#reactive dye ink

Explore tagged Tumblr posts

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

attention-seeker ミ●﹏

transformers reactions to human modifications. (tattoos, piercings, hair-dye.) headcanons!

optimus prime, bumblebee, prowl. tfa.

sfw / suggestive under cut.

may do more of them, i love this show to death.

optimus prime

"you do this stuff... for fun? huh."

try as he might, he does not understand the point much.

don't get me wrong, i see animated optimus to be the closest to a mid-twenties rascal as you can get. modifications aren't unheard of for bots. he's not a nun.

however ...

he sees humans as still pretty fragile. so the idea that you like going and having needles shoved into your flesh and jammed through your muscle isn't something he can wrap his helm around at first.

primus forbid you have lots.

imagine him trying to process you explaining that yes, your entire back is covered in ink and you're planning on about five different piercings in the next year.

"so you. you plan on getting two on your back. just because?"

"that's the plan, big guy."

poor mech is lost. though he does enjoy learning more about humanity when he isn't stressing too much about saving it.. so expect questions.

when you suggest getting one of the autobot emblem, his circuits nearly fry.

prowl

"so, what's the significance?"

i see prowl not writing off the behavior as weird and instead digging for why you pursued this journey.

yes, he sees your tattoo and piercing collection as a journey, because that's what it is, isn't it? years of work and pain to adorn your body to your liking.

he knows that humans are bundled with nerves. there's respect earned. he finds humans to be eerily resilient.

will ask you the meaning of each and every one. piercings less so.

"what does this bird represent?"

"mm.. my sense of liberty."

"a visual representation of the wish to stretch to new horizons. how fascinating. being small in a vast universe with the urge to still explore."

"i also just like hummingbirds."

"mm. i see."

will get onto you once he finds out about the "makeshift" work. finds the mistakes or even forgettable craftsmanship to make you endearing.

bumblebee

"whoa! sick paintjob, human!"

he LOVES human culture. and you guys can just... change your appearance? count him impressed!

you had dyed your hair to a nice golden yellow to match his frame and he almost jammed his intake shut.

"you can just. do that?!? b-but your helm used to be-"

"hair, bee."

"right, right. it wasn't always that color though!!!"

he thinks it's so cool. real dork about it. totally buzzed out once you spoke about the chemistry that it went to the process though.

he thinks piercings are cute. after all the fusion of metal and organic is kiiind of taboo. you pull it off great.

tattoos make him beg ratchet to let him upgrade his paint. poor old mech is grumpy and over bumble whining him to just let him "get some flames and that's it."

you draw a lot of inspiration from him. will gladly brainstorm your next big change and puff his chassis out like a lil peacock knowing you're willing to get something permanent done in his designation.

nsfw.

optimus prime

"you look like a painting. primus above, you're gorgeous..."

optimus prime enjoys tracing your tats. he kisses the patterns and images as if the pain of the needle remains, glossa licking along thick and thin ink with shuttered optics.

he likes to see goosebumps trail after. kind of a weird fetish (?) but he mostly enjoys how reactive you are and how your inkwork ripples with the movement.

when he finds out your piercings can make you sensitive ...

well, good luck.

optimus at his spark of sparks is such a tease. when you continue to surprise him, it's nice to be in control of that mutual fascination for once.

"you enjoy when i tug.. these?"

nipple piercings.

expect his glossa. he takes special care to even lubricate each of his digits just to toy with your sore nipples.

prowl

"that's it. fall apart for me. just like art..."

prowl is observant. so when you let it slip that you've been holding back on some of what's on your body...

you're on his berth and naked. his optics are hidden behind his sharp visor.

"holding back on me? that's a shame. i thought you knew better than to do that."

is he angry? hardly! but his processor is about to work overtime when you stammer just why you hadn't gone into depth.

genital piercings.

he doesn't say anything for a long time. doesn't ask the millions of questions bombarding his thoughts. his servos do that speaking before he can.

let's just say you start to understand why he deals with tedious and delicate situations. those hands are built for... meticulous attention.

bites. all the areas with piercings. focuses carefully damn near to the square inch of sensitive flesh where it drives you wild.

tattoos? he loves to scrape his digits down em.

loves to doll you up in lingerie that accentuates everything you hide. crotchless, cut-outs exposing yourself until he can't see where the inkwork begins and ends.

robolvrr 2024.

#first contact au#transformers x reader#transformers#transformers optimus#optimus x reader#tfa#bumblebee#bumblebee x reader#tf prowl#prowl x reader#transformers animated#valveplug#maccadam#headcanons

322 notes

·

View notes

Text

I made this blog because this project took so long and I’m really proud of these and want to show them off. (also the marks are back finally so I can't be accused of plagiarism if these images are online)

For context, where I live any student who takes Textiles for Year 12 (senior year) has to complete a major work which we start in October and submit them in August. It can be any area of textiles and based around any topic. For mine, I made fabric dust jackets for all of Aiden Thomas’ current (at the time) books.

