#Equipment Manufacturer

Explore tagged Tumblr posts

Text

Equipment manufacturer for Textile chemical industry - Stalwart international

Stalwart International is a leading chemical equipment manufacturer for textile industry. We are offering such as dyeing machines, finishing equipment, and textile printing machinery.

0 notes

Text

Valuable Tips For Choosing High Quality Medical chemical Suits

Chemical suits are protective suits that are often used in medical settings. They help to protect the wearer from being exposed to hazardous materials, like toxic substances, liquids and chemicals. Doctors and nurses often need to work in contaminated environments, and as a result, they must have protective gear that enables them to manage their professional responsibilities safely. While buying…

View On WordPress

#chemical manufacturer usa#chemical suit distributors#chemical suit manufacturer#chemical suit suppliers#chemical suit wholesaler#equipment manufacturer#medical equipment#medical equipment distributors#wholesale medical equipment

0 notes

Text

Top Biology Laboratory Equipment Supplier in India, Atico Export the best quality laboratory equipment for various research settings where the scientific study of living organisms and their environmental interactions is conducted.

0 notes

Text

Why These Process Equipment Manufacturers are Dominating the Market?

In the highly competitive industrial landscape, certain process equipment manufacturers have risen to the top, setting benchmarks for quality, innovation, and customer satisfaction. This article explores the reasons behind their dominance in the market, shedding light on their strategies, technologies, and unwavering commitment to excellence.

Commitment to Innovation and R&D

One of the primary reasons these manufacturers lead the market is their relentless focus on innovation and research and development (R&D). Investing heavily in R&D allows them to stay ahead of the technological curve and continuously improve their products.

1. Cutting-Edge Technologies

Leading manufacturers leverage cutting-edge technologies such as automation, Internet of Things (IoT), and artificial intelligence (AI) to enhance the performance and efficiency of their equipment. For example, IoT-enabled devices provide real-time data and analytics, enabling predictive maintenance and reducing downtime.

2. Sustainable Solutions

In response to global environmental challenges, top manufacturers are also pioneering sustainable solutions. They are developing energy-efficient equipment and integrating eco-friendly practices into their production processes. Innovations like energy-efficient heat exchangers and low-emission burners are just a few examples of how they are making industrial operations greener.

Customer-Centric Approach

Dominant process equipment manufacturers put their customers at the heart of their operations. They understand that meeting and exceeding customer expectations is crucial for long-term success.

(a) Customized Solutions

By offering customized solutions, these manufacturers can address the specific needs of their clients. This flexibility ensures that customers get equipment tailored to their unique operational requirements, enhancing efficiency and productivity.

(b) Exceptional Service and Support

Outstanding customer service and after-sales support further distinguish leading manufacturers. They provide comprehensive training, maintenance services, and technical support to ensure that their equipment performs optimally throughout its lifecycle.

Quality and Reliability

Quality and reliability are non-negotiable for top process equipment manufacturers. They adhere to stringent quality control measures and industry standards to ensure their products are durable and dependable.

(i) High-Quality Materials and Manufacturing Processes

Using high-quality materials and employing advanced manufacturing processes ensures that the equipment can withstand the rigors of industrial use. Rigorous testing and quality assurance protocols help maintain high standards.

(ii) Compliance with Industry Standards

Adherence to international industry standards and certifications, such as ISO 9001 and ASME, guarantees that the equipment meets the highest quality benchmarks. This compliance not only ensures safety and reliability but also boosts customer confidence.

Strategic Partnerships and Collaborations

Forming strategic partnerships and collaborations with other industry leaders and technology providers is another strategy that sets these manufacturers apart. Such alliances enable them to integrate the latest innovations and expand their market reach.

1. Collaborative R&D Projects

Collaborative R&D projects with academic institutions and research organizations help manufacturers stay at the forefront of technological advancements. These collaborations often lead to the development of groundbreaking solutions that address emerging industry challenges.

2. Supply Chain Optimization

Strategic partnerships with suppliers ensure a robust and reliable supply chain. By working closely with their suppliers, manufacturers can maintain consistent quality and timely delivery of components and materials.

Global Reach and Market Penetration

The ability to penetrate global markets is a significant factor in the dominance of these manufacturers. They have established a strong international presence through strategic market expansion and localization efforts.

(a) Local Manufacturing and Service Centers

Setting up local manufacturing and service centers enables manufacturers to cater to regional markets more effectively. This localized approach ensures faster delivery times, better customer support, and a deeper understanding of local market dynamics.

