#Electric-Actuators-in-Automation

Explore tagged Tumblr posts

Text

Introduction: Understanding Actuators

Actuators are devices responsible for controlling and moving mechanisms in automated systems. They convert electrical energy into mechanical motion, enabling the precise positioning and operation of various components. Electric actuators, specifically, utilize electric motors to generate the required mechanical force. These versatile devices find application across a wide range of industries, including manufacturing, aerospace, automotive, and more.

Types of Actuators

Electric actuators come in different types, each designed to fulfill specific requirements based on the application. Some common types of electric actuators include:

1) Linear Actuators

Linear actuators provide linear motion, allowing objects to move in a straight line. They are widely used in applications that require precise control over linear movement, such as opening and closing valves, adjusting machine components, or actuating robotic arms.

2) Rotary Actuators

Rotary actuators, on the other hand, provide rotational motion. These actuators convert electrical energy into rotary motion, making them ideal for applications like turning valves, operating industrial robots, or controlling the movement of conveyor belts.

3) Pneumatic Actuators

While this article primarily focuses on electric actuators, it's worth mentioning pneumatic actuators. Pneumatic actuators use compressed air to create mechanical motion, offering reliable and robust operation in various industrial environments.

Electric Actuators in Automation

The integration of electric actuators in automation systems brings numerous advantages. Their precise control and accuracy contribute to enhanced productivity and efficiency. With electric actuators, manufacturers can achieve repeatable and consistent motion, ensuring high-quality outputs. Moreover, these actuators can be easily integrated with other automation components, such as sensors and controllers, enabling seamless communication and coordination within the system.

The Significance of Atex Certification

Atex certification holds great significance in industries where explosive atmospheres may be present. It ensures that electric actuators and other equipment used in potentially hazardous environments comply with essential safety standards. Atex-certified actuators are designed to prevent the ignition of flammable substances, providing an extra layer of safety in applications such as oil and gas refineries, chemical plants, and mining operations.

Measuring instruments play a crucial role in automation systems by providing accurate data and feedback for optimal control. These instruments enable monitoring and control of various parameters such as temperature, pressure, humidity, and more. By integrating measuring instruments into automation systems, manufacturers can ensure precise and efficient operation while maintaining quality standards.

A Closer Look

Among the leading manufacturers of measuring instruments is Kimo Instruments, renowned for its high-quality and reliable products. We offers a wide range of instruments suitable for automation applications. Their advanced sensors and controllers enable precise measurement and control, enhancing the performance and accuracy of automated systems.

ConclusionElectric actuators are indispensable components of automation systems, enabling precise and controlled motion. From linear actuators to rotary ones, these devices offer versatility and efficiency across various industries. With Atex certification ensuring safety in hazardous environments and the integration of measuring instruments like KimoInstruments providing accurate data, electric actuators continue to play a vital role in driving automation forward.

#Actuators#Types-of-Actuators#Electric-Actuators#Electric-Actuators-in-Automation#Role-of-Electric-Actuators#Atex-certified-actuators#Kimo-Instruments

0 notes

Text

Growth Drivers in the Robotics Actuators Market: Technology, Smart Cities, and More

Robotics and Automation Actuators: Market Overview

With a projected CAGR of 13.9%, the Robotics and Automation Actuators Market is expanding from an estimated USD 18.7 billion in 2022 to USD 35.8 billion by 2027. This robust growth stems from continuous technological advancements, the rising need for streamlined automation, and the adoption of robotics in industries worldwide. Robotics and automation actuators play a crucial role in improving precision, efficiency, and operational flexibility in various sectors such as manufacturing, healthcare, aerospace, and defense.

This blog delves into how Robotics and Automation Actuators work, the factors driving their Robotics and Automation Actuators Industry growth, opportunities, Key Market Players, and recent developments shaping the industry.

Understanding Robotics and Automation Actuators

What Are Robotics and Automation Actuators?

Actuators are devices responsible for converting energy into motion within machinery, enabling automated systems and robots to perform tasks with precision. Robotics and automation actuators are crucial in driving robotic arms, controlling valves, adjusting positions, and various other functions in automation systems. Actuators can vary widely in design and function, with the main types including electric, hydraulic, and pneumatic actuators.

How Do Robotics and Automation Actuators Work?

Robotics and automation actuators operate through energy conversion, often from electrical or pneumatic power sources. Electric actuators convert electrical energy into mechanical movement, while hydraulic actuators use fluid pressure, and pneumatic actuators rely on compressed air. Each type has specific advantages depending on the application:

Electric Actuators: Known for high precision, clean operation, and easy integration, electric actuators are widely used in sectors requiring low-maintenance solutions. They offer advantages in feedback, control, and efficiency, with minimal power consumption.

Hydraulic Actuators: Suited for high-force applications, hydraulic actuators provide powerful force but can be costly and require more maintenance.

Pneumatic Actuators: Compact and ideal for rapid movements, pneumatic actuators are commonly used in factory automation, though they may require more regular maintenance.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=143328029

Robotics and Automation Actuators Market Growth Drivers

Technological Advancements in Actuator Design The demand for improved performance in various industries has driven advancements in actuator technology, leading to the development of compact pneumatic actuators, explosion-proof actuators, and smart electric actuators. Electric actuators, in particular, stand out for their reliability, long life, and low total operational costs.

Increased Demand Across Industries Robotics and automation actuators are increasingly utilized in manufacturing, aerospace, mining, and healthcare due to their ability to enhance efficiency, accuracy, and speed. This growing application scope is a key driver for market growth.

Smart City Development The ongoing trend of developing smart cities worldwide is creating new opportunities for actuators to be used in smart logistics applications, automated parking, surveillance robots, and more. The integration of IoT with actuators in smart city infrastructures enables decentralized management and facilitates efficient energy use and data sharing.

Market Opportunities

Expansion of Smart Cities Globally Smart cities require advanced actuators to manage interconnected sensors and devices. Electrically driven actuators equipped with feedback systems are increasingly used in such projects, leading to new market opportunities.

Increased Use in Industrial and Service Robotics The demand for both industrial and service robotics, especially in countries focused on automation, offers tremendous potential for actuators. Industrial robots are particularly essential in manufacturing processes, while service robots find application in healthcare, logistics, and home automation.

