#chemical suit manufacturer

Explore tagged Tumblr posts

Text

Valuable Tips For Choosing High Quality Medical chemical Suits

Chemical suits are protective suits that are often used in medical settings. They help to protect the wearer from being exposed to hazardous materials, like toxic substances, liquids and chemicals. Doctors and nurses often need to work in contaminated environments, and as a result, they must have protective gear that enables them to manage their professional responsibilities safely. While buying…

View On WordPress

#chemical manufacturer usa#chemical suit distributors#chemical suit manufacturer#chemical suit suppliers#chemical suit wholesaler#equipment manufacturer#medical equipment#medical equipment distributors#wholesale medical equipment

0 notes

Text

Exploring MS Plates: Varieties, Applications, and Their Design Impact with Top Brands from SteelonCall

Diverse Varieties of MS Plates

Mild Steel (MS) plates, celebrated for their robustness and adaptability, come in various types to suit different industrial and construction needs:

Standard MS Plates: These versatile plates are the go-to choice for general applications. Their balanced mix of strength and flexibility makes them ideal for structural supports, machinery parts, and general fabrication tasks.

High Strength Low Alloy (HSLA) Plates: Designed to offer enhanced strength without compromising weldability, HSLA plates are perfect for demanding applications. They are commonly used in heavy machinery, bridges, and other high-stress environments.

Corrosion-Resistant Plates: Coated or treated to withstand environmental wear, these plates are used in areas prone to moisture and chemicals. They are ideal for outdoor installations and marine applications where durability against corrosion is crucial.

Quenched and Tempered Plates: Through specific heat treatments, these plates gain exceptional hardness and impact resistance. They are utilized in heavy-duty machinery and equipment that require superior strength and durability.

Wide-Ranging Applications of MS Plates

The applications of MS plates span a diverse array of sectors, reflecting their integral role in modern industry and construction:

Construction: In construction, MS plates are essential for structural components like beams, columns, and reinforcements. They provide the necessary stability and strength for buildings, bridges, and infrastructure projects.

Manufacturing: The industrial sector relies on MS plates for machinery and equipment fabrication.

Automotive Industry: MS plates are used extensively in automotive production for vehicle bodies and chassis. Their strength and formability are key to producing safe and reliable automotive parts.

Shipbuilding: In the maritime industry, MS plates are fundamental in constructing ship hulls and decks.

Agricultural Equipment: MS plates are utilized in the production of agricultural machinery. Their toughness and ability to withstand heavy loads make them ideal for farming equipment.

Impact of MS Plates on Design Innovation

MS plates are not only functional but also inspire creative design solutions:

Architectural Innovation: In contemporary architecture, MS plates are often used for their sleek, industrial aesthetic. They feature prominently in building facades, decorative elements, and structural highlights, contributing to modern architectural styles.

Custom Fabrication: The flexibility of MS plates allows for custom designs and fabrications. From bespoke furniture to artistic installations, their ability to be cut, welded, and shaped supports unique and tailored design solutions.

Facade Solutions: For building facades, MS plates can create striking visual effects while providing durability. Various treatments and finishes offer designers flexibility in achieving distinctive and functional exterior designs.

Versatile Design Options: The range of finishes and treatments available for MS plates enables their use in diverse design contexts. This adaptability allows for integration into both interior and exterior designs, meeting varied aesthetic and functional requirements.

Premium MS Plates Available at SteelonCall

At SteelonCall, we offer a selection of high-quality MS plates from renowned brands, ensuring that you receive the best materials for your projects:

Vizag Steel: Renowned for its superior quality and reliable performance, Vizag Steel’s MS plates are ideal for a range of applications, providing both strength and durability.

SAIL: SAIL offers a wide array of MS plates known for their consistent quality and performance, suitable for various industrial and construction needs.

Jindal: Jindal’s MS plates are celebrated for their exceptional strength and resilience, making them a preferred choice for demanding applications in construction and manufacturing.

Conclusion

MS plates are a fundamental component in numerous industrial and construction applications, valued for their strength, versatility, and adaptability. At SteelonCall, we provide top-quality MS plates from leading brands like Vizag Steel, SAIL, and Jindal, complete with test certificates to ensure authenticity and performance. Whether you need MS plates for construction, manufacturing, or innovative design projects, our range of products meets your highest standards.

For the best prices and exceptional service, contact us at 08062212000 or visit our website at steeloncall.com. Discover how our premium MS plates can elevate your projects and meet your needs with excellence.

#MSPlates #SteelPlates #DesignInnovation #ConstructionMaterials #TopSteelBrands #SteelonCall #QualitySteel

#Diverse Varieties of MS Plates#Mild Steel (MS) plates#celebrated for their robustness and adaptability#come in various types to suit different industrial and construction needs:#Standard MS Plates: These versatile plates are the go-to choice for general applications. Their balanced mix of strength and flexibility ma#machinery parts#and general fabrication tasks.#High Strength Low Alloy (HSLA) Plates: Designed to offer enhanced strength without compromising weldability#HSLA plates are perfect for demanding applications. They are commonly used in heavy machinery#bridges#and other high-stress environments.#Corrosion-Resistant Plates: Coated or treated to withstand environmental wear#these plates are used in areas prone to moisture and chemicals. They are ideal for outdoor installations and marine applications where dura#Quenched and Tempered Plates: Through specific heat treatments#these plates gain exceptional hardness and impact resistance. They are utilized in heavy-duty machinery and equipment that require superior#Wide-Ranging Applications of MS Plates#The applications of MS plates span a diverse array of sectors#reflecting their integral role in modern industry and construction:#Construction: In construction#MS plates are essential for structural components like beams#columns#and reinforcements. They provide the necessary stability and strength for buildings#and infrastructure projects.#Manufacturing: The industrial sector relies on MS plates for machinery and equipment fabrication.#Automotive Industry: MS plates are used extensively in automotive production for vehicle bodies and chassis. Their strength and formability#Shipbuilding: In the maritime industry#MS plates are fundamental in constructing ship hulls and decks.#Agricultural Equipment: MS plates are utilized in the production of agricultural machinery. Their toughness and ability to withstand heavy#Impact of MS Plates on Design Innovation#MS plates are not only functional but also inspire creative design solutions:

