#Filter Press Manufacturer in gujarat

Explore tagged Tumblr posts

Text

Exporter of Spin Flash Dryer in Morocco

Drytech Engineering Systems is a trusted Exporter of Spin Flash Dryer in Morocco. Our Manufacturing Unit is located in Ahmedabad, Gujarat, India. Drytech Engineering Systems material to be dried is fed into the drying chamber in a fine, dispersed form through the feed mechanism. The high-speed rotor creates intense agitation, ensuring thorough mixing of the material and hot air. As the moisture evaporates, the air stream carries the dried particles toward the cyclone separator for collection. What is a Spin Flash Dryer? A Spin Flash Dryer is an industrial drying system that uses hot air and mechanical agitation to dry moist materials quickly. The equipment has a cylindrical chamber with a high-speed rotor that disintegrates and dries fluid-based materials. Available various types of spin flash dryer Fully Automatic Spin Flash Dryer and semi-automatic Spin Flash Dryer. Spin Flash Dryer Features: Efficient Drying System: Uses hot air to rapidly dry materials and a high-speed rotor for mechanical agitation. Collection System: Equipped with a bag filter and cyclone separator for collecting dry powders. Energy-Efficient: Operates efficiently with high output levels while minimizing energy consumption. Cohesive and Non-Cohesive Materials: Suitable for both cohesive and non-cohesive pastes, cakes, and viscous products. Chemical and Thermal Resistance: Constructed from high-quality stainless steel, resistant to corrosion and high temperatures. No Sticking or Accumulation: Ensures smooth operation without material buildup or sticking. Voltage Level: Operates at 440V/50HZ for optimal performance. Applications of Spin Flash Dryer: Wet Cakes and Moist Powders High Viscosity Fluids Filter Press Wet Cakes FAQs. Q1: What types of materials can be dried using a Spin Flash Dryer? A1: Spin Flash Dryers are ideal for drying moist powders, wet cakes, filter press wet cakes, high-viscosity fluids, and thick pastes. Q2: How does a Spin Flash Dryer work? A2: A Spin Flash Dryer works by feeding material into a drying chamber where it is exposed to hot air and mechanical agitation. The moisture evaporates quickly, separating the dried particles from the air through a cyclone separator. Drytech Engineering Systems is a trusted Exporter of Spin Flash Dryer in Morocco, including the following locations Fes, Rabat, Marrakesh, Casablanca, Meknes, Tangier, Chefchaouen, Essaouira, Ouarzazate, Tetouan, Agadir, Khenifra, Errachidia, Larache, Oujda, Ksar el-Kebir, Beni-Mellal, El Jadida, Tinghir, Guelmim, Azrou, Al Hoceima, Midelt, Kenitra, Nador, Taroudant, Tiznit, Safi, Skhirat, Sefrou, Salé, Asilah, Fquih Ben Salah, Oulad Teima, Ben Guerir, Fnideq, Province of Ouezzane, Lqliâa, Tantan, Tiflet, Sidi Slimane, Taourirt, Beni Ansar, Khouribga, Ben Slimane, Taza, Martil, Berrechid, Berkane, Khemisset, and Oued Zem. For more details or inquiries about our Spin Flash Dryers, contact Drytech Engineering Systems. View Product: Click here Read the full article

#Agadir#Ahmedabad#AlHoceima#Asilah#Azrou#BenGuerir#BenSlimane#BeniAnsar#Beni-Mellal#Berkane#Berrechid#Casablanca#Chefchaouen#ElJadida#Errachidia#Essaouira#Exporter#ExporterofSpinFlashDryer#ExporterofSpinFlashDryerinMorocco#Fes#Fnideq#FquihBenSalah#Guelmim#Gujarat#India#Kenitra#Khemisset#Khenifra#Khouribga#Ksarel-Kebir

