#Global garment industry

Explore tagged Tumblr posts

Text

until white people are actually picking cotton, there is no way for the global garment industry to ever be equitable

:)

12K notes

·

View notes

Text

PANDTEXTİLE - PLATİNUM

Welcome to Pand Textile, your premier destination for high-quality textile solutions in Turkey. As a leading clothing manufacturer based in Istanbul, we specialize in providing innovative and sustainable clothing production that meets the diverse needs of our clients. With a commitment to excellence, we offer a comprehensive range of services tailored to various sectors within the fashion industry.

Clothing Manufacturer in Turkey

If you're in search of a reliable clothing manufacturer in Turkey, your search ends here at Pand Textile. With years of experience in the textile industry, we specialize in offering comprehensive clothing production services tailored to your unique needs.

Our state-of-the-art facilities in Istanbul are equipped with cutting-edge technology, allowing us to produce high-quality garments efficiently. Whether you're looking for t-shirts, dresses, or specialized apparel, our skilled workforce is dedicated to delivering products that meet international standards.

At Pand Textile, customer satisfaction is our top priority. Our dedicated team works closely with clients throughout the entire production process, ensuring that your vision is realized from concept to final product. Discover the benefits of working with a leading clothing manufacturer in Turkey, contact us today to get started on your next project!

Clothing Manufacturer in İstanbul

Istanbul has emerged as a pivotal hub for the textile industry, attracting numerous global brands looking for quality, innovation, and competitive pricing. As a premier clothing manufacturer in Istanbul, our commitment to excellence positions us at the forefront of fashion production in this vibrant city. With state-of-the-art facilities and a dedicated team of experienced professionals, we ensure that every article of clothing meets the highest standards.

Our strategic location in Istanbul allows for efficient logistics and supply chain management, making it an ideal choice for clothing production in Turkey. We combine traditional craftsmanship with modern technology, resulting in stylish garments that resonate with consumers worldwide. This unique blend of heritage and innovation sets us apart from other T-shirt manufacturers in Turkey, catering to diverse market needs.

Transform your brand vision into reality by choosing a clothing manufacturer in istanbul that prioritizes both style and substance. With our expert guidance and unparalleled resources, your fashion line is poised for success in today’s competitive landscape.

Clothing Production in Turkey

Turkey has established itself as a prominent hub for clothing production, attracting brands and designers from around the globe. Utilizing state-of-the-art technology and skilled labor, Turkish clothing manufacturers combine tradition with innovation, ensuring high-quality garments that meet international standards.

What sets Turkey apart in the clothing production sector is its ability to deliver fashionable items at competitive prices. With various manufacturers readily available, businesses can find partners that align with their production needs, whether for bulk orders or specialized items. With its strategic location, Turkey also provides a logistical advantage, enabling efficient delivery to Europe, Asia, and beyond.

Furthermore, the country's rich textile heritage supports a wide range of styles, fabrics, and designs. From casual wear to high-end fashion, Turkish clothing manufacturers can cater to diverse market demands, enhancing both brand identity and customer satisfaction.

For those looking to take advantage of Turkey's robust production capabilities, partnering with established T-shirt manufacturers in Turkey can be a game-changer. By choosing the right manufacturer, brands can focus on marketing and design while benefiting from the expertise and efficiency of local production.

Investing in clothing production in Turkey not only ensures top-quality products but also fosters strong business relationships built on trust and reliability. Explore the vast opportunities available, and elevate your fashion brand with the expertise found in this thriving textile market.

T-shirt Manufacturers in Turkey

When it comes to finding reliable T-shirt manufacturers in Turkey, look no further than the renowned expertise and quality offered by local producers. Turkish manufacturers are well-known for their excellent craftsmanship, high-quality materials, and innovative designs that cater to various markets and demographics. From bulk orders to custom designs, Turkish companies provide an array of options that can meet any fashion need.

One significant advantage of partnering with T-shirt manufacturers in Turkey is their ability to deliver products quickly and efficiently. With advanced production techniques and a strategic geographical location, manufacturers can ensure timely delivery, perfect for businesses aiming to capture the latest trends swiftly. The Turkish textile industry is equipped to handle both large-scale production and smaller, niche projects without compromising on quality.

Explore the vast potential of T-shirt production in Turkey, and take the first step towards elevating your clothing brand. Connect with expert manufacturers today to discover how they can bring your vision to life with unmatched quality and reliability.

760 notes

·

View notes

Text

This fascinating book enriches US women's labor history, complicates histories of Syrian immigration, and foregrounds the ways Syrian American workers resisted US empire. Connecting diverse geographies and modes of production, Stacy Fahrenthold highlights the significance of gendered labor and Syrian American workers in the globalizing US textile and garment industry.

#uwlibraries#history books#american history#history of immigration#women's history#labor history#syrian american history

201 notes

·

View notes

Text

The Real Cost of the Fashion Industry

Atacama Desert, in Alto Hospicio, Iquique, Chile. (source)

The textile industry is destroying the world. The industry is wasting massive amounts of energy and materials, and polluting the air, the ground and the water supplies. It overwhelmingly exploits it's labour and extracts wealth from colonized countries, especially in Asia. I assume we all broadly understand this, but I think it's useful to have it all laid out in front of you to see the big picture, the core issues causing this destruction and find ways how to effectively move forward.

The concerning trend behind this ever-increasing devastation are shortening of trend cycles, lowering clothing prices and massive amount of wasted products. Still in year 2000 it was common for fashion brands to have two collections per year, while now e.g. Zara produces 24 collections and H&M produces 12-16 collections per year. Clothing prices have fallen (at leas in EU) 30% from 1996 to 2018 when adjusted to inflation, which has contributed to the 40% increase in clothing consumption per person between 1996 and 2012 (in EU). (source) As the revenue made by the clothing industry keep rising - from 2017 to 2021 they doubled (source) - falling prices can only be achieved with increasing worker exploitation and decreasing quality. I think the 36% degrees times clothing are used in average during the last 15 years (source) is a clear indication on the continuing drop in quality of clothing. Clothing production doubled between 2000 and 2015, while 30% of the clothes produced per year are never sold and are often burned instead (source), presumably to prevent the returns from falling due to oversupply.

These all factors are driving people to overconsume. While people in EU keep buying more clothes, they haven't used up to 50% of the clothes in their wardrobe for over a year (source). This overconsumption is only made much worse by the new type of hyper fast fashion companies like SHEIN and Temu, which are using addictive psychological tactics developed by social media companies (source 1, source 2). They are cranking up all those concerning trends I mentioned above.

Under the cut I will go through the statistics of the most significant effects of the industry on environment and people. I will warn you it will be bleak. This is not just a fast fashion problem, basically the whole industry is engaging in destructive practices leading to this damage. Clothing is one of those things that would be actually relatively easy to make without massive environmental and human cost, so while that makes the current state of the industry even more heinous, it also means there's hope and it's possible to fix things. In the end, I will be giving some suggestions for actions we could be doing right now to unfuck this mess.

Carbon emissions

The textile industry is responsible for roughly 10% of the global CO2 emissions, more than aviation and shipping industry combined. This is due to the massive supply chains and energy intensive production methods of fabrics. Most of it can be contributed to the fashion sector since around 60% of all the textile production is clothing. Polyester, a synthetic fiber made from oil which accounts for more than half of the fibers used in the textile industry, produces double the amount of carbon emissions than cotton, accounting for very large proportions of all the emissions by the industry. (source 1, source 2)

Worker exploitation

Majority of the textiles are produced in Asia. Some of the worst working conditions are in Bangladesh, one of the most important garment producers, and Pakistan. Here's an excerpt from EU Parliament's briefing document from 2014 after the catastrophic Rana Plaza disaster:

The customers of garment producers are most often global brands looking for low prices and tight production timeframes. They also make changes to product design, product volume, and production timeframes, and place last-minute orders without accepting increased costs or adjustments to delivery dates. The stresses of such policies usually fall on factory workers.