0 notes

Text

KEMYSTERY Chemicals Pvt Ltd is a manufacturer and supplier of chemicals for research, scale up and production to the pharmaceutical, diagnostic, lifesciences and other industries. Our Business Verticals include

Catalog

Sourcing

Production Please enquire on [email protected]

#big pharma#chemicals suppliers#chemistry#pcd pharma business#pcd pharma franchise#pharfaite#pharma manufacturing#pcd pharma india#pharma chemicals#pharma franchise company#chemical suppliers#chemical spill#chemical solutions#chemical suit

0 notes

Text

Industrial safety is of utmost importance in today's fast-paced and rapidly growing world. Whether you are a manufacturer, a supplier, or an end-user, ensuring the safety of your workforce is crucial. One of the most effective ways to ensure safety is by selecting the right protection. In India, there are many industrial safety products suppliers, safety equipment manufacturers, and safety equipment and products suppliers in Vadodara India. But, how do you choose the right protection? In this blog, we will discuss five features that you should consider when selecting protection in India.

#safetyproductsearch#industrial#alpha industries#industrial safety products supplier in india#industrial safety hand gloves supplier in india#industrial safety products supplier#industrial hand gloves supplier in india#safety products supplier in india#body protection suits supplier in india#fall protection supplier in india#industrial chemical protection equipment in india#safety equipment manufacturers in india#Safety Equipment and Products Supplier in Vadodara India#Safety Equipment and Products Supplier in Vadodara | Gujarat | India

0 notes

Text

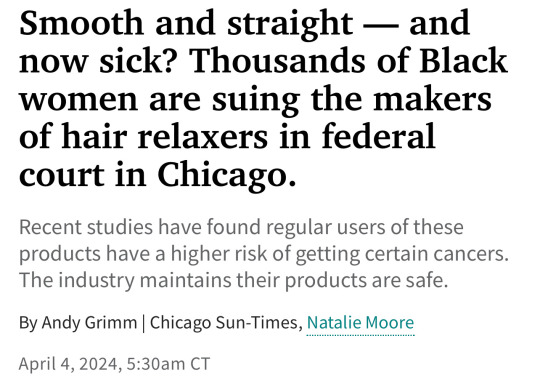

Traccye Love used hair relaxers for years and believes the chemicals in those hair products are related to her uterine fibroids. Love, of Oak Park, had a hysterectomy two years ago and is one of thousands of women who have filed suit against the hair care companies.

Growing up in Chicago’s Chatham neighborhood in the late 1990s, Traccye Love wished for the long, smooth tresses of pop star Aaliyah.

“That was the look then — smooth and straight,” said Love, of Oak Park. “My mom would press it (with a hot comb), but I wanted it to stay straight.”

Love wasn’t allowed to get her first chemical hair relaxer until she turned 18. For most of the women in her close-knit, predominantly Black community, the rite of passage of using relaxers to straighten their naturally kinky, thick hair had come much younger. Love’s mother worried about the dangers of using a relaxer: chemical burns or brittle hair caused by lye and similar chemicals in hair-straightening products.

Throughout college, and well into her 30s, Love slathered on chemicals from home straightening kits every six weeks or so. Then, in her late 30s, she began to feel knee-buckling abdominal pain during her menstrual cycles — on her worst days each month, Love downed five 200-milligram tablets of ibuprofen every four hours.

“It felt like someone was taking my ovary and twisting it like a balloon,” Love said.

After several years and trips to three different doctors, tests revealed Love had multiple, golf ball-sized fibroid tumors in her uterus. In 2022, at the age of 38, she had a hysterectomy. She was still using hair relaxers until her husband spotted a social media post about lawsuits targeting the manufacturers. She now thinks the relaxers caused her tumors.

“It had never occurred to me that there was serious risk to using relaxers,” Love said. “I thought the risk was getting scalp burns.”

In October 2022, the first of several thousand lawsuits was filed at the Dirksen Federal Courthouse in the Loop by a woman from St. Louis claiming that chemicals in hair relaxer products she used — such as Soft Sheen, Just for Me and Dark & Lovely — caused her cancer.

(continue reading)

#psa#hair relaxers#traccye love#black hair#carcinogens#hair straightening#natural hair#black hair care#straight perms#hair care

55 notes

·

View notes

Text

Can you imagine the chaos that would be Miles G and Peni interacting?

Like when Miles G joins the group to help fight the Spot for the big finale and he just kind of shuffles himself to the back of the group and Peni is there

And they both look at each other with resting depressed / bitch face and size each other up and scrutinize each other's tech and gear with their eyes and then at the same time they look at each other and say

"Huh... cool"

And then during the fight with The Spot, the whole time they're asking each other questions about each other's tech while attacking and dodging effortlessly because they're cool like that, and they get so engrossed in their tech conversations that the fight becomes more of an annoying background thing so they just lock in and do joint team duo attacks to help Miles so they can wrap up the fight and get back to their conversation on hydraulics faster

And after the group wins the fight and Hobie makes everyone secret watches- oh its so over

They both just drop into each other's dimensions at random times of the day and help each other with whatever tech or engine or weapon or gizmo or what have you and create the most tech thing ever that even regular Spider-Man villians couldn't understand

Miles G teaches Peni about present day tech (which is old tech to her) and Peni teaches Miles G about her present day tech (which is future tech to him) and they gain a wider understanding of the origins and mechanics of past and future tech and now with this knowledge they learn to build anything (Miguel has ranked them higher on the 'people to watch' list again) and Margo is involved in their shenanigans too.

They get into discussions about dubbed vs subbed anime, and Peni reintroduces Miles G to My Chemical Romance. Miles G is vibing with it, and Rio is entertained because Miles G has randomly entered his 'No one understands me' phase again

These two dimension hop to 1610B every other week just to go to the arcade house and kill it in some Dance Dance Revolution. They invite the others later (Miles: So you just invited me after you already did stuff without me in my dimension??).