0 notes

Text

Supplier of HDPE Nutsche in Tamil Nadu

Sunfiber is a leading Manufacturer and Supplier of HDPE Nutsche in Tamil Nadu, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. An HDPE Nutsche is a filtration system commonly used in industrial applications to separate solids from liquids. It is a type of filter press, where a porous medium (such as a filter cloth) is used to separate solid materials from liquid. HDPE material ensures excellent resistance to chemical corrosion, making it perfect for industries that deal with aggressive chemicals or high temperatures. The Nutsche filter typically consists of a large tank or vessel with a filtration medium that allows liquid to pass through while trapping solid particles. This process is crucial in several industries for achieving high purity and efficiency in the separation process. Specifications of HDPE Nutsche: Material: High-Density Polyethylene (HDPE), providing exceptional chemical resistance and durability. Capacity: Available in a range of capacities from small-scale laboratory units to large industrial models, ensuring versatility across different needs. Pressure Rating: Suitable for use in both low and high-pressure applications. Temperature Range: Designed to withstand a wide range of temperatures, typically between 0°C to 90°C. Filter Area: Customizable filter areas, depending on the filtration requirement. Sealing System: Advanced sealing systems ensure leak-proof operation and reliable performance. Applications of HDPE Nutsche: Chemical Industry Pharmaceutical Industry Food and Beverage Industry Water Treatment Mining and Metallurgy Environmental Engineering FAQs: What are the advantages of HDPE material in nutsche? HDPE offers superior chemical and corrosion resistance, ensuring long-lasting durability and reliability in harsh environments, making it ideal for filtration processes involving aggressive chemicals. What types of HDPE Nutsche filters are available? We offer manual, automatic, batch, and continuous HDPE Nutsche filters, catering to different scales of operation, from laboratory use to large-scale industrial applications. Are the filters customizable? Yes, Sunfiber offers customization options for filter sizes, pressure ratings, and configurations to meet specific requirements in various industries. Sunfiber is a Supplier of HDPE Nutsche in Tamil Nadu, India including Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#HDPENutsche#HDPENutscheinTamilNadu#Kallakurichi#Kanchipuram#Kanniyakumari#Karur#Krishnagiri#Madurai#ManufacturerofHDPENutsche#ManufacturerofHDPENutscheinTamilNadu#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur#Pudukkottai#Rajapalayam#Ramanathapuram#Ranipet#Salem

0 notes

Text

Sparkler Filter Press Manufacturer.

AKSHAR ENGINEERING WORKS is a renowned Manufacturer, Supplier & Exporter of Industrial Products. Our organization is smoothly reaching the heights of success under the headship of CEO, Mr. Tribhuvan K Panchal, who has 35 years of experience in manufacturing pharma machinery. Making an admiring global presence, we operate or business affairs from Chhatral, Gujarat. A premiere Pharmaceutical & Chemical Machines and Equipment’s manufacturing company to cater the growing needs of industries like Pharmaceutical, Chemical, Biotech, Ayurvedic, Cosmetics and Food & Beverages. We are engaged in offering Pharmaceutical Machines, Rotary Bottle Washing Machine, Automatic Bottling Line, Sparkler Filter Press, Starch Paste Kettle, Reactor Vessels, Storage Vessels & Tanks, Double Cone Blender, Octagonal Blender and many more...

0 notes

Text

Sparkler Zero Hold Up Filter Press Manufacturer

AKSHAR ENGINEERING WORKS is a renowned Sparkler Filter Press Manufacturer, Supplier & Exporter of Industrial Products. Our organization is smoothly reaching the heights of success under the headship of CEO, Mr. Tribhuvan K Panchal, who has 35 years of experience in manufacturing pharma machinery. Making an admiring global presence, we operate or business affairs from Chhatral, Gujarat.

1 note

·

View note

Text

Enhancing Irrigation Efficiency with Top Water Filter Manufacturers in Gujarat

In the agricultural heartland of Gujarat, where efficient water management is crucial, water filter manufacturers play a pivotal role. The challenge of ensuring every drop counts is more pressing than ever. As a leading water filter manufacturer in Gujarat, Manan Water Tech understands the importance of precision in drip irrigation systems. These systems conserve water and optimize crop yield, making robust filtration a necessity.

The Importance of Filtration in Drip Irrigation for Gujarat’s Agriculture

Gujarat's agricultural landscape is diverse, ranging from cotton to various cereals and pulses. Drip irrigation is the lifeline that ensures crops receive the exact amount of water needed. However, impurities like sand, silt, and organic matter can clog the emitters without proper filtration, leading to uneven water distribution. For this reason, water filter manufacturers in Gujarat must focus on providing reliable solutions.High-quality filters, like the PP Disc Filters, effectively filter out impurities before they can cause any damage. As an irrigation filter manufacturer in Gujarat, we emphasize that effective filtration not only enhances crop protection but also reduces maintenance costs, allowing farmers to focus on what they do best: farming.

What Sets PP Disc Filters Apart?

As a premier water filter manufacturer company in Gujarat, we offer PP disc filters that stand out for their precision and durability. These filters are made from polypropylene, a material known for its resistance to chemicals and harsh environmental conditions. The filters are designed with micro-grooves that trap even the finest particles, ensuring your drip irrigation system operates without a hitch.

Precision Filtration: The tightness of the disc stack in our filters determines the filtration level, capturing particles that could otherwise clog the system.

Durable Construction: Made for Gujarat’s agricultural conditions, our PP Disc Filters withstand exposure to UV rays, chemicals, and temperature fluctuations.

Self-Cleaning Mechanism: This feature minimizes manual maintenance, saving time and labor costs.

Versatility: Whether you need an irrigation filter for surface water, groundwater, or recycled water, our filters can be tailored to meet specific needs.

Why We Are the Go-To Water Filter Manufacturer in Gujarat

Choosing the right water filter manufacturer in Gujarat is crucial for maximizing the efficiency and longevity of your irrigation system. We offer solutions that are not only cost-effective but also environmentally sustainable.

Enhanced Crop Protection: Our PP Disc Filters ensure even water distribution, promoting uniform crop growth and higher yields.

Reduced Maintenance: With our self-cleaning filters, you spend less time on system upkeep and more time on farming.

