#Digital Textile Reactive Inks

Explore tagged Tumblr posts

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

Dyes : The World of Colors

Colors make our world vibrant, and dyes are the magical ingredients that bring life to everything around us. Let’s explore the colorful universe of dyes, breaking down the various types and their fascinating uses in everyday life.

Understanding Dyes:

Dyes are like special paints that add color to different things. Humans have been fascinated by colors for a long time, and dyes play a huge role in making our world colorful. There are two main types of dyes: natural and synthetic. They are used to add color to items like utensils, textiles, leather products, and even food.

Types of Dyes:

Basic Dyes:

These dyes are made in labs and give really bright colors. They are great for adding color to things like acrylic fibers and synthetic materials.

Direct Dyes:

These dyes dissolve in water and are used for coloring materials like cotton. They are commonly used in the textile industry.

Natural dyes :

Natural dyes are derived from sources in nature and may include substances like indigo, turmeric, or cochineal. While these dyes have a historical and cultural significance, they often present limitations in terms of color range and fastness.

Acid Dyes:

Perfect for coloring protein fibers like wool and silk, acid dyes are highly soluble in water. They are not suitable for materials like cotton but work well for leather and medical products.

Synthetic Dyes:

Man-made and chemically produced, these dyes come in a wide range of colors. They are used in many industries due to being affordable, but they can be harmful to the environment and humans.

Reactive Dyes:

Best for cellulose, protein, and polyamide fibers, these dyes are easy to use and have good light-fastness properties. They are popular in the textile industry.

Solvent Dyes:

Modern and non-toxic, these dyes are used in upcoming textile mills. They are convenient but may be more expensive. Solvent dyes are seen as alternatives to traditional harmful dyes.

Food Dyes:

Added to food to make it look attractive, food dyes come in various forms. It’s important to use them carefully as excessive consumption can lead to health problems. They are either natural or artificial.

Application of Dyes:

Textiles: Dyes are extensively used in the textile industry to color fabrics, clothing, and other textile products. They can be applied through various methods such as dyeing, printing, or painting.

Plastics: Dyes enhance the appearance of plastic products, providing them with a wide range of colors and finishes.

Printing: Inks, whether for traditional printing or modern digital printing, often contain dyes to produce vibrant and accurate colors.

Food: Food dyes are used to add color to various food products, making them visually appealing. These dyes can be natural or synthetic.

Industrial Use: Dyes find applications in various industrial processes, including coloring materials like leather, creating inks for pens and printers, and contributing to the production of a wide array of products.

17 notes

·

View notes

Text

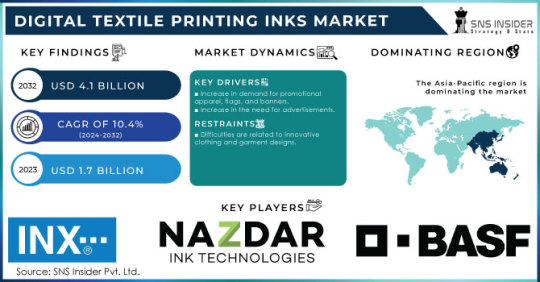

The Future of Digital Textile Printing Inks: Innovations and Market Growth

Rising Demand for Sustainable and High-Quality Printing Solutions Fuels Growth in the Digital Textile Printing Inks Market.

The Digital Textile Printing Inks Market size was USD 1.7 billion in 2023 and is expected to reach USD 4.1 billion by 2032 and grow at a CAGR of 9.6% over the forecast period of 2024-2032.

The Digital Textile Printing Inks Market is experiencing significant growth due to the increasing adoption of digital printing technology across the textile industry. These specialized inks play a vital role in achieving high-quality prints with vibrant colors, durability, and eco-friendly properties. With the rise in customized apparel, home textiles, and promotional products, the demand for efficient, cost-effective, and sustainable printing solutions has surged. Additionally, digital textile printing enables on-demand production, reducing fabric waste and water consumption, making it a preferred choice for textile manufacturers.

Key Players in the Digital Textile Printing Inks Market

INX International Ink (Expedition Inks, NSC Inks)

JK Group (Aqua Inks, J-Teck)

Nazdar Company (Nazdar 700 Series, Nazdar 120 Series)

BASF SE (Texaprint Reactive Inks, Desmodur Ink Systems)

Dover Corporation (Markem-Imaje Inks, DigiDot Inks)

DyStar Group (Remazol Inks, Dystar Pigment Inks)

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. (Hongsam Sublimation Inks, Hongsam Pigment Inks)

Huntsman Corporation (Huntsman Reactive Inks, Huntsman Disperse Inks)

Kornit Digital Ltd. (Kornit Allegro Inks, Kornit Storm Inks)

Sensient Technologies Corporation (Sensient Digital Inks, Sensient Sublimation Inks)

Future Scope of the Market

The future of the Digital Textile Printing Inks Market looks promising with:

Growing demand for sustainable, water-based inks with reduced environmental impact.

Expansion of e-commerce and customized textile products driving digital printing adoption.

Technological advancements leading to improved ink formulations with superior color fastness.

Increasing investments in high-speed digital printing machines for mass production.

Rising preference for pigment inks over dye-based inks due to their versatility and eco-friendliness.

Emerging Trends in the Digital Textile Printing Inks Market

The digital textile printing industry is rapidly shifting towards sustainable and high-performance ink formulations. Eco-friendly water-based inks, including pigment, reactive, and sublimation inks, are gaining traction due to stringent environmental regulations and growing consumer awareness. Moreover, advancements in nanotechnology and inkjet printing techniques are enhancing color vibrancy, print durability, and fabric compatibility. The demand for short-run and on-demand printing solutions is also fueling market growth, particularly in fashion, home décor, and sportswear industries. Additionally, the rise of automation and AI-driven printing processes is optimizing ink consumption and print efficiency.

Key Points:

Rising demand for sustainable, water-based textile printing inks.

Growth in personalized and on-demand textile printing applications.

Technological advancements improving print durability and efficiency.

Shift towards pigment inks for enhanced fabric compatibility.

Expanding adoption of digital printing in fashion, home décor, and industrial textiles.

Conclusion

The Digital Textile Printing Inks Market is set to experience substantial growth as the textile industry embraces digital transformation and eco-friendly practices. Innovations in ink formulations and printing technologies will further drive market expansion, catering to the evolving needs of fashion brands, home textile manufacturers, and industrial textile producers. Companies focusing on sustainability, high-performance inks, and digital printing advancements will gain a competitive edge in this dynamic market.

Read Full Report: https://www.snsinsider.com/reports/digital-textile-printing-inks-market-1458

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Digital Textile Printing Inks Market#Digital Textile Printing Inks Market Size#Digital Textile Printing Inks Market Share#Digital Textile Printing Inks Market Report#Digital Textile Printing Inks Market Forecast

0 notes

Text

How to Choose the Best Cotton Fabric Printing Machine for Your Business

Choosing the right cotton fabric printing machine is crucial for businesses in the textile industry. With advancements in digital textile printing, selecting the best machine can significantly impact print quality, production efficiency, and cost-effectiveness. Whether you are starting a new business or upgrading your existing setup, understanding the key factors that influence this decision is essential.

Orange O Tech is a leading brand in textile printing, offering cutting-edge solutions to meet the demands of modern businesses. In this guide, we will walk you through the essential factors to consider when selecting a cotton fabric printing machine that aligns with your business goals.

