#Textile Printing Ink Exporter

Explore tagged Tumblr posts

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

TEXTILE DESIGN IN 2023-24

Overview of top textile importer, exporter countries & manufacturing industries. Textile design is the art of creating designs for woven, knitted, or printed fabrics. It is an integral part of the textile industry, which encompasses the production of fibers, yarns, fabrics, and finished textile products. Textile design is a vast field that encompasses a wide range of techniques and processes, including drawing, painting, printing, weaving, and embroidery. In this article, we will explore the history of textile design, the various techniques used in textile design, and the current trends in the field. History of Textile Design Textile design has a long and rich history that dates back to prehistoric times. The first textiles were made by hand using natural fibers such as flax, cotton, and wool. These fibers were spun into yarn and woven into fabrics using simple looms. Textiles were used for clothing, bedding, and household items such as curtains and tablecloths. Over time, textile design became more complex as new techniques and materials were developed. The introduction of the spinning wheel in the Middle Ages allowed for the production of finer and more even yarns. The invention of the Jacquard loom in the 18th century enabled the production of intricate patterns and designs. The Industrial Revolution in the 19th century brought about significant changes in the textile industry, with the introduction of mechanized production methods. In the 20th century, textile design became an art form in its own right. The development of new synthetic fibers such as nylon and polyester allowed for new possibilities in textile design. The Bauhaus school, founded in Germany in 1919, played a significant role in the development of modern textile design. The school's emphasis on functional design and the use of new materials and techniques had a profound influence on the field. Techniques Used in Textile Design Textile design encompasses a wide range of techniques and processes. Some of the most common techniques used in textile design include: Drawing and Painting: Many textile designs begin as drawings or paintings. Designers use a variety of media, including pencil, pen, ink, and watercolor, to create designs that are then transferred to fabric. Printing: Printing is a common technique used in textile design. Designs are created on paper using a variety of techniques, such as block printing, screen printing, and digital printing. The designs are then transferred onto fabric using heat or pressure. Weaving: Weaving is the process of interlacing two or more sets of yarns or threads at right angles to create a fabric. Weaving can be done by hand on a loom or by machine. Knitting: Knitting is a technique used to create fabrics by interlocking loops of yarn. Knitting can be done by hand or by machine. Embroidery: Embroidery is the art of decorating fabric or other materials with needle and thread. It is often used to add texture and dimension to textile designs. Current Trends in Textile Design Textile design is a constantly evolving field, with new techniques and materials being developed all the time. Some of the current trends in textile design include: Sustainability: The textile industry is one of the most polluting industries in the world, and there is a growing trend towards sustainable textile design. This includes the use of organic and recycled materials, as well as the development of eco-friendly production methods. Digital Printing: Digital printing is a relatively new technique in textile design that allows designers to create complex designs with a high level of detail. It is also more environmentally friendly than traditional printing methods, as it uses less water and produces less waste. 3D Printing: 3D printing is a cutting-edge technology that is being used in textile design to create innovative fabrics with a variety of textures and shapes. Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive. Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive. They incorporate electronic components such as sensors, actuators, and microcontrollers to enable the fabric to sense and respond to its environment. Smart textiles can be used in a wide range of applications, from fashion to medical devices. For example, smart textiles can be used in clothing to monitor vital signs and adjust temperature, or in bedding to monitor sleep patterns and adjust the bed's firmness. Innovation in Materials: There is a growing trend towards innovation in materials in textile design. Designers are exploring new materials, such as sustainable and bio-based materials, to create fabrics with unique properties. For example, fabrics made from bamboo, soy, or hemp are becoming more popular due to their sustainable and eco-friendly properties. Mixing of Textures and Prints: There is a trend towards mixing different textures and prints in textile design. Designers are using contrasting textures and prints to create bold and visually striking designs. This trend is evident in fashion, where designers are using a combination of textures such as silk and velvet or prints such as stripes and florals to create unique and eye-catching garments. Digital Fabrication: Digital fabrication is the use of digital tools such as computer-aided design (CAD) and 3D printing to create textiles. This technique allows designers to create complex designs with a high degree of precision and accuracy. Digital fabrication is particularly useful for creating one-of-a-kind textiles or small production runs. Collaboration and Interdisciplinary Work: Collaboration and interdisciplinary work are becoming increasingly important in textile design. Designers are working with scientists, engineers, and other professionals to develop new materials and technologies. This collaborative approach is leading to innovative solutions and new possibilities in textile design. Textile design is a dynamic and constantly evolving field. From the early hand-woven textiles to the cutting-edge smart textiles of today, textile design has come a long way. The field encompasses a wide range of techniques and processes, from drawing and painting to digital fabrication and smart textiles. With the growing focus on sustainability and innovation, textile design is poised to continue to evolve and shape the future of fashion, interior design, and other related industries. TOP TEXTIL EXPORTER COUNTRY The textile industry is a global industry, with many countries producing and exporting textiles. The top textile exporting countries in the world are: - China: China is the world's largest exporter of textiles, accounting for around 35% of global textile exports. The country has a strong manufacturing base and is known for its production of cotton, silk, and woolen textiles. - India: India is the second-largest exporter of textiles in the world, with a share of around 12% of global textile exports. The country is known for its production of cotton textiles, including handloom textiles, and is also a significant exporter of silk and woolen textiles. - Bangladesh: Bangladesh is the third-largest exporter of textiles, with a share of around 6% of global textile exports. The country is known for its production of low-cost cotton textiles and is a major supplier to many western clothing brands. - Vietnam: Vietnam is the fourth-largest exporter of textiles, accounting for around 5% of global textile exports. The country has a growing textile industry and is known for its production of cotton and synthetic textiles. - Turkey: Turkey is the fifth-largest exporter of textiles, with a share of around 4% of global textile exports. The country has a well-established textile industry and is known for its production of high-quality cotton textiles and home textiles. Other significant textile exporting countries include Pakistan, Italy, Germany, Indonesia, and the United States. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth. TOP TEXTILE IMPORTER COUNTRIES The global textile trade is driven by demand from textile importing countries that rely on textile imports to meet their domestic demand. The top textile importing countries in the world are: - United States: The United States is the world's largest textile importer, accounting for around 16% of global textile imports. The country has a significant textile industry but also relies on imports to meet the demand for a wide range of textile products. - Germany: Germany is the second-largest textile importer, with a share of around 9% of global textile imports. The country has a well-established textile industry but also imports a significant amount of textiles to meet the demand for high-quality fabrics. - Japan: Japan is the third-largest textile importer, accounting for around 8% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for a wide range of consumer products, including clothing and home textiles. - United Kingdom: The United Kingdom is the fourth-largest textile importer, with a share of around 6% of global textile imports. The country has a significant textile industry but also imports a significant amount of textiles to meet the demand for a wide range of products. - France: France is the fifth-largest textile importer, accounting for around 4% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for high-quality fabrics and luxury goods. Other significant textile importing countries include Italy, Spain, Canada, Russia, and China. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth. TOP TEXTIL MANUFACTURING COMPANY The textile manufacturing industry is a highly competitive industry with many companies vying for market share. The top textile manufacturing companies in the world are: - China National Textile and Apparel Council (CNTAC): CNTAC is the world's largest textile manufacturing company. It is a state-owned enterprise that has a dominant position in the Chinese textile industry. CNTAC operates a large number of textile mills and produces a wide range of textile products, including cotton, silk, wool, and synthetic fabrics. - Indorama Ventures: Indorama Ventures is a global chemical and textile manufacturing company with a presence in more than 30 countries. The company produces a wide range of textile products, including polyester, nylon, and spandex fabrics. - Luthai Textile: Luthai Textile is a leading textile manufacturing company based in China. The company produces a wide range of cotton and polyester fabrics, including high-quality shirting fabrics. - Vardhman Textiles: Vardhman Textiles is one of the largest textile manufacturing companies in India. The company produces a wide range of cotton and synthetic fabrics, including home textiles, garments, and yarns. - Hyosung Corporation: Hyosung Corporation is a South Korean company that produces a wide range of textile products, including polyester, nylon, and spandex fabrics. The company has a significant global presence and operates textile mills in several countries. Other significant textile manufacturing companies include Toray Industries, Inc., Teijin Limited, Milliken & Company, and Arvind Limited. These companies are known for their high-quality textile products, innovative technologies, and sustainable manufacturing practices. TOP 10 BEST DIGITAL TEXTILE DESIGN COMPANIES The textile industry has rapidly adopted digital technologies, leading to the emergence of several digital textile design companies. The top 11 best digital textile design companies are:

- Mahashankh Design: Mahashankh Design is a India-based company that offers world most complex & convertible digital designs services in two format 1. Shared Design : in Shared Design copyright of design will remains to mahashankh design before the payment & After the payment only they have right to use in personal projects. 2. Dedicated Design : in Dedicated Design all rights will be goes to customer after payment . - Spoonflower: Spoonflower is a US-based company that offers digital printing services for custom fabric, wallpaper, and gift wrap designs. The company's platform allows customers to upload their designs and have them printed on a range of fabrics. - Printful: Printful is a Latvian-based company that offers on-demand printing and fulfillment services for custom apparel, home decor, and accessories. The company's platform allows customers to upload their designs and have them printed on a range of products. - Patternbank: Patternbank is a UK-based company that provides trend forecasting and digital textile design services to the fashion and textile industries. The company's platform offers a range of design tools and resources to help designers create unique and innovative designs. - Kornit Digital: Kornit Digital is an Israeli-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - Lectra: Lectra is a French-based company that offers software and hardware solutions for the fashion and textile industries. The company's platform includes design software, cutting machines, and automation tools designed to help manufacturers improve their production efficiency. - Epson: Epson is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - EFI: EFI is a US-based company that offers software and hardware solutions for the textile industry. The company's platform includes design software, printers, and automation tools designed to help manufacturers improve their production efficiency. - AVA CAD/CAM Group: AVA CAD/CAM Group is a UK-based company that provides digital textile design and print solutions to the fashion and textile industries. The company's platform includes design software, color management tools, and production planning tools designed to help textile manufacturers and designers improve their efficiency. - Mutoh: Mutoh is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - HP: HP is a US-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. These digital textile design companies are known for their innovative solutions and their ability to help designers and manufacturers create unique and high-quality textile products. Read the full article

3 notes

·

View notes

Text

Comprehensive Guide to Different Types of Dyes and Their Chemical Structures

Dyes are integral to industries like textiles, paper, plastics, and leather, providing a diverse palette of colors and properties tailored to specific needs. This guide delves into various dye types, their characteristics, and their chemical structures. Meghmani Global, a prominent manufacturer and supplier of dyes, plays a vital role in delivering sustainable and high-quality dye solutions worldwide.

1. Natural Dyes

Source: Derived from natural substances like plants, minerals, and insects.

Examples: Indigo (from plants), cochineal (from insects).

Applications: Eco-friendly options for textiles, food coloring, and cosmetics.

Chemical Structure: Composed of complex organic molecules like anthraquinones and flavonoids.

Read blog on Different Types of Dyes with Chemical Structure

2. Synthetic Dyes

Source: Produced chemically from petroleum derivatives.

Advantages: Vibrant colors, higher durability, and cost-effectiveness.

Categories: Includes several subtypes such as azo dyes and anthraquinone dyes.

Chemical Structure: Often includes azo groups (-N=N-) or aromatic rings.

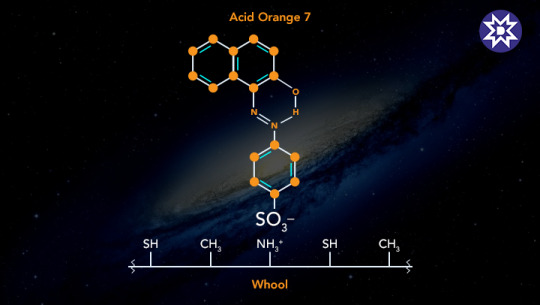

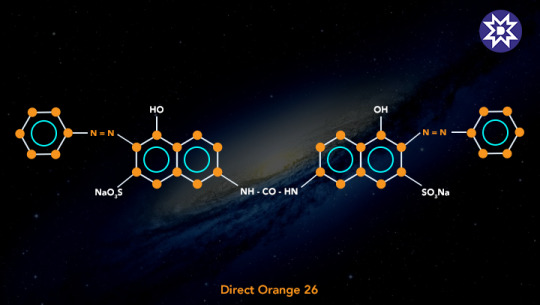

3. Direct Dyes

Features: Water-soluble and directly applied to materials like cotton and rayon.

Usage: Popular for dyeing cellulose fibers due to ease of application.

Chemical Structure: Contain azo or stilbene groups with water-solubilizing sulfonic acid groups.

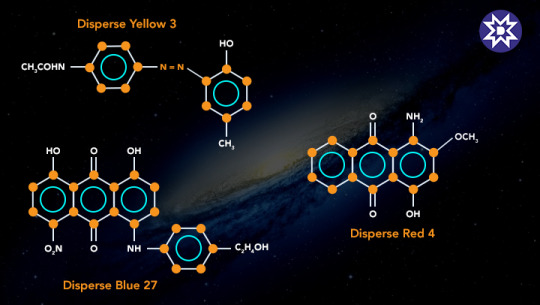

4. Disperse Dyes

Purpose: Designed for hydrophobic fibers like polyester and acetate.

Mechanism: Submicron particles are dispersed in water and absorbed by fibers under heat.

Applications: Used in textile printing and synthetic fiber dyeing.

Chemical Structure: Non-ionic, often featuring anthraquinone or azo structures.

5. Reactive Dyes

Features: Chemically bond with fibers, offering excellent colorfastness.

Applications: Ideal for natural fibers like cotton and wool.

Advantages: High wash fastness and vibrant shades.

Chemical Structure: Contain reactive groups (e.g., triazine) that form covalent bonds with fibers.

6. Solvent Dyes

Characteristics: Soluble in organic solvents but not water.

Applications: Used in plastics, inks, and petroleum products.

Advantages: Stability and vivid colors for industrial applications.

Chemical Structure: Non-polar molecules with aromatic and azo groups.

Meghmani Global: A Leader in Dye Manufacturing

Meghmani Global specializes in producing a comprehensive range of dyes, including reactive, direct, and solvent dyes. With over 27 manufacturing units and a global presence in 60+ countries, the company is known for its innovative products, sustainable practices, and commitment to quality. Our focus on eco-friendly processes and advanced technologies ensures compliance with international standards while minimizing environmental impact.

