#Industrial Oil Purification Systems

Explore tagged Tumblr posts

Text

Best Oil Purifier Machine – Advanced Industrial Oil Purification System

Industrial machinery relies heavily on clean and high-quality oil for smooth and efficient operation. However, contaminants like dirt, metal particles, sludge, and water degrade oil quality over time, leading to increased maintenance costs and reduced equipment lifespan. Investing in an oil purifier machine is a cost-effective solution that ensures oil purity, enhances machinery efficiency, and prevents system failures.

What Is an Oil Purifier Machine?

An oil purifier machine is an advanced filtration system designed to remove solid and liquid contaminants from industrial oil. These machines use various purification technologies, such as vacuum dehydration, centrifuge separation, and mechanical filtration, to enhance oil quality and performance.

By eliminating moisture, particulate matter, and oxidation by-products, an oil purification system helps industries maintain optimal machinery operation, reducing wear and tear while improving overall productivity.

Why Is Oil Purification Essential?

Extends Oil Life – Regular purification prevents oil degradation, reducing the need for frequent oil replacements.

Improves Equipment Performance – Clean oil ensures smooth machinery operation and minimizes downtime.

Reduces Maintenance Costs – Proper oil purification lowers the risk of equipment failure and expensive repairs.

Enhances Environmental Sustainability – Reusing and purifying oil minimizes industrial waste and promotes sustainability.

0 notes

Text

Industrial Oil Purification Systems for Cleaner, Efficient Operations in Africa & India

Revolutionizing Industrial Oil Purification Systems Across Africa & India

Industrial oil purification plays a vital role in maintaining the longevity and efficiency of machinery, ensuring smooth operations in a wide variety of industries. Whether in the heart of Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, or India, high-quality Industrial Oil Purification Systems are essential for improving oil cleanliness, reducing contaminants, and ensuring the optimal functioning of industrial equipment.

At AR Engineering, we specialize in providing state-of-the-art Industrial Oil Purification Systems that offer significant benefits, ensuring cleaner and more efficient oil for manufacturing, power generation, and other industrial processes.

What Are Industrial Oil Purification Systems?

An Industrial Oil Purification System is a high-tech solution designed to remove contaminants like water, dirt, metals, and oxidation products from industrial oils, extending the life of machinery and improving overall efficiency. These systems are used across industries such as power generation, manufacturing, and chemical processing, where high-performance oil is essential for smooth operations.

Benefits of Industrial Oil Purification Systems

Extended Equipment Life: By removing contaminants from oils, industrial oil purification systems help prevent wear and tear on machinery components, extending the life of expensive industrial equipment.

Improved Efficiency: Cleaner oil reduces friction and prevents clogging, leading to improved machinery performance and reduced downtime.

Cost-Effective Maintenance: Regular purification helps to extend the life of oils, reducing the need for frequent oil replacements, lowering operating costs over time.

Environmentally Friendly: Oil purification systems help reduce waste oil, minimizing environmental pollution by improving the efficiency of oil reuse.

Why Choose Industrial Oil Purification Systems for Africa & India?

Africa:

In countries like Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, and Zimbabwe, industries rely heavily on industrial oil purification to improve the performance of their machines and reduce maintenance costs. With the growing need for clean, efficient operations, AR Engineering offers advanced solutions for oil filtration and purification that can handle the diverse industrial challenges faced across the continent.

Botswana & Namibia: Oil purification systems are essential for industries that rely on heavy machinery in mining, construction, and power plants.

Nigeria & Kenya: As these countries continue to experience industrial growth, the demand for high-efficiency oil purification systems is increasing to support the energy, manufacturing, and transportation sectors.

South Africa & Zambia: With a strong industrial base, these countries benefit greatly from the ability to extend the life of oils used in power generation and heavy machinery by utilizing high-performance oil purification systems.

India:

In India, the demand for industrial oil purification systems is equally high, driven by the need for greater oil efficiency in diverse sectors like manufacturing, agriculture, and power generation. AR Engineering brings the latest purification technology to Indian industries, offering solutions tailored to the country’s evolving industrial needs.

Key Features of Industrial Oil Purification Systems

Our Industrial Oil Purification Systems are designed with cutting-edge technology and built to meet the specific needs of various industries in Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, and India. Here’s why you should choose our oil purification systems:

Advanced Filtration Technology: Our systems use state-of-the-art filtration methods to ensure the removal of particulate matter, water, and other impurities from oils.

Automatic Operation: The oil filtration systems are equipped with advanced automation, reducing the need for manual intervention and ensuring consistent results.

Energy-Efficiency: Designed to minimize energy consumption, our systems are optimized for cost-effective operations.

Compact and Durable: Our purification systems are compact and rugged, designed to handle the toughest industrial environments, while providing long-lasting performance.

Oil Purification in Africa & India: Key Markets

In Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, and India, oil purification technology plays a key role in transforming industrial operations. These countries are experiencing rapid industrialization and expanding their infrastructure, which significantly increases the demand for cleaner and more efficient operations.

Botswana and Ethiopia:

Industries in Botswana and Ethiopia benefit from the Industrial Oil Purification System to ensure smoother operations and reduce unplanned downtime due to equipment failure. With applications in mining and energy production, oil purification helps keep expensive machinery running efficiently.

Kenya and Namibia:

The growing demand for manufacturing and energy production systems in Kenya and Namibia calls for high-performing oil filtration systems to increase equipment longevity. Industrial oil purification reduces downtime, lowering the maintenance costs in these growing economies.

Nigeria and South Africa:

In countries like Nigeria and South Africa, where industries such as power generation and manufacturing dominate, the need for Industrial Oil Purification Systems is crucial for ensuring the continuous operation of high-performance machinery, lowering production costs, and reducing environmental impact.

Zambia and Zimbabwe:

In regions like Zambia and Zimbabwe, the oil purification system plays an important role in agriculture, power generation, and manufacturing, where large machinery is heavily relied upon to boost productivity.

India:

With its booming manufacturing and energy sectors, India increasingly relies on Industrial Oil Purification Systems to improve the efficiency of its industrial operations. The demand for cleaner oils is growing, and our systems are designed to cater to these evolving needs, ensuring smooth operation and minimizing costly repairs.

