#Hot Water Generator Manufacturers

Explore tagged Tumblr posts

Text

Hot water generator manufacturers in India

KBG Boilers Pvt. Ltd. is a premier name in the industrial heating industry, offering top-quality hot water generators that are engineered for reliability, efficiency, and durability. As a trusted hot water generator manufacturer, we are committed to delivering innovative solutions that cater to the diverse heating needs of industries such as pharmaceuticals, textiles, food processing, hospitality, and more. Our advanced hot water generators are designed to provide a steady supply of hot water for various applications, ensuring optimal performance and energy savings.

We take pride in being among the top hot water generator manufacturers in India, known for our precision engineering and adherence to stringent quality standards. Our hot water generators are crafted using cutting-edge technology and high-grade materials, ensuring durability and efficient heat transfer. Designed for both small-scale and large-scale operations, our systems are tailored to meet the specific requirements of our clients, providing them with reliable and cost-effective heating solutions.

Located in Ahmedabad, Gujarat, KBG Boilers Pvt. Ltd. is recognized as a leading hot water generator manufacturer in Ahmedabad and a reliable boiler manufacturer in India. With a robust manufacturing facility and a team of skilled professionals, we deliver products that exceed industry expectations.

Our hot water generators are energy-efficient and environmentally friendly, making them a preferred choice for industries seeking sustainable heating solutions. In addition to manufacturing, we also excel as a trusted hot water generator exporter in India, serving clients across global markets. Our expertise and commitment to excellence have earned us a reputation as one of the best hot water generator manufacturers.

At KBG Boilers Pvt. Ltd., our goal is to provide advanced heating solutions that enhance productivity and operational efficiency for our customers. Whether you require a reliable hot water generator manufacturer or a versatile industrial boiler, we have the expertise and resources to meet your needs. Partner with KBG Boilers Pvt. Ltd. for innovative, energy-efficient, and long-lasting hot water generators that redefine industry standards. Experience superior performance and unmatched quality with our trusted thermal solutions today. We prioritize customer satisfaction by offering customized solutions, timely delivery, and exceptional after-sales service, ensuring a seamless experience for our clients.

#Hot Water Generator#Hot Water Generator Manufacturers#Industrial Hot Water Generators#Hot Water Heating Systems

0 notes

Text

Hot Water Generator Manufacturer in Uttar Pradesh

Hot water generators have become essential in commercial settings such as hotels, hospitals, and manufacturing plants, where a continuous hot water supply is crucial. Unlike traditional boilers, hot water generators offer up to 90% energy efficiency and can reduce fuel consumption by 20-30%, leading to substantial savings. They are compact and space-efficient, making them perfect for commercial installations where space is limited. At Thermodynamic Services, a trusted hot water generator manufacturer in Uttar Pradesh, we provide reliable, high-performance generators that ensure seamless and cost-effective hot water supply.

For industries like hospitality, healthcare, and manufacturing, the benefits of a hot water generator are clear. In hotels, it enhances guest experience by providing consistent hot water for showers, kitchens, and laundry services. Healthcare facilities depend on a steady hot water supply for sanitizing equipment, while manufacturing plants need it for various cleaning and processing operations. A reliable generator reduces downtime, enhances productivity, and helps maintain high operational standards in these sectors.

Thermodynamic Services delivers quality hot water generators tailored to each industry’s needs. Our products are built from durable materials, ensuring long-term performance and efficiency. As a leading hot water generator manufacturer in Uttar Pradesh, we offer end-to-end support from installation to maintenance, making us a trusted partner in ensuring your business runs smoothly with minimal interruptions. Choose Thermodynamic Services to enhance your operations with the benefits of an energy-efficient hot water generator.

0 notes

Text

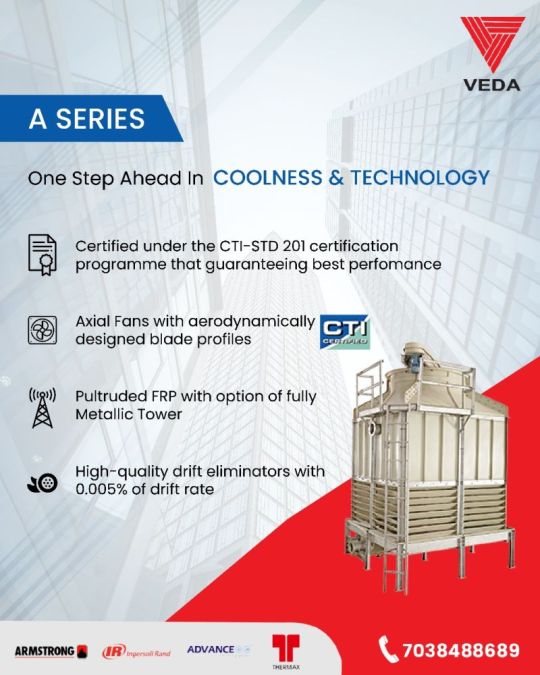

Enhancing Utility Engineering Solutions with Veda Engineering in Gujarat

Introduction:

In the dynamic landscape of utility engineering, finding a reliable partner who can deliver efficient, cost-effective solutions tailored to your needs is paramount. Veda Engineering stands out as a beacon of excellence in Gujarat, offering a comprehensive range of services spanning project execution, design, fabrication, audits, and consultancy. Let’s delve into how Veda Engineering is revolutionizing the industry.

Cooling Tower Supplier/Manufacturer in Gujarat:

Cooling towers play a crucial role in maintaining optimal temperatures in industrial processes, requiring robust and efficient solutions. Veda Engineering stands out as a premier supplier and manufacturer of cooling towers in Gujarat, offering innovative designs and superior construction. With a focus on fast-track schedules and uncompromising quality, Veda Engineering ensures that clients receive cooling towers that meet their specific requirements.

Thermax Dealer in Gujarat:

Veda Engineering proudly serves as a trusted Thermax dealer in Gujarat, bringing cutting-edge solutions in heat engineering to the forefront. With a focus on high efficiency output and cost control, Veda Engineering ensures that clients receive top-notch products and services that meet their specific requirements. Whether it's steam boilers, thermic fluid heaters, hot water generators, or cooling towers, Veda Engineering has you covered.