Conclusion

Understanding the types of dyes and their chemical structures is essential for optimizing applications in industries. From natural and reactive dyes to solvent and disperse dyes, each type offers unique benefits and uses. Meghmani Global exemplifies leadership in this sector, combining innovation with environmental stewardship to meet diverse market demands.

Get in touch

Email: [email protected]

Contact: 7926812918 | Contact Us

Website: https://www.meghmaniglobal.com/

0 notes

Text

Custom Solutions: Tailoring Rubber Rollers to Meet Specific Industry Needs at Anar Rubber

In the world of manufacturing, one-size-fits-all solutions are often not enough to meet the specific needs of various industries. At Anar Rubber, the company understands the importance of customization and offers tailored rubber roller exporter to meet the unique requirements of its clients. In this article, we will explore how Anar Rubber provides custom solutions for rubber rollers, catering to the diverse needs of various industries.

Understanding Industry-Specific Needs

Anar Rubber's team of experts takes the time to understand the specific needs of each industry, from printing and textile to food processing and pharmaceuticals. By working closely with clients, Anar Rubber's engineers and designers gain a deep understanding of the challenges and requirements of each industry. This knowledge is then used to develop customized rubber rollers that meet the exact specifications of each client. Whether it's a specific material, size, or surface finish, Anar Rubber's team is dedicated to delivering tailored solutions that meet the unique needs of each industry.

Material Selection

Anar Rubber offers a wide range of materials for its rubber rollers, each with its own unique properties and characteristics. From natural rubber to synthetic rubber, and from silicone to polyurethane, the company's team of experts helps clients select the best material for their specific application. By considering factors such as temperature, chemical resistance, and abrasion resistance, Anar Rubber's team ensures that the selected material meets the exact requirements of each industry. This attention to detail and commitment to quality ensures that Anar Rubber's rubber rollers deliver optimal performance and durability.

Customized Surface Finishes

Anar Rubber's rubber rollers can be customized with a variety of surface finishes, each designed to meet the specific needs of various industries. From smooth and glossy to textured and matte, the company's team of experts works with clients to develop the perfect surface finish for their application. By considering factors such as ink transfer, material handling, and product release, Anar Rubber's team ensures that the surface finish of its rubber rollers meets the exact requirements of each industry.

Size and Shape Options

Anar Rubber's rubber rollers are available in a wide range of sizes and shapes, each designed to meet the specific needs of various industries. From small and intricate to large and complex, the company's team of experts works with clients to develop customized rubber rollers that fit their exact specifications. By considering factors such as equipment design, material handling, and product size, Anar Rubber's team ensures that its rubber rollers meet the unique needs of each industry.

Specialized Coatings and Treatments

Anar Rubber's rubber rollers can be customized with specialized coatings and treatments, each designed to meet the specific needs of various industries. From anti-static coatings to chemical-resistant treatments, the company's team of experts works with clients to develop the perfect coating or treatment for their application. By considering factors such as material compatibility, product safety, and equipment performance, Anar Rubber's team ensures that its rubber rollers deliver optimal performance and durability.

Industry-Specific Solutions

Anar Rubber has developed a range of industry-specific solutions, each designed to meet the unique needs of various industries. From printing and textile to food processing and pharmaceuticals, the company's team of experts has developed customized rubber rollers that cater to the specific requirements of each industry. By working closely with clients and understanding their specific needs, Anar Rubber's team is able to deliver tailored solutions that meet the exact specifications of each industry.

Conclusion

In conclusion, Anar Rubber's commitment to customization and industry-specific solutions sets it apart from other rubber roller manufacturers. By working closely with clients and understanding their specific needs, Anar Rubber's team of experts is able to deliver tailored solutions that meet the exact requirements of various industries. Whether it's a specific material, size, surface finish, or coating, Anar Rubber's team is dedicated to delivering customized rubber rollers that deliver optimal performance and durability.

0 notes

Text

Pearl Pigment Powder by Jinoyal Industries Pvt Ltd

Jinoyal Industries Pvt. Ltd. is one of the established exporters of high-quality pearl pigment powder, serving diverse markets around the globe. Our pearl pigment powder comes with rich, bright, highly pleasing hues and an excellent luster. It comes with many different applications, thereby providing a premium that carries for each product.

Applications of Pearl Pigment Powder

Jinoyal Industries Pvt Ltd’ pearl pigment powder is widely used in several industries to capture the aesthetic appeal and functionality:

Cosmetics: Used in large quantities for making-up products such as eye-shadows, lipsticks, nail polishes, and highlighters for their glittering appearance and luxurious finish.

Paints and Coatings: Provides metallic or preadolescent effects for automotive paints, furniture coatings, and industrial finishes.

Plastics: Suitable for use in decorative effects in packaging, toys, and household items

Printing Inks: Gravure, screen, and offset printing; decorative printed or special designs on packaging, labels, and greeting cards.

Textiles: Adds a rich, glossy, and unique finish to fabric printing and dyeing.

Ceramics and Glass: Gives a wonderful, luxurious feel to the end product, with exquisite designs on tiles, ceramics, and ornamental glassware.

Art and Crafts: Excellent for creating DIY art pieces or resin crafts.

At Jinoyal Industries Pvt Ltd, we ensure that our pearl pigment powder meets the best global quality standards, and hence our customers get the best value. Contact us today for unparalleled brilliance and consistency.

Do check our Website For more Information visit www.jinoyal.com or contact us at | +91 9289666435

0 notes

Text

Mastering DTG Printing: A Step-by-Step Guide to Modern Apparel Design

Direct-to-Garment (DTG) printing has become a game-changer in the world of custom clothing, enabling designers and businesses to create vibrant, high-quality apparel with ease. By directly applying ink to textiles using advanced inkjet technology, DTG eliminates the limitations of traditional methods like screen printing. Whether you’re a small business owner, a hobbyist, or a designer exploring modern printing techniques, this guide will provide a step-by-step approach to mastering DTG printing.

What is DTG Printing?

DTG printing involves using a specialized inkjet printer to apply water-based inks directly onto fabric. This method supports detailed, full-color designs, making it ideal for custom apparel. Unlike screen printing, which requires separate screens for each color, DTG printing simplifies the process by digitally transferring designs to garments. It’s especially suited for small batches or on-demand orders, providing unparalleled flexibility and efficiency.

Benefits of DTG Printing

High-Quality Prints

DTG printing delivers detailed, vibrant prints that capture intricate designs and photo-realistic images. It allows for unlimited colors and gradients, ensuring artistic freedom.

Cost-Effective for Small Orders

Since DTG has minimal setup requirements, it’s a cost-effective solution for small runs or even single-item production. This makes it perfect for businesses offering personalized or on-demand apparel.

Eco-Friendly Solution

DTG uses water-based inks that are free of harmful chemicals, making it a more sustainable alternative to plastisol inks commonly used in screen printing.

Versatility

DTG works on a variety of textiles, including cotton and blended fabrics. It’s suitable for t-shirts, hoodies, tote bags, and other apparel types, offering creative flexibility.

Essential Tools and Materials

DTG Printer

Choose a reliable DTG printer like the Epson SureColor F2100 or the Brother GTX. These machines are designed for high-quality output and user-friendly operation.

Pretreatment Solution

Pretreatment is essential for vibrant and durable prints, especially on dark fabrics. You’ll need a pretreatment solution and a sprayer or pretreatment machine to apply it evenly.

