#Engineering Vehicle Powertrain Solutions

Explore tagged Tumblr posts

Text

AEAUTO Engineering Vehicle Powertrain Solutions

Against the backdrop of the global low-carbon and dual-circulation development pattern, electrification has become one of the important directions for the green development of engineering vehicles due to its full life cycle cost advantages.

Powertrain composition

The powertrain of an engineering vehicle is mainly composed of an engine, a gearbox, a drive shaft, and a travel system, among which the engine and gearbox are the core components of the powertrain.

engine

The engine is the power source of engineering vehicles, generally diesel engines or natural gas engines. Diesel engines have the advantages of high power and good economy, while natural gas engines have the advantages of good environmental protection and low working noise.

Gearbox

The gearbox is a key component for controlling the movement of engineering vehicles. Generally, a hydraulic gearbox or a mechanical gearbox is used. The hydraulic gearbox has the advantages of smooth shifting and strong load-bearing capacity, but the efficiency is low; the mechanical gearbox has high efficiency, but the shifting is not smooth.

Drive shaft and travel system

The drive shaft transmits the engine power to the travel system, which is generally in the form of tracks or tires. Tracks have the advantages of a strong ability to pass through bad terrain and good safety, but they are easy to wear and have high maintenance costs; tires have the advantages of good flexibility and long service life, but they are weak in the ability to pass through bad terrain.

Advantages of Engineering Vehicle Powertrain

Electric engineering vehicles are energy-saving and environmentally friendly products with zero fuel consumption and no emissions. Compared with diesel vehicles of the same model, it can not only respond to national policies and achieve zero-emission, energy-saving, and environmentally friendly transportation.

At the same time, unlike diesel engine maintenance and regular replacement of various filter elements, and the fact that electricity costs are far lower than the cost of diesel, the operating cost of electric vehicles can save up to more than 50%. Its salient features: are environmental protection, no pollution, low energy cost, and it can be widely used in various transportation conditions such as: logistics transportation, ore transportation , dock transportation, and other places.

AEAUTO engineering vehicle economic benefits advantage

Traditional engineering vehicles often encounter problems such as high failure rate , low energy efficiency , high operating noise , and environmental pollution during use. In order to solve the problems of traditional engineering vehicles , the following are the economic benefits of AEAUTO engineering vehicles :

1. Improve the stability of the powertrain

Use higher quality materials, strengthen the structural design of the powertrain, and improve the powertrain’s resistance to harsh environments, thereby reducing the failure rate.

2. Improve energy efficiency

Technologies such as oil pumps or hydraulic motors are used to improve the energy efficiency of the powertrain, extend the service life of engineering vehicles, and reduce energy consumption.

3. Reduce operating noise

The use of technical means such as acoustic isolation technology or noise-reducing materials can effectively reduce the noise generated by engineering vehicles during operation and improve the working environment of workers.

4. Battery costs will decrease

AEAUTO is committed to promoting technological innovation in the field of engineering vehicles and continuously investing in R&D to optimize powertrain solutions.

In the future, we will uphold the concept of innovation and continue to provide advanced, efficient, and reliable technical support and product services to the engineering vehicle industry to help engineering construction.

0 notes

Text

Pioneering the Future of Transportation: Innovative Car Engine Technologies

The automotive industry is undergoing a revolutionary transformation, driven by innovative car engine technologies that are shaping the future of nationwide car shipping. These advancements are crucial in improving vehicle performance, efficiency, and sustainability, paving the way for a new era of mobility. As environmental concerns and regulatory pressures mount, automakers are investing heavily in developing cutting-edge engine solutions that not only enhance performance but also reduce emissions and improve fuel economy.

Emerging Car Engine Solutions

1. Electric Powertrains

One of the most significant innovations in car engine technology is the rapid development of electric powertrains. Major automakers are investing heavily in electric vehicle (EV) production, aiming to become global leaders in electric mobility by 2030. Electric powertrains offer several advantages:

Zero direct emissions, contributing to reduced air pollution

Higher energy efficiency compared to traditional internal combustion engines

Instant torque delivery, providing improved acceleration and performance

By 2030, it is expected that 55 percent of all cars sold in Europe will be fully electric, highlighting the growing importance of this technology.

2. Advanced Internal Combustion Engines

While electric vehicles are gaining traction, innovative internal combustion engine designs are also being developed to improve efficiency and reduce emissions. These advancements include:

Variable compression ratio engines that adjust compression based on driving conditions

Homogeneous charge compression ignition (HCCI) engines that combine the best features of gasoline and diesel engines

These technologies aim to squeeze more power and efficiency out of traditional fuel sources, providing a bridge between conventional and fully electric vehicles.

3. Hybrid Powertrains

Hybrid powertrains, which combine internal combustion engines with electric motors, continue to evolve and offer a balance between traditional and electric technologies. Advanced hybrid systems provide:

Improved fuel efficiency through regenerative braking and electric-only operation at low speeds

Reduced emissions while maintaining long-range capabilities

Enhanced performance through the combination of electric and combustion power

4. Hydrogen Fuel Cell Technology

While still in the early stages of adoption, hydrogen fuel cell technology is gaining attention as a potential alternative to battery-electric vehicles. Fuel cell engines offer:

Zero emissions, producing only water vapor as a byproduct

Faster refueling times compared to battery charging

Longer range capabilities, especially for larger vehicles from the nationwide auto transport companies and long-distance transportation

The Future of Automotive Innovation

The continued development of advanced car engine technologies is set to transform the automotive landscape dramatically. As these innovations progress, we can expect to see:

Enhanced Vehicle Intelligence: The integration of AI and machine learning in engine management systems will lead to smarter, more responsive vehicles. For instance, BMW Group and NVIDIA Corporation's collaboration aims to integrate AI computing platforms into vehicles, enabling advanced autonomous driving capabilities and intelligent engine control features.

Improved Connectivity: The automotive industry is moving towards a more connected future. Ford Motor Company and Amazon Web Services (AWS) are developing a cloud-based platform for next-generation connected vehicles, enabling features like over-the-air software updates and predictive maintenance for engine systems.

Sustainable Transportation Solutions: With a focus on electric powertrains, hydrogen fuel cells, and more efficient combustion engines, the automotive industry is actively working towards reducing its environmental impact. This shift is expected to accelerate, with more automakers committing to sustainable practices and products.

Enhanced Performance and Efficiency: The combination of advanced engine control systems and innovative powertrain technologies will result in vehicles that are not only more efficient but also offer improved performance across various driving conditions.

Automakers are playing a crucial role in driving these innovations forward. Companies like General Motors, Volvo, Aston Martin, and Jaguar Land Rover are planning to manufacture only electric cars in the foreseeable future, demonstrating their commitment to sustainable mobility solutions.

Additionally, collaborative efforts between automakers, engine suppliers, research institutions, and government agencies are facilitating technology innovation, standardization, and scale economies that drive down costs and accelerate the adoption of cleaner, more efficient engines.

The future of auto transport services in california is being shaped by remarkable advancements in car engine technologies. From electric powertrains to advanced internal combustion engines and hydrogen fuel cells, these innovations are not only enhancing vehicle performance and efficiency but also contributing to a more sustainable automotive ecosystem.