Steam Boiler Supplier/Manufacturer in Gujarat:

As a leading steam boiler supplier and manufacturer in Gujarat, Veda Engineering understands the critical role of steam in various industrial processes. Leveraging expertise in mechanical design and fabrication, Veda Engineering delivers steam boilers that excel in efficiency, reliability, and performance. Clients can rely on Veda Engineering for customized solutions tailored to their operational needs.

Thermic Fluid Heater Supplier/Manufacturer in Gujarat:

Thermic fluid heaters play a vital role in numerous industrial applications, requiring precision engineering and top-notch quality. Veda Engineering emerges as a premier supplier and manufacturer of thermic fluid heaters in Gujarat, offering state-of-the-art solutions that ensure optimal heat transfer and energy efficiency. With a focus on thoroughness and quality, Veda Engineering guarantees unmatched performance and reliability.

Hot Water Generator Supplier/Manufacturer in Gujarat:

Hot water generators are essential for various industrial processes, demanding solutions that combine efficiency with durability. Veda Engineering, as a trusted hot water generators supplier and manufacturer in Gujarat, excels in delivering cost-effective and reliable solutions. With a commitment to high-quality fabrication and stringent quality control, Veda Engineering ensures that clients receive hot water generators that exceed expectations.

Conclusion:

In the realm of utility engineering, Veda Engineering emerges as a trusted partner, delivering highly efficient, cost-effective solutions tailored to clients' needs in Gujarat. Whether it's serving as a Thermax dealer, supplying steam boilers, thermic fluid heaters, hot water generators, or cooling towers, Veda Engineering remains committed to excellence, ensuring clients' success and growth in their endeavors. With Veda Engineering by their side, clients can confidently navigate the complexities of utility engineering with unparalleled expertise and support.

#Thermax dealer in Gujarat#Steam boiler supplier/manufacturer in Gujarat#Thermic fluid heater supplier/manufacturer in Gujarat#hot water generator supplier/manufacturer in Gujarat#Cooling tower supplier/manufacturer in Gujarat

0 notes

Text

Inside Isotex Corporation Pvt Ltd. : Unveiling the Heart of Our Corporate Identity

Unveiling the Heart of Our Corporate Identity at Isotex Pvt Ltd. Isotex Corporation Pvt. Ltd. stands as a formidable 500 Cr. Company, boasting a rich history spanning over 45 years and a global footprint in providing thermal solutions to industries. With a track record exceeding 8000 installations, Isotex’s expertise in thermal technology is evident, reflecting a commitment to customer satisfaction, value for money, and environmentally friendly solutions. Recognized as India’s leading heater and boiler exporter by EEPC India, Isotex global has demonstrated its excellence in both large turn-key projects and small-scale installations, showcasing versatility and expertise. Over the last four decades, Isotex global has been at the forefront of meeting heating demands worldwide, installing and commissioning more than 8000 units across various industries. The company’s dedication to engineering design and execution excellence is showcased on its website, featuring challenging and recent installations of Thermal Oil Heaters and Boilers. Isotex prides itself on delivering trouble-free performance, value for money, customer satisfaction, and on-demand support across a wide range of process industries globally.

#isotex global#boilermakers#isotex boiler#thermal energy#boiler manufacturer#thermic fluid heater#industrial boilers#hot water generator#corporate video#isotex corporation

0 notes

Text

A well written explanation involving Lithium Ion Batteries. 👇

Understanding Thermal Runaway in Lithium Ion Battery Fires. Thermal Runaway Explained:

Thermal runaway is a chain reaction within a lithium-ion battery that can lead to catastrophic failure, resulting in fires or explosions. Here’s a step-by-step breakdown of what happens during thermal runaway:

1. Initial Trigger: Thermal runaway can be initiated by several factors, such as physical damage (e.g., puncturing or crushing), overcharging, manufacturing defects, or exposure to extreme heat.

2. Internal Heating: Once triggered, a part of the battery starts to overheat. This can be due to an internal short circuit or a chemical reaction within the battery.

3. Chain Reaction: The heat generated from the initial trigger increases the temperature inside the battery. This heat can cause other parts of the battery to react, generating even more heat.

4. Rapid Temperature Rise: As the temperature rises, the electrolyte inside the battery—a flammable liquid—starts to vaporize and decompose, producing gases. This further increases the internal pressure and temperature.

5. Gas Release and Ignition: The increasing pressure can cause the battery casing to rupture, releasing flammable gases. These gases can then ignite, leading to a fire or explosion.

6. Propagation: If the battery is part of a larger battery pack, the heat and flames can spread to adjacent cells, causing them to undergo thermal runaway as well. This can result in a large, intense fire that is difficult to control.

Key Points: - Difficult to Extinguish: Thermal runaway fires require massive amounts of water to cool the batteries and stop the chain reaction. Traditional fire extinguishers are often ineffective.

- Toxic Gases: Burning lithium-ion batteries release toxic gases such as hydrogen fluoride, which can be harmful if inhaled.

- Reignition Risk: Even after the fire appears to be extinguished, there is a risk of reignition. The battery cells can remain hot and unstable for hours or even days.

Safety Measures:

- Distance: Establishing safety distances to keep people away from the danger zone.

- Continuous Monitoring: Using thermal imaging to monitor for any signs of reignition.

- Specialized Response: Firefighters need to use specialized techniques and equipment to handle lithium-ion battery fires safely.