Heat Press

A heat press is necessary for curing the ink and pretreatment, ensuring the print adheres properly to the fabric.

Garments

Select high-quality garments with a high cotton content, as DTG inks bond better with natural fibers.

Step-by-Step Guide to DTG Printing

Step 1: Design Creation

Prepare your design using graphic design software such as Adobe Illustrator or Photoshop. Ensure the resolution is at least 300 DPI for crisp and detailed prints. Export the design in a compatible format, like PNG, with a transparent background.

Step 2: Pretreatment Application

Apply a pretreatment solution to the garment if it’s a dark fabric. Use a pretreatment machine or a handheld sprayer for even application. The pretreatment helps the ink adhere better and enhances color vibrancy. After applying the solution, use a heat press to dry and flatten the fabric.

Step 3: Setting Up the DTG Printer

Load the garment onto the printer’s platen, ensuring it is flat and secure. Use the printer’s software to position your design on the garment and adjust settings like resolution and color profiles.

Step 4: Printing the Design

Start the printing process. The printer will apply ink directly onto the garment, layer by layer. Monitor the process to ensure everything runs smoothly.

Step 5: Curing the Print

Once printing is complete, use a heat press to cure the ink. This step is crucial for ensuring durability and washability. Follow the ink manufacturer’s recommended temperature and time settings for the best results.

Step 6: Quality Check

Inspect the final product for any imperfections or inconsistencies. Check the print’s durability by gently stretching the fabric or performing a quick wash test if necessary.

Tips for Success

Maintain Your Equipment

Regularly clean your DTG printer to prevent clogs and maintain print quality. Follow the manufacturer’s maintenance guidelines.

Experiment with Fabrics

While cotton is ideal for DTG, experimenting with blends or specialty fabrics can help you expand your product offerings.

Offer Customization

One of the biggest advantages of DTG printing is its ability to produce personalized apparel. Encourage customers to submit their designs or add custom text to boost engagement.

Conclusion

Mastering DTG printing opens a world of possibilities for modern apparel design. Its combination of precision, flexibility, and eco-friendliness makes it an invaluable tool for anyone in the custom clothing industry. By following the steps and tips outlined in this guide, you can create high-quality garments that meet the growing demand for unique and personalized fashion. Embrace the power of DTG printing and take your apparel business or creative projects to the next level.

0 notes

Text

Ashwini Industries: A Trusted Leader in Specialty Chemicals and Dyes

Ashwini Industries has carved a niche for itself in the global market, offering high-quality chemical solutions and dyes across various industries. As renowned Acid Black 2 Exporters, Antifoaming Agent AI-010 Manufacturers, Solvent Black 5 Manufacturers, Vat Paste Manufacturers, and Fluorescent Pigment Paste Manufacturers, We are committed to delivering innovative products that meet the highest industry standards.

Acid Black 2 Exporters

Ashwini Industries is a leading name among Acid Black 2 Exporters, providing premium-grade dyes for textiles, leather, and ink applications. Known for its deep black shade and excellent solubility, Acid Black 2 is widely used across various sectors. We ensures that the product is manufactured under strict quality control, offering consistency and reliability to its clients globally.

Antifoaming Agent AI-010 Manufacturers

Foam control is a critical factor in many industrial processes, and We excels as Antifoaming Agent AI-010 Manufacturers. Their AI-010 formulation, available in silicone and non-silicone variants, is designed to efficiently reduce and prevent foam in industries such as water treatment, textiles, and food processing. The environmentally friendly and non-toxic composition ensures that the product meets industry requirements while maintaining operational efficiency.

Solvent Black 5 Manufacturers

As leading Solvent Black 5 Manufacturers, We offers a versatile dye widely used in inks, coatings, and plastics. Solvent Black 5 is prized for its excellent solubility in organic solvents, making it a top choice for industries such as printing, leather, and synthetic materials. Ashwini's production processes ensure high-quality color consistency, meeting the specific demands of various industrial applications.

Vat Paste Manufacturers

Specializing as Vat Paste Manufacturers, Ashwini Industries produces concentrated dye pastes used in textile printing and dyeing. Known for their vibrant, long-lasting colors, vat pastes are commonly applied to natural fibers like cotton and wool. The paste undergoes a reduction process, allowing for deep, rich shades that offer excellent wash and light fastness, making it a popular choice in the textile industry.

Fluorescent Pigment Paste Manufacturers

Innovation in color technology is one of Ashwini’s strengths, especially as Fluorescent Pigment Paste Manufacturers. These pigment pastes are used to produce bright, eye-catching colors in industries such as printing, paints, and coatings. Ashwini’s fluorescent pigment pastes provide superior color strength and durability, making them an ideal choice for applications that demand vivid, high-visibility hues.

Why Choose Ashwini Industries?

With a focus on quality, sustainability, and innovation, We continues to lead the way in the specialty chemicals and dyes sector. Their expertise across a wide range of products ensures that industries worldwide can rely on them for high-performance solutions tailored to their specific needs.

Hence, whether you're looking for Acid Black 2, Antifoaming Agents, Solvent Black 5, Vat Pastes, or Fluorescent Pigment Pastes, We are your trusted partner for top-quality, reliable chemical solutions. Their commitment to excellence guarantees that your business benefits from the best products in the industry.

#Acid Black 2 Exporters#Antifoaming Agent AI-010 Manufacturers#Solvent Black 5 Manufacturers#Vat Paste Manufacturers#Fluorescent Pigment Paste Manufacturers

1 note

·

View note

Text

Nitro Cellulose Prices | Pricing | Trend | News | Database | Chart | Forecast

Nitrocellulose prices have been a focal point of concern within the chemical and manufacturing industries due to their impact on various sectors ranging from automotive to textiles. Nitrocellulose, a versatile compound used primarily in the production of lacquers, coatings, and explosives, has seen fluctuating prices in recent years. This volatility can be attributed to several factors including raw material costs, production processes, and market demand.

The price of nitrocellulose is significantly influenced by the cost of its primary raw material, cotton linters or wood pulp. Cotton linters, being an agricultural product, are subject to seasonal variations and market fluctuations. Any changes in agricultural output or global supply chain disruptions can lead to shifts in the availability and cost of these raw materials, which in turn affects the price of nitrocellulose. Additionally, wood pulp, another source of cellulose, also experiences price variations due to changes in forestry practices, trade policies, and environmental regulations.

Get Real Time Prices for Nitrocellulose: https://www.chemanalyst.com/Pricing-data/nitro-cellulose-1546Another important aspect affecting nitrocellulose prices is the production process itself. Nitrocellulose is produced by nitrating cellulose with a mixture of nitric and sulfuric acids. This process requires careful control and specialized equipment to ensure safety and quality, contributing to the overall cost of production. Advances in production technology or changes in regulatory standards can impact production costs, thereby influencing the final price of nitrocellulose.

Market demand plays a crucial role in determining nitrocellulose prices as well. The compound is widely used in various applications including paints, coatings, and printing inks, as well as in the manufacturing of explosives and propellants. Fluctuations in demand from these sectors can lead to price adjustments. For instance, a surge in the automotive or electronics industry can drive up the demand for nitrocellulose-based coatings, leading to an increase in prices. Conversely, a downturn in these industries can have the opposite effect.