(b) Global Distribution Networks

A robust global distribution network allows these manufacturers to reach customers worldwide. Strategic partnerships with distributors and agents ensure that their products are readily available in key markets.

Emphasis on Training and Development

Investing in the training and development of their workforce is another hallmark of leading process equipment manufacturers. A skilled and knowledgeable workforce is crucial for driving innovation and maintaining high-quality standards.

(i) Employee Training Programs

Comprehensive employee training programs keep the workforce updated on the latest technologies and best practices. These programs enhance the skills of employees, enabling them to contribute effectively to the company's success.

(ii) Talent Acquisition and Retention

Attracting and retaining top talent is a priority for these manufacturers. By offering competitive compensation, career development opportunities, and a positive work environment, they ensure that they have the best minds driving their operations.

Future Outlook and Continuous Improvement

Looking ahead, dominant process equipment manufacturers are committed to continuous improvement and staying ahead of industry trends. Their forward-thinking approach ensures they remain leaders in the market.

1. Adapting to Industry Trends

Manufacturers are closely monitoring industry trends such as digital transformation, Industry 4.0, and sustainability. By adapting to these trends, they can develop innovative solutions that meet future market demands.

2. Continuous Product Development

Ongoing product development efforts ensure that manufacturers can introduce new and improved equipment to the market. Continuous innovation helps them maintain a competitive edge and cater to evolving customer needs.

In conclusion, the dominance of leading process equipment manufacturers is the result of a multifaceted approach that includes a commitment to innovation, customer-centric strategies, uncompromising quality, strategic partnerships, global reach, and a focus on continuous improvement. By excelling in these areas, they set new standards in the industry and remain at the forefront of industrial progress.

If You Want to Discover More About Process Equipment Manufacturers then Visit the Site: Jasmino

#technology#manufacturing#manufacturing industry#manufacturer#process equipment#equipment manufacturer#industry trends#industry standards#innovative technology#technological advancements#strategicpartnerships#quality assurance#data & analytics

0 notes

Text

How to Choose the Right Weightlifting Equipment for Your Goals

Choosing the right weightlifting equipment for your goals involves considering several factors, including your fitness objectives, experience level, budget, and available space. Here's a comprehensive guide to help you make informed decisions:

Determine Your Fitness Goals:

Strength Building: If your goal is to increase muscle strength and power, focus on gym equipment such as barbells, dumbbells, and weight plates that allow you to progressively overload your muscles.

Muscle Hypertrophy: For muscle growth and hypertrophy, look for equipment like resistance bands, cable machines, and weight machines that target specific muscle groups with controlled resistance.

Endurance and Conditioning: If you're aiming to improve muscular endurance and cardiovascular health, consider incorporating equipment such as kettlebells, medicine balls, and battle ropes for dynamic, high-intensity workouts.

Functional Training: Opt for functional training equipment like suspension trainers (e.g., TRX), stability balls, and resistance bands to enhance stability, balance, and overall functional movement patterns.

Assess Your Experience Level:

Beginner: If you're new to weightlifting, start with basic equipment like dumbbells, resistance bands, and bodyweight exercises to master fundamental movements and build a solid foundation of strength and technique.

Intermediate: As you progress, gradually incorporate more advanced equipment such as barbells, kettlebells, and cable machines to challenge your muscles in new ways and continue making gains.

Advanced: For experienced lifters, consider specialized equipment like power racks, weightlifting platforms, and Olympic barbells to support heavy lifting and advanced training techniques.

Consider Budget and Space Constraints:

Budget-Friendly Options: If you're on a tight budget, prioritize versatile, multi-functional equipment like adjustable dumbbells, resistance bands, and bodyweight accessories that offer a wide range of exercises without breaking the bank.

Space-Saving Solutions: If you have limited space, choose compact, space-saving equipment like foldable benches, resistance bands with door anchors, and adjustable weight sets that can be easily stored when not in use.

Seek Quality and Safety:

Quality Construction: Invest in high-quality equipment made from durable materials that can withstand heavy use and provide long-lasting performance without compromising safety.

Safety Features: Look for equipment with built-in safety features such as non-slip grips, secure locking mechanisms, and adjustable settings to minimize the risk of injuries during workouts.

Personalize Your Selection:

Customize Your Equipment: Tailor your equipment selection to your specific preferences, training style, and favorite exercises to create a personalized workout environment that motivates and inspires you to achieve your fitness goals.