Understanding Cotton Fabric Printing

Cotton is one of the most widely used natural fibers in the textile industry due to its softness, durability, and breathability. However, printing on cotton requires specialized machines that ensure ink absorption, color vibrancy, and durability. Unlike synthetic fabrics that are compatible with sublimation printing, cotton requires direct-to-fabric (DTF) printing or pigment-based printing for optimal results.

Key Factors to Consider When Choosing a Cotton Fabric Printing Machine

1. Printing Technology

The printing technology you choose will determine the print quality, efficiency, and versatility of your business. Here are the primary technologies used in cotton fabric printing:

Direct-to-Fabric (DTF) Printing: Ideal for natural fibers like cotton, this method provides deep ink penetration and vibrant prints. It is widely used for both small and large-scale production.

Reactive Printing: Uses reactive dyes that chemically bond with the fabric, ensuring long-lasting prints with excellent wash durability.

Pigment-Based Printing: Eco-friendly and cost-effective, this method is suitable for businesses looking for a sustainable printing solution.

2. Production Speed and Capacity

Your production requirements will dictate the type of machine you need. If you are running a large-scale textile business, you need a high-speed cotton fabric printing machine that can handle bulk orders efficiently. Machines like those offered by Orange O Tech can print thousands of meters per day, making them ideal for high-volume operations.

If you are running a smaller business or a custom-printing service, a mid-range machine with moderate production speed may be more suitable.

3. Print Resolution and Quality

High-resolution printing ensures that designs are sharp, detailed, and vibrant. When choosing a machine, consider the dots per inch (DPI) resolution. Machines with advanced printheads, such as Kyocera or Epson, provide superior color accuracy and sharpness, ensuring professional-quality prints on cotton fabric.

4. Ink Compatibility

The type of ink used in your cotton fabric printing machine is crucial for achieving long-lasting, high-quality prints. Some of the best ink options for cotton fabric include:

Reactive Inks: Offer deep color penetration and excellent durability. Ideal for high-end fashion textiles.

Pigment Inks: Require minimal water usage and are environmentally friendly. Best for sustainable printing solutions.

Acid Inks: Used for delicate fabric printing but less common for cotton.

Ensure that the machine you choose is compatible with the ink type that best suits your business needs.

5. Eco-Friendliness

Sustainability is becoming a key factor in the textile industry. Modern cotton fabric printing machines incorporate eco-friendly technologies that reduce water and energy consumption. Orange O Tech offers machines that use minimal resources while delivering high-quality prints, making them a great choice for businesses looking to reduce their environmental impact.

6. Cost Considerations

While investing in a cotton fabric printing machine, consider both the initial purchase cost and the long-term operational expenses. Some key cost factors include:

Machine price: Higher-end machines may have a larger upfront cost but offer better efficiency and durability.

Ink costs: Some machines consume more ink than others. Choosing a machine with efficient ink usage can save money in the long run.

Maintenance costs: Regular servicing and spare part availability should be factored into your budget.

7. Technical Support and After-Sales Service

Having access to reliable technical support ensures that your business runs smoothly without frequent breakdowns. Orange O Tech provides comprehensive after-sales service, including training, troubleshooting, and maintenance support, ensuring minimal downtime for your business.

8. Versatility and Future Expansion

As your business grows, you may want to expand your printing capabilities. Investing in a versatile cotton fabric printing machine that can handle multiple fabric types, printing techniques, and customization options will help you scale your business without frequent equipment upgrades.

Why Choose Orange O Tech for Your Cotton Fabric Printing Machine?

Orange O Tech is a trusted name in the textile printing industry, offering state-of-the-art cotton fabric printing machines that cater to businesses of all sizes. Here’s why they stand out:

High-Speed Printing: Machines designed for bulk production, reaching up to 15,000 meters per day.

Superior Print Quality: Advanced printhead technology ensures high-resolution, durable prints.

Eco-Friendly Solutions: Machines designed to reduce water and ink wastage.

Comprehensive Support: Training and after-sales service for seamless business operations.

Cost-Effective Machines: Competitive pricing with low operational costs.

Whether you are a startup looking for an entry-level printer or an established textile business seeking high-performance machines, Orange O Tech has the perfect solution for your needs.

Final Thoughts

Selecting the best cotton fabric printing machine for your business is a crucial investment that requires careful consideration. By evaluating factors such as printing technology, production capacity, ink compatibility, cost efficiency, and technical support, you can make an informed decision that ensures long-term success.

Orange O Tech offers a range of high-performance textile printing machines that cater to various business needs, ensuring superior quality, efficiency, and sustainability. If you’re looking to upgrade your printing setup or start a new venture, choosing the right cotton fabric printing machine will set you on the path to success.

1 note

·

View note

Text

Numerous high-quality textile ink manufacturers gathered on May 19-21 Guangzhou ITCPE!

The textile digital printing technology blends fashion with creativity, so its quality is closely related to the aesthetics and durability of the final product. For this technology, the quality of textile digital printing ink undoubtedly plays a crucial role. It not only affects the definition of the print pattern, and color saturation, but also directly affects the wearing experience of the garment and the overall quality.

In recent years, with the rapid development of technology and the wide application of ink in various fields, the market demand for textile digital printing ink shows a trend of continuous growth. According to statistics, in 2023, the global inkjet ink market size has reached a staggering 15.683 billion yuan, and in China, an important consumer market of inkjet ink, the market size has also reached 3.221 billion yuan. This data not only reflects the huge potential of the market, but also predicts that the field will open up a broader prospect.

Some of the exhibitors (The following are in no particular order)

Shenzhen INKBANK Group Inc. — Booth No. T3009

Shenzhen INKBANK Group Inc. is a leading supplier of inkjet ink and digital application solutions in China, specializing in the research, development and manufacture of inkjet ink for 20 years. The company now has a modern R & D and production base of nearly 30,000 square meters, with an annual production capacity of more than 18,000 tons of products sold well at home and abroad in more than 100 countries and regions.

The products developed by the company mainly include: LED-UV curing ink, coating ink, heat sublimation ink, high temperature dispersion ink, reactive dye ink, acid dye ink, water-based pigment ink and water-based dye ink.

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. — Booth No. T4032

Hongsam digital adheres to the “Hongsam +” business philosophy, is rooted in the industry, and is willing to work with more companies to create a new digital life for mankind through extensive links, and in-depth cooperation. Following the value of “Hongsam Service”, we emphasize on channel construction externally, implement process management internally, and connect many channel partners and end-users with Hongsam technology and process services. Guided by the “user thinking” idea, we strengthen our technology and services, and unite upstream and downstream partners in the industry to form a huge network of customers. The “user thinking” idea makes customers and Hongsam connect closely together to become the “Hongsam+” community.

Foshan Kai Yan New Material Co., Ltd. — Booth No. T4017

Kai Yan New Material, a high-tech enterprise in the field of inkjet printing in China, one of the ink manufacturing supplier, owns a plant with an area of nearly 11,000 square feet so far, with the annual production capacity of more than 3,000 tons of UV ink, and more than 2,000 tons of water-based ink. The products are sold at home and abroad in different countries and regions. In just two years, the domestic sales of UV ink rose to rank amongst the top three, creating a miracle of the industry for a single ink product. The company is now in the forefront of the industry. The company focuses on the development of ink in the field of digital inkjet printing applications. We have always been adhering to the vision of “Doing business for well-being, developing ink with devoted will”, to provide customers with professional inkjet printing solutions and services. Our products cover areas such as the textile industry, labeling industry, building materials industry, advertising industry, special applications, and other daily necessities.

