminator, Nature’s Miracle)

Blue Buffalo (Natural pet food and treats)

Recent Developments:

Nestlé Purina launched personalized pet nutrition services using AI-based pet health data.

Mars Petcare expanded its veterinary telehealth services for remote pet consultations.

Zoetis introduced new pet vaccines and diagnostic solutions for preventive healthcare.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/40552-global-pet-health-and-wellness-products-market

0 notes

Text

Global Labels Market to Witness Robust Growth Amidst Rising Demand for Smart and Sustainable Labeling Solutions

Global Labels Market to Witness Robust Growth Amidst Rising Demand for Smart and Sustainable Labeling Solutions

Market Overview

The Global Labels Market is poised for substantial growth, driven by the increasing demand for product identification, branding, traceability, and regulatory compliance across various industries. Labels play a critical role in sectors such as food & beverages, pharmaceuticals, logistics, retail, and consumer goods, serving as an essential tool for marketing, authentication, and supply chain management.

With advancements in printing technologies, smart labeling, and eco-friendly materials, the industry is evolving to meet sustainability goals, digital transformation, and consumer engagement strategies. Companies are now adopting RFID labels, QR codes, and NFC-enabled solutions to enhance product tracking, anti-counterfeiting measures, and interactive consumer experiences.

Free Sample Report:- Sample Request | Labels Global Market Insights 2023, Analysis And Forecast To 2030, By Type, End User, Material Type, Printing Technique, And Ink Type

Market Insights & Trends

Rise of Smart and Interactive Labels: The integration of RFID tags, NFC chips, and QR codes is enhancing real-time product tracking, inventory management, and customer engagement.

Growing Preference for Sustainable Labeling: The push for biodegradable, recyclable, and linerless labels is increasing as businesses adopt eco-friendly packaging solutions.

Technological Advancements in Printing Techniques: Innovations in digital printing, UV-cured inks, and hybrid printing methods are revolutionizing label production with high-quality graphics, customization, and efficiency.

Increased Demand from E-commerce & Logistics: The growth of online retail and supply chain automation is driving demand for barcode labels, tracking labels, and tamper-evident packaging.

Regulatory Compliance & Transparency: Governments and industries are enforcing stringent labeling regulations for food safety, pharmaceutical traceability, and chemical hazard warnings, fueling demand for compliant and informative labels.

Key Players in the Market

The Global Labels Market is dominated by major players focusing on technological advancements, sustainable solutions, and industry collaborations. Key companies include:

Avery Dennison Corporation

CCL Industries Inc.

3M Company

UPM Raflatac

Mondi Group

Constantia Flexibles

Coveris Holdings S.A.

Brady Corporation

Fuji Seal International Inc.

Sato Holdings Corporation

These companies are actively investing in smart labels, environmentally friendly materials, and high-performance printing technologies to cater to evolving industry needs.

Full Report:- Labels Market Size, Scope & Growth Report 2030

Regional Insights

North America: The United States and Canada lead in technological innovation and stringent labeling regulations, with significant demand from retail, pharmaceuticals, and food industries.

Europe: Countries like Germany, France, and the UK are focusing on sustainable labeling solutions and compliance with EU regulations regarding packaging waste reduction.

Asia-Pacific: The fastest-growing region, driven by rapid industrialization, e-commerce expansion, and increasing consumer awareness in China, India, and Japan.

South America, Middle East & Africa: These regions are experiencing steady growth, driven by urbanization, rising consumer goods demand, and improved logistics infrastructure.

Market Outlook & Growth Prospects

The Global Labels Market is expected to grow at a CAGR of over 5% through 2030, driven by:

The rise of digital and smart labeling technologies

Growing emphasis on sustainable and recyclable materials

Increased demand from logistics, healthcare, and retail industries

Stricter regulatory requirements for product labeling and traceability

Advancements in ink and printing techniques for high-performance labeling

As the industry shifts toward sustainability, digital innovation, and compliance-driven solutions, the market will continue to expand, offering new opportunities for manufacturers, technology providers, and end-users.

Enquire Before Buy:- Enquire Before Buy | Labels Global Market Insights 2023, Analysis And Forecast To 2030, By Type, End User, Material Type, Printing Technique, And Ink Type

Conclusion

The Global Labels Market is undergoing a significant transformation with the adoption of smart, sustainable, and high-performance labeling solutions. As businesses prioritize brand differentiation, regulatory compliance, and customer engagement, the demand for advanced labels and printing technologies will continue to rise.

Top Trending Reports

Global More Electric Aircraft Market

Nigeria Oil and Gas Upstream Activities Market

Global Industrial Plastic Bags Market

Global Palladium Market

0 notes

Text

"Smart Packaging Solutions: Trends in Nano-Enabled Packaging"

"Nano-Enabled Packaging Market Size And Forecast by 2032

The global Nano-Enabled Packaging Market study provides an in-depth exploration of the industry, emphasizing key trends, evolving market dynamics, and the competitive landscape. It underscores the performance and strategies of leading companies shaping the market. The report delves into the Top 10 Companies in the [Nano-Enabled Packaging ] Market, analyzing their innovative approaches, financial outcomes, and their roles in driving market growth and capturing market share. This comprehensive overview enables stakeholders to understand the strategies fueling success in this dynamic industry.

Data Bridge Market Research analyses that the Global Nano-Enabled Packaging Market which was USD 43037.78 Million in 2022 is expected to reach USD 92389.58 Million by 2030 and is expected to undergo a CAGR of 10.02% during the forecast period of 2022 to 2030

Lastly, the study emphasizes the broader implications of these companies’ contributions to the Nano-Enabled Packaging Market growth and evolution. Their strategies, technological advancements, and market influence not only define current industry trends but also set the stage for future developments. By providing a comprehensive overview of the leading players, the report equips stakeholders with critical insights to understand competitive positioning, identify opportunities for collaboration, and develop strategies to thrive in this dynamic industry.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-nano-enabled-packaging-market

Nucleus is a secure, cloud-based platform designed to streamline data transfer and management for businesses. Its intuitive interface offers practice administrators and financial managers advanced filtering options, enhancing operational efficiency. By integrating various data sources, Nucleus enables effective prioritization of critical exposures, incorporating business context and threat intelligence to bolster security measures. Additionally, Nucleus supports seamless collaboration among multiple users across different applications, fostering rapid iteration and teamwork. Its deployment flexibility allows installation on-premises or via preferred cloud service providers, ensuring scalability and adaptability to meet diverse organizational needs.

Get More Detail: https://www.databridgemarketresearch.com/nucleus/global-nano-enabled-packaging-market

Which are the top companies operating in the Nano-Enabled Packaging Market?

The Top 10 Companies in Nano-Enabled Packaging Market operating in the Nano-Enabled Packaging Market are recognized for their innovation, market leadership, and strong presence across key regions. These companies invest heavily in research and development, driving continuous product innovation to meet evolving customer demands. Their extensive distribution networks, brand reputation, and technological expertise have solidified their positions as industry leaders. Additionally, these top companies are expanding through strategic partnerships, mergers, and acquisitions, enabling them to strengthen their market share and enhance their competitive advantages.

**Segments**

- **By Type**: The nano-enabled packaging market can be segmented based on the type into active packaging and intelligent packaging. Active packaging involves incorporating nanomaterials to actively interact with the packaged product to extend its shelf life or improve its safety. Intelligent packaging, on the other hand, includes features like sensors, indicators, and RFID tags that provide information about the product's quality and condition.