Industrial Oil Filter Machines: The Heart of the Purification Process

To complement our Oil Purification Systems, we also offer top-of-the-line Industrial Oil Filter Machines. These machines are integral to the purification process, designed to remove solid impurities from oils. Available across Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, and India, our Industrial Oil Filter Machines guarantee:

High Filtration Efficiency: Remove contaminants like dirt, dust, and particulate matter from oils, ensuring cleaner and longer-lasting oil.

Reliable and Low Maintenance: The filter machines are designed for minimal upkeep and offer consistent results, ensuring the smooth operation of your oil purification systems.

Why Choose AR Engineering for Oil Purification Systems?

At AR Engineering, we are committed to providing Industrial Oil Purification Systems that optimize the efficiency and longevity of your industrial operations. With decades of experience, we are the go-to supplier of oil filtration and purification solutions for industries in Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, and India.

Contact AR Engineering Today

Looking for high-quality oil purification systems that ensure your equipment runs at its best? Contact AR Engineering today for industrial oil purification solutions that increase the efficiency and lifespan of your machinery.

#Industrial Oil Purification Systems#Industrial Oil Purification Systems in Botswana#Industrial Oil Purification Systems in Ethiopia#Industrial Oil Purification Systems in Kenya#Industrial Oil Purification Systems in Namibia#Industrial Oil Purification Systems in Nigeria#Industrial Oil Purification Systems in South Africa#Industrial Oil Purification Systems in Zambia#Industrial Oil Purification Systems in Zimbabwe#Industrial Oil Purification#Industrial Oil Purification in Botswana#Industrial Oil Purification in Ethiopia#Industrial Oil Purification in Kenya#Industrial Oil Purification in Namibia#Industrial Oil Purification in Nigeria#Industrial Oil Purification in South Africa#Industrial Oil Purification in Zambia#Industrial Oil Purification in Zimbabwe#oil purification system#oil purification system in Botswana#oil purification system in Ethiopia#oil purification system in Kenya#oil purification system in Namibia#oil purification system in Nigeria#oil purification system in South Africa#oil purification system in Zambia#oil purification system in Zimbabwe#industrial oil filter machine#industrial oil filter machine in Botswana#industrial oil filter machine in Ethiopia

0 notes

Text

Understanding of the BETA factor

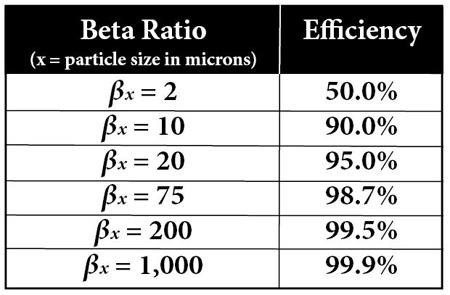

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

Enhancing Oil Quality with Industrial Oil Purification Systems

Efficient oil purification is critical to ensuring the longevity and performance of industrial machinery. At Conserve Your Oil, we provide cutting-edge Industrial Oil Purification Systems designed to meet the stringent demands of modern industries. Recognized as one of the leading Industrial Oil Purification System manufacturers and suppliers in India, we offer solutions that prioritize efficiency, reliability, and cost-effectiveness.

What is an Industrial Oil Purification System?

An Industrial Oil Purification System is an advanced technology designed to remove contaminants such as water, gases, and solid particles from industrial oils. These systems are essential for maintaining the quality of oils used in various machinery, ensuring operational efficiency and extending equipment lifespan.

Why Choose Our Industrial Oil Purification Systems?

As a trusted manufacturer and supplier in Pune and across India, we deliver high-performance oil purification systems that offer:

Enhanced Productivity: Clean oil reduces wear and tear, leading to improved machinery efficiency.

Cost Savings: Prolonged oil life reduces the need for frequent replacements.

Environmental Benefits: Minimized waste and sustainable oil usage.

Our Expertise in Oil Filtration Solutions

We specialize in a range of oil purification technologies, including:

Industrial Oil Filtration Plants: Comprehensive systems for large-scale industrial operations.

Oil Filter Machines: Compact and efficient devices for precise filtration.

Oil Filtration Machines: Versatile solutions tailored to various applications.

Oil Filtration Plants: Advanced setups for high-volume filtration needs.

Leading Manufacturer, Supplier, and Exporter

At Conserve Your Oil, we are proud to serve as a leading:

Industrial Oil Purification Systems Manufacturer in Pune and India

Industrial Oil Purification Systems Suppliers in Pune and across India

Exporter of Industrial Oil Purification Systems in Pune and globally

Our systems are engineered to meet international standards, making us a preferred choice for clients worldwide.

Applications of Industrial Oil Purification Systems

Our systems cater to diverse industries, ensuring seamless integration into existing operations:

Power Plants: Maintain the quality of turbine oils for uninterrupted performance.

Automotive Industry: Ensure the efficiency of hydraulic oils and lubricants.

Manufacturing Units: Prolong the life of machinery with clean and purified oil.

Innovative Features of Our Systems

High Efficiency: Removes contaminants with precision.

Robust Construction: Built for demanding industrial environments.

Customizable Solutions: Tailored designs to meet specific requirements.

Easy Maintenance: Simplified operations for hassle-free upkeep.

Trusted for Quality and Innovation

We take pride in our reputation as a leading provider of Industrial Oil Purification Systems in Pune, India, and internationally. Our commitment to innovation and quality has made us the go-to choice for businesses looking to enhance their operational capabilities.

Why Conserve Your Oil?

Experience and Expertise: Years of delivering reliable oil purification solutions.

Comprehensive Product Range: From oil filter machines to industrial oil filtration plants.

Global Reach: Recognized as a trusted exporter of Industrial Oil Purification Systems.

Customer-Centric Approach: Solutions tailored to your unique needs.

#Industrial Oil Purification System Manufacturers#Industrial Oil Purification System Suppliers in India#industrial oil filtration plant#Industrial Oil Purification Systems manufacturer in pune#Industrial Oil Purification Systems suppliers in pune#Industrial Oil Purification Systems exporter in pune#Industrial Oil Purification Systems manufacturer in india#Industrial Oil Purification Systems exporter in india#Industrial oil filtration machines#Industrial oil filtration plant#Oil filter machines#Oil filteration plants#Oil filtration machines

0 notes

Text

Fuck ‘Alternative’ Technology! Fuck the ‘Alternative’ Green Ghetto!