Innovation is the vitality of the development of enterprises. “Kaiyan New Material” pays more attention to R & D innovation, and is committed to the concept of “products lead the industry development, business innovation, win-win with partners in the future,” for the individual needs of different customers, the company gives full play to the spirit of innovation, while ensuring product quality.

Fully in accordance with the relevant national laws and regulations, the production of ink products is in line with RoHS, REACH, which marks our products to obtain the peer recognition from all around the world. Talent is the driving force of the enterprise development, so we keep on to establish talent incentive mechanism, and to provide a high-quality platform for capable, ambitious and aspiring talents, as well as a variety of conditions for the enterprise and the staff to grow together. In the future, Kaiyan New Material will always struggle for the goal of “becoming a company with vitality, innovation and faith”, and strive to make itself a bridge for you and me to grow and win together.

Guangzhou Unity Peak Company Ltd. — Booth No. T4009

Guangzhou Unity Peak Company Ltd. was founded in 2009. It is a national high-tech enterprise, and a specialized and sophisticated enterprise of Guangdong Province, located in Guangzhou Nansha Economic Development Zone. Since its inception, the company has been adhering to the “innovation, quality, integrity” business philosophy, and the route of green sustainable development, and focusing on the research and development and production of textile digital printing coating ink. The product has passed the Zurich (Switzerland)-based Oeko-Tex Standard 100, Class 1 certification for 12 consecutive years. The company’s laboratory has been equipped with Malvern particle size meter, ink drop observer, nano-mill and other professional equipment; in 2023, the company’s laboratory passed the CNAS certification, marking that the independent laboratory of Unity Peak new materials has met the international recognized standards in hardware facilities, testing capabilities and management level.

“Macheng” coating ink is the outstanding research and development achievement of the independent laboratory, which is used to research and develop textile digital printing pigment ink to replace imported ones.

After more than ten years of research, the R & D team in the coating ink application program has accumulated rich experience and improved the performance of the coating ink products to make them more in line with the application in Chinese market. At present, Unity Peak has formed a product matrix integrating thermal transfer machine production, coating ink research and development, white ink hot stamping paper and non-sensitive labels, which is a multi-wheel drive to recreate a new textile future. In the future, the company will increase investment in research and development to ensure the stability of product quality and perspectiveness.

Zhuhai Colour Spring Digital Technology Co., LTD — Booth No. T3038a

Zhuhai Colour Spring Digital Technology Co., LTD is located in the beautiful city, Zhuhai. It is a comprehensive enterprise specializing in the research and development, production and sales of digital inkjet ink. Colour Spring adheres to “rigorous attitude, first-class products, first-class service”. Relying on the company’s strong strength and a group of senior R & D, production and sales team, the company has established a number of series of advanced ink product lines, which are sold both at home and abroad.

The company’s products include: textile direct spray coating ink, white ink hot stamping film transfer ink, direct spray white ink, pretreatment fluid, moisturizing fluid, desktop printer compatible cartridge ink, ink tank printer ink, etc.

Zhuhai Colour Spring Digital is committed to providing environmental friendly, economical and high quality inkjet ink products for the global digital printing users. We are willing to build a win-win cooperation with global merchants and counterparts to create a strategic partnership for the future.

Foshan Createtide Digital Tech Co., Ltd. — Booth No. T4033

Guoci Kanglitai has set up more than twenty offices at home, and formed a business layout in foreign markets with seven major sales regions such as China and Africa, Tulsa, India, Middle East and North Africa, Mumbai, Indo-Malaysia-Taiwan, Southeast Asia and Europe, etc. It not only sets up branch offices in India, Turkey and other countries, but also will establish branch offices in the core countries and regions of the world one after another. In Dongying, Shandong Province, Guoci Kanglitai has built a large ink production base with a production capacity that ranks among the top in the world, with dozens of modernized and intelligent production lines, and an annual production capacity of 30,000 tons of ink. With “digital printing materials” as the core business, the company has expanded from ceramic ink to textile ink and other digital printing fields, and in 2024, its subsidiary, Foshan Createtide, newly launched the “COREMAX” digital textile printing ink brand. At present, COREMAX is mainly committed to the development and application of textile hot stamping ink and reactive ink. In the future, COREMAX will provide customers with a complete set of textile digital printing solutions, including but not limited to textile inkjet ink, digital printing process, pre-processing and post-processing of textile fabrics and raw materials, as well as provide customers with efficient and professional pre-sales and after-sales technical services. COREMAX has established several modern intelligent production lines in Sanshui, Foshan, with an annual production capacity of 10,000 tons of textile ink.

Zhuhai Chungkao New Material Tech Co., Ltd. — Booth No. T4025a

We have a strong professional R&D team, professional production team, professional sales team and after-sales service team, advanced laboratory, testing equipment, instruments and so on. The R&D team has more than 15 years of experience in inkjet printing and digital printing industry, and always keeps leading in the industry in R&D technology.

Our complete equipment and facilities and excellent quality control throughout all stages of production enable us to ensure the overall satisfaction of our customers. We insist on technological innovation, efficient production, strict management process and excellent service to provide our customers with perfect inkjet and textile coating ink products and a series of solutions.

We have ISO9001 quality management system certificate. If you are interested in any of our products, or you would like to negotiate customized orders, please feel free to contact us. Welcome to be our win-win partner.

Dongguan Kingjet Printers Consumables Co., Ltd. — Booth No. T3017

Dongguan Kingjet Printers Consumables Co., Ltd., a high-tech enterprise, was founded in 2007 in the “world factory” city — Dongguan. With 10 years of history, we have been focusing on ink research and development, production and sales as a whole. The company’s main operating brands are “Printing color king (印彩王)” and “KINGJET”.

The company now employs more than 50 people, managers and researchers with bachelor’s degree or above, respectively, from the high polymer materials, fine chemicals and business administration and other professions. The company insists on adopting advanced ink production process and formula, together with a series of advanced production inspection and testing equipment such as the laser particle size distribution meter and QUV weathering tester from abroad, as well as printing test equipment for many types of printheads; adopting imported high-grade raw materials and using advanced large-scale specialized production equipment, which guarantees stable quality, high quality and environmental protection of the products.

Kingjet’s products are suitable for Epson, Canon, HP, Brother, Ricoh, Lexmark, Starfire, Kyocera, Konica, Samba and other printheads of wide-format printers, UV flatbed printers, scanning and Single-Pass industrial machines, desktop inkjet printers and other machines and equipment; they can be widely used in digital textile printing industry, advertising printing industry, digital printing industry, digital imaging industry, digital decoration industry, office printing industry, and food industry.

Products applied in the digital textile industry: textile printing heat sublimation ink, textile printing high-temperature dispersion direct spray ink, textile printing paint direct spray ink, textile printing reactive ink, textile printing acid ink, leather odorless weak solvent ink, offset hot stamping ink, cross stitch dye ink.

Products used in the digital imaging industry, digital decoration industry, advertising spray painting industry, and digital printing industry: oil-based weak solvent ink, solvent ink, water-based weak solvent ink, advertising banner ink, UV ink, wide-format pigment ink, pigment ink for coated paper, wide-format dye ink, water-based latex (LATEX) ink, image printing ink, medical film ink, film ink.

