#Hydraulic Power Unit Market size

Explore tagged Tumblr posts

Text

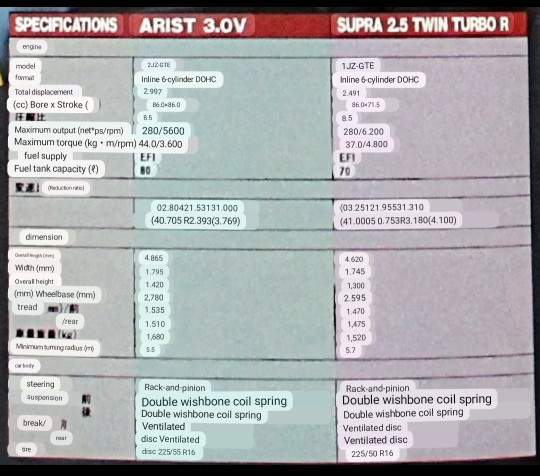

ARISTO vs SUPRA

go fast or have fun

Aristo vs Supra lap time comparison

ARISTO

1'11'33, 1'11'84, 1'11'84, 1'12'41, 1'11'19

SUPRA

1'11'79, 1'11'95, 1'12'51, 1'16'65, 1'13'00, 1'12'85

After all, the Aristo was faster... I didn't feel like it was when I was driving, but I was able to get a good lap time..." It's a word. "But I think the Supra is better when it comes to the fun of controlling it."

Recently, the surroundings of the car called Aristo are harsh. It is said to be the monster of a sedan with the largest torque of a domestic car.

As the voice grows louder,

I really wanted to confirm its ability.

Driver Takayuki Kinoshita, against Supra Twin Turbo R

And the stage is Tsukuba. Now, the actors are ready.

Text/Takayuki Kinoshita, Photos/Akira Takahashi

"It seems that a terrifyingly fast luxury sedan will be born, and it is said to be a sister car of the Crown." Is it true?

Indeed, in the Japanese automobile market, sporty cars with unparalleled potential are making their debuts one after another. However, even if Japan is a privilege, is it possible to establish a sporty model that belongs to the ultra-luxury car genre? If true, how much performance is hidden? I waited with bated breath for the appearance of the new model.

The engine, which combines an in-line 6-cylinder 3-liter DOHC unit with a two-way turbo, is the heart of a sporty car. It can be said that it is the real thing without any extra value. It exhibits excessive tenacity at low revs, and it blows all the way up to high revs.

An engine that draws a flat curve like NA

In addition to being given characteristics, maneuverability is somewhat

This is based on excellent stability that will not cause bankruptcy. Despite the fact that it has such extreme characteristics wrapped in oblate, it cannot hide the high power performance hidden inside. Although seemingly obedient, once it turns its fangs, it will turn into a ferocious wolf. It exuded an atmosphere similar to the killing that is peculiar to meat-eating animals. In that case, I want to release the chains and let it go wild. I want it to run around thoroughly. It is only natural to be seduced by such impulses. Therefore, there was no hesitation in running this kind of model with saloon characteristics.

Fast or slow? Fun or shrew?

In order to evaluate it, I ran it with Supra's top sporty grade "2.5 Twin Turbo R" on a circuit where there was no room for false intervention.

Aristo: There is something I would like to confirm before making an impression. "The Aristo is better than the Supra.

It was fast!" is the fact. It certainly did quite well on public roads. I feel the outstanding speed with my whole body. There was also the thought of “What if?” However, when it becomes a reality, Aristo's latent strength

I have no choice but to do it. Most likely, when I thought about running it on the circuit, I already had a premonition that Aristo would win. Or perhaps, somewhere in his heart, he was hoping that the refined driving that he experienced on the public road would lead to a lap time. Just making us think that is enough, isn't it? But Aristotle doesn't give up. In a world where there is no excuse for one lap time, the Supra was mercilessly thrown into the dust.

On the backstretch, the speedometer needle was pointing at 170km/h. Despite being a 4-speed AT, which should have a disadvantage in startup acceleration, it slightly exceeds the speed of the Supra. What's more, the four-wheel bench disc with hydraulic servo exerts a braking force approaching that of Gran Turismo in recent years. Therefore, it is possible to push deep into the corner.

The 245/40R16 tires (ADVAN HF-TU Type F), which are one size larger than the front, are overwhelmed by the rear, and will not break easily even at such times. Slightly higher speed than common sense

ARISTO IS DIGITAL AND SUPRA IS ANALOG

Even if you invade while creating a strong front wheel load from the road, you will still be firmly gripping the road surface. That's why you can attack without worrying about it. The grounding of the rear around here is at a high level that is by no means inferior even compared to the recently debuted sporty bike.

Sustainability at the front is similarly high. The responsiveness of the steering is tailored so that it cuts directly. The Piezo TEM S setting works to increase the roll rigidity from the beginning of the turn, so it does not roll more than necessary. As a result, it is possible to obtain handling that responds quickly and a feeling of turning without feeling uneasy.

However, it seems that the front response during cornering is set to be moderately lost, and understeer due to the pushing out of the rear wheels is slight but always occurring. Therefore, even if the throttle is opened roughly, the tail does not get in the way, and this setting allows the car to stand up with a stable tendency. I felt that the reason for the superior time was the excellent stability that allowed us to actively use the brakes and power. However, if you ask whether it is fun to run, the answer is "no" at this point. Because stability outweighs power, the driver doesn't feel like he's in control. There are almost no scenes where the tail sticks out and is pushed down on the counter, and it is driven within the range that does not exceed the performance of the car. Even if you try to force the tail slide and drive hard, the behavior will only become nervous as soon as the tire limit is exceeded. It is even more difficult to determine power drift within the limit

Moreover, the fact that information is transmitted only digitally is a factor that spoils the enjoyment. Steering always maintains the same steering force, so it is difficult to grasp the feel of the tires. Even TEMS, which is effective in ensuring squeezability, does not have a linear roll feeling, leaving a sense of incongruity in sporty runs.

It didn't feel like the car was lapping faster than the Supra.

As for my impression, "It's leaner than the Supra, but it doesn't look too fast." This is similar to the impression felt by the driver.

TWO DIFFERENT PERSONALITIES

In terms of this fun part, on the contrary, the Supra is leading by a large margin. Especially the fans who come from the high controllability near the actual world.

Verticality was overwhelming.

Certainly, the grip limit is inferior to Aristo

However, the flow and convergence of the rear wheels are poignant, and they are conveyed as if they were picked up. that's why,

Feel free to drift even in high-speed corners

All about driving

He clearly communicates his feelings analogically to Wakelists under his control.

To conclude, the Aristo is fast, but that's it, and the Supra is a fun car to drive.

However, the point that I do not feel fun with Aristo,

I have no intention of denying that it was inferior to the Supra's speed for this one shot. each

It's because the personality that can be put in is different.

The Mercedes 300E, BMW M5, which Aristo says is a rival, also cuts down on the fun of swinging at the price of outstanding stability, and even with the Z, which is a competitor of the Supra.

In addition, the control

Emphasis is placed on rollability.

If the concept is divided into the big genre of sporty cars, the concept becomes ambiguous. have a distinct personality

It's a sign of what you're trying to do.

As a means of transportation to safely reach your destination, Aristo is one of the world's highest standards.

become a car. If you want to enjoy the journey,

It's the world of the Supra. "Aristotle

or the Supra's time is slow."