Understanding thermal runaway helps in appreciating the complexity and danger of lithium-ion battery fires, highlighting the importance of safety precautions and effective response strategies. 🤔

#pay attention#educate yourselves#educate yourself#knowledge is power#reeducate yourself#reeducate yourselves#think about it#think for yourselves#think for yourself#do your homework#do some research#do your own research#ask yourself questions#question everything#lithium ion batteries#fires#thermal runaway#news#battery fires#electric vehicles#government corruption

61 notes

·

View notes

Text

explaining f1: tyres 🛞

first post in this series (will it be a series? we’ll see)

recently i think we’ve had some particularly interesting races in terms of tyre strategy and i readied in suzuka that i don’t totally understand it all, so this has been my little research project on tyres!

pirelli

pirelli are an italian tyre manufacturer who have been supplying f1 tyres since 2011. unlike some eras of f1, pirelli is currently the exclusive supplier in the sport.

in 2022, pirelli introduced a new 18-inch (the previous being 13-inch) tyre as part of sweeping changes to the technical regulations of the sport.

compounds

pirelli’s range is currently comprised of six ‘slick’ compounds (referred to as slick because they lack the grooves of normal road tyres - this is because these grooves exist to dispel water, something necessary for road tyres but that slows down an f1 car when not necessary) tyres, along with ‘intermediates’ and full ‘wets’ to account for weather conditions.

the six slick compounds (from hardest to softest) are referred to as follows: c0, c1, c2, c3, c4 and c5. from this range, pirelli pick three to be used at each grand prix, based on the track characteristics and climate.

the highest of the set is marked red and is known as the soft, the middle marked yellow and know as the medium, with the lowest marked white and known as the hard (intermediates are green and wets are blue).

theoretically, the softs have more grip over short periods of time, making them faster and better for qualifying runs. generally, the hard and medium compounds are more favourable on race day because they last longer.

rules

on most weekends, drivers are given 13 sets of slicks, 4 intermediates and 3 wets, with a set of softs reserved for drivers who reach q3 (the final round of qualifying). all drivers must return 2 sets after each of the 3 practise sessions, meaning only 7 sets are left for qualifying and the race. drivers must also use at least two different slick compounds during the race (provided the weather is dry).

on sprint weekends, the number of dry sets are reduced to 12. after the sprint, drivers must return the set they completed the most laps on.

tyre allocation is on a per-driver basis, teammates cannot share or swap tyres. in bahrain in 2020, mercedes mistakenly put bottas’ tyres on russell’s car when attempting a double stack. the team was fined €20,000 for this.

drivers must run the same compound on all four wheels at all times.

strategy

tyre plan for the weekend is the decision of the team, generally based on information from pirelli, observed degradation over practise, the circuit and the weather forecast.

if rain is expected, teams can draw from their wet weather allocation, and so they don’t need to be as cautious with their dry weather tyres. if it’s hot, teams have to make sure they can cover plenty of tyre changes.

if track layout means overtaking is tough, teams may want a higher number of pitstops to stop drivers getting stuck behind rivals. also, if the track is walled (and so safety cars are more likely) teams may plan for more stops.

terminology

scrubbed: teams often ‘scrub in’ a set of tyres by running them briefly during practise, this means that when they are later used in the race, they warm up much faster than brand new tyres.

blistering: when the inner part of tyre heats more than the outer, creating minor explosions which damage the surface of the tyre.

graining: when the outer surface is hotter than the inside of the tyre, leading to the outside rubber flexing, breaking and sticking to the tyre.

flat spot: a patch where the surface of the tyre looses its curve. this is usually caused by a driving locking up by breaking too late, meaning the tyre scrapes along the ground.

deg or degradation: refers to a steady loss of tyre performance due to general wear.

#obviously i’ve gone into a lot of detail here that you don’t really need to enjoy the race#but i think it’s interesting!#feel free to correct or add anything#f1#formula one#motorsports#max verstappen#charles leclerc#lando norris#carlos sainz#oscar piastri#logan sargeant#alex albon#fernando alonso#lewis hamilton#george russell#lance stroll#daniel ricciardo#yuki tsunoda#explaining f1

55 notes

·

View notes

Text

hot take but like why are we as a society still using lead in manufacturing processes in 2024...

anyway tldr of this is that you are not being exposed to lead unless the circular piece on the bottom of the cup is damaged. so, owning a cup like this will likely not result in lead exposure. this is similar to the fact that in older housing where lead paint has been painted over in subsequent decades, and that paint is in good condition, then it is not a risk. lead based paint only becomes an issue when it is deteriorating (chipping, cracking, peeling, chalking, etc) or being turned into dust during renovation activites. so yeah, in a similar way--you aren't going to get lead poisoning unless the steel compontent on this water bottles comes off.

but also this article says that these lead pellets that are used in the cups are an "industry standard" and i'm like: why? WHY is it industry standard in 2024? at least with lead pipes and lead based paint, we're just dealing with issues from prior decades. but this is current so there is a conscious decision to still use lead in products. also, i don't know enough about this subject (bottle manufacturing) to know why they prefer to use lead for this step, or where in the world they manufacture the cups, but my other concern is that even though the general public will likely not be exposed if it's covered, there are still workers who have to handle it during production.

anyway, i just find that i am constantly learning about more places that lead gets found and it's just. sigh. i know lead has many appealing properties which is why it is constantly found everywhere in everything but at this point it's incredibly clear that no benefits outweigh its risks....

#anyway. assimilating this into brain so that the next time i do public outreach i can answer this question lmao#it pays (quite literally for me) to learn as many of these sources as possible#so now i also get to tell parents they should be careful about their steel tumbler bottles getting damaged...#havent done enough research yet to determine if this is All brands or just stanley & the ones mentioned in the consumer product safety site#but it seems to be a common component of steel insulated bottles#will have to do more research later

66 notes

·

View notes

Note

Ok elaborate on the white water kayaking if you would like bc that’s incredible

this is. maybe the thing i think about most lol. NO idea how much people know about kayaking but uh. ask me!

so whitewater kayaking is interesting as a sport bc while there ARE major racing events (the green race!! the north fork championship!! go look them up they’re SICK) it is generally not a formalized racing series that culminates in a trophy like in motorsports. like there’s no seating for spectators even. you get to these races by hiking two hours through the woods and parking your ass on a rock by the river and hoping you don’t fall in bc you are BLASTED drunk. they’re big parties most of the time!