As we move forward, the continued collaboration between automakers, nationwide car carriers, and automotive industries will be essential in realizing the full potential of these groundbreaking technologies, ultimately transforming the way we travel and interact with our vehicles.

The automotive engine market is expected to grow from USD 94 billion in 2022 to USD 130.63 billion by 2028, with a CAGR of 5.48%. This growth underscores the importance of innovative engine technologies in shaping the future of the best nationwide auto transport.

As these technologies continue to evolve, they will not only revolutionize the driving experience but also play a crucial role in addressing global environmental challenges and creating a more sustainable future for mobility.

vimeo

7 notes

·

View notes

Text

Piaggio Brings the Moto Guzzi Stelvio to Indonesia

The good news, however, for adventure bike enthusiasts is well, Moto Guzzi Stelvio. Released by PT Piaggio Indonesia, this bike boasts sophisticated technology with iconic design. This motorcycle has been specially designed to ensure that no matter what kind of terrain one finds himself in, there will be comfort and security. New update- Piaggio Fast Forward (PFF) Rider Assistance Solution, constructed by Piaggio's robotics team at their headquarters in Boston, Massachusetts, USA. With radar, this system is now the first to be fitted on a two-wheeler; this is the new Moto Guzzi Stelvio. For adventurers For riders who want to take in the twisty roads of Asia, and still retain an appreciation for a combination of off-road capability and adventure travel, might end up falling under the spell of this motorcycle.

The Moto Guzzi Stelvio is available in two versions and has been designed to be a high way motorcycle as well as an off-road vehicle. That makes it fit perfectly for the needs of riders, who are accustomed to riding on various terrains. It has been very well designed to glide through highways or toss through roughest of terrains, complete assurance that the rider would face neither inconvenience nor safety.

As announced by PT Piaggio Indonesia's Managing Director and Country CEO Marco Noto La Diega, "We proudly unveil to you the new Moto Guzzi Stelvio, a high-tech two-wheeled rover designed with unique style." He further adds that this motorcycle's latest iteration boasts not only modern styling but also can offer great performance.

The Moto Guzzi Stelvio is founded on the technology that is possessed by Piaggio Fast Forward, which is a division the Piaggio Group made in 2015. PFF is located in Boston and is foremost involved with developing robotics and rider assistance systems in advanced technologies. The Moto Guzzi Stelvio designed with the Rider Assistance Solution of PFF is equipped with radar use to detect other cars and assists riders to have safe drive by controlling their situation and knowing exactly what is going on around them while on the road. Built for Performance

At the very heart of this Moto Guzzi Stelvio lies a 90° Compact Block V-twin engine. An engineering marvel that the company meant primarily to bring down vibrations sharply and to offer a rather very smooth ride even at high speeds, the powertrain breathes in just enough air to produce 84.6 kW of power at 8,700 rpm while peaking at a maximum torque of 105 Nm at 6,750 rpm. This motorcycle will suit the rider who hopes for comfort and is complemented with a balance of power and performance.

It has an attractive feature of functional design. The Stelvio Moto Guzzi was so designed as to be functionally effective and therefore, a type of terrain you had fixed for the day would matter nothing. Robust structures in modern features such as PFF radar systems make the ride adventurous and also very safe.

For more updated information about the automotive market, the latest cars & bikes, Please visit our website https://www.autoini.com

2 notes

·

View notes

Text

Ferrari unveiled the '296 Challenge' at the Finali Mondiali race at Mugello Circuit. The car is scheduled to debut in the Ferrari Challenge in the 2024 season and is the ninth model in the history of the single-make championship hosted by Ferrari. The Ferrari Challenge is currently in its 32nd season.

As riders around the world became more skilled and competitive, the 296 Challenge attempted to make bigger changes than the original model. The 296 Challenge continues Ferrari's long tradition of developing cars for gentleman drivers, but draws on the expertise accumulated in the '296 GT3' more than any other model. The 296 Challenge is a vehicle for drivers who are passionate about future GT racing. During the development of the 296 Challenge we made significant changes, not just minor changes to the model of the production car, but to make it a vehicle optimized for track driving. An extreme form of the vehicle was developed that improves overall performance while maintaining consistency and repeatability for testing and competition.

The 296 Challenge is the first car in Ferrari's single-brand range to be equipped with a V6 engine. So far, all models participating in the Challenge have been equipped with V8 engines. The biggest change compared to the 296 GTB is the elimination of the hybrid powertrain like the 296 GT3. As a result, while reducing the weight of the vehicle, the power output was increased to 700 horsepower (cv), setting a new record in this segment with an output of 234 horsepower per liter. In terms of aerodynamics, solutions derived from the 296 GT3 were taken and pushed to the extreme to achieve unprecedented downforce figures. These include the "S-shaped duct" (which draws air into the central radiator and exhausts it through the vents on the bonnet), the "swan-neck rear wing layout (another element inspired by the development of the 296 GT3)", and the A device that maximizes the stability of downforce generated in different trim conditions.

The braking system has also been completely redesigned. It's the first to feature the new "CCM-R PLUS" disc, which features technology derived from extreme track applications. New Pirelli tires developed specifically for the 296 Challenge also contributed significantly to improved performance. After its debut at the "2019 Finali Mondiali", the 296 Challenge set a record at the Mugello circuit approximately 2 seconds faster than its predecessor "488 Challenge Evo" which debuted in the 2020 season. From the early stages of development, the 296 Challenge discussed removing all hybrid components from the V6 powertrain, as in the 296 GT3. The electric motor and high-voltage battery have been eliminated, and the output of the twin-turbo V6 engine has been increased to 700 cv. This approach helps limit vehicle weight and overall unit complexity, which are fundamental factors in track driving.

Ferrari unveils '296 Challenge' race car with F1 technology

#cars#ferrari#ferrari f1#formula 1#scuderia ferrari#formula one drivers#formula one#296 Challenge#car

8 notes

·

View notes

Text

Audi announce new simulator driver as they take next step in F1 power unit development