That's what I mean.

PIC CAPTIONS

Aristo's corner link at the second hairpin in Tsukuba. As far as I can see, its behavior is stable and does not make me feel uneasy. Let's call it "quiet" cornering. It is so calm that it sometimes feels lacking in power. On the contrary, it will be a run with plenty of room.

Compared to the corner link of the Aristo, Supra, which also runs in the first hairpin, the behavior is greater. On the contrary, it also gives the impression that the driver is controlling the car and driving it.

#JZS147#Aristo#Toyota Aristo#JZS147 Aristo#2JZ-GTE#1JZ-GTE#JZA70#Supra#1JZ-GTE Supra#Supra twin turbo R#JDM

10 notes

·

View notes

Text

Comprehensive Study on the Mexico Oil and Gas Market

The Mexico oil and gas market size is expected to reach USD 243.50 billion by 2030, registering a CAGR of 3.4% over the forecast period, according to a new report by Grand View Research, Inc. Mexico's demand for oil & gas is anticipated to increase as a result of government subsidies and the liberalization of fuel prices. Additionally, it is anticipated that cooperation between Mexico and European nations for natural gas trading and the natural gas shortage experienced by European nations due to the conflict in Russia and Ukraine will further influence the oil and gas market growth.

Due to the adoption of horizontal drilling and hydraulic fracturing techniques by oil and gas companies in Mexico, natural gas and crude oil production is increasing.The transportation and power generation industries are the main final consumers of crude oil and natural gas. There are reputable local and international players in the Mexican oil and gas market. Due to the intense competition in the market, the majority of players are concentrating on how to set themselves apart from the competition. For product manufacturers, creating extremely effective sales channels is yet another crucial element. The oil and gas market in Mexico exhibits a direct sales channel.

Due to the high demand-supply gap for crude oil and natural gas as well as the current political unrest between Russia and Ukraine, prices for both commodities are skyrocketing. The Mexican government has implemented price controls on the sales of diesel, gasoline, liquefied petroleum gas, and natural gas intended for domestic use despite the skyrocketing cost of crude oil.

In terms of revenue, upstream segment dominated the market with a share of 62.60% in 2021. According to the U.S. Energy Information Administration (EIA), Mexico has enormous potential for shale gas and oil resources. These are expected to be stored in marine-deposited, source-rock shales distributed along the onshore Gulf of Mexico region. These factors are expected to boost the demand in the upstream segment over the forecast period.

Mexico Oil And Gas Market Report Highlights

In 2022, the upstream emerged as the largest segment and accounted for a revenue share of 62.75% owing to its enhanced efficiency, easy installation, and availability of three-phase variations

In February 2022, the geopolitical unrest in Eastern Europe with Russia Ukraine conflict has hampered manufacturing operations and disrupted supply chains

The oil and gas refining industry in Mexico, which is underdeveloped, is anticipated to expand at a CAGR of 4.1% over the forecast period. There are currently 6 refineries, and Mexico is dependent on refineries located in the United States. The state-owned oil and gas company Pemex will receive funding from the Mexican government in order to increase refining capacity. Such programs may aid in the growth of the downstream industry.

Mexico Oil And Gas Market Segmentation

Grand View Research has segmented the Mexico oil and gas market based on operations:

Mexico Oil & Gas Operations Outlook (Revenue, USD Billion, 2018 - 2030)

Upstream

Onshore

Offshore

Midstream

Downstream

Refining

Order a free sample PDF of the Mexico Oil And Gas Market Intelligence Study, published by Grand View Research.

0 notes

Text

0 notes

Text

The Oilfield Services Market is projected to grow from USD 134007 million in 2024 to an estimated USD 169756.05 million by 2032, with a compound annual growth rate (CAGR) of 3% from 2024 to 2032.The oilfield services (OFS) market plays a critical role in the global oil and gas industry. It encompasses a wide range of services required during various phases of exploration, drilling, production, and maintenance of oil and gas wells. The market's dynamics are driven by fluctuations in crude oil prices, technological advancements, and increasing demand for energy. As the world transitions toward a balanced energy mix, the oilfield services market continues to evolve, integrating new technologies and responding to the shifting needs of the oil and gas industry. This article explores the current trends, growth drivers, challenges, and future outlook for the oilfield services market.

Browse the full report https://www.credenceresearch.com/report/oilfield-services-market

Market Overview and Segmentation

Oilfield services are integral to the oil and gas value chain. They include services such as well drilling, formation evaluation, well completion, production optimization, and well intervention. The OFS market is typically segmented into three categories: 1. Drilling Services: Encompassing all services related to well drilling, such as rig operation, directional drilling, and logging. 2. Completion Services: These services ensure the well is ready for production, involving tasks such as casing, cementing, and hydraulic fracturing. 3. Production and Maintenance Services: Focused on optimizing well performance and extending its lifespan. This includes pressure pumping, enhanced oil recovery (EOR) techniques, and well intervention services.

The oilfield services market is directly influenced by the exploration and production (E&P) activities of oil and gas companies. Therefore, its performance closely correlates with oil price trends, geopolitical stability, and regulatory policies. As oil prices rise, investments in E&P projects increase, leading to higher demand for oilfield services. Conversely, a downturn in oil prices can result in reduced investments, slowing the OFS market.

Key Market Trends

1. Technological Advancements: One of the most significant trends shaping the oilfield services market is the adoption of advanced technologies. Innovations such as artificial intelligence (AI), big data analytics, automation, and Internet of Things (IoT) are transforming how oil and gas companies manage their operations. AI-powered predictive maintenance tools, for instance, help companies reduce equipment downtime and improve operational efficiency. Additionally, the advent of digital oilfields—integrating sensors, data analytics, and automated workflows—has enhanced productivity and decision-making capabilities.

2. Shift Toward Unconventional Resources: The growing focus on unconventional oil and gas resources, such as shale gas and tight oil, has opened new avenues for the OFS market. Horizontal drilling and hydraulic fracturing (fracking) have become common in unconventional resource extraction. As a result, demand for services related to well stimulation and reservoir evaluation has surged. North America, particularly the United States, has been at the forefront of this shift due to its large shale reserves, which has made it one of the most lucrative markets for oilfield services.

3. Energy Transition and Sustainability: As the world moves toward a low-carbon future, oil and gas companies are under increasing pressure to adopt sustainable practices. The oilfield services sector is responding by offering solutions that reduce environmental impact. These include greener fracturing fluids, carbon capture and storage (CCS) technologies, and waste management services. Moreover, the rise of renewable energy has prompted oilfield services companies to diversify their offerings and venture into supporting offshore wind, geothermal, and hydrogen projects.

Growth Drivers

1. Rising Energy Demand: The global demand for energy, driven by population growth and industrialization, is one of the primary factors driving the oilfield services market. Despite the push for renewables, fossil fuels still account for a significant portion of global energy consumption, and oilfield services are essential to ensuring continued production.

2. Recovery in Oil Prices: After experiencing a downturn during the COVID-19 pandemic, oil prices have gradually recovered, encouraging E&P companies to resume operations. This recovery has revitalized drilling and production activities, subsequently driving the demand for oilfield services.

3. Increasing Investments in E&P: With global oil demand expected to grow in the near term, many oil and gas companies are increasing investments in exploration and production activities. This is particularly true for deepwater and ultra-deepwater projects, which require sophisticated oilfield services, including drilling, completion, and subsea intervention.