Rising Demand in Asia-Pacific With significant investments in robotics and automation technologies, countries like China and Japan are experiencing growth in this sector. This regional expansion allows actuator manufacturers to broaden their markets and strengthen their positions globally.

Ask for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=143328029

Key Market Players

Some of the prominent companies leading the robotics and automation actuators market include:

ABB (Switzerland): A leader in robotics and automation, ABB provides actuators that are easy to install, maintain, and integrate into automation systems.

Rockwell Automation (US): Known for innovative automation solutions, Rockwell has recently partnered with Comau to simplify robot integration.

Altra Industrial Motion (US): Specializing in high-performance actuators, Altra Industrial Motion focuses on cost-effective solutions for diverse applications.

Moog (US): Moog’s actuators are widely used in aerospace, defense, and industrial applications for their high reliability and precision.

Curtiss-Wright (Exlar) (US): A key provider of electro-mechanical actuators, Curtiss-Wright is known for its robust solutions in mission-critical sectors such as defense.

Recent Developments

ABB (2022): ABB completed the installation and remote commissioning of new actuators for India’s largest paper and paperboard business, ITC. This update enables advanced diagnostics and reduces profile variability for increased efficiency.

Rockwell Automation and Comau Partnership (2021): Rockwell partnered with Comau to simplify robot integration for manufacturers, marking a step toward improved automation compatibility.

Curtiss-Wright Contract with Federal Equipment Company (2021): Curtiss-Wright’s Exlar electro-mechanical actuators are used in Ford-class aircraft carriers for mission-critical areas, enhancing operational reliability and automation.

Challenges in Robotics and Automation Actuators Market

Power Consumption and Design Limitations While essential for many applications, actuators face challenges related to power consumption, noise, and occasional design issues leading to leaks or inefficiencies.

Oil Price Volatility Actuators used in the oil and gas industry are impacted by fluctuating oil prices. Reduced exploration activities slow demand for automation components, including actuators.

Environmental and Noise Concerns Actuators, especially pneumatic types, may cause noise pollution, and some use chemicals that pose environmental risks if improperly managed. These issues highlight the importance of sustainable design in actuator development.

Frequently Asked Questions (FAQs)

1. What is driving the growth of the robotics and automation actuators market? The market growth is driven by advancements in actuator technology, expanding applications across industries, and increased demand in smart city projects worldwide.

2. What are the key types of actuators in this market? Key actuator types include electric, pneumatic, and hydraulic actuators, each suited to specific applications based on energy efficiency, force requirements, and precision.

3. Which region leads the robotics and automation actuators market? Asia-Pacific, especially China and Japan, leads the market due to significant investments in robotics and automation, driven by industrial automation demands.

4. How does smart city development impact the robotics and automation actuators market? Smart cities rely on IoT-enabled actuators for automated control systems, driving demand for efficient, network-ready actuators in urban development projects.

5. Who are the major players in the robotics and automation actuators market? Leading companies include ABB, Rockwell Automation, Altra Industrial Motion, Moog, and Curtiss-Wright, known for innovation and application-driven solutions.

To Gain Deeper Insights Into This Dynamic Market, Speak to Our Analyst Here: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=143328029

Key Takeaways

The Robotics and Automation Actuators Market is projected to reach USD 35.8 billion by 2027.

Market growth is primarily fueled by technological advancements and the demand for energy-efficient, high-precision actuators.

Smart cities and the Asia-Pacific region present significant market opportunities.

Electric actuators lead the market, offering benefits in precision, low maintenance, and integration capabilities.

Major players like ABB, Rockwell Automation, and Curtiss-Wright are investing in innovation and expanding their global footprints to capitalize on the growing demand.

The robotics and automation actuators market is poised for substantial growth, driven by technological advancements, expanding applications, and opportunities arising from smart city development and industrial automation across various regions. As actuators continue to evolve, they are becoming central to the automation ecosystem, enabling efficient, scalable, and sustainable solutions across industries.

#robotics actuators#automation actuators#robotics market trends#robotics automation technology#smart cities robotics#abb#rockwell automation#electric actuators

0 notes

Text

Actuator Valve: Enhancing Precision and Efficiency in Industrial Applications

In the fast-paced world of industrial operations, efficient control over fluid and gas flow is paramount. Actuator valves play a critical role in ensuring this control with precision, reliability, and automation. Whether you’re managing complex chemical processes, oil and gas operations, or manufacturing systems, actuator valves offer a streamlined solution that improves productivity while reducing manual intervention.

What is an Actuator Valve?

An actuator valve is a type of valve used to control the flow of a liquid or gas in a system, operated by an external actuator. Unlike traditional valves that require manual operation, actuator valves rely on pneumatic, hydraulic, or electric mechanisms to open, close, or adjust the valve position. This automation makes them an ideal choice for systems that require consistent and accurate regulation without the need for direct human input.

Types of Actuator Valves

There are several types of actuator valves, each designed for specific industrial requirements:

Pneumatic Actuator Valve: Powered by compressed air, these valves are commonly used in applications requiring fast response times and cost-effective operation.

Electric Actuator Valve: Using electric motors to operate, these valves are ideal for applications where energy efficiency is critical. They offer precise control and are often used in high-precision industries like manufacturing and automation.

Hydraulic Actuator Valve: Hydraulic-powered actuator valves are known for their strength and ability to operate under high-pressure systems, making them suitable for heavy-duty applications.

Key Benefits of Using Actuator Valves

Improved Efficiency: Automation of valve operations allows for better process control, minimizing errors and downtime. This leads to enhanced efficiency across your systems.

Precision and Consistency: Actuator valves are designed for accurate control, ensuring that flow rates are precisely regulated, which is crucial in industries where minor variations can lead to significant disruptions.

Safety: By automating the control process, actuator valves reduce the need for manual intervention in potentially hazardous environments, enhancing safety for workers.

Durability: Built from high-grade materials, actuator valves are designed to withstand extreme environments, from high pressure to corrosive conditions, ensuring long-lasting performance.

