#Double Screws Compost Turning Machine

Explore tagged Tumblr posts

Text

The market prospect of organic fertilizer is broad, and more and more medium and large farms choose to process livestock manure into organic fertilizer for sale. The most important step in the production of organic fertilizer is the fermentation of organic raw materials. During the fermentation process, the raw materials need to be turned over so that the middle materials can be fully exposed to the air for fermentation and decomposition and water removal. Due to large-scale production, the processing capacity of organic raw materials is very large, and it is unrealistic to carry out manual flipping, which requires the use of flipping equipment. There are many types of flipping equipment on the market, and it is difficult to choose a suitable flipping equipment. This article simply describes the common tossing equipment and use scenarios on the market.

1.Simple Compost Turning Machine

Fermentation tanks need to be built, and with the help of mobile cars, it is possible to rotate between multiple fermentation tanks and reduce investment.

Tossing depth 0.8-1.8 meters, width 3-6 meters.

Can advance 1-2 meters per minute, the walking speed depends on the density of the material, the density is large, the walking speed is slow.

Application scenario: Daily organic raw material processing capacity of more than 20 tons, annual output of 6,000 tons of organic fertilizer. There is no need for manpower when the tilting machine is working.

2.Wheel Type Windrow Compost Turning Machine

The requirements for the workshop are higher, the wall must be strong, and the indoor operation.

Flipping span up to 33 meters wide, depth up to 1.5-3 meters, suitable for deep flipping operations.

Application scenario: Daily organic raw material processing capacity of more than 30 tons, annual output of 10,000 to 20,000 tons of organic fertilizer. The tilting machine works automatically without manpower.

3.Double Screws Compost Turning Machine

Compared with the wheel type throwing machine, the double wheel disk as the name suggests is 2 roulette one operation, the efficiency is very high.

The requirements for the workshop are higher, the wall must be strong, and the indoor operation.

Flipping span up to 33 meters wide, depth up to 1.5-3 meters, suitable for deep flipping operations.

Application scenario: Daily organic raw material processing capacity of more than 30 tons, annual output of 10,000 to 20,000 tons of organic fertilizer. The tilting machine works automatically without manpower.

4. Chain Compost Turning Machine

Fermentation tanks need to be built, and with the help of the mobile car, it is possible to rotate between multiple fermentation tanks.

The walking speed is fast, the flipping depth can reach 2 meters, suitable for deep slot operation.

Equipped with a shifting machine to change the slot can realize the multi-slot operation of a flipping machine, saving investment.

Since the tilting plate is inclined, after each tilting, the material as a whole will move forward. The next time you stack the material, put it directly at the back of the field.

Application scenario: Small fermentation site, deep fermentation tank, daily organic raw material processing capacity of more than 30 tons, annual output of 10,000 to 20,000 tons of organic fertilizer. The tilting machine works automatically without manpower.

5.Crawler-type Turning Machine

No need to build a trough, just pile the fertilizer into strips. The stacking spacing is 0.8-1 meters, and the stacking height is 0.6-1.8 meters, which saves investment cost and is convenient for expansion.

The dump plane has a cockpit, and workers can isolate some of the odor when operating the machine.

Application scenario: Daily organic raw material processing capacity of more than 5 tons, annual output of 3,000 tons of organic fertilizer. When the tilting machine is working, a worker is required to operate the machine.

#Chain Compost Turning Machine#Crawler-type Turning Machine#Double Screws Compost Turning Machine#Simple Compost Turning Machine#Wheel Type Windrow Compost Turning Machine

0 notes

Text

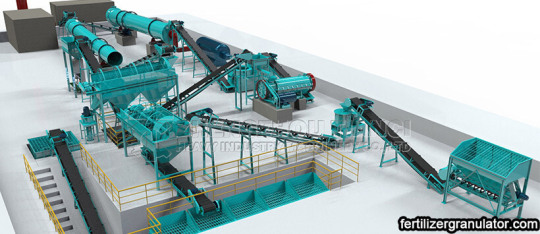

Organic Fertilizer Production Line equipment includes:

1. Common equipment of grinder

By working form: Chain Crusher;

By working principle: Compost Crusher;

By use: Cage Crusher;

2. Common equipment of mixer

By working mode: Horizontal Ribbon Mixer;

By working principle: Double Shafts Paddles Mixer;

3. Common equipment of screening machine

According to the working mode: Rotary Screening Machine、 Vibration Screening Machine;

According to the working principle: solid-liquid separator;

4. Common equipment of conveyor

According to the working form: Bucket Elevator、 Belt Conveyor (Large Angle Belt Conveyor、 Mobile Belt Conveyor);