Challenges

Despite the positive outlook, the oilfield services market faces several challenges. One of the most pressing is the volatility of crude oil prices, which can significantly impact the profitability of E&P activities and, consequently, the demand for oilfield services. Additionally, stringent environmental regulations and the increasing emphasis on reducing greenhouse gas emissions present hurdles for the industry.

Another challenge is the ongoing talent shortage. The oil and gas sector is facing a generational shift, with many experienced workers retiring and fewer young professionals entering the industry. This has led to a skills gap, which could hinder the efficient delivery of oilfield services.

Future Outlook

The oilfield services market is poised for growth in the coming years, driven by rising energy demand, the recovery of oil prices, and the need for technological advancements in the industry. However, the sector must also adapt to the evolving energy landscape, where sustainability and digital transformation will play a more prominent role.

Companies in the oilfield services market will need to embrace innovation and diversify their portfolios to stay competitive. By offering sustainable solutions and leveraging cutting-edge technologies, the oilfield services sector can continue to play a vital role in the global energy mix while meeting the demands of a rapidly changing world.

Key Player Analysis:

Baker Hughes Company

HALLIBURTON

SLB

Weatherford

Superior Energy Services

China Oilfield Services Limited

ARCHER OILFIELD ENGINEERS

Expro Group

TechnipFMC plc

Segmentation:

By Type

Equipment Rental

Field Operation

Analytical Services

By Service

Geophysical

Drilling

Completion & Workover

Production

Processing & Separation

By Application

Onshore

Offshore

By Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Browse the full report https://www.credenceresearch.com/report/oilfield-services-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Shale Gas Market Set for Robust Growth as Global Energy Demand Increases

The global Shale Gas Market is projected to witness significant growth over the coming decade, driven by increasing energy demands, advancements in extraction technologies, and the global shift toward cleaner energy sources. Shale gas, a natural gas found trapped within shale formations, has become a key contributor to the world’s energy mix, particularly in regions like North America. With technological innovations such as hydraulic fracturing (fracking) and horizontal drilling, shale gas extraction has become more economically viable, driving substantial growth in the market.

The Shale Gas Market size is valued at USD 57.4 billion in 2023. It is estimated to be USD 96.98 billion by 2032 and is likely to expand CAGR of 6.0% over the forecast period 2024–2032.

Download Sample Pages: https://www.snsinsider.com/sample-request/2709

Key Market Drivers

Rising Global Energy Demand: With global energy consumption on the rise due to population growth and industrialization, shale gas has emerged as an important resource to meet energy demands, particularly in electricity generation and industrial applications.

Advancements in Extraction Technology: Technological innovations such as hydraulic fracturing and horizontal drilling have greatly improved the efficiency and economic feasibility of shale gas extraction. These advancements have unlocked vast reserves that were previously inaccessible, driving growth in shale gas production.

Environmental Concerns and Shift to Cleaner Energy: As governments and industries seek to reduce their carbon footprints and move away from coal, shale gas is seen as a cleaner alternative due to its lower greenhouse gas emissions compared to traditional fossil fuels. This shift is accelerating the adoption of shale gas in energy production.

Energy Security: Countries with significant shale gas reserves, such as the United States and Canada, are increasingly focused on energy security and self-sufficiency. Shale gas plays a pivotal role in reducing reliance on foreign oil and natural gas imports, bolstering national energy independence.

Government Policies and Incentives: Supportive government policies, including tax incentives and subsidies for shale gas exploration and production, are fueling growth in the market. Additionally, countries are implementing regulatory frameworks to ensure safe and responsible extraction of shale gas.

Market Segmentation

The shale gas market can be segmented by technology, application, and region.

By Technology

Hydraulic Fracturing: Also known as fracking, this is the most widely used technology for shale gas extraction. It involves injecting high-pressure fluid into shale formations to create fractures, allowing trapped gas to flow to the surface. Hydraulic fracturing has been a game-changer for shale gas production, making it commercially viable on a large scale.

Horizontal Drilling: Horizontal drilling involves drilling wells horizontally within shale formations to access more of the gas-bearing rock. This method, combined with hydraulic fracturing, has significantly increased the efficiency of shale gas extraction.

3D Seismic Technology: This technology is used to create detailed images of underground rock formations, allowing for precise identification of shale gas reserves. 3D seismic technology helps optimize drilling and minimize environmental impact.

By Application

Power Generation: Shale gas is increasingly being used as a fuel for power plants due to its abundance, lower emissions compared to coal, and relatively stable prices. Natural gas-fired power plants are being constructed in many regions, particularly in the United States, where shale gas is readily available.

Industrial Use: The industrial sector uses shale gas for various processes, including heating, chemicals production, and fertilizer manufacturing. The availability of shale gas is driving growth in industries that rely on natural gas as a feedstock or energy source.

Residential and Commercial Heating: Shale gas is also used for heating in residential and commercial buildings, particularly in colder climates where natural gas is a primary heating source.

Transportation: Shale gas is beginning to make its way into the transportation sector, particularly in the form of compressed natural gas (CNG) and liquefied natural gas (LNG) for use in vehicles and ships. This is expected to increase as more countries adopt cleaner transportation fuels.

Buy Now: https://www.snsinsider.com/checkout/2709

Regional Insights

North America: The North American shale gas market, particularly in the United States, is the most developed in the world. The U.S. is the largest producer of shale gas, with major reserves in the Marcellus, Barnett, Haynesville, and Eagle Ford shale plays. Advances in hydraulic fracturing and horizontal drilling have made shale gas a key contributor to the U.S.’s energy independence. Canada also has significant shale reserves, particularly in the Montney and Horn River formations.

Asia-Pacific: The Asia-Pacific region is witnessing growing interest in shale gas, particularly in China, which has one of the largest shale gas reserves in the world. The Chinese government is investing heavily in shale gas exploration to reduce its dependence on coal and address air quality issues. India is also exploring its shale gas potential to meet rising energy demands.

Europe: The European shale gas market is in its nascent stage, with countries like Poland and the United Kingdom exploring the potential of shale gas reserves. However, environmental concerns and stringent regulations have slowed the development of the shale gas industry in Europe.

Latin America: Countries like Argentina and Brazil are emerging as key players in the Latin American shale gas market. Argentina’s Vaca Muerta formation is one of the largest shale gas reserves in the world, and the country is investing heavily in its development to boost domestic energy production.

Middle East & Africa: While the Middle East is traditionally known for its conventional oil and gas reserves, there is growing interest in the region’s potential for shale gas production. South Africa is also exploring its shale gas reserves to diversify its energy mix.

Current Market Trends

Global Investments in Shale Gas: Countries around the world are increasing investments in shale gas exploration and production as part of their long-term energy strategies. This trend is particularly strong in countries with large shale reserves, such as China, Argentina, and Canada.

Rising Use of Shale Gas in Power Generation: The growing adoption of shale gas for electricity generation is a major trend in the market. Natural gas power plants are more flexible and emit fewer pollutants than coal-fired plants, making shale gas an attractive option for meeting energy demands.

Environmental Concerns and Regulation: While shale gas offers a cleaner alternative to coal, its extraction process — particularly hydraulic fracturing — has raised environmental concerns, including water contamination and seismic activity. Regulatory frameworks are being strengthened in many regions to address these concerns and ensure responsible extraction practices.