so while the best kayakers in the world DO compete in these things and win them, the sport is frankly more about doing sick stunts with your friends on beautiful rivers all over the world than like. cutthroat fanatical competition. which bezz (who HATED racing against people as a kid never wanted to fight on the track to go fast) would LOVEEEE imo. also literally it is bad practice to go boating alone you NEED a homie with you at all times that’s how you run shuttle that’s how you set safety that helps you scout rapids it is a homie-based activity!!! and bez loves his friends SOOOO bad and especially loves to do dumb life-threatening stuff with them. that’s what big water boating IS.

and it’s just. some aspects of the stuff happening at the ranch and the broader culture of whitewater is very similar in terms of vibes to meeeee. like the adrenaline addiction the injuries the constant threat of death the long hair the dumb tats the earrings the SAME fucking sunglasses kayakers get just cheaper ones. the energy drink sponsorships the going skiing 24/7 in the off-season…. that’s a fucking kayaker to me lol. i look at him and genuinely question why he is not in a dry suit bombing waterfalls in chile. #beater #steazy #booflife he’d love it so bad.

and i AM saving all of my narrative thoughts on bezz kayaking for a fic one day maybe. problem is i don’t know shit about the whitewater scene in italy so i’d have to make these boys like. appalachian. but i do know cele would have the world’s most atrocious rookie crush on hot trip leader bezz and when cele dump trucks a raft and has to do a swim beer out of his nasty bootie (whitewater has like. a reverse shoey system where you only do them if you fuck up) and bezz like, puts his big hand on the back of cele’s neck as he chugs this nasty beer (for maximum crazy this is bezz’s shoe bc cele is a rookie and didn’t want to shell out for the whitewater specific shoe and is wearing chacos) and cele has a small religious experience and flushes BRIGHT RED.

anyways if you want to check out some sick kayakers and are curious regarding the vibe i recommend following aniol serrasolses (catalan legend), nouria newman (badass. has yelled at my brother), and evy liebfarth (from my hometown!). liebfarth is going to the olympics this year in kayaking slalom which IS a formalized racing series but one that generally takes place on closed courses and such and is a small niche in the broader culture of the sport. still very cool and very hard to do. there is also dane jackson who is the arguable GOAT of the sport i just think he’s kind of swagless and one time he put my brother on youtube after he dislocated his shoulder when they were paddling the royal gorge like. cmon man. also his daddy owns a major kayaking manufacturer booooo. he does win the green race like literally every year which IS annoying. to me.

#does this make sense. to anyone but me.#when i write the bez/cele whitewater au…. oh boy….#callie speaks#motogp#asks#if you get me going on kayaking i will not stop

37 notes

·

View notes

Text

Arkansas May Have Vast Lithium Reserves, Researchers Say. (New York Times)

Excerpt from this New York Times story:

Researchers at the United States Geological Survey and the Arkansas government announced on Monday that they had found a trove of lithium, a critical raw material for electric vehicle batteries, in an underground brine reservoir in Arkansas.

With the help of water testing and machine learning, the researchers determined that there might be five million to 19 million tons of lithium — more than enough to meet all of the world’s demand for the metal — in a geological area known as the Smackover Formation. Several companies, including Exxon Mobil, are developing projects in Arkansas to produce lithium, which is dissolved in underground brine.

Whether lithium harvesting takes hold in the region will depend on the ability of those companies to scale up new methods of extracting the valuable battery ingredient from salty water. The processing technique that Exxon and others are pursuing in Arkansas, known as direct lithium extraction, generally costs more than more conventional methods do, according to the consulting firm Wood Mackenzie.

Energy and mining companies have long produced oil, gas and other natural resources in the Smackover, which extends from Texas to Florida. And the federal and state researchers said lithium could be extracted from the waste stream of the brines from which companies extracted other forms of energy and elements.

“The potential for increased U.S. production to replace imports has implications for employment, manufacturing and supply chain resilience,” David Applegate, the director of the United States Geological Survey, said in a statement announcing the study. “This study illustrates the value of science in addressing economically important issues.”

Federal researchers also have identified other potential resources that could produce large quantities of lithium, including the Salton Sea in Southern California, where Berkshire Hathaway Energy and other companies are working to extract lithium from hot liquid pumped up from an aquifer more than 4,000 feet below the ground by geothermal power plants.

Exxon Mobil recently drilled exploratory wells in Arkansas and was evaluating whether it could extract lithium in a cost-competitive way, Dan Ammann, the president of the company’s Low Carbon Solutions business, said in an interview last month.

5 notes

·

View notes

Text

Sunday Steve - Day Eight

Things that would be new or unfamiliar to Steve in the 21st century, either due to the time period he grew up in, or his social-economic status and other such factors.

Day Eight: Shampoo and Conditioner

Shampoo: The origins of the word shampoo comes from an Indian hair and body massage called champooi/champo.

In the late 1800s and early 1900s shampoo was a water soluble, dry shampoo powder that would be dissolved by the teaspoon in a cup of hot water (Link). Shampoo could also come as bars of soap, which could lather or be grated and dissolved into boiling water and left to cool and solidify.

A 1908 New York Times shampoo guide claims "hair is best shampooed at night, following thorough combing and brushing, and singeing split ends. Castile soap is applied with a stiff brush and rinsed four times every month to six weeks." (Link)

Bathing had become more and more common as part of the hygiene routine in the early 1900s, but shampooing was generally recommended every two weeks—or every four to six weeks (preferably using castile soap or tar soap) because shampoo was known for drying out and damaging hair. (Link)

While at-home shampooing was slowly becoming more common, it was more common—for those who could afford it—to get it commercially done. Most shampoo ads were targeted towards women, but men in barbershops "transitioned from using hair tonics to using shampoos to remove the build-up of heavy styling products" (Link).

The liquid shampoo first really started hitting the market in 1927. So by the 30s at-home shampooing became even more common. This is due to a combination of most Americans have in-house plumbing, their own bathrooms, and the shampoo formulas becoming less harsh and drying. The combination of all this meant one could wash their hair every week. (Link) (Every day shampooing began to be marketed in the 70s since oily hairstyles were out of fashion.)