According to the working principle: Screw Conveyor;

5. Common equipment of granulator

According to the working mode: Disc Granulator、 Rotary Drum Granulator;

According to the working principle: Fertilizer Granules Compaction Machine、 Ball Shaping Machine;

By use: biological organic fertilizer granulator;

6. Common equipment of dryer

By working form: Rotary Dryer Machine;

By use: Pig manure dryer、 chicken manure dryer、 cow manure dryer、 sheep manure dryer;

7. Supporting equipment:

Common equipment

Formula Fertilizer Dosing System、 Fertilizer Coating Machine、 Rotary Cooler Machine、 Fertilizer Packing Machine、 Windrow Compost Turning Machine.

8. Organic fertilizer equipment is divided into three configurations:

High configuration: Chicken manure dewatering Machine、 Compost Turning Machine、 Compost Crusher、 Double Shafts Paddles Mixer、 Granulator、 Rotary Dryer Machine、 Rotary Cooler Machine、 Rotary Screening Machine、 Fertilizer Granules Coating Machine、Packaging equipment、 Belt Conveyor、 etc.

To configure: Compost Crusher、 Double Shafts Paddles Mixer、 granulator、 Rotary Dryer Machine、 Rotary Cooler Machine、 Rotary Screening Machinery、 Packaging Equipment、 Belt Conveyor、 etc.

Low configuration: Compost Crusher、 Double Shafts Paddles Mixer、 granulator、 Rotary Screening Machine、 Packaging Equipment.

0 notes

Text

In the exploration of sustainable agriculture and resource recycling, bagasse, which was once regarded as a waste material, is gradually showing its great potential as a raw material for organic fertilizer. Through the careful treatment of organic fertilizer production line, bagas can not only realize waste utilization, but also be converted into nutrient rich organic fertilizer, injecting new vitality into farmland.

The production and processing process of organic fertilizer revolves around the three core links of ripening, dehydration and granulation, and the addition of Sugarcaneadds new vitality to this process. On the Organic fertilizer production line, all kinds of advanced equipment work together to complete this green transformation.

Ripening stage: bagars are first mixed with appropriate amount of water, and regularly turned and aerated by organic fertilizer fermentation equipment -- Windrow Compost Turning Machine. This process promoted the activity of microorganisms, accelerated the decomposition and decay of organic matter in bagasse, and laid a good foundation for subsequent treatment.

Crushing and stirring: The decomposed Sugarcaneraw materials should be treated by a crusher. According to the humidity and characteristics of the raw materials, appropriate vertical or horizontal crusher should be selected for crushing. Subsequently, the Sugarcanewas thoroughly mixed with other organic materials using a blender (vertical or horizontal, uniaxial or biaxial) to ensure an even distribution of nutrients.

Screening and transportation: after crushing and stirring materials, through the roller screen or vibration grading screen for screening, remove impurities, improve product quality. Subsequently, the large Angle belt conveyor or screw conveyor will be screened after the material to the next process.

Pelleting and molding: In the pelleting process, Fertilizer Granules Compaction Machine with its unique double-roll extrusion technology, the Sugarcaneis mixed with other organic materials and extrudated into pellets. This step not only enhances the appearance and market value of the product, but also facilitates subsequent storage, transportation, and use. Of course, according to the market demand, some manufacturers will also choose to make the material directly into powder or extrusion into columns.

Drying and cooling: The organic fertilizer after granulation needs to be dried by a roller dryer to reduce moisture content and improve stability. A drum cooling machine is then responsible for cooling the dried particles to the appropriate temperature to avoid nutrient damage from overheating.

Packaging and sale: Finally, with the cooperation of automatic batching machine, conveyor and quantitative packaging scale and other equipment, the dried and cooled organic fertilizer is accurately measured and packaged into bags, ready to be sold to farmers or agricultural enterprises.

The green value of bagasse

The application of Sugarcaneas raw material of organic fertilizer not only realizes the resource utilization of agricultural waste, reduces environmental pollution, but also promotes the improvement of soil structure and the increase of crop yield. It is rich in cellulose, hemicellulose and mineral elements, which can release nutrients slowly in the soil and provide lasting and comprehensive nutritional support for plants.

The application of Sugarcanein organic fertilizer production is a vivid practice of agricultural circular economy. Through advanced organic fertilizer production lines and supporting equipment, we can convert this waste into valuable agricultural resources and contribute to the realization of sustainable agricultural development.