Key Players

The major players are Royal Dutch Shell PLC, ConocoPhillips, PetroChina Company Limited, Exxon Mobil Corporation, Chevron Corporation, Chesapeake Energy Corporation, and other players

About Us: SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US)

1 note

·

View note

Text

Global Double Drum Roller Market Trends and Future Analysis Report 2024 - 2031

The global double drum roller market is experiencing significant growth, driven by the increasing demand for efficient and high-performance compaction equipment in construction and infrastructure development. This article provides a detailed overview of the market dynamics, key trends, competitive landscape, and future outlook for double drum rollers.

Introduction to Double Drum Rollers

Double drum rollers are heavy construction equipment used primarily for compacting soil, asphalt, and other materials during road construction and civil engineering projects. These machines are equipped with two drums, both of which are driven and used for optimal compaction. Known for their efficiency and versatility, double drum rollers are essential for achieving a solid foundation in various construction applications.

The global double drum roller market presents considerable opportunities driven by rapid urbanization, infrastructure development, and technological advancements in construction equipment. While challenges such as high initial costs

Market Overview

Current Market Size and Growth

As of 2023, the global double drum roller market is valued at approximately $XX million, with projections to reach $XX million by 2030, growing at a CAGR of XX% during the forecast period. This growth is attributed to increased construction activities, urbanization, and infrastructure development across the globe.

Key Market Drivers

Rapid Urbanization: As cities expand and new infrastructures are developed, the demand for compaction equipment, including double drum rollers, is on the rise.

Infrastructure Development: Governments worldwide are investing heavily in infrastructure projects, including roads, bridges, and airports, boosting the demand for efficient compaction machinery.

Technological Advancements: Innovations in double drum roller technology, such as improved hydraulic systems and eco-friendly engines, are making these machines more efficient and attractive to users.

Challenges in the Market

Despite its growth potential, the double drum roller market faces several challenges:

High Initial Investment: The cost of purchasing double drum rollers can be substantial, which may deter small construction companies from acquiring them.

Operational Costs: Maintenance and operational costs associated with these machines can also be a concern for end-users, impacting profitability.

Types of Double Drum Rollers

1. Static Double Drum Rollers

Static double drum rollers are primarily used for compacting asphalt and soil without any vibration. These machines are ideal for smaller jobs where precision is more critical than power.

2. Vibratory Double Drum Rollers

Vibratory double drum rollers are equipped with a vibration mechanism that enhances compaction efficiency. These are commonly used in larger projects and are suitable for a variety of materials, including asphalt and granular soils.

3. Combination Double Drum Rollers

Combination double drum rollers feature both static and vibratory capabilities, allowing them to be versatile for different compaction tasks. These machines are favored for projects requiring both types of compaction.

Regional Analysis

North America

North America holds a significant share of the global double drum roller market, driven by extensive infrastructure development and maintenance activities. The United States is the largest market in this region, with a strong focus on upgrading road networks and public infrastructure.

Europe

Europe is witnessing steady growth in the double drum roller market, supported by increasing investments in construction and infrastructure projects. Countries such as Germany, France, and the UK are key contributors to market expansion.

Asia-Pacific

The Asia-Pacific region is expected to experience the highest growth rate, fueled by rapid urbanization and increasing investments in infrastructure development in countries like China and India. The booming construction industry in this region is a primary driver for demand.

Latin America and Middle East & Africa

The market in Latin America and the Middle East & Africa is gradually developing, with growing awareness of advanced construction techniques and the need for efficient compaction solutions. Infrastructure projects in these regions are propelling the demand for double drum rollers.

Competitive Landscape

Key Players

Caterpillar Inc.

Volvo Construction Equipment

Komatsu Ltd.

JCB

CASE Construction Equipment

These companies focus on product innovation, quality enhancements, and expanding their distribution networks to capture a larger market share.

Market Strategies

Product Development: Companies are investing in R&D to enhance the performance and efficiency of double drum rollers, incorporating advanced technologies and eco-friendly solutions.

Strategic Partnerships: Collaborations with construction firms and rental companies help manufacturers expand their market reach and improve service offerings.

Future Outlook

The global double drum roller market is poised for substantial growth in the coming years. As construction activities continue to rise globally, the demand for efficient and reliable compaction equipment will increase. Additionally, advancements in technology will likely lead to the development of smarter and more versatile double drum rollers.

Conclusion

The global double drum roller market presents considerable opportunities driven by rapid urbanization, infrastructure development, and technological advancements in construction equipment. While challenges such as high initial costs and operational expenses exist, the overall outlook remains positive. Stakeholders in the industry should focus on innovation and customer satisfaction to thrive in this dynamic market.

#Global Double Drum Roller Market Size#Global Double Drum Roller Market Trend#Global Double Drum Roller Market Growth

0 notes

Text

Nickel Alloys Market Poised to Garner High Revenues Owing to Growing Use in Aerospace Applications

Nickel alloys find widespread applications across various end-use industries such as aerospace, oil & gas, chemical processing, and power generation due to their high corrosion and heat resistance properties. In the aerospace industry, jet engine components such as turbine discs and compressor blades are manufactured using nickel alloys to withstand high temperatures and pressures.

The global nickel alloys market is estimated to be valued at US$ 30 Billion in 2024 and is expected to exhibit a CAGR of 14% over the forecast period 2024 to 2031. Key Takeaways Key players operating in the nickel alloys market are VDM Metals GmbH, Aperam S.A., Sandvik Materials Technology, Allegheny Technologies Incorporated, Carpenter Technology Corporation. The aerospace industry offers significant growth opportunities for Nickel Alloys Market Size owing to increasing aircraft deliveries and rising focus on lightweight materials to improve fuel efficiency.Growing demand from the power generation industry to manufacture steam turbines, gas turbines and other parts is expected to propel the market growth. Technological advancements such as development of novel corrosion resistant nickel alloys for use in semiconductor manufacturing equipment will further aid the market expansion. Market drivers Increasing demand from the aerospace industry: Nickel alloys find widespread use in the aerospace industry to manufacture jet engine components, aircraft landing gear, and hydraulic system parts owing to their high strength, fracture toughness and corrosion resistance at elevated temperatures. Growing aircraft deliveries, particularly in the commercial aviation segment, is expected to drive the demand. Rising power generation activities: Nickel alloys are extensively used in thermal and nuclear power plants to manufacture steam turbines, gas turbines, nuclear reactors and related components due to their heat and corrosion resistance properties. Increasing investments towards power capacity additions is expected to propel the demand. Current Challenges in Nickel Alloys Market Nickel alloys have widespread industrial applications owing to their resistance to corrosion and heat. However, the nickel alloys market faces certain challenges. One of the key issues is the volatility in nickel prices in the global commodities market. As nickel is a primary raw material, significant fluctuations in its prices impact production costs for alloy manufacturers. Moreover, the procurement of high-quality nickel continues to be a challenge due to constraints in mining capacities and regulated supplies from major producers. Alloy developers also face technical challenges to expand the application scope of nickel-based materials and develop new variants with superior characteristics as per evolving industry needs. SWOT Analysis Strength: Nickel alloys exhibit high strength, toughness and corrosion resistance. This makes them suitable for applications in petrochemical, aerospace and marine industries. Weakness: Manufacturing of nickel alloys involves complex production processes which increases costs. Volatility in nickel prices poses price risks for alloy producers. Opportunity: Growing demand for high-performance materials from end-use sectors presents opportunities for new product development. Adoption of nickel alloys for electrochemical applications and 3D printing is forecast to increase. Threats: Stringent environmental regulations pose challenges for mining companies. Substitution threat from alternative materials limits market expansion. Geographical Regions In terms of value, North America accounts for a major share of the Nickel Alloys Market Opportunity, led by the United States. This is attributed to widespread usage of these alloys in oil & gas refineries and chemical plants within the region. Asia Pacific is emerging as the fastest growing regional market for nickel alloys driven by expanding manufacturing activity in China, India, Japan and South Korea. The European nickel alloys market is concentrated in Germany, Italy, UK and France where key end-use industries including aerospace, marine and chemical processing are located. Usage of corrosion-resistant nickel alloys has also been rising steadily across Middle East & Africa due to growing oil & gas production in the Gulf economies.