Audi have signed Swiss racing pro Neel Jani as their new simulator driver as they take the next step in developing a power unit for their Formula 1 project. Jani, 39, is a former test and reserve driver for Red Bull Racing and, as a member of the Porsche factory team, he won the FIA World Endurance Championship in 2016 as well as the famous 24-hour race at Le Mans. German brand Audi announced last summer that they would enter F1 from 2026, when new regulations come in, and would be building their own power unit. They soon struck a deal to take over the Sauber works team – currently Alfa Romeo – for their entry. BARRETTO: How Sauber are preparing for Audi’s arrival – and keeping the pressure on in the midfield battle Plenty of preparation has gone into the project, with the likes of Andreas Seidl leaving McLaren in December to join as the new Sauber CEO while former McLaren technical director James Key will join the team in September. Jani, who has also driven in GP2 and Formula E, will now have his own important role to play for Audi as he supports the development of the power unit with his vast experience. An update of the dynamic driving simulator for the work on the F1 hybrid powertrain is also being run at Audi’s Neuberg site in parallel. Audi have signed Neel Jani as a simulator driver to aid in the development of their F1 power unit “I am delighted to accompany Audi on their way into Formula 1,” said Jani. “It is both an honor and a great responsibility to be involved in a project of this magnitude at an early stage. “I am sure that with my experience from Formula 1 and [sportscar] projects I can forge good links between theory and practice.” Oliver Hoffman, Member of the Board of Management for Technical Development of Audi AG, added: “Just like in production development, simulation plays a major role in our Formula 1 project. “Our simulator is an important tool for the power unit development. It requires a development driver who, in addition to a grasp of technology, brings versatile experience to the project, especially in terms of energy management in racing conditions.” Audi have also stated that, since the end of 2022, testing of a one-cylinder engine has been delivering “valuable results” for the development of the power unit. The manufacturer added that the continuing concept phase is laying the groundwork of the power unit for 2026, when the new regulations will provide for increasing electrification. This feature is currently not available because you need to provide consent to functional cookies. Please update your cookie preferences Explainer: F1 sustainable fuels The electric motor will deliver nearly the same output as the internal combustion engine and the 1.6-litre turbo engines will be powered by sustainable synthetic fuel. “At the moment, we are mainly focused on fundamental concept questions with high relevance to performance,” said Adam Baker, CEO of Audi Formula Racing GmbH. READ MORE: 'It's the next revolution' – Tech chief Pat Symonds explains why Formula 1 is leading the push for sustainable fuels “However, in evaluating various technical solutions we rely not only on digital methods. Know-how, experience and practically relevant development are indispensable elements of drawing the right conclusions from the simulation. "With that combination, we can assess various operating strategies at an early stage and pave the way for efficient energy management of the power unit.” Audi have also said the first hybrid power unit, consisting of the internal combustion engine, electric motor, battery and control electronics, is planned to be run on their dyno before the year is out. That will then provide the basis for the future vehicle concept going forward. via Formula 1 News https://www.formula1.com

#F1#Audi announce new simulator driver as they take next step in F1 power unit development#Formula 1

4 notes

·

View notes

Text

A list of Automotive Engineering Service Companies in Germany

Bertrandt AG, https://www.bertrandt.com/. Bertrandt operates in digital engineering, physical engineering, and electrical systems/electronics segments. Its Designing function includes designing of all the elements of the automotive.

Alten Group, https://www.alten.com/. ALTEN Group supports the development strategy of its customers in the fields of innovation, R&D and technological information systems. Created 30 years ago, the Group has become a world leader in Engineering and Technology consulting. 24 700 highly qualified engineers carry out studies and conception projects for the Technical and Information Systems Divisions of major customers in the industrial, telecommunications and Service sectors.

L&T Technology Services Limited, https://www.ltts.com/. LTTS’ expertise in engineering design, product development, smart manufacturing, and digitalization touches every area of our lives — from the moment we wake up to when we go to bed. With 90 Innovation and R&D design centers globally, we specialize in disruptive technology spaces such as EACV, Med Tech, 5G, AI and Digital Products, Digital Manufacturing, and Sustainability.

FEV Group GmbH, https://www.fev.com/. FEV is into the design and development of internal combustion engines, conventional, electric, and alternative vehicle drive systems, energy technology, and a major supplier of advanced testing and instrumentation products and services to some of the world’s largest powertrain OEMs. Founded in 1978 by Prof. Franz Pischinger, today the company employs worldwide highly skilled research and development specialists on several continents.

Harman International, https://www.harman.com/. HARMAN designs and engineers connected products and solutions for automakers, consumers, and enterprises worldwide, including connected car systems, audio and visual products, enterprise automation solutions; and services supporting the Internet of Things.

EDAG Engineering GmbH, https://www.edag.com/de/. EDAG is into vehicle development, plant planning and construction, and process optimization.

HCL Technologies Limited, http://www.hcltech.com/. HCL Technologies Limited is an Indian multinational information technology services and consulting company headquartered in Noida. It emerged as an independent company in 1991 when HCL entered into the software services business. The company has offices in 52 countries and over 210,966 employees.

Cientra GmbH, https://www.cientra.com/. Cientra expertise across VLSI, ASIC, FPGA, SoC engineering, and IoT accelerate our delivery of customized solutions to the Consumer, Aviation, Semiconductors, Telecom, Wireless, and Automotive industries across their product lifecycle.

Akka Technologies, https://www.akka-technologies.com/. AKKA supports the world’s leading industry players in their digital transformation and throughout their entire product life cycle.

IAV GmbHb, https://www.iav.com/en/. IAV develops the mobility of the future. Regardless of the specific manufacturer, our engineering proves itself in vehicles and technologies all over the world.

Altran Technologies, https://www.altran.com/in/en/. Altran expertise from strategy and design to managing operations in the fields of cloud, data artificial intelligence, connectivity, software, digital engineering, and platforms.

Capgemini Engineering, https://capgemini-engineering.com/de/de/. Capgemini Engineering is a technology and innovation consultancy across sectors including Aeronautics, Space, Defense, Naval, Automotive, Rail, Infrastructure & Transportation, Energy, Utilities & Chemicals, Life Sciences, Communications, Semiconductor & Electronics, Industrial & Consumer, Software & Internet.

2 notes

·

View notes

Text

Hinduja Tech’s Journey Of Growth: Following Up On The Drive System Design (DSD) Acquisition

Prakash Hinduja (One of the brothers from Hinduja Family)

In the ever-evolving landscape of mobility solutions, Hinduja Tech, a global engineering R&D services firm and subsidiary of Ashok Leyland, has carved out a unique position. Over the years, the company has embraced a strategy of acquiring key players in the industry to bolster its capabilities and enhance its global reach. One of the most significant steps in this journey was the acquisition of Drive System Design (DSD), which marked a major milestone in Hinduja Tech’s pursuit of delivering world-class mobility engineering services. This acquisition not only solidified Hinduja Tech’s reputation as a leader in the mobility sector but also enhanced its ability to offer advanced electronics and propulsion solutions globally.

Strategic Importance of the DSD Acquisition

The acquisition of Drive System Design (DSD), a UK-based engineering consultancy specializing in transmission, driveline, and electrified propulsion systems, was a strategic move that allowed Hinduja Tech to significantly enhance its engineering and technological capabilities. As the global automotive industry continues its shift toward electrification, there is a growing demand for innovative solutions in powertrain engineering, especially in the field of electric vehicles (EVs). DSD’s expertise in these areas was a perfect fit for Hinduja Tech, enabling the company to expand its service offerings and deliver cutting-edge technology to its global clients.

javascript:false

javascript:false

javascript:false

javascript:false

javascript:false

By integrating DSD's capabilities, Hinduja Tech has been able to offer end-to-end solutions, from design and development to testing and validation, in key areas like transmission systems and electrified powertrains. This has not only allowed them to strengthen its presence in the automotive engineering space but also positioned the company to meet the growing demand for electric mobility solutions. The acquisition has also given a competitive edge to them in the global market, allowing it to cater to a wide range of clients looking for advanced engineering solutions in electric and hybrid vehicle development.