Liquid shampoos were sold in glass bottles, while powdered shampoos came in tins.

Bottles of shampoo and lotions manufactured in the early 20th century by the C.L. Hamilton Co. of Washington, D.C., United States

It wasn't until 1934 that detergent-based (no-soap, modern) shampoos came onto the market (Link).

Sarah Rogers likely wouldn't have been able to afford to get her hair shampooed, but she could have made her own shampoo from castile soap bars (example youtube video) or bought shampoo powders which were then dissolved in water.

She would only wash her hair every few weeks, most likely brushing her hair and keeping it up in styles in-between washes. (Link) Using a clean brush to brush ones hair helped remove and evenly distribute oils.

In 1933 shampoo cost about 25-50 cents. (Link) (Link) I haven't dug deep to know exactly what kind of things Steve and Sarah would be able to afford. But it wouldn't surprise me if there were times they could and couldn't afford hair care products.

As for if Steve would shampoo his hair, he probably just used soap. Shampoo had soap in it until 1933 (which was why it was so drying) (Link). But men could afford to use soap on their hair since they usually had shorter hair and their natural head oils could help mitigate the damage.

I can find less information about men's hair routines if they couldn't afford to go to barbershops, so I'm less certain of what Steve would do. But 20s, 30s, and 40s men's hair styles had a lot of oil or greasy styling products. While these would need to be washed out for re-styling (probably weekly like women) the oil products would help against drying out the hair.

Men also always wore hats. Having stiff or slick-down hair was important so that hair styles wouldn't be ruined by putting on and removing hats. Hair oils would stain hats, chairs and other things heads came in contact with.

Circa 1920 Glostora hair oil and brush ad and Hair Slik ad

Don't be fooled by the ad. This vintage bottle of Glostora is 5 inches or 12.5 cm tall. It would be put on after shampooing, like conditioner.

In the Captain America: The First Avenger movie we can see that Steve's hair isn't slicked back. This could just be a modern day styling choice, but it could also show that Steve did not care about styling his hair.

Cleanliness was was important so he probably washed his hair every few weeks with soap and bathed regularly. But it doesn't look like he put heavy product in his hair. (Unlike Bucky, who probably had more reason to shampoo his hair. It wouldn't surprise me if Bucky went to the barbershop when he could afford it.)

Steve probably couldn't afford to do more to his hair than wash it with soap every few weeks. He likely made his own shampoo with castile or tar soap. This method makes more shampoo than the bottles of liquid shampoo being sold.

Conditioner: Conditioners originated from a product called brilliantine (developed in 1900) which was used to soften beards and moustaches. This product would be put on after styling in barbershops to make the hair shine and soften it. (Glostora and Hair Slik are similar products.) (Link)

"It was oil based, giving off a slimy residue to anything it touched. Homemakers knit lace doilies to cover the backs of high back chairs and couches to protect the furniture from men’s greasy heads" (Link)

Other items used similar to conditioners were hair tonics, or Wildwood Cream.

Conditioner became a necessity because of shampoo, as it is drying to the hair. So it wasn't used much until shampooing became more common (oil has a long history of being used to tame hair, but commercial conditioner products became more common along with shampoo use.) (Link)

Women caught on to these types of commercial products. I've had a hard time finding specific conditioner products from the 30s. Here is a hair care routine for women circa 1930 that mentions brillientine, so it looks like women began using brillientine as well before more specific conditioning products were developed.

There seemed to be more conditioner products developed by the 40s. Here's a conditioning cream from around the 40s, and a different one with a price (about 39¢).

1942 Drene Shampoo Hair Conditioner Vintage Print Ad

(Drene was the first modern synthetic (no soap) shampoo and you can see in the side panel of this ad they say "Don't rob your hair of its glamour by using soap or liquid soap shampoo—which always leave behind a dulling film that dims the natural lustre and color brilliance!")

Wrap up

Modern day hair routines would be recognisable but still somewhat unfamiliar to Steve. This is partially because men's hairstyles have changed drastically from the slick-back styles he is used to. Hats have also gone out of style.

Also, it is common now in America to wash one's hair around three times a week. This shift came about with the change in hair styles. Woman leaving hair down and covering it less necessitates the need to shampoo and condition it more. (Women shampooed their hair once a week in salons up to the 60s).

The products are also slightly different. Liquid shampoo is the dominate form now (I doubt Steve ever bought liquid shampoo) and they come in plastic bottles. The liquid shampoo is likely a much different formula than he's used to. Additionally, conditioning is a very specific step in the process and hair product ingredients have evolved.

There are also combination products like 2-1 shampoo and conditioner which came about in the late 1980s.

Along with the cultural changes, Steve's socioeconomic status would effect his perception of hair-care routines and buying hair products.

With modern (no soap) products, Steve's hair is probably softer and shinier. Steve would have been aware of no soap products, but I don't think he would have bought them. However, he could have had these products used on him during his USO tour. Interacting with the women there probably introduced him to many products he was less familiar with.

Men's hairstyling in the 1920s.

This post kind of got away from me! But I hope you enjoyed my deep dive into 20th century hair care.

#steve rogers#steve rogers meta#meta#sunday steve#1920s#1930s#1940s#american history#us history#history#shampoo#conditioner#hair care#vintage hair#hair styles#hygiene#20th century#long post

27 notes

·

View notes

Note

Can.. Can I request ceo ingo and emmet hcs?? 🥹

sure lmao

i'm sorry if it's kinda sucky

cw: CEO au

▲CEO Train Twins▽

● The twins work at one of the biggest companies in Unova, known especially for their train manufacturing. They admittedly had their hands in countless areas, but the two obviously focused and cared for the manufacturing more than the others. Their positions had been something they received from their father after he moved into investing and retired.

○ They take to donating a good chunk of many to the Battle Subway, one of their favourite places in all of Unova. Their company makes many of the trains used by them, so it never seemed odd to also fund them in general. In fact, it's not odd to catch them riding the trains whenever they can. Their unwavering love of trains is apparent.