Get More Insights on Nickel Alloys Market

Explore more articles Beryllium Market

For Enhanced Understanding, Dive into the Report in the Language that Connects with You.

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#nickel alloys market demand#nickel alloys market share#nickel alloys market size#nickel alloys market trends

0 notes

Text

Hydraulic Generator Market Size | Industry Research by 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Hydraulic Generator Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Hydraulic Generator Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Hydraulic Generator?

The hydraulic generator market is expected to grow at a CAGR of 8.3% during the forecast period of 2024 to 2032.

What are Hydraulic Generator Market?

A hydraulic generator is a device that transforms hydraulic energy into electrical power by utilizing the flow of pressurized fluid to drive a generator. Commonly used in industries like construction, marine, and other sectors where hydraulic systems are present, these generators efficiently convert the kinetic energy of moving fluid into electricity. Known for their durability, compactness, and ability to generate power in remote or mobile settings, hydraulic generators offer a practical and reliable solution for applications that require on-demand electrical power without a conventional power grid.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1917

What are the growth prospects and trends in the Hydraulic Generator Market industry?

The hydraulic generator market growth is driven by various factors and trends. The hydraulic generator market is experiencing consistent growth, driven by the rising demand for dependable and efficient power generation solutions across industries such as construction, mining, marine, and heavy industrial operations. Hydraulic generators are highly regarded for their capability to generate electricity in remote or off-grid environments by leveraging existing hydraulic circuits, making them essential for mobile equipment and heavy-duty machinery. Market expansion is further supported by increasing infrastructure development, innovations in hydraulic systems, and a shift towards sustainable energy practices. Major regions driving this growth include North America, Europe, and Asia-Pacific. Hence, all these factors contribute to hydraulic generator market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Power Rating:

Low Power Hydraulic Generators

Medium Power Hydraulic Generators

High Power Hydraulic Generators

By Application:

Construction

Mining

Oil & Gas

Telecommunications

Marine

Others

By End-Use:

Residential

Commercial

Industrial

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Atlas Copco

Generac Power Systems, Inc.

Enerpac Tool Group

Wacker Neuson SE

HIMOINSA S.L.

KOHLER Co.

Caterpillar Inc.

Cummins Inc.

Stanley Infrastructure, Ltd.

Mitsubishi Heavy Industries, Ltd.

Briggs & Stratton Corporation

Doosan Corporation

Discover more: https://www.reportsandinsights.com/report/hydraulic-generator-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Hydraulic Generator Market Size#Hydraulic Generator Market Share#Hydraulic Generator Market Demand#Hydraulic Generator Market Analysis

0 notes

Text

AEAUTO: Leading the new trend of electric steering-by-wire for commercial vehicles

At a time when heavy-duty commercial vehicles are undergoing electrification and autonomous driving, innovation in commercial vehicle steering systems is crucial. AEAUTO stands out in the field of commercial vehicle electric steering-by-wire with its superior technology and products.

At present, the development of autonomous driving functions for commercial vehicles has encountered technical difficulties. Foreign products are not sold in China, and the domestic commercial vehicle market has an increasingly strong demand for localization. Traditional and electric hydraulic steering dares to challenge and successfully develop the first generation of commercial vehicle electric wire-controlled steering systems, bringing a new solution to the industry.

Advantages of AEAUTO Electric Steering-by-Wire System

1. System efficiency increased by 30%.

There is no energy loss in the hydraulic link, and the design combines electric and wire control, which perfectly meets the needs of heavy-duty commercial vehicles such as electric vehicles and self-driving heavy trucks.

2. System weight reduced by 35%.

Compared with traditional hydraulic or electric hydraulic steering, this system eliminates five components such as the hydraulic pump and hydraulic steering gear, and steering is completely driven by an electric motor, which is light in weight and small in size.

The total system cost is reduced by 20%. After removing multiple components and amortizing the R&D investment and mold costs, the overall cost of parts is greatly reduced.

AEAUTO electric steering-by-wire system core technology advantages

1. 8000Nm high torque output.

Through a dual-winding motor, high-precision ball screw, and flat secondary enveloping toroidal worm reduction mechanism, as well as a 24V high power density motor and patented reduction mechanism, the 8000Nm high torque output required for heavy-duty commercial vehicles is achieved.

2. High-reliability redundant design.

Using a functional safety-based redundant architecture with dual-winding motors, dual MCUs, and dual control chips for heavy-duty commercial vehicles ensures high reliability and safety of the steering system, meeting the urgent needs of the electric steering system as a functional safety component.

3. The angle control response time does not exceed 50ms.

Based on the in-loop dynamic tracking and feedback control strategy of the power assist value, it adopts a low-inertia permanent magnet synchronous motor, determines the control mode through different sensor signals, and uses the control algorithm to accurately track the target parameters to achieve rapid response of EPS power assist, which is at the international leading level.

Compared with foreign competitors, AEAUTO has better performance in terms of system voltage and angle control response time. Although 48V voltage is designed to output more power, it is not a common standard. AEAUTO also achieves high power output with its unique reduction mechanism without affecting matching and compatibility. In addition, the company's control strategy and algorithm are outstanding, achieving a better angle control response time.

AEAUTO electric steering-by-wire helps heavy-duty trucks become more electrified and autonomous

Our products have undergone a series of rigorous tests, including performance tests, bench tests, and durability tests, and obtained the EU CE certification in June 2021. In terms of customer cases, the electric buses of Karsan in Europe and the products of Otokar, a leading Turkish bus company, both use AEAUTO's electric steer-by-wire system and are sold to many European countries and the United States.

In addition, AEAUTO has also built a heavy-duty commercial vehicle electric steering R&D test platform, which covers software-in-the-loop simulation, testing, calibration, reliability, and durability test benches, and has passed the assessment of Nanjing Engineering Technology Center.

With its advanced technology, excellent product performance, and reliable quality, AEAUTO has demonstrated strong competitiveness in the field of electric steer-by-wire for commercial vehicles and has made positive contributions to promoting the electrification and autonomous driving development of heavy-duty commercial vehicles.

0 notes

Text

The Ultimate Guide to Choosing the Best Paver Block Making Machine

Paver blocks have become an increasingly popular choice for driveways, walkways, patios and other outdoor surfaces. Their durability, aesthetic appeal, and ease of installation make them a preferred option for both residential and commercial projects. However, the quality and consistency of paver blocks depend heavily on the machine used to produce them. This guide will help you navigate the process of selecting the ideal paver block making machine for your needs.

