#Graphene Aerogel

Explore tagged Tumblr posts

Text

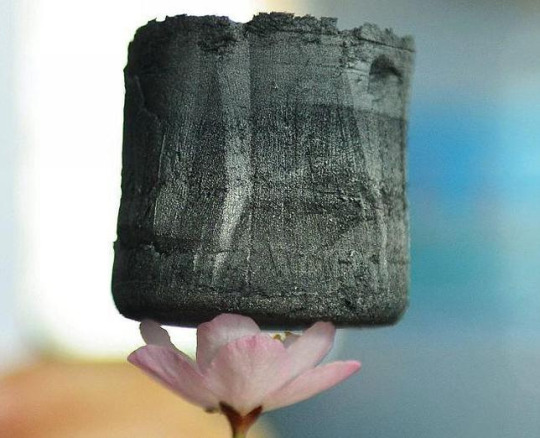

Graphene Aerogel is so light that a cubic inch of the material can be balanced on a blade of grass, the stamen of a flower, or the fluffy seed head of a dandelion.

2K notes

·

View notes

Link

The preparation method of gradient graphene aerogel with melamine foam as the skeleton is not only simple and easy, but also green and environmentally friendly. This mechanism not only improves the evaporation rate, but also enhances the salt collection efficiency, providing strong support for zero liquid discharge desalination.

#zero liquid discharge desalination#melamine foam#graphene aerogel#solar evaporator#gradient graphene aerogel

0 notes

Text

Types of Fillers in Construction

Introduction Fillers play a pivotal role in construction, providing stability, strength, and insulation. Their selection is critical, affecting the cost, durability, and environmental impact of a project. This article delves into the various types of fillers utilized in the construction industry. 1. Natural Fillers Natural fillers like sand, gravel, and stone are ubiquitous in construction due to…

View On WordPress

#aerogel insulation in construction#carbon fiber for structural reinforcement#composite fillers in construction#construction aggregate materials#construction filler selection guide#construction fillers#construction industry standards for fillers#construction material innovation#cost-effective fillers for construction#durable fillers for construction#eco-friendly construction fillers#EPS beads in construction#fiber-reinforced concrete#fiberglass in concrete#fly ash concrete filler#graphene in building materials#insulation panels in construction#lightweight construction fillers#mineral fillers in concrete#natural fillers in construction#organic fillers for construction#silica fume in construction#specialty construction fillers#sustainable building materials#synthetic fillers for building#thermal insulation fillers#types of construction fillers

2 notes

·

View notes

Photo

AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAA

Graphene aerogel supported by flower petals and stamens

#Graphene#aerogel#that weight is measured in tenths of a gram#It might have more air than not air#Materials Science#Density#Structure rigidity#banji-effect

4K notes

·

View notes

Text

Scientific funfact!

There's a certain metal that's the lightest material on earth! It's called Graphene Aerogel and it's 7 times lighter than air. Lighter than air. When I learned that, it broke my brain for some time to be honest, now you needed to learn it too!

12 notes

·

View notes

Text

Some more Hellopaint funnies + A Comet I forgot to ever post?

small thing but i personally hc MC Music Man to have the same speech pattern/voice(?) as The President in the Shadow the Hedgehog snapcube fandub

A fun dichotomy i see is that I see DJMM as sounding like Alfred's performance as Eggman but MCMM as his performance as The President

Daddy Long Legs lookin ass

He's indestinguishable from the night sky on account of the fact that he's like vantablack and absorbs all light that hits him - That and being crazy bright during the daytime that he seems to have no shadows, either. The outlines don't actually exist on him, and are purely just for visualizing what he looks like.

Despite him being, like, A Comet, I don't have a lot of thought into him biologically? He's just an entity. There's a lot of weirdness to him, like, if he is discovered (and doesn't want to be), he scares off the discoverer by making it appear that it's very quickly changing from day to night and screaming at them, and the fact that he is so light, he often makes it harder to find his shape by walking on the tops of trees, barely making them bend under his miniscule weight like he's a massive hunk of graphene aerogel.

He can also kind of walk/sit on water, which is a little important since during the daytime he walks out into the ocean so that there's nothing but more water and sky in the horizon.

Fritz in this AU is an astronomer who discovered him when he opened one of his eyes right into the lens of his telescope, and studied him further when he realized that Comet's "night sky disguise" actually is an identical projection of outer space. It eventually gets romantical

#ntls-24722#djmm#dj music man#music man#fnaf dj music man#Comet#Fritz#(almost) daily music man#digital

26 notes

·

View notes

Text

Hukam, Bathinda

25/11/2023 Sat, 12.11am

Gyaan ki Baat,

Graphene aerogel is very light weighted in the world. Which seven times lighter than air. In its per cubic centimetre the weight is only .16mg

3 notes

·

View notes

Text

The Evolution of Bags And How They Shaped Status and Style

Bags are more than an accessory — they exemplify human ingenuity shaped by artistry, innovation, and cultural shifts. Centuries of refinement have metamorphosed rudimentary pouches made from animal hides into ultra-modern designs that integrate high-performance fibers and space-age composites. The stitch and the material you see today have a backstory of progress, necessity, fashion, and technology.