Applications of Actuator Valves

Actuator valves are used across a variety of industries, including:

Oil and Gas: In the oil and gas sector, precise flow control is critical to the success of operations. Actuator valves help regulate the flow of gas and liquids through pipelines, ensuring smooth and safe operation.

Chemical Processing: In chemical plants, where accurate control of different fluids is necessary for reactions, actuator valves provide reliability and safety.

Manufacturing: Automation is the backbone of manufacturing, and actuator valves help in maintaining the precision and consistency needed in automated processes.

Why Choose Prabha Electronics' Actuator Valves?

At Prabha Electronics, we are committed to providing high-quality actuator valves that meet the unique demands of your industry. Our valves are engineered for durability, precision, and safety, ensuring reliable performance in even the most demanding applications. Whether you need pneumatic, electric, or hydraulic actuators, our extensive range is designed to seamlessly integrate with your systems, offering unmatched efficiency.

Conclusion

In today’s industrial landscape, actuator valves are more than just components; they are vital to the smooth functioning of critical systems. By choosing Prabha Electronics' actuator valves, you invest in quality, performance, and reliability. Explore our range today and take the first step toward optimizing your flow control systems for enhanced productivity and safety.

#Actuator valve#industrial actuator valve#flow control valve#automation valve#pneumatic actuator valve#electric actuator valve#fluid control valve#industrial valves

0 notes

Text

The Power of Rotation: A Comprehensive Look at Rotary Actuators

Transform Pneumatic, Hydraulic, or Electric Energy to Mechanical Rotation

In the realm of industrial automation, precise control over movement is paramount. Rotary actuators play a vital role in achieving this control, converting various forms of energy into rotary motion to power a wide range of applications. From the delicate movements of robotic arms to the powerful operation of valves and gates, rotary actuators offer a versatile and efficient solution for driving rotational tasks. This article delves into the world of rotary actuators, exploring their types, working principles, functionalities, and their diverse applications across various industries.

Understanding Rotary Actuators:

At their core, rotary actuators are mechanical devices that translate energy into rotary motion, or torque, around a specific axis. This energy source can be electric, pneumatic, hydraulic, or even manual. By converting this energy, rotary actuators enable precise control of angular displacement and rotational force, making them ideal for applications requiring positioning, opening, closing, or rotating various mechanisms.

Types of Rotary Actuators:

The diverse world of rotary actuators encompasses various types, each catering to specific needs and applications:

Electric Rotary Actuators: Powered by electric motors, these actuators offer precise control and are well-suited for automated applications. They come in various configurations, including stepper motors, servo motors, and DC gear motors, each offering distinct torque and speed characteristics.

Pneumatic Rotary Actuators: Utilizing compressed air as the energy source, these actuators are known for their speed and force output. They are commonly used in applications requiring high-speed actuation or limited space availability. Rack and pinion and vane types are two common configurations of pneumatic rotary actuators.

Hydraulic Rotary Actuators: These actuators rely on hydraulic fluid for power, offering exceptional force and torque capabilities. They are ideal for heavy-duty applications requiring high power output, such as operating large valves or manipulating massive machinery components.

Working Principles of Rotary Actuators:

The specific working principle of a rotary actuator depends on its type. Here's a simplified breakdown of the primary types:

Electric Rotary Actuators: An electric motor converts electrical energy into rotational motion of the motor shaft. This rotation can be geared down or up to achieve the desired output speed and torque. In stepper motors, the rotation occurs in discrete steps, offering precise positioning control. Servo motors provide continuous rotation with precise control over speed and position based on feedback signals.

Pneumatic Rotary Actuators: Compressed air enters the actuator body, pushing against a piston or vane, causing it to rotate. The direction of rotation is controlled by valves that direct the compressed air flow. Rack and pinion actuators convert the linear motion of the piston or vane into rotary motion using a gear rack and pinion gear. Vane actuators utilize the direct rotation of the vane within the actuator body.

Hydraulic Rotary Actuators: Hydraulic fluid, pressurized by a pump, enters the actuator body and exerts force on a piston or vane. The resulting linear motion is converted into rotary motion through a gear mechanism similar to pneumatic rotary actuators.

Functionalities of Rotary Actuators:

Rotary actuators perform a wide range of functions in various applications. Some key functionalities include:

Positioning: Rotary actuators can precisely position mechanical components or robotic arms to specific angles.

Opening and Closing: They can be used to open and close valves, gates, dampers, and other mechanisms requiring rotational movement.

Mixing and Stirring: Rotary actuators can power mixing blades or stirrers in various industrial processes.

Indexing and Material Handling: They can be used for precise indexing of materials in automated production lines or material handling equipment.

Clamping and Gripping: Rotary actuators can be used to clamp or grip objects in robotic applications or assembly lines.

Selection Considerations for Rotary Actuators:

Choosing the right rotary actuator for your application requires careful consideration of several factors:

Torque and Speed Requirements: The actuator's torque output and speed capabilities need to match the application's specific demands.

Power Source: Electric, pneumatic, or hydraulic power sources should be chosen based on available resources and desired control characteristics.

Duty Cycle: The frequency and duration of operation for the actuator must be considered to ensure proper sizing and prevent overheating.

Accuracy and Repeatability: The level of precision required for positioning or control should be factored in when selecting the actuator type.

Environmental Conditions: The operating environment, including temperature, humidity, and potential exposure to dust or liquids, should be considered to ensure proper material selection and protection for the actuator.

Applications of Rotary Actuators (Continued):

Building upon the previous section, here's a detailed look at some key industry applications of rotary actuators:

Oil & Gas: Rotary actuators are crucial in the oil & gas industry for:

Valve operation: Opening and closing valves for flow control in pipelines, refining processes, and wellheads.

Actuating blowout preventers (BOPs): Ensuring safety by closing wellbores in case of emergencies.

Positioning drilling equipment: Providing precise control over drilling heads and other downhole tools.

Power Generation: Rotary actuators are used in power plants for:

Valve actuation: Regulating fluid flow in cooling systems, boiler operations, and steam turbines.

Damper control: Adjusting air intake and exhaust dampers for combustion efficiency.

Positioning solar tracker systems: Optimizing the angle of solar panels to maximize sun exposure.

Food & Beverage: Rotary actuators contribute to automation in food processing by:

Operating valves for ingredient mixing, filling lines, and sterilization processes.