Supply chain dynamics also have a significant impact on nitrocellulose prices. The complexity of the supply chain, from raw material procurement to the distribution of finished products, can lead to price variability. Disruptions in the supply chain, such as transportation delays or geopolitical tensions, can affect the availability and cost of nitrocellulose. Companies involved in the production and distribution of nitrocellulose must navigate these challenges to manage costs and maintain price stability.

Regulatory factors also contribute to price fluctuations. Nitrocellulose is classified as a hazardous material due to its flammability and explosive properties, leading to stringent regulations governing its production, handling, and transportation. Compliance with these regulations often requires additional investments in safety measures and facilities, which can influence the cost of nitrocellulose. Changes in regulations or increased enforcement can impact production costs and, subsequently, prices.

The global market for nitrocellulose is also subject to economic conditions and trade policies. Economic downturns or fluctuations in currency exchange rates can affect international trade and impact the prices of imported and exported nitrocellulose. Trade policies and tariffs imposed by different countries can also influence market prices by altering the cost structure for producers and consumers alike.

In addition to these factors, technological advancements and innovations in the chemical industry can affect nitrocellulose prices. For example, the development of alternative materials or production methods that reduce the reliance on traditional raw materials can influence market dynamics. As new technologies emerge, they may offer cost-effective solutions that could lead to shifts in pricing trends.

Overall, nitrocellulose prices are subject to a complex interplay of factors including raw material costs, production processes, market demand, supply chain dynamics, regulatory requirements, and economic conditions. Businesses and consumers in industries that rely on nitrocellulose must stay informed about these factors to make strategic decisions and manage their costs effectively. Understanding the nuances of nitrocellulose pricing can help stakeholders navigate the challenges and opportunities within the market, ensuring they can adapt to changes and maintain a competitive edge in their respective fields.

Get Real Time Prices for Nitrocellulose: https://www.chemanalyst.com/Pricing-data/nitro-cellulose-1546

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Nitro Cellulose#Nitro Cellulose Prices#Nitro Cellulose Price#Nitro Cellulose Pricing#Nitro Cellulose News#Nitro Cellulose Demand

0 notes

Text

Carbon Black Pigment Manufacturers in Various Grades

SP Colour & Chemicals | AMP Pigments - Manufacturers and Exporters of Carbon Black in Various Grades

We Provide Various types of Carbon Black Grades

FW 2100 Carbon Black

FW 900 Carbon Black

FW 1500 Carbon Black

FW 1700 Carbon Black

Printex 35 Carbon Black

Carbon black uses in Various Applications:

Plastics: Enhancing colour and performance in plastic products.

Coatings and Paints: Providing colour intensity, UV resistance, and durability.

Inks: Ensuring sharp and consistent printing results.

Rubber: Reinforcing strength and enhancing wear resistance.

Textiles: Improving colouration and durability in fabric applications.

Cosmetics: It is used in Cosmetics, Providing Intense look.

Try Our Premium Quality of Carbon Black and Enhance your Products by this. We committed to maintaining the highest standards of quality and consistency

To know more Information about Our Premium Carbon Black

Visit us - www.spcolour.in

OR

Contact us

National : +91 9990286664

International : +91 9310048024

0 notes

Text

Indian textile players to announce new launches and developments at Gartex Texprocess India new Delhi 2024

Anticipating a boost in the manufacturing sector, the signing of the FTAs, the recent growth in the textile exports, bundled with the Indian government’s focus on making India a ‘global manufacturing hub’ has set up encouraging prospects for the stakeholders of the Indian textile value chain. This optimistic industry outlook is also evident in the spirit of the textile technology and apparel manufacturing players participating in the upcoming Gartex Texprocess India which is scheduled from 1 – 3 August 2024 at Yashobhoomi (IICC), Dwarka, New Delhi.

Regardless of the global economic and political landscape, the recent surge reported in textile exports and apparel at 9.59% and 9.70% respectively, in May 2024 as cited by the Confederation of Indian Textile Industry (CITI), marks a positive sign uplifting the spirits of the Indian textile players. As per IBEF, the market for Indian textiles and apparel is projected to grow at a 10% CAGR to reach USD 350 billion by 2030 with the exports expected to reach USD 100 billion. The Indian textile sector is further expected to be strengthened by innovations from the manufacturers of fabrics, garments and apparel, textile machinery companies, allied industries and future plans and policies from the Indian government.

As India’s leading expo covering garment and textile manufacturing, denim, accessories, textile printing technologies, and more, Gartex Texprocess India is slated to showcase 600+ brands, spread over an area of 15,000 sqm at Yashobhoomi (IICC), Dwarka, New Delhi. Besides India, the upcoming edition will demonstrate global excellence in textile solutions from countries like China, Italy, Japan, Singapore, Taiwan, and the USA.

The show floor is sold out with leading Indian brands like AT Inks, Aura Technologies, BABA Textile Machinery, Benz Embroidery, Britomatics India, Chetna Fashions, DCC Print Vision, Jaysynth Dyestuff India, and True Colors amongst others. International brands like Baoyou, Brother, Datatex, Dupont, Jack, Kansai, SinSim, Siruba, Yumei, and more will also add a global touch to the show.

New Product Launches:

The three-show days are lined up with more than a dozen of new product launches and the exhibitors showcasing their latest offerings. Some of the unmissable product launches will be from brands like: Amtex Dye Chem Industries, Behariji Enterprises, Codeverse Technologies, Creative Industries, LNJ Denims, Panchsheel Enterprises, Pro-Pioneer Eco Technologies, Rainbow Denim, Ranjan Fabrics, R&B DENIMS, SBT Textiles, Sitaram Spinners, Stas Biochem, Studio Next Technology, True Colors, The Tenth House, Venus Denims, Vertex Edge Tech, Vinod Denim and more.

Show Highlights:

The first edition to be organised at the state-of-the-art expo centre – Yashobhoomi, IICC, Dwarka, New Delhi

200+ exhibitors presenting 600+ brands from 7 countries

Featuring curated-zones for product categories like ‘Knitting, Sewing Machinery, Digital Printing, Embroidery, Fabrics & Trims.’

Expansion of the Trims segment with new exhibiting companies

International brands directly participating in the show

Curated knowledge-sessions with a panel consisting of Government officials from the concerned Ministries, industry experts and innovators from the textile associations and businesses

Exhibitors Perspective on Government Schemes:

As India shines in its glory of being the world’s 3rd largest producer of textiles raw materials like cotton, jute, silk and wool, it also embodies the strength of manpower, infrastructure, low production costs and innovations needed to push the contours of the Indian textile landscape. In an attempt to gather the view of the participating companies on the government schemes and initiatives – many of them shared that schemes and initiatives like PLI, ATUFs, RoDTEP & RoSCTL, NTTP, NHDP, PM MITRA Parks, Handloom Weavers’ Comprehensive Welfare Scheme, Integrated Skill Development Scheme (ISDS), schemes for MSMEs and amongst others, have served to be beneficial for not only growing their businesses but also expand the technical skillsets resulting in a healthy business atmosphere.