0 notes

Text

Aceforge: A Leading Automotive Parts Manufacturer in India

India has emerged as a global hub for automotive manufacturing, with a rapidly expanding automotive sector that contributes significantly to the country's economy. As a key player in this growth, Aceforge stands out as one of the premier automotive parts manufacturers in India, recognized for its innovative approach, precision engineering, and commitment to excellence.

With a strong legacy of manufacturing high-quality components, Aceforge has successfully established itself as a reliable partner for automakers both domestically and internationally. The company's advanced capabilities in producing critical automotive parts cater to a wide range of vehicle types, including passenger cars, commercial vehicles, and two-wheelers, contributing to the advancement of India's automotive industry.

Why Aceforge Is a Leading Automotive Parts Manufacturer in India

Aceforge has garnered a stellar reputation for its ability to produce complex, high-performance components. From engine parts to chassis systems, the company’s product portfolio spans across numerous categories that are essential for modern vehicle manufacturing. Here’s why Aceforge is considered one of the top automotive parts manufacturers in India:

1. High-Quality Manufacturing

One of the main factors that set Aceforge apart from its competitors is its commitment to quality. The company adheres to international quality standards, ensuring that every component manufactured is of the highest caliber. From forging, casting, and machining to assembly, Aceforge deploys cutting-edge technology and stringent quality control measures to guarantee that all parts are durable, reliable, and meet the performance expectations of OEMs (Original Equipment Manufacturers). Their adherence to ISO certifications and rigorous testing protocols ensures that each part performs seamlessly, even in the most demanding automotive applications.

2. Advanced Technology and Innovation

Aceforge invests heavily in state-of-the-art technology to stay ahead of the competition. The company uses advanced robotics, automated systems, and AI-powered manufacturing solutions to streamline production, reduce errors, and enhance the precision of its parts. Additionally, Aceforge focuses on continuous research and development (R&D) to stay in tune with the latest trends in the automotive industry, such as electric vehicles (EVs), lightweight materials, and fuel-efficient powertrains. This commitment to innovation positions Aceforge as a forward-thinking manufacturer capable of producing parts for the next generation of vehicles.

3. Wide Range of Automotive Components

Aceforge specializes in producing a diverse range of automotive parts that are integral to vehicle safety, performance, and functionality. Some of the key components include:

Engine Parts: Crankshafts, camshafts, connecting rods, and other essential engine components.

Chassis Systems: Suspension components, steering mechanisms, and structural parts.

Powertrain Components: Parts used in transmission and driveline systems for optimal power delivery.

Precision Machined Parts: Components requiring high accuracy for enhanced vehicle performance.

The company’s extensive product range ensures that it can cater to the needs of various vehicle segments, from high-performance sports cars to mass-market vehicles and commercial trucks.

4. Sustainability Focus

As the automotive industry shifts towards sustainability, Aceforge is at the forefront of adopting eco-friendly manufacturing processes. The company uses energy-efficient production methods, optimizes material usage, and is committed to reducing its carbon footprint. Aceforge also focuses on incorporating sustainable materials into its products, such as recycled metals, helping automakers meet increasingly stringent environmental regulations.

5. Domestic and Global Reach

Aceforge has successfully positioned itself as a leading automotive parts manufacturer in India, with an extensive network of manufacturing plants across the country. With a robust supply chain and the ability to scale production, the company is capable of meeting the diverse needs of both domestic and international clients. Aceforge exports components to several countries, supplying parts to global automotive OEMs and Tier 1 suppliers. This global reach enables Aceforge to stay competitive in an increasingly interconnected and demanding automotive market.

Conclusion

Its dedication to quality, innovation, and sustainability, combined with a comprehensive product range and cutting-edge technology, solidifies Aceforge’s position as one of the top automotive parts manufacturers in India. With the global automotive sector moving toward cleaner, more efficient, and technologically advanced vehicles, Aceforge’s expertise in crafting high-performance components makes it a vital player in shaping the future of the automotive industry, both in India and abroad.

0 notes

Text

Top 3 Contenders: EPARTRADE's Favorite Cast Iron Engine Blocks

For racing teams, car parts retailers, automotive professionals, and car mechanics, understanding the nuances of engine blocks is crucial. Enter the robust world of cast iron engine blocks, prized for their durability and strength. Let us explore the top three cast iron engine blocks that have set the standard in performance and reliability.

The Essential Role of Engine Blocks

Engine blocks are the foundational piece of any vehicle's powertrain, ensuring smooth engine operation. In racing, where every fraction of a second counts, the quality of an engine block can mean the difference between victory and defeat. Known for their durability and cost-effectiveness, cast iron engine blocks are a staple in racing circuits and garages worldwide.

The Top 3 Cast Iron Engine Blocks

1. MOTOR STATE DISTRIBUTING

With decades of experience in the performance automotive industry, Motor State Distributing offers a wide range of cast iron engine blocks from renowned brands such as Dart Machinery and World Products.

2. PLATINUM RACING PRODUCTS

Platinum Racing Products specializes in high-performance engine components, including top-of-the-line cast iron engine blocks designed for extreme racing applications.

3. WORLD PRODUCTS

World Products, Inc. has been a trusted name in the performance engine industry for over 40 years, known for their durable and reliable cast iron engine blocks.

Advantages of Cast Iron Engine Blocks

1. Durability and Strength

Cast iron engine blocks are revered for their durability and strength. Unlike their aluminum counterparts, cast iron blocks can withstand higher levels of heat and stress, making them ideal for high-performance applications. Their heavy-duty construction means they can endure the rigors of racing and everyday driving with ease.

2. Cost-Effectiveness

When it comes to cost, cast iron blocks offer significant advantages. They provide a cost-effective solution without sacrificing performance. For racing teams and automotive professionals working within budget constraints, cast iron engine blocks deliver the best of both worlds—affordability and reliability.

3. Material Comparison

Compared to other materials, such as aluminum, cast iron blocks maintain their shape and structure better under extreme conditions. While aluminum is lighter, it lacks the same level of heat resistance and stability, which are crucial in high-performance settings. This makes cast iron a preferred choice for many professionals in the automotive field.

All in All

In racing and automotive engineering, choosing the right engine block is crucial. Cast iron engine blocks are known for their durability, performance, and cost-effectiveness, exemplified by models like the Dart Big M Sportsman and Ford Racing Boss 351.

Exploring cast iron options can enhance engine capabilities, with platforms like EPARTRADE providing valuable resources. Whether a racing professional or automotive enthusiast, understanding cast iron engine blocks helps optimize performance.