Positioning robotic arms for food handling, packaging, and palletizing.

Controlling conveyor belts for product movement within the production line.

Automotive Industry: Rotary actuators play a role in:

Robotic welding and painting applications: Precise movement of robotic arms for welding and painting car bodies.

Assembly line automation: Positioning and manipulation of components during vehicle assembly.

Climate control systems: Adjusting air flow dampers for heating, ventilation, and air conditioning within vehicles.

Aerospace & Defense: Rotary actuators find application in:

Aircraft control surfaces: Moving rudders, ailerons, and flaps for aircraft maneuverability.

Landing gear deployment and retraction: Precise actuation of landing gear mechanisms.

Radar positioning: Controlling the movement of radar antennae for target detection and tracking.

Construction: Rotary actuators contribute to automation in construction by:

Operating valves in concrete mixing trucks and other heavy machinery.

Positioning robotic arms for automated welding and material handling.

Controlling the movement of construction equipment attachments like excavator buckets and bulldozer blades.

Beyond these specific examples, rotary actuators are present in countless other applications across diverse industries. Their versatility, reliability, and ability to convert various energy sources into precise rotational motion make them a cornerstone of industrial automation.

Freture Techno: Your Partner in Rotary Actuator Solutions

Freture Techno Pvt. Ltd., a leading manufacturer of rotary actuators in Mumbai, India, offers a comprehensive range of high-quality electric, pneumatic, and hydraulic rotary actuators. With a commitment to innovation and engineering excellence, Freture Techno caters to diverse industry needs. Their team of experts can assist you in selecting the optimal rotary actuator for your specific application, ensuring optimal performance, reliability, and efficiency. Visit their website today to explore their product portfolio and discover how Freture Techno can be your trusted partner in rotary actuator solutions.

#valves#automation#Pneumatic#Hydraulic#Electric#Rotary Actuators#Freture Techno#Manufacturer#Mumbai#India

0 notes

Text

Essential Skills Every Electronics Engineer Should Master

Electronics engineering is an exciting and constantly evolving field. With new technologies emerging every day, the need for skilled professionals has never been greater. If you're pursuing a B Tech in Electrical and Electronics Engineering or exploring options at B Tech colleges for Electrical and Electronics, it's crucial to know which skills can set you apart in this competitive domain.

Let’s dive into the essential skills every aspiring electronics engineer should master.

Strong Foundation in Circuit Design

Circuit design is at the heart of electronics engineering. Understanding how to create, analyze, and optimize circuits is a must-have skill. Whether you’re designing a simple resistor network or a complex integrated circuit, mastering tools like SPICE and PCB design software can make your designs efficient and innovative.

Programming Proficiency

Electronics and programming often go hand in hand. Languages like Python, C, and MATLAB are widely used to simulate electronic systems, automate processes, and even build firmware for devices. Engineers proficient in programming can troubleshoot problems effectively and add versatility to their skill set.

Knowledge of Embedded Systems

Embedded systems are everywhere—from your smartphone to your washing machine. As an electronics engineer, understanding microcontrollers, sensors, and actuators is crucial for creating devices that work seamlessly in our daily lives. Hands-on experience with platforms like Arduino and Raspberry Pi can be a great way to start.

Problem-Solving and Analytical Thinking

Electronics engineers often face unique challenges, such as debugging faulty circuits or improving system performance. Strong problem-solving and analytical thinking skills help them identify issues quickly and find effective solutions. To cultivate these skills, tackle real-world projects during your coursework or internships.

Familiarity with Power Systems

As the world moves toward renewable energy and smart grids, knowledge of power systems is becoming increasingly important. Engineers in this field should understand how electrical power is generated, transmitted, and distributed and how to design energy-efficient systems.

Effective Communication Skills

Electronics engineering often involves working in teams with other engineers, designers, or clients. Communicating your ideas clearly—whether through reports, presentations, or technical drawings—is just as important as your technical skills. Strong communication ensures that your brilliant ideas come to life effectively.

Adaptability to New Technologies

Technology evolves rapidly, and staying updated is essential for electronics engineers. Whether you’re learning about IoT (Internet of Things), AI integration, or 5G communication, an adaptable mindset will ensure you remain relevant and capable of tackling emerging challenges.

Hands-On Experience

While theoretical knowledge is important, nothing beats practical experience. Participating in labs, internships, or personal projects gives you the opportunity to apply what you’ve learned and develop confidence in your skills. Employers often value hands-on experience as much as your academic achievements.

Preparing for Success in Electronics Engineering

Pursuing a B Tech in Electrical and Electronics Engineering is the first step toward mastering these skills. The best B Tech colleges for Electrical and Electronics not only provide a strong academic foundation but also opportunities for practical learning and industry exposure. By focusing on the skills mentioned above, you can position yourself as a competent and innovative engineer ready to tackle real-world challenges.

3 notes

·

View notes

Photo

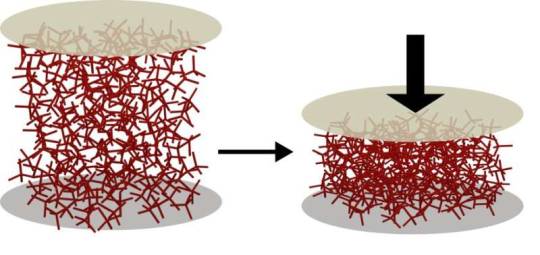

Framework structure with nanoscopic insulation enables components for soft robotics and flexible electronics

Classical robots, such as those used for manufacturing, can lift heavy loads and repeat automated processes precisely. But they are too rigid and bulky for delicate work and interaction with humans. The research field of soft robotics works on the development of robots made of soft, organic materials and flexible technical components. Materials researchers at Kiel University have now developed a novel soft conductive material.

Unlike conventional soft conductors, it shows remarkably stable electrical properties even upon deformation. The reason for this is the special structure of the material and a nanoscopic insulating thin film coating. The research team published its results in the current issue of the journal Advanced Functional Materials.