▲CEO Ingo▼

● Originally, he was the only one of the two twins to receive the job position, but Ingo simply refused to take it if Emmet was denied. It made him nervous to work away from his brother, and even if he was the older of the two, it made little difference in actual life experience. This ended up as a good call on his part, as Emmet ended up being an extremely helpful force with the workload and preventing him from overworking himself.

● He takes his job seriously and carries himself well, utterly afraid of tarnishing the company his father adored. Perfect business suits are common attire. Everything is worn as it should be. Even if it's hot, he's still seen wearing his suit jacket. Many people have remarked on how attractive he is and how dedicated he is to everything. This leads to numerous invitations for dates, which he never finds himself wanting to go on.

● Really, he has no interest in dating. While he would adore settling down and starting his own family, it just seemed impossible with his current level of work. Most of his socialising away from a few friends and his family was related to work. Parties, meals, meetings; everything was for work. It was impossible for him to just hold a normal conversation with most people. They saw him as a way to cement themselves in their wealth, or to use him as a way to climb even higher. He felt utterly lonely despite being almost in constant conversations.

● Well, that was until you came into his life. Hired originally as just an assistant, you quickly held his attention thanks to how you always treated him so kindly. It felt completely different from the faux politeness and air of tension from his peers in business. You spoke to him as a person, not even as an authority figured. Well, barring a few “sir 's” and “bosses” thrown around. But even then, you lightly teased him about things and made him feel less like he was drowning is business professionalism.

● You chatted with him about his genuine thoughts and feelings, making sure his schedule around the office was something manageable. It helped more than he realised. Many things you noticed about him helped him more than he would have realised. Forcing him to take his lunch breaks and actually eat, making sure he drank water as much as he drank his coffee, and trying to limit his long nights spent at the office. He felt at ease with you around.

● When you made the first romantic move towards him, he felt caught off-guard. You had started to pack him lunch, and when you had handed it off to him, you softly held his hand for a moment. Eyes avoided his, and you turned away quickly and left. His heart raced at the thought. Slowly, you became more and more daring. Hand brushes turned to cupping his face and eventually into hugs. Everything felt too real to him.

● A relationship did not follow long after a few dates, allowing him to feel more at ease around you. It was obvious to both coworkers and his brother that he felt more comfortable with you around than before you had arrived. Emmet's time nagging him to take time for himself and not work himself into an early grave slowed and ebbed out. Your concerns finally made him actually slow down.

● As a lover, he tries to dote on you with gifts and lavish dates, but he finds himself favouring evenings spent in with you more than them. He takes to cooking for you and chatting with you late in the nights spent at his apartment. Affection is common outside of work, too. He is deeply afraid his employees will see his tender kisses and long hand holds as something forced upon you, no matter how many times you initiate them yourself.

▽CEO Emmet△

○ He admits that working as a CEO wasn't truly his dream job, but Emmet would never leave his twin's side, especially when Ingo asked him specifically to work with him. While it might not be the conductor job he dreamed of, he deeply enjoys that he still gets to work with trains in a way and support his favourite Unovan battle facility, too. Not to mention, he has to make sure his older brother doesn't work himself to death.

○ Emmet dutifully does his job, helping lessen Ingo's workload and manage people around the company. He also decided to take up any disciplinary related meetings, as he knew that Ingo did not particularly enjoy them. His clothing imitates his brother, but he chooses to go with grey suits over his brother's favouritism towards black. People remark he has a certain level of attractiveness that his brother has and seems easier to approach, yet he always seems to scare them off with his manner of speaking.

○ The younger rarely goes on dates, but he does often find himself seeking out casual sex, as he finds that people are rarely interested in who he is as a person rather than his money and title. Emmet would love to have a romantic partner in his life, but it seemed most people either wanted him for the wrong reasons or just saw him as too innocent to be worth their time. He simply found it easier to calm is base desires and spend his time focused on helping his brother and hanging out with friends.

○ All that faded when you finally entered his life. An assistant hired on a whim to help better manage he and Ingo's meetings and paperwork, you caught his attention by playing with one of his Joltiks that had escaped his office. You treated him kindly and eagerly returned his conversation about his interests. It felt different from business talks and more like the ones he had with Elesa, instead. You even dared to joke and tease him, relaxing the tension heavily.

○ It was not long until you grew to notice little things about him. Chiding him about only eating desserts, making sure he actually finished his paperwork, and helping him with meetings that he obviously didn't want to hold. It made him feel closer to you, knowing that you clearly fretted over him. (It made his heart race, actually.)

○ Emmet accidentally made the first move. After a long night and bad morning, he came into work feeling awful. You, however, greeted him with a smile and surprised him with a piece of cake from a bakery that you had mentioned to him before. Naturally, his immediate response was to squeeze you into a hug, just as he did his brother and Elesa. You returned the affection without hesitation. It wasn't long until Emmet became more physically affectionate towards you. Hugs and hand kisses and holding became a common occurrence, much to your obvious pleasure.

○ A single date led to many more and a relationship. Emmet eagerly asked you out, and his joy radiated for days after. Ingo and your coworkers could only watch as he clung to you and hung around you throughout the day. It was fairly obvious how your relationship had changed. Despite Ingo scolding him so obviously showing his affection in front of their employees, Emmet openly showered you in affection.

○ He buys you many, many gifts, preferring to see you smiling. Though, a few were obviously things we wanted to catch you wearing both in and out of the office. Fancy and fun dates are common with the CEO, determined to enjoy his time with you to the fullest. Affection was doted on you everywhere and anywhere. Even moving into more intimate actions in places like the office, much to his brother's disdain.

#emmet x reader#ingo x reader#pokemon x reader#ingo/reader#emmet/reader#lately i've been feeling like might writings have been lame and idk why

74 notes

·

View notes

Text

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use

Welcome to Thermodynamic Services, your trusted partner for industrial air compressor solutions, air compressor installation services, Thermax products, industrial steam boilers, steam system engineering, hot water generators, STP plants for hotels and hospitals, ETP plants for industrial use, and RO plants for hotels and hospitals in Uttar Pradesh. We are your authorized dealer for top-notch Atlast Copco and Thermax products. Our commitment is to provide reliable and efficient solutions for your industrial needs.

