#Inconel Buttweld fittings

Explore tagged Tumblr posts

Text

https://bullionpipe.com/our-product/hastelloy-products/hastelloy-buttweld-fittings/hastelloy-c22-b2-buttweld-fittings-exporters/

Hastelloy B2 Buttweld Fittings - Bullion Pipe

Bullion pipe is the Manufacturer, Exporter & Suppliers of Hastelloy B2 Buttweld Fittings & Hastelloy C22 Buttweld Fittings, Hastelloy Buttweld Fittings in India. Hastelloy ASTM B366 Seamless Buttweld Fittings, Hastelloy Buttweld Fittings, Hastelloy Alloy Elbow these are types of Hastelloy B2 Buttweld Fittings. For more information visit the website today !!

0 notes

Text

Inconel 600 Buttweld Fittings Suppliers & manufacturers | Metalforgeindia

In the area of enterprise company agency business agency company applications wherein sturdiness, electricity, and resistance to immoderate environments are important, Inconel 600 buttweld fittings stand out as an outstanding choice. Known for their brilliant resistance to oxidation, corrosion, and excessive temperatures, Inconel 600 buttweld pipe fittings are considerably used within the route of numerous industries, collectively with chemical processing, aerospace, nuclear reactors, and electricity era.

For those looking to deliver the ones crucial components, choosing the right organization and manufacturer is important. In this weblog, we’ll find out the advantages of Inconel 600 buttweld fittings, why they will be a favored desire for demanding packages, and the way we are located as an excellent organization and producer within the market.

Understanding Inconel 600 Buttweld Pipe Fittings

Inconel 600 is a nickel-chromium alloy diagnosed for its wonderful resistance to oxidation and corrosion, particularly in environments subjected to immoderate temperatures. This alloy is well-known for extremely good mechanical houses, making it a remarkable material for fabricating buttweld pipe fittings, which might be vital in numerous business enterprise structures.

Buttweld fittings are used to trade the route, department off, or mechanically be a part of components inside a piping device. These fittings, which embody elbows, tees, reducers, caps, and crosses, are crucial in ensuring the integrity and normal everyday usual trendy fashionable performance of fluid and fuel transportation systems. When made from Inconel 600, the ones fittings provide terrific notable universal overall performance, in particular in environments that require resistance to immoderate warm temperature and corrosive substances.

Why Choose Inconel 600 Buttweld Fittings?

1. High-Temperature Resistance

One of the primary motives Inconel 600 is finished in buttweld fittings is its functionality to face as a whole lot as excessive temperatures. It can keep its mechanical houses and face up to oxidation in temperatures as amazing as 2000°F (1093°C). This makes it an incredible choice for industries like aerospace, wherein additives are uncovered to immoderate thermal pressure.

2. Excellent Corrosion Resistance

Inconel 600 offers advanced resistance to a large type of corrosive surroundings. It is especially obvious within the path of chloride-ion stress-corrosion cracking, a common hassle in masses of commercial enterprise agency business enterprise strategies. This makes it super for chemical processing industries wherein the tool is frequently uncovered to corrosive chemical substances.

3. Versatility in Applications

The versatility of Inconel 600 lets in it for use in numerous administrative center artwork, together with pipes, tubes, and fittings. In buttweld fittings, this versatility guarantees that they will be done in several applications beginning from immoderate-strain steam pipes to warm temperature exchangers, making sure reliability and sturdiness.

Applications of Inconel 600 Buttweld Pipe Fittings

Given their awesome homes, Inconel 600 buttweld fittings find out programs in numerous industries:

Chemical Processing: Inconel 600’s resistance to oxidation and corrosion makes it incredible for use in chemical processing vegetation, in which it may resist the aggressive chemical substances and immoderate temperatures.

Aerospace: Inconel 600 buttweld fittings are used within the aerospace company business company enterprise commercial enterprise corporation industrial organization industrial corporation business organization for additives that require strength and balance at excessive temperatures, which encompass exhaust systems and engine components.