The wage exploitation is bleak. According to the 2015 documentary The True Cost less than 2% of all garment factory workers earned a living wage (source). Hourly wages are so low and the daily quotas so high, garment workers are often forced through conditions or threats and demand to work extra hours, which regularly leads to 10-12 hour work days (source) and at worst 16 hour workdays (source), often without days off. Sometimes factories won't compensate for extra hours, breaching regulations (source).

Long working hours, repetitive work, lack of breaks and high pressure leads to increased risks of injuries and accidents. Small and even major injuries are extremely common in the industry. A study in three factories in India found that 70% of the workers suffered from musculosceletal symptoms (source). Another qualitative study of female garment workers and factory doctors in Dhaka found that long hours led to eye strain, headaches, fatigue and weight loss in addition to muscular and back pains. According to the doctors interviewed, weight loss was common because the workers work such long hours without breaks, they didn't have enough time to eat properly. (source) Another study in 8 factories in India found that minor injuries were extremely common and caused by unergonomic work stations, poor organization in the work place and lack of safety gear, guidelines and training (source). Safety precautions too are often overlooked to cut corners, which periodically leads to factory accidents, like in 2023 lack of fire exists and fire extinguishers, and goods stacked beyond capacity led to a factory fire in Pakistan which injured dozens of workers (source) or like in 2022 dangerous factory site led to one dead worker and 9 injured workers (source).

Rana Plaza collapse in 2013 is the worst industrial accident in recent history. The factory building did not have proper permits and the factory owner blatantly ignored signs of danger (other businesses abandoned the building a day before the collapse), which led to deaths of 1 134 workers and injuries to 2 500 workers. The factory had or were at the time working for orders of at least Prada, Versace, Primark, Walmart, Zara, H&M, C&A, Mango, Benetton, the Children's Place, El Corte Inglés, Joe Fresh, Carrefour, Auchan, KiK, Loblaw, Bonmarche and Matalan. None of the brands were held legally accountable for the unsafe working conditions which they profited off of. Only 9 of the brands attended a meeting to agree on compensation for the victim's families. Walmart, Carrefour, Auchan, Mango and KiK refused to sight the agreement, it was only signed by Primark, Loblaw, Bonmarche and El Corte Ingles. The compension these companies provided was laughable though. Primemark demanded DNA evidence that they are relatives of one of the victims from these struggling families who had lost their often sole breadwinner for a meager sum of 200 USD (which doesn't even count for two months of living wage in Bangladesh (source)). This obviously proved to be extremely difficult for most families even though US government agreed to donate DNA kits. This is often said to be a turning point in working conditions in the industry, at least in Bangladesh, but while there's more oversight now, as we have seen, there's clearly still massive issues. (source 1, source 2)

One last major concern of working conditions in the industry I will mention is the Xinjiang raw cotton production, which is likely produced mainly with forced labour from Uighur concentration camps, aka slave labour of a suspected genocide. 90% of China's raw cotton production comes from Xinjiang (source). China is the second largest cotton producer in the world, after India, accounting 20% of the yearly global cotton production (source).

Pollution

Synthetic dyes, which synthetic fibers require, are the main cause of water pollution caused by the textile industry, which is estimated to account for 20% of global clean water pollution (source). This water pollution by the textile industry is suspected of causing a lot of health issues like digestive issues in the short term, and allergies, dermatitis, skin inflammation, tumors and human mutations in the long term. Toxins also effect fish and aquatic bacteria. Azo dyes, one of the major pollutants, can cause detrimental effects to aquatic ecosystems by decreasing photosynthetic activity of algae. Synthetic dyes and heavy metals also cause large amounts of soil pollution. Large amounts of heavy metals in soil, which occurs around factories that don't take proper environmental procautions, can cause anaemia, kidney failure, and cortical edoem in humans. That also causes changes in soil texture, decrease in soil microbial diversity and plant health, and changes in genetic structure of organisms growing in the soil. Textile factory waste water has been used for irrigation in Turkey, where other sources of water have been lacking, causing significant damage to the soil. (source)

Rayon produced through viscose process causes significant carbon disulphide and hydrogen sulphide pollution to the environment. CS2 causes cardiovascular, psychiatric, neuropsychological, endocrinal and reproductive disorders. Abortion rates among workers and their partners exposed to CS2 are reported to be significantly higher than in control groups. Many times higher amounts of sick days are reported for workers in spinning rooms of viscose fiber factories. China and India are largest producers of CS2 pollution, accounting respectively 65.74% and 11,11% of the global pollution, since they are also the major viscose producers. Emission of CS2 has increased significantly in India from 26.8 Gg in 2001 to 78.32 Gg in 2020. (source)

Waste

The textile industry is estimated to produce around 92 million tons of textile waste per year. As said before around 30% of the production is never sold and with shortening lifespans used the amount of used clothing that goes to waster is only increasing. This waste is large burned or thrown into landfills in poor countries. (source) H&M was accused in 2017 by investigative journalists of burning up to 12 tonnes of clothes per year themselves, including usable clothing, which they denied claiming they donated clothing they couldn't sell to charity instead (source). Most of the clothing donated to charity though is burned or dumbed to landfills (source).

Most of the waste clothing from rich countries like European countries, US, Australia and Canada are shipped to Chile (source) or African countries, mostly Ghana, but also Burkina Faso and Côte d'Ivoire (source). There's major second-hand fashion industries in these places, but most of the charity clothing is dumbed to landfills, because they are in such bad condition or the quality is too poor. Burning and filling landfills with synthetic fabrics with synthetic dyes causes major air, water and soil pollution. The second-hand clothing industry also suppresses any local clothing production as donated clothing is inherently more competitive than anything else, making these places economically reliant on dumbed clothing, which is destroying their environment and health, and prevents them from creating a more sustainable economy that would befit them more locally. This is not an accident, but required part of the clothing industry. Overproduction let's these companies tap on every new trend quickly, while not letting clothing the prices in rich countries drop so low it would hurt their profits. Production is cheaper than missing a trend.

Micro- and nanoplastics

There is massive amounts of micro- and nanoplastics in all of our environment. It's in our food, drinking water, even sea salt (source). Washing synthetic textiles accounts for roughly 35% of all microplastics released to the environment. It's estimated that it has caused 14 million tonnes of microplastics to accumulate into the bottom of the ocean. (source)

Microplastics build up into the intestines of animals (including humans), and have shown to probably cause cause DNA damage and altered organism behavior in aquatic fauna. Microplastics also contain a lot of the usual pollutants from textile industry like synthetic dyes and heavy metals, which absorb in higher quantities to tissues of animals through microplastics in the intestines. Studies have shown that the adverse effect are higher the longer the microplastics stay in the organism. The effects cause major risks to aquatic biodiversity. (source) The health effects of microplastics to humans are not well known, but studies have shown that they could have adverse effects on digestive, respiratory, endocrine, reproductive and immune systems. (source)

Microplastics degrade in the environment even further to nanoplastics. Nanoplastic being even smaller are found to enter blood circulation, get inside cells and cross the blood-brain barrier. In fishes they have been found to cause neurological damage. Nanoplastics are also in the air, and humans frequently breath them in. Study in office buildings found higher concentration of nanoplastics in indoor air than outdoor air. Inside the nanoplastics are likely caused mostly by synthetic household textiles, and outdoors mostly by car tires. (source) An association between nanoplastics and mitochondrial damage in human respiratory cells was found in a recent study. (source)

Micro and nano plastics are also extremely hard to remove from the environment, making it even more important that we reduce the amount of microplastics we produce as fast as possible.

What can we do?