Here they are! I’m so happy with them. Details and more photos under the cut because I crammed a lot of easter eggs in these and no-one I know IRL has read the books. Warning it will be long.

!Spoilers for the books below!

I hand dyed all of the fabric, myself

The yellow dye is home-made marigold dye and there are embroidered marigolds in the corner of the back cover to represent Dia De Muertos

The church, headstones and stingray were printed with carved rubber stamps

The beading leading from the church to the water is meant to represent the rocky cave walls of the chamber

Yadriel’s portaje is included in the beads

The left side of everything has a gold outline to show the light from the sunset hitting it

I also screen printed ‘Thomas’ on the spine ‘cause my school librarian told me it wouldn’t look like a book otherwise. Screen printing stuff that small is a nightmare but I’m glad with how it turned out (mostly)

The inside shows the boys on the beach during halloween

The sky above them has Julian’s Scorpio star sign while the lining has Yadriel’s Cancer

I used sequins to be the sand and cover the raw edge of the fabric

The lining for all the books is ice dyed

The papel picado design on the lining is screen printed. I tried to make the pattern look simultaneously like gravestones and skulls with little marigolds in the corners

The jaguar print at the bottom is 100% meant to represent Bahlam and definitely not to cover a failed screen printing attempt

I used lace dyed with every colour imaginable to cover the fraying corners because the black dye turned navy for some reason

The front of this book is made from four sheer layers of mesh with sequins, painted silhouettes and applique in between to create the appearance of a shadow box, while being two dimensional

I dyed the fabric with light reactive dye and hung it to dry from a single point so that the folds would create the white radiating lines from the centre to add depth

To cut out the front bit of the tree I used a candle flame so that it wouldn’t fray and would have a slightly gnarled appearance

I also entirely underestimated how long that much backstitch embroidery would take

The appliqued trees are the only fabric I didn’t hand dye in this project

For the inside I painted the lighter fabric to look like Wendy and her brothers’ bedroom with the fairy lights, articles about deep sea exploration and portraits

The one in the bottom right corner is specifically modeled after the family photo in one of the character cards by Gibb_Arts on Graveyard Goods

The palm trees in the middle are meant to represent Neverland. I screen printed them and then painted the inside of the leaves with slightly sparkly paint

There are also the stars to get to Neverland above the trees

My teacher managed to wear me down into using bias binding for the edges of this cover and I’m glad I did but bias binding really is my enemy. It was so hard to work with D:

This cover was also dyed with the marigold dye

Each of the feathers were cut with a laser cutter, dip dyed and stitched on by hand. Each one is made from one layer of dyed suiting fabric, overlaid with the same sparkly fabric from the Lost in the Never Woods cover

I used heat transprint ink to get the pattern onto the gold ribbons, which was hard because they were so shiny. The pattern is based off of Aurelio’s collar on the print by Meowlayn on Graveyard Goods. I like that with this colour scheme it can also kinda looks like jaguar print for Ocelo

The sunburst crown in the left corner is painted. It’s hard to see but it is outlined in gold hand embroidery

The pattern beneath is meant to resemble a cut jade geode (but in black to represent Xio) It was made using light reactive dye and a stencil cut from a foil tray

The beads and chains across the top are inspired by the draping jewelry that many of the characters have in their trading cards (especially Aurelio and Dezi)

The beads are also in a ratio of 8 gold to 1 jade and 1 obsidian to represent the competitors, themselves

The inside cover has screen printed mountains for Niya and La Cumbre

The patterns on the side are based off of how the competitor results are shown at the end of each trial. The left shows the first trial while the right shows the last

If you read all this, thanks for sticking around! I'll probably add on to this series with a Celestial Monsters cover soon and I'll definitely make one for Espiritu in September (so so so excited for it!!!!!)

(Btw, the plush ghost in the first picture is called Julian in a German accent)

#aiden thomas#cemetery boys#the sunbearer trials#lost in the never woods#embroidery#textile arts#books#dust jackets

15 notes

·

View notes

Text

Dyes : The World of Colors

Colors make our world vibrant, and dyes are the magical ingredients that bring life to everything around us. Let’s explore the colorful universe of dyes, breaking down the various types and their fascinating uses in everyday life.

Understanding Dyes:

Dyes are like special paints that add color to different things. Humans have been fascinated by colors for a long time, and dyes play a huge role in making our world colorful. There are two main types of dyes: natural and synthetic. They are used to add color to items like utensils, textiles, leather products, and even food.

Types of Dyes:

Basic Dyes:

These dyes are made in labs and give really bright colors. They are great for adding color to things like acrylic fibers and synthetic materials.

Direct Dyes:

These dyes dissolve in water and are used for coloring materials like cotton. They are commonly used in the textile industry.

Natural dyes :

Natural dyes are derived from sources in nature and may include substances like indigo, turmeric, or cochineal. While these dyes have a historical and cultural significance, they often present limitations in terms of color range and fastness.