Constant electrical resistance even during deformation

Unlike classical robots, humans and animals can perform fluid and fine movements and adapt them to their environment. Inspired by nature, soft robotics therefore relies on elastic, organic materials made of carbon instead of conventional, rigid metals. In addition, soft robots need elastic electrical conductors for communication between their sensors and actuators.

Read more.

#Materials Science#Science#Soft materials#Robotics#Electronics#Deformation mechanisms#Conductors#Electrical resistance#Coatings#Kiel University

75 notes

·

View notes

Text

Control valve supplier in Dubai

UAE Valves is one of the top Control Valve Supplier in Dubai. A control valve is a mechanical device used in various industrial processes to regulate the flow of fluids, such as gas, steam, or liquid, through a pipeline or duct. It achieves this regulation by adjusting the size of the flow passage according to signals received from a controller.

Control valves are crucial components in systems requiring precise control of flow rate, pressure, temperature, or liquid level. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Working Principle:

The working principle of a control valve is straightforward. In an industrial setting, a control valve adjusts the size of an opening to control the flow of fluid through a pipeline. When the valve is fully open, it allows maximum flow, and when fully closed, it stops the flow completely. Between these extremes, the valve can be precisely adjusted to allow a specific amount of fluid to pass through.

This adjustment is typically performed automatically based on signals from a controller, which monitors conditions such as pressure, temperature, or flow rate. Essentially, a control valve acts like a gatekeeper, regulating the flow of fluid to meet the system's requirements.

Parts of a Control Valve:

Valve Body: The main structure that contains the fluid and through which the fluid flows.

Actuator: A device that moves or controls the valve's mechanism, often powered by air, electricity, or hydraulic fluid.

Closure Element: The component that makes contact with the seat to restrict or allow flow.

Trim: Internal components such as the plug, seat, and stem that modulate the flow.

Seat: A surface against which the closure element seals to stop flow.

Positioner: A device that adjusts the valve actuator's position based on control signals.

Bonnet: The top part of the valve body that houses the stem and provides a seal.

Yoke: A support structure that holds the actuator in place and connects it to the valve body.

Stem: A rod that connects the actuator to the closure element and transmits motion.

Packing: Material that provides a seal around the stem to prevent fluid leakage.

Advantages:

Precisely controls the amount of fluid passing through a system.

Maintains the desired pressure levels within the system.

Helps maintain a stable temperature by regulating fluid flow.

Reduces energy consumption by optimizing fluid flow.

Enhances system performance by maintaining consistent operating conditions.

Prevents system overpressure and potential hazards.

Easily adjustable for various operating conditions.

Allows for control from a distance and integration into automated systems.

Designed for durability and ease of maintenance.

Ensures consistent production quality by maintaining optimal conditions.

Meets industry standards and regulatory requirements.

Industries Using Control Valves:

Control valves are used across numerous industries, including nuclear power, oil and gas, power generation, manufacturing and process industries, automotive, aerospace, mining and minerals processing, water treatment and distribution, pulp and paper, refining, marine, renewable energy, chemical and petrochemical, and steel and metal processing. These valves play a critical role in ensuring operational efficiency, safety, and compliance within these diverse sectors.

Types of Control Valves:

Three-way control valve

Cage type control valve

Double seat control valve

O type shutoff control valve

Single seat control valve

Water control valve

Globe control valve

Angle type control valve

We are a Control Valve Supplier in Dubai, supplying valves in the following descriptions:

Available Materials: Stainless Steel (SS316, SS304), Ductile Iron, Super Duplex (F51, F53, F55), Cast Iron (WCB, WCC, WC6), LCC, LCB

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electro Pneumatic Operated and Pneumatic Operated

Size: 1/2” – 24”

Ends: Butt Weld, Flanged, Threaded, Socket Weld

Electric Actuator Details:

Torque: 3 – 9 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Configuration of a Pneumatic Actuator:

Torque: 3 – 9000 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Temperature Ranges:

Standard: -4°F to 200°F (-20°C to 93°C)

Low: -40°F to 176°F (-40°C to 80°C)

High: 0°F to 300°F (-18°C to 149°C)

Visit us: https://www.uaevalves.com/product-category/control-valve/

3 notes

·

View notes

Text

The Sant CI Butterfly Valve with Electric Actuator offers precision and automation for fluid control in industrial systems. Made from durable cast iron (CI), this valve is equipped with an electric actuator, providing efficient and remote control for high-pressure environments. Ideal for water management, HVAC, and industrial automation.

4 notes

·

View notes

Text

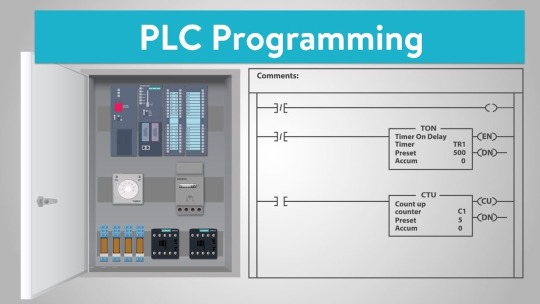

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

''Understanding Their Key Functions"

Introduction

Small gear motors are essential components used in various industries and applications. These compact devices play a crucial role in converting electrical energy into mechanical power, enabling precise and controlled motion. In this blog, we will explore the primary function of small gear motors and their significance in modern-day technology.

Function of Small Gear Motors

Power Transmission: The primary function of small gear motors is to transmit power from the input source (typically an electric motor) to the output shaft. The motor generates rotational energy, which is then transmitted to the gear assembly. The gears inside the motor are designed to mesh with each other, creating a mechanical advantage that enables the motor to deliver higher torque at reduced rotational speeds. This power transmission allows small gear motors to efficiently drive various mechanisms and devices.

Speed Reduction: Another critical function of small gear motors is speed reduction. By using gears with different numbers of teeth, the rotational speed of the output shaft can be reduced relative to the input shaft speed. This feature is particularly useful in applications that require slower, controlled movements, such as robotics, automated systems, and precise machinery.

Torque Amplification: Gear motors are also known for their ability to amplify torque. The gear assembly increases the torque output, making it easier for the motor to overcome resistance or load in the system. This torque amplification ensures that the motor can perform tasks that would be challenging or impossible with a direct drive system.

