#Hazardous materials

Explore tagged Tumblr posts

Text

"An environmental toxicologist in California is cleaning up areas contaminated with heavy metals or other pollutants using fungi and native plants in a win-win for nature.

Where once toxic soils in industrial lots sat bare or weed-ridden, there are now flowering meadows of plants and mushrooms, frequented by birds and pollinators: and it’s thanks to Danielle Stevenson.

Founder of DIY Fungi, the 37-year-old ecologist from UC Riverside recently spoke with Yale Press about her ongoing work restoring ‘brownfields,’ a term that describes a contaminated environment, abandoned by industrial, extraction, or transportation operations.

A brownfield could be an old railway yard or the grounds of an abandoned oil refinery, but the uniting factor is the presence of a toxic containment, whether that’s a petrochemical, heavy metal, or something else.

Noting that she had read studies about mushrooms growing around the Chernobyl nuclear plant, she came to understand further, through her work, that fungi are an extraordinarily resilient species of life that consume carbon, and even though petroleum products are toxic to plants, to mushrooms they are essentially a kind of carbon.

In fact, mushrooms break down several categories of toxic waste with the same enzymes they use to consume a dead tree. They can also eat plastic and other things made out of oil, like agrochemicals.

At the Los Angeles railyard, as part of a pilot project, Stevenson and colleagues planted a variety of native grass and flower species alongside dead wood that would incubate specific fungi species called arbuscular mycorrhizal fungi, which assists plants in extracting heavy metals like lead and arsenic from the soil.

Alongside traditional decomposer fungi, the mixture of life forms demonstrated tremendous results in this brownfield.

“In three months we saw a more than 50 percent reduction in all pollutants. By 12 months, they were pretty much not detectable,” Stevenson told Yale 360.

Decontaminating soil like this typically involves bringing in a bulldozer and digging it all up for transportation to a landfill. This method is not only hugely expensive, but also dangerous, as contaminated material can scatter on the winds and fall out of the backs of trucks carting it away.

By contrast, the plants that draw out the toxic metals can be harvested and incinerated down to a small pile of ash before cheap transportation to a hazardous waste facility.

The technique, which Stevenson says has some scaling issues and issues with approval from regulators, is known officially as bioremediation, and she’s even used it to safely break down bags of lubricant-soaked rags from bicycle repair shops.

“People who live in a place impacted by pollution need to have a say in how their neighborhood is being cleaned up. We need to empower them with the tools to do this,” she said."

-via Good News Network, July 16, 2024

#mushrooms#fungi#mycology#mushroom#contamination#bioremediation#hazardous waste#hazardous materials#soil#mining#heavy metals#good news#hope#ecopunk#solarpunk

1K notes

·

View notes

Text

"La Porte city spokesperson Lee Woodward told KTRK-TV that they don’t yet know what flows through the pipeline or how it will be shut down. People in nearby schools were told to shelter in place as law enforcement blocked off a wide area."

source 1

source 2

source 3

#destiel meme news#destiel meme#news#united states#us news#pipeline#toxic substances#deadly fires#oil? gas? we don't know yet so i can't tag fully#hazardous materials#evacuation#houston#texas#la pointe#harris county#san jacinto#stay safe y'all#will update i guess as we know more

152 notes

·

View notes

Text

Several train cars are immersed in the Yellowstone River after a bridge collapse near Columbus, Mont., on June 24, 2023.

40 notes

·

View notes

Text

Other websites: *generic product ad* *political ad for a party that wants me dead* *sexist mobile game ad*

Tumblr:

2 notes

·

View notes

Link

2 notes

·

View notes

Text

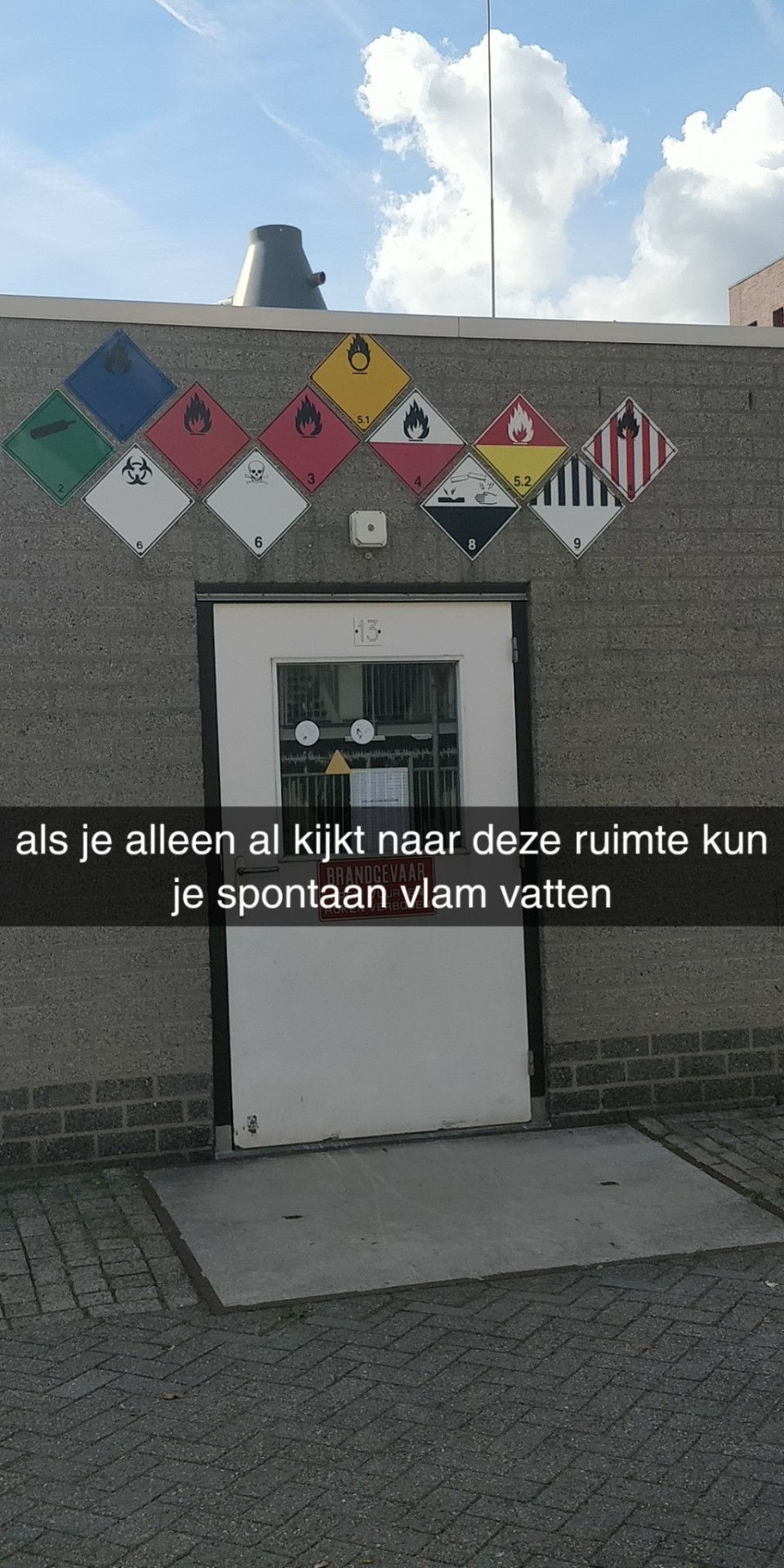

From left to right, the GHS Transport Pictograms read:

Green 2 gas tank: Non-toxic non-flammable gas.

Blue 4 flame: Substances which in contact with water emit flammable gases.