Acid Dyes:

Perfect for coloring protein fibers like wool and silk, acid dyes are highly soluble in water. They are not suitable for materials like cotton but work well for leather and medical products.

Synthetic Dyes:

Man-made and chemically produced, these dyes come in a wide range of colors. They are used in many industries due to being affordable, but they can be harmful to the environment and humans.

Reactive Dyes:

Best for cellulose, protein, and polyamide fibers, these dyes are easy to use and have good light-fastness properties. They are popular in the textile industry.

Solvent Dyes:

Modern and non-toxic, these dyes are used in upcoming textile mills. They are convenient but may be more expensive. Solvent dyes are seen as alternatives to traditional harmful dyes.

Food Dyes:

Added to food to make it look attractive, food dyes come in various forms. It’s important to use them carefully as excessive consumption can lead to health problems. They are either natural or artificial.

Application of Dyes:

Textiles: Dyes are extensively used in the textile industry to color fabrics, clothing, and other textile products. They can be applied through various methods such as dyeing, printing, or painting.

Plastics: Dyes enhance the appearance of plastic products, providing them with a wide range of colors and finishes.

Printing: Inks, whether for traditional printing or modern digital printing, often contain dyes to produce vibrant and accurate colors.

Food: Food dyes are used to add color to various food products, making them visually appealing. These dyes can be natural or synthetic.

Industrial Use: Dyes find applications in various industrial processes, including coloring materials like leather, creating inks for pens and printers, and contributing to the production of a wide array of products.

17 notes

·

View notes

Text

I want to make a BJD wig with raccoon stripes in the hair, but I wasn't sure which method would work best on tencel so time for science.

Results:

Left to right: Rit Dye, Rit Dyemore, Gouache, Acrylic, Alcohol ink, Pastel

Rit Dye works on tencel, but it's too hard to control for this stripey hair design I want.

Rit Dyemore doesn't stick. Wasn't really expecting it to stick super well since tencel isn't 100% synthetic. but threw it in the batch just to have results

Gouache somehow both doesn't stick and makes the tencel very crunchy??? Also gouache can be reactivated with water. Low key baffled someone said they've colored a wig with gouache

Acrylic works very well. It got a little crunchy on the stripe I used the most paint on, but it feels soft enough on the other two. I can probably use a lighter hand since I am using black paint. It doesn't really need multiple coarts for opacity.

Alcohol ink works well. Stays soft.

Pastel didn't stick too well.

8 notes

·

View notes

Text

First Night in Bangkok

Christopher Hitchens once said that however hard you try to avoid cliché, visiting communist Czechoslovakia forces you to reference Kafka at some point.

Anyways, Bangkok really is a fucking trip, man. I feel like I died two days ago and reincarnated in a William Gibson novel. So very much.

Inhuman cybercapital futurity assembling itself in a thousand gleaming Hong Kong-domiciled gigabanks and digital nomad cafés and dancing girls as it chokes old Buddhist temples and shantytowns and struggling palms in a traumatically transcultural miasma of a myriad reactive nitrous oxide species coughed up by a million two-stroke motors.

After a brief nap in my luxury burbclave hotel, security guard and English-fluent beaming hotel staff staff at post, me trying to do battle against 15 timezone hours' worth of jetlag, I register for the first time that I've been dissociating. I'm hobbling around on the air cast I wear for my foot sprain and a collapsible Walgreens cane, of the kind I imagine two-bit hustlers using to beat drug dealers poaching on their turf. But I'm in my favorite mass-market synthetic ink tie dye shirt, made somewhere in Central America I don't recall off hand, my blue tourist shorts, and my Buddhist beaded mala, engraved with Sanskrit I cannot read, on plastic draw string, so hopefully everyone knows I'm a chill dude.

I am in an eight floor mega shopping mall. There are robots serving white frat boys and dutiful waiters in white masks who could be robots serving local Thai prep school kids in sky blue school uniforms 500 baht sirloin steak dinners.

There are as many languages spoken here it feels like as New York City. And hotels, restaurant, massage parlors, tailors, purpose built to pander to rich Arabs, rich Chinese, rich Americans.

There is a strange amodernity to all the floating signifiers. White spring break kids approximating Thai names and wai hand clasps. Chinese shirts with a Markov chain’s chants of floating English prestige nonsense. Transcontinental fake gold watch arbitrageurs. More virtual market makers than a Jersey City server farm somehow spun up and cast into human form.

Sub-orbital resort vacationers in one corner. The state messages of the network monarch on a giant billboard overlooking a four-story expressway overpass on another. Everyone communicating in signs, gestures, and humble Buddhist bows. Hindu, Christian, Mormon, Jew, Shiite, Sunni, and so many Buddhists, all sitting and eating and shopping and praying and coughing and sputtering and fucking and bowing to one another at the end of the world before the self-aware chatbots reconstitute all the anthropomass on the third rock from the nuclear furnace. And of course, on TV, a narcissistic reality TV star in orange bronzer and an oversized navy blue Brioni suit and red tie is inaugurated president of the United States for a second time.