Products used in office printing and graphic digital printing industry: desktop printing dye ink, desktop printing thermal transfer ink, desktop printing pigment ink, HP page width printer pigment ink, EPSON page width printing pigment ink.

Products applied in the food industry: food-grade ink.

Products applied to the digital printing industry: POD newspaper and booklet digital printing pigment ink (newspaper and booklet digital printing machine, corrugated digital printing dye ink and pigment ink (EPSON i3200 printhead, HP 970/980/990 printhead corrugated digital printing machine), label digital printing pigment ink (EPSON i3200 label digital printing machine)

High quality is the root of enterprise survival; new products are the source of enterprise advancement and market development. The company’s products have been exported to Southeast Asia, South America, North America, Central Asia, South Asia, Africa, Europe, the Middle East and domestic provinces and cities. Company tenet: excellent quality, reasonable price, reputation first, customer first, integrity-based, continuous innovation.

Texca New Printing Materials Co., Ltd. — Booth No. T4026b

Texca New Printing Materials Co., Ltd. is a foreign (Canadian) joint venture, now located in High-tech Industrial Park, Daguan District, Anqing, Anhui Province, with a registered capital of 6.4 million U.S. dollars.

After the completion of the company, the printing ink project annual output reached 6,000 tons.The construction is completed in two phases, the first of which has an annual output of 3,000 tons of printing ink and 1,000 tons of digital printing ink.

Our company adheres to the development concept of “safe development, green environmental protection”, and will vigorously develop water-based ink, which is a nationally encouraged project, in the next five years. The company adheres to the enterprise spirit of “honesty, diligence, refinement, progress”, pursues the enterprise business philosophy of “quality is vital, service is essential”, and meets the market demand with first-class products and high-quality service.

Guangzhou SAVEN Technology Co., Ltd. — Booth No. 3001, 3002, 3003, 3004

With years of development experience, SAVEN has formed a good symbiotic relationship with many upstream material suppliers, and works closely with printer manufacturers and printhead manufacturers. 4200D, 4203D, 4203L, 4205 and fluorescent hot stamping inks are very popular, and the latest launches in 2022 are the breathable hot stamping ink 6040-1 and the permanent white anti-sublimation ink YB-12D. SAVEN would like to present the best products and development solutions to the customers.

Dongguan Shinycolor Tech Co., Ltd. — Booth No. T4004b

Eastern Tech Company — Booth No. T043C

Eastern Tech Company, founded in 1995, is a specialty ink & coatings manufacturer, headquartered in Milford, CT. Our experienced team of chemists and production technicians have researched, developed, and produced the highest quality ink products for various industries in the United States and worldwide.

Eastern Tech works directly with OEM partners, developing solutions for market. We target Ink Innovations in everything that we do.

With a stream-lined production facility, Eastern Tech has a production capacity of over 500 million yuan CNY or more of ink annually.

With the evolving digital print industry, Eastern Tech has innovated piezoelectric-compatible inkjet inks.

Since 2008, Eastern Tech has manufactured water-based pigmented ink for inkjet printing directly onto t-shirts and other textiles. Our chemists have effectively improved color vibrancy, washability, and maintenance of use. Along with specially formulated pretreatment and cleaning solution products, Eastern Tech offers the complete solution for the Direct-To-Garment (DTG) industry.

Eastern Tech has invested millions in R&D, production, and quality control equipment to further ink innovations.

0 notes

Text

How Does Chiffon Printing Differ from Other Fabrics?

Chiffon is a lightweight, sheer fabric that has gained immense popularity in the fashion industry. Whether used in elegant evening gowns, scarves, or formal wear, chiffon’s delicate nature requires specialized printing techniques to achieve high-quality results. Unlike other fabrics, chiffon printing involves a unique process that enhances its beauty while maintaining its softness and flow.

1. The Nature of Chiffon and Its Printing Challenges

Chiffon is made from silk, polyester, or nylon, giving it a soft, airy feel. Unlike cotton or linen, chiffon has a delicate weave that makes it more challenging to print on. The lightweight and sheer nature of the fabric requires precision in ink application to avoid smudging or distortion of designs. Advanced printing methods like digital sublimation and screen printing are commonly used to ensure intricate patterns appear crisp and vibrant.

2. Ink Absorption and Color Vibrancy

Compared to other fabrics, chiffon does not absorb ink the same way as cotton or wool. Since the fabric is translucent, colors must be carefully applied to maintain their vibrancy without bleeding. Digital and heat transfer printing are preferred for chiffon, as they allow for detailed designs without compromising the fabric’s texture.

3. Durability and Washability

Fabrics like cotton and polyester have a higher resistance to frequent washing, while chiffon requires gentle care to preserve printed patterns. Unlike heavier textiles, chiffon prints may fade if washed improperly. This is why fabric printing specialists use high-quality dyes and fixatives to ensure that the designs remain vibrant even after multiple wears.

4. Printing Techniques Best Suited for Chiffon

Unlike fabrics such as denim or canvas that can withstand traditional screen printing, chiffon benefits more from sublimation or reactive dye printing. These techniques allow the design to bond with the fabric fibers without affecting its softness or causing stiffness. The result is a breathable, lightweight material with flawless prints.

Conclusion

Chiffon printing differs significantly from printing on other fabrics due to its delicate texture, ink absorption, and durability requirements. By using specialized techniques, designers can create stunning patterns without compromising the fabric’s natural elegance. If you’re looking for high-quality chiffon printing solutions, visit Azooni Prints today!

0 notes

Text

How Digital Printing is Revolutionizing the Textile Industry

Introduction

In today’s fast-paced world, innovation is reshaping industries, and the textile sector is no exception. One of the most groundbreaking changes in recent years has been the rise of digital printing, which is revolutionizing how textiles are designed, produced, and delivered. As businesses increasingly seek to stay ahead of consumer demand for personalized, efficient, and sustainable solutions, digital printing is becoming a cornerstone of modern textile manufacturing. This article delves into how digital printing is transforming the textile industry, its key benefits for B2B clients, and what the future holds for this dynamic technology.

Overview of Digital Printing in Textiles

Digital textile printing is the process of printing designs directly onto fabric using inkjet technology. Unlike traditional printing methods such as screen printing, which rely on physical templates or screens, digital printing eliminates the need for such tools. This allows for a more efficient process, capable of producing highly detailed designs in smaller quantities and with greater customization.

Digital printing is gaining rapid momentum in the textile industry due to its flexibility, efficiency, and capacity for intricate designs. It is used across various sectors including fashion, interior design, and industrial textiles, and is especially appealing to B2B markets where precision, quick turnaround, and customization are critical.

clothing manufacturers India

Why Digital Printing is Gaining Popularity in the Textile Industry

The shift from traditional printing methods to digital printing is largely driven by the changing demands of the textile market. Today’s B2B clients are increasingly looking for solutions that offer greater flexibility, reduced waste, faster production times, and higher precision—all while maintaining competitive pricing.

Several factors contribute to the growing popularity of digital printing in textiles:

Customization: Digital printing allows for easy customization, making it ideal for businesses that need to produce unique or personalized fabrics.

Shorter Production Runs: Traditional methods require bulk production to be cost-effective, but digital printing is perfectly suited for short production runs, reducing inventory and waste.