Power Generation: The immoderate-temperature resistance of Inconel 600 makes it suitable to be used in strength era plants, especially in gasoline and steam generators.

Nuclear Reactors: Due to its capability to get up to oxidation and preserve its mechanical homes at immoderate temperatures, Inconel 600 is carried out in nuclear reactors, in which protection and reliability are paramount.

MetalForge India: Your Trusted Partner for Inconel 600 Buttweld Fittings

When it includes sourcing Inconel 600 buttweld fittings, we stand out as a prime company enterprise organization and manufacturer. With years of enjoy in the business enterprise, we've built a popularity for delivering exquisite merchandise that meet the stringent goals of several industries.

1. Extensive Range of Products

We offer an extensive form of Inconel 625 Round Bar, together with elbows, tees, reducers, caps, and crosses. These fittings are available in numerous sizes and thicknesses to fulfill the proper goals of your duties. Whether you need fashionable sizes or custom fittings, we've got the capability to supply.

2. Commitment to Quality

Quality is at the center of our operations. All Inconel 600 buttweld fittings are synthetic in compliance with global necessities which incorporate ASTM, ASME, and DIN. The employer’s power of will to incredible ensures that you get products that now do not outstanding meet but exceed your expectations.

3. Advanced Manufacturing Capabilities

We rent gift-day production facilities organized with present day- day generation. This permits the economic enterprise company employer business agency organization to deliver Inconel 600 buttweld fittings with precision and consistency. The use of superior machines moreover guarantees that the goods are loose from defects and prepared for use in essential packages.

4. Expertise and Experience

With a hard and fast of professional experts, we provide awesome information in the place of nickel alloys, which includes Inconel 600. The organization's experts are to provide technical manual and steerage, ensuring which you select out the right fittings for your precise applications.

5. Reliable Supply Chain

We are privy to the importance of well timed transport within the commercial enterprise corporation corporation corporation vicinity. The corporation employer has hooked up a dependable delivery chain that guarantees your orders are brought on time, each time. Whether you're sourcing for a small venture or a large-scale operation, you can anticipate us for regular delivery.

Conclusion

Inconel 600 buttweld pipe fittings are a vital detail in industries that require substances with wonderful resistance to excessive temperatures and corrosion. Their versatility, strength, and reliability stimulated them to be a desired preference for critical packages in chemical processing, aerospace, electricity generation, and nuclear reactors.

When sourcing those crucial components, it’s vital to select an enterprise and manufacturer with a tough and rapid up track file of handing over fantastic merchandise. We, with its massive form of Inconel 600 buttweld fittings, self-discipline to excellence, and advanced manufacturing capabilities, are counting on pals in ensuring the success of your duties.

For greater statistics on Inconel 600 buttweld pipe fittings or to find out an order, contact us in recent times. Experience the distinction that superb, facts, and reliability also can additionally furthermore furthermore need to make to your commercial company operations.

0 notes

Text

Pipe End Caps Exporter in Mumbai : Platinex Piping

About The Product

Butt-weld end cap manufacturer in Mumbai is a flange finishing a distribution after a piping is majored missed, often caused by a welding flaw.

An ASME B16.9 waterproof Butt weld End Cap is a type of specialty fitting that is made in accordance to the www.reference.com/science/end-cap-5b7713bd72370068. This gasket is employed to have hydraulic and pneumatic connections to be sealed, or closed up. To meet the needs of customers, it can be manufactured as a standard product or made in a customized way.

Grades in Pipe End Caps

Stainless Steel Pipe End Caps

Carbon Steel Pipe End Caps

Low Temperature Carbon Steel Pipe End Caps

Alloy Steel Pipe End Caps

Duplex Steel Pipe End Caps

Nickel Alloy Pipe End Caps

ANSI B16.9 Pipe Fitting is a kind of cap fitting that serves to cap the end of the pipe and fittings. We supply end cap sizes that are large, various materials and different dimension ranging. We have butt weld able cap fitting available made from materials like Stainless Steel Hastelloy , Inconel , Monel, and Duplex steel “DS”. As well as SMO 254.