#Organic fertilizer production line#Windrow Compost Turning Machine,Fertilizer Granules Compaction Machine

0 notes

Link

The Double Screws Compost Turning Machine is used for fermenting and dump of organic wastes such as livestock manure, sludge garbage, sugar factory filter mud, dregs cake and straw sawdust. Organic fertilizer production plant cost about 20000 yuan.

0 notes

Photo

1. The trough type double screw compost turning machine has the mixing function. In the organic fertilizer production line, some auxiliary materials must be added to adjust the carbon nitrogen ratio, pH value and water content of raw materials. The main raw materials and various auxiliary materials roughly piled together according to the proportion can be mixed evenly by the trough type double screw compost turning machine to achieve the purpose of tempering. 2. Adjust the temperature of the raw material pile. In the operation of the fertilizer equipment, the raw material pellets are fully contacted and mixed with the air, and a large amount of fresh air can be contained in the stacker, which is conducive to the active production of fermentation heat by aerobic microorganisms and the rise of the stacker temperature; when the temperature is high, the supplement of fresh air can reduce the stacker temperature. A state of alternating medium temperature, high temperature, medium temperature and high temperature is formed, and various beneficial microorganisms grow and propagate rapidly in the suitable temperature range.

0 notes

Text

How to choose fertilizer manufacturing process plant

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

1. Determine the type of fertilizer and producton site. Determining whether to produce organic fertilizer or compound fertilizer affects the choice of site. If organic fertilizer is produced, it should not be too far from the farm where raw materials are provided. The type of fertilizer determines whether compound fertilizer equipment or organic fertilizer equipment is needed. Different types of fertilizer equipment also have differences.

2. Determine the fertilizer granulator machine. Granulation is the key link in fertilizer production and plays an important role in the quality of manufactured fertilizer. Fertilizer granules are cylindrical, spherical and flat spherical in shape. The granules produced by granulators of different shapes are different. The choice of granulator is related to the scale of fertilizer plant construction and local market. Fertilizer factories have different investment scales, different production processes, and different supporting equipment.

If a small fertilizer plant is to be built, it is suggested to configure simple machinery and equipment to reduce investment in equipment. The small fertilizer production line is composed of crusher, mixer, granulator, drum screener and automatic packing machine. If organic fertilizer fermentation is needed, it can be carried out with batten fermentation and windrow turning machine. The advantages are that they are more in line with the principle of aerobic fermentation. It is not easy to form anaerobic fermentation. The fermentation is full and complete, and the fermentation speed is fast. Forklift trucks can also be used instead of turner (the effect is not as good as turner), which can be adopted in terms of saving investment. According to the local environmental protection requirements, choose dust removal settings, where environmental protection requirements are high, choose heavy dust settings to meet the local emission quality standards.

Investment in large and medium-sized fertilizer plants, fertilizer production equipment can choose turning machine, automatic batching system, loader feeding hopper, crusher, mixer, granulator, dryer, hot stove, cooler, feeder, screener, cyclone dust collector, packing machine, etc. Increase mechanical automation, save manpower and cost. Organic fertilizer tank fermentation, can choose simple compost turning machine, double screws compost turning machine (suitable for large yield).

3. Determine the manufacturer of fertilizer manufacturing process plant. Several fertilizer machine manufacturers were inspected, and the strength, scale and reputation of the manufacturer of fertilizer equipment were fully understood. It is better to inspect the production workshop, finishing workshop and assembly workshop of the enterprise, to know the product quality, processing equipment, production process of the enterprise, and whether the fertilizer equipment produced by the manufacturer is professional. Referring to the customer cases that the manufacturer has completed, on-site test machine, the production site can best show the real operation of the equipment. Looking for fertilizer equipment suppliers with perfect after-sales service, suppliers provide professional technicians to guide customers to install and debug equipment, so that the equipment can operate normally, and provide corresponding training services.

4. Determine the safety performance of fertilizer manufacturing process plant. Safety is the first, before purchasing, we need to consider whether the production line has safety devices, whether the machine design is reasonable, whether safety factors are taken into account, whether the parts are not welded properly, whether the bolts are tightened, whether there is pollution, and so on. In addition, whether the overall operation of the equipment is smooth and whether the design of the production line is reasonable are also matters needing attention, because it relates to the efficiency and quality of the operation of the equipment. With the permission of the manufacturer, the operator can try to operate it in practice and feel its state conveniently.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.

1 note

·

View note

Text

Application of compost turner machine in organic fertilizer production line

As a new type of compost turner machine, double-screws turning machine is widely used in animal manure organic fertilizer production line and bio-organic fertilizer production. It is the core equipment of aerobic dynamic composting, and it is based on the organic fertilizer manufacturing process and NPK fertilizer production machinery equipment family. The unique mechanical design and practical mechanical properties are rapidly multiplying, and it is the best substitute for replacing the manual and forklift materials. It is the mainstream product of the pre-fermentation application of organic fertilizer production line and biofertilizer project.

