#digital textile printing ink

Explore tagged Tumblr posts

Text

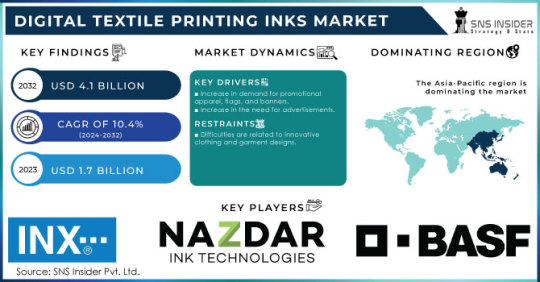

The Future of Digital Textile Printing Inks: Innovations and Market Growth

Rising Demand for Sustainable and High-Quality Printing Solutions Fuels Growth in the Digital Textile Printing Inks Market.

The Digital Textile Printing Inks Market size was USD 1.7 billion in 2023 and is expected to reach USD 4.1 billion by 2032 and grow at a CAGR of 9.6% over the forecast period of 2024-2032.

The Digital Textile Printing Inks Market is experiencing significant growth due to the increasing adoption of digital printing technology across the textile industry. These specialized inks play a vital role in achieving high-quality prints with vibrant colors, durability, and eco-friendly properties. With the rise in customized apparel, home textiles, and promotional products, the demand for efficient, cost-effective, and sustainable printing solutions has surged. Additionally, digital textile printing enables on-demand production, reducing fabric waste and water consumption, making it a preferred choice for textile manufacturers.

Key Players in the Digital Textile Printing Inks Market

INX International Ink (Expedition Inks, NSC Inks)

JK Group (Aqua Inks, J-Teck)

Nazdar Company (Nazdar 700 Series, Nazdar 120 Series)

BASF SE (Texaprint Reactive Inks, Desmodur Ink Systems)

Dover Corporation (Markem-Imaje Inks, DigiDot Inks)

DyStar Group (Remazol Inks, Dystar Pigment Inks)

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. (Hongsam Sublimation Inks, Hongsam Pigment Inks)

Huntsman Corporation (Huntsman Reactive Inks, Huntsman Disperse Inks)

Kornit Digital Ltd. (Kornit Allegro Inks, Kornit Storm Inks)

Sensient Technologies Corporation (Sensient Digital Inks, Sensient Sublimation Inks)

Future Scope of the Market

The future of the Digital Textile Printing Inks Market looks promising with:

Growing demand for sustainable, water-based inks with reduced environmental impact.

Expansion of e-commerce and customized textile products driving digital printing adoption.

Technological advancements leading to improved ink formulations with superior color fastness.

Increasing investments in high-speed digital printing machines for mass production.

Rising preference for pigment inks over dye-based inks due to their versatility and eco-friendliness.

Emerging Trends in the Digital Textile Printing Inks Market

The digital textile printing industry is rapidly shifting towards sustainable and high-performance ink formulations. Eco-friendly water-based inks, including pigment, reactive, and sublimation inks, are gaining traction due to stringent environmental regulations and growing consumer awareness. Moreover, advancements in nanotechnology and inkjet printing techniques are enhancing color vibrancy, print durability, and fabric compatibility. The demand for short-run and on-demand printing solutions is also fueling market growth, particularly in fashion, home décor, and sportswear industries. Additionally, the rise of automation and AI-driven printing processes is optimizing ink consumption and print efficiency.

Key Points:

Rising demand for sustainable, water-based textile printing inks.

Growth in personalized and on-demand textile printing applications.

Technological advancements improving print durability and efficiency.

Shift towards pigment inks for enhanced fabric compatibility.

Expanding adoption of digital printing in fashion, home décor, and industrial textiles.

Conclusion

The Digital Textile Printing Inks Market is set to experience substantial growth as the textile industry embraces digital transformation and eco-friendly practices. Innovations in ink formulations and printing technologies will further drive market expansion, catering to the evolving needs of fashion brands, home textile manufacturers, and industrial textile producers. Companies focusing on sustainability, high-performance inks, and digital printing advancements will gain a competitive edge in this dynamic market.

Read Full Report: https://www.snsinsider.com/reports/digital-textile-printing-inks-market-1458

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Digital Textile Printing Inks Market#Digital Textile Printing Inks Market Size#Digital Textile Printing Inks Market Share#Digital Textile Printing Inks Market Report#Digital Textile Printing Inks Market Forecast

0 notes

Text

UPDATE on the print project!!!!

It did loose a bit of pigment, it looks more gray than white now but that's fine I think. It's not terrible. And I kinda dig the faded look it has on the jeans! But the question is how it will hold up in multiple washes.... Also I have just printed my other design in red on white fabric to see if that works better. So I gotta wait 2 weeks again lol

btw I tried using actual fabric paint on the tshirt too but that print have literally disintegrated in the second wash which is very funny

Look at this test piece!! I got high hopes for this but if you know my luck something will surely go wrong lol

Anyway! I just gotta wait 1-2 weeks then its time to throw it in the washer! Some of the color will be lost but its a question of how much... and if it then holds up for multiple washes!

14 notes

·

View notes

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

From intricate patterns to photorealistic prints, digital textile printing inks enable designers to unleash their creativity and cater to evolving consumer demands for personalized, on-trend garments. At GTE, manufacturers witness live demonstrations and learn about the latest advancements in this rapidly changing field, empowering them to stay ahead of the curve.

0 notes

Text

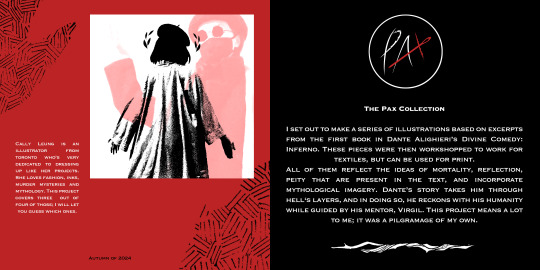

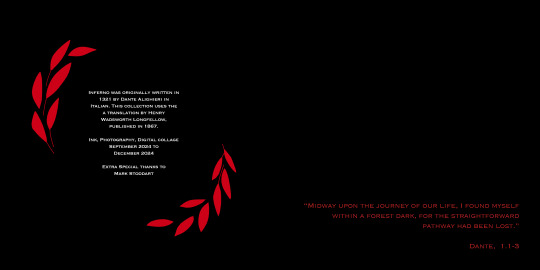

INFERNO PAX

So it begins...! Over the next week, I'll be posting designs I've created over the past four months. There'll be some merch on redbubble as well as colouring pages for those on patreon, tier 3 and up. Feel free to ask about tattoo passes as well :) Thank you for supporting my work, everyone!

art tag // commission info // inferno-pax tag // ko-fi // patreon

text:

Cally Leung is an illustrator from Toronto who's very dedicated to dressing up like her projects. She loves fashion, inks, murder mysteries and mythology. This project covers three out of four of those; I will let you guess which ones.