As the preparations for the event gear up, Mr Raj Manek, Executive Director and Board Member of Messe Frankfurt Asia Holdings Ltd shared: “I think India is evolving as a beacon of innovations and economic resilience. With the upcoming edition of Gartex Texprocess India 2024, the momentum has been set to present the transformations in textiles right from the textile manufacturing machinery, garment, fabric and denims to trims and accessories and lots more. Sustainability and Innovations in textiles are at the heart of the show and I am pleased to share that the participating Indian and international companies will display an unparalleled quality of products and finesse.”

Mr Gaurav Juneja, Director of MEX Exhibitions Pvt Ltd, added: “With the recent growth recorded in the textile exports and focus on boosting the manufacturing sector in India – it will take textile under its stride creating more business and job opportunities. Gartex Texprocess India has been known for presenting an exceptional showcase of innovations from the textile industry, primarily in textile manufacturing machinery, garments, fabrics, denim, screen printing solutions and accessories. In the upcoming edition in August, we are excited to share that our esteemed exhibitors are ready to display their latest innovations and many of them are also launching their new products which makes it a must-attend industry event for the textile enthusiasts and professionals.

Organized by Messe Frankfurt Trade Fair India Pvt Ltd and MEX Exhibitions Pvt Ltd, Gartex Texprocess India is a leading exhibition in the textile industry.

1 note

·

View note

Text

Digital Textiles in India – Bliss Impex in Gurgaon

One of the most striking things about visiting India is just how colorful everything is – from shopfronts and market stalls to the clothes that people wear out and about.

I wanted to get a better understanding of the Indian textile market and fortunately, Ekansh Jain, the owner of Bliss Impex, was happy to show me around his factory. The Bliss Impex name is already known to readers outside India, thanks to Durst’s marketing department announcing back in 2019 that the company had just bought four Durst Alpha textile printers.

At that time, Jain said that he invested in the four Durst machines in order to expand the company. This has obviously worked as he bought two more printers, one each from Epson and EFI, at the start of this year, both of which were being installed when I was there in February of this year.

http://indianprinterpublisher.com/wp-content/uploads/2024/04/BlissImpex_Reggiani_L1030251_WQ-web750cor.jpg

Three of the Durst Alpha 190s were set up with reactive inks and are still going strong, side by side. These have a print width of 190cm with a print resolution of up to 600 dpi. Jain was in the process of moving the fourth Durst machine, an Alpha 180, downstairs where it will become the first machine on a new production floor of the same size. This machine prints to transfer paper for dye sublimation to polyester.

Alongside the Alphas, a new Epson Monna Lisa 32000 was installed at the start of the year. This is fitted with 32 of Epson’s PrecisionCore printheads, which can produce up to 697 square meters an hour in a single pass at 300 x 600 dpi, or 423 square meters an hour in two passes at 600 x 600 dpi. It uses Epson’s Reactive Genesta inks. It’s available in 240cm and 340cm widths as well as the 180cm size installed at Bliss Impex.

Right at the end of the line was a brand new 32-head EFI Reggiani Power, for which they were still making the profiles. This can print to fabric at up to 1020 square meters an hour in a single pass at 600 x 300 dpi or up to four passes for 600 x 1200 dpi, which produces 295 square meters an hour. Again, Bliss Impex has opted for the 180cm size though Efi also offers 240 and 340cm widths.

There’s also an Atexco printer from China, which uses a camera for registration of double-sided prints to ensure the prints on the front and back line up. Bliss Impex uses the Atexco to produce a particularly nice effect of printing color on top of a material that’s already been embroidered.

Bliss Impex runs three shifts a day and Jain says that he only buys digital printers from vendors that have local service support. He says, “I always like to have a service team based here. Epson and EFI have their own team here. They will do the profiling and then they will leave one person to make sure that it runs.”

He adds, “Once the heads go, we recycle them. We have an agreement with the European companies so they take care of them. I would rather not run a faulty head but recycle it and get the right quality.”

http://indianprinterpublisher.com/wp-content/uploads/2024/04/Web750corr.jpg

Besides the digital machines, Bliss Impex also operates a range of conventional rotary and flatbed textile printing machines, as well as a label printer and also has an export arm. Jain says, “I have really upset the market by dropping the prices right down but the advantage is that I’m not trying to compete with other digital printers. I’m competing with my rotary.”

He continues, “When I first thought of putting these digital printers together people thought I was mad because it’s hard to run one machine let alone several big machines. My thinking was that I never had to compete with the market as I always competed with my own rotary work. I wanted to be in the market for this technology as I thought it was the future.

“And with digital I am putting more work through than with the rotary machines and it’s all on the same floor. It’s clean and hygienic. It’s better working conditions for the employees. It’s all sustainable.”

He says that a lot of people have now moved into digital printing but adds, “I would challenge anyone to find better quality with digital.” For this reason, he is also cautious about the current trend in textile printing towards pigment inks. He says, “I’m still going for reactive. I think that pigment needs more research and needs to be more cost-effective to really compete because it doesn’t have the easy hand feel of the reactive.”

He continues, “I can see a lot of advantage in bringing lower consumption of water but we still need to wait another few years more for pigment to reach the cost and performance of reactive.” He adds, “The pigment ink costs are more than double and the consumption is triple.”

http://indianprinterpublisher.com/wp-content/uploads/2024/04/BlissImpex_Alpha190_L1030244_WQWeb500.jpg

Naturally, with so many printers, he has considered investing in a single-pass inkjet machine but doesn’t think the print quality is as good. He explains, “The reason I don’t want to use single pass is that with the multi-pass you can increase the colour intensity by increasing the number of passes. But I can’t control this with a single-pass printer.” He adds, “And in my case, I have many other people to look after where I need to satisfy their quality and their color. And with the single pass, I would have to stop the production for the whole line. So I would rather have the multi-pass machines. But I’m still contemplating the single-pass printers.”

Jain says that the Covid pandemic did slow down the company’s growth though the effects of the pandemic are now receding. He says that it changed the world, and left established players with equipment and software that needed to be updated, which is one reason for investing in the new Epson and EFI machines. He adds, “You need the quality. If you don’t have the quality you can’t find the right buyer.”

But he also says that after the pandemic people wanted to use more imaginative materials and were concerned about the environmental issues, particularly around water use. This worked in his favor since he was already using digital printing.

Overall, the company is expanding and has a German partner for exports to Europe. Print quality is key to the business despite also facing the same cost pressures that are common to India. But Jain is relaxed with the air of a man who has little to worry about. And given that he’s preparing a second production floor, there’s every chance that we will be hearing more from Bliss Impex as the company continues to build up its digital production capability.

You can find further details on this company from blissimpex.in.

First published on15th April 2024 in the Printing and Manufacturing Journal. Reprinted by permission. www.nessancleary.co.uk

0 notes

Text

Middle East and Africa Carbon Black Market Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Middle East and Africa Carbon Black Market size at USD 430 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Middle East and Africa Carbon Black Market size to expand at a CAGR of 3.03% reaching a value of USD 530 million by 2030. The Middle East and Africa Carbon Black Market is propelled by the utilization of carbon black across diverse industries, notably in paints and coatings, as well as the tire and rubber sectors. To capitalize on revenue opportunities in developing nations, companies in the carbon black market prioritize product innovations. The surging demand for carbon black in the automotive sector emerges as a key driver steering the growth trajectory of the Middle East and Africa Carbon Black Market over the forecast period. Another driving force is the increasing adoption of electric and self-driving cars which presents a noteworthy growth opportunity. The Middle East and Africa Carbon Black Market is also expected to experience growth driven by the rising demand for specialty carbon black and its applications in the fiber and textile industries throughout the forecast period.