And my $4 dinner, served by surgically masked waitstaff at the shopping mall of the omega point. The terminal object in the category of mass market commercialism. Another floating signifier: a featured photo on Wikipedia of beautiful Jackson Hole, Wyoming, where I've actually been, here mobilized as a metonym for the kind of steak restaurant this place is supposed to be. Of course, probably no one who works here has been to America. It reminds me of Gilles Deleuze’s characterization of capitalism as an inherently deterritorializing process—one that makes every place into every other place, until no one knows where they are.

And the strangest thing is that somehow, between the tourists trying to immerse themselves in the fakery, and the shop workers trying to perform, something genuine is created, even though the thing the performance refers to is fake—and everyone knows it.

Actually, maybe the craziest moment was when I was walking past the clothing hawkers. Of which there were just so unbelievably many. And they were selling wildly unlicensed branded merch for Luis Vuitton and Ralph Loren and Balenciaga and GUESS, etc. Some of them laughably implausible. But others effectively the real thing. The Asian tourists love those in particular. And I asked myself, “how did these knockoffs get so good?”

And then I remembered: Thailand is the place where all of this crap actually gets made! It’s all outsourced to here. They’re just cutting out the middle men seeking rent on the brand. And so I’m not really sure who’s the fraud here. Is it the unlicensed shirt hawker trying to take me for a ride and fudge their “tax” calculations? Or is it the Italian fashion house trying to charge me 20x what it costs the Thai sweatshop workers to make?

I see a case for each.

Obviously not JUST Thailand makes this. There’s also Sri Lanka, Bangladesh, Honduras, Costa Rica, etc. All the groveling satellite states trying to scramble up the value-added ladder that capital and IP and telecom flows have turned into the 21st century's Manchester. All part of that big globalized textile mill.

Anyways, I got a pretty nice white dress shirt for like $15 and a truly label-less white bucket hat for $5. And I’m almost sure I got taken for a ride, but I was waaay too tired to haggle, and anyways, by any standard of justice as globalized as these clothing flows, I'm the one taking them for a ride.

I message my mother, half way around the world. It's 7:30 AM on the Eastern Seaboard of the US. It's 7:30 PM here in Bangkok. My mother says, "Keep your wits about you, man. You have to play the haggle game. It's in your Albanian blood. My grandmother would have taught you plenty, had she been there."

I can't help but think that they’d have been like, “no, please! Just take it! For free!! ” after 3 minutes of that. Those Bangkok street hagglers have never met an Albanian orphan.

Gonna go to a Buddhist temple tomorrow. First, tonight, a cocktail bar overlooking the city. In my $1000 black John Varvatos jacket with the Mandarin collar over the $15 off-brand shirt I just bought.

6 notes

·

View notes

Note

oh i have another question ! would it be difficult to make your own ink ? imagine making some paper from grass/leaves and using the liquid (boiled down and adding some gum arabic) to make ink and writing down on it :looking: . looking at pen & ink shops has really blown my mind tbh ! there’s so many bright colours and a sparkly two two chromatic inks i didn’t think could be possible (looking at Diamine Shimmer, Troublemaker and Cult Pens Exclusive)

honestly i have no idea!! there are so many really cool ways to make ink, but since fountain pens are easy to clog and require an extremely fine pigment/dye particle size, i think you'd have to look into what ink making methods would be suitable!

UPDATE as ive done some reading!! apparently it is both easy and rather uncomplicated to make fountain pen ink after all! that being said it's still good to be careful and research before you try an ink out. there are a lot of important factors to consider like acidity and reactivity with the pen materials. plus, a lot of simple recipes aren't gonna last long or be very lightfast! you don't really wanna leave egg yolk in your pen for a long time, etc.

i found this writeup pretty neat!

26 notes

·

View notes

Text

A couple of the designs I have available in my Spoonflower shop including a quilt that I made with one of my fabric panels.

A couple of the designs I have available in Art of Where shop including a quilt I made from one of my fabric panels.

Some stuff in my Sociey 6 shop.

Some of my designs in my Zazzle shop.

My designs on RedBubble.

& AranMade designs on Contrado.

I've been doing more digital designing lately since I injured my elbow and knee. Since I have all these designs, I started uploading them to many print-on-demand sites. It's been an interesting process. Some sites function better than others, but they all seem clunky.

My thoughts so far on the various print-on-demand marketplaces.

Spoonflower - I've purchased fabric yardage and a throw pillow cover from them. I used some of that fabric in the quilts and tote bags I made for my nieces.

I've been pleased with what I've received and the time it takes to make and ship. I've made a couple of quilts for gifts with my fabric panels from there, but I'm curious how the fabric will hold up over time. I think it will fade more because it's a direct ink printing process.

& Art of Where - I've purchased fabric yardage from them to make quilts. Their natural fabrics are dyed with reactive dyes, so they have much richer colors that don't fade as much.