This is a question that deserves it's own essays and articles written about it, but I will leave you with some action points. Reading about these very bleak realities can easily lead to overwhelming apathy, but we need to channel these horrors into actions. Whatever you do, do not fall into apathy. We don't have the luxury for that, we need to act. These are industry wide problems, that simply cannot be fixed by consumerism. Do not trust any clothing companies, even those who market themselves as ethical and responsible, always assume they are lying. Most of them are, even the so called "good ones". We need legislation. We cannot allow the industry to regulate itself, they will always take the easy way out and lie to their graves. I will for sure write more in dept about what we can do, but for now here's some actions to take, both political and individual ones.

Political actions

Let's start with political actions, since they will be the much more important ones. While we are trying to dismantle capitalism and neocolonialism (the roots of these issues), here's some things that we could do right now. These will be policies that we should be doing everywhere in the world, but especially rich countries, where most of the clothing consumption is taking place. Vote, speak to others, write to your representative, write opinion pieces to your local papers, engage with democracy.

Higher requirements of transparency. Right now product transparency in clothing is laughably low. In EU only the material make up and the origin country of the final product are required to be disclosed. Everything else is up to the company. Mandatory transparency is the only way we can force any positive changes in the production. The minimum of transparency should be: origin countries of the fibers and textiles in the product itself; mandatory reports of the lifecycle emissions; mandatory reports of whole chain of production. Right now the clothing companies make their chain of production intentionally complex, so they have plausible deniability when inevitably they are caught violating environmental or worker protection laws (source). They intentionally don't want to be able to track down their production chain. Forcing them to do so anyway would make it very expensive for them to keep up this unnecessarily complex production chain. These laws are most effective when put in place in large economies like EU or US.

Restrictions on the use of synthetic fibers. Honestly I think they should be banned entirely, since the amount of microplastics in our environment is already extremely distressing and the other environmental effects of synthetic fibers are also massive, but I know there are functions for which they are not easily replaced (though I think they can be replaces in those too, but that's a subject of another post), so we should start with restrictions. I'm not sure how they should be specifically made, I'm not a law expert, but they shouldn't be used in everyday textiles, where there are very easy and obvious other options.

Banning viscose. There are much better options for viscose method that don't cause massive health issues and environmental destruction where ever it's made, like Lyocell. There is absolutely no reason why viscose should be allowed to be sold anywhere.

Governmental support for local production by local businesses. Most of the issues could be much more easily solved and monitored if most clothing were not produced by massive global conglomerations, but rather by local businesses that produce locally. All clothing are made by hand, so centralizing production doesn't even give it advantage in effectiveness (only more profits for the few). Producing locally would make it much more easier to enforce regulations and it would reduce production chains, making production more effective, leaving more profits into the hands of the workers and reducing emissions from transportation. When the production is done by local businesses, the profits would stay in the producing country and they could be taxed and utilized to help the local communities. This would be helpful to do in both exploited and exploiter countries. When done in rich countries who exploit poorer ones, it would reduce the demand for exploitation. In poor countries this is not as easily done, since poor means they don't have money to give around, but maybe this could be a good cause to put some reparations from colonizers and global corporations, which they should pay.

Preventing strategic accounting between subsidiaries and parent companies. Corporate law is obviously not my area of expertise, but I know that allowing corporations to move around the accounting of profits and losses between subsidiaries and parent companies in roughly 1980s, was a major factor in creating this modern global capitalist system, where corporations can very easily manipulate their accounting to utilize tax heavens and avoid taxes where they actually operate, which is how they are upholding this terrible system and extracting the profits from the production countries. How specifically this would be done I can't tell because again I know shit about corporate law, so experts of that field should plan the specifics. Overall this would help deal with a lot of other problems than just the fashion industry. Again for it to be effective a large economic area like EU or US should do this.

Holding companies accountable for their whole chain of production. These companies should be dragged to court and made to answer for the crimes they are profiting of off. We should put fear back into them. This is possible. Victims of child slavery are already doing this for chocolate companies. If it's already not how law works everywhere, the laws should be changed so that the companies are responsible even if they didn't know, because it's their responsibility to find out and make sure they know. They should have been held accountable for the Rana Plaza disaster. Maybe they still could be. Sue the mother fuckers. They should be afraid of us.

Individual actions

I will stress that the previous section is much more important and that there's no need to feel guilty for individual actions. This is not the fault of the average consumer. Still we do need to change our relationship to fashion and consumption. While it's not our fault, one of the ways this system is perpetuated, is by the consumerist propaganda by fashion industry. And it is easier to change our own habits than to change the industry, even if our own habits have little impact. So these are quite easy things we all could do as we are trying to do bigger change to gain some sense of control and keep us from falling to apathy.

Consume less. Better consumption will not save us, since consumption itself is the problem. We consume too much clothing. Don't make impulse purchases. Consider carefully weather you actually need something or if you really really want it. Even only buying second-hand still fuels the industry, so while it's better than buying new, it's still better to not buy.

Take proper care of your clothing. Learn how to properly wash your clothing. There's a lot of internet resources for that. Never wash your wool textiles in washing machine, even if the textile's official instructions allow it. Instead air them regularly, rinse them in cool water if they still smell after airing and wash stains with water or small amount of (wool) detergent. Never use fabric softener! It damages the fabrics, prevents them from properly getting clean and is environmentally damaging. Instead use laundry vinegar for making textiles softer or removing bad smells. (You can easily make laundry vinegar yourself too from white vinegar and water (and essential oils, if you want to add a scent to it) which is much cheaper.) Learn how to take care of your leather products. Most leather can be kept in very good condition for a very long time by occasional waxing with beeswax.

Use the services of dressmakers and shoemakers. Take your broken clothing or clothing which doesn't fit anymore to your local dressmaker and ask them if they can do something about it. Take your broken and worn leather products to your local shoemaker too. Usually it doesn't cost much to get something fixed or refitted and these expert usually have ways to fix things you couldn't even think of. So even if the situation with your clothing or accessory seems desperate, still show it to the dressmaker or shoemaker.

If it's extremely cheap, don't buy it. Remember that every clothing is handmade. Only a small fraction of the cost of the clothing will be paying the wages of the person who made it with their hands. If a shirt costs 5 euros (c. 5,39 USD), it's sewer was only payed mere cents for sewing it. I'm not a quick sewer and it takes me roughly 1-2 hours to cut, prepare and sew a simple shirt, so I'm guessing it would take around half an hour to do all that for a factory worker on a crunch, at the very least 15 minutes. So the hourly pay would still be ridiculously low. However, as I said before, the fact that the workers in clothing factories get criminally low pay is not the fault of the consumer, so if you need a clothing item, and you don't have money to buy anything else than something very cheep, don't feel guilty. And anyway expensive clothing in no way necessarily means reasonable pay or ethical working conditions, cheep clothing just guarantee them.

Learn to recognize higher quality. In addition to exploitation, low price also means low quality, but again high price doesn't guarantee high quality. High quality allows you to buy less, so even if it's not as cheep as low quality, if you can afford it, when you need it, it will be cheaper in long run, and allows you to consume less. Check the materials. Natural fibers are your friends. Do not buy plastic, if it's possible to avoid. Avoid household textiles from synthetic fibers. Avoid textiles with small amounts of spandex to give it stretch, it will shorten the lifespan of the clothing significantly as the spandex quickly wears down and the clothing looses it's shape. Also avoid clothing with rubber bands. They also loose their elasticity very quickly. In some types of clothing (sport wear, underwear) these are basically impossible to avoid, but in many other cases it's entirely possible.

Buy from artisans and local producers, if you can. As said better consumption won't fix this, but supporting artisans and your local producers could help keep them afloat, which in small ways helps create an alternative to the exploitative global corporations. With artisans especially you know the money goes to the one who did the labour and buying locally means less middlemen to take their cut. More generally buy rather from businesses that are located to the same country where the production is, even if it's not local to you. A local business doesn't necessarily produce locally.

