#Hastelloy C276 Pipe Fittings Suppliers in Mumbai

Explore tagged Tumblr posts

Text

Hastelloy C276 Pipe Fittings Exporters

Pipe fittings are made of different alloys and metals. Nickel, chromium, inconel, and hastelloy are some of those. Hastelloy C276 pipe fittings ought to be reannealed and cold-worked. It helps in demolishing resistance to corrosion. Hastelloy pipe fittings are impenetrable to diminishing and oxidizing conditions. Hastelloy fittings should be used in serious, strong regions for experiences like chemical and oil. Hastelloy forged fittings are used in high-corrosion, slanted, and high-temperature applications. Hastelloy Tube Fittings are open in buttweld and seamless turn of events. Instrumental applications use seamless pipe fittings rather than buttweld.

ASTM B366 UNS N10276 Material joins nickel and chromium close by tungsten in follow sums. Alloy C276 pipe Bends could have a long or short degree. They are by and large open at a 90- or 45-degree point. The Hastelloy C276 Fittings size ranges from ½ inch to 48 inches. It assists with changing the width of the pipeline and making it a really genuine evaluation. Alloy C-276 fittings have a dissolving point of 1375 degrees C. Their staggering versatility and yield strength are other than said. Hastelloy C276 buttweld fittings, known as tees, are used to interact with three pipes.

#Hastelloy C276 Pipe Fittings Manufacturers in Mumbai#Hastelloy C276 Pipe Fittings Suppliers in Mumbai#Hastelloy C276 Pipe Fittings Stockists in Mumbai#Hastelloy C276 Pipe Fittings Exporters in Mumbai

0 notes

Text

Hastelloy C276 Pipe Fittings Manufacturers, Suppliers and Exporters in Mumbai, India

1 note

·

View note

Photo

Socket Weld Fittings Manufacturers in India, Stainless Steel Socket Weld 90° Elbow, Carbon Steel Forged Socket weld Tee Supplier, Duplex Steel Socket weld Cross Manufacturer, Manufacturer & Supplier of Socket Weld Fittings In India, Alloy Steel Socket Weld Coupling, Nickel Alloy Socket weld 45° Elbow Stockiest, Copper Alloys Socket weld Equal & Unequal Tees Exporters in India, ASME A182, ASME B16.9, ASME B16.11, MSS SP-43, MSS SP-95, BS3799 Forged Socket Weld Pipe Fittings Suppliers, Inconel Socket weld Fittings, Socket weld Fittings, Nickel Alloy 201 Socket weld Fittings, Monel K500 Socket weld Fittings Traders In India, SS Socket weld Fittings Wholesaler, SS 904l Socket weld Fittings, Stockholder Of Socket Weld Socket weld Fittings, Alloy 20 Socket weld Fittings, Socket weld Fittings, Nickel Alloy 200 Socket weld Fittings, Copper Nickel Socket weld Fittings Exporterd In Mumbai, India, Hastelloy C276 Socket weld Fittings, World Wide Supplier Of ANSI B16.9 Socket weld Fittings

0 notes

Text

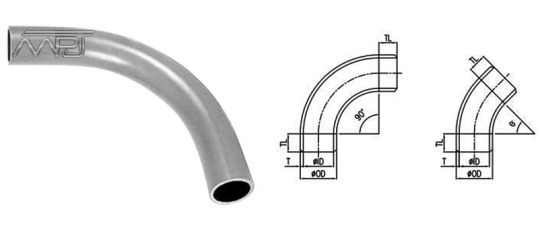

Piggable bends

M P Jain Tubing Solutions LLP is one of the leading Manufacturer, Stockist, and Exporter of ANSI/ASME B16.9 Piggable Bend in Mumbai, India. We are in this domain since 1972. We are ISO 9001:2015 certified company and most trusted Suppliers of Piggable Pipe Bends. We keep intensive stock of SS Piggable Bend to fulfill urgent requirements of our clients at reasonable prices.

One of the oldest Manufacturer, Stockist, Exporter of ANSI and ASME B16.9 Piggable Bend, Piggable Pipe Bends, Piggable Bend Suppliers at best price in India. We keep the largest stock of stainless steel Piggable bends, carbon steel Piggable bends, nickel alloy Piggable bends, alloy steel Piggable bends, Monel Piggable bends in all dimensions.

Benefits of Butt Weld Pipe Fittings

Butt welding fittings have the following benefits

Welded connection offers more robust connection

Continuous metal structure adds to the strength of the piping system

An option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counterparts.

Stainless Steel Welded Fittings are also available in SCH 10, allowing a thinner wall option.

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration.

allow a strong and leak-proof pipe to fitting connection

minimize the pressure drops and the turbulence along the pipeline

have a long service life

are rather cheap to purchase and deploy

Butt weld fittings with matching pipe schedules offer seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting.

ANSI and ASME B16.9 Piggable Bend Specifications

Type: Butt weld (BW)

Standards: ASME / ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings’ ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’

Dimension: A NSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313

Thickness: Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Schedule: Sch 5 TO Sch XXS.

Size: 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”)

ANSI and ASME B16.9 Piggable Bend Material and Grades

Stainless Steel Piggable Bend:

ASTM A403 WP316/316L

ASTM A403 WP304/304L

ASTM A182 F316L, 304L

DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Piggable Bend:

ASTM A234 Gr. WPB

ASTM A420 Gr. WPL6

ASTM A105

ASTM A350 Gr. LF2

Nickel Alloy Piggable Bend:

Monel 400 & 500

Inconel 600 & 625

Incolloy 800, 825

Hastelloy C22, C276

Hastelloy

Nickel

Monel

Inconel

Alloy20

Copper Nickel

Cupro-Nickel 90/10

Cupro-Nickel 70/30

Standard:

ASTM / ASME SB 336

UNS 10276 HASTELLOY C 276 Bend

UNS 2200 NICKEL 200 Bend

UNS 2201 NICKEL 201 Bend

UNS 4400 MONEL 400 Bend

UNS 8020 ALLOY 20 Bend

UNS 8825 INCONEL 825 Bend

UNS 6600 INCONEL 600 Bend

UNS 6601 INCONEL 601 Bend

UNS 6625 INCONEL 625 Bend

Alloy Steel Piggable Bend:

ASTM a234 wp1 / wp5 / wp9 / wp11 / wp22 / wp91

As a leading manufacturer, stockist, and exporters of ANSI and ASME B16.9 Piggable bend, we are providing high-quality Piggable bends, SS piggable bend, piggable bend radius at best price in India.

For More Details

Address: 205 Kika Street, Gulalwadi Mumbai, India

Tel: 022-23465538 / 022-23460403

Fax: +91-22-23424250

Mob: +91 9619390230

Email: [email protected]

Visit our site: http://www.mpjainco.com/

0 notes