The main characteristics of Buttweld End Cap Fittings Exporters include delivering high efficiency in both applications to water as well as gas. The plus point is also the ability of offering a diameter range f slide and wide tolerance gives a decrease in stock holding cost. They are built according to a new concept utilizing a hardware technology that has been tested and proven already. These devices can be your safety mechanism when you are not at home.

Butt weld Cap Eccentric Tube ship Eccentric Nozzle Elevated Pipe With the year 2050, so many scientists predict that our lifestyle and climate will bind to change significantly.

The tillage weld end cap coupling is used in the Water Supply System.

The valve ANSI B16.9 Butt weld End Caps Notebook uses, which is done by joining two pipes to form compound system. A mechanical and chemical property of this product makes the use of this system suitable for higher temperatures and pressures.

Butt weld End Cap Fit joining in the Paper & Pulp Industry is also one of the popular welding solutions.

The Necessity of the End Cap for General Purpose is Primarily Used In Different Applications.

For example, butt weld end cap process is composed by the fabrication industry.

Before the introduction of end caps in food industry, many people were faced with the difficult task of picking up the right kind of food when they did grocery shopping simply because the food packaging made it hard to see what was inside.

Besides the utility of the Top well and Flow cap Buttweld Caps are also pressed and welded at top, and bottom on the header to the pipes utilized in structural applications.

Those working under pressure whether it be popular culture or religious associations could assemble the ketogenic diet. EXAMPLE: The platinex welded bulge is inserted and threaded through the pipe ring. It can further be welded or screwed on joints for convenience. It is a prudence that an additional pipe should be allowed ahead of closing off the system. This option will enable the practice of any additional expansion of the staunchest system without its necessity to be unconditionally interrupted. The Butt weld natures types are: Stub End,SS Reducer, etc.

Platinex is the leading provider, manufacturer and exporter which offers butt weld end cap fittings of different sizes, dimensions and prices. Pipe Cap Fittings are the simplest way to cap off, and thus, are a push fitting. They are the easiest and simplest. They are placed in order to withstand stub outs, pressure testing; these can be used on wet and dry piping.

Applications

This category of fittings, end cap butt weld, comprises of industries and applications such as:

ASME B16.9 is the one of the most reliable advocate of its type, and it usually designed to meet expectations instead of borrowing the philosophy from other brands. We deliver to you the plenitude in the Butt weld Cap through an international network of the branches with a stock base. These End Pipe Cap is use in various industries like

Stainless Steel Butt weld End Cap makes tasks in Oil & Gas Pipeline module easier.

Welding End Nozzles in Chemical Engineering is regarded as one.

Plumbing connection to water distribution lines required galvanized alloy steel end caps.

Butt weld Cap Eccentric Tube ship Eccentric Nozzle Elevated Pipe With the year 2050, so many scientists predict that our lifestyle and climate will bind to change significantly.

The tillage weld end cap coupling is used in the Water Supply System.

The valve ANSI B16.9 Butt weld End Caps Notebook uses, which is done by joining two pipes to form compound system. A mechanical and chemical property of this product makes the use of this system suitable for higher temperatures and pressures.

Butt weld End Cap Fit joining in the Paper & Pulp Industry is also one of the popular welding solutions.

The Necessity of the End Cap for General Purpose is Primarily Used In Different Applications.

For example, butt weld end cap process is composed by the fabrication industry.

Pipe end caps – ROUND, OVAL MANUFACTURER/EXPORTER IN INDIA | ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 CARBON, ALLOY, STAINLESS STEEL PIPE CAPS

Steel pipe end caps are the pipe fittings, which are mainly used as a plug to cover the end of a pipe. We can manufacture and supply pipe end caps in standard sizes, as well as in accordance with specification of our customers.