Sustainability: Digital printing consumes less water and ink compared to traditional printing, making it an eco-friendly option.

Speed: With the ability to bypass many labor-intensive steps of traditional printing, digital methods drastically reduce turnaround times.

Understanding Digital Printing Technology

How Digital Printing Works in Textiles

Digital textile printing uses advanced inkjet technology to transfer digital designs directly onto fabric. Here’s a simplified breakdown of the process:

Design Creation: A digital image is created using graphic design software.

Fabric Preparation: The fabric is pre-treated to ensure proper ink absorption and durability.

Ink Application: Specialized inkjet printers apply the design onto the fabric. These printers use different types of inks depending on the fabric being printed.

Post-Processing: Once printed, the fabric undergoes heat treatment or steaming to fix the ink and ensure longevity.

Types of Digital Printing Methods

Direct-to-Garment (DTG): Ideal for printing on finished garments like t-shirts or bags, this method prints the design directly onto the fabric.

Dye Sublimation: This method uses heat to transfer dye onto polyester fabrics, creating vibrant and long-lasting prints.

Reactive Printing: Commonly used on natural fibers like cotton and silk, reactive printing ensures that the dye chemically bonds with the fabric for permanent designs.

Pigment Printing: This method involves applying a pigment onto the surface of the fabric, often used for a range of materials, including synthetic blends.

textile wholesalers in India

Key Advantages of Digital Printing Over Traditional Methods

Digital printing offers numerous advantages compared to traditional textile printing methods like screen printing or rotary printing. These advantages are particularly valuable in a B2B context where efficiency and quality are paramount.

No Minimum Order Requirements: Unlike screen printing, which requires bulk orders to justify the setup costs, digital printing allows for economical short runs.

Detailed Designs: Digital printing can reproduce intricate patterns and designs with a higher resolution, enabling businesses to offer more complex and visually appealing products.

Less Waste: The technology uses significantly less water and ink, contributing to lower waste and a more sustainable production process.

On-Demand Production: With digital printing, B2B clients can easily order fabrics on demand, reducing excess inventory and storage costs.

Applications of Digital Printing in Textiles

Customization and Personalization

One of the greatest strengths of digital textile printing is its ability to create customized fabrics. In sectors like fashion, interior design, and promotional products, customers increasingly demand unique items that reflect their personal tastes or brand identity. Digital printing allows manufacturers to offer this level of personalization without the need for costly setup processes.

Short Runs and On-Demand Printing

Traditional printing methods often require large production runs to be cost-effective. Digital printing, however, excels at producing short runs, making it a practical solution for B2B clients who need small quantities of fabric quickly. This is particularly useful for companies that need to test designs or produce limited-edition products.

Innovative Design Capabilities

With digital printing, there are no limitations on colors, patterns, or gradients. This opens the door to innovative and creative design possibilities, enabling manufacturers to produce textiles with photorealistic images, detailed patterns, and even 3D effects.

textile production company India

Benefits of Digital Printing for B2B Clients

Cost-Efficiency and Waste Reduction

For B2B clients, digital printing offers significant cost savings by reducing the need for large inventories and minimizing waste. By producing fabrics on demand, businesses can avoid the expense of overproduction and the costs associated with unsold inventory.

Faster Turnaround Times

In industries where speed is crucial, digital printing offers a competitive edge. The elimination of complex setup processes means orders can be fulfilled quickly, allowing businesses to respond to market demands with agility.

Higher Precision and Quality

Digital printing provides a level of precision that traditional methods can’t match. This high level of accuracy ensures that every detail of the design is captured, providing superior quality and reducing the risk of errors.

Case Studies: Companies Using Digital Printing Effectively

Successful Implementation of Digital Printing

Several companies in the textile industry have successfully integrated digital printing into their production processes. For instance, large fashion brands have utilized digital printing to create vibrant, unique designs that appeal to modern consumers.

B2B Partnerships Benefiting from Digital Printing

B2B partnerships benefit greatly from the flexibility of digital printing. From customized uniforms to branded promotional materials, digital printing allows businesses to provide their clients with high-quality, personalized textiles without the high costs associated with traditional printing methods.

Creative Applications of Digital Printing in Fashion and Beyond

Digital printing is not only transforming fashion but also extending into other sectors like home decor and industrial textiles. For example, companies in the interior design space are using digital printing to create bespoke curtains, upholstery, and wallpaper.

best textile companies in India

Challenges and Solutions in Digital Textile Printing

Overcoming Technical Challenges

Digital textile printing, while innovative, does come with technical challenges, including ensuring compatibility between ink types and fabric materials. However, continuous advancements in ink technology and printing machinery are helping to overcome these challenges, providing more seamless and consistent results.

Ensuring Color Consistency and Accuracy

One of the common concerns with digital printing is color consistency, especially when printing large quantities of fabric. Manufacturers are addressing this by investing in advanced color management systems that ensure uniformity across all prints.

Managing Costs and Equipment Maintenance

While digital printing offers cost savings in many areas, the initial investment in high-quality digital printers can be substantial. To manage costs, manufacturers often start with smaller-scale digital printing operations and gradually expand as they experience the benefits.

The Future of Digital Printing in Textiles

Emerging Technologies in Digital Printing

The digital textile printing industry is constantly evolving, with emerging technologies such as 3D printing, eco-friendly inks, and AI-driven systems pushing the boundaries of what’s possible. These advancements will continue to drive growth and innovation, offering new opportunities for textile manufacturers.

Impact on Global Supply Chains

Digital printing is also transforming global supply chains by enabling local, on-demand production. This reduces the need for long-distance shipping, shortens lead times, and makes it easier for manufacturers to respond to changing market conditions.

Predictions for Digital Printing Trends in 2024 and Beyond

Looking ahead, we can expect digital printing to play an even greater role in the textile industry. Sustainability will remain a key driver, with businesses increasingly turning to digital printing as a way to reduce their environmental footprint. Additionally, advancements in automation and artificial intelligence will further enhance the efficiency and precision of digital textile printing.

garment manufacturing process India

Conclusion

Summary of Digital Printing’s Impact

Digital printing is fundamentally changing how textiles are produced, offering a host of benefits for B2B clients, including customization, cost savings, faster production times, and higher quality. As technology continues to evolve, digital printing is set to become even more integral to the textile industry, shaping its future for years to come.

How to Integrate Digital Printing into Your Textile Business

If you're a B2B company in the textile industry, now is the time to consider integrating digital printing into your operations. Whether you need short-run production, customized fabrics, or faster turnaround times, digital printing can help you meet your clients' demands while keeping costs under control.

Final Thoughts on the Future of Textile Printing

The future of textile printing is undeniably digital. As the technology becomes more advanced and accessible, businesses that embrace digital printing will be well-positioned to thrive in an increasingly competitive market.

Company Introduction

At Labisa, we are committed to staying at the forefront of textile innovation. Based in Sion West, Dharavi, Mumbai, we offer cutting-edge digital printing solutions that cater to the B2B market. Our advanced digital printing technology ensures that we deliver high-quality, customized fabrics with quick turnaround times. Whether you're in the fashion, interior design, or industrial sectors, Labisa is your trusted partner for all your textile needs.