The earliest bags were created out of necessity. Early humans fashioned pouches from rawhide, animal intestines, and plant fibers to ensure essential tools and provisions remained within reach.

Leather, prized for its durability and flexibility, became a material of choice across civilizations. Ancient Egyptian hieroglyphs depict men carrying leather pouches, while in medieval Europe, tanned leather coin purses were indispensable to commerce. Today, leather remains a hallmark of quality and longevity, refined through centuries of tanning and craftsmanship.

As weaving techniques advanced, fabric became an essential material for bags. The 18th and 19th centuries saw the rise of embroidered silk reticules for women and sturdy canvas sacks for soldiers and laborers. Cotton and linen, lightweight and versatile, became staples for travel bags and luggage — a shift that brought function and aesthetics together in new ways.

The Industrial Revolution ushered in a new era of materials. Rubberized cloth, oilcloth, and waxed canvas introduced water-resistant properties that increased bag durability.

The 20th century saw the advent of synthetic materials — Nylon, introduced by DuPont in 1938, revolutionized the industry by making bags lighter, stronger, and more affordable. By the mid-century, polyester and PVC became dominant, which made durable and cost-effective bags more widely available.

Even as synthetics gained popularity, natural fibers remained integral to bag-making. Jute, hemp, and cotton continued to be widely used for their sustainability and biodegradability. Raffia, derived from palm leaves, has been woven into intricate bags for centuries, while cork, harvested from tree bark, offers a lightweight and water-resistant alternative to leather. More recently, mycelium-based leather — grown from fungi — has emerged as a promising eco-friendly substitute that offers both sustainability and the texture and durability of traditional leather.

Luxury brands have long relied on rare and exotic materials to set their designs apart. Crocodile, ostrich, and python skins have been used to create high-end bags, their unique textures symbolizing status and exclusivity. However, with increasing ethical concerns, alternatives like high-grade vegan leather and lab-grown materials have gained traction, offering a cruelty-free yet equally sophisticated option for luxury consumers.

Recent decades have brought unprecedented advancements in materials. Dyneema, an ultra-high-molecular-weight polyethylene known as the world’s strongest fiber, is now used in ultra-lightweight adventure backpacks. Carbon fiber, once reserved for aerospace engineering, has entered high-end bag designs with an unmatched strength-to-weight ratio. Cutting-edge innovations like aerogel-infused textiles, graphene-coated fabrics, and self-repairing polymers have redefined bags from mere carriers to adaptive, high-performance accessories.

A well-made bag relies on more than just its primary material. Canvas, denim, vinyl, and waterproof linings enhance durability and function. Polypropylene and fabric protective sprays increase longevity while interfacing strengthens the structure. Key hardware elements such as D-rings, magnetic snaps, sliders, rivets, and zippers add to the functionality. Webbing and reinforced bases add structural integrity. Even embellishments and bag labels affect the final product, which blends aesthetics with practicality.

Beyond materials, the structural integrity of a bag relies on precise construction techniques. Twist-lock closures, known for their secure fastening and stylish appeal, have become a mainstay in high-end bags. The reinforced bottom, often combined with wear rivet design, adds durability so the bag retains its shape and resists wear over time. Oil edge technology, a specialized finishing process, increases the leather’s resilience against fraying and moisture.

Various closure mechanisms serve different aesthetic and functional purposes. Hasp closures provide a classic, secure fastening for structured bags, while zippers ensure quick accessibility. Magnetic snaps offer a seamless and convenient opening system, and drawstring closures provide flexibility and ease for casual bags. Each closure type is carefully chosen to balance security, usability, and design aesthetics.

Sustainability is now at the forefront of bag design. Mycelium leather, biodegradable polyesters, and algae-derived fibers are paving the way for a more eco-conscious industry.

Smart bags, equipped with tracking chips, solar panels, and modular compartments, are redefining convenience in everyday carry. The global handbag market, valued at over $50 billion, continues to grow, with a projected annual increase of 6%, driven by the demand for sustainable and technologically advanced solutions.

If history is any indicator, the next evolution in bag design will be shaped by materials not yet fully realized. Could nanotechnology create self-cleaning fabrics? Will AI-integrated bags anticipate user needs before they arise? The evolution of bags is far from complete — just as human ingenuity continues to push boundaries, so too will the materials that define the way we carry our world.