Standing up on this hill, as the sun filters through the trees you occasionally catch the reflection of solar panels on the roofs of the houses beyond the wind farm. The gentle swishing of turbine blades is inaudible here, but the hum of a tractor is just perceptible as it sows next year’s bio fuel crop in the fields below...

Though the reality of alternative technology providing a “green” and sustainable life for us all in the 21st century may seem a long way off, may seem an almost impossible task of enormous proportions, it is becoming more widely accepted as a necessary step in the progress of our industrial society. It is, however, rarely seen for the sham it is.

The disastrously clichéd picture painted above is incomplete without a quick look behind the scenes. Though minute details of the industrial processes employed are beyond the scope of this article, and frankly do not interest me, even a cursory examination will show that the manufacture of photovoltaic panels, wind gennies and bio fuel production facilities is not a particularly green (or alternative) business. From mineral and metal ore extraction (think open cast, think indigenous land rights, think health and safety) to metal purification (think blast furnace, think slag heaps, think massive energy consumption) to manufacturing (think conveyer belts, think toxic effluents, think wage slavery) to transport (think container ships, think road deaths, think more and more fucking airports) to mass consumer society (think, no don’t think, consume), when western industrial society decides it wants something, regardless of the apparently benign nature of the product (or even it’s intended use in excusing the excesses of our society), the product has a price attached to it, namely the “concealed drudgery of many and the despoliation of the natural world” [1]

There seem to be many people in the alternative green ghetto who have become engrossed in the provision of power through ‘alternative’ means, usually at festivals and free parties, and who even see this as a form of green activism. Embarrassingly this mostly takes the form of boys playing with their (hi-tech) toys. An unfortunate group caught out by technological determinism. Just because it’s possible it doesn’t follow that it’s a good idea.

Many have been fooled into thinking that this new product of consumer capitalism will further the goals of those seeking sustainability without questioning the use of electricity itself and the innately unsustainable nature of all the industries involved in its consumption.

Although industrial production (of alt-tech gear or otherwise) is inherently unsustainable (surely with just a bit more technology...) some products are often justified if they, for instance, allow autonomy or independence to those in struggle, but then the same goes for making use of any of the tools of civilization in order to fight against it. But people tend to consume ‘alt tech’ as a lazy alternative to using more inventive methods, which are usually more in conflict with the system.

The problem arises around so-called ‘ethical’ consumption and the quasireligious zeal that surrounds the cult that is alternative-technology. Ethical consumption is steeped in petty moralism and guilt, but rarely challenges consumption itself.

As anarchists we shouldn’t look to the marketplace to fulfil our needs — but rather seek to feed off the detritus of civilization whilst attacking the pillars that are its foundation.

What are we doing with all this ‘alternative’ electricity? Whether it’s being fed into the grid or used where it’s made (via lead-acid batteries), it is the use of electricity itself that must be questioned, not where it comes from. In the same way that the suggestion that our vehicles could be fuelled by vegetable oil does not question car culture, the cult of electricity is rarely examined. From computers to sound-systems, light-bulbs to fridge-freezers all of these things just add to the devastation of the natural world, and severely limit any chance of salvaging a genuine unmediated human existence.

It would be foolish to forget that a green city is still a city. It comes down to whether you merely want to tinker with the system (however you dress that up in anarcho-leftist rhetoric), creating a green tinged society a la Bookchinite ‘Social Ecology’) whether your desire is to embark upon a project that seeks to dismantle all that curtails a more authentic exitence. Though there are apparently still some anarchists who believe that controlling the means of production would somehow allow the develoment of a libertarian society, it must be realised that the technological system is simply a part of the structure domination that (one would think) anarchists strive to destroy.

Technology is the sum of mediations between us and the natural world and the sum of those separations mediating us from each other. It is all the drudgery and toxicity required to produce and reproduce the stage of hyper-alienation we live in. [2]

It may have become apparent that I am using the terms “technology” and “alternative technology” interchangably, but it should be obvious by now that there can be no reasonable differentiation between them. The notion that technology is neutral and exists independently of social relationships has no basis.

Technology is not a simple tool which can be used in any way we like. It is a form of social organization, a set of social relations. It has its own laws. If we are to engage in its use, we must accept its authority. The enormous size, complex interconnections and stratification of tasks which make up modern technological systems make authoritarian command necessary and independent, individual decision-making impossible. (Fifth Estate Quoted from ‘The Primitivist Primer’ by John Moore).

At the heart of the technological system are the division of labour and specialisation. Resulting from these are dependency. We are held to ransom, dependent on others, childlike in the face of the complex organisation of technological society, alienated from the natural environment.

Most anarchists recognise that the state, private property, the commodity system, the patriarchal family and organized religion are inherently dominating institutions and systems that need to be destroyed if we are to create a world in which we are all free to determine our lives as we see fit. Thus, it is strange that the same understanding is not applied to the industrial technological system.[3]

It appears that what is needed is a seditious mutiny of the technological mindset that seems to be so pervasive even within so called ‘alternative’ green and radical circles. That ‘alternative’ technology will fail to avert any of the pitfalls of conventional technological approaches is clear. Therefore its status among many as some form of tool of a future ecological society is grounded in shallow and ill thought out analysis of the current technological society we find ourselves in and the historical forces that brought this about.

Never before have people been so infantalised, made so dependent on the machine for everything; as the earth rapidly approaches its extinction due to technology, our souls are shrunk and flattened by its pervasive rule. Any sense of wholeness and freedom can only return by the undoing of the massive division of labour at the heart of technological progress. This is the liberatory project in all its depth.[4]

#green#tech#anarchism#green anarchism#Green Anarchist#70#Mr. Blobby#technology#anarchy#anarchist society#practical anarchy#practical anarchism#resistance#autonomy#revolution#communism#anti capitalist#anti capitalism#late stage capitalism#daily posts#libraries#leftism#social issues#anarchy works#anarchist library#survival#freedom

5 notes

·

View notes

Text

Excerpt from this story from Anthropocene Magazine:

I write about the climate and energy for a living and even I can’t quite wrap my head around how cheap low-carbon power technologies have gotten. The cost of onshore wind energy has dropped by 70% over just the last decade, and that of batteries and solar photovoltaic by a staggering 90%. Our World in Data points out that within a generation, solar power has gone from being one of the most expensive electricity sources to the cheapest in many countries—and it’s showing little signs of slowing down.