They are, however, very slow to make and ship. My experience so far has been 3-4 weeks from the time of order until I receive it. But the print quality of their fabric yardage is excellent, so this is who I'm mainly using to print my quilt top panels.

Society 6 - I've ordered a rug from there before, and it's relatively thin, but I liked that about it. I've also ordered prints and been very happy with them. I like some of the home goods options they have on there (like credenzas), but I haven't gotten anything like that, so I'm not sure how the quality is.

Zazzle - I have not ordered anything from there yet, and uploading designs there is quite tedious, so I'm still working on this one. I do like that they have a cotton throw blanket option. I also get a lot of holiday cards from folks printed from Zazzle, so lots of folks must like what they make.

Contrado - I got all their fabric samples, and they have many lovely options! They use three different print methods depending on the material. Their natural fabric yardage is also reactive dye.

I ordered some neoprene with one of my designs to make a knee brace. I still need to make it, but the material looks great, and the print quality is excellent. The time to make and ship was also relatively quick.

Their products are also more spendy than the others on the list, but they are all made to order in the UK, and they make leather handbags and clothes with edge-to-edge print-to-cut methods.

My only issue with their site is that it only works sometimes when I click the link to my store.

#print on demand#made to order#made to measure#textile design#textile arts#textiles#tote bag#quilt#modern quilt#placemat#rug#spoonflower#art of where#society6#zazzle#contrado#made by dyslexia

2 notes

·

View notes

Text

Reliable Acetyl Chloride Manufacturer – Modi Chemical

Introduction to Acetyl Chloride

Acetyl chloride (CH3COCl) is an essential chemical compound widely used in various industrial applications, including pharmaceuticals, agrochemicals, and specialty chemicals. As a highly reactive acetylating agent, acetyl chloride plays a crucial role in organic synthesis and chemical production. At Modi Chemical, we take pride in being a trusted Acetyl Chloride Manufacturer known for providing high-purity and industry-grade chemicals to global clients.

Why Choose Modi Chemical as Your Acetyl Chloride Supplier?

When sourcing acetyl chloride, it is essential to select a manufacturer that guarantees high purity, reliability, and compliance with industrial standards. Here’s why Modi Chemical stands out:

High Purity & Quality Assurance We manufacture acetyl chloride using advanced production techniques to ensure a high level of purity, meeting stringent industrial and regulatory standards. Each batch undergoes rigorous quality control checks before dispatch.

State-of-the-Art Manufacturing Facility Our facility is equipped with modern machinery and high-tech production lines, allowing us to maintain consistent quality and efficiency in acetyl chloride production.

Stringent Safety & Compliance Standards Acetyl chloride is a highly reactive and volatile compound that requires careful handling. At Modi Chemical, we adhere to strict safety guidelines and environmental regulations to ensure a safe and sustainable production process.

Reliable Supply Chain & Timely Delivery With a well-established distribution network, we guarantee timely delivery of acetyl chloride to domestic and international clients, ensuring uninterrupted supply for your business needs.

Competitive Pricing & Customer Support We offer cost-effective pricing without compromising on quality. Our dedicated customer support team is always available to assist with orders, technical guidance, and customized chemical solutions.

Applications of Acetyl Chloride

Acetyl chloride is a vital compound used in numerous industries due to its acetylation properties. Here are some of its key applications:

1. Pharmaceutical Industry

Acetyl chloride is extensively used in the synthesis of pharmaceutical intermediates. It plays a crucial role in producing acetyl derivatives, including active pharmaceutical ingredients (APIs) such as acetaminophen and aspirin.

2. Agrochemical Industry

The agrochemical sector uses acetyl chloride for the production of pesticides, herbicides, and fungicides, contributing to enhanced crop protection and agricultural productivity.

3. Dye & Pigment Industry

Acetyl chloride is used in the manufacturing of dyes, pigments, and coatings, helping to improve color stability and chemical properties in textiles, paints, and printing inks.

4. Chemical Synthesis & Research

Being a strong acetylating agent, acetyl chloride is widely used in organic synthesis, laboratory research, and the production of specialty chemicals.

5. Plastic & Polymer Industry

Acetyl chloride is an essential compound in the synthesis of acetyl derivatives for high-performance polymers and resins.

Acetyl Chloride Manufacturing Process at Modi Chemical

At Modi Chemical, we follow a meticulous and efficient manufacturing process to produce high-quality acetyl chloride. Here’s an overview of our production process:

1. Raw Material Selection

We use high-purity raw materials, including acetic acid and chlorinating agents, to ensure the best possible chemical composition.

2. Chlorination Process

Acetyl chloride is synthesized through the reaction of acetic acid with chlorinating agents such as phosphorus trichloride (PCl3) or thionyl chloride (SOCl2). This process is carefully controlled to ensure optimum yield and purity.