#rareklub#travelbags#fashionbags#designer bags#bags for women#bagstyle#bags & purses#fashion#bags#america#usa#explore#blog#trending#trend#follow

1 note

·

View note

Text

Graphene Aerogels https://www.graphenemex.com/en/solutions-with-graphene/graphene-oxide/graphene-aerogels/

0 notes

Text

Now to make ships more buoyant, and also bringing down the weight of cargo containers as well as the packaging that goes around a product and you can make the packaging heat resistant as well as water resistant and lighter than air!!! Doing this trains planes, cargo ships. Semi trucks can carry more weight.And news overall less fuel!!!! Now putting this in seats of planes in seats of trains and other things, our cars, we can reduce the weight of a vehicle.We can reduce the weight of a semi.We can reduce the weight of a ship.We can reduce the weight of a plane... so making it multiple times lighter than air can help reduce the weight of a building... So this allows you to go taller in the building without having to increase the overall strength of the foundation... But this also makes the building more stable... So there are many applications to this, but let's think about ships and putting this in between the hall and a ship to make it more buoyant. Think about putting this in a cargo container in between the material, the interior and exterior panels of a cargo container, making the cargo containe Lighter than air!!! But also, you can see that the packaging can be incredibly waterproof making the cargo container waterproof airproof fireproof and I'll add the videos!!!! This is a way to increase fuel economy of cars, planes, trains, and so on, so we can bring consumption down, and that will make things much better reducing global warming and helping us reduce our footprint on the surface of the Earth and we can do this with clothing as well, and it will help humans. Feel less effect of gravity, and especially for seniors taking gravitational pressure, offer them... So this will help slow down aging!!

A new packaging material currently considered "lighter than air" is called aerographene, a type of graphene aerogel, which is considered the least dense solid material known, meaning it is significantly lighter than air itself; with some sources stating it can be up to six times lighter than air.

Key points about aerographene:

Extremely low density:

Aerographene has a density of around 160 grams per cubic meter, making it incredibly lightweight.

Composition:

It is made from graphene, a single layer of carbon atoms, arranged in a highly porous structure.

Potential applications:

Due to its lightweight nature, aerographene is being explored for use in insulation, aerospace applications, and potentially even as a packaging material.

Living on Earth: Science Note: Aerographite

Aug 10, 2012

Living on Earth

https://youtu.be/pDLEvALCY70?si=DBvMhR5kXIWbLr9n

So here is what this material can do, and we can use this to make incredible packaging to waterproof and fire resistance, and so on and so forth and incredible insulation, it can resist extreme cold, it can resist extreme heat!! And it's also incredibly lightweight!!

https://youtu.be/AeJ9q45PfD0?si=z39-Chr5FfjFsfsL

https://youtu.be/Qa-tTMJ8fkA?si=Mas4uOA2TdQQ67ci

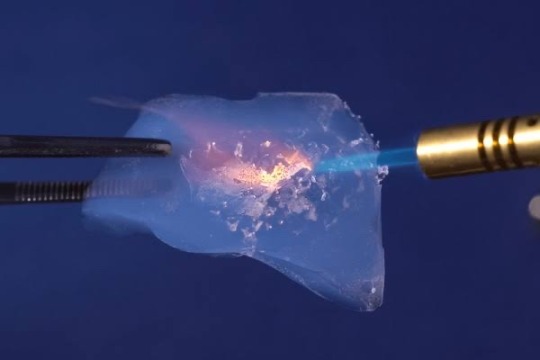

The maximum heat resistance of aerogel depends on its composition, but generally, most silica-based aerogels can withstand temperatures up to around 650°C (1200°F) before starting to sinter (densify), while specialized high-temperature aerogels made from materials like zirconia or alumina can reach much higher temperatures, even exceeding 1000°C depending on the specific formulation.

Key points about aerogel heat resistance:

Standard silica aerogel: Typically reaches its maximum operating temperature around 650°C.

Composite aerogel blankets: Can handle higher temperatures due to their design, with some reaching up to 650°C.

Advanced materials: Aerogels made from materials like zirconia or polyimide can withstand temperatures up to 1000°C or more.

Aerogel vs. Vacuum Insulation | Insulon® Technology

Jul 29, 2019 — Maximum operating temperatures for aerogel materials can vary. Silica-based aerogels and composite pyrogels operate until about 650°C. Airloys have ...

Concept Group LLC

Currently, silica aerogels can withstand temperatures up to 1500 °C, and their thermal conductivity at room temperature is as low as 0.014 W/(m·K).Apr 23, 2024

https://pmc.ncbi.nlm.nih.gov › PM...