Consult with Fitness Professionals: Seek guidance from certified personal trainers or fitness professionals who can provide expert advice and recommendations based on your individual needs, abilities, and goals.

By carefully considering these factors and selecting weightlifting equipment that aligns with your goals, experience level, budget, and space constraints, you can create an effective and efficient workout routine that supports your fitness journey and helps you achieve meaningful results.

#weightlifting equipment#Equipment Manufacturer#buy gym equipment#gym equipment online#purchasing gym equipment

0 notes

Text

The Importance of Quality Industrial Kitchen Equipment for Faridabad Restaurants

The restaurant business in Faridabad is booming, with many new establishments opening their doors to cater to the diverse tastes of the city’s growing population. To succeed in this competitive market, restaurants must invest in high-quality industrial kitchen equipment. This article will discuss the importance of partnering with the best commercial hotel kitchen equipment manufacturer in Delhi NCR & Faridabad and the benefits of using top-notch industrial restaurant kitchen equipment suppliers in Faridabad.

0 notes

Text

Press

13 notes

·

View notes

Note

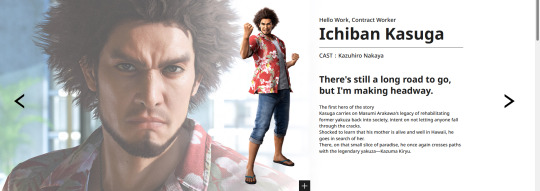

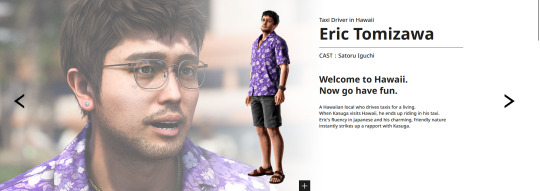

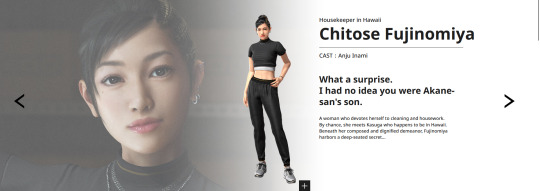

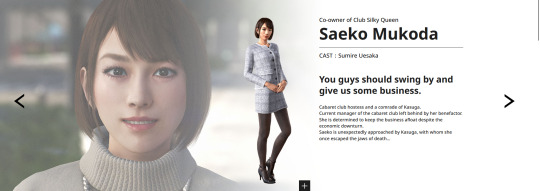

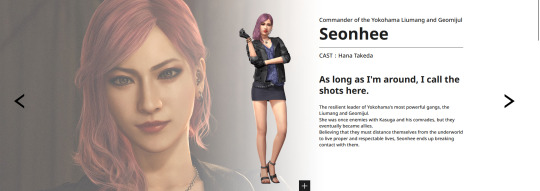

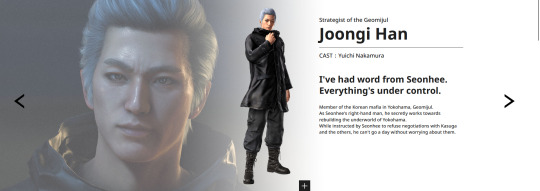

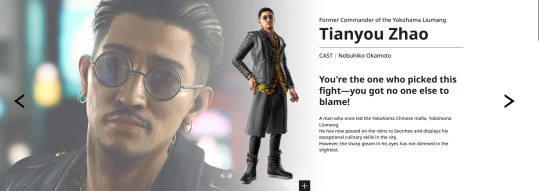

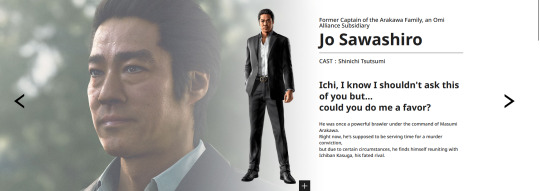

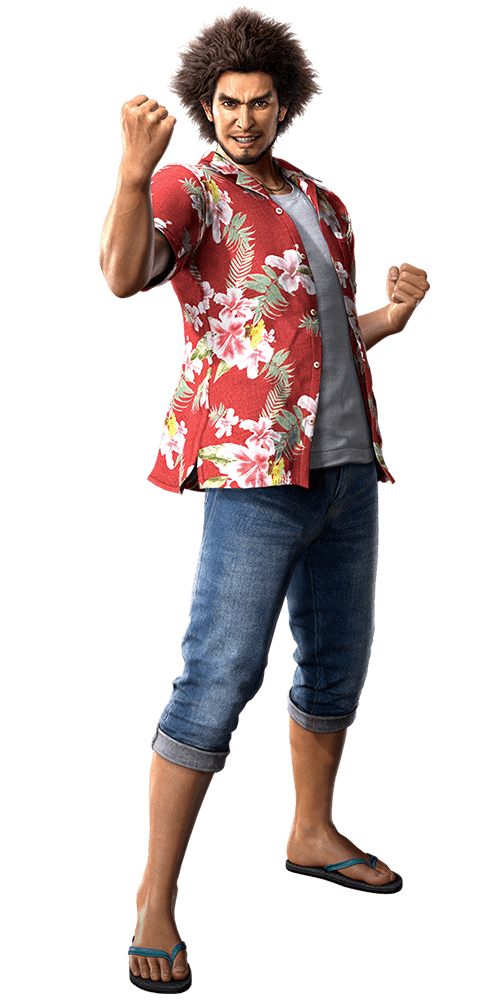

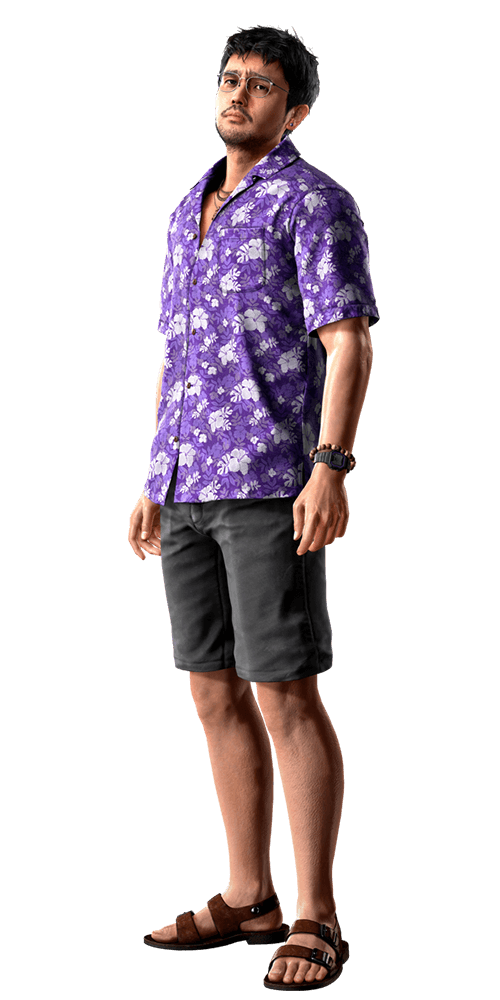

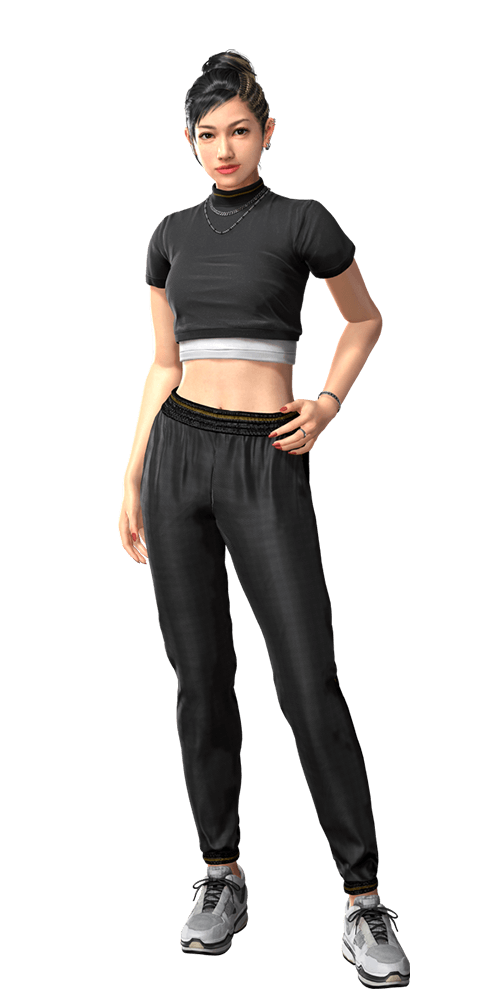

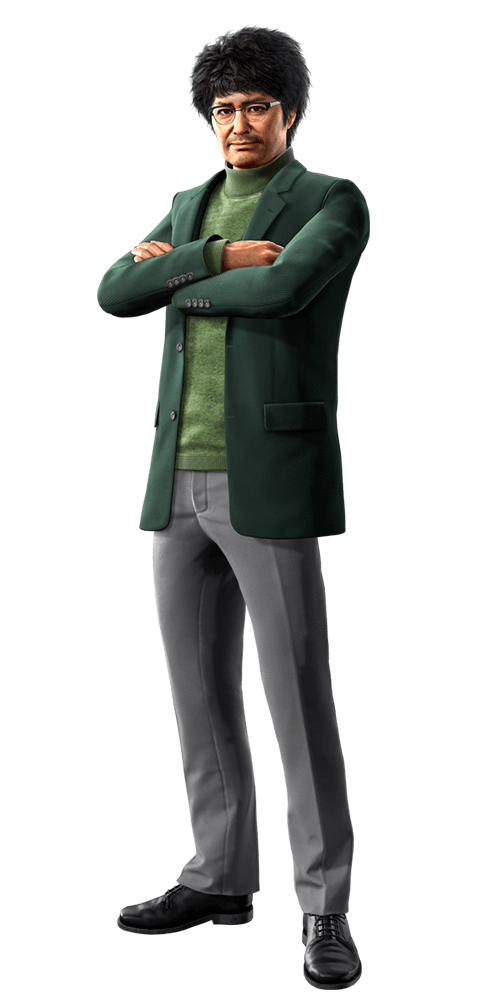

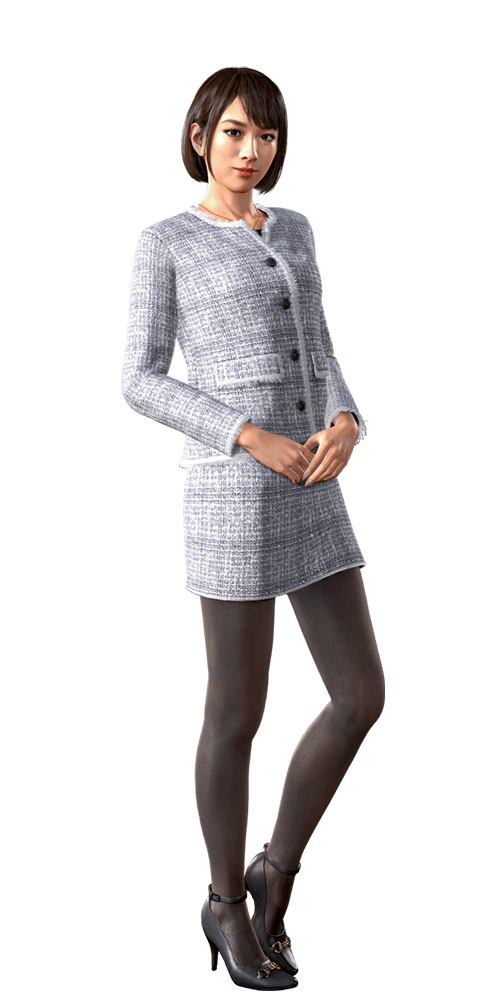

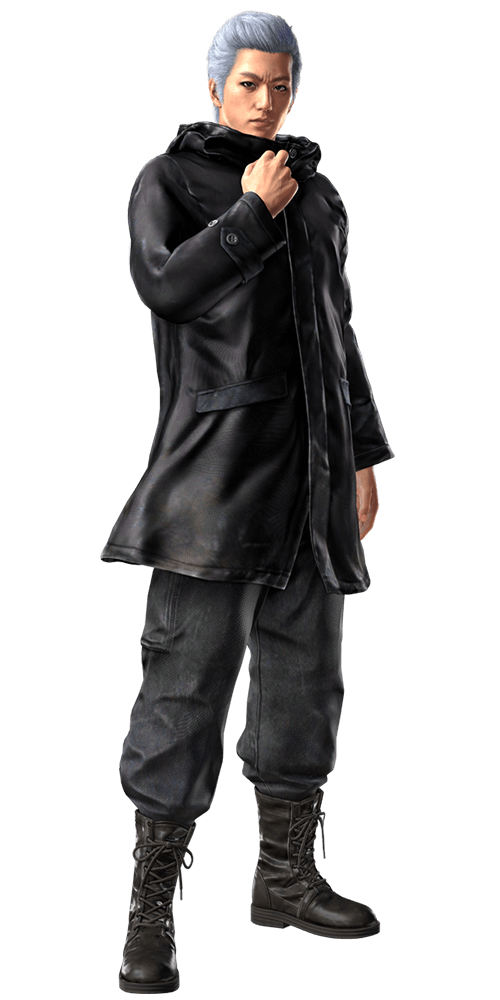

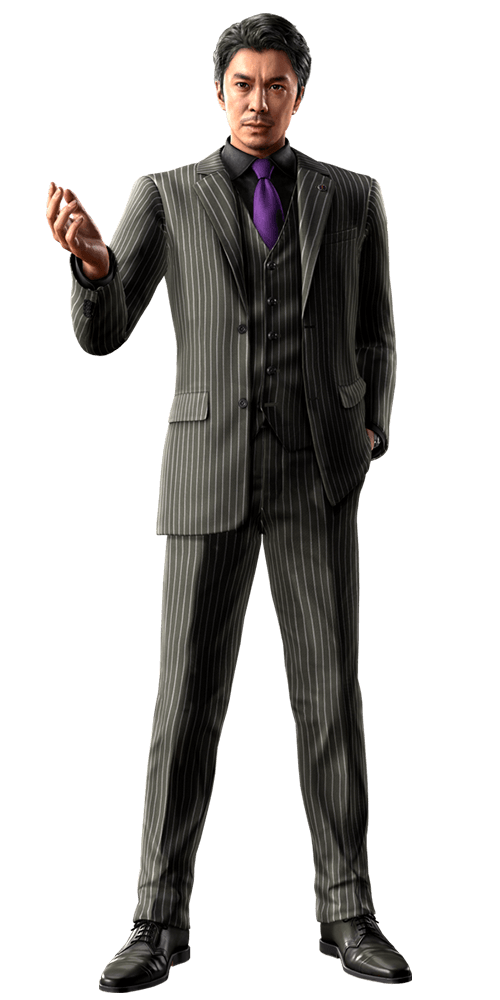

I'd screenshot every profile on here individually tbh but the new IW character lore is soooo juicy

i'll screenshot em for the team on tumblr cause i woke up sick today

renders under the cut. if anyone wanna look at em 👁️👁️