Understanding Paver Block Making Machines

A paver block making machine is specialized equipment designed to manufacture concrete paver blocks efficiently and consistently. These machines compress a mixture of cement, sand, aggregates, and water into molds to create blocks of various shapes, sizes, and designs. The right machine can significantly boost productivity, improve product quality, and reduce labor costs.

Key Factors to Consider

1. Production Capacity

One of the most critical factors in choosing a paver block making machine is its production capacity. Consider your current and projected future needs. Machines can range from small units producing a few hundred blocks per day to large-scale operations capable of manufacturing thousands of blocks in a single shift.

BTM Product offers a range of machines to suit different production requirements, from small-scale to industrial-level manufacturing.

2. Block Variety

Different projects may require various types of paver blocks. Look for a machine that can produce a wide range of block shapes, sizes, and designs. Versatility in production can help you cater to diverse customer needs and expand your market reach.

3. Automation Level

Paver block making machines come with varying degrees of automation. While fully automated systems require a higher initial investment, they can significantly reduce labor costs and increase efficiency in the long run. Semi-automated options offer a balance between cost and productivity.

4. Quality of Output

The consistency and quality of the paver blocks are paramount. Look for machines that produce uniform blocks with precise dimensions and smooth finishes. High-quality output not only satisfies customers but also reduces waste and rework.

5. Durability and Maintenance

Investing in a durable machine can save you money and headaches in the long term. Consider the machine's build quality, the materials used in its construction, and its reputation for reliability. Additionally, factor in the ease of maintenance and availability of spare parts.

6. Energy Efficiency

With rising energy costs, the power consumption of your paver block making machine can significantly impact your operational expenses. Look for energy-efficient models that can help reduce your carbon footprint and operating costs.

7. Safety Features

Prioritize machines with robust safety features to protect your workers and comply with industry regulations. Look for emergency stop buttons, safety guards, and other protective mechanisms.

8. Ease of Operation

User-friendly controls and intuitive interfaces can reduce training time and minimize errors. Consider the skill level of your workforce when selecting a machine.

Types of Paver Block Making Machines

1. Stationary Machines

These are fixed installations suitable for large-scale production. They offer high output and consistency but require a dedicated production area.

2. Mobile Machines

Ideal for on-site production, these machines can be moved to different locations. They're particularly useful for remote projects or when transportation of finished blocks is challenging.

3. Hydraulic Machines

Hydraulic systems provide consistent pressure, resulting in high-quality blocks. They're often more durable and suitable for heavy-duty production.

4. Mechanical Machines

These machines use mechanical force for block formation. While they may be less expensive, they might not offer the same level of consistency as hydraulic systems.

5. Egg-Laying Machines

These specialized machines produce blocks directly on the curing area, eliminating the need for additional handling of fresh blocks.

Cost Considerations

When budgeting for a paver block making machine, consider not just the initial purchase price but also:

- Installation costs - Training expenses - Ongoing maintenance and repair costs - Energy consumption - Potential labor savings - Projected return on investment

BTM Product offers competitive pricing across its range of paver block making machines, ensuring options for various budget levels.

Our Other Machines

fly ash brick making machine

interlocking tiles making machine

Technology and Innovation

The paver block industry is continually evolving, with new technologies enhancing production processes. Look for machines that incorporate the latest innovations:

- Computer-controlled systems for precise mix ratios and block formation - Advanced vibration technology for better compaction - Color mixing systems for creating multi-colored blocks - Sensors and diagnostics for predictive maintenance

Environmental Considerations

As sustainability becomes increasingly important, consider machines that support eco-friendly production methods:

- Ability to use recycled materials in the mix - Water recycling systems - Energy-efficient motors and hydraulics - Dust suppression mechanisms

BTM Product is committed to sustainability, offering machines designed with environmental considerations in mind.

After-Sales Support

The support you receive after purchasing your paver block making machine can be as important as the machine itself. Consider:

- Warranty terms and duration - Availability of technical support - Speed of response for repairs and maintenance - Training programs for operators - Availability of spare parts

BTM Product prides itself on comprehensive after-sales support, ensuring customers get the most out of their investment.

Case Studies and Customer Reviews

Before making a final decision, research case studies and customer reviews of the machines you're considering. Look for feedback on:

- Actual production rates compared to stated capacities - Reliability and downtime experiences - Quality of blocks produced - Customer service experiences - Return on investment timelines

Many satisfied customers have shared their positive experiences with BTM Product's paver block making machines, citing reliability, efficiency, and excellent support.

Customization Options

Every production setup is unique. Look for manufacturers willing to customize their machines to meet your specific requirements. This might include:

- Custom mold designs - Integration with existing production lines - Specific automation requirements - Special color mixing systems

BTM Product offers customization services to ensure their machines fit seamlessly into your production process.

Future-Proofing Your Investment

When selecting a paver block making machine, consider your future needs:

- Scalability: Can the machine's output be increased if needed? - Upgradability: Can new features or technologies be added later? - Versatility: Can the machine adapt to produce new block designs or use different materials?

Choosing a machine that can grow with your business can save you from costly replacements down the line.

Making the Final Decision

After considering all these factors, it's time to make your decision. Here's a final checklist:

1. Does the machine meet your current and projected production needs? 2. Is it within your budget, considering both initial and long-term costs? 3. Does it offer the quality and consistency required for your market? 4. Is the manufacturer reputable with good after-sales support? 5. Does the machine align with your sustainability goals? 6. Can it adapt to future market trends and production needs?

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price Get the Best Fly Ash Brick Making Machine in India

Conclusion

Selecting the right paver block making machine is a crucial decision that can significantly impact your business's success. By carefully considering factors such as production capacity, block variety, automation level, and long-term costs, you can make an informed choice that aligns with your business goals and market demands.

Remember that the cheapest option isn't always the most cost-effective in the long run. Invest in quality, efficiency, and reliability to ensure your paver block production thrives.

BTM Product offers a comprehensive range of paver block making machines designed to meet diverse needs and budgets. With a commitment to quality, innovation, and customer support, BTM Product stands ready to help you find the perfect machine for your paver block production journey.

Whether you're just starting in the industry or looking to upgrade your existing setup, take the time to thoroughly research and compare your options. The right paver block making machine can be the foundation of a successful and profitable business for years to come.

0 notes

Text

Minimac accepted the challenge to filter 72 kiloliters of Oil within 72 hours

Challenges and Problems are the fuel of Success. Such a challenging problem was faced by the UMPP (Ultra Mega Power Project) 2*800MW thermal power plant.

Challenges and Problems are the fuel of Success. Such a challenging problem was faced by the UMPP (Ultra Mega Power Project) 2*800MW thermal power plant.

In 2021, the plant called an annual shutdown, just before unit start-up, they found oil quality is not up to the mark to circulate it within the system. They had to run the plant within 3 to 4 days after cleaning 72 thousand liters of Oil to maintain the quality as per standard. The head of maintenance of the unit searched for a reliable and trustworthy name in the market for the task and then contacted Minimac Systems Pvt. Ltd. for the rescue.

Minimac is involved in manufacturing, supplying, exporting, and trading a range of oil purifications and reconditioning plants, allied machines, and laser particle counters. The Minimac team accepted the challenge to filter 72 kiloliters of Oil within 72 hours. The team knew its skills, but the enormous provocation was to transport the machine to the site and complete the task within time. They shipped the machine and later transported it with their personal vehicles. It took 8 hours to install the equipment, and they were ready to achieve the milestone.