A Review of High-Temperature Aerogels: Composition ...

Maximum operating temperatures for aerogel materials can vary. Silica-based aerogels and composite pyrogels operate until about 650°C.Jul 29, 2019

https://conceptgroupllc.com › high-...

Aerogel vs. Vacuum Insulation | Insulon® Technology

By selecting adhesives suitable for high temperatures, the aerogel insulation can be used up to ~320 °C.

https://www.gore.com › products

Aerogel Insulation for Better Thermal Protection - Gore

See making air freight lighter, but also this can be used in the liner of the plane for heat protection, protecting it from cold or heat, but also making the plane the wings the whole body of the plane lighter, then air itself. That means planes can take off and land they fly using less fuel!!!

YouTube · Logistics Insider

40+ views · 1 year ago

Making Air Freight Lighter: Innovation and Technology trims down ...

4:10

Making Air Freight Lighter: Innovation and Technology trims dow

3BL Media

https://www.3blmedia.com › news

Meet the New FedEx Efficient Containers. Lighter design. Less ...

Oct 3, 2013 — Efficient containers, which begin service with our maiden 767 flight later this month, will be significantly lighter than the models currently in our network.

To create an airframe lighter than air, you would need to design a structure that can be filled with a gas less dense than the surrounding air, like helium or heated air, which creates buoyancy and allows the craft to float, essentially acting like a large balloon with a controlled frame; this type of aircraft is commonly called an airship, blimp, or dirigible depending on its design and rigidity.

Key elements of a lighter-than-air airframe:

Lifting Gas Envelope:

A large, flexible or rigid container made from lightweight materials like fabric or composite materials designed to hold the lifting gas (helium is preferred due to its non-flammable nature).

Gondola or Cabin:

A separate compartment within the airship where passengers or cargo are housed, with necessary controls and equipment.

Structural Framework:

A supporting structure (rigid in a dirigible, flexible in a blimp) that maintains the shape of the envelope and provides stability.

Propulsion System:

Motors and propellers for controlled movement and steering.

Challenges in building a lighter-than-air airframe:

Gas Management: Ensuring the lifting gas remains contained and doesn't leak.

Weather Dependence: Sensitivity to wind conditions and potential for large-scale movement with changing weather patterns.

Payload Capacity: Balancing the weight of the structure and payload with the lifting capacity of the gas.

Examples of lighter-than-air vehicles:

Hot Air Balloon: A simple lighter-than-air craft where hot air is used as the lifting gas.

Blimp: A non-rigid airship with a flexible envelope.

Zeppelin: A rigid airship with a strong internal framework.

2:12

Lift: Lighter Than Air Aircraft (How Things Fly Demonstration)

YouTube ·

Smithsonian National Air and Space Museum

Lighter than air aircraft!!!

YouTube · Smithsonian National Air and Space Museum

3.4K+ views · 4 years ago

Lift: Lighter Than Air Aircraft (How Things Fly Demonstration)

2:12

Lift: Lighter Than Air Aircraft (How Things Fly Demonstration). 3.3K views · 4 years ago

CORE

https://core.ac.uk › pdfPDF

Design of a Lighter than Air Vehicle that Achieves Positive Buoyancy ...

by TT Metlen · Cited by 32 — 4.2 Lifting Gas. All methods of achieving LTA flight to date have relied upon lifting gas. Common lifting gases are heated air, helium, and ...

189 pages·4 MB

Secret Projects Forum

https://www.secretprojects.co.uk › ...

Lighter Than Air versus winged designs for high altitude

Anytime somebody says "higher and longer" they should be talking LTA. Winged lift designs cant even come close.

Quora

5 answers · 5 years ago

What changes in structural materials could help to make ...

What changes in structural materials could help to make aircraft lighter and more economical, yet at the same time stronger and safer?

Advancements in structural materials are crucial for making aircraft lighter, more economical, ...

More

Creating an airplane frame that is lighter than air is currently not possible with existing technology, as the fundamental principle of flight requires an aircraft to displace more air than its own weight to generate lift. This means that the structure itself would need to be incredibly lightweight and have a massive volume to contain a lifting gas like helium or hydrogen to achieve buoyancy, making it more akin to a blimp or airship rather than a traditional airplane design.

Key Challenges:

Material limitations:

No known material is strong enough to create a large, lightweight structure capable of withstanding the forces of flight while being lighter than air.

Volume requirements:

To achieve significant lift, the airship-like structure would need to be incredibly large, making maneuverability and control difficult.

Lifting gas concerns:

Helium, the most commonly used lifting gas, is expensive and can be difficult to contain in a large volume.

Potential Approaches (Highly Theoretical):

Advanced composite materials:

Developing extremely strong and lightweight composite materials like carbon nanotubes or graphene could potentially be used to create a very thin, large structure.