So where does this all end?

Back in the 1960s, the nuclear industry promised a future in which electricity was too cheap to meter. Decades later, the same vision seems to be on the horizon again, this time from solar. It seems, well, fantastic. Perhaps (almost) free renewable power leads to climate utopia. Then again, should we be careful what we wish for?

The Road To Decarbonization Is Paved With Cheap Green Power

1. More renewables = less carbon. The math isn’t complicated. The faster we transition to clean energy, the less carbon dioxide we’re adding to the atmosphere and the fewer effects of global warming we will suffer.While humanity is still emitting more greenhouse gases than ever, the carbon intensity of electricity production has been dropping for well over a decade.

2. Cheap, clean power also unlocks humanitarian goals. Modern civilization rests on a foundation of electricity. Beyond its obvious uses in heating, cooling, cooking, lighting and data, electricity can decarbonize transportation, construction, services, water purification, and food production. Increasing the supply and reducing the cost of green electricity doesn’t just help the climate, it improves equity and quality of life for the world’s poorest.

3. Scrubbing the skies will take a lot of juice. Once we get emissions under control, it’s time to tackle the mess we’ve made of the atmosphere. Today’s direct air capture (DAC) systems use about two megawatt hours of electricity for every ton of CO2 plucked from fresh air. Scale that up to the 7 to 9 million tons we need to be removing annually in the US by 2030, according to the World Resources Institute, and you’re looking at about 0.5% of the country’s current energy generation. Scale it again to the nearly 1,000 billion tons the IPCC wants to sequester during the 21st century, and we’ll need every kilowatt of solar power available—the cheaper the better.

Cheap Power Has Hidden Costs

1. Cheap technology doesn’t always mean cheap power. If solar cells are so damn cheap, why do electricity bills keep rising? One problem is that renewables are still just a fraction of the energy mix in most places, about 20% in the US and 30% globally. This recent report from think-tank Energy Innovation identifies volatility in natural gas costs and investments in uneconomic coal plants as big drivers for prices at the meter. Renewables will have to dominate the energy mix before retail prices can fall.

2. The cheaper the power, the more we’ll waste. Two cases in point: cryptocurrency mining and AI chat bots. Unless we make tough social and political decisions to fairly price carbon and promote climate action, the market will find its own uses for all the cheap green power we can generate. And they may not advance our climate goals one inch.

3. Centuries of petro-history to overcome. Cheap power alone can only get us so far. Even with EVs challenging gas cars, and heat pumps now outselling gas furnaces in the US, there is a monumental legacy of fossil fuel systems to dismantle. Getting 1.5 billion gas cars off the world’s roads will take generations, and such changes can have enormous social costs. To help smooth the transition, the Center for American Progress suggests replacing annual revenue-sharing payments from coal, oil, and natural gas production with stable, permanent distributions for mining and oil communities, funded by federal oil and gas revenue payments.

5 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Water Treatment Chemicals Market Technological Advancements Driving Growth

Water treatment chemicals play a crucial role in ensuring clean, safe, and usable water for industrial, municipal, and residential purposes. As the demand for clean water rises globally, the market for water treatment chemicals continues to grow, driven by various factors such as urbanization, industrial expansion, stringent environmental regulations, and increasing concerns over waterborne diseases. This article explores the key drivers fueling the growth of the water treatment chemicals market.

1. Increasing Demand for Clean Water

One of the primary drivers of the water treatment chemicals market is the escalating demand for clean water across industries, municipalities, and households. With the global population projected to surpass 9 billion by 2050, the need for potable water is rising exponentially. Many regions face water scarcity, necessitating advanced water treatment solutions to recycle and purify water for reuse.

2. Rapid Industrialization and Urbanization

The industrial sector is a major consumer of water, with industries such as power generation, food and beverage, chemicals, and oil & gas requiring significant amounts of treated water for various processes. As industrial activities increase, so does the demand for water treatment chemicals. Urbanization also contributes to higher wastewater production, driving the need for efficient water treatment solutions in cities and towns.

3. Stringent Environmental Regulations

Governments and regulatory bodies worldwide have imposed strict water quality standards to protect public health and the environment. Regulations such as the Clean Water Act in the U.S. and the European Water Framework Directive mandate the treatment of wastewater before discharge, leading to increased adoption of water treatment chemicals. Compliance with these regulations is a key driver for market growth.

4. Rising Concerns Over Waterborne Diseases

Contaminated water is a leading cause of diseases such as cholera, typhoid, and dysentery. The increasing awareness of the health risks associated with untreated water has prompted governments and private entities to invest in water treatment solutions. Water treatment chemicals such as disinfectants, coagulants, and flocculants play a critical role in eliminating pathogens and ensuring safe drinking water.

5. Advancements in Water Treatment Technologies

Technological innovations have revolutionized the water treatment industry. The development of high-efficiency water treatment chemicals, including biodegradable and eco-friendly options, has created new growth opportunities. Nanotechnology, advanced oxidation processes, and membrane filtration systems have enhanced the effectiveness of chemical treatments, making water purification more efficient and sustainable.

6. Growing Use of Desalination Technologies

With freshwater sources becoming increasingly scarce, desalination has emerged as a viable solution to meet the demand for potable water. Countries in the Middle East, North Africa, and parts of Asia are investing heavily in desalination plants, which require specialized water treatment chemicals such as scale inhibitors, antifoaming agents, and biocides. The expansion of desalination projects is boosting the demand for water treatment chemicals.

7. Expansion of the Power Generation Sector

The power generation industry is one of the largest consumers of water, primarily for cooling and steam generation. Thermal power plants, nuclear facilities, and hydropower stations require high-quality treated water to prevent scaling, corrosion, and microbial growth in boilers and cooling systems. As global energy demand rises, the need for water treatment chemicals in power plants is expected to grow significantly.

8. Increasing Adoption of Sustainable and Green Chemicals

Sustainability has become a key focus in the water treatment industry. Many companies are shifting towards green and biodegradable water treatment chemicals to reduce environmental impact. The demand for non-toxic coagulants, plant-based biocides, and organic corrosion inhibitors is rising as industries and municipalities strive to achieve sustainability goals.