White 6 biohazard: Infectious substances

Red 2 flame: Flammable gases

White 6 skull: Toxic substances with an LD50 value ≤ 300 mg/kg (oral) or ≤ 1000 mg/kg (dermal) or an LC50 value ≤ 4000 ml/m3 (inhalation of dusts or mists)

Red 3 flame: Flammable liquids

Yellow 5.1 O-flame: Oxidizing substances

White-top red-bottom 4 flame: Substances liable to spontaneous heating under normal conditions encountered in transport, or to heating up in contact with air, and being then liable to catch fire

White-top black-bottom 8: Corrosive substances, "which cause full thickness destruction of intact skin tissue on exposure time of less than 4 hours; or exhibit a corrosion rate of more than 6.25 mm per year on either steel or aluminium surfaces at 55 °C"

Red-top yellow-bottom 5.2 flame: Organic peroxides

Striped-top white-bottom 9: Miscellaneous dangerous substances and articles

Red-and-white striped 4 flame: Flammable solids, self-reactive substances and solid desensitized explosives, "which, under conditions encountered in transport, are readily combustible or may cause or contribute to fire through friction; self-reactive substances which are liable to undergo a strongly exothermic reaction; solid desensitized explosives which may explode if not diluted sufficiently"

These are similar to, but not exactly identical to, the US DOT placards.

In conclusion: About the only boxes this does not check are "explosive" and "radioactive". Probably do not use water to extinguish this building. Maintain a safe distance. Stay upwind.

caption translation: "just looking at this building can make you spontaneously combust"

3K notes

·

View notes

Photo

What Happens If You Mix Bleach and Vinegar?

#bleach#vinegar#bleach reaction#vinegar reaction#chemical reaction#cleaning tips#safety tips#home remedies#hazardous materials#midjourney#ai

0 notes

Text

When it comes to demolition, numerous factors must be considered to ensure a smooth and safe process. Whether you’re tearing down an old structure to make way for new construction or clearing out space, following these dos and don’ts can make a significant difference.

0 notes

Text

Hazardous Materials Shipping Frankfurt

Our Hazardous Materials Shipping Frankfurt service is designed to meet all your needs for transporting dangerous goods safely and efficiently. With our experienced team, state-of-the-art equipment, and adherence to all regulations, you can trust us to handle your hazardous materials with the utmost care and attention to detail.

Visit us at https://www.emexexpress.de/agent

#Hazardous Materials Shipping Frankfurt#Hazardous Materials Shipping#Hazardous Materials#Materials Shipping Frankfurt#germany

0 notes

Text

Hoarding can present significant challenges for property managers overseeing apartment buildings in Maryland. In such cases, enlisting professional hoarder cleanup services is crucial to restoring residential properties to safe and habitable conditions. These services specialize in efficiently clearing clutter and hazardous materials, ensuring compliance with real estate regulations, and maintaining property value.

0 notes

Text

Biological Safety Cabinets: An Essential Piece of Equipment for Microbiological Laboratories