Opportunities – Focus on specialty grades

Specialty carbon black, recognized as pigment black, exhibits superior purity with minimal ash, sulfur, and contaminants. Particularly, in industrialized regions like the United States, the market for specialty carbon black is rapidly expanding, compensating for the slower growth in traditional carbon black demand. Distinguished by its enhanced conductivity, viscosity, and UV-protection, specialty carbon black is gaining prominence across various applications, excluding rubber, where substantial growth is anticipated in the coming years. The surge in demand for specialty black is notably expected in sectors, such as printing and plastic inks. Leading carbon black manufacturers are augmenting production capacities and modifying their conventional manufacturing lines to meet the escalating demand for specialized carbon black. Concurrently, investments in research and development facilities offer these companies a strategic advantage in the competitive specialty carbon black market.

Sample Request @ https://www.blueweaveconsulting.com/report/middle-east-and-africa-carbon-black-market/report-sample

Impact of Geopolitical Tensions on Middle East and Africa Carbon Black Market

The Middle East and Africa Carbon Black Market is impacted by geopolitical tensions in several ways. Escalating geopolitical tensions in the region manifest in disruptions across the supply chain, particularly in the access to vital raw materials, such as oil and natural gas, essential for carbon black production. The imposition of trade restrictions and tariffs, a common consequence of geopolitical conflicts, further complicates the export-import dynamics of carbon black, affecting market accessibility and cost considerations in the MEA region. The economic uncertainties stemming from geopolitical instability can lead to a downturn in investments and consumer spending, subsequently slowing industrial activities and diminishing the demand for carbon black in manufacturing processes. Currency fluctuations arising from geopolitical tensions pose challenges to the cost competitiveness of MEA-based carbon black producers in the global market. The investment climate, crucial for industry growth, may suffer as political instability deters foreign investments, hindering the development of production facilities and technological advancements. Additionally, given the energy-intensive nature of carbon black production, fluctuations in energy prices resulting from geopolitical tensions can exacerbate production costs. Disruptions in infrastructure and transportation networks may impede the distribution of carbon black, presenting challenges in ensuring timely deliveries. In essence, the intricate interplay of these factors underscores the necessity for companies in the MEA Carbon Black Market to closely monitor geopolitical developments and adeptly adjust strategies to navigate the associated challenges.

Middle East and Africa Carbon Black Market

Segmental Information

Middle East and Africa Carbon Black Market – By Application

On the basis of application, the Middle East and Africa Carbon Black Market is divided into Tire, Non-Tire Rubber, Inks & Toners, and Plastics segments. The tire segment holds the highest share in the Middle East and Africa Carbon Black Market by application. Its crucial role as a filler and reinforcing material in car tires enhances mechanical and dynamic qualities. Used extensively in various rubber formulas, carbon black contributes to tailored performance attributes in tires, particularly in inner liners, sidewalls, and carcasses. Its addition to rubber composites delivers benefits such as heat dissipation, improved handling, tread wear, and enhanced fuel economy.

Middle East and Africa Carbon Black Market – By Country

The in-depth research report on the Middle East and Africa Carbon Black Market covers the market in the region’s major countries including Saudi Arabia, UAE, Qatar, Kuwait, South Africa, Nigeria, Algeria, and Rest of MEA. Saudi Arabia holds the highest market share and is expected to maintain its dominance throughout the forecast period. The Kingdom’s dominance is expected to persist over the forecast period, driven by key sectors like the tire, plastics, paints, and coatings industries. With an escalating demand for tires, companies, such as Kumho Tire, have announced plans to establish tire manufacturing plants, addressing the absence of such facilities in the country. The Saudi-South Korean Business Forum led to the partnership between Kumho Tire and Blatco, aiming for a manufacturing capacity of a trillion tires annually, slated to commence production in Q3 2023. The surge in automotive sales further propels the consumption of these tires, with popular brands like Toyota, Hyundai, and Mazda dominating the market. In addition to the tire industry, carbon black plays a pivotal role in plastics production, aligning with Saudi Arabia's substantial investments in the sector, contributing significantly to total industrial investments. The paints and coatings industry also thrives, driven by major manufacturers like Jotun, Jajeera Paints, AkzoNobel NV, Sigma Coatings, and National Paints Factories.

Competitive Landscape

The Middle East and Africa Carbon Black Market is fragmented, with numerous players serving the market. The key players dominating the Middle East and Africa Carbon Black Market include Alexandria Carbon Black Company, Abu Zaabal Company for Speciality Chemicals, Himan Investment Group, Iran Carbon, Iran Carbon Black Company, Abu Dhabi National Oil Company, and Sabic. The key marketing strategies adopted by the players are facility expansion, product diversification, alliances, collaborations, partnerships, and acquisitions to expand their customer reach and gain a competitive edge in the overall market.

Contact Us:

BlueWeave Consulting & Research Pvt Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Dyes and Pigments Market Growth and Development (2023-2033)

Research Nester published a report titled “Dyes and Pigments Market: Global Demand Analysis & Opportunity Outlook 2033” which delivers detailed overview of the global dyes and pigments market in terms of market segmentation by product, application and by region.

Further, for the in-depth analysis, the report encompasses the industry growth indicators, restraints, supply and demand risk, along with detailed discussion on current and future market trends that are associated with the growth of the market.

The global dyes and pigments market is anticipated to grow with a CAGR of ~5% during the forecast period, i.e. 2023-2033. The market is segmented by application into dyes and pigments. The dyes segment is further segregated into printing inks, textiles, paper, leather, and others. Out of these the textiles segment is attributed to garner the highest market share in the forecast period, owing to the huge production of textile fibers. According to recent data, the worldwide production volume of textile fibers rose from 100 thousand metric tons in 2017 to 110 thousand metric ton in 2020.

The global dyes and pigments market is estimated to garner a noteworthy revenue by 2033. Recently, there has been a high demand from various application industries, such as textiles, paints & coatings, construction, and plastics of dyes and pigments. This trend is expected to majorly drive the market growth in the assessment period. Additionally, a large portion of producers are actively venturing into enhancing their products by utilizing advanced technologies for the efficient removal of hazardous pollutants during the manufacturing process.

Geographically, the global dyes and pigments market is segmented into five major regions including North America, Europe, Asia Pacific, Latin America and Middle East & Africa region. Out of these, the market in Asia Pacific region is estimated to garner the largest market share by the end of 2033, on the back of increasing demand of textile fabrics by the growing population and the presence of the major textile manufacturing companies. Also, the export and import value of textile in APAC region along with the employment of population in garment sector are another growth factors of the market.

The research is global in nature and covers detailed analysis on the market in North America (U.S., Canada), Europe (U.K., Germany, France, Italy, Spain, Hungary, Belgium, Netherlands & Luxembourg, NORDIC [Finland, Sweden, Norway, Denmark], Poland, Turkey, Russia, Rest of Europe), Latin America (Brazil, Mexico, Argentina, Rest of Latin America), Asia-Pacific (China, India, Japan, South Korea, Indonesia, Singapore, Malaysia, Australia, New Zealand, Rest of Asia-Pacific), Middle East and Africa (Israel, GCC [Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman], North Africa, South Africa, Rest of Middle East and Africa). In addition, analysis comprising market size, Y-O-Y growth & opportunity analysis, market players’ competitive study, investment opportunities, demand for future outlook etc. has also been covered and displayed in the research report.