The PAX collection: I set out to make a series of illustrations based on excerpts from the first book in Dante Alighieri's Divine Comedy: Inferno. These pieces were then worshipped to work for textiles but can be used for print. all of them reflect the ideas of mortality, reflection, piety that are present in the text and incorporate mythological imagery. Dante's story takes him through Hell's layers, and in doing so, he reckons with his humanity while guided by his mentor, Virgil. This project means a lot to me; it was a pilgrimage of my own.

Inferno was originally written in 1321 by Dante Alighieri in Italina. This collection uses a translation by Henry Wadsworth Longfellow, published in 1867. Ink Photography, Digital collage. September 2024 to December 2024. Extra special thanks to Mark Stoddart.

"Midway upon the journey of our life, I found myself wihin a forest dark for the straightforward pathway had been lost." Dante, 1.1-3

#sunshan draws#classic literature#Dantes inferno#dante alighieri#the divine comedy#ink#traditional art#graphic illustration#sketch#art#doodles#inferno pax#illustration#inferno

13 notes

·

View notes

Note

I want to know more about the m9 artist au!! I remember reading a post or two about it a billion years ago (and would love to read them again) 💜

hi jess!!!! thank u for being interested hehe :")

so ever since i drew that lil thing of essek painting a frank stella inspired painting (or even before), ive been thinking of what kinds of art each of the m9 would do. essek ofc is inspired by a minimalist show that i went to here, all the big names from that movement were shown, but those really dark, sinkhole-like paintings are speaking to me. another artwork of boxes made of mirrors also seems like the thing he would do too

there's a kiln here that we visited which was huge, and surrounding it were artists' studios and some other ceramic sellers, i imagine the clay family having a place like this in the middle of nowhere amongst the trees, and caleb would do his work there

anyways because at heart im a shadowgast luver its centred around them,, they meet at an artist residency or something like that and its an incredibly slow burn that involves talking and not-talking and looking and not-looking. in the end i am but a simple wong kar wai fan so. that kinda vibes would definitely influence this, i would describe it as a quiet burning i guess?? time skipy and words that are not said

i think im gonna rant a bit more about their different mediums and styles so i'll keep it under the cut

i think caleb sculpts figures and portraits, but in a sad, kathe kollwitz charcoal vibe. maybe some funky looking animals, perhaps some pots and vases to look at the pretty glazes. he's interested in using fire to burn texture into different mediums, like ive seen it being used on shellac to make a really cool net of ink looking structure.. but yknow, just seeing the aftermath of glazed ceramic from the kiln is enough, and probably better for him to keep his distance anyways

the clay family produces most of the ceramic to sell, vases, pots, plates, cups, teapots, yknow just a whole array. and its really colourful too, depicting every family members different style. i think caduceus would do some matte glazes with a lot of different colours, theyre all a little wonky but theyre better off that way anyways. he does some really mean ink calligraphy and painting though

jester definitely does,, everything, whatever her heart desires kinda thang. she makes pastel textile installations and lighthearted cute paintings, but theyre always so contemplative and soothing. she gets m9 a lot of work cus her mom has connections, etc etc. i really love the idea of jester creating works that talk about the female body and femininity (definitely not projecting no)

beau is a printmaker and photographer who's really experimental, she loves cyanotypes and printing flowers (for yasha), idk she seems like she would put fabric and rocks into the washing machine to see what would happen. u would probably catch her in someone elses studio learning about what they do or in the library learning about what old people did

veth works in a museum as a curator, getting beau to help her sometimes with gathering artworks and artists etc. she probably organises community art projects for kids and public art installations. her house is full of m9's artworks and various other artists shes worked with.

yasha does bouquets as her post-retirement part time job, prior to that no one really knows what she did ("she probably murdered a bunch of people and is now hiding from the government"). fjord draws comics for fun but is also not a job for him, molly is a question mark for me. but these guys probably wont be in it as much anyways

im still not sure what format i wanna do this in, im actually having fun just writing it in my notebook now (digital does not facilitate the creative juices) but i do want to do some visuals like fake movie stills or storyboards. maybe they will work together well???? dunno. working on the other shadowgasty thing im doing made me realise how much easier it is to draw when there's a script already there, so im writing the script for myself

im definitely not as practiced in writing as i am in drawing, but idk im just gonna have some fun and see where that takes me, meanwhile try not to feel too bad that its fanart HAHA (very bad habit)

edit: i just saw my previous thoughts on beau being an art journalist, but i kinda like this better.. but maybe she can do both muah

#working tag for this ->#the kiln#honestly if u had any tips for writing#i'd love to hear..#i was insulted once on my writing and never wrote again HADHSFHF#oh and also emo smoking#that is somethng i want to draw more of

30 notes

·

View notes

Text

Dyes : The World of Colors

Colors make our world vibrant, and dyes are the magical ingredients that bring life to everything around us. Let’s explore the colorful universe of dyes, breaking down the various types and their fascinating uses in everyday life.

Understanding Dyes:

Dyes are like special paints that add color to different things. Humans have been fascinated by colors for a long time, and dyes play a huge role in making our world colorful. There are two main types of dyes: natural and synthetic. They are used to add color to items like utensils, textiles, leather products, and even food.

Types of Dyes:

Basic Dyes:

These dyes are made in labs and give really bright colors. They are great for adding color to things like acrylic fibers and synthetic materials.

Direct Dyes:

These dyes dissolve in water and are used for coloring materials like cotton. They are commonly used in the textile industry.