9. Growing Investments in Wastewater Treatment Infrastructure

Governments and private players are heavily investing in wastewater treatment plants to address water pollution and scarcity. Developing economies, particularly in Asia and Africa, are expanding their wastewater treatment infrastructure to support urbanization and industrial growth. This increasing investment in wastewater treatment facilities is directly boosting the market for water treatment chemicals.

10. Climate Change and Water Scarcity

Climate change is significantly impacting water resources, leading to droughts, declining groundwater levels, and reduced freshwater availability. As a result, water recycling and reuse are becoming essential, driving demand for chemical treatment solutions that enhance water recovery and purification. The adoption of chemical-based water treatment methods is crucial in ensuring water security amid changing climatic conditions.

Conclusion

The water treatment chemicals market is experiencing robust growth, driven by increasing water demand, regulatory compliance, technological advancements, and environmental concerns. As industries and governments continue to focus on sustainable water management practices, the demand for innovative and efficient water treatment chemicals is expected to rise. With continuous investments in research and infrastructure, the future of the water treatment chemicals market looks promising, ensuring access to clean and safe water for generations to come.

0 notes

Text

Vacuum Impregnation Plant Exporters – AR Engineering.

AR Engineering, an ISO Certified Company, is India’s most trusted brand in Trickle Impregnation Technique and Industrial Oil Purification Systems. We specialize in Vacuum Impregnation Plants, ensuring the highest standards in oil conservation and machinery efficiency.

Why Choose AR Engineering?

With years of expertise, AR Engineering is committed to providing high-performance industrial oil purification and impregnation solutions that help industries conserve oil, reduce maintenance costs, and enhance equipment efficiency.

📞 Contact us today for the best Vacuum Impregnation Plants and Oil Filtration Systems in India! 🚀

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

How to Choose the Right Rubber Gasket for Your Application?

Rubber gaskets are essential components used to create a secure and leak-proof seal between two surfaces. They play a critical role in various industries, including automotive, food processing, pharmaceuticals, oil and gas, and chemical processing. At Arvico, we offer a wide range of small rubber gaskets manufactured from high-quality materials to meet the most demanding applications.

Our gaskets are known for their durability, flexibility, and resistance to extreme temperatures, chemicals, and pressure. With years of expertise in the industry, we provide reliable and innovative sealing solutions tailored to specific needs.

Importance of Rubber Gaskets

Rubber Gaskets serve as a vital sealing solution, preventing leakage and contamination in various applications. Their flexibility allows them to conform to different surfaces, providing a secure barrier against moisture, gas, and fluids. Properly installed gaskets help reduce maintenance costs, enhance operational efficiency, and improve equipment longevity.

Types of Rubber Gaskets

We offer a diverse range of rubber gaskets, each designed for specific applications and requirements.

1. Flange Gasket

Flange gaskets are used in piping systems to provide a tight seal between two flanges. They prevent leaks of liquids, gases, and other substances, ensuring operational efficiency and safety.

Applications:

Oil and gas pipelines

Water treatment plants

Chemical processing industries

HVAC systems

2. Diecut Gasket

Diecut gaskets are precision-cut to fit specific shapes and sizes. These gaskets offer exceptional sealing capabilities and are widely used in industrial applications.

Applications:

Automotive engines and fuel systems

Electrical enclosures

Industrial machinery

Aerospace equipment

3. Butterfly Valve Gasket

Butterfly valve gaskets are designed to provide an effective seal in butterfly valve applications. They are highly flexible and offer excellent resistance to pressure and temperature variations.

Applications:

HVAC systems

Food and beverage industries

Pharmaceutical processing

Power generation plants

4. TC Gasket

TC gaskets are commonly used in sanitary applications where cleanliness and hygiene are of utmost importance. TC (Tri-Clamp) gaskets ensure a secure seal in food-grade and pharmaceutical pipelines.

Applications:

Dairy and beverage production

Biopharmaceutical manufacturing

Water purification systems

Brewing industry

5. Rubber Washers

Rubber washers provide cushioning and sealing in various mechanical applications. They are highly resistant to wear and tear, making them a reliable choice for many industries.

Applications:

Plumbing and pipe fittings

Automotive assemblies

Industrial machinery

Marine applications

Material Options for Rubber Gaskets

Depending on the application, our rubber gaskets are available in different materials:

EPDM Rubber Gasket – Offers excellent weather, ozone, and heat resistance, making it suitable for outdoor and industrial applications.

Silicone Rubber Gasket – Ideal for high-temperature applications and food-grade uses due to its flexibility and resistance to extreme conditions.

Neoprene Rubber Gasket – Provides good oil and chemical resistance, commonly used in marine and automotive industries.

Nitrile Rubber Gasket – Suitable for applications involving fuel and oil exposure, offering strong sealing in petroleum-related industries.

Viton Rubber Gasket – Ensures high performance in extreme temperatures and aggressive chemical environments, frequently used in aerospace and automotive applications.

How to Choose the Right Rubber Gasket

Selecting the right rubber gasket depends on several factors, including:

Operating Temperature: Ensure the gasket material can withstand the required temperature range.

Chemical Compatibility: Choose a gasket that resists chemical exposure in the application.

Pressure Rating: Verify that the gasket can endure the pressure conditions of the system.

Flexibility & Durability: Opt for a material that provides the necessary elasticity and longevity.

Why Choose Arvico Rubber Gaskets?

At Arvico, we prioritize quality, precision, and customer satisfaction. Our gaskets are manufactured using cutting-edge technology and the highest industry standards. Here’s why we stand out:

Premium Quality: We use only the best raw materials to ensure longevity and performance.

Customization Options: We offer custom rubber gaskets tailored to your specific requirements.

Wide Industry Applications: Our gaskets serve diverse industries, from pharmaceuticals to heavy engineering.

Reliability: With decades of experience, we guarantee durable and dependable sealing solutions.

Technical Expertise: Our team provides expert guidance in selecting the right gasket for your needs.

Conclusion

Rubber gaskets manufacturer play a crucial role in maintaining leak-proof and secure connections across various industries. Arvico offers a comprehensive range of high-quality rubber gaskets, including flange gaskets, diecut gaskets, butterfly valve gaskets, TC gaskets, and rubber washers, among others. Our commitment to quality, innovation, and customer satisfaction ensures that we provide the best sealing solutions tailored to your needs.