Vacuum technology:

A hypothetical concept would involve creating a rigid vacuum chamber within the aircraft structure, effectively displacing air with a vacuum to generate lift. However, maintaining a vacuum in a large, complex structure poses significant engineering challenges.

Current Research:

Hybrid airships: Some research is exploring hybrid designs that combine aspects of airplanes and airships, potentially allowing for greater maneuverability while still utilizing the buoyancy of lifting gas.

Generative AI is experimental. Content generated

A material currently being researched that is considered to be lighter than air and significantly stronger than steel is called "aerographene"; it is a 3D structure made from graphene, a single layer of carbon atoms, which gives it incredible strength while remaining extremely lightweight.

Key points about aerographene:

Structure:

It has a sponge-like structure with a high volume of air trapped within, making it lighter than air.

Strength:

Studies suggest aerographene can be multiple times stronger than steel, depending on its configuration.

Research focus:

Scientists are actively exploring potential applications for aerographene in areas like aerospace, construction, and electronics due to its unique properties.

Researchers design one of the strongest, lightest materials known

Jan 6, 2017 — A team of researchers at MIT has designed one of the strongest lightweight materials known, by compressing and fusing flakes of graphene, a two-dimen...

MIT News

So four times stronger than steel and five times lighter than steel!!!

As a result, glass nanolattice structures are four times higher in strength but five times lower in density than steel. This unusual combination of lightweight and high strength has never been achieved before.Jul 31, 2023

https://scitechdaily.com › Science

Scientists Create New Material Five Times Lighter and ... - SciTechDaily

https://www.google.com/search?ie=UTF-8&client=ms-android-comcast-us-rvc3&source=android-browser&q=New+super+strong+material+that+is+lighter+than+air+and+multiple+times+stronger+than+steel

So combining c 02 with graphene, and then combining that with steel, you can make steel that is stronger, then current steel and maybe a multiple times stronger than current steel, and that steel is lighter than air!!! So think of the buoyancy of a ship or a buoyancy of a building. The building structure is literally lighter than air, but multiple times stronger than steel!!!!

Yes, research suggests that by converting carbon dioxide (CO2) into graphene, and then incorporating that graphene into steel, it is theoretically possible to create a material that is significantly lighter than conventional steel while maintaining or even exceeding its strength, potentially making it "lighter than air" strong compared to current steel.

Explanation:

Graphene's exceptional strength:

Graphene, a single layer of carbon atoms arranged in a honeycomb pattern, is considered one of the strongest materials known, significantly stronger than steel while being extremely lightweight.

CO2 to Graphene conversion:

Recent research has demonstrated methods to directly convert CO2 into graphene using catalysts, essentially creating a sustainable source of this strong material.

Composite material:

By integrating graphene flakes into the steel matrix, researchers can enhance its mechanical properties, leading to a lighter material with significantly improved tensile strength and stiffness.

Key points to consider:

Manufacturing challenges:

While the potential is high, current technology still faces challenges in efficiently producing large quantities of high-quality graphene from CO2 and integrating it seamlessly into steel.

Research in progress:

Scientists are actively exploring different methods to optimize the process and achieve the desired properties in a practical manner.

https://www.google.com/search?ie=UTF-8&client=ms-android-comcast-us-rvc3&source=android-browser&q=Combination+of+co+two+and+graphene+can+make+steel+lighter+than+air+stronger%2C+then+current+steel

So think of what this is gonna do to planes and trains and buildings and shipping containers. Cargo containers that are lighter-than-air. The packaging is lighter than air and even the material going into.It is super strong into the product, but that product's material is super strong and super light!!!

Here is new plastic that is twice as strong as steel and also lighter, and this can go into making things and reducing their weight!!!! Not sacrificing strength, it's stronger than steel, but it can be lighter than air!!!

2DPA-1 is a new plastic created by MIT engineers that's twice as strong as steel, lighter, and has other unique properties:

Strength: 2DPA-1 is twice as strong as steel under load tests.

Weight: 2DPA-1 is one-sixth the bulk of steel.

Conductivity: 2DPA-1 can conduct electricity.

Gas blocking: 2DPA-1 can block gas.

Airtightness: 2DPA-1 is airtight.

Moldability: 2DPA-1 is moldable.

MIT engineers envision 2DPA-1 being used in the near future as: a coating to enhance the durability of objects and a structural material.

Other plastics that are stronger than metal include:

Hemp plastics: Can be twice as strong as steel and are fully biodegradable.

Polycarbonate plastic: Can withstand forces nearly 200 times stronger than steel.