Natural dyes :

Natural dyes are derived from sources in nature and may include substances like indigo, turmeric, or cochineal. While these dyes have a historical and cultural significance, they often present limitations in terms of color range and fastness.

Acid Dyes:

Perfect for coloring protein fibers like wool and silk, acid dyes are highly soluble in water. They are not suitable for materials like cotton but work well for leather and medical products.

Synthetic Dyes:

Man-made and chemically produced, these dyes come in a wide range of colors. They are used in many industries due to being affordable, but they can be harmful to the environment and humans.

Reactive Dyes:

Best for cellulose, protein, and polyamide fibers, these dyes are easy to use and have good light-fastness properties. They are popular in the textile industry.

Solvent Dyes:

Modern and non-toxic, these dyes are used in upcoming textile mills. They are convenient but may be more expensive. Solvent dyes are seen as alternatives to traditional harmful dyes.

Food Dyes:

Added to food to make it look attractive, food dyes come in various forms. It’s important to use them carefully as excessive consumption can lead to health problems. They are either natural or artificial.

Application of Dyes:

Textiles: Dyes are extensively used in the textile industry to color fabrics, clothing, and other textile products. They can be applied through various methods such as dyeing, printing, or painting.

Plastics: Dyes enhance the appearance of plastic products, providing them with a wide range of colors and finishes.

Printing: Inks, whether for traditional printing or modern digital printing, often contain dyes to produce vibrant and accurate colors.

Food: Food dyes are used to add color to various food products, making them visually appealing. These dyes can be natural or synthetic.

Industrial Use: Dyes find applications in various industrial processes, including coloring materials like leather, creating inks for pens and printers, and contributing to the production of a wide array of products.

17 notes

·

View notes

Text

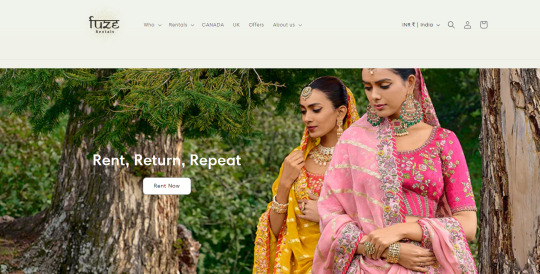

A Guide to Waste Reduction in Indian Weddings

In a world that's becoming increasingly conscious of environmental impact, it's time for weddings to take on a green hue. indian wedding, known for their grandeur, can also be a source of significant waste. However, with a few thoughtful choices, you can turn your wedding into an eco-friendly celebration. Here's a guide to waste reduction in Indian weddings.

Eco-friendly Invitations

Embrace the digital age and send out e-invitations instead of traditional paper ones. Not only does this reduce paper waste, but it also makes it easier for guests to RSVP and stay connected throughout the wedding festivities.

Image courtesy - freepik

Rent Your Outfits:

Consider renting your wedding attire instead of buying it. This not only saves money but also reduces the demand for new clothing production. Many platforms offer the opportunity to rent wedding dresses, allowing you to express your style without contributing to the environmental impact of textile waste.

Wedding Decor:

Opt for local and seasonal flowers for your wedding decor. Not only do they add a touch of freshness, but choosing local blooms also minimizes the carbon footprint associated with transporting flowers over long distances. Consider repurposing decor items or donating them to reduce waste further.

Image courtesy - freepik

Eco-friendly Dining:

Say goodbye to single-use plastic cutlery and plates. Instead, opt for reusable or biodegradable alternatives. This small change can significantly reduce the environmental impact of your wedding, and your guests will appreciate the effort to make the celebration more sustainable.

Image courtesy - Shaadiwish

Minimize Food Waste:

Plan your wedding menu carefully to minimize food waste. Work closely with your caterer to estimate portion sizes accurately. Consider donating excess food to local charities or food banks. It not only helps the community but also ensures that the surplus food doesn't end up in landfills.

Image courtesy - bollywoodshaadis

Digital Photo Albums :

Choose a wedding photographer who offers digital photo albums instead of traditional printed ones. This not only reduces the use of paper and ink but also makes it easier for you to share and cherish your memories in a digital format.

Image courtesy - pikperfect

Spread the Green Message:

Share your waste reduction efforts with your guests. Include a small note in your wedding program or have a display showcasing your eco-friendly choices. By doing so, you not only inspire others to adopt similar practices but also contribute to raising awareness about the importance of sustainability in celebrations.

Image courtesy - via The Knot

Your wedding day is a celebration of love, and what better way to express that love than by being mindful of the planet? With these simple yet impactful steps, you can make your Indian wedding a beacon of eco-friendliness, setting a positive example for future celebrations. Let your special day not only mark the beginning of a new chapter in your life but also stand as a testament to your commitment to a sustainable future.

3 notes

·

View notes

Text

okay about the art school au

tell me if you have any bright sparkling ideas for this au bc god knows i would eat them up. like i said before i know johanna is a graphic designer now but she has roots in illustration theyre like siblings. she leans towards children's books, making up stories and weird wonderful characters out of thin air. her work is also very botanical - her doodles in the show are full of winding plants and flowers. she could fill a page with dense undergrowth.

gerda is a student too but she's like that one teacher that just LOVES fonts. she is graphic design, product design, interior design, going back and forth between the computer room and the workshop to lasercut something or to build a weird chair. she could probably run a company marketing department at 18.

i also said kaisa is an analogue photography girl. she doesn't really care for most commercial photography she's like a man ray superfan and probably gets snotty about using digital cameras sometimes but loves to mess around with unconventional and cameraless methods. she might smell like chemicals. she doesn't want anyone close enough to be able to tell. she has always been an academic nerd and it shines in her artist research, drawing from the most conceptual artworks and fascinating herself with what there is to discover about them. she would love mike nelson.

edmund is perpetually covered in ink, of all colours, on his hands and his face. he's constantly workshopping prints of all kinds, one of his final pieces being a gigantic woodcut relief print depicting mythical creatures with lots of iconographic detail (think luke pearson's norse-inspired patterns o_<). he takes print room safety VERY seriously. do not put your hands or hair anywhere near the roller on the press. he will get you.

ive got like an outline idea for 6-8 chapters depending on whether i do it as a comic or writing? comics take so much effort for comparatively less story coverage so it would be a big endeavor but i would really love to have it all in visuals (also i'm not a superstar writer?) it's so difficult because some things i want to describe like in written word but some things i want to have visual 😭 artwork between paragraphs could be good but idk how cohesive it would be and it might be a bit jarring to suddenly be reading what you were looking at and vice versa.. that kind of thing works really well for a memoir like alison bechdel's fun home but not so much straightforward fictional story idkkkk... i can like see some panels in my head but i also want to do long descriptions and idrk if i want to mash them together. if i really do this it's going to take some PLANNING

victoria is still crazy but in a much more creative way. she loves to discuss everyone's work with them, she loves weird and experimental stuff. she likes to make elaborate and unconventional sets, props, and costumes for her colourful multi-media short films. she loves any art that moves, and makes great use of audio, sampling heavy thunderstorms pretty often.