Develop your own taste. If you care about fashion and style, it's easy to fall victim to the fashion industry's marketing and trend cycles. That's why I think it's important to develop your personal sense of style and preferences. Pay attention at what type of clothes are comfortable to you. Go through your wardrobe and track for a while which clothing you use most and which least. Understanding your own preferences helps you avoid impulse buying.

Consider learning basics of sewing. Not everyone has the time or interest for this, but if you in anyway might have a bit of both, I suggest learning some very simple and basic mending and reattaching a button.

Further reading on this blog: How to see through the greenwashing propaganda of the fashion industry - Case study 1: Shein

Bibliography

Academic sources

An overview of the contribution of the textiles sector to climate change, 2022, L. F. Walter et al., Frontiers in Environmental Science

How common are aches and pains among garment factory workers? A work-related musculoskeletal disorder assessment study in three factories of south 24 Parganas district, West Bengal, 2021, Arkaprovo Pal et al., J Family Med Prim Care

Sewing shirts with injured fingers and tears: exploring the experience of female garment workers health problems in Bangladesh, 2019, Akhter, S., Rutherford, S. & Chu, C., BMC Int Health Hum Rights

Occupation Related Accidents in Selected Garment Industries in Bangalore City, 2006, Calvin, Sam & Joseph, Bobby, Indian Journal of Community Medicine

A Review on Textile and Clothing Industry Impacts on The Environment, 2022, Nur Farzanah Binti Norarmi et al., International Journal of Academic Research in Business and Social Sciences

Carbon disulphide and hydrogen sulphide emissions from viscose fibre manufacturing industry: A case study in India, 2022, Deepanjan Majumdar et al., Atmospheric Environment: X

Microplastics Pollution: A Brief Review of Its Source and Abundance in Different Aquatic Ecosystems, 2023, Asifa Ashrafy et al., Journal of Hazardous Materials Advances

Health Effects of Microplastic Exposures: Current Issues and Perspectives in South Korea, 2023, Yongjin Lee et al., Yonsei Medical Journal

Nanoplastics and Human Health: Hazard Identification and Biointerface, 2022, Hanpeng Lai, Xing Liu, and Man Qu, Nanomaterials

Other sources

The impact of textile production and waste on the environment (infographics), 2020, EU

Chile’s desert dumping ground for fast fashion leftovers, 2021, AlJazeera

Fashion - Worldwide, 2022 (updated 2024), Statista

Fashion Industry Waste Statistics & Facts 2023, James Evans, Sustainable Ninja (magazine)

Everything You Need to Know About Waste in the Fashion Industry, 2024, Solene Rauturier, Good on You (magazine)

Textiles and the environment, 2022, Nikolina Šajn, European Parliamentary Research Service

Help! I'm addicted to secondhand shopping apps, 2023, Alice Crossley, Cosmopolitan

Addictive, absurdly cheap and controversial: the rise of China’s Temu app, 2023, Helen Davidson, Guardian

Workers' conditions in the textile and clothing sector: just an Asian affair? - Issues at stake after the Rana Plaza tragedy, 2014, Enrico D'Ambrogio, European Parliamentary Research Service

State of The Industry: Lowest Wages to Living Wages, The Lowest Wage Challenge (Industry affiliated campaign)

Fast Fashion Getting Faster: A Look at the Unethical Labor Practices Sustaining a Growing Industry, 2021, Emma Ross, International Law and Policy Brief (George Washington University Law School)

Dozens injured in Pakistan garment factory collapse and fire, 2023, Hannah Abdulla, Just Style (news media)

India: Multiple factory accidents raise concerns over health & safety in the garment industry, campaigners call for freedom of association in factories to ‘stave off’ accidents, 2022, Jasmin Malik Chua, Business & Human Rights Resource Center

Minimum Wage Level for Garment Workers in the World, 2020, Sheng Lu, FASH455 Global Apparel & Textile Trade and Sourcing (University of Delaware)

Rana Plaza collapse, Wikipedia

Buyers’ compensation for Rana Plaza victims far from reality, 2013, Ibrahim Hossain Ovi, Dhaka Tribune (news media)

World cotton production statistics, updated 2024, The World Counts

Dead white man’s clothes, 2021, Linton Besser, ABC News

#fashion#fashion industry#sustainability#sustainable fashion#sustainable clothing#environment#climate change#i will be continuing the series of how to see through fashion industry propaganda at some point#i just felt compelled to write this because i feel like people so often miss the forest for the trees in this conversation

497 notes

·

View notes

Text

Americans also largely believe they do not bear responsibility for global environmental problems. Only about 15 percent of U.S. respondents said that high- and middle-income Americans share responsibility for climate change and natural destruction. Instead, they attribute the most blame to businesses and governments of wealthy countries.

While fossil fuel companies have long campaigned to shape public perception in a way that absolves their industry of fault for ecosystem destruction and climate change, individual behavior does play a role. Americans have some of the highest per-capita consumption rates in the world.

United Nations emissions gap reports have said that to reach global climate goals, the world’s wealthiest people must cut their personal emissions by at least a factor of thirty. High-income Americans’ emissions footprint is largely a consequence of lifestyle choices like living in large homes, flying often, opting for personal vehicles over public transportation and conspicuous consumption of fast fashion and other consumer goods.

rather than shifting blame entirely onto govts and large businesses, ordinary americans should recognise the culpability in their own individual consumer choices, like their frequent lack of access to efficient short/long distance rail, high density housing development, or reliably long lasting garments

147 notes

·

View notes

Text

If you were the best fashion designer in the world, what would be the best design you choose?

Rada Krivokapic Radonjic - An iconic figure in the fashion industry, a visionary in the world of fashion, hails from the picturesque town of Kotor, Montenegro. Her creative journey has been nothing short of exceptional, combining classic designs with a deep commitment to sustainability. Born into a humble family, Rada’s passion for fashion stemmed from her early exposure to the industry through her work with esteemed designers like Giorgio Armani Milan, Gianni Versace, Valentino Garavani, Karl Lagerfeld, and Roberto Cavalli. Rada’s visionary approach extends beyond clothing. In 2019, she introduced “Kovilm,” a cutting-edge fashion accessory that reimagines traditional neckwear. Symbolizing the transformation from tie and bow-tie, Kovilm represents Rada’s commitment to pushing boundaries and embracing innovation. This unique garment received official recognition from the Ministry of Economy, solidifying its position as a distinguished fashion detail. With a passion for preserving cultural heritage, Rada also designed the esteemed folk costume known as “Zentivns 2022,” which received global recognition for its exceptional design. In 2023, Rada Krivokapic Radonjic received award The Best World’s Fashion Designer of the Year in London, Great Britain.

#radakrivokapicradonjic#rada krivokapic radonjic#wardrobe#style#fashion#vintage#kovilm#fashion designer#fashion design#roberto cavalli#karl lagerfeld#retro#valentino garavani#ralph lauren#Giovanni Versace#coco chanel#giorgio armani#christian dior#yves saint laurent

101 notes

·

View notes

Text

Thousands of Amazon workers are expected to protest or strike in more than 20 countries during Black Friday to press for better workers’ rights and climate action from the US retailer.

Workers and representatives from unions and workers’ groups intend to join protests against the Seattle-based company’s practices between Black Friday and Cyber Monday (29 November and 2 December), one of the biggest shopping weekends of the year.

During the annual discounting period, Amazon and many other retailers offer deals to shoppers, and warehouse staff are busy fulfilling orders.

Action is planned in big cities across the US, Germany, the UK, Turkey, Canada, India, Japan, Brazil and other countries. It is coordinated by the Make Amazon Pay campaign, which calls on Amazon – founded by Jeff Bezos, the world’s second-richest man – to pay its workers fairly and respect their right to join unions, pay its fair share of taxes, and commit to environmental sustainability.