Contact us today to learn more about how we can help you revolutionize your textile production:

Afzal: +91 98929 39564

Labisa Sales: +91 81699 85975

Email: [email protected], [email protected]

Address: Sion West, Dharavi, Mumbai, Maharashtra 400017

0 notes

Text

Digital Textiles in India – Bliss Impex in Gurgaon

One of the most striking things about visiting India is just how colorful everything is – from shopfronts and market stalls to the clothes that people wear out and about.

I wanted to get a better understanding of the Indian textile market and fortunately, Ekansh Jain, the owner of Bliss Impex, was happy to show me around his factory. The Bliss Impex name is already known to readers outside India, thanks to Durst’s marketing department announcing back in 2019 that the company had just bought four Durst Alpha textile printers.

At that time, Jain said that he invested in the four Durst machines in order to expand the company. This has obviously worked as he bought two more printers, one each from Epson and EFI, at the start of this year, both of which were being installed when I was there in February of this year.

http://indianprinterpublisher.com/wp-content/uploads/2024/04/BlissImpex_Reggiani_L1030251_WQ-web750cor.jpg

Three of the Durst Alpha 190s were set up with reactive inks and are still going strong, side by side. These have a print width of 190cm with a print resolution of up to 600 dpi. Jain was in the process of moving the fourth Durst machine, an Alpha 180, downstairs where it will become the first machine on a new production floor of the same size. This machine prints to transfer paper for dye sublimation to polyester.

Alongside the Alphas, a new Epson Monna Lisa 32000 was installed at the start of the year. This is fitted with 32 of Epson’s PrecisionCore printheads, which can produce up to 697 square meters an hour in a single pass at 300 x 600 dpi, or 423 square meters an hour in two passes at 600 x 600 dpi. It uses Epson’s Reactive Genesta inks. It’s available in 240cm and 340cm widths as well as the 180cm size installed at Bliss Impex.

Right at the end of the line was a brand new 32-head EFI Reggiani Power, for which they were still making the profiles. This can print to fabric at up to 1020 square meters an hour in a single pass at 600 x 300 dpi or up to four passes for 600 x 1200 dpi, which produces 295 square meters an hour. Again, Bliss Impex has opted for the 180cm size though Efi also offers 240 and 340cm widths.

There’s also an Atexco printer from China, which uses a camera for registration of double-sided prints to ensure the prints on the front and back line up. Bliss Impex uses the Atexco to produce a particularly nice effect of printing color on top of a material that’s already been embroidered.

Bliss Impex runs three shifts a day and Jain says that he only buys digital printers from vendors that have local service support. He says, “I always like to have a service team based here. Epson and EFI have their own team here. They will do the profiling and then they will leave one person to make sure that it runs.”

He adds, “Once the heads go, we recycle them. We have an agreement with the European companies so they take care of them. I would rather not run a faulty head but recycle it and get the right quality.”

http://indianprinterpublisher.com/wp-content/uploads/2024/04/Web750corr.jpg

Besides the digital machines, Bliss Impex also operates a range of conventional rotary and flatbed textile printing machines, as well as a label printer and also has an export arm. Jain says, “I have really upset the market by dropping the prices right down but the advantage is that I’m not trying to compete with other digital printers. I’m competing with my rotary.”

He continues, “When I first thought of putting these digital printers together people thought I was mad because it’s hard to run one machine let alone several big machines. My thinking was that I never had to compete with the market as I always competed with my own rotary work. I wanted to be in the market for this technology as I thought it was the future.

“And with digital I am putting more work through than with the rotary machines and it’s all on the same floor. It’s clean and hygienic. It’s better working conditions for the employees. It’s all sustainable.”

He says that a lot of people have now moved into digital printing but adds, “I would challenge anyone to find better quality with digital.” For this reason, he is also cautious about the current trend in textile printing towards pigment inks. He says, “I’m still going for reactive. I think that pigment needs more research and needs to be more cost-effective to really compete because it doesn’t have the easy hand feel of the reactive.”

He continues, “I can see a lot of advantage in bringing lower consumption of water but we still need to wait another few years more for pigment to reach the cost and performance of reactive.” He adds, “The pigment ink costs are more than double and the consumption is triple.”

http://indianprinterpublisher.com/wp-content/uploads/2024/04/BlissImpex_Alpha190_L1030244_WQWeb500.jpg

Naturally, with so many printers, he has considered investing in a single-pass inkjet machine but doesn’t think the print quality is as good. He explains, “The reason I don’t want to use single pass is that with the multi-pass you can increase the colour intensity by increasing the number of passes. But I can’t control this with a single-pass printer.” He adds, “And in my case, I have many other people to look after where I need to satisfy their quality and their color. And with the single pass, I would have to stop the production for the whole line. So I would rather have the multi-pass machines. But I’m still contemplating the single-pass printers.”

Jain says that the Covid pandemic did slow down the company’s growth though the effects of the pandemic are now receding. He says that it changed the world, and left established players with equipment and software that needed to be updated, which is one reason for investing in the new Epson and EFI machines. He adds, “You need the quality. If you don’t have the quality you can’t find the right buyer.”

But he also says that after the pandemic people wanted to use more imaginative materials and were concerned about the environmental issues, particularly around water use. This worked in his favor since he was already using digital printing.

Overall, the company is expanding and has a German partner for exports to Europe. Print quality is key to the business despite also facing the same cost pressures that are common to India. But Jain is relaxed with the air of a man who has little to worry about. And given that he’s preparing a second production floor, there’s every chance that we will be hearing more from Bliss Impex as the company continues to build up its digital production capability.

You can find further details on this company from blissimpex.in.

First published on15th April 2024 in the Printing and Manufacturing Journal. Reprinted by permission. www.nessancleary.co.uk

0 notes

Text

Revolutionizing Textiles: Exploring the Digital Textile Printing Machines Market

In the dynamic world of textile manufacturing, digital textile printing machines are ushering in a new era of innovation, efficiency, and creative possibilities. These advanced machines leverage digital technology to transfer designs directly onto fabric, offering manufacturers greater flexibility, customization, and speed compared to traditional printing methods. In this article, we delve into the dynamics of the digital textile printing machines market, exploring key trends, innovations, and considerations driving the industry forward.

Digital textile printing machines have revolutionized the textile industry by streamlining the printing process and enabling on-demand production of high-quality fabrics with intricate designs and vibrant colors. Unlike conventional printing techniques such as screen printing or rotary printing, which require separate screens or cylinders for each color and design, digital printing allows for direct printing from digital files, eliminating the need for costly setup processes and reducing lead times.

One of the defining trends in the digital textile printing machines market is the shift towards sustainability and eco-friendliness. As consumers become increasingly aware of the environmental impact of textile production, there is a growing demand for greener printing technologies that minimize water consumption, chemical usage, and waste generation. Digital textile printing machines offer inherent sustainability advantages, such as reduced water usage, minimal setup waste, and the ability to print on demand, thereby reducing overproduction and excess inventory.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS25064

Moreover, digital textile printing machines enable greater design freedom and customization options, allowing manufacturers to produce unique, personalized fabrics tailored to individual preferences and market trends. With digital printing, designers can create intricate patterns, photorealistic images, and complex color gradients that would be difficult or impossible to achieve with traditional printing methods. This versatility and flexibility open up new opportunities for product differentiation and market segmentation in the textile industry.