The Double-screws Turning Machine comprises a traverse device, a traveling device and a tumbling device, wherein the tumbling device comprises two reducers fixed to the frame, a screw shaft connected to the respective reducer via a coupling member and fixed with a spiral blade. When the device is walking on a specific track, the screw shaft will no longer work, and the screw shaft will automatically rotate to move against the work when walking to the effective work surface. The fermentation rate is increased, the compost is rapidly decomposed, the odor is prevented from being generated, and the fermentation time is shortened. Double-screws Turning Machine performance characteristics:

1. Fully stir the doping to make the material meet the granulation demand quickly.

2. Due to the large stacking force, the material is supplemented with more fresh air, which helps the aerobic microbial fermentation to heat up, and constitutes a process of high-temperature exchange, which helps all kinds of beneficial micro-bacteria to develop and multiply in the temperature range where it adapts.

3. The turner system can process the material into small clumps, making the thick and dense material pile loose and elastic, and forming a suitable porosity.

4. After the raw materials are turned over and fermented, there is certain water content. The consumption of raw materials by a large amount of microorganisms generated after turning over the piles will also release the water in the carrier. Therefore, as the fertilizer process reduces water, in addition to the evaporation of the heat transfer composition, the turning machine flips the raw materials to form a forced water vapor volatilization.

5. Achieve special requirements for the composting process. For example, the breaking of the raw material, the shape of the raw material pile or the quantitative shift of the raw material is achieved. As one of the important equipment in the fermentation equipment and organic fertilizer production process, the turner has been at the forefront of the development of the times, making great contributions to the organic fertilizer production line and biofertilizer project.

0 notes

Text

Huaqiang fertilizer compost turning machine for you

Zhengzhou Huaqiang Heavy Industry Technology Co.Ltd is a modern high-tech comprehensive manufacturing enterprise in China.

It has developed and produced the suitable equipment for the organic fertilizer and bio organic fertilizer production, such as the compost equipment, drying equipment, granulating equipment, screening systems and batching systems, and a full set of fertilizer equipment.

As we know, the fermentation compost turning machine is helpful in the fermentation process,

Fermentation is one important part of the organic fertilizer production, the quality of the fermentation affect the production directly. Our factory produces several kinds of the equipment, now let me introduce them for you.

1.Simple Groove Turning Machine:

https://www.bestfertilizermachine.com/fermentation-compost-turning-series/simple-groove-turning-machine.html

The simple groove turning machine is used for fermenting and dumping of organic wastes, such as livestock manure, sugar factory filter mud, dregs cake and straw sawdust, this simple groove turning machine is suitable for aerobic fermentation, and can be used in conjunction with solar energy fermentation room, fermentation tank and moving machine. It can be used together with the moving machine to realize the function of many of slots for one machine.

2.Crawler Type Turning Machine:

https://www.bestfertilizermachine.com/fermentation-compost-turning-series/crawler-type-turning-machine.html

This crawler type turning machine is a new product exclusively owned by our company in the market. The compost turnover equipment fills the market gap of large wheel compost equipment at the scene. Without steering wheel, the driver only needs to control two bars, turning it to the left or right, and braking about 180 degrees.

3.Hydraulic Type Groove Turning Machine:

https://www.bestfertilizermachine.com/fermentation-compost-turning-series/hydraulic-type-groove-turning-machine.html

Hydraulic Type Groove Turning Machines are widely used in the fermentation and removal of water in organic fertilizer plant, sludge waste plant, gardening farm and BIS mushroom plant.

The fermenting and dumping of organic wastes, such as livestock manure, sugar factory filter mud, dregs cake and straw sawdust.

4.Double-screws Turning Machine:

https://www.bestfertilizermachine.com/fermentation-compost-turning-series/double-screws-turning-machine.html

The double-screws turning machine is used for fermenting and dump of organic wastes such as livestock manure, sludge garbage, sugar factory filter mud, dregs cake and straw sawdust. It is widely used in the fermentation and removal of water in organic fertilizer plant,gardening farm and BIS mushroom plant. It overcomes the limitation of the width and depth of the traditional groove turning machine.

5.Chain Compost Turning Machine:

https://www.bestfertilizermachine.com/fermentation-compost-turning-series/chain-compost-turning-machine.html

The chain compost turning machine is suitable for the deep groove composting of organic solid wastes, such as the livestock manure, sludge and garbage, the machine walks along the rail of the fermentation groove, and its high efficiency turning operation is conductive to speeding up the fermentation of materials in the fermentation tank, reducing moisture content and improving composting quality, the series specifications of the machine can meet the width of various fermentation grooves.