#CastIronEngineBlocks#RacingTech#AutomotiveExcellence#epartrade#engineperformanc#RacingTeams#DurabilityAndPerformance#AutomotiveProfessionals#CarPartsRetailers#World Products#Platinum Racing#Motor State Distributing#EngineBlocks#Performanceparts#RacingBusinesses#RacingManufacturers#RacingSuppliers#RacingDistributors#CastIronRacingProducts#HighPerformance

0 notes

Text

Rise of Electric Powertrain Market: Trends and Predictions

The global electric powertrain market was valued at USD 83.30 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 15.3% from 2023 to 2030. The COVID-19 pandemic significantly impacted the automotive industry, leading to a reduction in electric powertrain growth due to decreased automotive sales and changing requirements. However, the implementation of stringent emission regulations by government bodies—such as the U.S. Environmental Protection Agency (EPA) establishing emission standards for Greenhouse Gas (GHG) emissions, BS-VI norms in India, and China VI regulations—is propelling market growth. Additionally, the recovery of sales in both pure and hybrid electric vehicles following the pandemic serves as a key driver for the electric powertrain sector. The increasing acceptance of electric cars, along with attractive government incentives aimed at boosting domestic electric vehicle production, is also expected to enhance the global demand for electric powertrains.

Electric vehicles are increasingly viewed as the future of the automotive industry, with traditional fuel vehicles anticipated to decline over the coming years. These electric vehicles are gaining popularity due to their environmental advantages and lower total cost of ownership compared to internal combustion engine vehicles. In response, many countries have introduced rigorous policies to promote the adoption of alternative fuel vehicles, particularly electric ones.

Gather more insights about the market drivers, restrains and growth of the Electric Powertrain Market

Component Insights

The battery segment held the largest market share at 63.6% in 2022, highlighting its critical role in vehicle electrification. Batteries serve as the primary power source for battery electric vehicles (BEVs) and are also integrated with other power sources in hybrid and green vehicles. Notably, in BEVs, the battery pack accounts for approximately 50% of the total vehicle cost, underscoring its significance in the overall electric vehicle framework. The growth of this segment is driven by several factors, including a rising demand for electric vehicles, advancements in battery technology, and supportive policies from governments that promote electric vehicle adoption.

On the other hand, the motor/generator segment is expected to experience a remarkable compound annual growth rate (CAGR) of over 30% throughout the forecast period. This surge in demand for electric motors is largely fueled by the increasing adoption of BEVs and plug-in hybrid electric vehicles (PHEVs) worldwide. These types of vehicles often utilize similar configurations for their electric motors, which facilitates manufacturing and reduces costs. Furthermore, suppliers and original equipment manufacturers (OEMs) are poised to take advantage of the growing need for electric powertrains by forming strategic joint ventures aimed at developing and enhancing electric motor technologies. For example, in 2019, Nidec Corp., a well-known e-motor manufacturer, partnered with GAC Components Co., Ltd. to establish a joint venture focused on the production of automotive traction motors. This collaboration illustrates the proactive steps being taken within the industry to meet the rising demand for innovative electric powertrain solutions.

Order a free sample PDF of the Electric Powertrain Market Intelligence Study, published by Grand View Research.

#Electric Powertrain Market#Electric Powertrain Market Report#Electric Powertrain Market Analysis#Electric Powertrain Industry

0 notes

Text

Maximizing Efficiency with Modern Forklift Industrial Equipment

Maximizing Efficiency with Modern Forklift Industrial Equipment

In the dynamic world of industrial operations, efficiency is the key to maintaining a competitive edge. Forklifts, as essential components of material handling, have evolved significantly over the years. Modern forklift industrial equipment is designed to maximize efficiency, safety, and productivity. This article explores how businesses can leverage the latest advancements in forklift technology to streamline their operations and enhance overall efficiency.

Electric Powertrains: Electric forklifts are becoming increasingly popular due to their environmental benefits and cost savings. They produce zero emissions, making them ideal for indoor use, and have lower operating costs compared to traditional internal combustion engine (ICE) forklifts.

Telematics Systems: These systems provide real-time data on forklift performance, usage, and maintenance needs. By monitoring key metrics, businesses can optimize fleet management, reduce downtime, and enhance overall productivity.

Automated Guided Vehicles (AGVs): AGVs are autonomous forklifts that use sensors and software to navigate and perform tasks without human intervention. They are ideal for repetitive tasks and can operate 24/7, increasing efficiency and reducing labor costs.

Advanced Safety Features: Modern forklifts are equipped with a range of safety features, such as collision detection systems, stability control, and operator assistance technologies. These features help prevent accidents and ensure a safer working environment.

Strategies to Maximize Efficiency with Modern Forklifts Implementing a Preventive Maintenance Program

Regular maintenance is crucial for ensuring the optimal performance and longevity of forklifts. Implementing a preventive maintenance program helps identify potential issues before they lead to costly breakdowns. Scheduled inspections, routine servicing, and timely replacement of worn-out parts can significantly reduce downtime and maintenance costs.

Training and Certification for Operators

Well-trained and certified forklift operators are essential for maximizing efficiency and safety. Providing comprehensive training programs that cover forklift operation, safety protocols, and best practices ensures that operators can handle the equipment effectively. Continuous training and refresher courses help keep operators updated with the latest technologies and safety standards.

Optimizing Warehouse Layout

An efficient warehouse layout can significantly impact forklift operations. By organizing storage areas, reducing travel distances, and ensuring clear pathways, businesses can streamline material handling processes. Implementing a systematic inventory management system and using appropriate shelving and racking solutions also contribute to improved efficiency.

Utilizing Telematics and Data Analytics

Leveraging telematics and data analytics allows businesses to gain valuable insights into forklift operations. By analyzing data on usage patterns, fuel consumption, and maintenance needs, companies can make informed decisions to optimize fleet performance. Telematics systems also enable real-time tracking and monitoring, helping to identify inefficiencies and implement corrective measures promptly.

Investing in the Right Forklift Models

Choosing the right forklift models for specific applications is crucial for maximizing efficiency. Factors such as load capacity, lifting height, maneuverability, and power source should be considered when selecting forklifts. Investing in forklifts that are tailored to the specific needs of the operation ensures optimal performance and productivity.

The Future of Forklift Technology The future of forklift technology is promising, with ongoing innovations aimed at further enhancing efficiency, safety, and sustainability. Some of the emerging trends include:

Electric and Hydrogen Fuel Cell Forklifts: As the demand for eco-friendly solutions grows, electric and hydrogen fuel cell forklifts are gaining traction. These forklifts offer longer run times, shorter refueling/recharging periods, and reduced environmental impact.

Integration of IoT and AI: The integration of the Internet of Things (IoT) and Artificial Intelligence (AI) in forklift technology will enable predictive maintenance, automated decision-making, and real-time optimization of operations. These technologies will help businesses achieve higher levels of efficiency and productivity.

Enhanced Human-Machine Collaboration: Collaborative robots (cobots) and advanced operator assistance systems will improve human-machine interaction, making forklift operations more intuitive and efficient. These technologies will enhance safety and reduce the physical strain on operators.

Conclusion Modern forklift industrial equipment offers a wealth of opportunities for businesses to maximize efficiency and productivity. By embracing the latest advancements in forklift technology, implementing effective maintenance programs, providing comprehensive operator training, optimizing warehouse layouts, and leveraging data analytics, companies can achieve significant improvements in their material handling operations. The future of forklift technology is bright, and businesses that stay ahead of the curve will be well-positioned to thrive in the competitive industrial landscape.