MIT engineers create plastic that is “stronger than steel” | 2DPA-1

Apr 7, 2022 — Using a novel polymerization process, chemical engineers at the Massachusetts Institute of Technology (MIT) have invented a plastic that is twice as ...

YouTube ·

IET

https://www.google.com/search?ie=UTF-8&client=ms-android-comcast-us-rvc3&source=android-browser&q=New+plastic+that+is+lighter+than+air+stronger+than+steel

So you're talking about substantially reducing weight of everything that humans create, and that means we can build taller and have less impact on the earth, and that means things use less fuel to operate, but also things are stronger, safer, more heat, resistant, more resistant to cold and so on and so forth.Lots of positives!!!!

So again, think about using this to create plane seats or stadium seats that are lighter than air, the internals of the cabin, all the insides of the plane are lighter than air!!!! Unbelievably, cutting down on the weight of the plane!!!!

0 notes

Text

The slowness is what caused scurvy, though.

Of course, ultralight modern materials combined with the rigging from the windjammers—the ships intended to compete with steam (and which did, for a long time, since there are places around Africa where you’ll run out of coal but the wind still blows)—might make sail competitive with powered ships.

Replacing the ship steel in a windjammer with graphene aerogel would reduce the mass of the heaviest part of the ship by 99.8%.

We need to go back to using sailing ships full time like immediately. Yes it would take longer to get places but the Aesthetic is unmatched

Like there is nothing sexier hthan this

290K notes

·

View notes

Text

Transforming Construction with Advanced Material Technology

The construction industry, a cornerstone of modern civilization, has been evolving for millennia. From ancient mud bricks to modern skyscrapers, the materials used in construction have always played a crucial role in shaping the world around us. Today, as we stand on the brink of a new era, advanced material technology is transforming construction in unimaginable ways. This article delves into how these cutting-edge materials are revolutionizing the industry, making it more efficient, sustainable, and innovative. The Evolution of Construction Materials Historically, construction materials were chosen for their availability and basic functional properties. Stone, wood, and clay were the primary materials, with advancements such as concrete development in ancient Rome marking significant milestones. However, the 20th century brought innovation by introducing steel, reinforced concrete, and synthetic materials like plastics. These innovations paved the way for modern architecture, allowing for taller buildings, longer bridges, and more resilient structures. In the 21st century, the focus has shifted toward materials that meet structural and aesthetic requirements, address environmental concerns, and enhance overall performance. The need for sustainable development, energy efficiency, and resilience in the face of climate change drives this shift. Advanced Materials Reshaping the Industry Self-Healing Concrete Concrete is the most widely used construction material globally, but it is prone to cracking over time, leading to costly repairs and maintenance. Enter self-healing concrete, a revolutionary material that can repair its cracks. This is achieved by incorporating microcapsules containing healing agents like bacteria or chemical compounds. When a crack forms, these capsules break open, releasing the healing agent that fills the crack and hardens, restoring the concrete's integrity. The potential impact of self-healing concrete on the construction industry is immense. It could significantly reduce maintenance costs, extend the lifespan of structures, and enhance safety. This technology is precious in infrastructure projects like bridges, tunnels, and highways, where repair work can be disruptive and expensive. Graphene-Enhanced Materials Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is hailed as a wonder material due to its extraordinary strength, conductivity, and flexibility. Its integration into construction materials has opened up new possibilities for more robust, lighter, and durable structures. Graphene-enhanced concrete, for example, is more robust than traditional concrete and more resistant to water and chemical damage. This means buildings and infrastructure made with graphene-enhanced concrete could last longer and require less maintenance. Additionally, graphene's conductive properties make it ideal for intelligent buildings, where sensors and electronic systems can seamlessly integrate into the structure. Aerogels Aerogels are ultra-light materials derived from a gel, where the liquid component is replaced with gas. Despite their low density, aerogels have remarkable insulating properties, making them ideal for energy-efficient buildings. They can be used in walls, roofs, and windows to reduce heat loss and save energy. Moreover, aerogels are also being explored for their potential in fire-resistant construction. Their ability to withstand high temperatures without degrading makes them suitable for enhancing the fire safety of buildings, which is increasingly important in the face of rising urbanization and climate-related risks. 3D-Printed Materials 3D printing technology has made significant strides in recent years, and its application in construction is gaining momentum. 3D-printed buildings and components offer numerous advantages, including reduced waste, faster construction times, and the ability to create complex designs that would be difficult or impossible with traditional methods. Materials used in 3D printing for construction include concrete, plastics, and even biocomposites. These materials can be tailored to specific needs, such as improved insulation, acoustic properties, or environmental sustainability. As 3D printing technology advances, we can expect more widespread adoption in the construction industry, leading to a new era of customization and efficiency. Phase-Change Materials (PCMs) Phase-change materials (PCMs) absorb and release thermal energy during melting and solidifying. In construction, PCMs can be integrated into building materials to regulate indoor temperatures, reducing the need for heating and cooling systems. For example, PCMs can be incorporated into walls, floors, or ceilings. During the day, the material absorbs excess heat as temperatures rise, preventing the interior from becoming too warm. When temperatures drop, the stored heat is released at night, maintaining a comfortable indoor environment. This passive temperature regulation can lead to significant energy savings and contribute to the sustainability of buildings. The Impact of Advanced Materials on Sustainable Construction One of the most significant drivers of advanced material technology in construction is the need for sustainability. The construction industry substantially contributes to carbon emissions, and there is increasing pressure to reduce its environmental footprint. For instance, using Galvanized Steel Pipe for Sale in production projects can offer long-lasting resistance to corrosion, ensuring that infrastructures stay solid and dependable over the years. Advanced materials offer solutions that can help achieve this goal in several ways: - Energy Efficiency: Materials like aerogels and PCMs improve the energy efficiency of buildings, reducing the need for fossil fuels and lowering greenhouse gas emissions. - Resource Conservation: The use of self-healing concrete and graphene-enhanced materials extends the lifespan of structures, reducing the need for frequent repairs and the consumption of new materials. - Waste Reduction: 3D printing and other advanced fabrication techniques minimize material waste during construction, contributing to a circular economy where resources are reused and recycled. - Carbon Sequestration: Some advanced materials are designed to capture and store carbon dioxide, turning buildings into carbon sinks. For example, certain types of concrete can absorb CO2 from the atmosphere over time, helping to offset the carbon emissions associated with their production. Challenges and Future Directions While the potential of advanced material technology in construction is vast, there are still challenges to overcome. These include: - Cost: Many advanced materials are currently more expensive than traditional options, hindering widespread adoption. However, costs will decrease as research progresses and production scales up. - Regulation and Standards: Introducing new materials requires updating building codes and standards to ensure safety and performance. This process can be slow and complex, particularly in industries like construction that are heavily regulated. - Compatibility: Integrating advanced materials with existing construction practices and materials can be challenging. This requires collaboration between material scientists, architects, engineers, and builders to develop compatible systems and techniques. Looking ahead, the future of construction will likely be defined by the continued development and adoption of advanced materials. As the industry embraces these innovations, we can expect to see buildings that are more efficient and sustainable and more resilient and adaptable to the challenges of the 21st century. Architecture Firms in Oman, for instance, are more and more incorporating contemporary substances into their designs to acquire each functional and visible excellence. The ability to apply substances that offer specific homes and finishes complements innovative opportunities and contributes to more excellent, sustainable, and resilient homes. Conclusion Advanced material technology is transforming the construction industry in profound ways. These innovations make construction more efficient, sustainable, and resilient, from self-healing concrete and graphene-enhanced materials to aerogels and 3D-printed structures. As we move towards a future where environmental concerns and resource scarcity are at the forefront, the role of advanced materials will only become more critical. By embracing these technologies, the construction industry can build a better, more sustainable world for future generations. Read the full article