They watch Big Hero Six together, and immediately try to figure out how to make those little magnet things (they do it in a day) and help each other upgrade Sp//dr with Baymax related protocols they like

Peni helps Miles upgrade his own suit of course and it gets the coolest most badass design known to man, his mask can translate 1000 different languages, has built in 'prowler-sense' to detect danger, and God knows what else and Kingpin, Doc Ock, Scorpion, Lizard, and the rest of the Sinister Six and related villians are baffled because they have no idea how someone could've built or manufactured a suit like that on their own (and they can't replicate it).

Eventually they become so airtight that they just start chillin and talking to each other in Spanish and Japanese and they both understand each other and meanwhile the others in the Spiderband Ensemble (Miles and the others) are wracking their brains trying to figure out how they defeated over 20,000 villians on their own over the past year with just the two of them, and how they have 3 successful self published mangas about their Ocs together in 3 different dimensions

#these two are an unstoppable force and cannot be contained#just wait until miles g introduces peni to /his/ favorite music#I need to see them rap in spanish and japanese together#yeah they're gonna release a successful album too#it'll be the only thing to top the charts of that Spiderman Christmas album from Itsv#miles g morales#prowler miles#miles 42#peni parker#sp//dr#spiderband#miles morales#margo kess#atsv#across the spiderverse

47 notes

·

View notes

Text

By John Klar American Thinker

January 9, 2025

Germany’s once-envied efficient economy is in freefall, and the climate change cult and European Green Deal are directly to blame. State policies subsidizing EVs and other products, shutting down coal and nuclear plants, and mandating forced conversion to untested, unimplemented “renewables” resources for energy have decimated industrial efficiency. Industries and blue-collar jobs are fleeing Germany for polluting, profitable operations in China, India, and elsewhere abroad. Will the United States follow suit?

As natural gases skyrocket during a European cold snap, and Russian gas pipelines through Ukraine are shut down for the first time since 1991, Germany has transitioned from Europe’s economic darling to its leading economic anchor. Followed closely by France and the UK, similarly weighted by economically destructive climate fantasies that are crashing to Earth like ideological meteors, the latest blow to gas supplies compounds the crisis occasioned by the mysterious sabotage of Nord Stream 1 and 2.

The results of this disastrous state-controlled economic carbon dioxide experiment continue to be as evident as explosives in a controlled demolition. Germany terminated massive EV subsidies at the end of 2023; EV sales promptly fell 69%. Despite gushing economic promises of “high-paying jobs” in the renewables industry, Germany announces more layoffs almost daily. Chinese companies, unhindered by escalating energy and regulatory costs, are leading in EV and other manufacturing technologies while spewing more chemicals into the ecosystem than German manufacturing industries.

5 notes

·

View notes

Text

G Witch Onscreen Text: Episode 6

GRAAAHH!! This is part SEVEN in my attempt to transcribe and discuss all the onscreen text in G Witch!! Because I CAN!!! GRAHH!! We're on episode 6, halfway through season 1!! Grah Graaaahh!!!

Click here to go back to Episode FIVE!! Grahhh!!!

Let us begin.

Not text, but during Bel and Prospera's initial confrontation, the building they're in has art pieces on display. Maybe it's some kind of museum?

Not text again, but we don't get very many looks into the common areas of the 3 branches, so here's Jeturk House's. It's really flashy and gold, huh? It also matches the aesthetic of Vim's office.

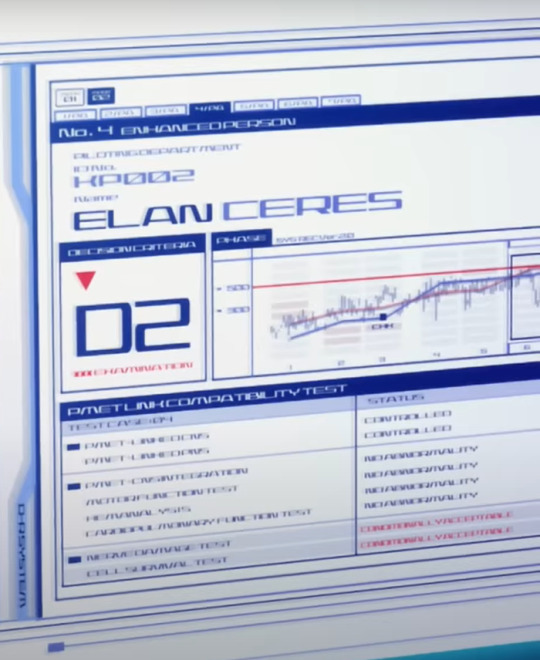

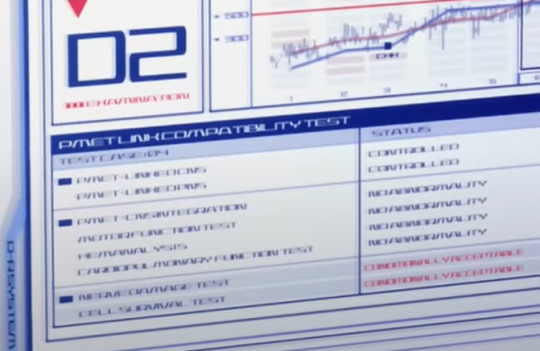

During the scene with Bel and El4n, Bel consults the data on this monitor when she tells him that he'll be fine piloting the Pharact for the duel against Suletta. We get a couple of shots of this monitor, so I'll do my best to glean what information I can from it.

On the left side of the monitor is a mockup of the Pharact. TEXT: (Top Left) REGISTERED NAME: PHARACT MS: FP/A-77 PMET CODE: P017-0046

(Bottom Left) MANUFACTURER: PEIL TECHNOLOGIES STATUS: IN TEST OPERATION

We see the Pharact's Permet Code here, that being PO17-0046. The 'P' probably stands for 'Peil.' Also, have you noticed the the MS IDs for all of Peil's mobile suits have a '/' in them? The 3 branches all have their own unique naming conventions when it comes to their MS codes. It's obvious, sure, but it's something you might not have noticed unless you were looking at it.