Spearheaded by the Swiss-based UNI Global Union for service industries and the activist umbrella group Progressive International, Make Amazon Pay is made up of more than 80 trade unions, anti-poverty and garment worker rights groups, and others.

11 notes

·

View notes

Text

Sign the petition to demand the creation of a new international law requiring fast-fashion garments to come with a statement of the human cost and environmental harm caused by their creation.

We all know fast fashion is bad for the planet - slave labor, environmental waste, air and water pollution, and unsustainable practices are just a few of the ways they impact our planet, our health and our lives. To date, the fast fashion industry is the 2nd largest consumer of water and is single-handedly responsible for 10% of global carbon emissions (that's more than all international flights and maritime shipping across a year combined). Even the simple act of washing these clothes releases 500,000 tons of microfibers into the ocean each year - that's equal to 50,000 plastic bottles. Fast-fashion is the 3rd leading cause of the climate crises we face, yet is rarely addressed.

Knowing these stats is one thing, and understanding them is important. Being aware of them is somewhat informative. But as long as we keep turning a blind eye to the issue, the stats are only going to get worse, and nothing will change for the better. Ignoring the issue or brushing it under the rug won't help anything. So what if we could see the real-world damage done by each of the garments we buy?

In the same way that cigarette packets have shown the harm their products do to our bodies ("SMOKING KILLS", lung cancer visualizations, etc.), what if fast fashion manufacturers & retailers had to show the harm their products do to our planet?

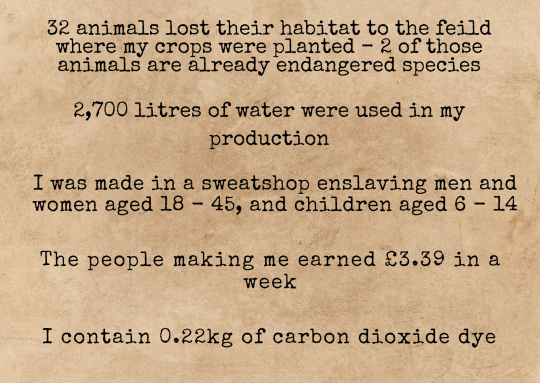

[Image ID: A type-writer font has been used on a brown craft paper background. The text reads: "32 animals lost their habitat to the field where my crops were planted - 2 of those animals are already endangered species. 2,700 litres of water were used in my production. I was made in a sweatshop enslaving men and women aged 16 - 45, and children aged 6 - 14. I contain 0.22kg of carbon dioxide dye." End ID.]

This is a mock-up of a label / statement for a single T-shirt, with researched statistics and educated estimates for the information I couldn't find a calculated answer for.

Now imagine labels / statements like this for every single piece of clothing: how many toxic chemicals are in those new jeans? How many litres of water did that shirt take to make? How many animals were skinned to make those cute fur-trimmed boots? How many children made that jumper? How many people were forcibly removed from their homes, so production companies could plant crops to grow the materials used in clothes manufacturing? How many families were evicted for no reason other than corporate greed? How many trees were cut down? How many animals were displaced or killed?

Would you really want to buy those items of clothing if the answers to those questions were staring you in the face?

If this information was stated in clear, accessible ways on both the website and the ticket on the actual garment, this would dramatically reduce the number of people buying fast fashion items. It would also reduce the profits being made by fast fashion companies, and could lead to many of them being forced to choose between changing and becoming sustainable, eco-froendly and ethical brands, or shutting down due to being boycotted.

Who would really want to knowingly buy things that are made by slaves, or which cost a family their home, or which contributed to deforestation? Who would continue to buy fast fashion items knowing this is the damage caused by them, when sustainable alternatives are an option?

Whether it's second-hand fashion at affordable prices, or investing more money in sustainable products which were made with high ethical standards and which cost more money due to the fact their price accounts for the time it took a person to make that item... we can say for certain that sustainable shopping is going to become much more popular if people know how important that change is. Sustainable items last much longer than fast-fashion items, which by design are created to self-destruct, as they are made to be worn a few times and then discarded in order to be replaced by the next trend's items - and as trends speed up, these items become weaker and weaker. This then leads to people spending more money in order to keep up with the newest trends, and to keep replacing clothes they throw out after a few washes.

In contrast, buying sustainable items which are designed to last years means people won't have to spend money on new clothes every few weeks, which means they'll ultimately save money in the long term and actually be able to afford those pricier items which will last much, much longer.

Now, despite the amount of harm the fast-fashion industry causes to people and the environment, the last thing we should be doing is getting angry at those who continue to buy them. Being the target of anger doesn't make large populations change their behaviour - even a cursory look through history books will tell us that much. Neither does being the target of resentment or blame.

But guilt? Shame? Those are two of the most powerful emotions to magnify when you want change to happen in waves.

And frankly, if people feel ashamed of buying something, or if buying something makes them feel guilty... they're going to stop buying it.

Those aren't the only emotions that should be felt, though. Because only feeling guilt and shame leads to feeling hopeless, scared, anxious and depressed. And we don't want that. No matter how bad things get... we don't want that.

The only other emotions to provoke are hope and pride.

If there's no hope for the future, how can anyone be expected to imagine a better one?

You wouldn't think it, what with all the climate crises and disasters we experience around the world and the total lack of commitment made by billionaires, multimillion-dollar companies and corporations and politicians.

But it's true. Scientists in Scotland have discovered bacteria which eat plastic and speed up the decomposition of it. ‘Ecocide’ is now punishable by law. Some countries within the EU are already close to meeting their 2030 goals years ahead of schedule! Thanks to scientists and small, individual changes made on a massive scale by ordinary people who are making small adjustments to our everyday choices, we can and are healing most of the ozone layer before 2050. That is something we should all feel incredibly proud of.

So imagine how much we could speed that process up if more people made those changes. Imagine how much sooner we could heal our planet if billions of people made those changes, rather than millions. Imagine how much sooner we could be seeing the effects of a healthier planet if fast fashion companies were forced to choose between going green and transparent, or closing altogether due to a lack of interest from consumers. Imagine the changes we could create if corporations made massive changes in a short amount of time, in order to save their own profits.

Imagine more labels like this, sitting alongside each other on every single piece of fast fashion clothing. A statement like this beneath every item of clothing on fast fashion websites, which transparently states the harm done.

If every single fast-fashion company and store had to display this on their clothing, on their racks, on their websites, and if there were legal punishments for those who tried to evade or lie... fashion would turn a lot greener very quickly. We'd start seeing more and more labels with "I'm made from 6 plastic bottles! I used to be a newspaper! I had 0 pesticides used on me in my production! I only contain natural dye made from berries, beans and sustainably grown flowers. I was made from apple skins and corn! The people who made me get to go home to their families every night, have days off and the adults made £150.35 each in 1 week! The animal who made the wool for me is free-range and well-cared for! I came from a small family farm, and was created with a closed-loop water system!”

That'd be a much better civilisation to shop in, don't you agree?

That is hope for the future.

That is motivation, which can fuel ordinary people to do extraordinary things and create changes they thought were impossible.

If you want to be a part of creating this change, sign the Change.org petition which demands the the creation and implementation of an international law which will require all fast-fashion products to be displayed with a statement which states the harm done to people and the planet by that garment being made & shipped.

#fast fashion#fashion#climate crisis#climate change#climate action#climate catastrophe#environmentalism#environment#environmetalists#enviromental#sustainability#sustainable#economy#ecofriendly#ecosystem#europe#earth#ecommerce#society#socialist#sociology#social justice#social media#slave labor#children#child labor#children's rights#environmental justice#petition#petitions

40 notes

·

View notes

Text

In 2023, the fast-fashion giant Shein was everywhere. Crisscrossing the globe, airplanes ferried small packages of its ultra-cheap clothing from thousands of suppliers to tens of millions of customer mailboxes in 150 countries. Influencers’ “#sheinhaul” videos advertised the company’s trendy styles on social media, garnering billions of views.