0 notes

Text

AEAUTO powertrain system enhances the efficiency of commercial vehicles

In the ever-evolving landscape of the auto industry, the powertrain system stands as a crucial element. With the growing awareness of ecological protection, emission requirements for commercial vehicles are becoming increasingly stringent. Reducing fuel consumption has now become of utmost importance for the development of the auto industry and the improvement of vehicle conditions.

The powertrain system is designed to enhance the power and fuel economy of commercial vehicles, ensuring they meet industry standards and regulations while also improving vehicle comfort, reliability, and safety.

This powertrain system boasts several remarkable advantages:

Power Provision: The powertrain system utilizes the engine to rotate and transmit power to the vehicle, enabling it to operate normally and smoothly on the road.

Transmission Ratio Conversion: As an integral component of the powertrain system, the transmission can cleverly select the appropriate transmission ratio based on the driver's needs. This allows for a perfect balance between vehicle power and economy under diverse road conditions, enhancing the driving experience and efficiency.

Cooling and Lubrication System: The cooling system and lubrication system within the powertrain system play a vital role in ensuring the normal operation of the engine. They effectively reduce the engine temperature, minimize wear and tear, and significantly extend its service life, saving both costs and resources for vehicle owners.

Auxiliary Systems: The powertrain system also encompasses auxiliary systems such as electronic fuel injection, cooling, and other essential components. The proper functioning of these systems guarantees the high efficiency and low emissions of the engine, contributing to a cleaner environment and better performance.

The powertrain system is truly the driving force behind commercial vehicles. It determines the power performance and economy of these vehicles and has a profound impact on their service life and environmental friendliness. When it comes to the powertrain system, we should not only focus on the user's vehicle usage conditions but also comprehensively consider the overall fuel consumption as a key indicator of the vehicle's overall performance.

In the specific application of AEAUTO, let's take commercial trucks as an example. Under the standard load use condition, users typically expect the speed to be maintained within the most fuel-efficient range of 80 - 90 km/h. The main function of the AEAUTO powertrain system solution is to optimize these specific working conditions to minimize the fuel consumption of the vehicle while meeting the power, emission, and noise requirements.

It is also essential to track and analyze the operating conditions of customer vehicles. Different truck products have distinct operating conditions, and by collecting and statistically analyzing the corresponding data, we can obtain standard cycle conditions for evaluating the power and economy of trucks. For instance, the cycle conditions of some heavy trucks in Europe require driving cycle data information composed of adjusted acceleration and deceleration.

AEAUTO powertrain system solutions are propelling the development of commercial vehicles with professional technology. By accurately optimizing various working conditions and reducing fuel consumption, they are meeting the demands of the market. Through continuous tracking and analysis, AEAUTO is able to provide customers with even better services, ensuring a more sustainable and efficient future for the auto industry.

0 notes

Text

Automotive Electronic Components & Thermal Management Solutions - Techni3

For more than two decades, Laird, a DuPont business, has capitalized on its materials science expertise to help Tier 1 automotive suppliers resolve complex electronics design challenges where the structure of the module causes EMI suppression and heat channeling issues. We are designers helping designers avoid wasted effort – and costs – and speeding the time-to-market for key automotive components.

Review our portfolio of automotive component protection solutions. Then contact us today.

Superior Protection From a Global Innovator in Material Science

EV Powertrain Electronics

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard automotive powertrain electronics from heat and EMI issues while resolving complex structural issues.

Examples include PFC chokes and transformers, which by their nature are not perfectly efficient and generate heat. Each must be housed individually – and thermally potted.

We get behind the wheel to help with thermal management solutions issues facing electric vehicles and offer two key differentiators. First, we are vertically integrated down to the magnetic ceramic powder. Second, as a significant thermal compounds supplier we are again vertically integrated down to the resins and fillers.

These differentiators help give us the green light to assume responsibility for automotive powertrain electronics performance and quality assurance across a much larger swath of the supply chain than our competitors.

LED Component Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help suppress EMI crosstalk from LED automotive component systems. And to improve thermal management for electric vehicles, for example.

Modern lighting systems are comprised of a power supply, a digital control board, and a light source – all ideally physically separated from each other. The pressure to reduce size frequently results in placing the analog, digital, and optical functions close together and not electrically isolated. This can create electrical crosstalk and can expose the optics to processing chemicals needed for the analog and digital circuits.

Laird has a complete line of non-silicone and low outgassing silicone-based pads, greases and dispensable products. Most importantly, we have the experience to advise you about deploying a variety of strategies. Our multi-functional solutions help cool components and suppress EMI simultaneously – using a single space-saving product.

EV Powertrain ElectronicsADAS / Autonomous Driving Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard ADAS electronic components from EMI and excessive heat while resolving complex structural issues.

Progressive ADAS sensor designs consume more power and emit more heat. To remain competitive, manufacturers must ensure optimum sensor efficiency or face the risk of throttled power, in turn sacrificing sensitivity, range and performance.

electromagnetic interference solutions is a barrier to function and compliance. Increasing transistor switching speeds cause various device fundamentals and harmonics to interact with each other, and the outside world, in unanticipated ways.

EV/PHEV Battery Packs

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard EV/PHEV battery packs from the consequences of excessive heat.

With increased charging speeds, battery packs emit ever increasing amounts of heat. Are packs actively or passively cooled? Must the thermal material act as a dielectric barrier? Is the pack silicone- or non-silicone mandated? Are the thermal materials themselves relied upon for mechanical support or for high compliance?

Ultimately, the appropriate choice of thermal interface materials satisfies the design constraints while simultaneously satisfying the economics. It comes after extensive evaluation of the total cost of ownership and true cost of implementation in a serial production setting. Huge material volumes are required. The importance of fast placement of preferred materials cannot be overstated.

Infotainment/Cluster Systems

Our team of engineers applies extensive industry knowledge of mechanical, thermal and electronic design to help safeguard infotainment/cluster systems from heat and EMI issues while resolving complex structural issues.

Infotainment electronics are employing greater functionality and higher speeds, causing more pronounced EMI and thermal challenges. A passive cooling strategy is imperative to eliminate the fan without relinquishing any gains in the power budget.

Following 20+ years of experience in infotainment electronics, Laird has a first-hand perspective on strategies that have succeeded and failed. We consult with our customers comprehensively on ridding systems of unwanted EMI and growing thermal loads, and on helping design teams succeed as they go-to-market.

0 notes

Text

EV Powertrain Software Development

October 23, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

EV Powertrain Software Development for electric vehicles (EVs) is a complex process requiring careful preparation, ongoing testing, and quick iteration. Powertrain systems have several interconnected parts that must function flawlessly, such as control units, inverters, battery management systems, and electric motors. Ensuring that the control software connects with these components flawlessly while preserving efficiency, safety, and performance presents a problem.

Identifying bugs later might result in substantial cost increases, delays, and costly troubleshooting. To address these issues, a Model-Based Design (MBD) strategy in conjunction with cutting-edge technologies from top players in the market, such as Dorleco, can be extremely helpful in reducing time-to-market, maximizing resource utilization, and producing reliable, high-quality solutions.

The EV Powertrain Control Software Development Stages

It’s critical to comprehend the essential phases of EV powertrain software development before delving into the details of the MBD approach and how Dorleco tools support development.