3. Purification & Quality Control

The crude acetyl chloride undergoes distillation and purification to remove any impurities. Our quality control team conducts extensive testing to verify chemical purity and consistency.

4. Safe Packaging & Storage

Acetyl chloride is stored and transported in specialized containers to prevent contamination and ensure safety. We use high-grade packaging materials that comply with international safety standards.

Safety Measures for Handling Acetyl Chloride

Due to its high reactivity and volatility, acetyl chloride must be handled with care. At Modi Chemical, we implement strict safety measures, including:

Proper Ventilation & Equipment: Ensuring adequate ventilation and using corrosion-resistant storage containers.

Protective Gear: Employees wear gloves, safety goggles, and protective clothing while handling the chemical.

Emergency Response Training: Our team is trained to handle accidental spills, exposure, and fire hazards.

Regulatory Compliance: We comply with all relevant environmental and safety regulations for the responsible manufacturing and distribution of acetyl chloride.

Global Reach: Supplying Acetyl Chloride to Various Industries

As a leading acetyl chloride supplier, Modi Chemical serves clients across multiple industries and regions. Our extensive distribution network allows us to cater to businesses in:

India (Domestic Market)

Asia-Pacific

Europe & Middle East

North & South America

We ensure prompt international shipping with adherence to all global safety and export regulations.

Why Modi Chemical is the Best Acetyl Chloride Manufacturer

Choosing Modi Chemical as your acetyl chloride manufacturer means partnering with a trusted industry leader. Here’s why we are the best:

Decades of Expertise in Chemical Manufacturing

Cutting-Edge R&D & Innovation

Compliance with International Quality Standards (ISO, GMP, REACH, etc.)

Customer-Centric Approach & Technical Support

Commitment to Environmental Sustainability

Contact Us for Bulk Orders & Inquiries

If you are looking for a reliable acetyl chloride manufacturer and supplier, Modi Chemical is your go-to partner. We offer bulk supply solutions, custom formulations, and technical assistance to meet your industry needs.

📩 Email: [email protected] 🌐 Website: www.modichemical.com

Conclusion

Acetyl chloride is a critical chemical for various industrial applications, and sourcing it from a trusted manufacturer is crucial for ensuring quality and consistency. Modi Chemical is dedicated to providing high-purity acetyl chloride with top-tier quality control, safety standards, and customer service. Contact us today for your acetyl chloride supply needs and experience unparalleled reliability in chemical solutions!

0 notes

Text

T-Shirt Design Ideas That Are Seriously Next-Level

T-shirts have always been a staple in everyone’s wardrobe, but the latest trends in custom T-shirt design are taking things to a whole new level. Whether you're looking for unique branding ideas, personal expression, or something fun for an event, creativity is the key. If you’re searching for inspiration, here are some next-level T-shirt design ideas that will make your brand or personal style stand out.

1. Minimalist Typography – Less is More

Typography-based T-shirts are a timeless trend, but modern designs focus on minimalism. Simple, bold fonts with meaningful quotes or single words create an elegant and sophisticated look. Brands and individuals looking for subtle yet powerful statements love this design trend.

Pro Tip: Use neutral colors like black, white, or earthy tones for a premium look. Many t shirt manufacturers in Chennai specialize in high-quality minimalist prints that last long.

2. Vintage-Inspired Graphics – A Blast from the Past

Retro and vintage-inspired T-shirt designs are making a huge comeback. Whether it's 80s neon vibes, 90s grunge, or classic distressed prints, these styles add a nostalgic touch to any wardrobe.

Example: A custom T-shirt featuring an old-school band logo, cassette tapes, or vintage comic art.

If you’re working with t shirt manufacturers in Chennai, ask them about screen printing for a genuine vintage feel.

3. 3D and Optical Illusion Designs – Mind-Bending Creativity

Want a T-shirt that grabs attention instantly? 3D and optical illusion prints create a mind-blowing effect, making the design look as if it's popping out of the fabric.

Best Use Cases:

Event merchandise

Limited edition fashion collections

Streetwear brands

For high-quality 3D prints, look for t shirt manufacturers in Chennai that offer advanced digital printing techniques.

4. Eco-Friendly & Sustainable Designs – Fashion with a Purpose

With sustainability becoming a priority, many designers are creating T-shirts using organic fabrics and eco-friendly dyes. T shirt manufacturers in Chennai are increasingly offering sustainable options, ensuring your designs are both stylish and environmentally friendly.

Why Choose This?

Supports ethical fashion

Reduces environmental impact

Appeals to eco-conscious customers

5. Glow-in-the-Dark and UV-Reactive Prints – Stand Out at Night

If you’re designing T-shirts for parties, concerts, or night events, glow-in-the-dark and UV-reactive prints are a fantastic choice. These designs remain subtle in daylight but illuminate in the dark or under UV light.

Where to Use This?

Nightclub merchandise

Festival fashion

Glow party outfits

Several t shirt manufacturers in Chennai provide specialty ink options to achieve this eye-catching effect.