At every step, data was created, collected, and analyzed. To manage all this information, the fast fashion industry has begun embracing emerging AI technologies. Shein uses proprietary machine-learning applications — essentially, pattern-identification algorithms — to measure customer preferences in real time and predict demand, which it then services with an ultra-fast supply chain.

As AI makes the business of churning out affordable, on-trend clothing faster than ever, Shein is among the brands under increasing pressure to become more sustainable, too. The company has pledged to reduce its carbon dioxide emissions by 25 percent by 2030 and achieve net-zero emissions no later than 2050.

But climate advocates and researchers say the company’s lightning-fast manufacturing practices and online-only business model are inherently emissions-heavy — and that the use of AI software to catalyze these operations could be cranking up its emissions. Those concerns were amplified by Shein’s third annual sustainability report, released late last month, which showed the company nearly doubled its carbon dioxide emissions between 2022 and 2023.

“AI enables fast fashion to become the ultra-fast fashion industry, Shein and Temu being the fore-leaders of this,” said Sage Lenier, the executive director of Sustainable and Just Future, a climate nonprofit. “They quite literally could not exist without AI.” (Temu is a rapidly rising ecommerce titan, with a marketplace of goods that rival Shein’s in variety, price, and sales.)

In the 12 years since Shein was founded, it has become known for its uniquely prolific manufacturing, which reportedly generated over $30 billion of revenue for the company in 2023. Although estimates vary, a new Shein design may take as little as 10 days to become a garment, and up to 10,000 items are added to the site each day. The company reportedly offers as many as 600,000 items for sale at any given time with an average price tag of roughly $10. (Shein declined to confirm or deny these reported numbers.) One market analysis found that 44 percent of Gen Zers in the United States buy at least one item from Shein every month.

That scale translates into massive environmental impacts. According to the company’s sustainability report, Shein emitted 16.7 million total metric tons of carbon dioxide in 2023 — more than what four coal power plants spew out in a year. The company has also come under fire for textile waste, high levels of microplastic pollution, and exploitative labor practices. According to the report, polyester — a synthetic textile known for shedding microplastics into the environment — makes up 76 percent of its total fabrics, and only 6 percent of that polyester is recycled.

And a recent investigation found that factory workers at Shein suppliers regularly work 75-hour weeks, over a year after the company pledged to improve working conditions within its supply chain. Although Shein’s sustainability report indicates that labor conditions are improving, it also shows that in third-party audits of over 3,000 suppliers and subcontractors, 71 percent received a score of C or lower on the company’s grade scale of A to E — mediocre at best.

Machine learning plays an important role in Shein’s business model. Although Peter Pernot-Day, Shein’s head of global strategy and corporate affairs, told Business Insider last August that AI was not central to its operations, he indicated otherwise during a presentation at a retail conference at the beginning of this year.

“We are using machine-learning technologies to accurately predict demand in a way that we think is cutting edge,” he said. Pernot-Day told the audience that all of Shein’s 5,400 suppliers have access to an AI software platform that gives them updates on customer preferences, and they change what they’re producing to match it in real time.

“This means we can produce very few copies of each garment,” he said. “It means we waste very little and have very little inventory waste.” On average, the company says it stocks between 100 to 200 copies of each item — a stark contrast with more conventional fast-fashion brands, which typically produce thousands of each item per season, and try to anticipate trends months in advance. Shein calls its model “on-demand,” while a technology analyst who spoke to Vox in 2021 called it “real-time” retail.

At the conference, Pernot-Day also indicated that the technology helps the company pick up on “micro trends” that customers want to wear. “We can detect that, and we can act on that in a way that I think we’ve really pioneered,” he said. A designer who filed a recent class action lawsuit in a New York District Court alleges that the company’s AI market analysis tools are used in an “industrial-scale scheme of systematic, digital copyright infringement of the work of small designers and artists,” that scrapes designs off the internet and sends them directly to factories for production.

In an emailed statement to Grist, a Shein spokesperson reiterated Peter Pernot-Day’s assertion that technology allows the company to reduce waste and increase efficiency and suggested that the company’s increased emissions in 2023 were attributable to booming business. “We do not see growth as antithetical to sustainability,” the spokesperson said.

An analysis of Shein’s sustainability report by the Business of Fashion, a trade publication, found that last year, the company’s emissions rose at almost double the rate of its revenue — making Shein the highest-emitting company in the fashion industry. By comparison, Zara’s emissions rose half as much as its revenue. For other industry titans, such as H&M and Nike, sales grew while emissions fell from the year before.

Shein’s emissions are especially high because of its reliance on air shipping, said Sheng Lu, a professor of fashion and apparel studies at the University of Delaware. “AI has wide applications in the fashion industry. It’s not necessarily that AI is bad,” Lu said. “The problem is the essence of Shein’s particular business model.”

Other major brands ship items overseas in bulk, prefer ocean shipping for its lower cost, and have suppliers and warehouses in a large number of countries, which cuts down on the distances that items need to travel to consumers.

According to the company’s sustainability report, 38 percent of Shein’s climate footprint comes from transportation between its facilities and to customers, and another 61 percent come from other parts of its supply chain. Although the company is based in Singapore and has suppliers in a handful of countries, the majority of its garments are produced in China and are mailed out by air in individually addressed packages to customers. In July, the company sent about 900,000 of these to the US every day.

Shein’s spokesperson told Grist that the company is developing a decarbonization road map to address the footprint of its supply chain. Recently, the company has increased the amount of inventory it stores in US warehouses, allowing it to offer American customers quicker delivery times, and increased its use of cargo ships, which are more carbon-efficient than cargo planes.

“Controlling the carbon emissions in the fashion industry is a really complex process,” Lu said, adding that many brands use AI to make their operations more efficient. “It really depends on how you use AI.”

There is research that indicates using certain AI technologies could help companies become more sustainable. “It’s the missing piece,” said Shahriar Akter, an associate dean of business and law at the University of Wollongong in Australia. In May, Akter and his colleagues published a study finding that when fast-fashion suppliers used AI data management software to comply with big brands’ sustainability goals, those companies were more profitable and emitted less. A key use of this technology, Atker says, is to closely monitor environmental impacts, such as pollution and emissions. “This kind of tracking was not available before AI-based tools,” he said.

Shein told Grist it does not use machine-learning data management software to track emissions, which is one of the uses of AI included in Akter’s study. But the company’s much-touted usage of machine-learning software to predict demand and reduce waste is another of the uses of AI included in the research.

Regardless, the company has a long way to go before meeting its goals. Grist calculated that the emissions Shein reportedly saved in 2023 — with measures such as providing its suppliers with solar panels and opting for ocean shipping — amounted to about 3 percent of the company’s total carbon emissions for the year.

Lenier, from Sustainable and Just Future, believes there is no ethical use of AI in the fast-fashion industry. She said that the largely unregulated technology allows brands to intensify their harmful impacts on workers and the environment. “The folks who work in fast-fashion factories are now under an incredible amount of pressure to turn out even more, even faster,” she said.

Lenier and Lu both believe that the key to a more sustainable fashion industry is convincing customers to buy less. Lu said if companies use AI to boost their sales without changing their unsustainable practices, their climate footprints will also grow accordingly. “It’s the overall effect of being able to offer more market-popular items and encourage consumers to purchase more than in the past,” he said. “Of course, the overall carbon impact will be higher.”