#snap chats#pissed forever because there's an uneven number but this is fine this is fine this is fine this is f#idk why it makes me happy that nanba's working at a medical equipment manufacturer but it do :]]#JOON-GI BEING UNABLE TO STAY AWAY FROM THE GANG THO 😭 THE ICHIGANG NOT THE YOKOHAMA ONE#i mean he still there but.. it cute how he doesnt wanna leave ichi and the team alone </3 they're fam.....#love how ichi is referred to as jo's 'fated rival' my brother in christ it's the equivalent of having beef with your step son#'fated rival' THE DRAMA. enough.#at the family bbq and yall bein DISORDERLY anyway.#idk 'brawler' is such a funny description for him like. TECHNICALLY sure yeah that works. Technically#seemed to be more of a weapons guy but semantics#ANYWY THESE ARE SO FUN epic.... can january get here already...#and then after january can it be february so i can have my aoki plushie..

105 notes

·

View notes

Text

the gendering of baby clothes is obviously profoundly stupid. however, having a boy has made me realize that construction equipment is actually very cool. all the machines are gigantic and they do cool stuff and I pay more attention to them now when I spot them in the wild.

#sorry the connection here is that#he has lots of inherited outfits with construction equipment printed all over them#baby clothes manufacturers are like here is your interest set: construction. dinosaurs. sharks.

16 notes

·

View notes

Text

The Role of Process Equipment Manufacturers in Industrial Operations

Process equipment manufacturers play a crucial role in industrial operations, providing the machinery and tools necessary for various manufacturing processes. From the food and beverage industry to pharmaceuticals and beyond, these manufacturers are instrumental in ensuring the smooth and efficient operation of factories and plants worldwide.

1. Supplying Essential Machinery

One of the primary functions of process equipment manufacturers is to supply essential machinery to industries. This includes equipment such as reactors, heat exchangers, pumps, valves, and other devices necessary for manufacturing processes. Without these critical components, many industries would struggle to produce goods efficiently and effectively.