Industrial Air Compressor and Installation Services:

At Thermodynamic Services, we offer a comprehensive range of industrial air compressors and professional installation services throughout Uttar Pradesh. Our team ensures that your air compressor system is installed efficiently, optimizing your production processes while reducing energy consumption.

Thermax Dealer in Varanasi and Lucknow:

As the authorized Thermax dealer in Varanasi and Lucknow, we bring you cutting-edge solutions for heating, cooling, and power generation. Our Thermax products are renowned for their quality and efficiency, ensuring that your industrial processes run smoothly.

Industrial Steam Boiler Manufacturer in Uttar Pradesh:

Our state-of-the-art industrial steam boilers are designed to meet the highest standards in performance and safety. We are the top industrial steam boiler manufacturer in Uttar Pradesh, offering tailored solutions for your specific requirements.

Steam System Engineering Services:

Thermodynamic Services specializes in steam system engineering services. Our team of experts will analyze, design, and implement the most efficient and cost-effective steam systems for your industrial operations in Uttar Pradesh.

Hot Water Generators for Hospitals & Hotels:

For hospitals and hotels in Uttar Pradesh, we provide high-quality hot water generators. These systems ensure a continuous and reliable supply of hot water, meeting the demands of your customers and patients.

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use:

We offer sustainable solutions for waste management with STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) installations. Ensure your business is environmentally responsible and compliant with regulations.

RO Plant for Hotels and Hospitals:

Our RO (Reverse Osmosis) plants are ideal for hotels and hospitals, providing clean and safe drinking water. We prioritize the health and well-being of your guests and patients.

Conclusion:

Thermodynamic Services is your one-stop solution for all industrial needs in Uttar Pradesh. We pride ourselves on offering top-quality products and services that enhance your industrial operations. Partner with us to ensure efficiency, compliance, and sustainability. Contact us today for all your industrial requirements and enjoy the benefits of our trusted solutions.

conatct us on 91 78600 24711 or https://thermodynamic.co.in/

#Air Compressor Installation Services in Uttar Pradesh#Thermax Dealer in Varanasi#Thermax Dealer in Lucknow#Industrial Steam Boiler Manufacturer in Uttar Pradesh#Steam System Engineering Services in Uttar Pradesh#Hot Water Generator for Hospitals & Hotels#STP Plant for Hotels/Hospitals#ETP Plant for Industrial Use#RO Plant for Hotels and Hospitals

0 notes

Text

Go For a Ride Day

Go For a Ride Day, celebrated on November 22, urges you to just get up and get out! Do you ever feel like you’re tied to your laptop/phone/tablet screens? We’ve become a pretty sedentary bunch — a far cry from the people who discovered countries, oceans, and animals simply by getting off the couch and exploring. Make today a day to set your spirit free and enjoy your wanderlust on whatever mode of transportation suits you best. Bike, boat, car, skateboard, sleigh—it doesn’t matter what you choose! Pick a location you’ve always wanted to visit and make today the day you’ll go.

History of Go For A Ride Day

Birthdays are fun and Christmas means presents (if you’re lucky), but nothing quite compares with the magical day you get your driver’s license. That’s when your world truly changes forever. Why? Cars mean freedom. You can suddenly go anywhere at anytime (as long as your parents are cool with your plans). Such is the nature of transportation — something we in the 21st century take for granted. We all grew up with planes, trains and automobiles — so we’re quite used to getting where we need to go.

But it wasn’t always that way. When President Jefferson asked Lewis (and, eventually, Clark) to explore the American West in 1804, there were no nonstop flights from St. Louis to the Oregon coast. As the History Channel describes it: “The excursion lasted over two years. Along the way they confronted harsh weather, unforgiving terrain, treacherous waters, injuries, starvation, disease and both friendly and hostile Native Americans. Nevertheless, the approximately 8,000-mile journey was deemed a huge success and provided new geographic, ecological and social information about previously uncharted areas of North America.”

And today we complain about trying to squeeze our carry-ons into the overhead bin.

Americans have always loved to “go for a ride” — with whatever mode of transportation existed. Horses. Boats. Bicycles. And of course, the ubiquitous car. The nation had a long love affair with automobiles starting in the mid 20th century and lasting until recently — as a new generation of car buyers, born after the car craze, loses interest in design — focusing instead on practicality. Stellar gas mileage makes Priuses as sexy as Porsches. Well, almost.

Go For A Ride Day timeline

1950s Car culture

Cars inspired new businesses like drive-through restaurants and drive-in movie theaters, and employed one in six working Americans.

1956 Interstate highways

President Eisenhower authorizes $25 billion for the construction of 41,000 miles of the Interstate Highway System.

1964 ‘Pony car’

Ford introduces the sporty and powerful Mustang — the automaker's most successful launch since the Model A.

2019 Driverless cars get smarter

MIT engineers develop a system to help autonomous cars determine if there’s a moving object coming around the corner.

Go For A Ride Day FAQs

What does Go For A Ride Day celebrate?

Go For a Ride Day 2019 encourages us to get out in the world, as opposed to seeing it on a screen. Any mode of transportation will do on this day. What was America’s first car company?

Brothers Charles and Frank Duryea founded the Duryea Motor Wagon Company in 1893, becoming the first American automobile manufacturing company. What happened to supersonic jet travel?

The Concorde, which flew faster than the speed of sound, never turned a profit. When the plane broke the sound barrier (about 760 mph), it created shock waves that would hit the ground with a loud and sudden sonic “boom.” The FAA eventually banned all commercial aircraft from flying at supersonic speeds over land.

Go For A Ride Day Activities

Make it fun

Make it easy

Make it memorable

Dare yourself to try something new and adventurous. Why not try a mode of transportation you’ve never used before? Suggestions include jet skiing, parasailing, or going on a hot air balloon ride. In colder climates you could try a sleigh ride, or a horse drawn carriage.

Maybe you weren’t born to be wild, but don’t let that stop you from joining in the fun. Play tourist in your own city or neighborhood. Use public transit and see the sights like visitor.