0 notes

Video

youtube

Complete set of organic fertilizer production process equipment

The complete set of organic fertilizer production equipment mainly includes the following several kinds, which coordinate production to realize the automated industrial production of organic fertilizer. 1. Raw material composting and fermentation equipment-trough turning machine and windrow turning machine. The trough turner has a new design of one machine with multiple slots, which can effectively save space and equipment investment funds. Tianci Heavy Industries, China's leading fertilizer machine manufacturers, provides the overall solution for the construction of bio-organic fertilizer plants to maximize economic benefits with minimal investment. 2. Half-wet material crusher, including vertical crusher and horizontal crusher, with chain and hammer internal structure.

3. Fertilizer mixer, including vertical mixer, horizontal mixer, two-axis strong mixer, drum mixer, etc. The internal stirring structure is divided into stirring knife type and screw type. The proper mixing structure is designed according to the characteristics of the material. The outlet opening is designed for cylinder control and baffle control. 4. Fertilizer granulator. In the production process of organic fertilizer, the suitable granulator of organic fertilizer should be selected according to the characteristics of raw materials. We supply disc granulator, new type organic fertilizer granulator, flat die pellet mill, etc. Organic fertilizer granulator breaks through the conventional granulation process of organic materials. Some of the raw materials need not be reformed before granulation. After crushing, the raw materials can be directly proportioned to produce spherical particles, which can save a lot of energy. 5. Rotary drum dryer-alias bio-organic fertilizer dryer. 6. Rotary drum cooler. It is similar to the shape of the dryer, but different in material and performance. The main machine of the dryer is made of boiler steel, and the main machine of the cooler is made of carbon steel plate. 7. Screening machine. Screening machine includes drum type and vibration type. Screening machine is divided into three sieves, two sieves and so on. 8.Particle coating machine, machine shape and dryer, cooling machine similar, internal structure is very different. The inside of the wrapping machine is made of stainless steel or polypropylene. The whole machine includes the powder pulverizer and oil pump for matching. 9.Automatic metering packing machine, including spiral and DC type, single head and double head, made of stainless steel and carbon steel, customized according to customer's actual needs. 10. Conveying equipment, including belt conveyors, screw conveyors, bucket elevators, etc.

#bio-organic fertilizer#organic fertilizer production process#organic fertilizer production equipment

0 notes

Text

How much does it cost to build a small fertilizer production line of chicken manure?

The chicken manure organic fertilizer production equipment can process organic fertilizer, increase yield and benefit, and promote pollution-free production. At present, the processing of organic fertilizer with chicken manure has a very broad prospect. Further expansion of the scale will enable more manure from farms to be recycled and turned into treasure. At the same time, biogas residue is also a good organic fertilizer, so that chicken manure can be fully recycled. Self propelled compost windrow turner: mobile wheel compost windrow turner, crawler compost windrow turner. Trough compost turning machine, chain plate compost turning machine, screw compost turning machine. Fertilizer granulator: disc granulator, roll extrusion granulator, column extrusion granulator, special granulator for organic fertilizer, internal rotating agitator granulator, double roller granulator. Large dryer, cooler, coating machine, excrement dehydrator, crusher, mixer, screening machine, automatic batching machine, automatic packaging scale and other complete equipment. The treatment of chicken manure has become a headache for large-scale chicken farmers. Chicken manure, pig manure and cow manure are piled everywhere, and the bad smell also causes certain pollution to the environment. The production line of chicken manure organic fertilizer and the equipment of pig manure organic fertilizer are all organic fertilizers made from the manure of livestock and poultry. Zhengzhou Tianci heavy industry provides organic fertilizer production technology formula, bio organic fertilizer equipment technology, fertilizer production line and other one-stop services, and all the procedures and technologies for chicken manure processing into organic fertilizer. Those useless chicken manure, mixed with fermentation bacteria and fermented for 5-7 days, will become organic fertilizer rich in nitrogen, phosphorus, potassium, iron, zinc, calcium and other trace elements through equipment. In order to expand the impact, free to let around fruit farmers, vegetable farmers, flower farmers try, after use by farmers friends and foreign merchants welcome, economic benefits are very considerable.

0 notes

Text

In the exploration of sustainable agriculture and resource recycling, bagasse, which was once regarded as a waste material, is gradually showing its great potential as a raw material for organic fertilizer. Through the careful treatment of organic fertilizer production line, bagas can not only realize waste utilization, but also be converted into nutrient rich organic fertilizer, injecting new vitality into farmland.