AND! if i included the creatures (as people) then tontu would be a fashion & textiles tutor. i shan't be taking questions.

also thank you for the inspiring tags @the-hilda-librarians-wife 😭 your hospital au was so awesome i might find myself doing footnotes like you did, describing techniques and stuff where it would be out of place to just straight up write it down in the story.. bc i am gonna get SCIENTIFIC with the photography

(if it was a comic i'm thinking about the fun I'd have with speech bubbles especially in a classroom/studio - one of my hugest ever inspirations is anatola howard and this comic is so spectacular for speech bubbles lol)

#workin hard or hardly workin ahaha aha#sketchbook#johanna#kaisa#art school au#sketchbook ship#hilda the series#hilda netflix

5 notes

·

View notes

Text

Behind the Scenes: How T-Shirt Manufacturers in Chennai Ensure Quality at Scale

When it comes to high-quality, custom-made apparel, Chennai has emerged as a leading hub for T-shirt manufacturing. The city's robust infrastructure, skilled labor, and world-class textile ecosystem make it the perfect destination for businesses looking for bulk T-shirt production. But what happens behind the scenes to ensure that every T-shirt meets quality standards at scale? Let’s take an in-depth look at the process.

Chennai, home to numerous reputable t shirt manufacturers in chennai, is known for its ability to produce premium T-shirts that match global standards, all while maintaining affordable pricing. From fabric selection to printing and quality control, every step in the manufacturing process plays a crucial role in delivering high-quality products consistently. If you are considering T-shirt manufacturing for your brand or event, knowing what goes into the process will help you make an informed decision.

Understanding the Manufacturing Process

The first step in ensuring high-quality T-shirt production is choosing the right materials. Quality fabric is the foundation of every great T-shirt, and t shirt manufacturers in chennai have a reputation for sourcing top-notch fabrics. Whether it’s cotton, polyester, or a blend of materials, manufacturers in Chennai offer a wide range of fabric options tailored to different needs—be it for fashion brands, corporate uniforms, or custom event T-shirts.

Chennai's close proximity to cotton-growing regions like Tamil Nadu ensures that manufacturers have easy access to high-quality raw materials. This is one of the reasons why t shirt manufacturers in chennai can provide both affordability and excellent fabric quality, setting them apart from competitors.

The Role of Cutting and Sewing in Quality Assurance

Once the fabric is selected, the next step is cutting and sewing. Skilled artisans and modern machinery work together to ensure precise cutting and stitching. T shirt manufacturers in chennai use cutting-edge technology, including automated cutting machines, to reduce fabric waste and ensure each T-shirt is cut to the exact specifications.

The sewing process is equally important. Experienced seamstresses ensure that each T-shirt is sewn with attention to detail, ensuring durability and comfort. High-quality stitching not only enhances the appearance of the T-shirt but also adds to its overall lifespan. The final product is checked for consistency in stitching, fit, and finish, ensuring that every piece that leaves the factory meets the highest standards.

Printing and Customization: Precision and Innovation

One of the defining features of t shirt manufacturers in chennai is their ability to offer various printing techniques, from screen printing and direct-to-garment (DTG) printing to embroidery. The choice of printing method depends on factors like design complexity, color preferences, and order size.

For large orders, t shirt manufacturers in chennai typically prefer screen printing, as it allows for mass production while maintaining vibrant colors and fine details. DTG printing is ideal for more intricate, multicolored designs, offering high-resolution prints without the need for screens.

What sets Chennai manufacturers apart is their commitment to using eco-friendly inks and advanced printing technologies. For example, water-based inks and digital printing methods are gaining popularity due to their lower environmental impact and higher durability. By choosing such sustainable methods, t shirt manufacturers in chennai ensure that the final product is not only high-quality but also environmentally conscious.

Quality Control: Ensuring Consistency Across Bulk Orders

One of the biggest challenges for t shirt manufacturers in chennai is maintaining consistent quality, especially when handling large-scale orders. To meet this challenge, reputable manufacturers implement strict quality control measures at every stage of production.

Before the T-shirts are printed or embroidered, they undergo a thorough inspection. Any fabric defects are identified and rectified immediately. Similarly, once the T-shirts are printed, they undergo another round of inspection to ensure the design is aligned, and there are no defects in the print or fabric.

For bulk orders, t shirt manufacturers in chennai also conduct random sampling to check the quality across multiple units. This ensures that even if thousands of T-shirts are being produced, the final batch will have the same high quality as the first.

Meeting Deadlines Without Compromising Quality

Another key factor that sets t shirt manufacturers in chennai apart is their ability to meet deadlines without compromising on quality. Chennai’s manufacturers have honed their ability to produce large volumes of custom T-shirts quickly, thanks to years of experience in handling bulk orders for corporate clients, educational institutions, and fashion labels.

Efficient supply chain management, state-of-the-art machinery, and a skilled workforce enable manufacturers in Chennai to deliver quality products within tight deadlines. Whether you need custom T-shirts for an event in a week or a large order for a retail launch, t shirt manufacturers in chennai can meet your needs with precision and timeliness.

Sustainability and Ethical Manufacturing Practices

Sustainability is becoming an increasingly important factor in apparel production, and t shirt manufacturers in chennai are no exception. Many manufacturers are shifting towards sustainable production methods, from using eco-friendly dyes and water-based inks to sourcing organic cotton. These practices not only benefit the environment but also appeal to consumers who prioritize sustainability in their purchasing decisions.