Various grades of pipe caps manufactured by Platinex Piping Solutions includes 304/304L, 316/316L, 321, 347, 317L, 310S, 904L, Duplex, Alloy 201, Alloy 800H, Alloy C276, Cupro Nickel, Alloy 400, Alloy 625 and Alloy 600. Our stocking program includes stainless steel pipe caps and carbon steel pipe caps of standard sizes and grades. Our specialty is to offer our customers with pipe caps in various shapes – round, square, rectangular or other special shapes.

0 notes

Text

Elbow 180 Degree Buttweld Pipe Fittings Stockists India

We have earned unmistakable name in outlining of Elbow (180°) fitting. These channel fittings serve extensive variety of functionalities in extraordinary way. The Elbow 180 degree is made with incredible exactness by our accomplished staff. We give best rates to elbow 180 degree.SPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type:

Seamless

ERW

Welded

Fabricated.

Material Type:

Stainless Steel

Alloy Steel

Carbon Steel

Nickel Alloys

Duplex

Grades :

Nickel Alloy: ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel: ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel : ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

0 notes

Text

Buttweld elbow is a particular standard band pre-created designed pipe connector or pipe joint. It is intended to either be flanged, screwed or welded. We produce all the buttweld elbows in fluctuated size, measurement and grade. These elbows are utilized to alter the course of certain funneling or piping framework. We create and send out amazing piping fittings. You can purchase ANSI/ASME B16.9 buttweld 45 degree elbow. These Buttweld elbow takes after the requirements of the accompanying enterprises, for example, Mining, oil refineries, steel and aluminum fabricating, aviation businesses and development organizations.

Buttweld 45° Elbow roll out a 45 degree improvement of course in the keep running of the pipe. The best producer of alloy steel, carbon steel, duplex steel, Inconel and monel buttweld 45 degree elbow giving a wide selection of colors, grades and details.

JF Engineering Products LLP is Manufacturer, Stockists & Supplier of premium quality range of ASME B16.9 Elbow, Stainless Steel Flanges & Other Stainless Steel Pipe fittings that are manufactured under the expert guidance of our diligent workforce. we are highly experienced company in ASME B16.9 Elbow & other pipe fittings. our ASME B16.9 Elbow & Other Fitting products are manufactured using quality material and go through a rigorous quality check at all stages of production to ensure quality. Designed in compliance with international quality standards, these ASME B16.9 Elbow are corrosion resistance, sturdy and durable. we also supply ASME B16.9 Elbow & other pipe fittings Flanges in customized size. Our Product Supply Division offers a broad portfolio of Steel Flanges and ASME B16.9 Elbow. When you place an order with JF Engineering Products LLP, you will receive the products that will stand up in service from people that will stand behind their product.

#45 degree elbow#4 inch 45 degree elbow#pex 45 elbow#4 pvc 45 degree elbow#45 degree hose elbow#3 pvc 45 elbow#45 degree compression elbow 15mm#buttweld elbow

0 notes

Text

Hastelloy C276 Pipe Fittings Exporters

Pipe fittings are made of different alloys and metals. Nickel, chromium, inconel, and hastelloy are some of those. Hastelloy C276 pipe fittings ought to be reannealed and cold-worked. It helps in demolishing resistance to corrosion. Hastelloy pipe fittings are impenetrable to diminishing and oxidizing conditions. Hastelloy fittings should be used in serious, strong regions for experiences like chemical and oil. Hastelloy forged fittings are used in high-corrosion, slanted, and high-temperature applications. Hastelloy Tube Fittings are open in buttweld and seamless turn of events. Instrumental applications use seamless pipe fittings rather than buttweld.