This info here, on the right side of the monitor, is much more interesting. TEXT (Header) No. 4 ENHANCED PERSON >PILOTING DEPARTMENT >ID. NO: KP002 NAME: ELAN CERES

This screen is how we learn that El4n is indeed the 4th Enhanced Person in the show proper.

Underneath the header is this info box and a graph. The box on the left says DECISION CRITERIA D2 ***EXAMINATION

What this box means is mostly speculation on my part, but I believe this is a grading system that evaluates the remaining health/usefulness of an enhanced person. There's a red arrow pointing down, implying that this grade, D2, is worse than the grade from the previous evaluation.

The graph to its right is a bit harder to analyze.

It's exceedingly similar to the graph shown during the Shin Sei Inquiry by Shaddiq, that measured Aerial's Permet Influx, but they probably aren't measuring the same thing.

I think it's probably closer to the little bit of this graph we see in the prologue, that I speculated was a measurement of a pilot's exposure to a data storm.

The graph has no title, it only says PHASE on the header, followed by Sys REC Ver. 2.0, which means this data was either recorded from the Pharact of El4n's body. The highlighted point is labelled CHH.

My BEST guess is it's measuring the amount of Permet radiation his body is suffering from.

Underneath the graph is this subfield TEXT (top to bottom.) PMET LINK COMPATIBILITY TEST TEST CASE: 04 | STATUS PMET LINKED CNS | CONTROLLED PMET LINKED PNS | CONTROLLED PMET-CNS INTEGRATION | NO ABNORMALITY MOTOR FUNCTION TEST | NO ABNORMALITY HEMANALYSIS | NO ABNORMALITY CARDIOPULMONARY FUNCTION TEST | NO ABNORMALITY NERVE DAMAGE TEST | CONDITIONALLY ACCEPTABLE CELL SURVIVAL TEST | CONDITIONALLY ACCEPTABLE

This is an evaluation of El4n's body, and from this we get a really good look into the true danger of piloting a Gundam.

To start, CNS stands for Central Nervous System, and PNS stands for Peripheral Nervous System. The first box is analyzing the status of the artificial nervous system implanted into El4n's body.

PMET-CNS INTEGRATION can thus be assumed to be analyzing its integration with the rest of El4n's body. MOTOR FUNCTION TEST is self evident, an analysis of El4n's motor skills. HEMANALYSIS is an analysis on the chemical composition of one's blood. CARDIOPULMONARY FUNCTION TEST is a test evaluating the strength and health of your heart and lungs.

NERVE DAMAGE TEST and CELL SURVIVAL TEST are self evident, but what's most important about them is that, unlike the rest of his results, they're labeled CONDITIONALLY ACCEPTABLE. If he hadn't been disposed of by Peil, we can see that this is probably what would have killed him. A combination of Cellular Necrosis and Nerve Damage.

We can glean from this chart that over exposure to Permet primarily affects the Nervous, Cardiovascular, and Pulmonary systems, as well as cause cellular necrosis.

Finally, though we unfortunately never get a closer look at it than this, there's this final box here, labeled EEG[???], and contains what i think is a CT scan of El4n's brain.

TEXT: PROPULSION CONTROL SYSTEM HIGH MANEUVER MODE

When Suletta is piloting the Aerial to test out the thrusters, we can see the system and mode being tested.

When talking to Miorine and Nika in their shuttle, we can see SS/O.M is added to the com screen on Suletta's phone. Not sure what it means !

Not text but I love Mio's face here after she finishes giving Suletta the pep talk, but before she responds to Nika. She's like, hm! Helping Suletta felt really good. I hope this doesn't awaken anything in me.

El4n doesn't have anything in his room whatsoever.

When Suletta asks to talk to El4n, they can't get a hold of him directly, so they just do a HOUSE WIDE BROADCAST instead.

TEXT: MECHANICAL DEPARTMENT ID No: KM079 NAME: EARLTON WELLS.

Not important, but one of the two students Suletta speaks to is named Earlton Wells.

During the duel, Bell can tell that El4n isn't doing well because his flight path is jagged, he can't fly straight anymore.

We can't read this error message, but we can read PMET SCORE 4, so its most likely an error related to that.

We can see the alert message on El4n's screen when he's about to run into the meteor. It just says ALERT.

When Suletta is trapped and Aerial increases its Permet Score, we can see little whispy things on the main monitor. Oooohhh..pretty...

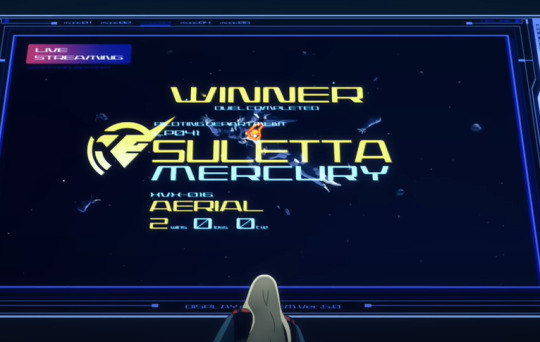

So, bit of a mixup here, before, when Suletta defeated Guel in the rematch, it said she had 2 wins, which made it seem like her previous win had been reinstated. That wasn't true! It was just a mistake, because when she defeats El4n here, she still only has 2 wins. Can't win em all !

Here, we can see that time and temperature in Asticassia's simulated environment. It says 26 degrees and is sunny, which means that Asticassia uses Celsius and not Farenheit.

When Bel begs the Peil Witches to reconsider, if you look at the monitor, you can see Elan hanging up in front of the laser. They're watching him die here, and Bel saw it too.

AND THATS IT!!! HUAAAAHHH!!! THANK YOU FOR READING! I NEED TO GO! YOUR FINAL GIFT:

You ever notice how since the beginning the Enhanced Persons were alluded to be like Eri because only 4 and 5 were ever able to see and hear her when they're overloaded with Permet?

Click here to go to Episode 7!

Click here to go to the Masterpost!

41 notes

·

View notes

Text

Excerpt from this story from DeSmog Blog:

Environmental groups are teeing up a legal challenge to new Environmental Protection Agency (EPA) rules on pollution from chemical and plastics plants, citing concerns the EPA relied too heavily on lowball industry estimates as it sized up the risks to people’s health posed by ethylene oxide (EtO), chloroprene, and other toxic air pollution.