Chennai’s manufacturers are also committed to ethical labor practices, ensuring fair wages and safe working conditions for their employees. This commitment to both sustainability and ethical manufacturing practices has made Chennai a preferred destination for global brands and entrepreneurs who value these principles.

Why Choose SK T-Shirts for Your Custom T-Shirt Manufacturing Needs?

If you’re looking for high-quality T-shirt manufacturing in Chennai, SK T-Shirts is the perfect choice. With a proven track record and a focus on delivering top-tier products at competitive prices, SK T-shirts stands out as one of the leading t shirt manufacturers in chennai.

Their team offers personalized consultations, high-quality fabrics, a wide range of customization options, and eco-friendly production methods. They ensure that every T-shirt that leaves their facility is crafted to perfection, meeting both your expectations and your budget.

Conclusion:

Ready to experience the best int shirt manufacturers in chennai Contact SK T-Shirts today to discuss your project needs. Whether you need bulk orders for your event, corporate branding, or a new fashion collection, their team is ready to provide you with high-quality, affordable solutions.t shirt manufacturers in chennai and make your vision a reality today!

0 notes

Text

Ink Receptive Coatings Market Witnesses Increased Application in Sustainable Paper and Film Alternatives

The ink receptive coatings market has seen substantial growth over the past decade, largely due to advancements in digital printing technologies, the rise of customization in consumer goods, and the increasing demand for sustainable printing solutions. However, like many markets, it has not been immune to volatility. Market volatility refers to the unpredictable and sometimes rapid changes in demand, pricing, supply chain stability, and input costs. In the case of ink receptive coatings, several factors ranging from raw material fluctuations to shifting industry demands contribute to this volatility. Understanding these factors is essential for manufacturers, suppliers, and end-users aiming to navigate and adapt to market uncertainties.

Supply Chain Disruptions and Raw Material Price Fluctuations

One of the key sources of volatility in the ink receptive coatings market is the fluctuation in raw material prices. Most ink receptive coatings are composed of complex chemical formulations that rely on polymers, resins, solvents, and other additives. Many of these inputs are derived from petrochemical sources, making them highly sensitive to changes in global oil prices and geopolitical tensions.

For instance, when oil prices surge due to conflict or regulatory constraints, the cost of production for solvent-based and even some water-based coatings rises. These increased production costs are often passed down the supply chain, affecting pricing and margins at multiple levels. Additionally, supply chain disruptions, such as those experienced during the COVID-19 pandemic or due to geopolitical unrest, can lead to delays in raw material procurement. This not only slows down manufacturing but also causes price spikes, adding to market unpredictability.

Shifting Regulatory Landscape

Environmental regulations are another major driver of market volatility. Around the world, governments are tightening regulations on the use of volatile organic compounds (VOCs) and other environmentally harmful substances found in certain types of coatings. While this has led to a positive shift toward eco-friendly formulations, it has also introduced instability for manufacturers that must rapidly adapt their formulations to stay compliant.

For example, new environmental rules may render a commonly used ingredient non-compliant, requiring reformulation or the search for alternative materials both of which take time and investment. This can temporarily disrupt production and affect market supply. Moreover, compliance costs can rise unpredictably as regions impose differing environmental standards, making it challenging for global manufacturers to maintain a consistent product line across markets.

Technological Shifts and Evolving End-Use Demands

The ink receptive coatings market is closely tied to the printing industry, which is itself undergoing rapid change. The rise of digital printing technologies such as inkjet and UV printing is reshaping the landscape, pushing demand for more specialized coatings that can handle a broader range of substrates and ink types.

However, this evolution also brings volatility. As new technologies emerge, older formulations may become obsolete, and demand can shift rapidly. Coating manufacturers must be agile, investing in R&D to stay relevant. At the same time, end-user industries from packaging to textiles to electronics are constantly updating their preferences and performance expectations. This can lead to fluctuations in demand, with sudden increases for some formulations and declines for others.

The growing trend toward personalization and short-run printing also introduces instability. While digital printing and ink receptive coatings are perfectly suited to meet these demands, they often require smaller batches and rapid formulation adjustments, making production and inventory management more complex.

Global Economic Uncertainty

Macroeconomic factors also play a significant role in market volatility. Economic slowdowns, inflation, currency fluctuations, and interest rate changes can affect both the demand for printed products and the investment capacity of manufacturers. For example, in times of economic uncertainty, businesses may cut back on marketing and packaging expenditures, leading to a temporary reduction in demand for ink receptive coatings.

Likewise, interest rate hikes and inflation can impact borrowing costs and operational expenses, making it harder for smaller coating manufacturers to invest in innovation or expand capacity. These macroeconomic pressures contribute to an uneven market landscape where sudden booms may be followed by equally sudden contractions.

Navigating Volatility: Strategies for Stakeholders

To address and adapt to market volatility, stakeholders in the ink receptive coatings sector are adopting several strategies:

Diversification of raw material sources to minimize the impact of supply chain disruptions.

Investment in research and development to stay ahead of technological changes and evolving customer needs.

Agile manufacturing practices that allow for quick formulation changes and batch flexibility.

Geographical diversification to spread risk across multiple markets and regulatory environments.

By embracing these strategies, companies can not only cushion themselves against volatility but also find new avenues for growth and innovation.

Conclusion

The ink receptive coatings market, while full of promise, is subject to a range of volatile forces. From supply chain instability and raw material price swings to regulatory shifts and technological disruption, stakeholders must remain vigilant and adaptable. Volatility, while challenging, can also drive innovation pushing companies to become more resilient, responsive, and forward-thinking in their approach. For those willing to invest in agility and innovation, the ink receptive coatings market continues to offer significant opportunities despite its inherent unpredictability.

0 notes

Text

Emerging Trends in the Latin America Large Format Printer Market

The global large format printer market is expected to reach USD 12.70 billion by 2030, with a CAGR of 5.0% from 2024 to 2030, as per a report by Grand View Research, Inc. This growth is primarily driven by the increasing demand for large format printers across a wide range of industries such as advertising, packaging, textiles, and decor. Businesses are increasingly relying on these printers to create visually striking materials for out-of-home advertising, signage, banners, and building wraps, all aimed at attracting target audiences and boosting sales revenue.