1. Requirement gathering and analysis:

Development teams examine the functional and performance needs of the electric vehicle powertrain system at the outset of the process. At this point, it’s important to comprehend how the various parts of the powertrain will work together as well as how the control software will operate the entire system to meet objectives like performance, safety, efficiency, and range optimization.

2. Control Design and Architecture:

Creating the control system architecture comes next after defining the requirements. This involves defining the control logic and creating algorithms that can manage the intricacies of the powertrain, such as coordinating motor control and controlling energy flows. At this point, interactions with further parts, such as the battery and transmission systems, are also specified.

3. Model-Based Design:

Model-Based Design (MBD) is used in this situation. The powertrain system’s physical components are represented mathematically by MBD, which also simulates their interactions in a controlled setting. By taking this step, it is certain that design problems can be found and fixed early on, which lowers the expense of repairing them later.

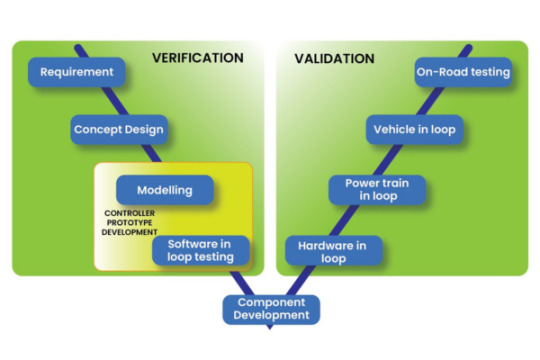

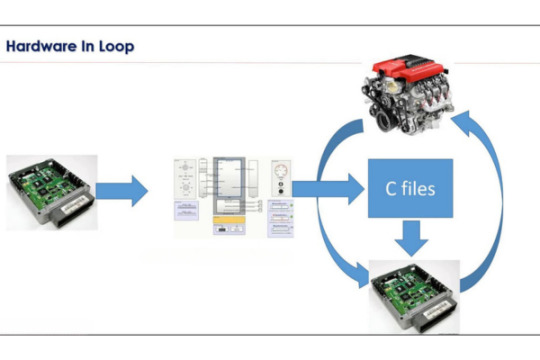

4. Testing and Validation:

Model-in-the-loop (MIL) testing is the first step in the testing process. It involves simulating and testing the control logic inside a virtual model of the system. Once confirmed, the control logic is tested in a more thorough simulation that closely resembles the actual system during the Software-in-the-Loop (SIL) phase. During the last phase, known as Hardware-in-the-Loop (HIL) testing, the control logic is implemented on hardware in real-time, and the software’s ability to communicate with physical components is tested.

5. Hardware Prototyping and Deployment:

After the simulation has been used to verify the control software, real hardware is used for testing. After verifying proper input/output responses through open-loop operation, the controller is placed through a battery of tests to verify its real-world performance.

6. Testing Hardware-in-the-Loop (HIL):

During this phase, engineers can test the controller without requiring the physical components to be present because HIL testing simulates the full plant (motor, inverter, battery system, etc.) in real time. Rapid testing under a variety of conditions is made possible by the HIL test bench, which functions as an effective virtual vehicle.

Model-Based Design (MBD) and Its Benefits

1. EV Powertrain Software Development has been transformed by Model-Based Design (MBD), which helps teams reduce the risks associated with late-stage testing and debugging. MBD provides several advantages:

2. Continuous Testing: When using MBD, testing starts at the design phase and doesn’t stop until the project is finished. This reduces the amount of time needed for debugging and rework since errors and inconsistencies are found early.

3. Enhanced Collaboration: Development teams can work on various system models concurrently, allowing them to exchange updates and share progress in real-time. This lessens the possibility of integration problems, which generally occur when control software components are combined.

4. Efficient Development: Without the requirement for real prototypes, developers may simulate and test control software under a variety of scenarios by using models. This makes it possible to evaluate edge cases early and optimize system performance before the hardware is released.

To handle the increasing complexity of EV Powertrain Software Development, where controllers must be closely connected with both mechanical and electrical systems, MBD’s continuous integration and testing environment is essential.

Advanced Tools for EV Powertrain Software Development

Advanced tools like Infineon, Vector, and Typhoon HIL can assist in further optimizing the development process. These technologies offer great fidelity and precision in the development of control software, and they facilitate hardware prototyping, testing, and validation.

1. AURIX™ TC3xx Automotive MCUs

The AURIX™ TC3xx microcontrollers (MCUs) from Infineon are made to withstand the severe demands of contemporary EV powertrain systems. The 32-bit TriCore™ processing architecture, upon which these MCUs are based, provides real-time performance, functional safety, and power efficiency. Numerous EV applications, such as motor control, battery management, and inverter management, are supported by the AURIX™ TC3xx series.

AURIX™ TC3xx MCUs are equipped with hardware security and safety measures that guarantee reliable and secure operation of the control software, even in demanding settings. The MCUs meet the strictest safety standards (ASIL-D) required for use in automotive applications.

2. The VX1000 System from Vector for ECU Calibration

The VX1000 system from Vector offers engineers a high-performance ECU measurement and calibration solution. The VX1000 facilitates quick and accurate data collection by connecting the ECU to measurement and calibration instruments. This enables engineers to guarantee that the software satisfies performance requirements and optimizes control algorithms.

Through a smooth integration with test benches and labs, the VX1000 system enables developers to measure ECUs in real-time driving scenarios. Additionally, it facilitates high transfer rates for quick data processing, which boosts testing and calibration process effectiveness.

3. Highest Fidelity Ultra-HIL Testing

Thanks to its robust simulation capabilities, an extremely realistic hardware-in-the-loop (HIL) testing platform allows developers to test control software before building physical prototypes. Typhoon HIL allows for comprehensive testing under a variety of scenarios by simulating the behavior of real powertrain components (such as motors, inverters, and battery systems) in real-time.

With the help of HIL’s platform, developers can create digital twins, or virtual versions of actual powertrain systems, which let them mimic how the systems would behave in various operating scenarios. Additionally, the platform facilitates automated testing, which enables developers to run intricate test scenarios, repeat test cycles, and guarantee that every control software release satisfies reliability requirements.

4. NXP S32K3XX Microcontrollers

Dorleco uses this microcontroller in their VCUs. It covers the primary characteristics of the S32K344 White Board, which may be used to assess various applications, including T-boxes, Domain Controllers, BCM, and Gateways. Along with a thorough description of connectors and interfaces, jumper configurations, and precise MCU pin assignments on the board, it also describes the White Board’s power supply architecture.

Conclusion

Creating EV powertrain control software is difficult and complex, requiring sophisticated tools, thorough testing, and careful planning. Developers may guarantee continuous testing, early error detection, and enhanced teamwork by implementing Model-Based Design (MBD). Better software, shorter development cycles, and lower costs are the outcomes of this.

The EV Powertrain Software Development process is further streamlined by sophisticated tools from leading companies in the field, such as Vector and Dorleco HIL, which provide reliable solutions for hardware prototyping, testing, and validation. By accelerating test cycles and guaranteeing that the control software satisfies the highest criteria of performance, safety, and dependability, these solutions assist lessen the need for physical prototypes.