Make sure you subscribe to our YouTube channel for the latest updates on Technology and Free Webinars: Click here

The oil was tested and found NAS10 before they started filtering the oil. At an interval of 18 hours, the oil samples were getting checked for work progress, and after the 3rd round of the quality test, the Minimac team achieved the target and got a favorable result of NAS6. Further, the machine was run to achieve NAS5. Minimac had to finish the task much before 72 hours and it was done only in 40 hours. This was a challenging task for the team, nearly like a world record if they could filter 72 thousand liters of oil in 40 hours using a compact size filtration trolley.

We used only a single set of correct filters i.e., the MR series filter element to achieve the goal. We did it with 2X FS-150-2S-H-V to get a favorable result for the client satisfaction to meet the standards. Nothing is impossible if we take up the challenge with great zeal and passion. This synergy happened because of the perfect combination of methodology and technology. Completing the task within the timeline was a challenge, but as it is often said and we strongly believe "hard work always pays off". Minimac is on a mission to change the way lubrication is being performed in the core sector's industrial plants. We strive to provide better machine efficiency and reduce the cost of maintenance and downtime by promoting Zero Mechanical Breakdown in rotary and hydraulic equipment through lubrication management.

Connect with our experts today to optimize the operational life of your equipment - Drop an Inquiry

#frf#oil flushing#minimac systems#power#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#hydraulic oil filter#oil purification system#transformer oil filtration#oil filtration#oil filteration#oil filter systems#oil testing#oil filters#oil industry#oil and gas#oil#oil dehydration systems#frf condition systems#electrostatics lube cleaner#transformer oil#transformer oil cleaning#coalescer separator#diesel oil purification#hydraulic oil cleaning#lube oil flushing#chemical cleaning

0 notes

Text

Market Outlook and Key Players in the Precision Planting Market

The global precision planting market size is estimated to be USD 5.0 billion in 2022 and is projected to reach USD 8.2 billion by 2027, at a CAGR of 10.3% during the forecast period.

Some of the major factors contributing to the growth of precision planting market includes the substantial cost-savings associated with precision planting and seeding equipment, surge in the adoption of advanced technologies in precision agriculture to reduce labour cost, and increasing promotion of precision planting techniques by governments worldwide. Moreover, climate change and need to meet rising demand for food will also drive the growth of the industry in the near future.

Key Players:Deere & Company (US), Trimble Inc. (US), CNH Industrial N.V. (UK), Kinze Manufacturing, Inc. (US), and Precision Planting (brand of AGCO) (US) are among the major players in the precision planting companies.

Download PDF:https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=96394217

By System Segment, High-speed precision planting systems to led the precision planting market during the forecast period

Precision planting market share will continue to be dominated by high-speed precision planting systems in 2022 and similar trend is expected to be continued by 2027. Farmers are becoming more aware of the benefits of using these planting systems as well as the high return on investment (ROI). With GPS-based auto-guidance planters, growers can reduce seed overlap during the planting process, thereby reducing input costs substantially.

By Offering, Hardware segment to account for largest market share of precision planting market during the forecast period

Precision planting market share is expected to remain high in the hardware segment until 2027. Increasing adoption of automation and control devices, such as drones/unmanned aerial vehicles (UAV), GPS devices, control systems, guidance systems, delivery systems, and display systems, has contributed to the growth of this segment. Planters use hardware such as delivery systems, control systems, seed meters, sensors, and GPS devices to ensure accurate seed placement and uniform seed distribution. Agricultural vehicles use GPS-based auto-guidance technology to reduce overlapping during field mapping, which in turn saves fuel, labor, and time, and compacts soil. Precision planting hardware market growth is expected to be driven by the increasing adoption of advanced planting and seeding equipment with new features such as VRT and guidance systems for precision planting.

By drive type segment, precision planting market is expected to see higher growth rate for the electric drive segment during the forecast period

The electric drive makes precision planter and seeding systems simpler. Farmers for whom corn is a secondary crop say the cost of a new planter forces them to keep fixing, modifying, and upgrading the older unit. By using electric motors, farmers or growers are able to control individual row units at a variable rate. As energy consumption on farm equipment increases, they have a clear advantage over mechanical, hydraulic, and pneumatic components. The power delivery of an electric motor is consistent and uniform. The regulation of electricity is more precise than any other power source.

By Region, North America is expected to lead the precision planting market share during the forecast period.

The Americas is segmented into North America and South America. North America is expected to account for the largest share of the precision planting market during the forecast period, owing to the presence of a substantial number of large-sized farms and major players, such as Deere & Company (US), Precision Planting (brand of AGCO) (US), Kinze Manufacturing Inc. (US), and Topcon Positioning Systems (US) in this region. These companies have contributed to the growth of the precision planting market by launching innovative products and services, and extensively investing in the R&D of precision planting technologies.

0 notes

Text

North And Latin America Water Pumps Market is Estimated to Witness High Growth owing to Rising Construction Activities

The North and Latin America water pumps market consists of various product segments including centrifugal pumps, rotary pumps and reciprocating pumps. Centrifugal pumps function on the principle of centrifugal force to transport water from a low-pressure system to a high-pressure system. They are ideal for large flow rate applications like commercial HVAC systems, agriculture and wastewater treatment. Rotary pumps use a roller or sliding vane to push water from the inlet to the outlet. They are energy efficient and commonly used for hydraulic applications. Reciprocating pumps utilize a plunger or piston to transport water in a linear back-and-forth motion. They are suitable for high-pressure applications like boiler feed water and desalination. The water pumps find extensive usage in industrial, municipal, agriculture and residential sectors for applications like irrigation, drainage, filtration, dosing and liquid transfer.

North and Latin America water pumps market is estimated to be valued at US$ 12.72 Bn in 2024 and is expected to exhibit a CAGR of 4.7% over the forecast period from 2024 to 2031.

Key Takeaways Key players operating in the North and Latin America water pumps are KSB AG, Ruhrpumpen Group, Flowserve Corporation, Kirloskar Brothers Limited, Sulzer AG, Xylem Inc., Ebara Corporation, Wilo SE, GRUNDFOS, and The Weir Group PLC.

The market provides significant opportunities in sectors like construction, agriculture, irrigation, wastewater treatment and power generation. Rising investments in infrastructure projects are fueling the demand for water pumps.

North And Latin America Water Pumps Market Demand are expanding to Latin American countries like Brazil, Mexico and Argentina through acquisitions, partnerships and distribution agreements to take advantage of opportunities in the growing regional market.

Market drivers The main driver for the growth of North and Latin America water pumps market is the rising construction activities in the residential, commercial and industrial sectors. There is rising expenditure on construction of buildings, roads, bridges and other infrastructure which involves extensive usage of water pumps. The development of water supply and wastewater treatment infrastructure is another key factor driving the market growth.

PEST Analysis Political: The regulations for water pumps vary in different countries across North America and Latin America. There are regulations regarding the efficiency and safety of pumps.

Economic: The economic growth and investment in industries like agriculture, mining will drive the demand for water pumps in the region. Repair and replacement of aging infrastructure also boosts market growth.

Social: Access to clean water is increasing in the region. Population growth and urbanization requires efficient water distribution which supports market growth.