2. Ensuring Quality and Reliability

Process equipment manufacturers are also responsible for ensuring the quality and reliability of their products. This involves rigorous testing and quality control measures to ensure that each piece of equipment meets industry standards and is safe to use. Manufacturers also provide ongoing support and maintenance services to ensure that their equipment remains in optimal condition throughout its lifespan.

3. Innovating for Efficiency

In recent years, there has been a growing emphasis on efficiency and sustainability in industrial operations. Process equipment manufacturers are responding to this demand by innovating new technologies and solutions to improve efficiency. This includes developing equipment with higher energy efficiency, reduced waste generation, and improved performance overall.

4. Adapting to Industry Trends

Process equipment manufacturers must also adapt to changing industry trends and regulations. For example, as industries become more environmentally conscious, manufacturers are developing equipment that meets stricter environmental standards. Similarly, as digitalization and automation become more prevalent, manufacturers are incorporating these technologies into their products to improve efficiency and productivity.

5. Collaborating with Industries

Successful process equipment manufacturers often collaborate closely with industries to understand their specific needs and requirements. This collaboration helps manufacturers develop tailored solutions that meet the unique challenges of each industry. By working closely with their customers, manufacturers can ensure that their products are not only high-quality but also well-suited to the needs of the industries they serve.

Conclusion

In conclusion, process equipment manufacturers play a vital role in industrial operations. From supplying essential machinery to ensuring quality and reliability, these manufacturers are essential partners in the success of many industries. By innovating for efficiency, adapting to industry trends, and collaborating with industries, process equipment manufacturers are helping to drive innovation and improve the efficiency and sustainability of industrial operations worldwide.

If You Want to Discover More About the Role of Process Equipment Manufacturers then Visit the Site: Jasmino

#technology#manufacturing industry#manufacturing#equipment manufacturer#process equipment#industrial standards#industry trends#industrial operations#manufacturing technology#manufacturing processes

0 notes

Text

*taps you on the shoulder* *opens my hand to show you my tiny pistol* :)

#txt#2mm kolibri pistol my beloved#i KNOW that they stopped being manufactured by 1914#and the bullets were weaker than a punch#but imagine some poor austro-hungarian bastard sent to the balkan front#equipped with nothing but this

63 notes

·

View notes

Text

youtube through the TV gave me an ad with shitty TTS voice for a mini space heater. lives will be lost.

#needless to say but do not trust random manufacturers selling a product notorious for starting fires#even space heaters made by good brands can start fires! they're dangerous pieces of equipment!

22 notes

·

View notes

Text

Hey laptop manufacturers, if y'all could just actually say what size A/C adapter tip your machines use, that'd be fan-fucking-tastic. If it's USB-A, just say that it's USB-A. Don't call it a "box plug" or a "slim tip" or any of that bullshit. Just call it what it is: USB-A. And if it's a round or barrel tip, you NEED to give the interior and exterior dimensions. Round/barrel tips come in dozens of sizes. Just saying "round tip" or "barrel tip" doesn't tell the consumer jack shit.

#laptop manufacturers can eat my ass#i should not have to go to 5 different 3rd party sites to find the specs of YOUR equipment

6 notes

·

View notes

Text

The Long-Term Gains of Investing in Superior Kitchen Equipment

Quality kitchen equipment isn’t just a luxury; it’s a necessity for a thriving business. Here’s why choosing the best equipment is worth every penny.

Durability and Longevity: Why high-quality materials like stainless steel outlast cheaper alternatives.

Consistent Performance: Maintain food quality and customer satisfaction with reliable tools.

Energy Savings: How energy-efficient equipment reduces costs over time.

Enhanced Safety: The role of quality in minimizing risks and maintaining hygiene standards.

Long-Term Value: Invest once, and enjoy years of hassle-free service.

At Nilkanth Equipments, we believe in delivering only the best. Explore our wide range of durable, high-performance products designed to elevate your kitchen.

2 notes

·

View notes

Text

Cup Filler Machines Manufacturer in Haryana

A Cup Filler Machines Manufacturer in Haryana specializes in producing automated machines for filling pre-formed cups with liquids, powders, or granules. These machines ensure precise filling, fast processing speeds, and minimal waste, making them ideal for the food, beverage, and pharmaceutical industries. With a focus on innovation and quality, the manufacturer provides tailored solutions to meet diverse packaging needs.