0 notes

Text

The Future of Mechanical Engineering: Trends to Watch in 2024

The future of Mechanical Engineering is on the brink of a transformative era in 2024, driven by technological advancements, sustainability, and innovative practices. This evolution is characterized by several key trends that will shape the industry's future.

Emerging & Sustainable Trends in Mechanical Engineering for 2024

1. Integration of Artificial Intelligence and Robotics

The fusion of Artificial Intelligence (AI) and robotics is revolutionizing mechanical engineering. AI technologies, including machine learning and computer vision, enhance automation and efficiency in manufacturing processes. For instance, AI-driven robots can perform complex tasks with high precision, such as assembly and quality control, while also adapting to new situations through continuous learning. This shift not only improves productivity but also reduces human error and operational costs.

2. Advancements in Additive Manufacturing

3D printing, or additive manufacturing, continues to disrupt traditional manufacturing methods. This technology allows for the creation of intricate designs and customized parts on demand, significantly reducing material waste and production time. In 2024, mechanical engineers are leveraging 3D printing to produce lightweight components for industries like aerospace and healthcare, enhancing performance while minimizing costs.

3. Emphasis on Sustainability

Sustainability remains a critical focus in mechanical engineering. Engineers are increasingly tasked with developing eco-friendly materials and processes to combat climate change. Innovations such as biodegradable materials, energy-efficient designs, and renewable energy technologies are gaining traction. The transition to electric vehicles (EVs) is a prime example, with engineers designing advanced powertrains and charging infrastructures that promote cleaner transportation solutions.

4. Digital Transformation through IoT

The Internet of Things (IoT) is transforming mechanical systems by enabling real-time monitoring and predictive maintenance. By connecting machines and gathering data, engineers can optimize performance and reduce downtime significantly. Smart factories equipped with IoT sensors allow for enhanced operational efficiency through data-driven decision-making.

5. Development of Digital Twins

Digital twins—virtual models of physical systems—are becoming essential tools for engineers. They allow for simulations that predict how systems will behave under various conditions before actual implementation. This capability enhances design accuracy and speeds up the development process by identifying potential issues early on.

6. Automation in Manufacturing Processes

Automation continues to streamline manufacturing operations. The use of robots for repetitive tasks not only increases production speed but also improves safety by reducing human involvement in hazardous environments. Collaborative robots (cobots) are particularly noteworthy; they work alongside human operators to enhance productivity while ensuring workplace safety.

7. Innovations in Materials Science

Advancements in materials science are crucial for developing stronger, lighter materials that meet modern engineering demands. The exploration of nanotechnology and other innovative materials enables the creation of components that offer superior performance while minimizing environmental impact.

Mechanical Engineering Innovations

1. Artificial Intelligence and Machine Learning

The integration of Artificial Intelligence (AI) and machine learning is revolutionizing mechanical engineering processes. AI algorithms are increasingly used for:

Predictive Maintenance: Machines equipped with AI can analyze operational data to predict when maintenance is needed, significantly reducing downtime and repair costs

Quality Control: AI-powered systems can detect defects in products more accurately and faster than humans, ensuring higher quality standards in manufacturing. This leads to improved product consistency and reduced waste.

2. Robotics and Automation

Robotic systems are becoming integral to mechanical engineering, particularly in manufacturing environments. Innovations include:

Collaborative Robots (Cobots): Designed to work alongside humans, cobots enhance productivity while maintaining safety in the workplace. They can perform repetitive tasks, allowing human workers to focus on more complex activities

Autonomous Systems: AI-driven robots are capable of executing complex tasks such as assembly and material handling with high precision, thereby improving efficiency in production lines

3. Additive Manufacturing (3D Printing)

3D printing, or additive manufacturing, continues to disrupt traditional manufacturing methods by allowing for:

Custom Designs: Engineers can create intricate geometries and customized parts on demand, which leads to reduced material waste and faster prototyping. This technology is particularly valuable in industries like aerospace and healthcare, where lightweight and tailored components are crucial.

On-Demand Production: The ability to produce parts as needed minimizes inventory costs and accelerates the supply chain process

4. Sustainable Engineering Practices

Sustainability is at the forefront of mechanical engineering innovations. Key developments include:

Eco-Friendly Materials: Engineers are exploring biodegradable materials and sustainable manufacturing processes that reduce environmental impact. The shift towards using renewable energy sources is also gaining traction.

Energy Efficiency: AI algorithms optimize energy consumption in mechanical systems by adjusting operational parameters in real-time, which is essential for industries like HVAC where energy costs are significant.

5. Digital Twins and Simulation Technologies

The concept of digital twins—virtual replicas of physical systems—is gaining popularity among mechanical engineers. This technology allows for:

Enhanced Design Processes: Engineers can simulate how systems will behave under various conditions before actual implementation, leading to more accurate designs and reduced development time

Real-Time Monitoring: Digital twins facilitate continuous monitoring of physical assets, enabling better decision-making based on real-time data analysis.

6. Advanced Materials Science

Innovations in materials science are crucial for developing new materials that meet modern engineering demands:

Lightweight and Strong Materials: The exploration of nanotechnology enables the creation of materials that offer superior performance while minimizing weight, which is particularly beneficial in aerospace applications

Materials: These materials can adapt to environmental changes, offering new possibilities for responsive designs in various applications.

Opportunities for Mechanical Engineers

1. Expanding Job Market

As industries increasingly adopt advanced technologies like AI, robotics, and additive manufacturing, the demand for skilled mechanical engineers continues to grow. Opportunities exist in sectors such as:

Automotive Industry: With the rise of electric vehicles (EVs) and autonomous driving technologies, engineers are needed to design innovative powertrains and charging infrastructures

Renewable Energy: Mechanical engineers can contribute to the development of sustainable energy solutions, including wind turbines, solar panels, and energy-efficient systems

2. Interdisciplinary Collaboration

Mechanical engineers have the opportunity to collaborate with professionals from diverse fields such as computer science, materials science, and environmental science. This interdisciplinary approach fosters innovation and leads to the development of cutting-edge solutions that address complex challenges.

3. Focus on Sustainability

With increasing awareness of climate change and environmental issues, mechanical engineers can play a crucial role in developing sustainable technologies. This includes creating efficient manufacturing processes, designing eco-friendly products, and contributing to renewable energy projects.

4. Advancements in Education

Educational institutions are evolving their curricula to include emerging technologies such as AI and robotics within mechanical engineering programs. This prepares future engineers for the challenges they will face in a rapidly changing industry.

Conclusion

As we look toward 2024, mechanical engineering stands at a pivotal point marked by technological advancements and a commitment to sustainability. The integration of AI, robotics, IoT, and innovative manufacturing processes will not only enhance productivity but also address pressing global challenges such as climate change and resource efficiency. Mechanical engineers must embrace these trends to remain competitive and drive the Future of Mechanical Engineering innovations that will shape industries worldwide.

Source: Click Here

#best btech college in jaipur#top engineering college in jaipur#best btech college in rajasthan#best private engineering college in jaipur#best engineering college in jaipur

0 notes