Directional Control: Small gear motors offer precise directional control. By reversing the rotation of the input motor or changing the gear arrangement, the output shaft can rotate in the opposite direction. This capability is crucial in applications where bidirectional motion is required, like in the operation of conveyor belts, valves, and actuators.

Compact Size and Efficiency: The compact size of small gear motors makes them ideal for applications with limited space. Their efficiency in converting electrical energy into mechanical power also contributes to their widespread use. They can achieve efficiency levels of 70-90%, making them highly energy-efficient solutions.

Conclusion

In conclusion, small gear motors play a pivotal role in modern engineering and technology. Their primary functions include power transmission, speed reduction, torque amplification, directional control, and efficiency. As these devices continue to evolve and improve, we can expect them to remain a key component in various industries, ranging from robotics and automation to automotive and aerospace.

2 notes

·

View notes

Text

Exploring the Marvel of Piezoelectric Tubes in Modern Engineering

In the realm of advanced engineering and technology, piezoelectric materials stand as exceptional performers, fueling innovative solutions across various industries. Among these fascinating components, piezoelectric tubes hold a special place due to their unique properties and applications.

In this blog post, we will dive into the world of piezoelectric tubes, exploring their working principle, versatile applications, and the profound impact they have on modern engineering.

For More Information Please visit, piezo tube

1. Understanding Piezoelectric Tubes:

Piezoelectric tubes are cylindrical structures made of piezoelectric materials that exhibit the piezoelectric effect. This remarkable property enables them to convert electrical energy into mechanical motion and vice versa, making them highly versatile and sought-after components in the realm of precision engineering.

2. The Working Principle:

When an electric field is applied to a piezoelectric tube, it undergoes dimensional changes, either expanding or contracting. This phenomenon is known as the "d33 effect" and is responsible for the generation of mechanical motion. Conversely, when the piezoelectric tube experiences mechanical stress, it generates an electric charge, known as the "d31 effect."

3. Precision Actuation and Control:

Piezoelectric tubes are renowned for their exceptional precision in motion control. Due to their ability to respond rapidly to electrical signals, they can achieve sub-micrometer level displacements, making them invaluable in applications that require fine adjustments and positioning with unparalleled accuracy.

4. Applications Across Industries:

The versatility of piezoelectric tubes has led to their adoption in various industries and fields, including:

Medical Technology: In ultrasound transducers, piezoelectric tubes facilitate high-resolution imaging, enabling non-invasive medical diagnostics.

Mechanical Engineering: Piezoelectric tubes find applications in precise positioning systems, micro- and nanopositioning stages, and vibration control devices.

Industrial Automation: They are used in ultrasonic cleaning equipment, flow meters, and high-precision pumps, enhancing efficiency and productivity.

Aerospace: Piezoelectric tubes play a vital role in active vibration damping and structural health monitoring of aircraft components.

5. Energy Harvesting and Acoustic Applications:

Piezoelectric tubes are also employed in energy harvesting systems, converting mechanical vibrations into electrical energy. Additionally, they serve as components in acoustic devices like speakers, providing clear and crisp sound reproduction.

6. Miniaturization and Integration:

Due to their compact size and high functionality, piezoelectric tubes are ideal for miniaturized devices and space-constrained applications. Their integration into various systems allows for streamlined designs and improved performance.

7. Advancements in Material Technology:

Continuous research in material science has led to the development of innovative piezoelectric materials, further enhancing the capabilities of piezoelectric tubes. These advancements open up new possibilities for even more efficient and powerful devices in the future.

Conclusion:

Piezoelectric tubes stand as a testament to the wonders of piezoelectricity, offering unparalleled precision and versatility in motion control and sensing applications. As industries continue to evolve, these remarkable components will play an instrumental role in driving technological advancements, paving the way for a more connected, efficient, and innovative future.

2 notes

·

View notes

Text

Enhance Efficiency and Flexibility with DIN Rail Mounted Terminal Blocks in India

Introduction:

In today's rapidly evolving industrial landscape, efficient and reliable electrical connections are crucial for ensuring smooth operations. DIN rail mounted terminal blocks have emerged as a preferred solution for creating secure and organized electrical connections in a wide range of applications. With their versatility, durability, and ease of installation, these terminal blocks have gained immense popularity among professionals in India. In this blog post, we will explore the benefits and applications of rail mounted terminal blocks and highlight their importance in the Indian industrial sector.

What are DIN Rail Mounted Terminal Blocks?

DIN rail mounted terminal blocks are electrical connectors that provide a convenient and standardized method for connecting and distributing power or signals in industrial control systems. These blocks are specifically designed to be mounted on DIN rails, which are widely used for organizing and securing electrical components in control panels, switchgear cabinets, and equipment enclosures.

Benefits of DIN Rail Mounted Terminal Blocks:

Space-saving and Modular Design: DIN rail mounted terminal blocks feature a compact design that allows for optimal use of available space. Their modular construction enables easy customization and expansion as per the specific requirements of an application, making them highly adaptable.

Secure and Reliable Connections: These terminal blocks ensure secure and reliable connections, thanks to their robust construction and advanced connection technologies. They provide a sturdy grip on wires and facilitate excellent contact, minimizing the risk of loose connections and electrical failures.

Easy Installation and Maintenance: With their tool-less and user-friendly design, DIN rail mounted terminal blocks simplify installation and maintenance procedures. The snap-on mounting feature of these blocks allows for quick and hassle-free assembly, reducing overall downtime during system installation or upgrades.

Enhanced Safety: Rail mounted terminal blocks adhere to stringent safety standards and offer features like finger-safe design, which prevents accidental contact with live components. This ensures the safety of both the equipment and the personnel working with them.

Applications of DIN Rail Mounted Terminal Blocks:

Industrial Automation: Rail mounted terminal blocks are extensively used in industrial automation systems, where they serve as a vital component for connecting sensors, actuators, motors, and other devices. These blocks provide a reliable interface for transmitting power and signals between various control elements.

Power Distribution: DIN rail mounted terminal blocks play a crucial role in power distribution systems, allowing for easy and organized connection of power supply lines to different equipment. They enable efficient energy management and facilitate the distribution of power to multiple devices within a control panel.