The EPA just announced the new rules in April, saying they’re intended to “significantly reduce” dangerous pollution from chemical plants and some plastics plants.

But the Environmental Integrity Project, Earthjustice, Sierra Club, California Communities Against Toxics, Air Alliance Houston, and others filed suit this week in the federal D.C. Circuit Court of Appeals, with attorneys for the groups telling DeSmog they believe the EPA’s rules remain too weak.

“The EPA’s underestimation of the risks posed by chemical facilities puts nearby communities in grave danger,” Earthjustice attorney Deena Tumeh said in a statement announcing the litigation. “By downplaying ethylene oxide emissions, the EPA fails to protect public health adequately.”

When contacted by DeSmog, the EPA declined to comment, citing pending litigation.

Roughly 200 plants, dotted across the country but heavily clustered along the Gulf Coast, are covered by the new rules. Those plants primarily make chemicals and “polymers and resins,” or plastics — and they release dangerous chemicals into the air in the process.

The new rules, years in the making, update Clean Air Act standards on a half dozen pollutants from those plants, including the highly carcinogenic EtO and benzene, chloroprene (used to make the neoprene that’s found in wetsuits), vinyl chloride (which was notoriously burnt off in the East Palestine, Ohio, train derailment), a vinyl chloride precursor known as ethylene dichloride, and 1,3 butadiene (used to make synthetic rubber).

The EPA has said its rule “will provide critical health protections to hundreds of thousands of people living near chemical plants.”

The environmental groups’ lawsuit comes shortly after Denka Performance Elastomers asked the D.C. Circuit to block the rules from going into effect in May. Denka, a Japanese company, alleged that the EPA allowed too little time for the company to slash chloroprene emissions from its LaPlace, Louisiana, operations, giving the company just 90 days, while other chemical manufacturers would be allowed two years to curb their emissions.

Denka’s claims have drawn public support from the state’s governor, Jeff Landry, and Louisiana attorney general Liz Murrill, who also filed a D.C. Circuit challenge, citing concerns that the Denka plant could be shut down.

Back in April, DeSmog first reported on concerns that loopholes in the rules, combined with plans from companies like Koch Industries to expand their operations, could mean Louisiana’s Cancer Alley won’t see a decrease in total toxic air pollution.

A July 16, E&E News investigation found that tightened EPA regulations governing hazardous air pollution from oil refineries – a similar set of rules to the ones covering chemical and plastics plants – successfully tamped down dangerous emissions from most of the 130 refineries reviewed. Dozens of other refineries, however – mostly located in communities of color – saw emissions rise. Troy Abel, a Western Washington University professor of environmental policy, faulted “less stringent rules enforcement in some states versus others.”

This week’s legal challenge to the rules for plastics and chemical plants doesn’t specify what criticisms the groups intend to raise before the court.

But attorneys for environmental groups behind the new lawsuit filed July 16 said that while EPA’s rule marks an improvement in many ways, it also contains some dangerous flaws.

“The basic structure of the rule is good, we just don’t think it runs far enough,” Abel Russ, a senior attorney for the Environmental Integrity Project, told DeSmog.

12 notes

·

View notes

Text

Nectar-crystallizing plants

These plants gather nutrients from the soil, and crystallize nectar into a single hard pellet that grows atop their stem. They are vital to the food chain, being consumed by nearly every creature on the planet's surface--If I catch a beast during a meal, it may spit out a fully undigested pellet when it is slain! How wild! These appear to be plants at a first glance, but they seem to share the half-beast-half-plant nature of the Pikmin and the Onions...could these be distant evolutionary cousins?

The Pellet Posies try to attract nearby creatures by altering their own chemical makeup in real time-- Somehow, they can sense the colors of nearby creatures and rapidly manufacture nutrients hypertargeted to them, breaking down the old nutrients and reusing them like molecular playing blocks. Through what mechanism, it's unclear, but they appear to be attuned to the Pikmin in particular.

Once a Pellet is felled from its stalk, it remains the color it had originally been, for it can no longer produce new nutrients. The smallest of these pellets, when brought to an Onion of the same color can produce 3 pikmin. Other Onions can't seem to use the nutrients as efficiently, only bearing 1 pikmin.

The Wild Wedelia is a flower with a colorful patterned seed, reminiscent of the Onions in a way. Unlike the Pellet Posies, this flower seems to have a balanced nutritional value, and every Onion is able to produce 3 Pikmin when this seed is retrieved.

Something unique about this flower's seed is how it acts with Onions that had merged with another-- somehow, it produces 3 Pikmin of each type residing within the Onion, doubling its efficiency! I'll never be able to wrap my mind around the inner workings of these strange beings!

The Thorned Thistle is a plant that grows rather tall! Its stem is covered in prickles that most of the Pikmin would rather avoid, but Thorn Pikmin can climb up and retrieve the seeds resting at the very top.

The seeds are covered in tiny, hairlike thorns, that make them impossible to carry for all but the Thorn Pikmin. I tried picking one up myself, and it stuck to my suit and I couldn't put it down! I'm just glad the Onion doesn't seem to mind their barbs…

The River Root grows, peeking its head just out of reach above the water's surface. Its roots reach impossibly deep into the depths…what could be the purpose of such a long stem? I was able to reach it solely with the help of the Lily Pikmin--thank heavens they can float!

These pellets don't seem to have a distinguishable marking on them, compared to their cousins. Perhaps they were swept away in the water's changing currents? The chaotic swirls seem to hint at some hidden order that I'm not yet capable of fully understanding.

The Burst Berry was a terrifying encounter, for what I had considered to be a dormant plant. Normally, I walked by these unassuming red bushes and they sat, like most plants do, inactive. But when I passed them with Candy Pikmin in my party, out of nowhere, a giant Berry burst from the ground! Did it sense their sugary steps?

At first, the Pikmin were unable to bring it back to the Onion--its roots were tucked firmly into the ground, and it did not wish to leave its spot. But when I returned with a Fruiting Candy Pikmin, I found that I was able to "burst" it open, revealing a small pink pearl, tucked away at the center!