Biological Safety Cabinets Microbiological safety cabinet, also known as biosafety cabinets, are essential equipment used in microbiological laboratories to protect researchers, laboratory personnel, and the environment from exposure to infectious agents. There are three main classes of microbiological safety cabinet - Class I, Class II, and Class III - with Class II being the most commonly used type in academic and pharmaceutical laboratories. Each class has different features and protection levels depending on the types of procedures being conducted. Class I Biological Safety Cabinets Class I microbiological safety cabinet, also called biosafety cabinets class I, provide personnel and environmental protection but no product protection. Airflow in Class I cabinets is drawn through the work area and directed out through an exhaust plenum. This design provides protection from microorganisms suspended in the air inside the cabinet. However, the cabinet offers no barrier between the product and sterile internal environment. As such, Class I cabinets are typically used for work that does not require product protection, such as for storage of non-hazardous material or preparation of low to moderate risk biological agents. Class II Microbiological safety cabinet Class II microbiological Biological Safety Cabinets come in Type A1, A2, B1, and B2 configurations with varying degrees of personnel, environmental, and product protection. All Class II cabinets provide heated, HEPA-filtered air to the work zone that separates the work from the external environment. The downward laminar flow provides product and environmental protection by preventing contamination of the work surface and material inside the cabinet. Class II Type A1 and A2 cabinets draw 70% of the filtered air across the work area and 30% across the HEPA filters at the rear grill. These types are suitable for low to moderate risk biohazardous work. Class II Type B1 and B2 cabinets re-circulate over 70% of the air through additional HEPA filtration for enhanced containment and are used for more hazardous manipulations. Class III Microbiological safety cabinet Class III microbiological safety cabinet, also known as glove boxes or laminar flow biosafety cabinets class III, provide the highest level of containment. They are completely enclosed with closed front, HEPA-filtered inlet, and HEPA-filtered exhaust air that passes through two sets of HEPA filters or highefficiency particulate absorption (HEPA) filters. The user manipulates materials inside the cabinet through attached rubber gloves that are permanently sealed to the access ports or openings in the cabinet. Class III cabinets are specifically designed for work with agents requiring Biosafety Level 4 practices and containment, such as highly pathogenic microbes that pose a high risk of life-threatening disease. Certification of Microbiological safety cabinet Ensuring proper installation and operation of microbiological safety cabinet is critical for personnel and environmental protection. As such, all microbiological safety cabinet must undergo certification upon installation to verify correct airflow patterns and HEPA filter integrity. Routine recertification is typically required annually to certify the cabinet is functioning as intended. The certification process involves smoke studies, inflow velocity measurements, and HEPA filter leak tests to National Sanitation Foundation (NSF) standards. Properly certified and maintained microbiological safety cabinet provide the highest level of protection for laboratory personnel working with biohazardous materials. Get more insights on Biological Safety Cabinets

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Biological Safety Cabinets#Containment#Laboratory Safety#Biosafety#Hepa Filter#Clean Air#Sterile Environment#Hazardous Materials#Ventilation System

0 notes

Text

Python: Extract UNSPSC from a PDF

Using the UNSPSC (United Nations Standard Products and Services Code) to identify hazardous materials is beneficial because it provides a global classification system that is standardized and consistent. This system facilitates the identification and categorization of products and services, including hazardous materials. Please note that the data source may contain information that is not…

0 notes

Text

The Ultimate Guide to Asbestos Removal: Everything You Need to Know

Asbestos, once hailed for its fire-resistant and insulating properties, is now recognized as a hazardous material linked to serious health risks when its fibers are inhaled. If your property contains asbestos-containing materials (ACMs), proper removal is essential to mitigate health hazards and ensure compliance with safety regulations. This comprehensive guide covers everything you need to know about asbestos removal, from testing to disposal.

Understanding Asbestos

Asbestos is a naturally occurring mineral fiber used extensively in construction materials before its health risks were widely known. Common applications include insulation, roofing materials (asbestos roof), floor tiles, and textured paints. There are two main types of asbestos: friable (easily crumbled) and non-friable (bonded within a material).

Health Risks

Exposure to asbestos fibers, particularly when disturbed during renovations or demolition, can lead to severe respiratory diseases such as lung cancer, asbestosis, and mesothelioma. These diseases often develop years after exposure, making early detection and safe removal critical.

Asbestos Testing

Before any renovation or demolition work, especially in older buildings, it’s crucial to conduct asbestos testing. Licensed professionals collect samples of suspected ACMs and send them to accredited laboratories for analysis. Testing identifies the presence of asbestos and determines its type and condition.

Licensing and Regulations

Asbestos removal is heavily regulated to protect public health and safety. In most regions, contractors must hold specific licenses for asbestos removal. They must comply with strict protocols for containment, removal, and disposal of asbestos waste, ensuring it does not become airborne and contaminate other areas.

Choosing an Asbestos Removal Company

Selecting a reputable asbestos removal company is essential. Look for firms with proven experience, proper licensing, and adherence to safety regulations. They should offer comprehensive services, including asbestos testing, containment, removal, cleanup, and final clearance testing.

Safety Measures

During asbestos removal, strict safety measures must be followed. Workers should wear appropriate personal protective equipment (PPE) and use specialized tools to minimize fiber release. Containment barriers and negative air pressure systems prevent asbestos fibers from spreading to uncontaminated areas.