Technological: Advances in material, design and variable frequency drives has improved pump efficiency. Integration of IoT enables remote monitoring of pumps.

Geographical regions with high market concentration The United States accounts for the largest North And Latin America Water Pumps Market Size And Trends backed by investments in irrigation and water supply projects. Mexico, Canada and major countries in Central and South America also contribute significantly to the regional market.

Fastest growing region Central and South America are projected to experience strong growth during the forecast period due to ongoing infrastructure projects, economic development and improving access to water and sanitation facilities across the region. Countries like Brazil, Colombia and Peru are expected to drive the future demand. Get More Insights On, North and Latin America Water Pumps

About Author: Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#North and Latin America Water Pumps Market Demand#North and Latin America Water Pumps Market Size#North and Latin America Water Pumps Market Trends#North and Latin America Water Pumps#North and Latin America Water Pumps Market

0 notes

Text

U.S Elevator Maintenance Market - Forecast(2024 - 2030)

U.S Elevator Maintenance Market Overview

The market for U.S. Elevator Maintenance Market is estimated to surpass $ 6.1 billion in 2026 and is analyzed to grow at a CAGR of 2.9% during forecast period 2021-2026. Moreover, Institutional building applications include hospitals, governmental, federal, municipal, and many other strategic institutions. Institutional buildings have been highly focusing towards replacing the obsolete traditional elevators with advanced technology based elevators systems. Such growing shift towards emerging technology based systems from institutional will contribute towards elevator maintenance market in U.S. Implementation of predictive maintenance for elevator systems in order to improve the regular monitoring standards helps in avoiding the extra costs incase of higher damages in the future. Such factors have been causing its higher adoption across low rise building applications, thus propelling the elevator maintenance market.

U.S. Elevator Maintenance Market Report Coverage

The report: “U.S. Elevator Maintenance Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the U.S. Elevator Maintenance Market.

By Elevatpr Type – Hydraulic Elevators (Conventional Hydraulic Elevators, Hole-less Hydraulic Elevators, Roped Hydraulic Elevators), Traction Elevators (Geared Traction Elevators, Gear-less Traction Elevators), Machine-Room-Less Elevators.

By Building Size – Low Rise, Mid Rise, High Rise.

By Speed – Below 1.5m/s, 1.6 – 2.5 m/s, 2.6m/s and above.

By Component Type – Controllers, Door Equipment, Cabin Enclosures, Signaling Fixtures, Power Units, Others.

By End User – Residential buildings, Commercial (Malls, Hotels, Offices, Hospitals), Marine & Off-Shore, Industrial (Power Plants, Steel Plants, Cement Plants), Institutional (Education, Government, Transportation Hubs and Others), Others.

Request Sample

Key Takeaways

Global U.S. Elevator Maintenance Market is dominated by low rise building which is growing at the highest CAGR of 4.0% attributed to the rising technological advancements in order to enhance elevator maintenance standards across the various low rise building sites

Commercial is analyzed to be the dominant vertical with a revenue of $2,141.27 million in 2019 due to the growing construction of malls, hospitals, offices, hotels and others in this region

One of the major factors attributable to the increasing adoption of elevator maintenance services are a rapid rise in industrialization and construction activities.

The growing concern about accidents in the elevators is expected to affect the market, thereby hindering the market growth during the forecast period 2021 – 2026.

U.S Elevator Maintenance Market Segment Analysis – By Type

U.S. Elevator Maintenance Market by type is dominated by Traction Elevators in 2020 with a revenue of $2.3 billion. Rise of elevator accidents towards mid and high rise buildings in U.S have been creating major demands toward regular monitoring and maintenance of traction elevators in order to ensure high level safety for the building residents. With the increasing growth of high and mid-rise buildings in the country, traction elevators face high dominance in order to ensure efficient transportation systems. Since the traction elevators leverage ropes and sheaves, regular monitoring and maintenance is highly required to avoid critical conditions in the long run, as they are deployed across different industrial environments. With continuous wear and tear, the traction between the sheave and the cables gets reduced and slippage becomes more regular, which ultimately reduces efficiency standards and can become dangerous if left unchecked. Such factors cause high requirements towards scheduled maintenance for improving the productivity of such elevators, thereby boosting the market.

Inquiry Before Buying

U.S Elevator Maintenance Market Segment Analysis – By End User

Commercial vertical is analyzed to be the dominant vertical with a revenue of $2.2 billion in 2020. Growing construction of malls, hospitals, offices, hotels and others in this region leads to increase in demand for elevators that in turn drives the market for elevator maintenance. Moreover, rising advancements have caused various market players to invest towards smart elevator systems due to rising construction of commercial buildings. Usage of advanced features including cloud technologies help the authorities towards proper maintenance of elevators across hospitals, hotels, malls and many others. Such factors have been propelling market demands towards improving elevator maintenance standards.

U.S Elevator Maintenance Market Segment Analysis – By Building Size

Global U.S. Elevator Maintenance Market is dominated by low rise building which is growing at the highest CAGR of 4.0% through 2026. Rising technological advancements in order to enhance elevator maintenance standards across the various low rise building sites has been also acting as a major driver towards higher dominance of elevators in the market. Elevator maintenance combined with automatic operations such as door closing and opening without the tapping of buttons, improves the functionality of the machines, thus helping in creating high demand across low rise building operations. Since technology is advancing at a rapid pace, construction of low rise buildings such as hotels, hospitals and many others have been also facing high shift towards improving use of smart technology based elevators.

U.S Elevator Maintenance Market, By Building Size

Schedule a Call

U.S Elevator Maintenance Market Drivers

Installation of elevators majorly in every field drives the market forward:

Continued expansion in the construction market and improved economic conditions would allow the Elevator Maintenance industry to continue its upward trajectory. Planned improvements in the US real estate market will drive growth primarily as the markets for residential, industrial, commercial and institutional construction expand. These downstream markets collectively account for almost three-quarters of the total market for the industry. Consequently, strong growth across these downstream markets is expected to increase the demand for contractors for installation services, benefiting industrial operators.

Rapid Growth in Industrialization and high demand for security:

The factors attributable to the increasing adoption of elevator maintenance services are a rapid rise in industrialization and construction activities. As per U.S Census Bureau, the total value of public construction in 2020 amounted to $ 353,300 million in June as compared to $ 355,751 million and $ 351,318 in May and April respectively. Such growth of residential as well as non-residential buildings construction in the country has been causing high adoption towards elevators.

U.S Elevator Maintenance Market Challenges

Rise in Elevator Causalities:

The growing concern about accidents in the elevators is expected to affect the market. More than 30 people are killed in the U.S., according to the U.S. Bureau of Labor Statics and Consumer Product Safety Board, and about 17,000 are seriously injured in elevator accidents each year. Incidents with the elevator are responsible for about 90% of deaths and 60% of serious injuries. According to the Center for Construction Research and Training, elevators are responsible for an estimated 27 deaths a year in the United States, and around 10,000 injuries. Most of these include maintenance workers who install or fix elevators or work close to an elevator shaft.

Buy Now

U.S Elevator Maintenance Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the U.S. Elevator Maintenance Market. U.S. Elevator Maintenance Market is expected to be dominated by major companies such as ThyssenKrupp AG, Otis elevator, Pine state, KONE Corporation, Mitsubishi electric, FUJITEC, dover corporation, amtec, Anlev and Armor among others.

Acquisitions/Technology Launches/Partnerships