The production and processing process of organic fertilizer revolves around the three core links of ripening, dehydration and granulation, and the addition of Sugarcaneadds new vitality to this process. On the Organic fertilizer production line, all kinds of advanced equipment work together to complete this green transformation.

Ripening stage: bagars are first mixed with appropriate amount of water, and regularly turned and aerated by organic fertilizer fermentation equipment -- Windrow Compost Turning Machine. This process promoted the activity of microorganisms, accelerated the decomposition and decay of organic matter in bagasse, and laid a good foundation for subsequent treatment.

Crushing and stirring: The decomposed Sugarcaneraw materials should be treated by a crusher. According to the humidity and characteristics of the raw materials, appropriate vertical or horizontal crusher should be selected for crushing. Subsequently, the Sugarcanewas thoroughly mixed with other organic materials using a blender (vertical or horizontal, uniaxial or biaxial) to ensure an even distribution of nutrients.

Screening and transportation: after crushing and stirring materials, through the roller screen or vibration grading screen for screening, remove impurities, improve product quality. Subsequently, the large Angle belt conveyor or screw conveyor will be screened after the material to the next process.

Pelleting and molding: In the pelleting process, Fertilizer Granules Compaction Machine with its unique double-roll extrusion technology, the Sugarcaneis mixed with other organic materials and extrudated into pellets. This step not only enhances the appearance and market value of the product, but also facilitates subsequent storage, transportation, and use. Of course, according to the market demand, some manufacturers will also choose to make the material directly into powder or extrusion into columns.

Drying and cooling: The organic fertilizer after granulation needs to be dried by a roller dryer to reduce moisture content and improve stability. A drum cooling machine is then responsible for cooling the dried particles to the appropriate temperature to avoid nutrient damage from overheating.

Packaging and sale: Finally, with the cooperation of automatic batching machine, conveyor and quantitative packaging scale and other equipment, the dried and cooled organic fertilizer is accurately measured and packaged into bags, ready to be sold to farmers or agricultural enterprises.

The green value of bagasse

The application of Sugarcaneas raw material of organic fertilizer not only realizes the resource utilization of agricultural waste, reduces environmental pollution, but also promotes the improvement of soil structure and the increase of crop yield. It is rich in cellulose, hemicellulose and mineral elements, which can release nutrients slowly in the soil and provide lasting and comprehensive nutritional support for plants.

The application of Sugarcanein organic fertilizer production is a vivid practice of agricultural circular economy. Through advanced organic fertilizer production lines and supporting equipment, we can convert this waste into valuable agricultural resources and contribute to the realization of sustainable agricultural development.

#Organic fertilizer production line#Windrow Compost Turning Machine,#Fertilizer Granules Compaction Machine

0 notes

Photo

The trough type double screw compost turner machine improves the permeability of the raw material pile. This fertilizer equipment can process materials into small lumps, making the thick and dense material pile become fluffy and elastic, forming appropriate porosity

The water content of the raw material pile is adjusted by the trough type double screw compost turner machine. The suitable water content of raw material fermentation is above 55%, and the water standard of finished organic fertilizer is below 20%. In fermentation, biochemical reaction will generate new water, and microorganism consumption of raw materials will make water lose carrier and free out. Therefore, with the organic fertilizer production line, the water content will be reduced in time. In addition to the evaporation formed by heat conduction, the forced water vapor emission will be formed when the material is turned by the double screw compost turner machine .

0 notes

Video

tumblr

Where to sell hog manure turner for pig farm

The treatment and reuse of pig manure can be realized by using compost turner machine. The goal of modern breeding is to protect the environment and health of the breeding environment. The sustainable development of animal husbandry can only be realized by implementing a healthy and ecological breeding mode in the process of breeding. In the pig farm, the modern organic fertilizer production equipment realizes the recycling utilization of the cultivation waste, which makes the ecological and clean animal husbandry mode come true.

Organic fertilizer aerobic fermentation

Organic fertilizer raw material fermentation is to use the continuous propagation of fermentation bacteria to degrade the materials. In this process, the materials will keep heating up. When the temperature reaches 60℃, it is necessary to use pig manure turner machine to dump the materials, so that the materials can be ventilated. Generally, the materials can be turned over every two days, so that the circulation can be repeated for about two weeks, and the materials can be thoroughly decomposed.