Building Automation: In building automation systems, DIN rail mounted terminal blocks provide a convenient solution for connecting various electrical components, such as lighting controls, HVAC systems, security systems, and more. Their modular design allows for easy integration and maintenance of these systems.

Rail Mounted Terminal Blocks in India:

The Indian industrial sector is witnessing significant growth, and the demand for reliable electrical connectivity solutions is higher than ever. Rail mounted terminal blocks have gained traction in India due to their versatility and ability to meet the diverse requirements of industries ranging from manufacturing to infrastructure development. Manufacturers and suppliers in India offer a wide range of DIN rail mounted terminal blocks, catering to different voltage and current ratings, wire sizes, and connection types.

Conclusion:

Rail mounted terminal blocks have revolutionized the electrical connectivity landscape in India, providing efficient, secure, and organized solutions for various industrial applications. Their space-saving design, ease of installation, and robust construction make them indispensable for creating reliable connections in control systems and power distribution networks. As the industrial sector continues to thrive in India, the importance of DIN rail mounted terminal blocks as a key component in electrical installations cannot be overstated. By embracing these advanced terminal blocks, Indian industries can enhance efficiency, reduce downtime, and ensure safe and reliable operations.

#Rail Mounted Terminal Blocks India#DIN Rail Mounted Terminal Blocks India#Power BusBar Terminal#Finger Safe Power Terminal blocks#Barrier Terminal Block Manufacturer in India#electrical wire termination technology#manufacturer#terminal block#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#DIN rails channels#digital voltmeter#digital ammeter#power and signal#current transformer#railway#renewable energy#elmex#electrical company#electrical industry

2 notes

·

View notes

Text

This is freaking awesome and definitely an efficient solution to this problem. I really detest the way the IT tech companies have twisted the world into making these kinds of advancements reliant upon enslavement to both their cloud based systems (which are often shite) and to the data mining madness around us. I have wanted to use a PLC to carry out home automation for the longest time (just the whole life, needing to work thing sucking up all my energy) to avoid this very toxicity. For those who don't know, PLCs are programmable controllers that have hard wired inputs and outputs that you can connect to sensors and actuators in the real world and are used extensively in automation throughout the world. I have a few Micrologix controllers that I have rescued from the scrap heap and they are really great for something like this. It requires some electrical know how to wire them up but the great thing is that when you do, you can play to your heart's content. You want your roller shutters to come up at an appropriate time every morning? No problem just program it in. You want the two big plasma balls sitting on your desk to activate as you walk into the room? With the right sensor you can make that happen. The best thing is that the actual control software is open for YOU to be the one who in charge, not pre-programmed rubbish options that you have to choose from (just setting up the automated sprinkler system using the provided app had me on the verge of kicking the crap out of the controller!) The best thing about the micros was that the software was (and still is) free. You download it and you're free to go. The best example I have of when this setup really worked well was when one of my workplaces ended up getting hacked and was locked out of their entire IT system. It was panic stations all round and a huge drama. The funny thing was, the PLC network was not connected to the internet. It was just a happy little local network so production could actually carry on regardless of this. This scenario is my worst fear for home automation. "Oh shit, I can't even get through my front door because my system was hacked" or " damn! The internet is down so I guess I can't turn on the lights". There's alot of push for off-grid power, I feel we also need to have a serious think about off-grid automation as well. If anyone is curious about experimenting with this type of system a somewhat cheaper thing to experiment with as actually Lego Mindstorms kits. The programming language is actually surprisingly close the PLC programming and it's neat entry level stuff (also LEGO!!) Ok that's enough Omnissiah worship for today 😅

Accessibility tip:

If you want to automate your home a bit, but you don't want any "smart" tech, you can just buy remote controlled power sockets instead

They are a lot cheaper and easier to set up and use than some home automation smart tech nonsense

They don't need an app (but some models come with optional apps and there are apps that are compatible with most of these)

Many of them use the 433mhz frequency to communicate, which makes most models compatible with each other, even if they are from different manufacturers

The tech has been around for a long time and will be around for a long time to come

You don't have to put any fucking corporate listening devices like an amazon echo in your home

Models for outdoors exist as well

36K notes

·

View notes

Text

Control Systems In Pune

Enhance Your Operations with Advanced Control Systems In Pune by Perfecto Robotics. Are you looking for Control Systems In Pune? Perfecto Robotics offers specialized expertise as well as innovative solutions to optimize industrial processes.

Why Choose Perfecto Robotics for Control Systems?

Expertise.

Innovation.

Customization.

Collaboration.

What is a Control System?

A control system manages, commands, directs, or regulates the behavior of other devices as well as systems using control loops.

Control Systems range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial control systems that are used for controlling processes or machines. The control systems are designed via a control engineering process.

Use of Control System:

Boiler controls in heating and power plant systems.

Pipeline monitoring.

Water distribution systems.

Wastewater treatment systems.

Electricity distribution systems.

How are control systems used?

Agriculture.

Chemical plants.

Pulp and paper mills.

Industrial and manufacturing quality control.

Boiler controls and power plant operations.

Environmental control.

Water and sewage treatment plants.

Food and food processing.

Metal and mines.

Pharmaceutical manufacturing.

Sugar refining.

Control System Main Types:

Open Loop:

Closed Loop

Linear Systems

Applications Control System:

CONTROL USING PID

CONTROL USING LQR

CONTROL USING RFID

Features of Control Systems:

Feedback Mechanism.

Setpoint Adjustment.

Error Detection and Correction.

Closed-Loop Operation.

Integration with Sensors and Actuators.

Safety and Fault Tolerance.

Ready to elevate your industrial automation with advanced control systems in Pune? Look no further—contact Perfecto Robotics today to schedule a consultation. Let us help you harness the power of cutting-edge control technology to achieve operational excellence and drive business growth.

Drive Efficiency and Reliability with Perfecto Robotics – your trusted partner for control systems in Pune.

If you want to add value to your operations with advanced control systems, please do not hesitate to contact us. With Perfecto Robotics, you can achieve custom-designed solutions that can transform your business. Our team will guide you at every step of the decision-making process, from initial consultation and system installation up to after-sales support.