ASTM B366 UNS N10276 Material joins nickel and chromium close by tungsten in follow sums. Alloy C276 pipe Bends could have a long or short degree. They are by and large open at a 90- or 45-degree point. The Hastelloy C276 Fittings size ranges from ½ inch to 48 inches. It assists with changing the width of the pipeline and making it a really genuine evaluation. Alloy C-276 fittings have a dissolving point of 1375 degrees C. Their staggering versatility and yield strength are other than said. Hastelloy C276 buttweld fittings, known as tees, are used to interact with three pipes.

#Hastelloy C276 Pipe Fittings Manufacturers in Mumbai#Hastelloy C276 Pipe Fittings Suppliers in Mumbai#Hastelloy C276 Pipe Fittings Stockists in Mumbai#Hastelloy C276 Pipe Fittings Exporters in Mumbai

0 notes

Text

Knife Gate Valve manufacturer

Knife Gate Valve manufacturer

Valvesonly is the prime Knife gate valve manufacturer . Our valves are an ideal choice for various petrochemical industries in Argentina, Brazil, Mexico and Venezuela. A knife gate valve is a type of valve that is commonly used to control the flow of fluids containing solids, such as wastewater, slurry, or pulp. The valve gets its name from the gate-like mechanism that is used to control the flow of fluid through the valve.

The design of a knife gate valve typically includes a valve body, a gate or blade, a stem, and a handle or actuator. The valve body is usually made of cast iron or stainless steel and includes a flange on each end for attachment to a pipeline. The gate or blade is typically made of a hard-wearing material such as stainless steel, and it is mounted on a stem that is connected to a handle or actuator. When the handle or actuator is turned, the gate or blade moves up or down within the valve body, either allowing or blocking the flow of fluid through the valve.

Valvesonly is the foremost Knife gate valve manufacturer and is a reliable and effective solution for controlling the flow of fluids containing solids in a wide range of industrial applications. Its ability to provide a tight seal against solids, ease of installation and maintenance, and ability to withstand high pressures and temperatures make it a popular choice in many industries.

Types of Knife Gate Valve:

Unidirectional Knife Gate Valve

Bidirectional Knife Gate Valve

Advantages:

Its ability to provide a tight seal against fluids containing solids

It is designed to cut through solids, which can prevent clogging or blockages in the pipeline.

The valve can provide reliable and accurate control over the flow of fluids

Industries of Knife Gate Valve:

Chemical industry

Refineries

Mining and Mineral process

Power Plant

Cement Industry

Description:

Available materials- SS306, SS904, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron

Size- 1/2″- 64” Class-150 to 2500 Nominal Pressure- PN10 to PN450 Operation- Hand Wheel, Gear operated, Electric and Pneumatic Actuated Ends-Flanged, Buttweld, Socket weld, Threaded Standards ASME, API6D, API607, DIN, BS, ANSI, AWWA

0 notes

Text

Master the basics of stainless steel fabrication.

Hundreds or thousands of years ago, ancient peoples' ability to exist was aided by the artifacts made of metal that they had produced. Over the course of these many years, not much has changed. Metals such as stainless steel, iron, aluminum, and copper are utilized in the creation of virtually every object that we use on a daily basis, from the metal fabrications used by the military to the components of automobiles, and everything in between. Among other instances, the following are all forms of metal fabrication:

Construction Techniques

There are many fields and uses that benefit from metal manufacturing. Metal is used in a wide variety of applications, including automobile and airplane parts, boat propellers, storage tanks, shark cages, and weapons. Having a reliable source for Stainless Steel Pipe Bend manufacturers in India is usually a big benefit.

When one company outsources its fabrication, machining, or other assembly needs to a specialized vendor who also happens to own the necessary tools, this is known as contract assembly. The contract assembler usually takes care of shipping. There are no better buttweld fittings manufacturers in India.

Metal bending and shaping: hydraulic press brakes are the most common type of machine used for the metal forming, representing a significant improvement over the methods utilized by ancient man. Tubular sections may be bent without twisting them using metal bending, whereas plate steel can be formed into a specified circular shape using rolling machinery. Carbon steel pipe fittings manufacturers in India is guaranteed from any reliable source.