Removal Process

The removal process varies depending on the type and condition of asbestos. Friable asbestos is more hazardous and requires meticulous handling. Non-friable asbestos may be encapsulated or removed intact, following specific procedures to prevent fiber release.

Disposal of Asbestos Waste

Asbestos waste is categorized as hazardous material and must be disposed of according to local regulations. Licensed removal companies transport asbestos waste in sealed containers to approved disposal sites. Proper disposal prevents environmental contamination and protects public health.

Post-Removal Inspection and Clearance

After asbestos removal, a licensed inspector conducts a thorough visual inspection and air monitoring to ensure all asbestos fibers have been effectively removed. Clearance certificates are issued upon satisfactory results, confirming the area is safe for reoccupation or renovation.

Asbestos Awareness and Prevention

Educating homeowners, contractors, and workers about asbestos risks and safe handling practices is crucial for prevention. Regular inspections of older buildings and prompt asbestos removal when necessary help reduce exposure risks.

Conclusion

Asbestos removal is a complex process requiring expertise, adherence to regulations, and a commitment to safety. Proper planning, including asbestos testing, choosing a licensed removal company, and following stringent safety protocols, ensures effective removal without compromising health or environmental safety. By understanding the risks associated with asbestos and taking proactive measures, property owners can safeguard occupants and maintain compliance with regulatory requirements. Always consult with qualified professionals for asbestos-related concerns to ensure safe and effective mitigation of this hazardous material.

#asbestos removal#professional asbestos removal#asbestos roof#asbestos services#removal services#hazardous materials#health

0 notes

Text

3 Mistakes to Avoid When Shipping Hazardous Materials

Shipping hazardous materials safely requires careful planning. It can be tricky, which is why we at GFFCA, experts in specialized freight shipping, have put together a list of three big mistakes you should avoid:

Common Mistakes in Shipping Hazardous Materials

Here are some common mistakes people make when Hazardous goods shipping:

Not Labeling Hazardous Materials Correctly

A frequent mistake is not labeling the packages that contain hazardous materials properly. It’s important to clearly mark these packages so that everyone handling them knows they contain dangerous goods. For example, if you’re sending flammable liquids, you need to label the package as “Class 3 hazardous materials” and include any special handling instructions. Failing to do this can be dangerous and might even cause your shipment to be turned away. Always take the time to label everything clearly.

Assuming Something is Not Hazardous

There are nine different categories of hazardous materials, and many items fall into these categories. Sometimes, people handling shipments might not check if an item is hazardous or might assume it’s safe when it’s not. This can lead to serious fines if you’re caught shipping these as regular items.

Some commonly overlooked hazardous items include:

*Magnetized materials

*Lithium batteries

*Dry ice

*Samples from patients

*Pneumatic accumulators

*Scientific instruments with gases

*Engines with leftover fuel

*Charged capacitors

Choosing the Wrong Way to Ship

Some hazardous materials need to be kept at a certain temperature-controlled shipping. If this is the case, you should use a temperature-controlled truck instead of a regular truck to prevent any risks due to temperature changes. It’s best to work with a professional shipping company to make sure your goods are transported safely and correctly.

To learn more about how to ship hazardous materials and other shipping services we offer, please contact GFFCA through our online contact form. Our team is here to help you find the best shipping solutions for your needs.

#logistics company in canada#logistics company#freight forwarders near me#hazardous goods shipping#hazardous materials#ocean frieght services#sea freight forwarder#LCL Shipping Canada#cargo logistics#freight international services#freight forwarding solutions#freight forwarding company#cargo logistics canada#global freight solutions

0 notes

Text

Shipping ammunition within the United States involves several considerations and regulations to ensure the safe and legal transport of these potentially hazardous materials. As a trusted ammunition manufacturer in Las Vegas, Nevada, we strive to be compliant not just as a duty to our country but as part of our commitment to our patrons.

0 notes