6. Interactive & Augmented Reality Designs – The Future of Fashion

Augmented reality (AR) technology is revolutionizing T-shirt designs. With AR-enabled T-shirts, users can scan the design with their smartphones to unlock animations, music, or additional digital content.

Industries Benefiting from AR T-Shirts:

Music & entertainment

Gaming & esports

Brand promotions

For tech-infused designs, partner with t shirt manufacturers in Chennai that offer digital integration printing.

7. Cultural & Regional Designs – Celebrating Heritage

Showcasing cultural heritage through T-shirt designs is an emerging trend. Many brands incorporate traditional motifs, regional scripts, or folk art into their designs.

Popular Themes:

South Indian temple motifs

Tamil calligraphy

Hand-painted traditional art

Local t shirt manufacturers in Chennai can help bring these intricate designs to life with high-quality craftsmanship.

8. Custom Photo & Portrait Prints – Personal & Meaningful

Personalized T-shirts featuring family portraits, pet photos, or favorite travel memories are a unique way to keep special moments close. Digital printing techniques now allow for high-resolution photo prints on fabric.

Best For:

Gifts for loved ones

Memorial or tribute T-shirts

Pet lovers

Look for t shirt manufacturers in Chennai that specialize in sublimation or direct-to-garment (DTG) printing for lifelike image quality.

Final Thoughts: Elevate Your T-Shirt Game

T-shirt design is more than just printing graphics on fabric – it’s about making a statement, expressing creativity, and embracing innovation. Whether you're an individual looking to create a unique wardrobe or a brand wanting to stand out, the right design can make a huge impact.

Ready to Bring Your T-Shirt Design to Life?

Work with professional t shirt manufacturers in Chennai to ensure top-notch quality, durability, and stunning prints. Whether you need bulk orders for a brand launch or a single custom piece, Chennai’s top manufacturers have you covered.

Explore the best designs and start creating T-shirts that truly turn heads today!

0 notes

Text

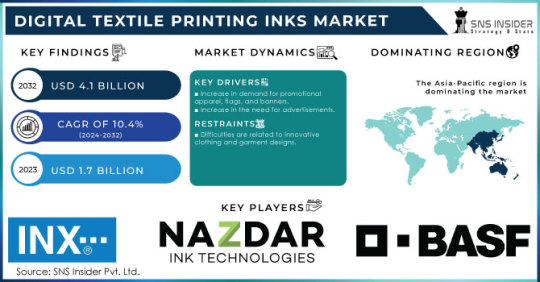

The Future of Digital Textile Printing Inks: Innovations and Market Growth

Rising Demand for Sustainable and High-Quality Printing Solutions Fuels Growth in the Digital Textile Printing Inks Market.

The Digital Textile Printing Inks Market size was USD 1.7 billion in 2023 and is expected to reach USD 4.1 billion by 2032 and grow at a CAGR of 9.6% over the forecast period of 2024-2032.

The Digital Textile Printing Inks Market is experiencing significant growth due to the increasing adoption of digital printing technology across the textile industry. These specialized inks play a vital role in achieving high-quality prints with vibrant colors, durability, and eco-friendly properties. With the rise in customized apparel, home textiles, and promotional products, the demand for efficient, cost-effective, and sustainable printing solutions has surged. Additionally, digital textile printing enables on-demand production, reducing fabric waste and water consumption, making it a preferred choice for textile manufacturers.

Key Players in the Digital Textile Printing Inks Market

INX International Ink (Expedition Inks, NSC Inks)

JK Group (Aqua Inks, J-Teck)

Nazdar Company (Nazdar 700 Series, Nazdar 120 Series)

BASF SE (Texaprint Reactive Inks, Desmodur Ink Systems)

Dover Corporation (Markem-Imaje Inks, DigiDot Inks)

DyStar Group (Remazol Inks, Dystar Pigment Inks)

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. (Hongsam Sublimation Inks, Hongsam Pigment Inks)

Huntsman Corporation (Huntsman Reactive Inks, Huntsman Disperse Inks)

Kornit Digital Ltd. (Kornit Allegro Inks, Kornit Storm Inks)

Sensient Technologies Corporation (Sensient Digital Inks, Sensient Sublimation Inks)

Future Scope of the Market

The future of the Digital Textile Printing Inks Market looks promising with:

Growing demand for sustainable, water-based inks with reduced environmental impact.

Expansion of e-commerce and customized textile products driving digital printing adoption.

Technological advancements leading to improved ink formulations with superior color fastness.

Increasing investments in high-speed digital printing machines for mass production.

Rising preference for pigment inks over dye-based inks due to their versatility and eco-friendliness.

Emerging Trends in the Digital Textile Printing Inks Market

The digital textile printing industry is rapidly shifting towards sustainable and high-performance ink formulations. Eco-friendly water-based inks, including pigment, reactive, and sublimation inks, are gaining traction due to stringent environmental regulations and growing consumer awareness. Moreover, advancements in nanotechnology and inkjet printing techniques are enhancing color vibrancy, print durability, and fabric compatibility. The demand for short-run and on-demand printing solutions is also fueling market growth, particularly in fashion, home décor, and sportswear industries. Additionally, the rise of automation and AI-driven printing processes is optimizing ink consumption and print efficiency.