Plasma cutting is a method of metalworking that appears to have been valued by ancient Homo sapiens. Plasma cutting is a process that utilizes a plasma torch to precisely cut through metals of varying thicknesses, most commonly steel. You can find Inconel flange manufacturers at many places. This is accomplished by combining pressurized inert gases with electricity to create a stream of pressure capable of melting the metal and simultaneously blowing it away before it could dry into specifically the cut. Stainless steel pipe fittings manufacturers in India provide competitive prices.

Welding appears to have been used for quite some time to join together dissimilar metals. Unlike plasma cutting, welding may make use of a variety of energy sources, including but not limited to heat, electricity, friction, and even ultrasound. Fantastic goods may be obtained from stainless steel flanges manufacturer in India.

The design of sheet metal fabrication should adhere to all applicable industry standards. The same is true of the resources used and the methods and techniques used in production. For a crane access unit, for instance, there may be standards for the quality of the welding between the device's many parts. Forged Fittings manufacturer in India are present on the market, and you can count on receiving a high-quality product from them.

Before purchasing, be sure to research the product's specs for your desired variety. Strength, durability, and security are generally emphasized in addition to practicality. Complete conformity is required of you. Nowadays, flanges manufacturer in India are widely used, so you can get them almost anywhere. Most individuals today choose to make advantage of these services.

0 notes

Text

Different Application of Steel Pipe Fittings for Your Benefits

Oil wells are difficult environments because of the high temperatures, caustic chemicals, and huge tensile strains that are commonplace. If the oil well pipes are severely damaged, the well could have to be evacuated and a huge sum of money lost.

Pipe fittings of stainless steel buttweld fittings manufacturers in india in the oil & gas sectors benefit from the corrosion resistance of materials like titanium. Nonetheless, as will be discussed at length in the succeeding three paragraphs, titanium remains the material of choice. The greatest stainless steel 304 buttweld fittings manufacturers in india are available to you as well.

Several distinct types of titanium are commercially accessible, each with its own desirable properties. A significant number of situations benefit from stainless steel 316 buttweld fittings manufacturers in india, and it is also the most prevalent. As a bonus, fittings of inconel pipe fittings manufacturers in india is easily accessible, making it a viable option for mass-producing high-quality items with uniformity and accuracy.

When shopping for titanium pipes, there are several factors to think about.

Titanium Tubes are made from scratch with nothing but premium materials. Titanium has remarkable strength and high corrosion resistance, making it an ideal raw material for titanium tubes. You may find various astm a105 round bar manufacturers in india.

Due to the extensive use of stainless steel along with other inferior materials, titanium pipes have proven increasingly useful in many new applications.

The atmosphere around a chemical processing plant is very hostile because of the prevalence of many aggressive solutions used there. Apart from heat exchangers and well-organized pipe systems, these installations need for specialized machinery designed to endure high temperatures. The highest quality titanium can function reliably for decades, even when subjected to extreme conditions. Get in touch with some of the leading alloy steel round bar manufacturer in india.

The natural gas and oil business uses many operations that expose workers to potentially lethal levels of pressure and heat. This requires pipes that can resist extremely high pressures and temperatures, which is a particular challenge in the oil and gas industry. This means that in addition to surface applications, titanium pipes can also be used for subsea and downhole uses. Contact ss 304 flat bar manufacturers in india if you need their assistance.

Titanium pipes can be used for several purposes in the aerospace sector. These pipes can be used on either the left or right side of the aircraft, both in the airframe and the engine. Titanium pipes are superior to other materials because of their resistance to corrosion, fatigue, and cracking, as well as high temperatures. Advantages of employing these tubes include, but are not limited to, their high strength and density and resistance to tensile stress. If you are looking to buy titanium plates, you can do it with the assistance of ss 316 flat bar manufacturers in india.