Hog Manure Windrow Turner

The stacking depth of our company's windrow turner is generally between 80-130cm. When stacking fermented materials, hog manure should be evenly sprayed on the litter, and fermenting bacteria should be added. During the mixing process of the windrow turning machine, the air in the material is circulated, and the litter is fully fermented. About two weeks, composting is realized, and finally organic fertilizer is produced. During the fermentation process, the temperature of the compost increased rapidly, and water was increased, thereby achieving zero discharge of manure. The windrow turning machine speeds up the processing of the overall fertilizer manufacturing process and improves the production efficiency.

The price of pig manure turner varies according to the model, and the wider the span, the higher the price. Therefore, customers should consider the factors of equipment price, site, etc. when purchasing the tipper, and choose a suitable model according to the investment and the production scale of organic fertilizer. In addition to the windrow turner, our company also produces double screws turner, trough compost turner and so on, with a variety of specifications for customers to choose.

When the compost material is thoroughly decomposed, it is sent to the organic fertilizer production line and processed into special commercial fertilizer by the fertilizer granulator machine. It can also be directly crushed into powder organic fertilizer for use.

0 notes

Text

Advantages of solid organic waste fermentation equipment

Organic fertilizer fermentation equipment can easily produce organic fertilizer which is popular with customers. As a special machine for making organic fertilizer, the market of organic fertilizer fermentation equipment is very broad. This series of high-temperature fermentation equipment for organic fertilizer is a turnover machine independently developed by Tianci company. It can match the organic fertilizer production equipment according to customer demand and capital capacity, and 2-4 workers can complete continuous production. The following is a detailed explanation of the advantages of organic fertilizer fermentation equipment.

Organic fertilizer fermentation turner machine

https://www.fertilizergranulator.com/fermentation-compost-turning-series/double-screws-compost-turning-machine.html

1. Low energy consumption

It is easy to operate and has low energy consumption. When fermenting, the temperature is 80-100 ℃, completely killing pests and harmful bacteria, and eliminating crop pests and diseases from the root.

2. Short processing time and strong compatibility

The treatment time of the dumper is short each time, and the organic wastes such as waste fungus bag, Chinese medicine dregs, dead branches, vegetable leaves, sludge, chicken manure, cattle manure, pig manure, kitchen waste, etc. are treated on the same day, which can produce organic fertilizer and biological fertilizer that meet the standards, and meet the requirements of industrial promotion.

3. High conversion rate

After high temperature and rapid fermentation of organic fertilizer, the conversion rate can reach 95% of the amount of organic waste.

4. The operation of the turner machine is simple and safe

The operation of the compost turning machine is simple, the machine is operated automatically, and the workers can work after simple training. The equipment is equipped with various safety protection measures, which can effectively prevent various mechanical, electrical and personal safety accidents.

5. Recycling waste in line with environmental requirements

High temperature and rapid fermentation of organic fertilizer, after dedusting, deodorization and sewage treatment, the discharge of waste gas and waste water meet the environmental standards, without secondary pollution. The dumper has carried out thorough harmless treatment of waste in the production process.

Tianci fertilizer equipment factory provides fermentation turning equipment, complete set of organic fertilizer production equipment, compound fertilizer equipment, disc granulator machine, rotary drum granulator, flat die pellet mill, organic fertilizer granulator. We have advanced technology and equipment, strong technical force, with the ability of R & D, manufacturing and installation of large-scale equipment.

0 notes

Video

youtube

What are used for the fertilizer fermentation process

The production of any qualified and high quality organic fertilizer must go through composting and fermentation process. Fermentation composting is a process in which organic matter is continuously degraded and stabilized through the action of microorganisms under certain conditions, and a product suitable for land use is produced.

After the high temperature stage of composting process, the amount of antagonistic bacteria can reach a high level; the organic matter in the composting process is not easy to decompose, stable and easily absorbed by crops under the action of microorganisms; at the same time, under the high temperature condition, the toxicity of heavy metals to microorganisms can reach a high level. In a certain range, microorganisms can reduce metal oxides. Fermentation is a simple and effective fertilizer manufacturing process, which is conducive to the development of ecological agriculture. The organic fertilizer production equipment processes the waste into compost and further processes it into organic fertilizer.

What is used in the fertilizer fermentation process

Main ingredients: fruit dregs, dry bagasse, mushroom dregs, distiller's grains, beer dregs, sugar dregs, vinegar dregs, starch dregs, cassava dregs, soy sauce dregs, tofu dregs, delicacies dregs, oil dregs, oil cake dregs, cotton rapeseed dregs, sludge, brewery's dregs, leftovers, animal excrement, etc.Excipients: Crop straws, leaf weeds.