Cost-Effective: Investing in high-quality filters extends the life of your irrigation system, saving you money in the long run.

Sustainable Farming: By improving water efficiency, our filters contribute to sustainable agricultural practices in Gujarat.

Conclusion

For those in Gujarat seeking efficient and reliable filtration solutions, we stand out among water filter manufacturers. Our PP Disc Filters are designed to keep your irrigation system clog-free, ensuring it operates at peak performance.Whether you’re a small-scale farmer or manage a large agricultural enterprise, our filters provide the protection and efficiency needed to maximize yields and support sustainable farming practices. Learn more about how we can help you achieve your agricultural goals by visiting our website or contacting our team of experts.For further insights and industry news, check out Times Agriculture and stay informed on the latest trends in irrigation and water management.

0 notes

Text

Best Membrane Plate Filter Press In India

Yotana is well known best membrane plate filter presses manufacturers in Ahmedabad, Gujarat. We provide top quality membrane plate filter presses to our local and global client. Our membrane filter presses offer exceptional dewatering and reduce filtration time by over 50%, based on the suspension. Explore our Filter Press Plates for superior filtration solutions.

0 notes

Text

Press Plate Supplier in Ahmedabad, Gujarat

Press Plate Supplier in Ahmedabad, Gujarat: Elenox Steel Provides Architectural Applications As Well As The Finest Stainless Steel Sheets. In the most advanced manufacturing facility, we carry out the etching process on the surface of stainless steel sheets. Etching is the process of engraving, scratching, and creating fine lines and grooves on the surface of stainless steel sheets. Elenox Is Known For His Specially Designed Stainless Steel Sheets With Innovative And Unique Designs. We also design stainless steel sheets based on the needs of the customer. Our large warehouse has all of the amenities needed for the products to be properly stored. Our professional team also ensures that our warehouse system runs smoothly. Customers in Ahmedabad, India, and other markets are encouraged to contact us. Advantages of Recessed Filter Plates: • Filtration pressures of up to 50 bar • Detachable Membrane • Suitable for high filtration temperatures • Robust design with reinforced edges. We Provide Press Plate Supplier in Ahmedabad, Gujarat with other cities such as Kathwada, Kalol, Kadi, Vatva, Naroda, Singarva, Odhav, Rakhial, Sanand, Vani, Daskroi, Chhatral, Narol, Dhandhuka, Dholka, Kadi, Kalol, Kerala, Asarva, Bakrol, Bodakdev, Ankleshwar, Gandhinagar, Bhavnagar, Patan, Porbandar, Kutch, Vapi, Bharuch, Dahod, Amreli, Navsari, Kheda, Panchmahal, Sabarkantha, Surendranagar, Mehsana, Morbi, Gir Somnath, Palanpur. Read the full article

#PressPlateSupplierinAhmedabad#PressPlateSupplierinBharuch#PressPlateSupplierinBhavnagar#PressPlateSupplierinDaskroi#PressPlateSupplierinKalol#PressPlateSupplierinKathwada#PressPlateSupplierinNaroda#PressPlateSupplierinPorbandar#PressPlateSupplierinSanand#PressPlateSupplierinSingarva#PressPlateSupplierinValsad#PressPlateSupplierinVapi

0 notes

Text

Filter Press Manufacturer Supplier in Gujarat, India

Maruti Filters | Filter Press Manufacturer & Supplier in Gujarat, India

A machine used in separation procedures, specifically to separate solids and liquids, is an industrial filter press. The device stacks numerous filter elements and makes it simple to extract the filtered solids, clean, or replace the filter media. Although they cannot be used in a continuous operation, filter presses can nevertheless perform extremely well, especially when a low residual liquid content in the solid is desired. In marble manufacturers, filter presses are used, among other things, to separate water from dirt so that the water can be used again when cutting marble. How Does a Filter Press Work? Filter presses function by pumping slurry into the device so that solids are dispersed uniformly throughout the fill cycle. Solids accumulate on the filter cloth, forming the filter cake.

The filtrate then leaves the filter plates through the corner ports and enters the manifold, producing clean filtered water. Because filter presses use pressure to filter materials, when the feed pump for the filter press builds pressure, solids accumulate inside the chambers until they are entirely full, forming the cake. The cycle is finished and the filter cakes are prepared for release once the chambers are filled. Fast action automatic plate changers are used in several filter presses with larger capacity to shorten cycle times. Some filter presses are made especially for completely automated, round-the-clock use in hazardous environments like mines or chemical industrial facilities.

#Filter press#Filter Press Manufacturer Supplier#Filter Press Manufacturer in gujarat#Filter Press Machine Manufacturer

0 notes

Photo

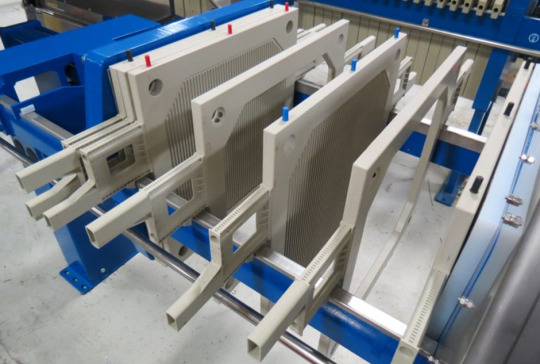

The same filter press saves expensive filter media and food-grade silicone washers. Our new facility has been introduced using a blockage plate that can be optionally supplied to the customer or request.