I'm still uncertain how these beings benefit from attracting predators, and giving away such vital nutrients...perhaps it is a way of ensuring propagation; coating their true seeds in such an abundance of nutrients ensures that even beyond digestion, the seeds will have more than enough food to grow, themselves...I will have to keep an eye out in order to learn more.

43 notes

·

View notes

Note

Every fandom has its bad side and worse side. I am not ok with trolls going around saying Vince sacrificed Skylar for fame either

the real people to blame for this is boeing and rocketdyne. They were the ones releasing radiation and dumping chemicals near the neighborhood where Vince and sharise lived at getting people sick and giving them cancer and unfortunately Skylar was a victim who did not survive

Also let it be known that a lot of these manufacture and chemical companies are still dumping toxic waste close to residents today!

Hello, anon! Thank you for your wise words and bringing awareness to the situation. It is very unfortunate how this whole thing occurred.

For anybody who wants to know more I will provide a short excerpt from an article I found. I will also paste the link for those who want to read the article in its entirety.

The lead singer for Mötley Crüe has sued Boeing North American Inc., claiming that his daughter's death by cancer in 1995 was caused by radioactive material dumped in the soil and ground water near his former home near the Santa Susana Field Laboratory.

Vince Neil and his ex-wife, Sharise, bought a home in Chatsworth in 1991, a few miles east of Boeing's Rocketdyne Division. Boeing acquired the property in 1996 when it bought Rockwell International's aerospace and defense businesses.

The suit claims that Boeing, Rockwell, and Rocketdyne knowingly dumped hazardous materials, such as plutonium and uranium, near the Neils' Summit Ridge Circle residence southeast of Simi Valley.

Their 4-year-old daughter, Skylar, was diagnosed with a rare form of cancer in April 1995 and died four months later. The suit claims that her death came "as a direct result of the activities conducted by defendants."

https://www.latimes.com/archives/la-xpm-1999-aug-18-me-1368-story.html

It’s disgusting how these companies are still getting away with this!

#hopefully this will educate the trolls#go after the companies not Vince#cine has spoketh#vince neil#motley crue#mötley crüe#nikki sixx#tommy lee#mick mars

6 notes

·

View notes

Text

Humans have been harnessing the power of yeast for thousands of years. These fungi allow fermentation, the molecular process whereby living cells typically transform sugar or starch into more complex molecules or chemicals. Discovered 10,000 years ago, the technology of liquid fermentation—from mead to beer to spirits—and solid-state fermentation—bread and cheese—helped put humanity on a rapidly accelerating path of evolution and advancement.

Fast forward 9,950 years. Around three decades ago, humans applied the potential of liquid fermentation to create medicines. In 1978 Arthur Riggs and Keiichi Itakura produced the first biosynthetic insulin using E. coli as a single-celled manufacturing plant. The epiphany that single-celled bacteria and yeast are sugar-powered microfactories that can be utilized to synthesize novel compounds is one of the most powerful discoveries of the past 100 years.

Since that revolutionary insight occurred, science has been devoted to understanding, cultivating and ultimately reprogramming single-celled organisms such as yeast, bacteria and algae, and we've been using the process to make more lifesaving drugs, biobased fuels such as corn ethanol, fragrances and a growing suite of small biological molecules.

24 notes

·

View notes

Text

Protecting the Environment: The Importance of Oil Absorbent Pads in Spill Response

Oil spills, whether accidental or intentional, pose a significant threat to the environment. From industrial accidents to marine disasters, these incidents can have devastating consequences for wildlife, ecosystems, and human health. Effective spill response is crucial to minimizing environmental damage and ensuring a swift and efficient cleanup. This blog post will explore the vital role of Oil Absorbent Pads in oil spill response and how they contribute to environmental protection.

The Importance of Oil Absorbent Pads:

Oil Absorbent Pads are specialized materials designed to quickly and efficiently absorb oil and other non-polar liquids. They are an essential tool in any spill response kit, offering numerous benefits:

Rapid Response: Oil Absorbent Pads can be deployed immediately to contain spills, preventing further contamination of the surrounding environment.

High Absorbency: These pads are highly absorbent, capable of absorbing large volumes of oil in a short period.

Versatility: Oil Absorbent Pads are available in various sizes and thicknesses to suit different spill scenarios.

Ease of Use: These pads are easy to handle and deploy, making them ideal for emergency response situations.

Environmental Friendliness: Many Oil Absorbent Pads are made from environmentally friendly materials, minimizing the impact of the cleanup process itself.

PARKNONWOVEN: Providing High-Performance Oil Absorbent Pads

At PARKNONWOVEN, we specialize in manufacturing high-quality nonwoven fabrics that are ideal for use in Oil Absorbent Pads. Our products offer:

Exceptional absorbency: Our nonwoven fabrics exhibit excellent absorption capabilities, ensuring rapid and efficient oil containment.

Durability and chemical resistance: Our pads are designed to withstand harsh conditions and resist degradation from oil and other chemicals.

Customizable solutions: We can tailor our products to meet specific requirements, such as oil type, spill volume, and environmental conditions.

Eco-friendly materials: We prioritize the use of sustainable and environmentally friendly materials in the production of our Oil Absorbent Pads.

Conclusion:

Oil spills pose a significant threat to our environment, but with effective response measures, we can minimize their impact. Oil Absorbent Pads are essential tools for any spill response kit, offering rapid containment, high absorbency, and ease of use. By choosing high-quality, environmentally friendly Oil Absorbent Pads from PARKNONWOVEN, you can contribute to a safer and cleaner environment.

[email protected] 0124-4816111 Corporate Office: Park Non Woven Pvt. Ltd., Gurugram, HR

#non woven battery gaunlets#pet acoustic panel#compressor felt#fiber glass felt#high efficiency media#breather fabric#light weight insulation#plastic extrusion profile#lint free wipes#pp + pet felt

2 notes

·

View notes

Text

"Manufacturing Processes Used by Mild Steel Dowel Bars Manufacturers in Sweden"

INTRODUCTION

Mild steel dowel bars are indispensable in the construction industry, especially for enhancing the durability and stability of concrete structures. Known for their exceptional strength and adaptability, these bars play a crucial role in ensuring efficient load transfer across joints in pavements, slabs, and other structural applications. This article explores the intricate manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden, focusing on precision, quality, and innovation.