One of the major factors contributing to the growth of this market is the adoption of UV-curable inks. These inks have had a significant impact on the industry due to their various benefits, which include fast drying times, outdoor durability, and reduced operating costs. UV-curable inks also help increase productivity by reducing the time needed for prints to dry, and they decrease ink usage, which contributes to cost savings and enhances the overall efficiency of the printing process. This shift toward UV inks is fueling greater demand for large format printers across various sectors.

Technological advancements in the printing industry are also driving the market. Improvements in ink formulations, print head designs, and color management systems have enhanced the capabilities and versatility of large format printers, making them more efficient and accessible to a broader range of industries. These innovations have led to higher-quality prints and faster production times, making large format printers even more attractive for businesses looking to produce high-quality, large-scale materials.

In addition to technological improvements, the demand for visually compelling and dynamic advertising displays is on the rise, especially with the growth of digital marketing initiatives. Companies are increasingly turning to large format printers to produce signage, banners, and posters that grab attention and effectively communicate their brand messages. This is particularly important in industries where outdoor advertising and point-of-purchase displays are key drivers for attracting customers and increasing sales.

Moreover, the growing trend of customization and personalization in marketing strategies has contributed to the expansion of the large format printer market. Businesses are seeking printing solutions that allow them to produce variable data prints and short print runs, enabling them to tailor their advertising materials to individual customer needs and preferences. As customization becomes more integral to marketing campaigns, the demand for large format printers capable of delivering such services continues to grow.

Overall, the combination of technological advancements, the increasing need for dynamic marketing materials, and the shift towards more personalized and efficient printing solutions is driving the growth of the global large format printer market. As industries continue to rely on eye-catching visuals to capture customer attention and deliver targeted messaging, the market for large format printers is expected to thrive well into the future.

Get a preview of the latest developments in the Large Format Printer Market? Download your FREE sample PDF copy today and explore key data and trends.

Global Large Format Printer Market: Frequently Asked Questions (FAQ)

1. What is the projected size of the global large format printer market?

The global large format printer market was valued at USD 9.11 billion in 2023 and is projected to reach USD 12.70 billion by 2030, growing at a CAGR of 5.0% from 2024 to 2030.

2. Which industries are the primary users of large format printers?

Key industries utilizing large format printers include:

• Advertising & Signage: For creating banners, billboards, and building wraps.

• Packaging: For producing large-scale packaging materials.

• Textiles: For printing on fabrics and apparel.

• Decor: For producing wall art and interior decorations.

• CAD & Technical Printing: For architectural and engineering designs.

3. Which region leads the large format printer market?

North America dominated the market with a revenue share of 34.4% in 2023, driven by investments in infrastructure projects, construction, and advertising across various industries.

4. What are the major segments in the large format printer market?

The market is segmented by:

• Technology: Ink-based and toner-based printers.

• Ink Type: Aqueous, solvent, UV-cured, latex, and dye-sublimation inks.

• Printing Material: Porous and non-porous materials.

• Connectivity: Wired and wireless options.

• Print Width: Ranges from 17" to 72" and above.

• Application: Includes signage, decor, apparel, and CAD printing.

• Region: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

5. Who are the key players in the healthcare education market?

• ARC Document Solutions, LLC

• Canon Inc.

• Dover Corporation

• Durst Group AG

• Electronics For Imaging, Inc.

• HP Development Company, L.P.

• Konica Minolta Holdings, Inc.

• MIMAKI ENGINEERING CO., LTD.

• Mutoh

• Ricoh

Order a free sample PDF of the Large Format Printer Market Intelligence Study, published by Grand View Research.

#Large Format Printer Market#Large Format Printer Market Size#Large Format Printer Market Share#Large Format Printer Market Analysis

0 notes

Text

Tech Meets Textile: The Future of Custom Printed Fabric

In the ever-evolving world of fashion and design, custom printed fabric has emerged as a game-changer, blending creativity with cutting-edge technology. Gone are the days when fabric choices were limited to mass-produced patterns. Today, the ability to personalize textiles has opened up endless possibilities for designers, brands, and even individual creators. But what does the future hold for this innovative sector? Let's dive into how technology is reshaping the textile industry and what lies ahead for custom fabric printing.

The Rise of Digital Print Fabric

At the heart of this transformation is digital printing technology. Unlike traditional methods, which often involve time-consuming and costly processes, digital printing allows for precise, high-quality designs to be transferred directly onto fabric. This not only reduces waste but also enables small-batch production, making it easier for emerging designers to bring their visions to life. With the ability to print intricate patterns and vibrant colors on demand, digital printing is democratizing the textile industry, empowering creators to experiment without the constraints of large minimum orders.

China's Role in Print Fabric Innovation

When it comes to global textile production, China print fabric manufacturers are at the forefront. Known for their expertise in both traditional and modern textile techniques, Chinese companies are embracing digital printing innovations to meet the growing demand for customization. From high-fashion runways to everyday apparel, China's fabric printing industry is setting new standards in quality and efficiency. As sustainability becomes a priority, many Chinese manufacturers are also adopting eco-friendly practices, such as waterless printing and the use of organic materials, further enhancing their appeal in the global market.

The Art of Print Design on Fabric

While technology provides the tools, the true magic lies in the creativity behind print design on fabric. Designers are no longer bound by the limitations of screen printing or dyeing techniques. Instead, they can experiment with complex patterns, gradients, and even photographic images, all while maintaining the fabric's texture and durability. This freedom has led to a surge in unique, one-of-a-kind textiles that reflect personal stories, cultural influences, and artistic expression. As consumers increasingly seek out products that resonate with their individuality, the demand for bespoke fabric designs is only set to grow.

The Future: Personalization, Sustainability, and Smart Textiles

Looking ahead, the future of custom printed fabric is bright and is being influenced by 3 key trends:

Personalization: As consumers crave unique products, the ability to customize everything from clothing to home décor will become standard. Imagine designing your own fabric patterns from a smartphone app and having them printed on demand.