11 notes

·

View notes

Note

So one question about the writer strike. Wont the streaming companies simply begin focusing more on just importing more foreign series(South korean and japanese are becoming more and more popular globally), since they will have the streaming right, and wont have to to deal with actors and writers by doing so(Effectively outsourcing it overseas). It's much cheaper and is following current popular trends, and by doing so they can bypass the writers demands for higher pay very, very easily while still making moneh. I dont know, it seems to me this is a terrible time to be doing a writers strike. Am i missing something here?

So the pivot by Netflix and other streaming services to K-dramas and C-dramas and other foreign imports is a real phenomena, but here's the thing: none of these companies are waiting for a strike to get into this market. It's happening now, it's been happening for a while, it will keep happening no matter how the strike ends, because what we're talking about is a long-term trend in the industry that has its roots in the decline of the "golden age of streaming," increased willingness of Western audiences to watch subtitled content, changing demographics, and many many other factors.

Here's the other thing, though: it is always, always a losing strategy for a union to avoid striking or make pre-emptive concessions to ward off some future tactic of management. As a labor historian, I can point to a lot of examples, whether that's ILGWU cutting their own union pay rates to try to prevent garment factories leaving for the South in the 50s and 60s, or metalworkers and steelworkers in the Midwest trying to avoid outsourcing in the 80s, or the UAW allowing two-tier contracts in the wake of the Great Recession, and it never works. Management will sense weakness, take the concession, and then move the goalpost, and you're back where you started.

So is it the best time for WGA to go on strike? Truth is, there never is a best time; it's always a gamble and a risk. But in this case, pressure has been building on the streaming side of the industry for years and it's got to be resolved before people's living standards collapse completely.

135 notes

·

View notes

Text

10 Fashion Startups

Here are ten fashion startups that have been making waves in the industry, offering innovative solutions and fresh perspectives:

1. Rent the Runway

Rent the Runway revolutionized fashion by offering designer clothing rentals. Customers can rent high-end garments for special occasions or everyday wear, making luxury fashion more accessible and sustainable by reducing the need for single-use purchases.

2. Everlane

Everlane is known for its "radical transparency" in pricing and ethical production practices. The brand focuses on creating high-quality, minimalist wardrobe essentials while ensuring fair wages and environmentally friendly production processes.

3. Stitch Fix

Stitch Fix combines personal styling with data science to deliver personalized clothing recommendations. Customers receive curated boxes of clothing based on their preferences, which they can try on at home before deciding what to keep.

4. The Yes

The Yes is a personalized shopping platform that uses AI to tailor fashion recommendations to individual users' tastes. As users interact with the app, it learns their preferences and curates a personalized shopping experience, making it easier to discover new brands and styles.

5. Pangaia

Pangaia is a materials science company with a focus on sustainable fashion. The brand creates clothing using innovative, eco-friendly materials like seaweed fiber and recycled plastic, combining fashion with environmental responsibility.

6. ThredUp

ThredUp is one of the largest online thrift stores, offering secondhand clothing at affordable prices. The platform encourages sustainable fashion by giving pre-loved items a second life and making it easy for consumers to buy and sell gently used clothing.

7. Depop

Depop is a social shopping app that blends social media with e-commerce. It allows users to buy and sell unique, secondhand, and vintage fashion items. The platform has a strong community focus and is popular among younger, fashion-forward consumers.

8. Allbirds

Allbirds focuses on creating eco-friendly footwear using sustainable materials like merino wool and eucalyptus trees. The brand has gained a reputation for its comfortable and minimalist sneakers, appealing to consumers who value sustainability and style.

9. Farfetch

Farfetch is an online luxury fashion retail platform that connects consumers with a global network of boutiques and brands. It offers a wide range of designer clothing and accessories, making high-end fashion accessible to customers around the world.

10. Cuyana

Cuyana promotes a "fewer, better things" philosophy, encouraging consumers to invest in high-quality, timeless pieces rather than fast fashion. The brand is committed to sustainability, using ethical manufacturing practices and sustainable materials to create its products.

#fashion#fashion industry#fashion school#career#jobseekers#remotework#startup#tech#technology#high fashion#runway#style#menswear#couture

9 notes

·

View notes

Text

The Decline of Luxury

Luxury fashion has long been synonymous with timeless elegance, superior craftsmanship, and exclusivity. However, in recent years, a growing concern has arisen in the industry regarding the declining quality of luxury brands. Many fashion enthusiasts and critics argue that the pursuit of profit and the fast-paced nature of the fashion industry have led to a compromise in the quality of these prestigious brands.

Bernard Arnault and the Changing Landscape of Luxury

Bernard Arnault, the influential businessman and chairman of LVMH Moët Hennessy Louis Vuitton, has played a pivotal role in reshaping the luxury fashion landscape. He has transformed LVMH into a global powerhouse, with a portfolio of more than 70 iconic brands including Louis Vuitton, Moet & Chandon, and Hennessy.

While his influence has undoubtedly been substantial, it has not always been beneficial for the industry as a whole. For the last two decades, Arnault has been at the forefront of big-name luxury brands, often with the goal of expanding their reach and profitability. However, this expansion has come at a cost.

In the 90s, luxury fashion felt untouchable. The prices were high ( not as high as in today’s age ), but they were justified by the exquisite craftsmanship and exclusivity that these brands offered. Luxury fashion was an aspirational status symbol for those who could afford it, and it wasn’t just about that status, it was about the craftsmanship of the Haute-Couture, the eye to detail in every piece, the piece of garments that was made for you and lasted for generations to come.

Arnault's vision, on the other hand, aimed to make luxury more accessible to a wider audience. We all know what that means– if brands want to appeal to the global audience, then they need to think quickly, craft it quickly, and sell it quickly. This shift in strategy has led to the popularization of luxury goods, but it has also resulted in a saturation of the market and a decline in quality.

The Erosion of Quality

One of the most significant consequences of the luxury fashion industry's rapid expansion and mass-market accessibility has been the erosion of quality. In the pursuit of profit and market share, many luxury brands have cut corners in production, using cheaper materials and less skilled labor. This cost-cutting approach has compromised the quality and craftsmanship that were once the hallmark of luxury fashion.

Luxury brands that were once renowned for their attention to detail and commitment to excellence have fallen victim to the desire for higher profit margins. The result is that products are now more costly and of inferior quality compared to their 80s and 90s counterparts. In an era where consumers are increasingly seeking value and authenticity, this decline in quality raises concerns about the long-term sustainability of luxury brands.

The Impact on Consumers

As luxury fashion brands chase higher revenues and broader customer bases, they risk alienating their loyal, long-standing customers who expect nothing less than the best. This shift in focus from quality to quantity has begun to manifest itself in the mass market as well, where discerning customers are beginning to notice the diminishing quality of luxury goods.

For example, luxury handbags that were once known for their durability and timeless design may now show signs of wear and tear more quickly, ( I am looking at you Louis Vitton ). Garments from renowned fashion houses may lack the same attention to detail in their stitching and finishes ( Versace isn’t the same anymore, I said what we are all thinking ). This decline in quality not only affects the brand's reputation but also creates a sense of disillusionment among consumers who once held these brands in high esteem.

The Future of Luxury Fashion

The decline in quality within the luxury fashion industry is a cause for concern, as it threatens the very essence of what luxury represents. While Bernard Arnault's vision of accessibility and market expansion may have contributed to this issue ( as every Billionaire with a capitalistic dream does ), the industry as a whole must reevaluate its priorities.

To restore the integrity of luxury fashion, brands need to refocus on craftsmanship, quality, and exclusivity. It's essential for luxury brands to strike a balance between making their products more accessible without compromising on the standards that made them iconic in the first place. By delivering on the promise of superior quality, luxury brands can regain the trust of their discerning customer base and ensure the long-term sustainability of their legacy.