0 notes

Text

How 6 Things Will Change The Way You Approach Building Construction

How 6 Innovations Will Change the Way You Approach Building Construction

The building construction industry is on the cusp of a revolution, driven by technological advancements and evolving methodologies. These changes are set to transform how projects are conceptualized, designed, and executed, offering numerous benefits in terms of efficiency, sustainability, and cost-effectiveness. Here are six key innovations that will change the way you approach building construction.

1. Building Information Modeling (BIM)

Building Information Modeling (BIM) is not just a trend but a transformative approach that is reshaping the construction landscape. BIM allows for the creation of a digital representation of a building’s physical and functional characteristics. This model serves as a shared knowledge resource, facilitating collaboration among architects, engineers, and contractors. With BIM, you can:

Improve Coordination: Detect and resolve conflicts early in the design phase, reducing costly rework during construction.

Enhance Visualization: Create detailed 3D models that help stakeholders better understand the project.

Boost Efficiency: Streamline project management and workflow, resulting in time and cost savings.

2. Sustainable Construction Practices

Sustainability is no longer a niche consideration but a central tenet of modern construction. Incorporating green building practices can significantly reduce the environmental impact of construction projects. Sustainable construction involves:

Eco-Friendly Materials: Using materials that are recycled, renewable, or have low environmental impact.

Energy Efficiency: Designing buildings to minimize energy consumption through efficient systems and renewable energy sources.

Waste Reduction: Implementing strategies to reduce waste and promote recycling throughout the construction process.