Optimize. Automate. Innovate. Perfecto Robotics secures your business in Pune’s hands, helping unlock a whole new scale for your potential, thereby paving its path toward successive growth. Get set to propel the transformation journey for your operations in Pune today.

0 notes

Text

Global Welding Equipment Market Insights: Key Players and Industry Trends Shaping the Future

The global welding equipment market is anticipated to reach USD 27.77 billion by 2030 and is anticipated to expand at a CAGR of 5.1% from 2024 to 2030, according to a new report by Grand View Research, Inc. The demand for welding equipment is fueled by growing consumer preference for automated devices such as robotic welding equipment and laser welding techniques in comparison to manual ones. The majority of the demand for welding equipment is associated with end-use industries such as automotive, aerospace, transportation, and construction, which are also experiencing operational difficulties owing to macro-economic factors.

According to HIS Markit, new vehicle sales accounted for 82.4 million globally in 2022, which is up by 3.7% in 2021. The continually increasing demand for automobiles worldwide is anticipated to increase the demand for tools and robots in the automotive industry. This, in turn, is expected to boost the demand for welding equipment over the projected period.

Heavy industries, building & construction, and transportation are among the important end-use industries of welding equipment. In the transportation sector, welding equipment is commonly utilized to fabricate various vehicle body components. According to the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2022, the worldwide output of vehicles was 81,628,533 units. Innovations and technical advancements, such as automation, robotics, IIoT, and others, in the automotive sector to meet rising customer demand are anticipated to increase the demand for welding equipment. In addition, the increasing sales of electric vehicles are expected to further propel the adoption of the welding equipment industry in the coming years.

The rise in construction activities globally, coupled with swift urbanization in developing nations like China, India, Brazil, and those in the Middle East and Africa, is poised to propel the expansion of the construction sector. Increased disposable incomes and enhanced consumer spending capabilities are expected to drive investment in new building construction. Furthermore, government initiatives emphasizing urban planning and infrastructure development in multiple countries are likely to provide additional momentum to the growth of the construction sector. Consequently, the positive trajectory of the construction industry is anticipated to have a favorable impact on the expansion of the market.

Welding Equipment Market Report Highlights

In 2023, automatic welding equipment dominated the global market, accounting for 56.4% of the total revenue share. This dominance is attributed to its capacity to enhance productivity, reduce cycle duration, and improve efficiency in welding processes. The widespread adoption of automatic welding equipment on a global scale has surged in recent years, driven by its ability to achieve rapid weld cycle times, deliver high output, and substantially lower welding costs

In 2023, the arc welding technology segment held the largest share of the global revenue in 2023. The growing prevalence of arc welding technology can be attributed to its inherent characteristics, including flexibility and adaptability to diverse conditions. Notably, continuous advancements in robotic arc welding play a pivotal role in propelling the growth of the arc welding segment within the welding equipment market

The aerospace end-use segment is projected to witness growth at the fastest CAGR from 2024 to 2030 owing to the growing applications in aerospace manufacturing, including heating elements, circuit board traces, electronic components, actuators, fine ribbon welding, inductors, mesh welding, and hybrid micro-weld devices

Asia Pacific dominated the global market on account of the robust automotive industry. Increasing demand for electric and hybrid cars is expected to benefit the demand for welding equipment

In February 2023, Miller Electric Mfg. LLC launched the miller Deltaweld 852, Deltaweld 402, Deltaweld 602, welding machines in Southeast Asia. These machines specifically cater

Welding Equipment Market Segmentation

Grand View Research has segmented the welding equipment market based on technology, type, end-use and region:

Welding Equipment Technology Outlook (Revenue, USD Billion; 2018 - 2030)

Arc Welding

Shielded Metal/Stick Arc Welding

MIG

TIG

Plasma Arc Welding

Others

Resistance Welding

Laser Beam Welding

Oxy-Fuel Welding

Others

Welding Equipment Type Outlook (Revenue, USD Billion; 2018 - 2030)

Automatic

Semi-Automatic

Manual

Welding Equipment End-use Outlook (Revenue, USD Billion; 2018 - 2030)

Aerospace

Automotive

Building & Construction

Energy

Oil & Gas

Marine

Others

Welding Equipment Region Outlook (Revenue, USD Billion; 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Asia Pacific

China

India

Japan

Australia

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

South Africa

Saudi Arabia

List of Key Players

The Lincoln Electric Company

ACRO Automation Systems, Inc

Miller Electric Mfg. LLC

Ador Welding Limited

Mitco Weld Products Pvt. Ltd.

voestalpine Böhler Welding Group GmbH

Carl Cloos Schweisstechnik GmbH

OTC DAIHEN Inc.

Illinois Tool Works Inc.

Panasonic Industry Co., Ltd.

Coherent, Inc.

ESAB

Polysoude S.A.S.

Kemppi Oy.

Cruxweld Industrial Equipments Pvt. Ltd.

Recent Developments

In February 2023, Miller Electric Mfg. LLC launched the Copilot Collaborative Welding System in February 2023. It is a cobot with advanced capabilities intended for welders and shops new to robotic welding who are looking for solutions to keep up with demand.

In March 2023, voestalpine Böhler Welding Group GmbH launched Böhler Welding`s Crane & Lifting Full Welding Solution. The product helped the company to achieve 50% faster welding speed.

Order a free sample PDF of the Welding Equipment Market Intelligence Study, published by Grand View Research.

0 notes

Text

Premium Actuated Butterfly Valves for Precision Flow Control

Discover top-quality actuated butterfly valves for precise flow control in industrial and commercial systems, FlowCon IVC PN16 and PN25 lugged electric actuated butterfly valves produce precise regulation of flow, enhancing efficiency and reliability in industrial applications.. Engineered for efficiency, these valves are ideal for automated operations in water, gas, and chemical applications. Durable, cost-effective, and easy to integrate, they ensure reliable performance. Upgrade your system with our advanced actuated butterfly valves. Contact us today for expert guidance and custom solutions. For More Details :- https://www.flocontrol.ltd.uk/, Contact Us :- +44 1282 564425

#PICV Valve function#PICVs#PICV Valve#PICV Valves#PICV#PICV Valve Package#PICV Valve for AHU#PICV Installation#PICV Valve for FCU

0 notes