Proper gasket selection, maintenance, and installation significantly impact equipment performance and longevity. Partnering with Arvico, a trusted rubber gasket supplier, ensures you receive high-performance rubber gaskets that enhance safety, reliability, and efficiency in your operations.

For more information on our rubber gaskets and to find the perfect solution for your application, contact Arvico today!

youtube

0 notes

Text

Leading Industrial Oil Purification Unit Manufacturer in Satara, Pune, Maharashtra, and India

At AR Engineering, we take pride in being a leading industrial oil purification unit manufacturer based in Satara, Maharashtra, and extending our services across Pune, Maharashtra, and throughout India. With years of experience and advanced technological solutions, we specialize in providing top-notch industrial oil purification units that serve various sectors in need of efficient and reliable oil filtration solutions.

Premium Industrial Oil Filtration Units & Systems

We offer high-quality industrial oil filtration plants and oil purification systems tailored for industries like manufacturing, energy, and mechanical systems. Our products are specifically designed to remove contaminants, impurities, and moisture from industrial oils, ensuring optimal performance and longevity of machinery.

Why Choose AR Engineering for Oil Purification Systems?

Expert Manufacturing in Pune and Satara: Our industrial oil purification units are crafted in our well-equipped facilities in Pune and Satara, known for precision engineering and quality assurance.

Comprehensive Solutions Across India: With a wide reach across Maharashtra and India, we ensure that industries from various sectors have access to advanced oil filtration and purification solutions that increase efficiency and reduce downtime.

Customizable Systems for Different Needs: Whether you need a small-scale oil filtration system for local operations or large-scale purification plants, our solutions are designed to cater to every business size and industry need.

Eco-friendly and Cost-efficient: Our industrial oil purification units are engineered with energy efficiency and environmental responsibility in mind, delivering not only effective filtration but also cost-saving solutions.

Proven Expertise & Customer Satisfaction: Having served clients across India, our industrial oil purification systems have gained recognition for their durability, performance, and reliability.

Types of Oil Purification & Filtration Solutions We Offer

Industrial Oil Purification Systems in Pune & Satara: These systems effectively separate contaminants and moisture from oil to ensure its longevity and high performance in machinery and equipment.

Oil Filtration Plants for Large Industries in Maharashtra: We provide large-scale industrial oil filtration plants that offer continuous oil purification to support high-demand manufacturing and industrial processes.

Custom Oil Purification Solutions Across India: With a focus on customization, our systems can be tailored to meet specific industrial needs, whether for small workshops or large-scale factories.

Serving Industries Nationwide

Our industrial oil purification units serve a variety of sectors, including:

Manufacturing and Engineering

Automotive and Heavy Machinery

Energy and Power Generation

Textile and Chemical Industries

At AR Engineering, we are committed to providing reliable, high-performance, and cost-effective industrial oil filtration and purification solutions to businesses across Pune, Satara, Maharashtra, and India. Reach out today for advanced oil filtration systems tailored to your industrial needs!

#industrial oil purification unit manufacturer#industrial oil purification unit manufacturer in pune#industrial oil purification unit manufacturer in satara#industrial oil purification unit manufacturer in India#industrial oil purification unit manufacturer in maharashtra#industrial oil filtration plant#industrial oil filtration plant in pune#industrial oil filtration plant in satara#industrial oil filtration plant in maharashtra#industrial oil purification systems manufacturer in pune#industrial oil purification systems manufacturer in satara#industrial oil purification systems manufacturer in maharashtra

0 notes

Text

Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil filtration machine#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration systems#oil testing#oil analysis#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbinemaintenance#gas turbine market trends#power industry#metal#mining#oil purification system#oil purification machine#oil filtration system#transformer oil#transformer oil cleaning#transformation oil purification#transformer oil filtration

0 notes

Text

Odour Control in Petrochemical Industries

The petrochemical industry plays a crucial role in producing essential products, but it also generates strong and often unpleasant odours. These odours arise from volatile organic compounds (VOCs), sulfur compounds, and other airborne pollutants. Effective odour control is vital for environmental compliance, workplace safety, and community well-being. In this blog, we explore the sources of odour, its impact, and the best techniques for odour management in the petrochemical sector.

Why Odour Control Matters in Petrochemical Industries

Odour emissions are more than just a nuisance—they can have serious consequences for the environment, worker safety, and community relations. Uncontrolled odours can lead to:

Environmental Degradation: VOCs and sulfur compounds contribute to air pollution.

Health Risks: Prolonged exposure to odorous compounds can cause respiratory issues, headaches, nausea, and other health problems.

Community Discontent: Persistent odour problems often result in public complaints, legal challenges, and reputational damage for companies.

Sources of Odour in Petrochemical Industries

Petrochemical plants process crude oil, natural gas, and other raw materials to produce fuels, plastics, and chemicals. The key sources of odour emissions include:

Storage Tanks: Crude oil, gasoline, and chemical storage tanks release VOCs through evaporation.

Refining Processes: Units like catalytic crackers and hydro-treaters produce sulphur-based odours.

Wastewater Treatment: Industrial effluent contains organic matter and sulfur compounds that emit foul smells.

Venting: Process venting can release strong odours into the air.

Leaks and Spills: Accidental leaks from pipelines and equipment contribute to odour pollution.

Strategies for Effective Odour Control

Several advanced techniques can be implemented to mitigate odour emissions in petrochemical industries:

1. Activated Carbon Filters

Carbon adsorption effectively captures VOCs and sulfur-based compounds from air streams, reducing odour intensity.

2. Biofiltration Systems

Biological treatment systems use microorganisms to break down odour-causing compounds into harmless substances.

3. Chemical Scrubbers

Wet and dry scrubbers neutralize odorous gases using chemical reactions, especially for hydrogen sulfide (H2S) and ammonia.

4. Enclosed Storage and Vapour Recovery Units

Using enclosed storage tanks with vapour recovery systems minimizes VOC emissions and reduces odour dispersion.

5. Leak Detection and Repair Programs

Regular inspections and maintenance help prevent leaks, ensuring that fugitive emissions are minimized.

6. Advanced Oxidation Processes (AOPs)

These include ozone treatment and photocatalytic oxidation, which help break down complex odorous compounds efficiently.

Elixir Enviro Systems’ Odour Control Services

At Elixir Enviro Systems, we specialize in providing comprehensive odour control solutions for petrochemical industries. Our services include:

Customized Odour Control Systems: Tailored solutions based on specific industrial requirements.