Request Report Sample@ https://www.researchnester.com/sample-request-4408

Expansion in the Production of Paints & Adhesives to Drive the Market Growth

The increment in production of high-performance dyes and pigments across various end-use industries is owing to their long lasting characteristics. Thus, the advantages offered by the dyes and pigments and its usability across various industries is expected to propel the demand for dyes and pigments market. Further, the rising environmental awareness among a larger section of population have propelled many manufacturers are focusing on development of bio-based dyes and pigments. Also, the number of initiatives focused on controlling global warming and the impact of climate change, this trend is expected to remain prominent moving forward.

Additionally, the burgeoning population is expected to play a prominent role in driving the demand for apparels globally, which is anticipated to propel the demand for dyes and pigments market from the textile sector.

However, the frequent changes in regulatory standards along with additional external expenses and stringent government rules is expected to operate as key restraint to the growth of the global dyes and pigments market over the forecast period. This report also provides the existing competitive scenario of some of the key players of the global dyes and pigments market which includes company profiling of Clariant International Ltd, DIC Corporation, Sudarshan Chemical Industries Limited, Atul Ltd, BASF, Huntsman International LLC, Cabot Corporation, Tronox Incorporated, DuPont de Nemours, Inc., KRONOS Worldwide, Inc., and others. The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the global dyes and pigments market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

0 notes

Text

Dye Sublimation Paper Market Is Estimated To Witness High Growth Owing To Increasing Demand in Textile Printing

The global Dye Sublimation Paper Market is estimated to be valued at US$ 560.1 million in 2021 and is expected to exhibit a CAGR of 5.3% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights. Market Overview: Dye sublimation paper is a specially coated paper that is used in dye sublimation printing, which is a popular method for transferring high-quality and vibrant images onto various substrates such as fabrics, ceramics, metals, and plastics. This type of paper offers several advantages including excellent color reproduction, sharp details, durable prints, and fast drying time. The need for Dye Sublimation Paper Market is associated with the growing demand for textile printing. The textile industry is witnessing significant growth worldwide, driven by factors such as increasing population, rising disposable income, and evolving fashion trends.

Dye sublimation printing is extensively used in the textile industry to create customized designs, patterns, and graphics on fabrics. Therefore, the demand for dye sublimation paper is expected to witness substantial growth in the coming years. Market Key Trends: One key trend observed in the dye sublimation paper market is the increasing adoption of eco-friendly products. The textile industry is under increasing pressure to adopt sustainable practices and reduce its environmental impact. As a result, there is a growing demand for eco-friendly dye sublimation papers that are free from harmful chemicals and are recyclable.

Manufacturers are investing in research and development to develop sustainable alternatives to conventional dye sublimation papers. For instance, Ahlstrom-Munksjö, one of the key players in the market, offers a range of eco-friendly dye sublimation papers that are manufactured using renewable raw materials and are compostable. PEST Analysis: Political: The political factors influencing the dye sublimation paper market include government regulations and policies related to the textile industry, trade agreements affecting import and export of textiles, and political stability in major manufacturing regions. Economic: Economic factors such as GDP growth, disposable income, inflation rates, and consumer spending patterns impact the demand for textiles and, thereby, the demand for dye sublimation paper. Social: Social factors like changing fashion trends, growing preference for customized products, and increasing awareness about sustainable practices influence the demand for textile printing and, consequently, dye sublimation paper.

Technological: Technological advancements in the field of dye sublimation printing, such as improved ink formulations and digital printing technologies, are driving the adoption of dye sublimation papers. Key Takeaways: - The global dye sublimation paper market is expected to witness high growth, exhibiting a CAGR of 5.3% over the forecast period, due to increasing demand in textile printing. - Asia Pacific is the fastest-growing and dominating region in the dye sublimation paper market. This can be attributed to the presence of a large textile industry in countries like China and India, coupled with the growing popularity of digital textile printing. - Key players operating in the global dye sublimation paper market include Guangdong Guanhao High-Tech, Hansol Paper Co., Ltd., Sappi Group, Neenah Coldenhove, Ahlstrom-Munksjö, The Felix Schoeller Group, Beaver Paper & Graphic Media Inc., Jiangyin Allnice Digital Technology, Seiko Epson Corporation, and B.N Papeis. These players focus on product innovation, strategic partnerships, and expansion to strengthen their market presence.

0 notes

Text

The Ultimate Guide to Print on Demand DTF Dominating Google Search

Introduction

Welcome to our comprehensive guide on Print on Demand DTF, where we delve into the depths of this exciting technology and its potential to transform your business.

Print on Demand DTF from its definition and benefits to how it can boost your e-commerce sales and why it is essential to your online success.

Print on Demand DTF: What is it?

Using the state-of-the-art printing method known as Print on Demand DTF, or Direct to Fabric, you may directly produce personalized designs on a variety of textiles.

For e-commerce companies, it has changed the game by allowing them to sell customized products to their clients without maintaining any inventory.

You can easily print vivid and durable graphics on fabrics such as clothing, decoration, accessories, and more with Print on Demand DTF.

How Print on Demand DTF Boosts Your E-Commerce Sales

Diversifying Product Range

With Print on Demand DTF, you can effortlessly expand your product range without the limitations of traditional manufacturing. From t-shirts, hoodies, and tote bags to pillowcases, curtains, and more – the possibilities are endless. This diverse offering attracts a broader customer base, boosting your chances of making more sales.

Enhancing Brand Visibility

Personalized products create an emotional connection with customers, turning them into brand advocates. They are more likely to share their unique purchases on social media, increasing your brand's visibility organically. Word-of-mouth marketing is a powerful tool in today's digital landscape, and Print on Demand DTF can help you tap into that potential.

Staying Ahead of Trends

The fashion and home decor industries are highly influenced by trends. With Print on Demand DTF, you can quickly adapt to changing consumer preferences by updating your designs and products on-the-fly. This agility allows you to stay

Global Reach

Print on Demand DTF enables you to reach customers worldwide without the hassle of managing international inventory and shipping logistics. Expand your market reach and cater to a global audience without the complexities associated with traditional exporting.

Future of DTF Print on Demand

Future developments in Print on Demand DTF are anticipated to be much greater as technology continues to grow. The options are endless, ranging from quicker printing procedures and enhanced color brightness to eco-friendly inks and materials.

You can make sure your e-commerce business is successful and competitive by being on the cutting edge of these advancements.

Conclusion

Print on Demand DTF has revolutionized the e-commerce industry by offering unparalleled customization, inventory flexibility, reduced production time, and cost-effectiveness.

By diversifying your product range, enhancing brand visibility, staying ahead of trends, and reaching a global audience, you can boost your e-commerce sales to new heights.

Embrace the power of Print on Demand DTF and leverage its advantages to create a compelling, customer-centric e-commerce experience. With the ability to cater to individual preferences and deliver unique, high-quality products, you'll stand out in a crowded online marketplace.

Remember, the key to success lies in continuously innovating and adapting to the ever-changing landscape of e-commerce.

So, what are you waiting for? Embrace Print on Demand DTF and take your online business to the next level!

0 notes

Text

Small thickness 12mm tape