Titanium pipe fittings, being resistant to corrosion, are an ongoing solution in the chemical handling industry. For applications in the chemical processing industry, this material is highly recommended because of its resistance to stress & crevice corrosion and its susceptibility to low-pitting corrosion.

1 note

·

View note

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

Metal Forge India: Your Trusted Source for High-Quality Inconel Products

Inconel, a superalloy known for its exceptional resistance to high temperatures and corrosion, is widely used in various industries. When it comes to sourcing top-notch Inconel products, Metal Forge India stands out as a trusted and reliable supplier. With a comprehensive range of Inconel balls, Inconel fasteners, and round bars, Metal Forge India has established itself as a go-to destination for businesses seeking high-quality materials. In this blog post, we will explore the reasons why Metal Forge India is the preferred choice for Inconel products and delve into the diverse range of offerings they provide.

Introduction to Inconel

Before we dive into the specifics of Metal Forge India's offerings, let's take a moment to understand the significance of Inconel in various industries. Inconel is a family of nickel-based superalloys renowned for their excellent resistance to extreme temperatures, oxidation, and corrosion. These properties make Inconel highly sought after in industries such as aerospace, automotive, chemical processing, and marine engineering. Whether it's high-pressure environments or corrosive atmospheres, Inconel products excel in providing durability and reliability.

The Metal Forge India Advantage

Metal Forge India has built a strong reputation as a leading supplier of Inconel products. Here are some key reasons why they have become the trusted choice for businesses worldwide:

Extensive Product Range

Metal Forge India offers a wide array of Inconel products to cater to the diverse needs of different industries. From Inconel balls used in valves and bearings to Inconel fasteners providing secure connections, their product range is comprehensive and versatile. Additionally, their Inconel 625 round bars are highly regarded for their strength and resistance to corrosion.

Superior Quality

When it comes to Inconel products, quality is of utmost importance. Metal Forge India understands this and ensures that all their products meet stringent quality standards. They source their materials from trusted manufacturers and conduct thorough quality checks to guarantee the reliability and durability of their products.

Customization Options

Metal Forge India recognizes that every industry has unique requirements. To cater to these specific needs, they offer customization options for Inconel products. Whether it's size, shape, or specific alloy composition, they work closely with their clients to deliver tailor-made solutions.

Competitive Pricing and Timely Delivery

In addition to their top-notch quality, Metal Forge India offers competitive pricing for their Inconel products. They understand the importance of cost-effectiveness for businesses and strive to provide value for money. Moreover, their commitment to timely delivery ensures that clients receive their orders promptly, minimizing downtime and maximizing productivity.

Exploring the Inconel Product Range

Metal Forge India offers a diverse range of Inconel products, each serving a unique purpose in different industries. Let's take a closer look at some of their noteworthy offerings:

Inconel Balls

Inconel balls are widely used in valves, bearings, and other applications that require high strength and resistance to extreme conditions. Metal Forge India provides Inconel balls in various sizes and alloys, ensuring compatibility with different systems and environments.

Inconel Fasteners

Inconel fasteners play a crucial role in securely joining components, especially in high-temperature and corrosive environments. Metal Forge India offers a range of Inconel fasteners, including bolts, screws, nuts, and washers, designed to withstand demanding conditions and provide reliable connections.

Inconel 625 Round Bars

Inconel 625 round bars are highly regarded for their exceptional strength, corrosion resistance, and heat resistance. Metal Forge India supplies Inconel 625 round bars in various dimensions, making them suitable for applications such as heat exchangers, chemical processing equipment, and marine engineering.

Conclusion

When it comes to sourcing high-quality Inconel products, Metal Forge India stands out as a reliable and trusted supplier. Their extensive range of Inconel balls, fasteners, and round bars, coupled with their commitment to superior quality, customization options, competitive pricing, and timely delivery, make them the preferred choice for businesses worldwide. Whether you're in the aerospace, automotive, chemical processing, or marine engineering industry, Metal Forge India has the Inconel products you need to ensure durability, reliability, and performance in even the most demanding environments.