Another key trend driving the digital textile printing machines market is the integration of advanced technologies such as inkjet printing, dye sublimation, and reactive dye printing. These technologies offer advantages such as fast printing speeds, high-resolution output, and compatibility with a wide range of fabric types, including natural fibers like cotton and silk, as well as synthetic materials like polyester and nylon. Additionally, ongoing advancements in ink formulations and printhead technology are enhancing print quality, durability, and colorfastness, further expanding the application potential of digital textile printing.

Furthermore, the digital textile printing machines market is witnessing innovations in automation, workflow optimization, and software integration to streamline production processes and enhance operational efficiency. Integrated software solutions for color management, file preparation, and print job scheduling enable manufacturers to achieve greater consistency, accuracy, and productivity in their printing operations. Additionally, robotics and automation technologies are being deployed to automate tasks such as fabric loading, printing, and unloading, reducing labor costs and minimizing human error.

In conclusion, digital textile printing machines are driving a paradigm shift in the textile industry, offering manufacturers unprecedented flexibility, efficiency, and creativity in fabric production. With advancements in sustainability, customization, and technology integration, digital printing is poised to become the preferred method for textile printing in the years to come. As manufacturers embrace digitalization and invest in state-of-the-art printing solutions, the digital textile printing machines market will continue to thrive, unlocking new possibilities for innovation and growth in the global textile industry.

0 notes

Text

Embracing Tomorrow: Future Trends in Digital Printing on Fabric

In the ever-evolving landscape of textile and fashion, digital printing on fabric stands at the forefront of innovation. As we look ahead, several exciting trends are poised to shape the future of this technology, revolutionizing the way we design, produce, and interact with textiles.

1. Sustainable Practices: As environmental consciousness continues to grow, the future of digital printing on fabric is undoubtedly green. Consumers are increasingly drawn to eco-friendly options, and the industry is responding by adopting sustainable practices. Expect to see a surge in water-based inks, recycled fabrics, and energy-efficient printing processes, making digital printing on fabric a more planet-friendly choice.

2. 3D Printing on Textiles: The integration of 3D printing technology with fabric printing opens up a realm of possibilities. Imagine garments with three-dimensional textures and patterns, adding depth and tactile interest to clothing. This futuristic approach to digital printing on fabric could redefine not just how we wear textiles but also how we experience them.

3. Smart Fabrics and Wearables: The intersection of digital printing and smart textiles is another trend to watch. Incorporating conductive inks and interactive elements into fabrics, digital printing can contribute to the creation of smart garments. From temperature-regulating clothing to garments that monitor health metrics, the fusion of technology and fabric printing is set to create a new era of functional and fashionable wearables.

4. Augmented Reality (AR) in Fabric Design: Imagine being able to visualize and customize your fabric designs in real-time through augmented reality. This trend is on the horizon, allowing designers and consumers alike to preview patterns and colors on virtual models or within physical spaces. This not only streamlines the design process but also enhances the shopping experience, bringing a new level of interactivity to digital printing on fabric.

5. Mass Customization: The demand for personalized products is driving the trend of mass customization. Digital printing on fabric is uniquely positioned to cater to this demand by offering cost-effective and efficient ways to produce customized textiles. From bespoke clothing lines to one-of-a-kind home decor, the future will see a surge in products that reflect the individuality of consumers.

6. Artificial Intelligence (AI) in Pattern Generation: AI is making waves in the design world, and digital printing on fabric is no exception. Machine learning algorithms can analyze trends, consumer preferences, and historical data to generate unique and on-trend patterns. This not only accelerates the design process but also ensures that printed fabrics align with current market demands.

7. Advancements in Ink Technologies: The quality and variety of inks used in digital printing on fabric will continue to improve. Expect innovations in color accuracy, longevity, and even functionalities like thermochromic or UV-reactive inks. These advancements will contribute to a broader spectrum of creative possibilities for designers and manufacturers.

In conclusion, the future of digital printing on fabric is teeming with innovation and promise. From sustainable practices to the integration of cutting-edge technologies, the textile industry is on the brink of a transformative era. As these trends unfold, we can anticipate a more personalized, sustainable, and technologically advanced landscape for digital printing on fabric, shaping the way we interact with textiles in the years to come.

0 notes

Link

#Digital Inks Market#digital printing ink#digital textile printing ink#reactive dye ink#solvent-based inks#water-based inks#uv-cured inks

0 notes

Text

Primary Types of Industrial Dyes and Pigments

Industrial dyes are quite often used in multiple industries these days; so is the case with pigments. If we talk about industrial dyes, they are basically coloring, ionizing, and aromatic compounds that are used in numerous applications across various industries. Dyes have the property to show an affinity towards the substrate. But, they should be used cautiously because some industrial dyes are toxic and carcinogenic in nature. Anyway, at present, dyes found their application in industries like plastic, cement, cosmetics, rubber, paper, textiles, medicine, to name a few. Some primary varieties of industrial dyes are mentioned under:

1) Digital Textile Printing Dyes: In digital printing, computer controlled ink-jet nozzles or charged drums are used. The physical surfaces over which the digital prints are reproduced include common paper, photographic paper, plastic, cloth, etc. The popular varieties of dyes used for this purpose are acid inks, disperse inks, reactive inks, and dye based inks.

2) Leather Dyes: Tanneries usually make use of around 50-100 different varieties of leather dyes. Each dye produces a diverse desired effect over the leather. The dyes used in this industry include direct, acid, mordant, reactive, and basic dyes, among others.

3) Optical Brighteners: Also known as optical agents, optical brighteners are the dyes that possess the attribute of absorbing the violet and ultraviolet region of the electromagnetic spectrum, which results in the prominent re-emission of light in the blue region. This dye is not suitable to be used in water (like in aquarium, etc.), due to its toxic nature.

4) Sublimation Dyes: These dyes primarily found their application in various types of printing. They can be found in several forms like inkjet inks, ribbons for thermal transfer, and toner for laser printers. Sublimation dyes are applied by the process called heat-transfer. Their main varieties include acid, disperse, vat, direct, and reactive.

Now, as you might have got some idea about the industrial dyes and their primary varieties, let's discuss about industrial pigments and their types. Pigments are basically the materials that make a modification in the color of the transmitted light owing to their attribute of selective absorption of the wavelength. The change in the transmission of light varies with fluorescence, phosphorescence, as well as with other forms of luminescence, in which a material emits light. Pigments are generally used in inks, coloring paints, cosmetics, eatables, etc. Nowadays there are various types of pigments available in the market, out of which some primary types of pigments are given under:

1) CLC Pigments: Cholesteric Liquid Crystal (CLC) pigments are made from CLC films. These pigments are nowadays increasingly used in security machines and also as an impediment to the counterfeit of currency notes, legal documents, etc.

2) Fluorescent Pigments: These pigments have the quality of changing the ultraviolet light into the desired color. They form the vital element of any kind of fluorescent material. The fluorescent pigments are mostly used in textile field, solvent based paper coating, and paints and aerosol coating.

3) Organic Pigments: Organic pigments consist of solid particles and they are insoluble in the application medium. There are two basic varieties of these pigments, namely natural and synthetic. Organic pigments are generally used for coloring or coating purposes (both decorative and protective) on plastics, candles, paper, rubber materials, pharmaceuticals, etc.

4) Ultramarine Pigments: They are a kind of inorganic pigments, which are non-poisonous and non-irritating in nature. They are also one of the oldest varieties of pigments. They have two basic types, viz., ultramarine blue and ultramarine violet. Ultramarine pigments found their application in coating, coloring, printing inks, cosmetics, and artist colors.

