#Feed Mixers Market Size

Text

Feed Mixers Market Share, Trends, Analysis, Report and Forecast 2023-2028

Feed mixers are industrial equipment that are used to feed ingredients and mix premixes in feed mills. They play a crucial role in the right and efficient mixing of feed and thus help in the process of feed production.

0 notes

Text

Making Organic Chicken Feed

A solid, well-balanced feed is necessary to grow healthy and big chickens. Although the readily available chicken feeds are simple fixes, are they enough for your poultry?

The commonly available chicken feed has been nutritionally calculated. But when it concerns business, one cannot rely on packaged goods.

In addition, the idea of the “green revolution” has encouraged people to produce their feed from all-natural products.

You may produce your chicken feed on your farm using only organic material. There are generally four different types of chicken feed.

These varieties include mashes, crumbles, pellets, and whole grains.

The chickens on a farm are fed avariety of feeds.

Do you intend to use organic feed to feed your flocks of chickens?

Continue reading the post to discover how to make organic chicken.

Required Ingredients

Chickens need a diet that is balanced nutritionally, with an appropriate amount of lipids,proteins, minerals, vitamins, and carbohydrates, just like humans need.

Additionally, fresh water is a crucial component of the diet in chicken feed.

You should check the water needed every two hours because chickens drink twice as much water as they feed.

In addition, individuals frequently overlook the additional nutritional components of vitamins and minerals in chicken feed.

The age of the chicken is a key consideration when creating the chicken feed.

Different types of feed are required for poultry at different developmental stages.

Similarly, adult chickens that lay eggs require a significant amount of calcium in their diet.

To improve food digestion and strengthen the chicken’s immune system, additional nutrients, such as oregano, cayenne, and probiotics, are added.

Making Organic Chicken Feed: The Process

Feeding your chickens organic chicken feed is safer and more nutrient-dense.

While creating your blend, you must pay special attention to the macronutrients and micronutrients.

Another crucial aspect to take into account while grinding one’s own organic chicken feed is food texture.

Chicken food’s textures

1. Mash

Like newborn babies, the newly hatched chicks’ digestive systems are still developing.

Furthermore, the chicks’ beaks are still growing.

Thus, they are unable to consume the coarse feed.

As a result, the meal for the young chickens begins as a mash and has a consistency akin to potting soil.

Starter feed is another name for the food intended for young chicks. It is high in protein to suit their nutritional needs.

This feed is given to the baby from birth to 8 to 12 weeks.

2. Crumble

The size and texture of crumbles are a little bit larger and more gritty than mash, similar to granola.

By the chicken’s 12 weeks of age, this is often fed.

Chicken breeders frequently use crumbles as a mediator diet to switch between mash and pellets.

The chick is fed until it begins to lay eggs for the layers.

3. Pellets

The chicken is fed pellets made of entire grains once it has reached adulthood and maturity. Only chicken that has reached an age of at least 18 weeks is best suited for this food texture.

These feeds are more extensive and more challenging to digest. The pellets are in good shape, making them simple to store and giving them to backyard poultry.

Making Organic Chicken Feed: The Step-by-Step Process

Making organic chicken feed at home can be time-consuming and labor-intensive. The steps involved are as follows:

Gather the necessary items, such as corn, fish meal, peas, oatmeal, kelp, and aragonite. All kinds of essential nutrients must be present in the elements.

Obtain a reliable supply of vitamins and minerals. You can also choose the readily accessible vitamin and mineral combination on the market.

Dry off and wash all the organic raw ingredients. Now crush those components in a spotless mixer grinder.

In an enormous container, combine the components in an appropriate ratio for the age group. The growing chicken needs to be fed more proteins than carbohydrates.

Feed mixture created from organic ingredients. Due to their distinct growing requirements and weak digestive systems, extremely young chicks may not be acceptable for the recipe above.

Follow these steps to create an organic feed for young chickens:

Incorporate at least 22% protein into the feed composition.

To mix and mash the meal before giving it to the chicks, grind it into a fine powder.

Brewer’s yeast, sunflower oil, and other mineral mixtures are available for use as chicken feed.

For young chicks, water is a crucial component of their diet.

Despite being wholesome and risk-free, homemade organic chicken feed has several drawbacks. These are a few of the penalties:

It can be challenging to search for each item in lesser quantities.

Making the feed is a highly time-consuming and laborious task.

These DIY feeds are not subject to quality inspection. As a result, it is impossible to know whether the meal contains all nutritional benefits of the chicken feed.

2 notes

·

View notes

Text

Leading Fly Ash Brick Making Machines Available in India

In the rapidly evolving construction industry of India, the demand for sustainable and cost-effective building materials has never been higher. Fly ash bricks have emerged as a popular alternative to traditional clay bricks, offering superior strength, durability, and environmental benefits. As a result, the market for fly ash brick making machine in India has grown significantly. This article explores the leading fly ash brick making machines available in India, their features, and the advantages they offer to manufacturers and construction professionals.

The Rise of Fly Ash Bricks in India

Fly ash, a byproduct of coal combustion in thermal power plants, has found a valuable application in the construction industry. By utilizing this waste material, fly ash bricks not only reduce environmental impact but also provide excellent building properties. The Indian government's push for sustainable construction practices has further accelerated the adoption of fly ash bricks across the country.

Types of Fly Ash Brick Making Machines

1. Automatic Fly Ash Brick Making Machines

Automatic fly ash brick making machines are at the forefront of brick production technology. These machines offer high production capacity, consistent quality, and minimal human intervention. Key features include:

- Hydraulic pressure system for uniform compression

- PLC-controlled operations for precision and efficiency

- Automatic material feeding and brick ejection mechanisms

- Capacity ranging from 10,000 to 50,000 bricks per day

BTM Product's advanced automatic fly ash brick making machine in India stands out for its robust construction and energy-efficient design, making it a top choice for large-scale manufacturers.

2. Semi-Automatic Fly Ash Brick Making Machines

Semi-automatic machines strike a balance between production capacity and initial investment. They are ideal for medium-scale operations and offer:

- Manual material feeding with automated compression and ejection

- Simplified controls for ease of operation

- Production capacity of 5,000 to 15,000 bricks per day

- Lower power consumption compared to fully automatic machines

3. Manual Fly Ash Brick Making Machines

For small-scale producers and startups, manual fly ash brick making machines provide an affordable entry point into the industry. These machines typically feature:

- Hand-operated levers for compression

- Simple design for easy maintenance

- Production capacity of 1,000 to 3,000 bricks per day

- Minimal power requirements

Key Components of Fly Ash Brick Making Machines

Understanding the essential components of these machines is crucial for operators and potential buyers:

1. Mixer: Ensures thorough blending of fly ash, cement, sand, and water

2. Mould box: Determines the size and shape of the bricks

3. Hydraulic system: Provides the necessary pressure for brick formation

4. Control panel: Manages machine operations and settings

5. Conveyor system: Facilitates smooth material flow and brick transportation

Factors to Consider When Choosing a Fly Ash Brick Making Machine

When selecting a fly ash brick making machine in India, consider the following factors:

1. Production capacity requirements

2. Available space and infrastructure

3. Budget constraints

4. Energy efficiency and operating costs

5. Ease of maintenance and availability of spare parts

6. Versatility in producing different brick sizes and shapes

BTM Product offers a range of fly ash brick making machines to suit various production needs and budgets, ensuring that businesses can find the right fit for their operations.

Benefits of Investing in a Quality Fly Ash Brick Making Machine

1. Increased productivity and efficiency

2. Consistent brick quality and dimensional accuracy

3. Reduced labor costs and human error

4. Improved workplace safety

5. Enhanced profitability through economies of scale

6. Ability to meet growing market demand for sustainable construction materials

Interlocking Tiles and Paver Blocks: Expanding Your Product Line

While fly ash bricks form the core of many construction projects, manufacturers can diversify their offerings by investing in machines capable of producing interlocking tiles making machine in India and paver block making machine in India. The interlocking tiles making machine in India has gained popularity due to the increasing demand for decorative and functional outdoor flooring solutions.

Similarly, the paver block making machine in India offers manufacturers the opportunity to tap into the growing market for landscaping and urban development projects. These machines often share similar technology with fly ash brick making machines, allowing for easy integration into existing production lines.

BTM Product's versatile machinery lineup includes high-quality interlocking tiles making machine in India and paver block making machine in India, enabling businesses to expand their product range and capture new market segments.

Maintenance and Optimization of Fly Ash Brick Making Machines

To ensure longevity and optimal performance of your fly ash brick making machine, consider the following maintenance tips:

1. Regular cleaning and lubrication of moving parts

2. Timely replacement of wear-and-tear components

3. Periodic calibration of pressure and timing settings

4. Proper training of operators for efficient machine usage

5. Implementing a preventive maintenance schedule

BTM Product provides comprehensive after-sales support and maintenance services to keep your machines running at peak efficiency.

Environmental Impact and Sustainability

The fly ash brick making machine in India plays a crucial role in promoting sustainable construction practices. By utilizing fly ash, a waste product from thermal power plants, these machines contribute to:

1. Reduction of landfill waste

2. Lower carbon emissions compared to traditional brick manufacturing

3. Conservation of natural resources like clay and topsoil

4. Energy-efficient production processes

Investing in a fly ash brick making machine aligns with India's commitment to sustainable development and can provide a competitive edge in an increasingly eco-conscious market.

Future Trends in Fly Ash Brick Making Technology

As the construction industry continues to evolve, fly ash brick making machines are expected to incorporate advanced features such as:

1. IoT integration for remote monitoring and control

2. Artificial intelligence for predictive maintenance and quality control

3. Enhanced energy recovery systems for improved efficiency

4. Automation of material handling and packaging processes

BTM Product remains at the forefront of these technological advancements, continuously innovating to meet the changing needs of the industry.

Conclusion

The fly ash brick making machine in India has revolutionized the construction materials industry, offering a sustainable and cost-effective alternative to traditional brick production. From small-scale manual machines to high-capacity automatic systems, there is a wide range of options available to suit various production needs and budgets.

By investing in quality equipment from reputable manufacturers like BTM Product, businesses can capitalize on the growing demand for fly ash bricks while contributing to sustainable construction practices. The versatility of these machines, which can often be adapted to produce interlocking tiles making machine in India tiles and paver block making machine in India, provides additional opportunities for market expansion and diversification.

As the industry continues to evolve, staying informed about the latest technological advancements and maintaining your equipment properly will be key to long-term success in the fly ash brick manufacturing sector. With the right machine and a commitment to quality production, manufacturers can play a vital role in building a more sustainable future for India's construction industry.

#fly ash brick making machine in India#paver block making machine in India#interlocking tiles making machine in India

0 notes

Text

Small Concrete Plant For Sale

Small concrete plant is a kind of equipment specialized in producing concrete, which is usually used in small projects or construction sites. It is characterized by small size, easy to move, simple operation, etc., and is suitable for a variety of smaller-scale construction projects.

The following are several common models of small concrete plant for sale:

1.HZS25 concrete batching plant:

This is a small concrete plant with a capacity of 25 cubic meters per hour, which is suitable for small construction projects or precast concrete plants. It has the features of simple structure, convenient operation, low maintenance cost, convenient construction, relatively low investment cost, favored by users. This model concrete batching plant equipment has a low price, small footprint, low personnel requirements, and is very suitable for large precast component plants and small industrial and civil construction projects such as roads and bridges.

2.HZS35 concrete batching plant:

Its theoretical production capacity is 35 cubic meters per hour, using JS750 forced concrete mixer, users can choose double or single machine station according to the specific output requirements. It is suitable for small and medium-sized building projects or road construction. It has the advantages of high efficiency and energy saving, good stability, low investment cost, etc., and the market demand is large.

3.HZS50 concrete batching plant:

This is a small concrete batching plant with a capacity of 50 cubic meters/hour. HZS50 concrete batching plant is actually a simple configuration of HZS60 concrete batching plant, which adopts js1000 concrete mixer, but the feeding method adopts crawler hopper feeding (also known as elevating hopper lifting up the material), which occupies less capital, occupies less area, and is equipped with fewer equipments than HZS60 concrete batching plant. It is suitable for small and medium-sized concrete production plants or commercial concrete projects. It is characterized by high automation, high production efficiency, stable quality and strong market competitiveness.

In general, small concrete plant has a certain demand in the market, especially in urban construction and infrastructure construction, small concrete plant is more widely used. With the acceleration of urbanization and the development of the construction industry, the market prospect of small concrete batching plant is more optimistic.

This resource is from http://www.concrete-mix-plant.com/news/small-concrete-plant-for-sale.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

Feed Robotics Market by Product Type (Feed Pushers, Feed Mixers, Feeding robots), Farming Environment (Indoor, Outdoor), End Use Application (Dairy Farms, Poultry Farms, Swine Farm), Functionality, Farm Size & Region - Global Forecast to 2029

0 notes

Text

The Self Loading Feed Mixer Market is anticipated to grow from USD 719.4 million in 2024 to USD 996.73 million by 2032, achieving a compound annual growth rate (CAGR) of 4.16%.The agricultural industry is witnessing a revolution, driven by advancements in technology and machinery. One of the pivotal innovations reshaping this landscape is the self-loading feed mixer. These sophisticated machines are designed to streamline the process of mixing and distributing feed, offering substantial efficiency gains for farmers. The global self-loading feed mixer market is experiencing significant growth, propelled by the increasing demand for automated farming solutions, the need for enhanced feed quality, and the overall push towards sustainable agricultural practices.

Browse the full report at https://www.credenceresearch.com/report/self-loading-feed-mixer-market

Market Overview

Self-loading feed mixers are multifunctional machines that combine the capabilities of loading, mixing, and discharging feed. They are engineered to handle various types of feed, including silage, hay, and grains, ensuring a homogeneous mixture that meets the nutritional needs of livestock. The market for these machines is expanding rapidly, with significant demand from both small-scale and large-scale farming operations.

Key Drivers of Market Growth

1. Technological Advancements: Continuous innovation in agricultural machinery has led to the development of more efficient and user-friendly self-loading feed mixers. Advanced models come equipped with features such as programmable controls, precise weighing systems, and real-time monitoring capabilities, which enhance operational efficiency and feed quality.

2. Labor Shortages: The agricultural sector is grappling with a shortage of skilled labor, prompting farmers to adopt automated solutions. Self-loading feed mixers reduce dependency on manual labor, allowing for more consistent and timely feeding schedules.

3. Rising Livestock Production: With the global demand for meat and dairy products on the rise, livestock producers are under pressure to improve productivity. Self-loading feed mixers play a crucial role in optimizing feed management, contributing to better animal health and higher yields.

4. Sustainability Concerns: Environmental sustainability is becoming a priority in agriculture. Self-loading feed mixers can minimize feed wastage and reduce the environmental footprint of farming operations by ensuring precise feed distribution.

Market Segmentation

The self-loading feed mixer market can be segmented based on several factors:

1. Type:

- Vertical Mixers

- Horizontal Mixers

2. Capacity:

- Small (up to 10 cubic meters)

- Medium (10-20 cubic meters)

- Large (above 20 cubic meters)

3. Application:

- Dairy Farms

- Poultry Farms

- Swine Farms

- Others

4. Region:

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Regional Insights

North America and Europe dominate the self-loading feed mixer market, driven by advanced farming practices and significant investments in agricultural technology. In these regions, the adoption of automated feeding solutions is particularly high, supported by government initiatives and subsidies aimed at modernizing the agricultural sector.

The Asia-Pacific region is emerging as a lucrative market, with countries like China and India experiencing rapid growth in livestock production. The rising population and increasing demand for animal protein are key factors propelling market expansion in this region. Furthermore, improving economic conditions and growing awareness about the benefits of automated feed mixers are encouraging farmers to invest in these machines.

Competitive Landscape

The self-loading feed mixer market is highly competitive, with several key players vying for market share. Prominent companies include Kuhn Group, Trioliet, Faresin Industries, and Storti SpA. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position.

For instance, Kuhn Group has introduced a range of self-loading feed mixers equipped with advanced features such as the IntelliMix control system, which enhances mixing efficiency and reduces fuel consumption. Similarly, Trioliet’s Solomix series is renowned for its robust design and versatility, catering to the needs of different farming operations.

Future Prospects

The future of the self-loading feed mixer market looks promising, with several trends expected to shape its trajectory. The integration of smart technologies, such as IoT and AI, is anticipated to revolutionize feed management, offering farmers real-time insights and predictive analytics. Moreover, the shift towards sustainable farming practices will continue to drive demand for efficient and eco-friendly feed mixers.

Key Player Analysis

Supreme International

Trioliet

KUHN

RMH Lachish Industries

Jaylor

Casale

Segments:

Based on Capacity:

5 to 12m³

12 to 20m³

20 to 28m³

28 to 36m³

Others (more than 36m³)

Based on Application:

Farms:

Small Farms

Medium Farms

Large Farms

Feed Factories:

Small Feed Factories

Medium Feed Factories

Large Feed Factories

Based on the Geography:

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Apollo Carmix: Self Loading Concrete Mixer, Transit Mixer & Dumper Manufacturer & Supplier

In the realm of construction projects, the efficiency of concrete handling and mixing equipment holds paramount importance, directly impacting project progress and final quality. Choosing services from reputable organizations becomes imperative. Apollo Infratech Pvt. Ltd. stands out as a distinguished provider of a diverse range of concrete equipment tailored for construction purposes.

In an exciting development, Apollo Infratech Pvt. Ltd. has forged a formidable partnership with Carmix, a global heavyweight in heavy-duty equipment supply. This strategic alliance, now known as ACEPL, marks a significant leap forward, promising enhanced production and distribution of the highly sought-after self-loading concrete mixer.

The evolution of ACEPL has been marked by steady growth, bolstering the company's reputation as a leader in the construction industry. With the recent joint venture, ACEPL is poised to transcend borders, catering to international markets. Among its flagship offerings are the self-loading mixers, available in two sizes: the 25 FX and the 4 TT. ACEPL's product lineup includes a comprehensive range, featuring the Carmix One, Carmix 2.5 TT, Carmix 5.5 XL, Carmix Dumper D6, and

Carmix Carsilos.

At the helm of Apollo Carmix is a highly skilled management team, dedicated to delivering superior products and concrete mixing equipment that add tangible value to clients' projects. The company's proactive approach includes hosting various roadshow events, such as the recent Karnataka event, which provided invaluable insights to building contractors and industry stakeholders.

Self-Loading Concrete Mixer:

Featuring a mechanism that seamlessly feeds unmixed materials into the mixer, the 25FX model boasts a capacity of 3450 liters, delivering up to 2.5 m3 of concrete. Equipped with a hydrostatic 4-wheel drive transmission, a water-cooled 4-stroke engine with a turbocharger, and a loading shovel with a 400-liter capacity and hydraulic opening gate, this Concrete mixers exemplifies efficiency and performance.

Self-Loading Transit Mixer:

With versatile capacities of up to 4 cubic meters, the self-loading concrete mixers covers a substantial concrete area. User-friendly operation and a design conducive to constant agitation ensure consistent quality mixes, while durability remains a hallmark of this equipment.

Dumper:

The Carmix dumpers, available through ACEPL, boasts a load capacity of up to 1362 gallons when properly heaped. Powered by a turbocharged, water-cooled engine delivering a maximum power of 80 kW, and featuring Dana Spicer axles and front axle steering, this dumper mixer is engineered for rugged performance. Industrial-grade off-road tires with high resistance to wear and tear enhance grip and longevity.

Apollo Infratech Pvt. Ltd. stands as a beacon of quality and innovation in the construction industry. Through its partnership with Carmix – Italy, Apollo Carmix introduces a range of self-loading mixers that redefine efficiency and reliability standards.

Committed to continual innovation and customer satisfaction, Carmix mixer remains a frontrunner in the concrete mixing plant, driving progress and setting new benchmarks of excellence with each passing day. Explore the future of concrete mixing with Carmix – where innovation meets reliability.

0 notes

Text

Bakery Processing Equipment Market Size, Share, Growth, Trends, Demand and Opportunity Analysis

Bakery Processing Equipment Market report is an important manuscript for every market enthusiast, policymaker, investor, and market player. The market research and analysis conducted in this report assists clients in forecasting the investment in an emerging market, growth of market share or success of a new product. In addition, this business report endows with a delegate overview of the market where it identifies industry trends, determines brand awareness, potency and insights and provides competitive intelligence. Report contains strong and weak points of the competitors and analysis of their strategies with respect to product and industry. Bakery Processing Equipment Market is the most established tool and hence used widely to generate market research report.

With the complete understanding of business environment that is best suitable for the requirements of the client, Bakery Processing Equipment Market business report has been generated. Businesses can also achieve insights into profit growth and sustainability programs with this market report. Market drivers and market restraints explained in this report gives idea about the rise or fall in the consumer demand for the particular product depending on several factors. This market document contains all the company profiles of the major players and brands. Each of the topics is properly elaborated with the in-depth research and analysis for generating an absolute Bakery Processing Equipment Market survey report.

Bakery Processing Equipment Market, By Equipment Type (Ovens, Mixers, Slicers and Dividers, Proofers, Retarders, Sheeters, Moulders, Depanners, Freezers and Coolers, Chillers, Dough Feeding Systems, Pan Greasers and Depositors, Handling Systems, Piston Filling Injectors, and Others), Mode of Operation (Automatic and Semi-Automatic), Function (Baking, Kneading, Mixing, Extrusion, Cooling, Molding, Filling, Enrobing, and Others), Application (Cookies and Biscuits, Breads, Cakes and Pastries, Donuts and Croissants, Pizza Crusts, Muffins, Bagels, Crackers, Pies, Waffles, and Others), End-Use (Bakery Processing Industry and Food Service Industry), Distribution Channel (Direct and Indirect) – Industry Trends and Forecast to 2031.

Access Full 350 Pages PDF Report @

Bakery Processing Equipment Key Benefits over Global Competitors:

The report provides a qualitative and quantitative analysis of the Bakery Processing Equipment Market trends, forecasts, and market size to determine new opportunities.

Porter’s Five Forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make strategic business decisions and determine the level of competition in the industry.

Top impacting factors & major investment pockets are highlighted in the research.

The major countries in each region are analyzed and their revenue contribution is mentioned.

The market player positioning segment provides an understanding of the current position of the market players active in the Personal Care Ingredients

Table of Contents: Bakery Processing Equipment Market

1 Introduction

2 Global Bakery Processing Equipment Market Segmentation

3 Executive Summary

4 Premium Insight

5 Market Overview

6 Bakery Processing Equipment Market, by Product Type

7 Bakery Processing Equipment Market, by Modality

8 Bakery Processing Equipment Market, by Type

9 Bakery Processing Equipment Market, by Mode

10 Bakery Processing Equipment Market, by End User

12 Bakery Processing Equipment Market, by Geography

12 Bakery Processing Equipment Market, Company Landscape

13 Swot Analysis

14 Company Profiles

Critical Insights Related to the Bakery Processing Equipment Included in the Report:

Exclusive graphics and Illustrative Porter’s Five Forces analysis of some of the leading companies in this market

Value chain analysis of prominent players in the market

Current trends influencing the dynamics of this market across various geographies

Recent mergers, acquisitions, collaborations, and partnerships

Revenue growth of this industry over the forecast period

Marketing strategy study and growth trends

Growth-driven factor analysis

Emerging recess segments and region-wise market

An empirical evaluation of the curve of this market

Ancient, Present, and Probable scope of the market from both prospect value and volume

Some of the major players operating in the global bakery processing equipment market are:

Robert Bosch GmbH (Germany)

Merand (France)

Zibo Taibo Industrial Co., Ltd (China)

Kaak (Netherlands)

RONDO BURGDORF AG (Switzerland)

FRITSCH (Germany)

MECATHERM SAS (France)

CandyWorx (U.S.)

Reading Bakery Systems (U.S.)

Silvestri S.r.l (Italy)

Aasted ApS (Denmark)

The Henry Group, Inc. (U.S.)

GOSTOL-GOPAN d.o.o. Nova Gorica (Slovenia)

LINXIS GROUP (France)

APPLE Machinery (India)

Illinois Tool Works Inc. (U.S.)

RHEON Automatic Machinery Co., Ltd. (U.S.)

Browse Trending Reports:

Quick Service Restaurants and Fast Food Market Size, Share, Key Drivers, Trends, Challenges and Competitive Analysis https://www.databridgemarketresearch.com/reports/global-quick-service-restaurants-and-fast-food-market

Functional Beverages Market Size, Share, Demand, Future Growth, Challenges and Competitive Analysis https://www.databridgemarketresearch.com/reports/global-functional-beverages-market

Food Industry Pulsed Electric Field (PEF) Systems Market Size, Share, Trends, Growth Opportunities and Competitive Outlook https://www.databridgemarketresearch.com/reports/global-food-industry-pulsed-electric-field-pef-systems-market

Baby Food Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus https://www.databridgemarketresearch.com/reports/global-baby-food-market

Guacamole Market Size, Share, Trends, Demand, Future Growth, Challenges and Competitive Analysis https://www.databridgemarketresearch.com/reports/global-guacamole-market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

#Bakery Processing Equipment Market Size#Share#Growth#Trends#Demand and Opportunity Analysis#market trends#market report#market size#markettrends#marketresearch#market research#market share#market analysis

0 notes

Text

Dual-Shaft Paddle Feed Mixer: A Revolutionary Tool for Agricultural Feed

In the agricultural sector, the role of feed mixers is crucial. They play an irreplaceable role in improving feed quality, ensuring livestock nutrition intake, and enhancing the overall efficiency of agricultural production. In recent years, dual-axis paddle feed mixers have gradually gained a foothold in the market with their unique advantages and efficient performance.

As the name suggests, a dual-axis paddle feed mixer is characterized by having two mixing shafts, each equipped with multiple paddles. This design ensures a more uniform and thorough mixing process. During mixing, the feed is thoroughly blended, with various nutrients evenly distributed, significantly improving feed quality.

Moreover, dual-shaft paddle feed mixers boast high mixing efficiency, capable of completing a large amount of feed mixing work in a short period, greatly enhancing productivity. Additionally, they exert strong mixing force, capable of handling feeds of various textures and particle sizes, meeting the diverse needs of different farms.

Operating a dual-shaft paddle feed mixer is straightforward, and maintenance is convenient. With its reasonable design and sturdy structure, it can operate stably for extended periods, reducing production interruptions caused by equipment failures. Furthermore, both the paddles and mixing shafts are detachable, facilitating cleaning and replacement and lowering maintenance costs.

Furthermore, dual-shaft paddle feed mixers exhibit excellent environmental performance. They effectively control dust generation during mixing, reducing environmental pollution. Additionally, their efficient mixing performance minimizes feed wastage, aligning with the modern agricultural concept of sustainable development.

In summary, with its unique design, efficient performance, ease of operation, and good environmental performance, the dual-axis paddle feed mixer has become a revolutionary tool in the field of agricultural feed mixing. It will continue to play a significant role in advancing feed mixing technology and boosting agricultural production in the future.

However, the selection and use of any equipment need to be based on specific production environments and requirements. Therefore, when selecting a dual-axis paddle feed mixer, factors such as farm scale, types and particle sizes of feed, and mixing efficiency requirements need to be fully considered to choose the most suitable equipment.

Furthermore, daily maintenance and upkeep of equipment are also crucial. Only by maintaining equipment properly can its long-term stable operation and production efficiency be ensured.

With the advancement of technology and the development of agriculture, we have reason to believe that dual-axis paddle feed mixers will continue to be optimized and improved in the future, providing stronger support for agricultural production. Whether in improving feed quality, enhancing production efficiency, or improving environmental performance, dual-axis paddle feed mixers will demonstrate their unique advantages and value.

Therefore, for farms seeking efficient, environmentally friendly, and high-quality agricultural production, dual-axis paddle feed mixers are undoubtedly a premium equipment worth considering and choosing. With its powerful performance and advantages, it will contribute to the sustainable development of agricultural production, bringing more green and beauty to our lives.

0 notes

Text

Embowering Small Businesses: The Chapatti Maker Revolution

In recent years, the food industry has witnessed a technological revolution, with innovations aimed at improving efficiency and meeting the growing demand for convenience. One such innovation making waves in the culinary landscape is the industrial chapatti-making machine, India. Traditional chapatti making involves a labour-intensive processes, making kneading the dough to cooking each chapatti individually. Chapatti making machines have emerged as a game-changer by automating and streamlining this process. These machines have evolved from simple designs to sophisticated systems, capable of producing a large volume of chapatis with minimal human intervention. Chapatti making machines are equipped with advanced features such as automated dough feeding, rolling and cooking mechanisms. These machines often consist of a dough mixer, conveyor belts, a rolling units and a cooking station. Some models even incorporate artificial intelligence for precise control and consistent quality.

Benefits of chapatti making machines:

These machines can produce a high volume of chapatis in a short time, significantly increasing production efficiency compared to traditional methods. Automation ensures uniformity in size, thickness and cooking, leading to consistent quality across all chapatis produced. By reducing the need for manual labour, industrial chapatti maker contribute to significant cost saving for businesses. The closed and automated process minims human contract with the dough and chapatis, enhancing hygiene standards and food safety. Many machines allow adjustments in thickness, size and cooking parameters, providing flexibility to cater to different consumer preferences.

Impact on the food industry:

The adoption of industrial chapatti maker has had profound impact on the food industry. Small and large-scale businesses alike are leveraging these machines to meet the rising demand for chapatis in a cost-effective and efficient manner. Additionally, the increased production capacity enables business to explore new markets and distribution channels.

Challenges and future developments:

While industrials chapatti makers offer numerous advantages, challenges such as initial setup costs and maintenance expenses need to be considered. Continuous research and development are underway to address these challenges and enhance the capabilities of these machines further. The advent of industrial chapatti maker has transformed the traditional chapatti making process, bring efficiency, consistency and cost-effectiveness to the forefront. As technology continues to advance, these machines are likely to play a pivotal role in shaping the future of the chapti industry, offering a glimpse into a more automated and streamlined culinary landscape.

Chapatti makers tailored for small businesses are designed with affordability and space constraints in minds. These machines often feature a compact footprint, making them suitable for limited working spaces typical of small-scale ventures. The initial investment is comparatively lower than large industrial machines, making it accessible for entrepreneurs with modest budgets.

User-friendly operation:

One of the key advantages for small businesses is the user-friendly operation of this chapatti maker. Most models are equipped with intuitive controls allowing operators with minimal training to efficiently handle the entire chapatti production process. This simplicity not only saves time but also minimizes the need for highly skilled labour.

Flexibility production capacities:

Chapatti maker for small businesses come in various capacities, enabling entrepreneurs to choose a model that aligns with their production requirements. This flexibility is crucial for businesses that experience fluctuating demand, allowing them to scale production up or down as needed.

Time and labour savings:

Automating the chapatti maker process translates to significant time and labour savings for small businesses. These machines can handle tasks such as dough preparation, rolling and cooking, reducing the need for manual labour. This efficiency not only increases output but also frees up manpower for other essential aspects of the business.

Consistent quality for customer satisfaction:

Maintain consistent quality is paramount for small businesses seeking to build a loyal customer base. Chapatti maker ensures uniformity in size, thickness and cooking, guaranteeing consistent products meets customer expectations. From dough to plate, chapatti maker turn simplicity into precision. This reliability contributes to customer satisfaction and helps in building a positive brand image. While the benefits are evident, small business owners should consider factors such as maintenance costs, available space and the local market demand before investing in a chapatti maker. Regular maintenance and proper cleaning are essential to ensure the longevity and optimal performance of the equipment. The integration of chapatti maker in small businesses goes beyond mere automation; it empowers entrepreneurs to complete effectively in a dynamic market. By streamlining operations and reducing dependence on manual labour, these machines allow small ventures to focus on growth, diversification and meeting the evolving demands of their customers.

The chapatti-making machine for small business represents a significant leap towards enhancing efficiency, reducing costs and improving product consistency. As more entrepreneurs embrace this technology, the landscape of small-scale food enterprises is poised for positive transformation, creating opportunities for sustainable growth and increased competitiveness in the market.

0 notes

Text

0 notes

Text

SICOMA Concrete Mixer 2000L

The sicoma concrete mixer 2000l is a kind of efficient concrete mixing equipment, which is mainly used for concrete mixing and mixing plant production. It is mainly used as the main machine of HZS120 concrete mixing plant, which is suitable for mixing plastic, dry hard, light aggregate concrete and all kinds of mortar and mortar.

The following are the equipment parameters and advantages of the sicoma mixer 2000l:

1. Equipment parameters:

Feeding capacity: 3200L

Discharge capacity: 2000L (i.e. 2 square meters per discharge)

Theoretical productivity: 120 cubic meters per hour

Aggregate maximum particle size: 80/60mm

2. Advantage:

– Efficient mixing: SICOMA concrete mixer adopts specially designed mixing blades and mixing drum structure, which can mix concrete quickly and evenly, ensuring the quality and uniformity of concrete.

– Stable and reliable: the equipment adopts high-quality materials and advanced manufacturing technology, which has stable and reliable performance, and can operate continuously for a long time to ensure the productivity of the mixing plant.

– Easy to operate: the equipment adopts humanized design, easy to operate, easy to control and maintain, reducing labor cost and maintenance cost.

– Multiple specifications for choice: SICOMA concrete mxier 2m3 has multiple specifications and models for choice, you can choose the right mixing capacity and power according to the actual needs of the construction site, to meet the requirements of different projects.

– Easy maintenance: The mixing arm, scraper, liner plate and other parts are made of good material with long service life, which reduces the replacement frequency and maintenance cost. Floating sealing ring and other components are reasonably designed and easy to maintain, which reduces the overall operating costs of customers.

– Wide range of application: it is suitable for various scales and types of construction projects, such as residential buildings, commercial buildings, roads, bridges, etc. It is a kind of multifunctional and efficient concrete mixing equipment.

In a word, sicoma concrete mixer 2000l has the advantages of high efficient mixing, stable and reliable, easy operation, multiple specifications optional, etc. It is suitable for all kinds of concrete mixing production of construction projects, and it is a kind of mixing equipment with superior performance, and it occupies an important position in the market of concrete mixing equipment.

This resource is from https://www.concretebatchplant24.com/sicoma-concrete-mixer-2000l.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

2-3t/H Feed Pelletizer for Poultry Feed Making

2-3t/H Feed Pelletizer Introduction

2-3T/H feed pelletizer is a combination of crushers, pulse dust collectors, screw conveyors, mixers, pelletizers, bucket elevators, countercurrent cooling pellet dryers, vibrating screens, and other equipment with good performance.

youtube

The poultry feed-making machine integrates the functions of crushing, mixing, lifting, granulating, cooling, screening, etc., with automatic feeding, rapid feeding, and smooth discharging. It is a medium-sized feed unit with low investment and quick results.

The Feature of Feed Pelletizer:

1. The feed pelletizer has a compact structure, beautiful appearance, convenient installation, operation and maintenance, and reliable work.

2. The feed pelletizer is equipped with ring molds with various apertures such as φ6, φ8, φ10, etc., users can choose according to different needs, and can customize ring dies with different apertures for users.

3. The feed pelletizer adopts variable frequency speed control feeding, extended conditioner wide-opening cleaning method, and is equipped with external discharge and overload protection devices, and a hoop-shaped ring die. Fully imported bearings and oil seals in the transmission box, serpentine spring couplings transmit power, etc.

The feed pelletizer is suitable for the pelleting of various raw materials, such as sawn wood, straw, various forages, mixtures of sludge and sawn wood, coal, etc.

The Advance of Feed Pelletizer:

1. The ring dies pellet machine adopts mechanically forced feeding, high-speed rotation, and centrifugal distribution into the pelletizing chamber, and the scraper is used to distribute the material, the feeding is uneven; the flat die pelletizer depends on the weight of the material to enter the compression chamber vertically, which can be uniform Feeding.

3. The ring die has a high speed, and the damage rate is high when the material is discharged; while the flat die has a low speed, and the damage rate is low.

4. If the ring dies granulator uses the two screws on the eccentric wheel in the middle of the pressure wheel to adjust the pressure; the flat die granulator adopts the threaded screw m100 central adjustment mechanism, the top force is 100 tons, the falling is stable, and the impact is soft. The pressure is even. It can adopt two ways of rotating manual and hydraulic automatic adjustment.

https://www.hermmachinery.com/wp-content/uploads/2023/06/Feed_Pelletizer_for_Poultry_Feed_Making-3.jpg

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Whatsapp: 0086 13196770111

0 notes

Text

Sustainable Growth Opportunities in the Feeding Systems Market

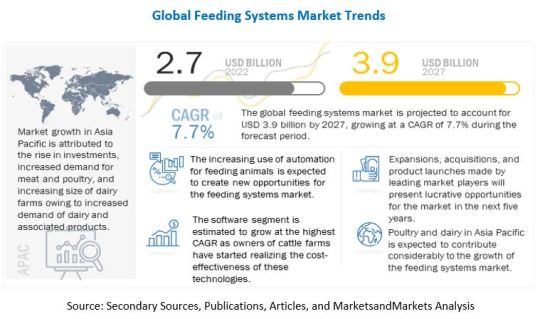

The global feeding systems market is projected to reach USD 3.9 billion, by 2027, at a CAGR of 7.7% from 2022 to 2027. The growing size of dairy farms, increasing focus of major companies on technological advancements as well as product launches and developments, and substantial cost savings associated with automated feeding systems are the major driving factors for the market. The market also faces some challenges like high capital requirements at the initial stage of installation, which may discourage small and medium-sized farms from automating the feeding process.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=102235948

DeLaval is a market leader providing integrated milking solutions designed to improve dairy farmers’ production, animal welfare, and overall quality of life. The company develops and manufactures equipment for milk production and animal husbandry, including feeding systems worldwide. DeLaval offers highly efficient system solutions for milking, farm and herd management, animal traffic control, feeding, cooling, manure handling, ventilation, and energy recovery. The company supplies highly efficient solutions for cattle feeding, which help in reducing costs and increasing productivity. It has a strong global presence, spanning Europe, the Middle East, Africa, the Americas, and the Asia Pacific. In November 2018, DeLaval (Sweden) announced a partnership with CEJA (European Council of Young Farmers Home) to help farmers in the European Union for better sustainability in the long-term process of farming.

Trioliet B.V provides various solutions mainly to cattle farming. The solutions offered by the company include feeders, weighing systems, and loading equipment. The various feeders devised by the company for feeding bovine animals include mixer feeder wagons and self-loading mixer feeders. The company also provides feeding solutions to dairy farms worldwide. It has a presence in over 50 countries. In 2020, the company launched Triotrac M. It is self-propelled machine and has one vertical auger and a cutting-loading system with a loading rotor to load the feed into the mixing tub. The unique loading system ensures that the feed is processed cleanly and without any wastage during the loading process.

Get 10% Free Customization on this Report:

https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=102235948

Lely provides automated feeding, forage harvesting, and milking robot solutions for the agricultural sector. It also offers milking solutions such as robotic milking systems, used milking robots, and detection systems. The company’s product portfolio comprises feeding solutions such as feed pushers, individual feeders, calf feeders, selection boxes, animal feeding solutions, and housing solutions (including lighting systems, mobile barn cleaners, hygienic housing products, and cubicle solutions). Lely sells its products through dealers in Canada, Ireland, Australia, New Zealand, the UK, the US, Spain, Italy, Norway, Portugal, Sweden, Japan, Israel, Estonia, Czech Republic, South Korea, Slovakia, Iceland, and Cyprus. The company is widening its product portfolio and launched Lely Exos in October 2020, first concept for the fully autonomous harvesting and feeding of fresh grass.

The importance of feeding systems is increasing in the region due to the increasing demand for performance-boosting feed for cattle and animal welfare. There has been an increasing shift from conventional to automated systems in the region over the last 30 years due to technological advancements and the high affordability of animal rearers in the region. North American farm owners are focusing on catering to the growing demand from consumers for dairy and meat products. This has led various companies in the global market to develop innovative feeding systems such as individual feeders and group feeders.

In North America, the demand for feeding systems has picked up rapid pace, particularly in the US. Seeing this demand, Lely (Netherlands) introduced Lely Park, its new commercial hub and complex, launched in June 2022. With this development, Lely will be able to greatly boost its production capacity to fulfill the rising needs of North American farmers.

Request Sample Pages:

https://www.marketsandmarkets.com/requestsampleNew.asp?id=102235948

#Feeding Systems Market#Feeding Systems Market Size#Feeding Systems Market Share#Feeding Systems Market Growth#Feeding Systems Market Trends#Feeding Systems Market Forecast#Feeding Systems Market Analysis#Feeding Systems Market Research Report#Feeding Systems Market Scope#Feeding Systems Market Overview#Feeding Systems Market Outlook#Feeding Systems Market Drivers#Feeding Systems Market Report

0 notes

Text

0 notes