Sustainability: With growing awareness of fashion's environmental impact, eco-friendly printing methods and materials will dominate. Expect to see more fabrics made from recycled fibers and printed with non-toxic inks.

Smart Textiles: The integration of technology into fabric is already underway. From fabrics that change color based on temperature to those embedded with sensors, the line between tech and textile is blurring.

Pioneering the Future of Custom Fabric

At the forefront of this exciting movement is Prinstitch, a company dedicated to pushing the boundaries of custom fabric printing. By combining state-of-the-art digital technology with a passion for design, this company is helping creators and brands bring their boldest ideas to life. Whether you're a designer looking to launch a new collection or an individual seeking a unique fabric for your next project, we provide you with all the tools and expertise you need to make your dreams come true.

As technology continues to meet textile in innovative ways, the future of custom printed fabric is not just about what we wear - it's about how we express ourselves, protect our planet, and embrace the digital age. The possibilities are endless, and the journey has only just begun.

0 notes

Text

Understanding the Technology Behind Modern Printing Machines

In today’s fast-paced fashion and textile industries, staying ahead means embracing cutting-edge technology. Modern printing machines have come a long way, transforming how businesses approach textile printing with increased speed, accuracy, and customization. Whether you're in apparel, home décor, or promotional goods, understanding how these machines work can help you make better decisions for your production process.

From Traditional to Digital: The Evolution of Textile Printing

For decades, traditional screen printing dominated the textile world. While effective for large orders, it had limitations in terms of design complexity and color variation. Today, digital textile printing has revolutionized the industry by offering more efficient, flexible, and eco-friendly solutions.

Digital textile printers use inkjet technology to apply designs directly onto fabric. This method allows for high-resolution, full-color prints without the need for screens or plates. For businesses looking to produce small runs or highly detailed prints, this is a game-changer.

The Rise of Sublimation Printing

Among modern methods, sublimation printing stands out for its ability to deliver vibrant, long-lasting designs on polyester fabrics. Sublimation works by turning solid dye into gas, which then bonds with the fabric at a molecular level. The result? Prints that don’t crack, peel, or fade over time.

Because it embeds the design into the fabric rather than placing it on top, sublimation is ideal for sportswear, activewear, and custom fashion. It’s no wonder it’s become a preferred choice in the world of textile printing.

Key Features of a Modern Printing Machine

Today’s printing machines are built with advanced features that enhance productivity and print quality. Here are a few standout elements:

High-Speed Performance: Machines today can print hundreds of meters per hour without compromising quality.

Precision Ink Delivery: Digital heads can place ink with pinpoint accuracy, essential for photo-quality prints.

Automated Workflow: Integrated software handles everything from file setup to color management.

Eco-Friendly Inks: Many machines now use water-based inks, reducing the environmental footprint of textile production.

These innovations are not only improving outcomes but also making printing more accessible to small and medium-sized businesses.

How True Colors Group Leverages Modern Printing Tech

At True Colors Group, we combine the power of digital textile printing, sublimation printing, and advanced printing machines to deliver premium quality fabric prints to our clients. Our state-of-the-art equipment ensures vibrant colors, sharp details, and durable finishes that meet the highest industry standards.

Whether you're a fashion designer, interior decorator, or custom product seller, our solutions are tailored to help you bring your vision to life. With a commitment to quality and innovation, True Colors Group continues to lead the way in the textile printing industry.

Conclusion

Modern printing machines have completely redefined the landscape of textile printing. With technologies like digital textile printing and sublimation printing, businesses now enjoy unmatched design flexibility, quality, and sustainability. By partnering with experienced providers like True Colors Group, you can unlock the full potential of these innovations and keep your brand ahead of the curve.

0 notes

Text

The DTG Printing Process Explained: A Step-by-Step Guide for Beginners

Direct-to-Garment (DTG) printing has revolutionized the custom apparel industry. With its ability to produce high-quality prints directly onto fabric, DTG is the go-to solution for designers, small business owners, and hobbyists looking to bring their creative visions to life. Whether you're thinking of starting a clothing line or simply curious about how this technology works, understanding the DTG process is essential. This beginner’s guide breaks down the DTG printing workflow step-by-step, so you can grasp how garments are transformed into wearable art.

What is DTG Printing?

DTG printing is a digital process that uses specialized inkjet technology to print designs directly onto textiles, typically cotton-based garments. Unlike traditional screen printing, which involves using stencils and layers of ink, DTG is more flexible and suited for small-batch orders or intricate designs with many colors and fine details. The process uses water-based inks that are absorbed by the fabric fibers, producing a smooth, soft finish with excellent color vibrancy.

Step 1: Preparing the Artwork

Every DTG print starts with a digital design file. Most DTG printers support common formats such as PNG, TIFF, or high-resolution JPEGs. The image should be created or edited in design software like Adobe Photoshop or Illustrator to ensure high quality and the correct dimensions. It’s crucial to use a transparent background and a resolution of at least 300 DPI (dots per inch) for crisp results.

Design placement is also key. Before printing, you’ll decide where the image will appear on the garment — typically centered on the chest or back. Good artwork preparation avoids common issues such as pixelation, blurred edges, or awkward sizing once printed.

Step 2: Pretreating the Garment

Pretreatment is a critical step in the DTG process, especially for dark-colored fabrics. The pretreatment liquid acts as a primer that helps the white ink adhere to the surface of the fabric, ensuring the colors stay vibrant and don’t soak into the material. Without pretreatment, prints may appear dull or washed out.

The garment is sprayed evenly with the pretreatment solution and then dried using a heat press or tunnel dryer. Proper drying ensures the shirt is smooth and flat, which allows the ink to lay properly during printing.

Step 3: Loading the Garment

Once the shirt is pretreated and dry, it’s time to load it onto the DTG printer’s platen. The platen is the flat surface that holds the garment in place during printing. It’s essential to align the shirt properly to avoid any crooked or misaligned prints.

The garment must be smooth and wrinkle-free, as any folds can disrupt the ink flow. Adjustments are made to center the print area and secure the shirt so that it doesn’t shift during the process.

Step 4: Printing the Design

With everything in place, the printer starts the process by applying white ink as a base layer (if the garment is dark). Then, it prints the full-color design on top. On light-colored fabrics, white ink may not be necessary, and the printer can apply the colors directly.