We are one of the leaders among manufacturers and suppliers of Dyestuff & Dyes, Textile Dyestuff, Pigments, Colorants offered by SD Chemical LLC, Cibolo, Texas, USA

1 note

·

View note

Link

I compared which textile you can do the best with digital textile printing. I compared all fabrics, for example polyester and cotton. And came to the conclusion to choose cotton:

Cotton is a natural fiber which, especially within the fashion industry, is widely used for clothing because of its high moisture control, comfort, and durability. With a digital textile printing machine, you can print on cotton. To obtain the highest quality possible, most digital printers use reactive inks since this type of ink provides the highest wash fastness for prints on cotton.

Also, you can choose precisely with cotton for the best sustainable option, with my focus on GOTS cotton.

1 note

·

View note

Text

Textile Dyeing and Printing

Dyeing and printing processes are employed in the conversion of raw textile fibers into finished goods that add much to the appearance of textile fabrics. DYEING Dyeing is the application of dyes or pigments on textile products such as fibers, yarns, and textiles with the goal of accomplishing color with preferred color fastness. Dyeing is usually done in a special option consisting of dyes and particular chemical product. Dye particles are fixed to the fiber by absorption, diffusion, or bonding with temperature level and time being vital managing elements. The bond between dye particle and fiber may be solid or weak, depending on the dye made use of. Dyeing and printing are different applications; in printing, color is applied to a local location with desired patterns. In dyeing, it is related to the whole textile. The main source of dye, historically, has been nature, with the dyes being drawn out from animals or plants. Considering that the mid-19th century, however, people have actually created synthetic dyes to accomplish a wider range of colors and to render the dyes extra stable to washing and general use. Various classes of dyes are utilized for various sorts of fiber and at different phases of the textile manufacturing procedure, from loose fibers via yarn and towel to complete garments.

Polymer fibers are dyed with fundamental dyes, while nylon and protein fibers such as wool and silk dye with acid dyes, and polyester thread is colored with disperse dyes. Cotton is dyed with a series of dye types, consisting of barrel dyes, and contemporary synthetic reactive and direct dyes. THERE ARE THREE CATEGORIES: •Cellulose fiber dye. •Protein fibers dye. •Synthetic fibers dye. THERE ARE MANY CLASS OF DYE IN THE FOLLOWING: •Reactive dye: •Disperse Dye •Direct Dye •Basic dye •Acid dye •Sulphur dye. •Vat dye •Azoic Dye •Oxidation dye •Optical dye or Fluorescent •Solvent Dye METHODS OF DYEING •Direct Dyeing •Stock Dyeing •Top Dyeing •Yarn Dyeing •Skein Dyeing •Package Dyeing •Warp Beam Dyeing •Garment Dyeing ADVANCES TECHNOLOGIES OF DYEING •Advanced DENIM concept •Supercritical fluid dyeing (SFD) •Ultrasound technology •Powder dyes from textile fibers •DyeCoo PRINTING Printing is a process of decorating textile fabrics by application of pigments, dyes, or various other associated materials in the form of patterns. Although apparently developed from the hand paint of materials, such approaches are also of great antiquity. There is evidence of printing being carried out in India throughout the 4th century BCE, and a printing block dated at about 300 CE has been discovered in the burial grounds of Akhmīn in Upper Egypt. Textile printing has actually ended up being highly sophisticated and has involved the skills of several musicians and designers.

The four major methods of textile printing are block, roller, display, and heat transfer printing. In each of these approaches, the application of the color, usually as a thick paste, is followed by fixation, usually by steaming or home heating, and afterwards removal of excess colour by cleaning. Printing styles are classified as direct, discharge, or stand up to. In straight printing, coloured pastes are published straight on the cloth. For discharge printing, the cloth is first dyed with a background color, which is ruined by reagents, or lowering representatives, lugged in a print paste. This activity may leave the released design white on a tinted history, although print pastes might additionally consist of tinting matters not destroyed by the discharging representative, generating a colored design. In the resist process, the cloth is first published with a compound called a withstand, safeguarding these published locations from accepting color. When the cloth is colored or pigment cushioned only those components not published with the withstand are colored. A special application of this strategy, passing on plissé results, is the printing of the fabric with a resist, complied with by therapy with caustic soda. TYPES OF TEXTILE PRINTING: •Block printing •Roller printing •Heat transfer printing •Digital Printing •Screen Printing •Flexography printing •Litho Printing •Engraving •Embossing •Embroider Printing ADVANCES TECHNOLOGIES OF PRINTING •Nanotechnology for printing •Water-based printing •Smart Cutting for B1 and B2 formats •Biodegradable printer inks •Conductive inks •3D Printing Thanks for reading the post, Please visit our website to know more about textile dyeing and printing.

1 note

·

View note

Text

Sun Chemical to highlight transformational solutions at FuturePrint 2024

Sun Chemical will present its extensive portfolio of solutions for a variety of wide format applications on stand K090 at FuturePrint 2024 (July 10-13, 2024) in São Paulo, Brazil under the theme of ‘Experience. Transformation.’

“FuturePrint is a key flagship show for the wide format industry and the perfect place to present our extensive portfolio of solutions for digital printing,” said Renato Rossi, Business Manager Latin America, Sun Chemical. “The event’s importance to the industry underscores its significance to Sun Chemical. As the largest producer of inks and coatings, we´re excited to exhibit at the show once again while connecting with customers to demonstrate ways they can experience transformation.”

Solutions on display will include Sun Chemical’s wide format and super wide format inkjet inks, textile inkjet inks, screen inks and industrial inks, and solutions from Sun Chemical’s digital inkjet brand, SunJet.

Wide Format

Sun Chemical will promote its Streamline range of eco-solvent inkjet inks for wide format printers. Formulated with low odor chemistry, the Streamline ink series is GREENGUARD Gold certified for low indoor emissions.

The Streamline portfolio highlighted will include wide format product solutions, offered in industry standard cartridges and pouches and designed for easy installation with printers widely used in the sign, display, and graphics markets. New for 2024, the Streamline ESL 2 and Ultima inks have been updated to add compatibility with the Epson i3200 and Brother printheads used with the latest generation of eco-solvent printers.

Streamline offers a team of fully trained, experienced engineers, offering on-site and remote support for ink conversions, color profiling, and perfecting press setup to ensure customers can optimize use of Streamline inks.

Super Wide Format

With the increasing popularity of new industrial 3.2m solvent inkjet presses, Streamline offers tailored ink solutions to support presses with Konica Minolta, Spectra Starfire, and Epson i3200 printheads. Optimized for the inkjet droplet specification and the end-user print application requirements, the latest addition to the range is Sun Chemical’s Streamline SGR, a solvent ink series for presses using Ricoh Gen 5 printheads.

Aqueous Inks

Sun Chemical will promote its patented Streamline aqueous ink technology for printing on paper substrates such as billboard poster, corrugated, and décor. These aqueous inks help meet increased demand for sustainable developments in ink technology.

Available for Kyocera and Ricoh Gen 5 printheads, Streamline aqueous inks offer high color strength which dries faster and reduces ink consumption. The inks also offer improved print finish, color vibrancy, and lower energy consumption costs.

Digital Textile Inks