Fermentation composting tools - compost turning machine

In the fermentation process, the compost needs to be turned over. The double screws compost turner is suitable for large-scale organic fertilizer factory to ferment and compost. Generally, when the composting temperature exceeds the peak value and the temperature decreases, the turner can mix the inner materials with the outer materials, and remix the materials with different decomposition temperature. If the humidity is not enough, some water can be added to promote the compost fermentation.In the process of composting, the death of various organisms and microorganisms, substitution and material transformation are carried out simultaneously. From any point of view, these reactions can not be completed in a short time, so even if the temperature, humidity, humidity and microorganism are well controlled, composting still needs 45-60 days. We provide the compost processing equipment, organic fertilizer granulator will ferment the compost into granules, increasing the value of fermentation products.

0 notes

Text

How to Operate Cow Manure Organic Fertilizer Manufacturing Process

How to deal with cow dung in cattle farm? In the process of cattle breeding, if the cow dung is not handled in time, it will cause air pollution, breed a large number of mosquitoes and flies, pollute the surrounding environment of the farm and cause cattle diseases. Treating cow dung to turn waste into treasure can also bring huge benefits.

Making cow dung into organic manure is one of the main methods to treat cow dung. Dry cow dung contains 10%-20% crude protein, 1%-3% crude fat, 20%-30% nitrogen-free extract and 15%-30% crude fiber, so it has high nutrients. An organic fertilizer production line can efficiently convert cow dung into organic fertilizer.

Cow Dung Organic Fertilizer Production Equipment and Process Step

1.Fermentation is the first important step

The cow dung produced by a cow in one year requires 4 to 6 cubic meters of space. According to the scale of farming, reasonable construction of cattle dung accumulation fermentation site. Adding 10%-15% straw, rice bran and other supplementary materials to cow dung, and adding appropriate water, the water content of cow dung can be controlled at about 60%, inoculated with starter, and the fermentation time is 15-40 days (depending on the season).

In organic fertilizer fermentation, turning is an important phase. Its purpose is to enable the materials mixed. By the thrown over, it course of the materials make the most contact with the air and get the best fermentation.

Fermentation compost turning machine (Strong maneuverability of mechanical dump operation)

Trough Compost Turning Machine, Double Screws Compost Turning Machine(Suitable for large field flip), Windrow Compost Turning Machine(Suitable for strip stacking).

2.Crushing raw material

The fermented materials and other additives are crushed, proportioned and mixed through material grinder and mixer in a certain proportion. The function of this system is to crush, mix and mix compost materials, inorganic fertilizers of nitrogen, phosphorus, potassium and other additives in a certain proportion. Based on years of experience, the following equipment is recommended:

Half-wet Material Crusher

The machine is mainly used to crush materials of biological fermentation organic fertilizer with moisture of 25%~50%. Have good effect on grinding the glass brick, ceramics and broken stone such kinds of hard matter from the city life garbage organic fertilizer.

Horizontal Mixer

Horizontal mixer stir material in batches, material can be mixed completely. High mixing rate, less residual suitable for feed, concentrated feed, premix additives mixing.

3.Pelletizing

New Type Organic Fertilizer Granulator is used to granulate the material. The organic fertilizer granulator is the newest technology products by our years of research experience. It process fertilizer powder into granules, it also can be achieved the better effect of grain making to acid and municipal sludge.

4.Drying, cooling and screening

After granulating, the fertilizer moisture is a little high. Use organic fertilizer Rotary Dryer, further remove water, to achieve the standard requirements of organic fertilizer moisture content.

Cooling the particulate matter with a Rotary Cooler helps to store the heat particulate matter from the top of the dryer to the counter-flow cooler. Under the action of the cooling fan, the dry air enters from the lower part of the cooler and exchanges sufficiently with the wet and hot particles from the upper tribe and the lower tribe.

There are some differences in particle sizes of the particles exported from the pelletizing and forming system, which requires sieving and grading. Drum Screener Machine has the advantages of low vibration, low noise and convenient screen change. The organic fertilizer manufacturing process is equipped with automatic feed-back system, which screens the unqualified large and small particulate materials, conveys them through belt hoist, re-crushes them and sends them to the granulator to continue granulating, which is helpful to improve the continuous operation ability of the production line.

5.Packing

Packing Machine weighs and packs the particulate matter quantitatively. Automatic quantitative packaging of powder and granules, suitable for flour, starch, feed, food, chemical industry, light industry, building materials industries.

Using cow dung as raw material to produce organic fertilizer has the advantages of low cost, stable quality, fluffy soil, improved land consolidation, improved soil fertility, and great marketing space. As a leading fertilizer equipment manufacturer in China, we have a professional organic fertilizer manufacturing process, which can make cow manure into organic fertilizer with high efficiency and benefit.

0 notes