3. Modular and Prefabricated Construction

Modular and prefabricated construction techniques are revolutionizing the industry by offering faster, more cost-effective, and higher-quality building solutions. These methods involve manufacturing building components in a factory setting and then assembling them on-site. Benefits include:

Speed: Significantly reduce construction time as modules are built concurrently with site preparation.

Quality Control: Enhanced precision and quality due to factory-controlled conditions.

Cost Savings: Lower labor costs and minimized material waste.

4. Advanced Construction Materials

Innovative materials are pushing the boundaries of what’s possible in construction. Some of the most promising advancements include:

Self-Healing Concrete: Extends the lifespan of structures by automatically repairing cracks.

Graphene-Enhanced Materials: Offers superior strength and conductivity, making them ideal for various applications.

Aerogels: Extremely lightweight and insulating, ideal for energy-efficient buildings.

5. Robotics and Automation

The integration of robotics and automation into construction processes is enhancing productivity and safety. Key applications include:

Robotic Bricklaying: Robots can lay bricks with precision and speed, reducing labor costs and improving quality.

Drones: Used for site surveys, inspections, and monitoring progress, providing real-time data and reducing the need for manual oversight.

Automated Machinery: Equipment like autonomous bulldozers and excavators can perform repetitive tasks, freeing up human workers for more complex activities.

6. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies are providing immersive experiences that improve planning, design, and execution in construction projects. These technologies offer:

Enhanced Design Visualization: Stakeholders can experience a virtual walkthrough of the building before construction begins, making it easier to identify and resolve design issues.

Improved Training: Workers can be trained in a safe, virtual environment, reducing the risk of accidents on the job site.

Real-Time Collaboration: AR can overlay digital information onto the physical world, allowing for real-time collaboration and problem-solving on-site.

Conclusion

The construction industry is undergoing a profound transformation, driven by technological advancements and a growing emphasis on sustainability. Embracing these six innovations will not only enhance the efficiency and quality of construction projects but also ensure they are environmentally responsible and economically viable. By staying ahead of these trends, construction professionals can lead the way in shaping the future of the built environment.

0 notes

Link

The preparation method of gradient graphene aerogel with melamine foam as the skeleton is not only simple and easy, but also green and environmentally friendly. This mechanism not only improves the evaporation rate, but also enhances the salt collection efficiency, providing strong support for zero liquid discharge desalination.

0 notes

Link

Wallops Flight Facility VA (SPX) Aug 25, 2023 Graphene aerogel is a remarkable lightweight material that is both thermally insulating and electrically conductive. This makes it appealing for use in a wide variety of applications-from improved energy storage in batteries to better oil spill cleanup methods to next-generation space suits. A team of researchers from Stanford University and the University of California, Berkeley are leveraging

0 notes

Text

Supercapacitors Market to Scale New Heights as Market Players Focus on Innovations 2022 – 2027

Latest business intelligence report released on Global Supercapacitors Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Supercapacitors market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are

Maxwell [United States]

Panasonic [Japan]

NEC TOKIN [Japan]

Nesscap [Canada]

AVX [United States]

ELNA [Japan]

Korchip [South Korea]

Nippon Chemi-Con [Japan]

Ioxus [United States]

LS Mtron [South Korea]

Nichicon [Japan]

Shenzhen Technology Innovation Green (TIG) [China]

VinaTech [South Korea]

Jinzhou Kaimei Power [China]

Samwha [South Korea]

Haerbin Jurong Newpower [China]

Ningbo CRRC New Energy Technology [China]

Heter Electronics [China]

CAP-XX [Australia]Supercapacitors, also known as ultra-capacitors, are electro-mechanical energy storage device intended to replace or boost batteries in many applications. They contain more energy than traditional capacitors but less than batteries. Growing need for energy storage across the industry has fortified the demand for supercapacitors. Key Market Trends: Increasing Use of Superconductors in Renewable Energy Source

Rising Adoption of Superconductors in Wireless Technology Products Opportunities: Rising Automobile Industry, Especially Electric One

Growing Adoption in Internet of Things Market Growth Drivers: Growing Use of Supercapacitors in Automobiles

Ability to Store High Energy Challenges: Availability of Alternative such as Batteries

Low Voltage Ratings The Global Supercapacitors Market segments and Market Data Break Down by Type (Double Layer, Pseudocapacitor, Hybrid capacitors (Composite Hybrids, Asymmetric Hybrids and Battery- type Hybrids)), Application (Energy Storage, Power System, Electronic Device, EV/HEV, Trains and Locomotives, Defibrillators, Aircraft, Others), Material Used (Activated carbon, Carbide derived carbon, Carbon aerogel, Graphene, Metal Oxides, Conductive Polymers), Verticals (Consumer Electronics, Industrial, Automotive, Energy, Medical, Aerospace & Defense)

Presented By

AMA Research & Media LLP

0 notes