Advanced Air Purification Technologies: Integration of cutting-edge filtration and scrubbing techniques.

Emission Monitoring and Compliance Support: Ensuring adherence to environmental regulations.

Ongoing Maintenance and Optimization: Regular inspections and improvements for continuous performance.

Conclusion

Effective odour control in petrochemical industries is essential for regulatory compliance, environmental protection, and community well-being. By adopting modern odour management strategies, companies can significantly reduce emissions, improve air quality, and maintain a positive relationship with surrounding communities. Investing in sustainable odour control technologies ensures a healthier and safer industrial environment.

At Elixir Enviro Systems, we are committed to delivering innovative and sustainable odour control solutions. Whether you’re looking to upgrade your existing systems or implement new technologies, we’re here to help. Contact us today to learn more about how we can support your odour control needs and contribute to a cleaner, greener future.

#petrochemicals#blog#odourcontrol#ecofriendly#elixirenvirosystems#airpollution#biofilter#sustainability

0 notes

Text

Customized Water Filtration Solutions in Perth for Every Need

Water Filters in Perth: Clean, Safe, and Refreshing Drinking Water

Having access to clean, safe drinking water is essential for maintaining good health and overall well-being. At [Company Name], we offer high-quality Water Filter in Perth to ensure that your home or office always has fresh, great-tasting water. Our Water Filtration System in Perth effectively removes impurities such as chlorine, heavy metals, and bacteria, providing a reliable solution for pure drinking water.

Why Choose Our Water Filtration Solution in Perth?

When it comes to water filtration, you need a system that is both effective and affordable. Our range of Water Filter in Perth is designed to meet various needs, whether you require a solution for your home, office, or specialized industrial applications. Here’s why our customers trust us:

Advanced Filtration Technology: Our systems utilize state-of-the-art filtration technology to eliminate harmful contaminants, ensuring the highest water quality.

Affordable & Long-Lasting: Our filters are cost-effective and built to last, reducing the need for frequent replacements.

Eco-Friendly & Great-Tasting Water: Our filtration solutions provide water that is not only safe to drink but also enhances its taste and purity without harming the environment.

Comprehensive Water Filtration System in Perth

We provide a variety of Water Filtration Solution in Perth tailored to different requirements, including:

1. Whole House Filtration Systems

These systems provide clean water for your entire home, ensuring that every tap delivers purified water free from contaminants.

2. Under-Sink Filters

Ideal for home kitchens and office spaces, these compact filters are installed under the sink, providing on-demand access to pure drinking water.

3. Reverse Osmosis Systems

For those who need the highest level of purification, our Water Filtration System in Perth effectively removes even the smallest impurities, including dissolved salts and bacteria.

Specialized Filtration for Oil Water Separator Systems

At Allflow, we understand the importance of maintaining oil water separator systems with high-quality filters. Our selection includes:

Blue Filter – An effective and durable solution for various filtration needs.

Mycelx Filters – Advanced filtration technology for superior purification.

Oil Absorbing Cartridges – Specifically designed to remove oil contaminants from water.

Absorption Bags – Ideal for industrial applications that require specialized filtration.

Customized Water Filtration Solution in Perth

Different water sources have unique challenges, and we offer customized water filtration solutions to address specific issues. Whether you’re dealing with hard water, chlorine taste, or other water quality concerns, we have the perfect system for you.

Our Custom Solutions Include:

Hard Water Treatment – Prevents scale buildup and enhances the efficiency of appliances.

Chlorine Removal – Eliminates unpleasant chlorine taste and odor for better-tasting water.

Specialized Filtration – Designed to meet unique filtration needs for residential, commercial, or industrial applications.

Get the Best Water Filter in Perth Today

At [Company Name], we are committed to providing Perth residents with top-notch Water Filtration System in Perth. Whether you need a whole-house system, an under-sink filter, or specialized filtration for industrial use, we have the right option for you.

Contact Us

Office Address: Unit 3, 30 Walters Drive Osborne Park WA 6017 Postal Address: PO Box 1771 Osborne Park DC WA 6916 Phone: (08) 9244 4622 E-mail: [email protected]

Contact us today to learn more about our Water Filtration Solution in Perth and enjoy clean, safe, and refreshing water every day!

#WaterFiltersPerth#CleanDrinkingWater#WaterFiltrationPerth#SafeWaterForAll#PureWaterSolutions#HealthyHydration#EcoFriendlyWaterFilters#ReverseOsmosisPerth

0 notes

Text

How Pyrolysis Plants Work: Turning Waste into Fuel, Oil, and Gas

In an era where waste management and renewable energy are critical global priorities, pyrolysis plants have emerged as a transformative technology. These innovative facilities are designed to convert waste materials—such as plastic, rubber, and biomass—into valuable resources like fuel, oil, and gas. But how exactly do pyrolysis plants achieve this? This article delves into the working mechanism of pyrolysis plants, their key components, and their role in sustainable waste-to-energy conversion.

What is Pyrolysis?

Pyrolysis is a thermochemical process that breaks down organic and inorganic materials at high temperatures in the absence of oxygen. Unlike combustion, which requires oxygen and produces harmful emissions, pyrolysis occurs in an oxygen-free environment, making it a cleaner and more environmentally friendly process. The end products of pyrolysis include pyrolysis oil, syngas, and biochar, all of which have practical applications in energy production and industrial processes.

The Working Mechanism of Pyrolysis Plants

The operation of a pyrolysis plant involves a series of well-defined steps, each crucial to the efficient conversion of waste into usable resources. Here’s a step-by-step breakdown of how pyrolysis plants work:

1. Waste Collection and Pre-Processing

The first step in the pyrolysis process is the collection and preparation of waste materials. These materials can include plastic waste, rubber tires, agricultural residues, or even municipal solid waste. The waste is sorted, cleaned, and shredded into smaller pieces to ensure uniformity and improve the efficiency of the pyrolysis process.

2. Feeding the Reactor

The prepared waste is then fed into a pyrolysis reactor, which is the core component of the plant. The reactor is designed to withstand high temperatures and is sealed to prevent the entry of oxygen. This oxygen-free environment is critical for the pyrolysis process to occur.