#Cup Filler Machines Manufacturer in Haryana#Form Fill Seal Machines Manufacturer in Haryana#Auger Filler Machines Manufacturer in Haryana#Automatic Pouch Packaging Machine Manufacturer in Faridabad#Packaging Equipment Manufacturer in Faridabad

2 notes

·

View notes

Text

Industry 4.0 and the Demand for Smart Manufacturing in Pharma: A New Era for CMOs

The pharmaceutical industry is experiencing a paradigm shift with the advent of Industry 4.0 and smart manufacturing technologies. For contract manufacturing organizations (CMOs), these improvements are not just optional but necessary to remain competitive in a rapidly evolving marketplace. By leveraging cutting-edge technology, CMOs can increase productivity, reduce costs, and deliver better results for their customers. Let’s explore how Industry 4.0 is transforming medicine and the critical role CMOs play in this new era

What is Industry 4.0 in Pharma?

Industry 4.0 refers to the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, data analytics, etc. In medicine, these technologies enable real-time monitoring, predictive maintenance and automated quality control for smarter and more efficient production

For CMOs, adopting Industry 4.0 means embracing these innovations to streamline operations and meet the stringent demands of pharmaceutical procurement. With an increased focus on quality and speed, smart manufacturing gives CMOs a competitive advantage by ensuring accuracy and compliance.

Key benefits of Industry 4.0 for CMOs

1. Improved productivity

Industry 4.0 technology empowers CMOs to optimize production processes. Using IoT-enabled devices and sensors, production lines can be monitored in real-time, in order to instantly identify bottlenecks and malfunctions. This ensures minimal downtime and increases productivity.

2. Quality control

AI-powered quality assurance systems help CMOs identify deficiencies early in the process.

Real-time data collection and analysis ensures that each batch meets the highest standards, reducing the risk of recalls and compliance issues.

3. Debt reduction

Smart design reduces waste, energy consumption and labor costs. Predictive maintenance enabled by the IoT reduces device failures and extends device life, saving CMOs operating costs.

4. Quick time to market

With automated processes and flexible workflows, CMOs can reduce development cycles. This is especially important in the pharmaceutical industry, where time to market can determine the success of a product.

Projects 4.0 Technologies for CMO transformation

1. Internet of Things (IoT) .

IoT devices provide seamless communication between devices, systems and people. For CMOs, IoT ensures real-time visibility into production, inventory levels, and supply chain management.

2. Artificial Intelligence (AI) .

AI-driven analytics provide CMOs with actionable insights, enabling them to streamline their processes and improve decision-making. Machine learning algorithms can predict demand, optimize resource allocation, and improve process efficiency.

3. Robotics and Automation

Automation technologies are transforming medicine. Robots perform tasks with repeatedly increasing accuracy, freeing up humans for more subtle activities to improve stability.

4. Digital twins

Digital twins are virtual replicas of physical objects or systems. CMOs can use these to simulate and optimize processes, reduce trial-and-error methodologies, and accelerate innovation.

Challenges for CMOs to adopt Industry 4.0

While the benefits are undeniable, CMOs face several challenges in implementing Industry 4.0 technologies:

Significant initial investment: Implementing smart manufacturing processes requires significant upfront costs, which can be a barrier for smaller CMOs.

Skills Gap: The transition to Industry 4.0 requires a workforce with advanced technology skills, which may require significant training and recruitment efforts.

Data Security Issues: As manufacturing becomes increasingly digital, ensuring data security and protecting intellectual property becomes increasingly important.

The future of CMOs is in the industry 4.0 era

Adopting Industry 4.0 technologies is not a luxury but a necessity for CMOs to remain competitive. As pharmaceutical companies demand faster, superior solutions and lower costs, CMOs need to invest in smarter manufacturing processes to meet these expectations

The future of pharmaceuticals is collaboration and innovation. By partnering with technology providers and taking advantage of advanced systems, CMOs can position themselves as leaders in the industry. As Industry 4.0 continues to evolve, CMOs that embrace this shift will not only survive but thrive in this time of change

conclusion

Industry 4.0 and smart manufacturing are reshaping the medical landscape, creating unparalleled opportunities for CMOs to advance their capabilities. From real-time analytics to AI-driven analytics, these technologies empower CMOs to deliver exceptional value to their clients. By overcoming challenges and investing in innovation, CMOs can play a key role in shaping the future of medicine.

2 notes

·

View notes