Exploring is an adventure, but it can be even more fun if you have someone to share it with. Bring along an adventurous friend or family member to help make some memories. If your local friends are sticks in the mud, then bring your more adventurous friends along virtually by posting your adventure to Facebook, Instagram, or Twitter.

Why We Love Go For A Ride Day

It’s an escape from reality

It can be great exercise

It helps us be spontaneous

Every now and then we just need something to break up the status quo and make us feel alive! Go For A Ride Day exists for that very reason. It can be hard to get motivated to see new places or even try new foods, but Go For A Ride Day provides the momentum.

You can try skateboarding or using a scooter. How about getting out your helmet and going for a long bike ride? Did you know you can burn over 400 calories an hour horseback riding?

Our lives tend to run to the predictable, and for the most part, that predictability helps the world go round. But we all still have a small streak of rebellion, and that's what Go For a Ride Day helps bring out.

Source

#Banff National Park#Fort Vermillion#Glacier National Park#USA#rental car#summer 2024#Sweden#original photography#travel#road trip#vacation#Chevrolet Suburban#Chevrolet Tahoe#Canada#Go For a Ride Day#22 November#NationalGoForARideDay#Ford Expedition#Jeep Wagoneer#street scene#Yellowknife#Edmonton#Oregon#Alberta#Northwest Territories#Idaho#Montana#California#Nevada#Yukon

5 notes

·

View notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

Discover the Strength and Versatility of GI Flange

Q1: What are the key processes involved in the manufacture of GI flanges?

A: The key processes in the manufacture of GI flanges include:

Material Preparation: Raw materials like steel plates or sheets are cut to size.

Forming: The material is shaped into the flange design using processes like stamping or forging.

Welding: If needed, flanges may be welded to create specific designs.

Galvanization: The flanges are coated with zinc through hot-dip galvanization or electro-galvanization to enhance corrosion resistance.

Finishing: Final finishing processes include cleaning, inspection, and surface treatment to ensure quality.

Q2: Which materials are typically used in the production of GI flanges?

A: The primary material used in the production of GI flanges is carbon steel, which is coated with zinc to provide corrosion resistance. Depending on specific requirements, other materials such as stainless steel may also be used.

Q3: How do manufacturing standards affect the quality of GI flanges?

A: Manufacturing standards, such as ASTM, ANSI, and ISO, provide guidelines for the design, material specifications, and testing of GI flanges. Adhering to these standards ensures consistency, reliability, and safety in the final product, significantly affecting its overall quality.

Q4: What industries commonly utilize GI flanges?

A: GI flanges are commonly used in various industries, including:

Construction

Oil and gas

Water and wastewater treatment

HVAC (Heating, Ventilation, and Air Conditioning)

Shipbuilding

Q5: Can you customize GI flanges according to specific project requirements?

A: Yes, GI flanges can be customized based on specific project requirements, including size, thickness, pressure rating, and design specifications, to meet the needs of different applications.

Q6: What certifications should a manufacturer of GI flanges have?

A: A manufacturer of GI flanges should ideally have certifications such as:

ISO 9001 (Quality Management System)

ISO 14001 (Environmental Management)

API (American Petroleum Institute) certifications for oil and gas applications

Other industry-specific certifications as required.

Q7: How does the manufacturing process ensure corrosion resistance in GI flanges?

A: Corrosion resistance is ensured through the galvanization process, where flanges are coated with zinc, which serves as a sacrificial anode. This protects the underlying steel from rust and corrosion when exposed to moisture and other corrosive elements.

Q8: What are the advantages of using GI flanges over other types of flanges?

A: The advantages of using GI flanges include:

Cost-Effectiveness: Generally less expensive than stainless steel flanges.

Corrosion Resistance: The zinc coating provides excellent protection against rust.

Versatility: Suitable for a wide range of applications and environments.

Strength and Durability: Good mechanical properties make them reliable under pressure.

Q9: How does the cost of manufacturing GI flanges compare to other flange types?

A: The cost of manufacturing GI flanges is typically lower than that of stainless steel or other specialty flanges, primarily due to the lower cost of raw materials and the manufacturing processes involved.

Q10: What quality control measures are in place during the manufacture of GI flanges?

A: Quality control measures during the manufacture of GI flanges may include:

Regular inspections and testing of raw materials.

In-process inspections to ensure dimensional accuracy and adherence to specifications.

Testing for corrosion resistance, mechanical strength, and other relevant properties.

Final product inspections before shipment to ensure compliance with standards and customer specifications.

#GIFlanges#GalvanizedIron#IndustrialFlanges#SteelManufacturing#CorrosionResistance#FlangeManufacturing#ConstructionMaterials#MSMEs#QualityControl#B2BIndustry#PipeFittings#FlangeDesign#ManufacturingStandards#EngineeringSolutions#CustomFlanges

2 notes

·

View notes

Text

I think an interesting place in terms of historical preservation is fayette, mi. they still have some of the shacks that the lowest level workers lived in, but the other things they have are really scattershot. they were smelting iron ore up there from 1867-1891 and shipping it out across lake michigan so it was quite a manufacturing hub at the time. it even had a hotel with hot water and an outhouse on stilts so guests staying on the second floor could cross to it via covered walkway. but mining dried up and the town died and eventually became a state park

the hotel exterior is maintained quite well but they only have two rooms you can go inside and only one is decorated

the former general store is still standing after burning down at least once but this is the level to which they've been able to restore it

there's places like this all over the world, right. they boomed due to an industry that fell apart and the town crashed along with it. some of them get preserved and rebuilt and become tourist destinations. and some of them don't really. in fayette's case the closest town (30 miles away) of any size is manistique and that size is 2000 people. the largest city in the peninsula, marquette (20,000 people) is 90 miles away

you have to be pretty serious about seeing fayette to go there. so this fascinating snapshot of the past is kind of limping along bc they're not THAT unique and they're very hard to get to for most vacationers

but governor whitmer is giving them 6 million dollars so that's something

5 notes

·

View notes