1. Raw Material Selection

The manufacturing process begins with selecting high-quality mild steel, known for its optimal balance of strength and ductility. Manufacturers in Sweden adhere to stringent quality standards to ensure that the raw material meets the requirements for construction-grade dowel bars.

2. Cutting and Sizing

Once the raw mild steel is procured, it is cut into specific lengths based on the application requirements. Precision cutting ensures uniformity, which is essential for effective load transfer and durability in concrete structures. Advanced cutting tools, including laser and hydraulic cutters, are often used to achieve accuracy.

3. Surface Preparation

Surface preparation is a vital step in the manufacturing process. The steel is cleaned to remove impurities, such as rust, grease, or mill scale, that may affect its bonding with concrete or its durability. Abrasive blasting or chemical treatments are commonly used for thorough cleaning.

4. Heat Treatment for Strength Enhancement

To enhance the mechanical properties of mild steel, manufacturers employ heat treatment techniques. This process improves the tensile strength and resilience of the bars, making them suitable for high-stress applications. Controlled heating and cooling cycles ensure uniformity and consistent quality.

5. Corrosion-Resistance Coating

Mild steel is susceptible to corrosion, especially in harsh weather conditions or when exposed to moisture. To mitigate this, manufacturers in Sweden apply protective coatings, such as epoxy or galvanization. These coatings not only extend the lifespan of the dowel bars but also ensure compliance with environmental and safety standards.

6. Straightening and Finishing

After heat treatment and coating, the bars are straightened to ensure they meet precise alignment specifications. Advanced machinery is used for this step, eliminating any deformations and achieving a smooth, uniform surface.

7. Quality Inspection and Testing

Quality assurance is a cornerstone of the manufacturing process. Mild Steel Dowel Bars Manufacturers in Sweden conduct rigorous testing to ensure that the bars meet international construction standards. Key tests include tensile strength analysis, corrosion resistance evaluation, and dimensional accuracy checks.

8. Packaging and Distribution

Once the dowel bars pass all quality checks, they are packaged using materials that protect them during transportation and storage. Proper labeling and documentation ensure that the bars reach their destination with traceability and compliance intact.

Advantages of Swedish Manufacturing Processes

Precision Engineering: Swedish manufacturers utilize advanced machinery and technology to achieve unmatched precision in dowel bar production.

Sustainability Practices: The focus on eco-friendly methods, such as recycling and reducing waste, aligns with Sweden's commitment to sustainability.

Compliance with Global Standards: By adhering to stringent international construction norms, Swedish manufacturers ensure that their products are recognized worldwide for quality and reliability.

Conclusion

The meticulous manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden highlight their dedication to quality and innovation. From raw material selection to final packaging, each step ensures that the dowel bars are robust, durable, and suited for a wide range of construction applications. These processes set a benchmark for the global industry, making Sweden a leader in the production of high-quality mild steel dowel bars.

3 notes

·

View notes

Text

Creative Ways to Incorporate Sisal Products into Your Interior Design

Sisal products have become increasingly popular in interior design due to their natural aesthetic, durability, and versatility. Among these, sisal rope and sisal twine stand out as unique materials that can add texture and charm to your home decor. In this article, we will explore creative ways to incorporate sisal rope and sisal twine into your interior design, showcasing how these simple materials can elevate your space.

Decorative Accents with Sisal Rope

Sisal rope is a versatile material that can be used in various decorative applications around the home. Here are some creative ideas to get you started:

Wrapped Furniture

One of the most impactful ways to use sisal rope is by wrapping furniture pieces. For example, you can wrap the legs of a chair or a table with sisal rope to add a rustic touch. This not only enhances the visual appeal of the furniture but also adds texture to the room.

Sisal Rope Wall Art

Creating wall art with sisal rope can add a unique focal point to your space. You can arrange the rope in various shapes or patterns, such as geometric designs or abstract forms. This DIY project allows you to express your creativity while incorporating a natural element into your decor.

Hanging Planters

Sisal rope is perfect for creating hanging planters that can bring a touch of greenery indoors. By crafting a macramé-style planter using sisal rope, you can create a beautiful display for your favorite houseplants.

Sisal Twine for Crafting and Decorating

Sisal twine is another fantastic product that can be utilized in various interior design projects also top applications for home and garden. Its natural look and sturdy texture make it ideal for crafting and decorating.

Gift Wrapping and Tags

Using sisal twine for gift wrapping can add a charming, rustic touch to your presents. Instead of standard ribbons, consider tying your gifts with sisal twine for a more personalized and eco-friendly presentation. You can also attach handmade tags made of kraft paper for an added touch.

Photo Displays

Create a unique photo display using sisal twine. You can stretch the twine across a wall and use clothespins to hang your favorite photos or artwork. This simple yet stylish display allows you to showcase your memories while adding a decorative element to your space.

Woven Baskets

Sisal twine can be used to enhance woven baskets, creating functional storage solutions that are both stylish and practical. You can wrap the top rim of a basket with sisal twine or create decorative accents on the sides.

Suggested Products

Twisted Sisal Rope

Need a tough, all-natural rope that's completely chemical-free? Look no further than SGT KNOTS® twisted sisal rope! Made in Brazil from the fibers of the Agave sisalana plant, this rope is woven and twisted using a manufacturing process that involves no chemicals, oils, or other treatments. Durable and moisture-resistant, this natural rope is perfect for applications that require a bit of stretch.

Whether you're replacing or building a scratching post for your feline friends, baling hay, or decorating your ranch-themed home, this twisted sisal rope is suited for a variety of tasks, both indoors and outdoors. Designed to withstand harsh weather, you can count on this rope for tie-downs, marine-bound binding, and many more applications.

Key Features:

Material: 100% natural sisal fibers, chemical-free and environmentally friendly.