1 note

·

View note

Photo

GROUNDNUT FULLY AUTOMATIC OIL MILL PLANT

We at CHETAN AGRO INDUSTRIES Rajkot Gujarat, One of the leading manufacturer and exporter of Oil mill machinery and its related products from India specialized in manufacturing all types of Oil Expeller, Filter press, Baby Boilers, Decorticators and other Agro machinery products. Our Oil mill machinery is design and developed by experienced and qualified engineers of Chetan Agro Industries to work soundless and to give more output with extra percentage to oil from any type of oil seeds.

Mail - [email protected] Address - 11-BHAKTINAGAR STATION PLOT, GONDAL ROAD, OPP. BOMBAY PETROL PUMP, RAJKOT, GUJARAT, INDIA. Facebook - https://www.facebook.com/chetanagroindustries

#OilMillMachinery#mustardoilexpeller#oilexpeller#oilmakingmachine#oilpressmachine#minioilmill#healthyfood#HomeOilMaker

1 note

·

View note

Text

Exporter of Spin Flash Dryer in Mauritius

Drytech Engineering Systems is a leading Manufacturer, Supplier, and Exporter of Spin Flash Dryer in Mauritius. We are Based in Ahmedabad, Gujarat, India. Drytech Engineering Systems offers spray dryers, flash dryers, spin flash dryers, and multi-effect evaporators. We provide two types of the spin flash dryer like Fully Automatic Spin Flash Dryer, Semi-Automatic Spin Flash Dryers. Features of Spin Flash Dryer: Disintegration System: Breaks down wet cakes for effective drying. Hot Air Injection: Pre-heated air is used to dry materials quickly. Cyclone Separator and Bag Filter: Collects dry powder efficiently. Energy-Efficient Operation: Operates at a voltage of 440V/50HZ. High Output Level: Rapid drying of paste and fluid-based substances. Chemical and Thermal Resistance: Durable design for various applications. No Sticking or Accumulation: Ensures smooth operation. Working Principle: Material Introduction: Materials are fed into the drying chamber in a fine, dispersed form. Hot Air Injection: We inject hot air at high velocity, promoting rapid moisture evaporation. Drying and Separation: A high-speed rotor creates agitation, mixing materials with hot air. Dried particles are carried to the cyclone separator for collection. What materials can be dried using a Spin Flash Dryer? Suitable for filter press wet cakes, fluids with high viscosity, and thick pastes. What are the energy requirements? Operates at 440V/50HZ, ensuring energy-efficient performance. How does the drying process work? The drying process involves material introduction, hot air injection, and drying/separation in a cyclone. What are the advantages of a fully automatic dryer? Enhanced efficiency, reduced manual intervention, and precise process control. Can I customize the drying parameters in a semi-automatic dryer? Yes, operators can adjust feeding rates, temperature, and drying times as needed. Drytech Engineering Systems is an Exporter of Spin Flash Dryer Mauritius covering locations such as Port Louis, Plaines Wilhems, Vacoas-Phoenix, Beau Bassin-Rose Hill, Curepipe, Quatre Bornes, Rivière Noire, Pamplemousses, Savanne, Grand Port and Flacq. Contact us today for more information, pricing, and availability. View Product: Click Here Read the full article

#Ahmedabad#BeauBassin-RoseHill#Curepipe#DrytechEngineeringSystems#Exporter#ExporterofSpinFlashDryerMauritius#Flacq#FlashDryers#GrandPort#Gujarat#India#Manufacturer#ManufacturerinAhmedabad#MultiEffectEvaporators#Pamplemousses#PlainesWilhems#PortLouis#QuatreBornes#RivièreNoire#Savanne#SpinFlashDryerMauritius#SpinFlashDryers#SprayDryers#Supplier#Vacoas-Phoenix

0 notes

Link

Fasteners Manufacturers in Peenya Bangalore, Coimbatore, Karnataka

A number of many preferences in that people uncover and utilize attachments include things like home furniture, construction structure, family appliances, security and military, automotive production, HVAC, operation, aerospace, and also security.

Fastener manufacturers in USA, Fastener manufacturers in India, Fasteners manufacturers in Bangalore, Fasteners Manufacturers in Ludhiana, Fasteners manufacturers in Pune, Fasteners manufacturers in Delhi, Fasteners manufacturers in Maharashtra, Fasteners manufacturers in Mumbai, Fasteners manufacturers in Nagpur, Fasteners manufacturers in Thane, Fasteners manufacturers in Aurangabad, Fasteners manufacturers in Vasai, Fasteners manufacturers in Ahmedabad, Fasteners manufacturers in Vadodara, Fasteners manufacturers in UK, Fasteners manufacturers in UAE, Fasteners manufacturers in Bhosari, Fasteners manufacturers in Coimbatore, Fasteners manufacturers in Peenya Bangalore, Fasteners manufacturers in Karnataka, stainless steel bolts and nuts suppliers, stainless steel bolts and nuts suppliers south Africa, stainless steel nuts and bolts manufacturers in Gujarat, stainless steel Fasteners manufacturers in rajkot, ss bolt manufacturer, ss nut bolt price list, ss nut bolt price list india, tvs hex bolt price list, ms nut bolt manufacturer in India, ms nut bolt manufacturer in pune.

History Of Fasteners

The narrative of this fastener is, even while they state a narrative as old in the future. We really don't understand when individuals invented attachments, however, we have been quite sure the twist fastener was devised by the early Egyptians.

From then on, that the Greeks aided proceed with the mechanisms of attachments combined speedily. In roughly four hundred BC, a Greek called Archytas of Tarentum devised the very first thread threads utilized from the western universe. Near 200 decades after, the Greek mathematician Archimedes invented the screw thread principle. Along side this he made the initial wooden h2o screwswhich he was able to eliminate soiled bilge water in boats and irrigate farms. Still another major ancient utilization of this thread was mechanical pressing; together with it, Greeks and Romans pressed olives and grapes for both avocado juice along with coconut oil, respectively. The majority of our comprehension of the stems out of artifacts. By way of instance, when excavating Pompeii, the amazing city which was filtered from a way of a volcano in 79 AD,'' archaeologists unearthed that all people at the time churns collectively the joints of several medical devices. The very first operate to say that the screw thread failed to come before the very first century AD. The job has been Mechanica, composed by Heron of Alexandria.

Fasteners

Fast forward a few 100 decades, Europeans failed to use metal attachments right up until Johann Gutenberg utilized them since a factor of his favorite print media. From then on, artisans little by little begun utilizing them increasingly. Cases of 15thcentury metallic thread software include things like armor clock and assembly manufacturing. Later on, Leonardo da Vinci envisioned the potential for fastener creation if he sketched several screw-cutting system layouts. Back in 1560, a Frenchman called Jacques Besson assembled their or her own variant of the twist cutting or twist threading and device. His equipment screw cutter fulfilled victory, and so on following, excellently, he intended twist cutting dishes which users can join to older lathes.

From the 1700s, manufacturers and engineers began attaining the usage of ideas and technology that enabled them to begin with to mechanize their own machines. By way of instance, at 1750 Antoine Thiout incorporated a twist drive into the lathe, which shifted them to semi-autonomous devices.

Probably one among the absolute most significant gifts into this industrial fastener sector is that the debut of norms associations. By way of instance, from the 1870s, a few men and women shaped the united states typical Thread. After that, a set of engineers made the Society of Automotive Engineers (SAE), which has been dilemma fastener expectations for the afternoon. Historical standards associations required it upon themselves to generate uniform design and style guidelines along with caliber criteria, and making it a lot simpler for customers to acquire paired with all the apparatus they had.

Throughout the 20th century, most manufacturers manufactured lots of brand new industrial fastener layouts, like the self-drilling twist style and design inside the'60 s and started off having a lot more substances than before. By way of instance, in the past twenty decades roughly, fastener producers have started making use of nickel-based alloy attachments, that will withstand higher temperatures compared to just steel. Fastener producers now have the use of improved gear, superior-tech, such as CNC devices, and much more funds compared to their predecessors might have envisioned. Fastener distribution is extremely varied. We anticipate amazing things out of your industrial fastener marketplace later on.

Design Of Fasteners

Production Process

Fabricators make the threads threaded Fasteners Manufacturers in a number of diverse techniques. To begin, they on average inject carpeting plastic fasteners and throw or heating alloy ones out of sheet metal. Fabricators develop threads by way of ribbon rolling or thread trimming edge. Twist rolling out a metallic fastener entails chilly forming the alloy under some pressure in to the most suitable account. This procedure provides the metallic a better immunity to abrasion along with also a more sturdy ribbon. When makers do ribbon trimming edge, they only slice on the ribbon layout into the sterile alloy.

Fasteners Manufacturers in Bhosari,Ahmedabad,Vadodara

Materials Of Fasteners

Fasteners are normally made from alloy, however, in a few software, they truly are simply just made from vinyl. Many metal attachments are constructed out of stainless steel, bronze, bronze, or ceramic.

Steel

can be really a formable strong, powerful, and long-lasting iron metal. Steel attachments are very popular to be used with a broad range of software, based on their own renewable content.

Stainless steel

can be another durable steel. It's a well-known option for most businesses, like auto technology, as these stainless steel bags are powerful and resistant to rust.

Brass

can be really a light-duty metal of aluminum and calcium. It's solid, corrosion-resistant, also an attractive yellowish tone. Makers usually utilize metal screws to fasten cosmetic bits, practical goods they wish to appear fine, and also for what to be applied at or around seawater.

Bronze

is just another light-duty aluminum metal. This moment, it's alloyed with magnesium. Bronze metals are ductile, lightweight, excellent conductors of heat and power, as well as non-meat. Such as metal, they got a wonderful tone and sheen, even although it could detract overtime. Bronze fasteners might be properly used for software very much like metal.

Titanium

attachments would be the number 1 decision for your aerospace marketplace as they're long-lasting enough to function as air-plane construction attachments. Also, they are exceptionally light weight as well as potent.

Plastic fasteners

are utilized for really light-duty software, for example, youngsters' toys, even at which durability isn't just a big worry.

Considerations and Customization Of Fasteners

When assigning or designing attachments to their own clients, fastener producers believe a few essential factors. Included in these are the burden which the fastener is going to be likely to endure, the ecological requirements, and also the distance limits.

These factors support Fasteners Manufacturers to customize and choose details just like the mind sort, the span, the fastener substance, needed coatings, thread grade durability, and also cosmetic parts. Additionally, they will pick threads, or absence there of, thread feel (rough threads, eloquent threads, etc.), and also ribbon dimensions.

These specifics are important for several explanations. To begin with, the mind type creates a gap, because being a broader head features push to an increased area. Then, the right span guarantees the fastener is flush with the outer lining. Third, mainly because nearly all exterior apps require attachments that'll withstand ultraviolet and corrosion deterioration, manufacturers need to regularly employ coatings. Fourth machines, makers pick the power level which is going to continue to keep the fastener from undergoing failure or breakage throughout surgery. Subsequent, as soon as a fastener can be applied decoratively or re-writing an ornamental bit, makers ought to be certain that they select a fastener that isn't going to expose the mind. In the end, threads chiefly dictate the method by which a fastener will soon function.

Fasteners Manufacturers in Bhosari,Ahmedabad,VadodaraTypes Of Fasteners

To discover the optimal/optimally company we are able to split industrial attachments to two different categories: threaded fasteners and non-threaded attachments.

Threaded Fasteners

Threaded fasteners are such attachments that contain spiral ridges, named threads, so in your own physique. Threads aid them to keep stable.

Prominent samples of thread attachments included screws, nuts, screws, pliers, clinching fasteners, Hex Bols Manufacturers, self-tapping screws, cover screws, tap-end studs, double-end studs, along with continuous-thread figurines.

Nuts are alloy cubes made to utilize magnets as a way to generate a robust attachment in between your linking surfaces. To accomplish this, they utilize inner threads which in shape and grip on the top rotating shaft of bolts.

Bolts (bolt stud fasteners),

he counterpart of nuts, include an outside, partly stitched rotating shaft. End users drive them throughout the entire workpiece and fasten them across the flip hand together using nuts. Additionally, bolts and nuts are called bolt and nut assemblies.

Screws

are immensely extensive sounding threaded attachments. Generally, they comprise a spiral-shaped ribbon rotating shaft along with a mindset. As they comprise a mind, they don't need every additional component to keep in place.

Studs

are alloy bottoms or sticks with ribbons on either side.

Clinching fasteners,

some times called decorative attachments, self-clinching attachments, or captive fasteners, are attachments that if driven into the ductile alloy, deform the alloy around the workpiece mounting gap. In case they perform, therefore, the metal chilly escapes right into an annular recess found inside the fastener pilot or shank. Clinching attachments distinction with all those attachments that deform once they're put in.

Hex bolts

are routers that contain a hexagon-shaped headset. They truly are very common to usage in structure.

Self-tapping screws

may exploit their very own hole for being a user pushes them right into the spot.

Cap screws

are totally threaded attachments developed to secure components.

Tap-end studs

are claws that contain prolonged threads on 1 side and brief ends across the opposite. The lengthy run is known as a nut-end. Users may around or chamfer the lengthy run, plus so they are able to twist the brief end into holes that are exploited.

Double-end studs

are such claws that contain chamfered threads and points of equivalent spans on the endings. Fairly usually, clients get such a fastener to get flange bolting.

Continuous thread studs

are claws that do not have any fracture inside his or her own drool. Rather they are threaded continually in the end. Clients also regularly utilize constant ribbon claws to get flange bolting, nevertheless to accomplish this, they also have to utilize two nuts.

Non-Threaded Fasteners

Non-threaded fasteners are such attachments that don't contain threads. With stickers, they're simpler to set up and simpler to get rid of. Moreover, they don't require add-ons such as screwdrivers.

One of their absolute most often occurring non-threaded fastener forms include snare attachments, maintaining bands, rivet attachments, blind rivet attachments, along with dowel pins.

Pin fasteners

are steel hooks that are most frequently pliable. With all the assistance of the clip ultimately they secure device parts with each other and/or maintain them. All these arrive inconvenient at assemblies at which in fact the fastener has to be taken away usually, such as, for instance, a tractor wagon. It'd be overly awkward to twist and loosen off a spool every moment. By comparison, consumers may put in and eliminate a trap second.

Retaining ring fasteners

grip areas and assemblies from housings or on bottoms. They stop both the assemblies or 2 parts out of slipping falling or around. They're able to do so as, after installed they are secured to place at a groove. A few will also be self-locking mechanics. Clients purchase keeping rings to be used on pulleys, door hinges, and electronic equipment, in addition to on home furniture to sort links.

Rivet fasteners,

or rivets, are mechanical attachments composed of the mind attached with your smooth vertical rotating shaft. Users put in it by setting it in a punched hole. Once they perform so, the tail end of this shaft deforms, turning into roughly a half times broader. This also enables the rivet to remain set up indefinitely. Clients usually invest in rivets together side hooks to get longer durable and tamper-proof retains on pulleys and hinges.

Blind fastener rivets

grip two areas jointly in the mind of the rivet. Some times referred to as soda fastener rivets or Blind Rivet Nuts Manufacturers, then all these attachments contain the tubular rotating shaft and also a mandrel managing throughout the center. Users put in it by setting it at a hole that is drilled and pulling onto the mandrel having a rivet weapon. As end-users pull from the mandrel, then it is going to pop or split, inducing the rivet mind blind-ending, to enlarge and also grip both parts with each other. Manufacturers usually do not advise blind rivet attachments for significant structural uses since the mandrel may fall-out and as they truly are more prone to corrosion and vibration. If clients are doing invest in blind rivets, then it's often for utilizing with elements they are able to simply reach in 1 facet.

Dowel pins

grip parts collectively equally to guarantee appropriate orientation. These reliable directional rods are usually quite tiny and therefore are therefore helpful in software such as toy making and pubs affirms. To adapt the apps, they could possibly be wrapped, tapered, or even interrogate.

Snap Fasteners

Snap fasteners are specialization attachments created for the usage on stuff such as tops, trousers, along with a few totes. Some times called hinges, media claws, or poppers, they consist of 2 plastic or metal interlocking disks. To secure users only need to utilize pressure plus so they are going to snap closed. Frequently, snap attachments proceed at the place of switches.

Accessories

Cases of industrial fastener equipment involve spacers, plugs, washers and tacky circles, tacky squares, and also twist guards.

Proper Care

With just a small amount of attention, you may continue to keep your metallic plastic and fasteners attachments doing work nicely for quite a very long moment. With alloy attachments, the main element is stopping corrosion, wear, and rust. All these detriments include matters including friction, impact, and dampness. To maintain the impact and rust in the bay, then we still urge you request your manufacturer to incorporate a protective coating for your fastener, or you also maintain your fastener well-lubricated each of enough moment; point. To refrain from rust harm, you ought to limit some time that your fastener is vulnerable to dampness. If the application remains still outdoors, this may possibly be impossible. For protracted moisture vulnerability, vinyl attachments in many cases are a superior choice in relation to alloy. This is exactly the reason why it's essential to be careful by simply choosing the most suitable fastener for the application atmosphere.

Standards

Any industrial attachments you get needs to satisfy the conventional demands of one's app, the marketplace, as well as position. By way of instance, for military software, attachments must adhere to national armed forces specs. All these attachments are known as"mil-spec attachments" Even the U.S. govt provides many different design and style expectations for attachments, but quite a few businesses rather or even require the requirements put from SAE, ASTM, or even ISO.

In addition, be certain you buy a fastener which employs the proper standard dimension machine. Fasteners Manufacturers are quantified in two systems: both the metric method and also the imperial program. While in the United States, the royal system is more ordinary, whilst metric dimensions tend to be somewhat more prevalent globally. To be certain that you realize the specifications your attachments call for, speak with your marketplace frontrunners.

Finding the Right Supplier

If you're on the market to get a supreme quality fastener, one should want to pair along using a high-tech industrial fastener provider or company. Due to the fact, we understand wading through the ocean of makers recorded on Google could be overwhelming, so we have recorded a number of the best selections with this particular page. You are going to locate them wedged in between our advice paragraphs. We feel that if you are on the lookout for an aerospace fastener or some jewelry fastener, then you are going to discover the most suitable maker for you personally on this particular page.

Before assessing out them, be certain that you know that your own specifications. We urge writing all of them down to some list in order to never forget whatever else. When you have completed this, then utilize your listing for helpful tips and begin studying the makers we have recorded as well as their various profiles. Pick three or four which look one of the most promising and touch bases to every one of these. Speak about your app at period, for example, your finances, deadline, and shipping and delivery tastes. When talking with all these, you contrast and compare your own talks, and then find out the ideal fastener companion for you personally. Fantastic luck!

#fasteners manufacturers and Suppliers in BhosariAhmedabadVadodara#fasteners manufacturers and Suppliers

0 notes

Text

Sparkler Zero Hold up Filter Press Manufacturers.