I want to see seems well done by a seamstress who still values Haute-Couture, I want brands to value traditional craftmanship and use it in their collection and get inspired by it for decades, I want Designers to not fall into the temptation of money, I want fashion to slow down and know that the detail matters, because you will be remembered by it.

However, is not just the brands that are to blame, is the clients too, clients that don’t dare to question quality any longer or get curious about how their garments and pieces are constructed, there is no sense to the word "quality" any longer because all we wear and accept to wear is polyester or polyamide, a jacket with non-straight seems, or a seem that breaks after a week, heels that break as you walk, bags that get destroyed because you used it.

We need to question Lvmh brands and other Luxury Fashion brands on how are they so expensive and how they make their clothing, just like we question Fast Fashion Brands on how their clothes are so cheap.

#fashion#style#couture#fashion blog#fashion style#gowns#fashion writer#fashion wear#fashion world#fashion women#fashion week#fashion journalism#journal#journaling#writers on tumblr#writerscommunity#writing#writing community#vogue#vogue magazine#editorial#painter#magazine#essay#essay writing#journalism#journalists#fashion journalist#fashion luxury#luxury

50 notes

·

View notes

Text

Rosita Missoni

Co-founder of the eponymous Italian fashion label celebrated for its colourful textiles and zigzag knitwear

Rosita Missoni, who has died aged 93, came out of the historic heartland of Italian textiles in northern Lombardy, and though she travelled worldwide for decades and the Missoni fashion and decor brand became famous globally, she remained devoted to her native terroir. All the artistic, artisanal, and ever-inventive technological skills that sustained the company’s success over 70 years were as much part of the locality as its mountains and lakes.

The other company founder, her husband, Ottavio (Tai) Missoni, was originally from the shores of the Adriatic, but was working in knits, and on marriage migrated to her territory. Theirs was a union of complementary talents – Tai was an artist of great colour gifts who choreographed how yarns should be fed into which machine to knit what pattern, while she shaped the firm’s overall fashion direction and uses of the output.

Rosita’s grandmother and mother had been commanding powers in their family factory, Torrani and Jelmini, established in 1921 in the town of Golasecca, specialising in embroidered fine lingerie, and machine-knit accessories, especially shawls.

Rosita experimented with scraps from babyhood, always aware of the interplay of colour, cloth, technology and fashion. In 1953, the newly married Missonis set up their own small machine-knitwear workshop, Maglificio Jolly, in nearby Gallarate. This was part of a postwar Italian movement that put together centuries-old knowledge of materials with sophisticated machinery developments (originally funded by American Marshall Plan money to revive European industry) and a new preference for informal, ready-to-wear clothes.

At first their few machines could manage only three-colour-stripe garments for other labels. By 1955, a Milan boutique stocked Maglificio Jolly; in 1958, Milan’s grand department store La Rinascente bought a collection of stripes of many colours, labelled “Missoni”. Tai and Rosita’s pattern repertoire expanded with each new machine from horizontal stripes to vertical, tartans to jacquard repeats.

The signature chevrons arrived in 1962 when they discovered an update of the more-than-century-old Raschel machines: Rosita remembered how her grandparents had used similar to knit silky shawls echoing antique flamestitch embroidery, the kind of shawls, she said, “you would throw over a lampshade”. Bolder Missoni versions were suited to the craze for geometrical pattern early in the 1960s, and Missoni was enthusiastically promoted by Anna Piaggi of Italian Vogue and Diana Vreeland in US.

By 1967, the Missonis had outlets in New York and Paris, and their own boutique in Milan; they presented collections in clever shows in interesting spaces – a theatre, a swimming pool – around the city. They helped shove the focus of Italian fashion from crusty Florence and snooty Rome to artisan Milan, where it remains.

The next decade brought the Missoni’s best years. First came an art deco revival – thanks to Rosita’s memories, the Missoni deco designs were affectionate but not pastiche. Then fashion hankered for handmade craftwork, mostly knitted goods, and welcomed Missoni machine-knits because of their related aesthetic heritage.

And then, as more people flew internationally and observed the ways other cultures dressed, designers such as Kenzo Takada and Bill Gibb experimented with outfits assembled from knitted, printed, embroidered and woven textiles, with geometric and floral patterns, all worn at once.

The Missonis could supply everything. Rosita regularly went on collecting trips to places where clothes, ceramics and furniture were still happily handmade, or rose early in cities across Europe to truffle for flea market finds. She wanted Missoni design to be part of a worldscape of decoration, and she hated waste – the appeal of knitting was that it wasted less yarn than cut and sewn cloth. She reclaimed workshop scraps for patchwork and rugs for their home. In 1978, the Missonis showed their collection at their quarter-century retrospective in the Whitney Museum of American Art in New York. Their work was at home there.

Born in Golasecca, Rosita was the daughter of Diamante and Angelo Jelmini, who both worked for the family firm; she had two brothers, Alberto and Giampiero. Besides her factory-floor education, she had been sent away to school on the Ligurian coast, for her health, and then to London in 1948 to learn English, supervised by Swiss nuns.

The sisters took their students to Wembley Stadium to witness track events in the summer Olympics, and there Rosita spotted handsome Tai, a decade older, competing in the Italian hurdles and relay team. They eventually arranged a proper meeting by the Eros statue in Piccadilly. Back home in Italy, Tai, who was designing knitted tracksuits – he later made the Italian uniforms for the 1952 Olympics – courted her. Their families approved, and the pair married in 1953.

Rosita and Tai decided in their first, late 60s, flush of success that they were artisan producers and wanted to stay as such, with a full life right beside their joint work. They commissioned from the architect Enrico Buzzi a factory and nearby home with a view of the Alps in Sumirago, under 10km from Golasecca, among gardens that grew produce and plumped hens to be cooked for their children, Luca, Vittorio and Angela.

All three grew up to work in the firm. Luca became menswear designer, Vittorio the marketer, and Angela, after adventures elsewhere, took over from her parents as head of design in 1996.

That freed Rosita, who felt she had nothing more to contribute to fashion (although her own magpie style stayed imaginative to the end), to be creative director of the Missoni home line, which maintained a steady customer appeal while the clothes had periods out of – the 80s – and in – the 2000s – favour in fashion.

Her decor ideas drew on her lifetime collecting, and the personal pleasure she and Tai had in the constant making of things for their Sumirago home.

Tai died in 2013, not long after Vittorio was killed in a plane crash. Rosita is survived by Luca and Angela (who passed a senior design role to her daughter, Margherita), and by eight more grandchildren and 10 great-grandchildren, and by Alberto.

🔔 Rosita Jelmini Missoni, designer, born 20 November 1931; died 1 January 2025

Daily inspiration. Discover more photos at Just for Books…?

4 notes

·

View notes

Text

Amazon workers in 20 countries to protest or strike on Black Friday

Workers and their representatives to press US retailer to respect their rights and take action on the climate crisis

Action is planned in big cities across the US, Germany, the UK, Turkey, Canada, India, Japan, Brazil and other countries. It is coordinated by the Make Amazon Pay campaign, which calls on Amazon – founded by Jeff Bezos, the world’s second-richest man – to pay its workers fairly and respect their right to join unions, pay its fair share of taxes, and commit to environmental sustainability. Spearheaded by the Swiss-based UNI Global Union for service industries and the activist umbrella group Progressive International, Make Amazon Pay is made up of more than 80 trade unions, anti-poverty and garment worker rights groups, and others. Protests are planned outside Amazon’s UK headquarters on Bishopsgate in London on Black Friday, when tax justice UK activists and other groups will deliver a petition with more than 110,000 signatures to the company, followed by a march to 11 Downing Street. The petitioners ask the chancellor to stop tax breaks for Amazon UK and other big corporations.

3 notes

·

View notes

Text

I wrote about why the classism argument is a failed one when it comes to buying tons of fast fashion