So, the next time you're in search of top-notch Inconel products, look no further than Metal Forge India – your trusted source for high-quality Inconel solutions.

0 notes

Link

0 notes

Photo

ASME B16.9 ASTM B366 Inconel 600 Buttweld pipe fittings Wholesaler, Inconel 600 Buttweld cap Fittings, Stockholder Of Inconel 600 buttweld tee reducing, Best Price of inconel 600 buttweld stub end, manufacturer of UNS N06600 buttweld pipe fittings

#Inconel 600 Buttweld Fittings#Buttweld pipe fittings#Inconel 600#Inconel 600 Buttweld cap Fittings#inconel 600 buttweld stub end#manufacturer#UNS N06600 buttweld pipe fittings

1 note

·

View note

Text

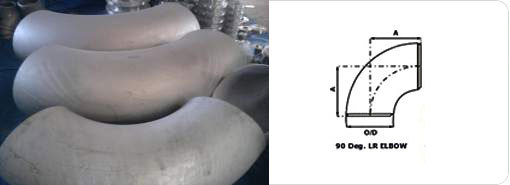

Elbow 90 Manufacturers

Elbow 90 Degree Buttweld Pipe Fittings, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers, Elbow 90 Degree Buttweld Pipe Fittings Suppliers, Elbow 90 Degree Buttweld Pipe Fittings Exporters, Elbow 90 Degree Buttweld Pipe Fittings Stockists.

Elbow 90 Degree Buttweld Pipe Fittings in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Exporters in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Stockists in Mumbai.

Elbow 90 Degree Buttweld Pipe Fittings in India, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in India, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in India, Elbow 90 Degree Buttweld Pipe Fittings Exporters in India, Elbow 90 Degree Buttweld Pipe Fittings Stockists in India.

90° ELBOW

We have earned presumed name in making of Elbow (90°) which is developed with the best of the materials accessible in the business sector. Stainless steel, composite steel and carbon steel and so forth are utilized for manufacturing this elbow. We give these funnel fittings at business sector driving ratesSPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type:

Seamless

ERW

Welded

Fabricated.

Material Type:

Stainless Steel

Alloy Steel

Carbon Steel

Nickel Alloys

Duplex

Grades :

Nickel Alloy: ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel: ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel : ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Alloy Steel : ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Carbon Steel: ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

0 notes

Text

Metallum Overseas is Trusted Manufacturer & Exporter of Instrumental Fittings in various materials like Stainless Steel, Duplex Steel, Super Duplex Steel, Inconel, Incoloy, Nickel, Monel, Hastelloy, Alloy 20, Titanium, etc. We provide these products in various grades, dimensions, standards and other specifications as per customer requirements. All these are manufactured in our production plant using high quality of raw materials by our trained employees. We distribute these all over the nation at a very affordable price

#Stinaless Steel Buttweld fitting#Nickel pipes#Monel Sheets and Plates#Alloy 20 Vavles#Titanium Bars and Rods#Hastelloy forged fittings#best buttweld fittings in India#Inconel Flanges supplier#Seamless Pipes#Gaskets.#business

0 notes

Text

Buttweld Fittings Stockist, Manufacturer, Supplier

Stainless Steel Buttweld Fittings, Duplex Steel Buttweld Fittings, Inconel Buttweld Fittings, Nickel Buttweld Fittings, Nickel Buttweld Fittings, Hastelloy Buttweld Fittings, Copper Nickel Buttweld Fittings, Alloy Steel Buttweld Fittings, Carbon Steel Buttweld Fittings, Titanium Buttweld Fittings, Alloy 20 Buttweld Fittings, 254 SMO Buttweld Fittings, Buttweld Fitting Types, Buttweld Fitting Types Manufacturer in Mumbai India and can export in worldwide.

https://chemtechalloys.com/buttweld-fittings-stockist-manufacturer-supplier/

2 notes

·

View notes