Durability: Tough and moisture-resistant, suitable for outdoor use.

Applications: Ideal for scratching posts, agricultural tasks, crafting, and decorative projects.

Resistance: Good UV resistance; however, it has poor resistance to rot, mildew, acids, and alkalis.

Dimensions Available: Diameters of 3/16", 1/4", 3/8", and 1/2".

Lengths Available: Options of 10ft, 25ft, 50ft, 100ft, 1000ft, or 2500ft.

Unoiled Sisal Twine

Discover the versatility of all-natural unoiled sisal twine made from Agave sisalana fibers. This eco-friendly twine is a popular choice for various applications, including craft beer brewing, cucumber twine, farming, agriculture, crafting, and home decoration. 100% biodegradable and compostable, this sisal twine is food-safe and free from scents, fumes, chemicals, dyes, bleaches, or added treatments. It's easy to use for arts & crafts, and practical enough for your bushcraft needs. Keep some on hand in your bug-out bag, backpack, or workshop to always be prepared for any task.

Key Features:

Material: 100% natural sisal fibers, unoiled and chemical-free.

Biodegradable: Fully compostable and safe for the environment.

Tensile Strength: Approximately 120 lbs, making it strong for various uses.

Diameter Available: 1/8".

Lengths Available: Options of 100ft and 8000ft.

Crown Sisal Twine

Crown Sisal Twine is an all-natural, crown sisal twine made from Agave sisalana fibers. This two-ply twine offers double the strength and is an affordable choice for various applications such as craft beer brewing, cucumber twine, farming, agriculture, crafting, and home decoration. It knots well and does not stretch, making it reliable for tasks that require secure binding.

Like its counterpart, this sisal twine is 100% biodegradable and compostable, decomposing over time without harming the planet. It’s perfect for tying cardboard boxes, paper, and other recyclable materials, making it a practical addition to your eco-friendly practices.

Key Features:

Material: 100% natural sisal fibers, unoiled and chemical-free.

Strength: Two-ply construction for added durability.

Biodegradable: Fully compostable and environmentally friendly.

Applications: Ideal for tying, crafting, and agricultural tasks.

Lengths Available:

2 Ply, #8T: 150ft

2 Ply, #16T: 300ft

FAQs

1. What are the benefits of using sisal products in interior design?

Sisal products are eco-friendly, durable, and versatile. They add natural texture and warmth to any space and are biodegradable, making them a sustainable choice for home decor.

2. Can sisal rope and twine be used outdoors?

Yes, sisal rope and twine can be used outdoors, but they should be protected from prolonged exposure to moisture to prevent degradation. They are ideal for temporary outdoor decorations or in covered areas.

3. How do I clean sisal products?

For general cleaning, simply dust sisal products or vacuum them with a brush attachment. For stains, use a damp cloth with mild soap, but avoid soaking the fibers.

Conclusion

Incorporating sisal rope and twine into your interior design can add a unique and natural touch to your home. From decorative accents and wall art to functional storage solutions, these versatile materials can enhance your space while promoting sustainability. Whether you're wrapping furniture or creating hanging planters, the creative possibilities are endless with sisal products. Embrace their charm and texture to elevate your interior design!

2 notes

·

View notes

Text

Are European Sunscreen's Really Better For Us?

(Image: Nast, Condé. “No, You Shouldn’t Skip Sunscreen While at Home.” Teen Vogue, 6 May 2020.)

If you’re a skincare fanatic like me, you’ve likely fallen down the Reddit rabbit holes on skincare and makeup.

Amongst all the makeup/skincare hacks, dupes, and tutorials, you’ll find there's always one recurring theme: Sunscreen.

While the importance of sunscreen to our overall health, beyond aesthetics, is immense, it can be really easy to get lost within all the terms thrown around in online forums and blogs. Once you do a little digging, you’ll come to find that not all sunscreens are built the same. They can vary in texture, formula, SPF, consistency, duration, and much more. Furthermore, some sunscreens are specifically for makeup, while others are meant for outdoor sports.

Thankfully, most if not all of these aspects of choosing the right sunscreen can be addressed by walking into a store and browsing around the different options in order to choose what best suits your needs.

However, the intricacies of sunscreen only seem to get deeper, as we delve into the topic of international sunscreens…

So, what are these international sunscreens, and why are they so special?

One of the two main competitors in sunscreen are European vs. American sunscreens, and these are the ones we’ll be discussing today.

When considering the differences between these sunscreens, it’s essential to consider the vast differences in regulations between American and European sunscreen manufacturers.

Some of the main differences between these sunscreens are:

Chemicals

The US FDA has currently approved 3 chemicals that protect skin against UVA rays. In comparison, there are 7 approved chemicals in Europe. This allows for more options, as well as increased levels of protection. (“Why You Should Ditch American Sunscreen.” Healthline, 8 June 2017.)

UVA vs. UVB

Research conducted by the Memorial Sloan Kettering Cancer Center in New York, revealed that just 11 out of 20 American sunscreen products complied with the protection standards set by Europe. However, this is specifically impactful in the way that the sunscreen protects us from UVA rays. It has been found that many American sunscreens protect us from UVB rays, but are not as good at protecting us from the more deeply penetrating rays: UVA rays -at least not as well as European sunscreens do! (“Why You Should Ditch American Sunscreen.” Healthline, 8 June 2017.)

While European sunscreen companies offer more options for protection against the sun’s rays, shopping internationally does not come without its own setbacks. When purchasing online, it's important to make sure that you’re accessing your products from a reputable source.

However, this blogpost is not to say that American sunscreens are bad, it’s actually the opposite! Wearing any kind of sunscreen is good, especially as the weather heats up and summer approaches us. However, if you’re looking to expand your skincare horizons and try different formulas, it may be a good idea to look abroad at the different options that may not be available regionally.

Nonetheless, both American and European sunscreen manufacturers offer great and diverse options that are sure to meet any skincare needs that you may have. The main takeaway is to consider the importance of sunscreen to our overall health, as any sunscreen is better than no sunscreen :)

Do you think you would give European sunscreen a try? Why or why not?

4 notes

·

View notes