3. Thermal Decomposition

Inside the reactor, the waste is heated to temperatures ranging from 300°C to 900°C, depending on the type of material being processed. In the absence of oxygen, the waste undergoes thermal decomposition, breaking down into smaller molecules. This process produces three primary byproducts:

Pyrolysis Oil: A liquid fuel that can be used as an alternative to conventional fossil fuels in industrial boilers, generators, and even vehicles.

Syngas: A mixture of hydrogen, carbon monoxide, and other gases that can be used for electricity generation or as a feedstock for chemical production.

Biochar: A solid residue that can be used as a soil amendment to improve soil fertility or as a raw material in manufacturing processes.

4. Byproduct Collection and Purification

The byproducts generated during pyrolysis are collected and purified to remove any impurities. The pyrolysis oil is stored in tanks, the syngas is filtered and compressed, and the biochar is cooled and packaged for further use.

5. Energy Recovery

One of the most significant advantages of pyrolysis plants is their ability to generate energy from waste. The syngas produced during the process can be used to power the plant itself, making it self-sustaining and energy-efficient. Excess energy can also be exported to the grid or used for other industrial applications.

Key Components of a Pyrolysis Plant

A pyrolysis plant consists of several essential components, each playing a vital role in the process:

Reactor: The heart of the plant, where the pyrolysis process takes place.

Feeding System: Transports waste materials into the reactor.

Heating System: Provides the high temperatures required for pyrolysis.

Condensation System: Converts syngas into liquid pyrolysis oil.

Gas Cleaning System: Removes impurities from the syngas.

Control System: Monitors and regulates the entire process to ensure optimal performance.

Pyrolysis Plant Manufacturers in India

India, with its rapidly growing population and increasing waste generation, has recognized the potential of pyrolysis technology. Several pyrolysis plant manufacturers in India are at the forefront of designing and producing advanced pyrolysis plants tailored to the country’s waste management needs. These manufacturers focus on creating efficient, cost-effective, and environmentally friendly solutions to address India’s waste crisis.

Indian manufacturers are known for their innovation and adaptability, offering customized pyrolysis plants that can process a wide range of waste materials. By investing in advanced technology and sustainable practices, these manufacturers are contributing to India’s transition toward a circular economy.

Applications of Pyrolysis Plants

Pyrolysis plants have diverse applications across various industries:

Plastic Waste Management: Converting non-recyclable plastic waste into fuel.

Tire Recycling: Processing end-of-life tires to recover oil, gas, and carbon black.

Biomass Conversion: Transforming agricultural and forestry waste into biochar and renewable energy.

Industrial Waste Treatment: Safely disposing of hazardous industrial waste while recovering valuable resources.

Conclusion

Pyrolysis plants are a game-changing technology that turns waste into valuable resources, offering a sustainable solution to the global waste crisis. By understanding how these plants work, we can appreciate their potential to revolutionize waste management and energy production. With the growing presence of pyrolysis plant manufacturers in India, the country is well-positioned to harness this technology and achieve its environmental and economic goals. As the world moves toward a greener future, pyrolysis plants will undoubtedly play a pivotal role in shaping sustainable waste management practices.

0 notes

Text

Industrial Oil Filters in India – AR Engineering

Industrial Oil Filters in India – AR Engineering

AR Engineering, an ISO Certified Company, is India’s most trusted brand in oil filtration machines, industrial oil filters, and oil filtration plants. Our Industrial Oil Filters are designed to remove contaminants, improve oil quality, and enhance the performance of machinery across industries.

Why Are Industrial Oil Filters Essential?

Oil contamination can lead to equipment failures, increased maintenance costs, and reduced efficiency. Our Industrial Oil Filters effectively remove solid particles, water, and sludge, ensuring clean and high-performing oil for various industrial applications.

AR Engineering, an ISO Certified Company, is India’s most trusted brand in oil filtration machines, industrial oil filters, and oil filtration plants. Our Industrial Oil Filters are designed to remove contaminants, improve oil quality, and enhance the performance of machinery across industries.

Why Are Industrial Oil Filters Essential?

Oil contamination can lead to equipment failures, increased maintenance costs, and reduced efficiency. Our Industrial Oil Filters effectively remove solid particles, water, and sludge, ensuring clean and high-performing oil for various industrial applications.

Comprehensive Oil Filtration & Cleaning Solutions

We offer a wide range of oil filtration systems to ensure optimal equipment performance:

✅ Turbine Oil Cleaning Systems – Eliminates contaminants to enhance turbine efficiency. ✅ Oil Cleaning Machines – Designed to remove impurities from various industrial oils. ✅ Turbine Oil Filtration Plants – Ensures high oil purity for extended turbine life. ✅ Gear Oil Filtration Systems – Enhances the longevity of gear oils and reduces friction. ✅ Double Stage Oil Transformer Machines – Advanced dual-stage filtration for deep oil purification. ✅ Thermic Oil Filtration Systems – Keeps thermic oils clean for better heat transfer efficiency. ✅ Hydraulic Oil Online Filters – Ensures continuous filtration for hydraulic systems. ✅ Transformer Oil Filtration Systems – Maintains the dielectric strength and purity of transformer oils.

Portable & On-Site Oil Filtration Solutions

We provide Mobile Oil Filtration Plants, Portable Oil Filtration Systems, and Online Oil Cleaning Systems, enabling on-site oil testing and cleaning without system downtime.

Advanced Transformer Oil Filtration & Reclamation

For transformer maintenance, we offer:

🔹 Transformer Oil Filtration Plants 🔹 Transformer Evacuation Systems 🔹 Two-Stage Transformer Oil Filtration Plants 🔹 Transformer Oil Reclamation Units

We also supply Oil Testing Equipment, including Visgage Oil Test Kits and Karl Fischer Moisture Measurement Equipment, ensuring precise oil analysis.

Cutting-Edge Oil Monitoring & Filtration

Our Online Inline Particle Counters, Laser Particle Counters, Online Oil Contamination Sensors, and Industrial Filters provide real-time oil quality monitoring for various applications.

Your Reliable Partner for Industrial Oil Filtration in India

With years of expertise, AR Engineering delivers high-performance industrial oil filtration solutions that enhance efficiency, reduce downtime, and extend equipment life.

📞 Contact us today for top-quality Industrial Oil Filters and Oil Filtration Systems in India! 🚀

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes