#fly ash brick making machine in India

Explore tagged Tumblr posts

Text

High-Quality Paver Block Making Machine for Durable Construction

In the ever-evolving world of construction, efficiency and quality are paramount. BTM Product understands this need and offers cutting-edge solutions to meet the demands of modern construction

projects. Our high-quality paver block making machine stands at the forefront of innovative technology, designed to produce durable and aesthetically pleasing paver blocks for various applications.

The Importance of Quality Paver Blocks

Paver blocks have become an integral part of urban landscaping and construction projects. They offer numerous benefits, including:

1. Enhanced aesthetics 2. Improved water drainage 3. Easy installation and maintenance 4. Durability in various weather conditions 5. Versatility in design and patterns

To achieve these benefits, it's crucial to have a reliable and efficient paver block making machine that can consistently produce high-quality blocks.

BTM Product's Paver Block Making Machine: A Cut Above the Rest

At BTM Product, we pride ourselves on offering the best paver block making machine in the industry. Our state-of-the-art equipment is designed with precision and built to last, ensuring that you can meet the demands of your construction projects with ease.

Advanced Technology

Our paver block making machine incorporates the latest advancements in manufacturing technology. With computerized controls and automated processes, you can achieve consistent quality and high production rates.

Versatility in Block Production

Whether you need standard pavers, interlocking blocks, or custom designs, our machine can handle it all. The versatile mold system allows for quick changes, enabling you to produce a wide range of block sizes and shapes to suit various project requirements.

Energy Efficiency

We understand the importance of reducing operational costs. That's why our paver block making machine is designed with energy efficiency in mind. The optimized hydraulic system and intelligent power management ensure that you get maximum output with minimal energy consumption.

Key Features of Our Paver Block Making Machine

1. High production capacity 2. Precise vibration control for optimal compaction 3. User-friendly interface for easy operation 4. Quick mold change system 5. Robust construction for long-term reliability 6. Low maintenance requirements 7. Customizable settings for different mix designs

The BTM Product Advantage

When you choose a paver block making machine from BTM Product, you're not just getting equipment; you're investing in a complete solution. Our team of experts provides comprehensive support, from initial setup to ongoing maintenance and troubleshooting.

Training and Support

We offer thorough training programs to ensure that your staff can operate the machine efficiently and safely. Our technical support team is always available to address any questions or concerns you may have.

Quality Assurance

Every paver block making machine that leaves our facility undergoes rigorous quality checks. We stand behind our products with a solid warranty and after-sales service to give you peace of mind.

Expanding Your Product Line: Fly Ash Brick Making Machine

In addition to our paver block making machine, BTM Product also offers a high-quality fly ash brick making machine. This eco-friendly option allows you to produce durable bricks using industrial waste products, contributing to sustainable construction practices.

Benefits of Fly Ash Bricks

1. Environmentally friendly 2. Cost-effective production 3. High strength and durability 4. Excellent thermal insulation properties 5. Uniform size and shape

Our fly ash brick making machine is designed to deliver the same level of quality and efficiency as our paver block equipment, ensuring that you can diversify your product offerings without compromising on standards.

Choosing the Right Machine for Your Needs

Selecting the best paver block making machine or fly ash brick making machine for your business depends on various factors, including:

1. Production capacity requirements 2. Available space 3. Budget considerations 4. Types of blocks or bricks needed 5. Local market demand

BTM Product offers a range of models to suit different needs, from small-scale operations to large industrial setups. Our experienced sales team can help you assess your requirements and recommend the perfect machine for your business.

Success Stories

Many of our clients have seen significant improvements in their operations after incorporating our paver block making machine into their production line. For instance, a mid-sized construction company in the Midwest reported a 40% increase in production efficiency and a 25% reduction in material waste within the first six months of using our equipment.

Another client, a landscaping firm on the East Coast, was able to expand their product offerings and secure larger contracts thanks to the versatility and quality of blocks produced by our machine.

The Future of Construction: Embracing Innovation

As the construction industry continues to evolve, staying ahead of the curve is crucial. BTM Product is committed to ongoing research and development, ensuring that our paver block making machine and fly ash brick making machine remain at the cutting edge of technology.

We're exploring advancements in materials science, automation, and sustainable practices to bring you even more innovative solutions in the future. By choosing BTM Product, you're not just investing in today's technology but also positioning your business for tomorrow's opportunities.

Conclusion

In the competitive world of construction and landscaping, having the right equipment can make all the difference. BTM Product's high-quality paver block making machine offers the perfect blend of efficiency, versatility, and durability to help your business thrive.

Whether you're looking to start a new venture or upgrade your existing production line, our paver block making machine and fly ash brick making machine are designed to meet your needs and exceed your expectations. With BTM Product as your partner, you'll have the tools and support necessary to deliver outstanding results in all your construction projects.

Contact BTM Product today to learn more about our innovative solutions and how we can help take your business to the next level. Experience the difference that comes with choosing the best paver block making machine in the industry.

0 notes

Text

Working mechanism of fly ash brick making machine

Brick Machinery is an industry that is in the business of supplying complex and efficient brick making machine to the market. Brick Machinery is primarily focused on advanced technologies such as the fly ash brick making machine in India to transform the construction market. These machines play a crucial role of encouraging sustainable construction processes where industrial wastes like fly ash are transformed into quality bricks.

It is important for the users as well as the investors of the fly ash brick making machine to understand the operating principles of the specific equipment. This knowledge ensures the machine is well used thus enhanced production of the bricks which are long lasting as per the market. Thus enabling the businesses to achieve enhanced productivity and also support solutions to Eco-friendly building.

A fly ash brick making machine is a kind of equipment used in making bricks from fly ash which is a waste product in the coal fired power stations. This machine is useful in producing Eco-friendly bricks by using the fly ash which if not used harms the environment. The primary goal of the fly ash brick making machine is a proper formation of the bricks that will be both cheap to make and environmentally friendly for use in construction.

The Working Mechanism

The first process in fly ash brick making machine process is the preparation of the raw material which includes fly ash, lime, and gypsum sand at an ideal ratio. These powders make this composite which serves as the base material for the bricks. This is a crucial stage which determines the right proportion of the mixture for the brick to gain the right strength and durability as expected.

After mixing the raw materials, they are conveyed to the feeding system through a conveyor belt system. It also assures the means of putting material through the machine on an unending and efficiency basis thereby cutting on manpower. The feeding system determines the measure of raw materials required for each brick and is consistent in this process.

The molding stage involves placing the mixed material in to molds where pressure is applied by a hydraulic press. This is important since it helps to compress the materials and hold them together which makes the brick uniform and resilient to any external forces. Accurate measurements in the fly ash brick making machine via hydraulic press determines the quality of the bricks.

Following the molding process, the bricks are then exposed to heat treatment so that the moisture content is removed and the strength is attained. Curing generally entails heating the bricks to a particular temperature and humidity for a particular number of hours. This process also strengthens the bricks and this makes them appropriate for many uses in construction projects.

The last process includes checking the bricks as to find out whether they match the standard quality or not. This involves inspection for regularity and structural integrity, as well as appearance. Any related bricks not conforming to these standards are rejected from the production line.

Brick Machinery as your fly ash brick making machine in India come with optimum solutions that encompass advanced technology, flexible options, and excellent services once delivered. They are made for Quality, Longevity and Eco-friendly manufacturing thus making them highly suitable for green building initiatives. Are you ready for the next level? Read more about our fly ash brick making machine or call our sales representatives to order one for your business today at Brick Machinery’s website.

#fly ash brick making machine#fly ash brick making machine in gujarat#fly ash brick plant#fly ash brick making machine in India#brick making machine#hydraulic brick making machine#brick making machine in india#brickmakingmachine#brickmachine#block making machine#brick making machine manufacturer

0 notes

Text

The Ultimate Startup Guide for Fly Ash Brick Manufacturing

🔥 Wanna be your own boss? Start by mastering the art of Fly Ash Brick Manufacturing! 🧱💼 Let's unlock your entrepreneurial potential! 💥 #SmallBusinessTips #flyashbrickmachine #manufacturingbusiness #flyashbricksmakingmachine

With India’s construction industry adopting sustainable practices, the popularity of eco-friendly fly ash bricks is rising. Previously, clay bricks dominated the market; however, cement bricks have gradually become favoured, and now fly ash bricks are gaining traction. Fly ash is a coal combustion byproduct, and India has it in abundance, making it ideal for brick production. Launching a fly ash…

View On WordPress

#automatic fly ash bricks machine#best business ideas#business ideas#fly ash brick machine#fly ash brick making#fly ash bricks#fly ash bricks business#fly ash bricks business plan#fly ash bricks machine#fly ash bricks making business#fly ash bricks making machine#fly ash bricks manufacturing process#how to start a fly ash brick manufacturing business#how to start fly ash brick business#manufacturing business ideas 2024#manufacturing business ideas in india#mini manufacturing business ideas#new business ideas#new business ideas 2024#small business ideas

0 notes

Text

Automatic Flyash Brick Making Machine Belt Type – 15 Bricks

The Automatic Flyash Brick Making Machine Belt Type – 15 Bricks is an advanced solution designed to meet the growing demand for sustainable and efficient brick manufacturing. As a leading automatic fly ash brick machine manufacturer in Coimbatore, we focus on delivering precision-engineered equipment that ensures quality and durability.

This state-of-the-art model, ABMH 8SP Ultra DX 15 Bricks System, is powered by a 15 H.P hydraulic motor and features a brick eject system supported by a 2 H.P motor. The machine is built to perform under high pressure with a maximum of 440 BAR, utilizing a turbo twin vane hydraulic pump for seamless operations. Its efficient conveyor system, driven by a 3 H.P motor, ensures smooth material handling. Complementing the process is a 20 H.P pan mixer that guarantees uniform mixing of fly ash, cement, and other materials.

Engineered for reliability, the machine’s robust build includes 63 EN8 grained hard-chromed sliding rods and steel casting sliding bushes. The ejector conveyor, made from tough polymer, ensures quick and easy mold changes, reducing downtime. With a cyclic time of just 15 seconds, this automatic fly ash brick making machine can produce up to 15 bricks per cycle, maximizing productivity while minimizing labor costs.

Ideal for industries requiring high-quality fly ash bricks, this system is backed by PLC control for precision and automation. It requires a 1.5-acre land area and a shed of 60’x120’ feet for operation, along with a water capacity of 15,000 liters per shift.

Recognized as a trusted automatic fly ash brick machine exporter in Coimbatore, India, we provide machines that cater to both domestic and international markets. This model’s durability, ease of maintenance, and high efficiency make it a top choice for businesses seeking reliable brick manufacturing solutions.

Website Link : -http://www.bennyenterprises.net/

Contact no : - 9360623765

Mail id : - [email protected]

Address :- Site No:13, Thadagam Road,K.N.G.Pudur Pirivu,Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108,Tamil Nadu, India

Socail media link

facebook link :- https://www.facebook.com/Bennyindustries

short describiton :- Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

#brick manufacturing#Automatic Flyash brick making machine belt type#Automatic Flyash brick making machine#Automatic Flyash brick making

0 notes

Text

Block Making Machine Manufacturer in India

Indian Trade Bird connects you with a vast selection of high-quality Block Making Machines, the foundation for constructing walls, buildings, and infrastructures. These machines efficiently transform raw materials like concrete, fly ash, or interlocking bricks into uniform and durable blocks. Indian Trade Bird connects you with reputable Indian manufacturers and suppliers, ensuring quality and reliable equipment for your projects. Block making machines significantly increase production output compared to manual methods, saving time and labor costs. Machines ensure consistent block sizes and quality, leading to stronger and more durable structures. Block making machines cater to various construction projects, from residential buildings to commercial spaces and infrastructure development.

For more details clicks here - https://www.indiantradebird.com/product/block-making-machine

0 notes

Text

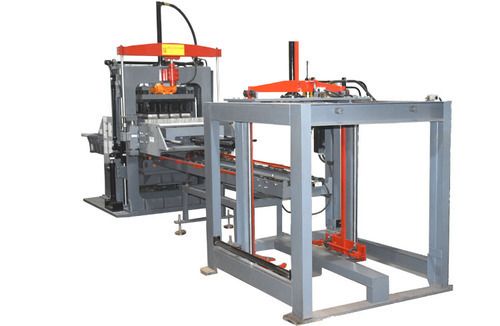

Laying Machines, Hydraulic Concrete Block Making Machines, Manufacturer

Laying Machines, Hydraulic Concrete Block Making Machines, Machinery, Turnkey Plant Projects, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India. Our hydraulic concrete block making machines provide easy, Eco-friendly and low cost to quicken the construction works.

Laying Machines, Hydraulic Concrete Block Making Machines, Fly Ash Brick Machines, Fly Ash Brick Machine, Turnkey Plant Projects, Automatic Fly Ash Brick Machines, Automatic Fly Ash Brick Machine, Semi Automatic Fly Ash Brick Machines, Semi Automatic Fly Ash Brick Machine, Interlocking Paver Block Machines, Interlocking Paver Block Machine, Paving Block Machines, Paving Block Machine, Pan Mixers, Pan Mixer, Belt Conveyors, Belt Conveyor, Box Feeders, Box Feeder, Press Feed Hoppers, Press Feed Hopper, Press Feeding Systems, Press Feeding System, Cellular Light Weight Concrete Machines, Cellular Light Weight Concrete Machine, CLC Concrete Machines, CLC Concrete Machine, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India.

0 notes

Text

Force aac plant provide the best aac plant, AAC Block Plant, CLC Plant, CLC Block Plant Making Machine at best cost. It is the best aac plant manufacturers, AAC Block Plant, CLC Plant, CLC Block Plant Making Machine Supplier, Manufacturer company in Pune, Mumbai, Nashik, Kolhapur, Satara, sangli, Bangalore, Chennai, Gujrat, Ahmedabad, India

0 notes

Text

a thousand Bricks Price in India

Introduction

a thousand Bricks Price in India have been a quintessential setting up material for centuries, and their demand continues to upward push in India due to the booming constructing industry. The cost of bricks can fluctuate considerably based totally definitely on endless factors, alongside with the variety of brick, quality, and market demand. In this article, we are going to delve into the factors that have an have an impact on on the price of bricks in India and provide insights into the latest market trends.

Factors Affecting the Price of Bricks

Several factors make contributions to the cost of bricks in India. These include:

Raw Material Costs: The price of raw resources used in brick manufacturing, such as clay, sand, and cement, can have an have an effect on on the final price.

Manufacturing Process: The method used to manufacture bricks, whether or not or no longer it is ordinary kiln-fired or present day machine-made bricks, can have an impact on the price.

Quality and Durability: High-quality bricks that are lengthy lasting and long-lasting have a tendency to be greater expensive.

Location: The location of the brick manufacturing unit and the proximity to raw materials and markets can have an have an effect on on the price.

Government Regulations: Government policies, taxes, and insurance policies can moreover affect the cost of bricks.

Types of Bricks and Their Prices

Hyderabad builders there are a quantity of kinds of bricks available, each and every with its non-public fee range. Some ordinary kinds include:

Clay Bricks: Traditional clay bricks are substantially used and are frequently affordable, with charges ranging from ₹3 to ₹5 per brick.

Fly Ash Bricks: These eco-friendly bricks made from fly ash and cement are gaining popularity due to their reduce cost, ranging from ₹2 to ₹4 per brick.

Concrete Bricks: Concrete bricks are lengthy lasting and versatile, with fees ranging from ₹4 to ₹6 per brick.

AAC Blocks: Autoclaved Aerated Concrete (AAC) blocks are lightweight and have super thermal insulation properties, on the other hand they are greater expensive, ranging from ₹30 to ₹50 per block.

Cost of Labor and Transportation

Apart from the price of raw materials, labor and transportation prices moreover make contributions to the closing charge of bricks. Skilled labor is required for brick manufacturing, and their wages can have an impact on the common cost. Additionally, transportation costs, alongside with gasoline charges and distance, can have an impact on the last rate of bricks.

Market Trends and Demand

The demand for bricks in India is relatively pushed by way of the constructing industry, which is experiencing fast growth. Factors such as urbanization, infrastructure development, and authorities initiatives like much less high priced housing schemes make a contribution to the developing demand for bricks. As a result, the prices of bricks may additionally moreover fluctuate specially based totally on market tendencies and demand-supply dynamics.

Conclusion

The charge of bricks in India is influenced by means of way of a vary of factors, inclusive of raw cloth costs, manufacturing processes, quality, and market demand. Understanding these factors can help builders and customers make educated options when shopping for bricks for constructing projects.

FAQs

What is the frequent charge of bricks in India?

The frequent charge of bricks in India varies relying on the type and quality, ranging from ₹2 to ₹50 per brick.

Are AAC blocks higher luxurious than fashionable clay bricks?

Yes, AAC blocks are generally greater costly due to their manufacturing method and most extremely good properties.

How can I reduce the charge of bricks for my constructing project?

You can find out desire picks like fly ash bricks or concrete bricks, which are more low price than preferred clay bricks.

Do authorities insurance plan insurance policies have an impact on the rate of bricks?

Yes, authorities policies, taxes, and insurance policies can have an have an impact on on the price of bricks via influencing raw cloth prices and manufacturing processes.

What are the key factors to replicate onconsideration on when shopping for bricks?

Key factors to mirror onconsideration on embody the form of brick, quality, durability, and price per unit.

0 notes

Text

Advanced Fly Ash Brick Making Machines for Durable Bricks

Brick Machine is stand out as a trusted name in the industry. We are providing modern fly ash brick making machines designed to deliver durable and high-quality bricks. Our advance machinery incorporate the latest technology to make sure that superior brick strength and efficiency making it a perfect solution for sustainable construction projects. These machines are designed to minimize manual effort while you maximizing production capacity and we are providing an perfect balance between innovation and practicality for brick manufacturers.

Brick Machine is make strong commitment to quality and performance or we can delivered unparalleled reliability in the field of fly ash brick production. Our machine are built to meet various small scale manufacturer or a large industrial setup production requirement. Our machine are compete to help business succeed in the competitive construction sector with their energy efficiency and robust construction. Choose Brick Machine for your fly ash brick making needs and experience unmatched excellence.

Brick Machine is perfect solution for your brick manufacturing needs with advance fly ash brick making machines. Our machines are designed for durability and efficiency or we can make sure that our machine are superior quality and high production capacity for sustainable construction. Visit Our Website brickmachinery.in to learn more about our innovative product and how they can improve your business operations.

#fly ash brick making machine#brick making machine#hydraulic brick making machine#paver block making machine#brickmakingmachine#fly ash brick making machine in gujarat#brick making machine in india#brickmachine#fly ash brick plant#block making machine

0 notes

Text

Govind Industry - https://govindindustry.com/

Title- Machinery Manufacturer | Rice Mill | Fly Ash Bricks | Katghora |Chhattisgarh

Description: "Govind Industry" is a distinguished Manufacturer of a wide array of Brick Making Machine, Fly Ash Brick Making Machine, Paper Dona Machine, etc. Our range is available in various specifications as per the client’s requirements. We have successfully created a niche in the market in the last few months by bringing forth a matchless range of products. We work as a team in understanding the needs of the customers, keeping each other’s business interest intact so that we can deliver products at the right time and at the most competitive rates.

Keywords - Govind Industry, Machinery Manufacturer , Service, Pan India, Best, Katghora, Chhattisgarh

Social Media -

0 notes

Text

Best Automatic Flyash Brick Making Machine Manufacturer

Rexnear Systems, headquartered in Greater Noida, Uttar Pradesh, India, is a highly reputable manufacturer and supplier specializing in the production of Automatic Flyash Brick Making Machine Manufacturer. Our comprehensive product line includes Fly Ash bricks plants, Paver Block making Machines, Hollow block making machines, and more. Our commitment is centered on delivering top-notch quality by utilizing premium raw materials and cutting-edge machinery, ensuring both durability and cost-effectiveness. Whether you require bulk or urgent orders, we offer competitive prices to cater to your needs. Feel free to visit our location at Plot No. 358 B, Udyog Kendra – 1, Ecotech – 3, Greater Noida, Uttar Pradesh, India, 201306.

0 notes

Text

Advantages of Automatic Flyash brick making machine belt type - 10 Bricks

Experience unmatched efficiency with our advanced Automatic Flyash Brick Making Machine - Belt Type, designed to produce 10 high-quality bricks in one cycle. Built for durability and precision, this machine ensures consistent performance and superior output, making it ideal for large-scale production.

Advantages:

High Productivity: Delivers 10 bricks per cycle, boosting production efficiency.

Energy Efficient: Optimized design reduces power consumption.

Low Maintenance: Robust construction ensures minimal downtime.

Precise Operations: Ensures uniform brick size and superior finish.

Eco-Friendly: Utilizes fly ash, contributing to sustainable construction practices.

Upgrade your brick production with this reliable and eco-conscious solution today!

Company Name: benny enterprises

Website Link : http://www.bennyenterprises.net/

Contact no : 98431 80444

Mail id : [email protected]

address : Site No:13, Thadagam Road, K.N.G.Pudur Pirivu, Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108. Tamil Nadu, India

Socail media link

facebook link https://www.facebook.com/Bennyindustries

short describiton : Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

0 notes

Text

Fly Ash Brick Making Machine Manufacturer in India

Indian Trade Bird provides these machines, which utilize fly ash, a by-product of coal combustion, to create eco-friendly and cost-effective bricks . As the world strives for sustainable building practices, Fly Ash Brick Making Machines offer an innovative solution. By utilizing fly ash waste, these machines reduce dependence on conventional brick production methods, which can have a negative environmental impact . Fly ash is a readily available and inexpensive material, leading to significant cost savings in brick production compared to traditional methods. Fly ash bricks are known for their strength, dimensional accuracy, and fire resistance, making them ideal for various construction applications.

For more details clicks here - https://www.indiantradebird.com/product/fly-ash-brick-making-machine

0 notes

Text

CLC Block Making Machines, Cellular Light Weight Concrete, Foamed Cement, India

CLC Block Making Machines, Cellular Light Weight Concrete, Foamed Cement, Light Weight Concrete Block Making Machine, Turnkey Plant Projects, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India.

CLC Block Making Machines, Cellular Light Weight Concrete Machines, Cellular Light Weight Concrete Machine, Fly Ash Brick Machines, Fly Ash Brick Machine, Foamed Cement, Automatic Fly Ash Brick Machines, Automatic Fly Ash Brick Machine, Semi Automatic Fly Ash Brick Machines, Semi Automatic Fly Ash Brick Machine, Interlocking Paver Block Machines, Interlocking Paver Block Machine, Paving Block Machines, Paving Block Machine, Pan Mixers, Pan Mixer, Belt Conveyors, Belt Conveyor, Box Feeders, Box Feeder, Press Feed Hoppers, Press Feed Hopper, Press Feeding Systems, Press Feeding System, CLC Concrete Machines, CLC Concrete Machine, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India.

0 notes

Text

RKI-10 Automatic Brick Making Machines

We are offering Automatic cement fly ash Brick Making Machine to our client. we are a manufacturer of fly ash brick making machine and suppliers in all India.

It’s important to note that the specific capabilities, features, and output capacity of the RKI-10 automatic brick-making machine may vary based on the manufacturer and model. If you require detailed information about the RKI-10 model, it would be best to consult the manufacturer or supplier directly, The RKI-10 automatic brick making machine is a specific model of an automatic brick-making machine. Although I couldn’t find detailed information on this specific model, I can provide you with a general overview of what an automatic brick-making machine typically entails

0 notes

Text

0 notes