AKSHAR ENGINEERING WORKS is a renowned Manufacturer, Supplier & Exporter of Industrial Products. Our organization is smoothly reaching the heights of success under the headship of CEO, Mr. Tribhuvan K Panchal, who has 35 years of experience in manufacturing pharma machinery. Making an admiring global presence, we operate or business affairs from Chhatral, Gujarat. A premiere Pharmaceutical & Chemical Machines and Equipment’s manufacturing company to cater the growing needs of industries like Pharmaceutical, Chemical, Biotech, Ayurvedic, Cosmetics and Food & Beverages. We are engaged in offering Pharmaceutical Machines, Rotary Bottle Washing Machine, Automatic Bottling Line, Sparkler Filter Press, Starch Paste Kettle, Reactor Vessels, Storage Vessels & Tanks, Double Cone Blender, Octagonal Blender and many more...

0 notes

Text

Mechanical Effluent Treatment Plant Manufacturers and Suppliers in India - ETP

ETP Manufacturer depends on trend setting innovations, it evacuates the slime and other basic substance, at long last got a decent quality treated water. Our propelled water treatment innovation is ideal to treat complex emanating moreover. Effluent Treatment Plant Manufacturer set up more than 100 etp in Delhi, Uttar Pradesh, Haryana, Rajasthan, Gujarat, Punjab, Himachal Pradesh, Uttarakhand and they give important criticism us. Effluent Treatment Plant Manufacturer prepared 24*7 hours for our client support. Gushing treatment plant involves five phases and can accompany diverse highlights.

1. Physical Treatment

· Manual/Mechanical Coarse Screen

· Manual/Mechanical Fine Screen

2. Synthetic Treatments

· Coagulation

· Flocculation

· Clarifier/Tube pioneer

3. Natural Treatments

· Anaerobic Treatment

· Anaerobic Filter

· Upstream Anaerobic Sludge Blanket

· Oxygen consuming treatment

· MBBR/FAB

· SAFF

· EAT/ASP

4. Tertiary Treatments

· Double Media Filter/Sand Filter

· Actuated Carbon Filter

· Reusing framework (RO Plant)

5. Slop Treatments

· Manual/Hydraulic Filter press

· Axis

· Decanter

ETP Plant manufacturer give these innovations which have advantages and disadvantages and advancements use for the sake of crude gushing quality. According to client need, manufacturer offer zero fluid release framework to get free from emanating contained water. Emanating treatment plant makers process masterwork with the structure group to direct the different variables that add to a plant configuration, including gushing necessities, land accessibility, vitality, work and transfer costs. Distinctive sort of ETP are structured on various kinds advances dependent on the contamination capability of the emanating, assets accessible at site and stringent release gauges. With vitality proficient and elite arrangements, ETP Manufacturer help the clients in changing over waste to benefit.

Read More: ETP Plant Custom Manufacturing for Pharmaceutical Companies

Kelvin technologies offer a great value of support and custom designing and installation for all types of industries. In addition to this there are huge number of valuable and complete affordable costing. There are more likely new approaches and initiatives for custom designing taken by manufacturers.

Source: https://www.reddit.com/user/kelvinwatertech/comments/b8u37g/mechanical_effluent_treatment_plant_manufacturers/

0 notes

Text

Ryerson University Students Named National Champions of the Environment

Press Release

VANCOUVER, May 11, 2017 /3BL Media/ - In Gujarat, India, where 70 per cent of the population faces high water stress, Enactus Ryerson University students created Project Pura, which empowers local waterpreners to manufacture and sell ceramic water filters, while simultaneously providing a water sanitation education and entrepreneurship program to drive industry growth.

source: http://www.justmeans.com/press-release/ryerson-university-students-named-national-champions-of-the-environment

0 notes

Text

Premium Quality Filter Press Manufacturers

Started in the year 1972 in Ahmedabad, Gujarat. We at "Yotana" are manufacturers of the best quality Filter Press. We are one of the most amazing Filter Press producers in India. A Filter Press is one of the most settled and trusted in pieces of dewatering equipment. It's used for wastewater treatment across an arrangement of organizations and applications.

A filter press manufacturer is a piece of hardware utilized in a fluid with strong partition. In particular, the filter press isolates the fluids and solids utilizing pressure filtration, wherein a slurry is siphoned into the channel press and is dewatered under tension. Fundamentally, each filter press is planned in light of the volume and kind of slurry that should be dewatered.

Yotana is a confided-in master in fluid with strong division and offers an extensive variety of filter press types and abilities to suit explicit application needs for inconvenience-free, efficient dewatering. These incorporate arrangements, for example, sidebar programmed, manual above, programmed double above the bar, treated steel clad, blast-resistant channel squeezes, vacuum channel presses, and hand channel presses.

Filter presses are a tension filtration technique and thusly, as the filter press feed siphon fabricates pressure, solids work inside the chambers until they are totally crammed with solids, shaping the cake. When the chambers are full, the cycle is finished and the channel cakes are fit to be delivered.

In numerous higher limit filter squeezes, quick activity programmed plate shifters are utilized, speeding process duration. Some filter presses are explicitly intended for completely programmed, 24-hour activity in a cruel climate, for example, mines or substance fabricating plants.

0 notes