DTG printers use CMYK (Cyan, Magenta, Yellow, and Black) ink to mix and reproduce a wide range of hues. The ink is jetted onto the fabric with precision, and the colors are layered smoothly to create sharp, vibrant images. This stage can take a few minutes per shirt, depending on the complexity and size of the design.

Step 5: Curing the Print

After the design is printed, it’s not yet ready to wear. The ink needs to be cured to bond permanently with the fabric. This is typically done using a heat press or a conveyor dryer. Curing temperatures usually range between 320°F and 360°F and take around 90 to 180 seconds, depending on the equipment used.

Curing solidifies the ink and makes the print durable and washable. Skipping or rushing this step can lead to cracking, fading, or premature wear of the design.

Step 6: Final Inspection and Packaging

Once the ink is fully cured, the garment is cooled and inspected for quality. This includes checking for color consistency, alignment, and any imperfections in the print. If the design passes inspection, the shirt is folded, packaged, and ready for delivery or sale.

Proper storage and handling at this stage ensure that the final product remains in perfect condition until it reaches the customer.

Conclusion

DTG printing combines modern technology with creative freedom, making it a powerful option for producing high-quality custom apparel. Its ease of use, minimal setup, and ability to handle detailed artwork make it ideal for on-demand printing and small business ventures. By following the DTG process from artwork preparation to curing, you can achieve professional-grade results that both look and feel great.

Whether you're launching a brand or printing your first shirt, understanding the DTG process helps you make informed decisions and avoid costly mistakes. The more you practice and refine your workflow, the better your results will be.

0 notes

Text

Printing Ink and Toner Market: Growth Driven by Packaging, Sustainability, and Technological Advancements

The global printing ink and toner market has undergone significant transformation over the years, shaped by evolving consumer needs, technological advancements, and changing industrial applications. These products—critical to both commercial and consumer printing—are essential across various industries, from publishing and packaging to textiles and electronics. The market is driven by several key factors that continue to shape its growth trajectory and strategic direction.

1. Growth in Packaging and Labeling Industry

One of the most prominent drivers of the printing ink and toner market is the rapid expansion of the packaging and labeling sector. As consumer demand for packaged goods increases, especially in emerging economies, the need for high-quality and visually appealing packaging grows in parallel. Printing inks and toners are essential in achieving attractive, durable, and informative packaging. This trend is particularly strong in the food and beverage, cosmetics, and pharmaceutical sectors, where branding and regulatory information are critical.

Additionally, the rise of e-commerce has amplified the need for packaged goods, resulting in greater usage of labels and printed shipping materials. This surge in online shopping has increased demand for both functional and aesthetic packaging, reinforcing the importance of printing materials in the supply chain.

2. Technological Advancements in Printing

The development and adoption of advanced printing technologies, such as digital printing, inkjet, and laser printing, have fueled the growth of the ink and toner market. Digital printing, in particular, has revolutionized the industry by offering flexibility, reduced turnaround times, and cost-effective short runs. These advantages are especially beneficial for small and medium-sized enterprises (SMEs) that require customized packaging or promotional materials.

In parallel, innovations in ink formulations—such as UV-curable, water-based, and eco-solvent inks—have improved performance, sustainability, and versatility. These new formulations cater to a broader range of substrates and applications, including textiles, ceramics, and electronics. As print technology continues to evolve, so does the demand for high-performance inks and toners that can support these capabilities.

3. Environmental Regulations and Demand for Sustainable Solutions

Environmental concerns and regulatory mandates are compelling manufacturers to develop eco-friendly inks and toners. Traditional solvent-based inks have been criticized for their volatile organic compounds (VOCs), which contribute to air pollution and pose health risks. In response, the industry has seen a significant shift toward sustainable alternatives such as water-based, soy-based, and bio-based inks.

These alternatives not only meet regulatory requirements but also align with growing consumer awareness and demand for sustainable products. In many markets, especially across Europe and North America, sustainability is no longer optional—it is a competitive necessity. Companies that can offer environmentally responsible printing solutions are more likely to secure partnerships with eco-conscious brands and institutions.

4. Expansion of the Textile and Apparel Printing Market

The growth of digital textile printing is another important driver. The fashion and home décor sectors have increasingly embraced digital printing due to its design flexibility, lower waste generation, and rapid prototyping capabilities. Inks designed specifically for fabrics—such as sublimation, reactive, and pigment inks—are seeing increased demand.

This trend is further fueled by the customization boom, where consumers and businesses alike seek personalized apparel, accessories, and interiors. As a result, the printing ink industry is investing heavily in R&D to develop ink systems that deliver vibrant, long-lasting colors on various textile materials.

5. Commercial Printing and Publishing Resilience

Although digital media has affected traditional publishing, commercial printing remains an enduring market segment, particularly in regions where physical media still dominates education, advertising, and documentation. Books, magazines, brochures, and promotional materials continue to be printed in large quantities, especially in developing economies with growing literacy rates.

Moreover, certain niches within publishing, such as art books, coffee table editions, and limited-run publications, have maintained steady demand. These applications often require premium inks that deliver high-definition print quality and color accuracy.

6. Rapid Industrialization and Urbanization in Emerging Economies

Emerging markets in Asia-Pacific, Latin America, and Africa are seeing rapid urbanization and industrial expansion, leading to increased demand for printed materials across sectors. From consumer packaging to administrative documents, these economies rely heavily on printed content for communication, branding, and operational efficiency.

As infrastructure develops, so too does the retail, healthcare, and education sectors—each of which contributes to rising consumption of printing inks and toners. Furthermore, the presence of cost-effective labor and manufacturing capabilities in these regions encourages the establishment of printing and packaging hubs.

Conclusion

The global printing ink and toner market is being propelled by a complex interplay of technological, economic, and environmental factors. The shift toward digital and sustainable printing, coupled with rising demand from industries such as packaging, textiles, and commercial printing, continues to drive innovation and investment. Market players must remain agile, continuously innovating to meet evolving customer needs, comply with environmental standards, and leverage emerging market opportunities. As industries increasingly embrace customization, sustainability, and digital workflows, the printing ink and toner sector is well-positioned for steady, diversified growth.

0 notes