Key Points:

Rising demand for sustainable, water-based textile printing inks.

Growth in personalized and on-demand textile printing applications.

Technological advancements improving print durability and efficiency.

Shift towards pigment inks for enhanced fabric compatibility.

Expanding adoption of digital printing in fashion, home décor, and industrial textiles.

Conclusion

The Digital Textile Printing Inks Market is set to experience substantial growth as the textile industry embraces digital transformation and eco-friendly practices. Innovations in ink formulations and printing technologies will further drive market expansion, catering to the evolving needs of fashion brands, home textile manufacturers, and industrial textile producers. Companies focusing on sustainability, high-performance inks, and digital printing advancements will gain a competitive edge in this dynamic market.

Read Full Report: https://www.snsinsider.com/reports/digital-textile-printing-inks-market-1458

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Digital Textile Printing Inks Market#Digital Textile Printing Inks Market Size#Digital Textile Printing Inks Market Share#Digital Textile Printing Inks Market Report#Digital Textile Printing Inks Market Forecast

0 notes

Text

Essential Industrial Chemicals and Their Role in Various Industries

The industrial sector relies heavily on high-quality chemicals for applications across various fields, including water treatment, agriculture, pharmaceuticals, and manufacturing. Essential chemicals such as liquid chlorine gas, sodium sulphate, anhydrous ammonia, aluminium sulphate, and sodium metabisulfite are widely used in different industries to enhance efficiency, safety, and productivity. Leading manufacturers in this field ensure a steady supply of these vital chemicals, meeting industry standards and contributing to global economic growth.

The Importance of Liquid Chlorine Gas

Liquid chlorine gas is one of the most significant chemicals used in multiple sectors, particularly in water purification, sanitation, and chemical synthesis. Liquid Chlorine Gas Manufacturers play a crucial role in providing chlorine for municipal water treatment plants, where it acts as a disinfectant, ensuring clean and safe drinking water. Additionally, liquid chlorine is widely used in the production of PVC, solvents, and other industrial chemicals. The pharmaceutical and textile industries also depend on chlorine derivatives for various processes, including bleaching and fabric treatment. Food industries utilize chlorine as a disinfectant in processing and packaging. Due to its reactive nature, chlorine gas requires careful handling and storage, making it essential to source it from trusted manufacturers who adhere to strict safety guidelines.

Applications of Sodium Sulphate in Various Industries

Another important chemical with widespread applications is sodium sulphate. Sodium Sulphate Manufacturers cater to industries such as detergents, glass manufacturing, pulp and paper, and textiles. In the detergent industry, sodium sulphate is commonly used as a filler in powdered laundry detergents, improving cleaning efficiency. Glass manufacturers use it to remove air bubbles from molten glass, ensuring a smooth and clear finish. The pulp and paper industry relies on sodium sulphate for bleaching and pulping processes, while textile manufacturers use it to promote even dye absorption. With increasing demand across multiple industries, sodium sulphate remains an essential industrial chemical.

The Role of Anhydrous Ammonia in Agriculture and Industry

Anhydrous ammonia is another crucial compound extensively used in agriculture and refrigeration. Anhydrous Ammonia Manufacturers provide this nitrogen-rich chemical primarily for fertilizers, where it enhances soil fertility and improves crop yields. In the refrigeration industry, anhydrous ammonia is a preferred cooling agent in large-scale industrial cooling systems due to its efficiency. Additionally, it serves as a precursor in the production of nitric acid, urea, and ammonium nitrate, which are vital for various chemical applications. In the water treatment sector, it helps regulate pH levels, ensuring optimal water quality. Given its highly volatile nature, anhydrous ammonia requires careful handling and transportation, making it essential to work with experienced manufacturers who follow stringent safety protocols.

Uses of Aluminium Sulphate in Water Treatment and Manufacturing

Aluminium sulphate, commonly known as alum, plays a significant role in water purification and industrial processing. Aluminium Sulphate Manufacturers produce this chemical for use as a coagulant in municipal and industrial water treatment plants. It effectively removes impurities and sediments from water, ensuring it is safe for consumption. The paper industry utilizes aluminium sulphate in the sizing process, which improves ink absorption and print quality. In the textile industry, it is used in fabric dyeing to enhance color fixation, ensuring vibrant and long-lasting colors. Additionally, aluminium sulphate is widely used in construction for soil stabilization and concrete production. Due to its ability to purify water efficiently and support various industrial applications, it remains a valuable chemical in numerous sectors.

Significance of Sodium Metabisulfite in Various Applications

Sodium metabisulfite is a versatile chemical with applications in food preservation, water treatment, pharmaceuticals, and mining. Sodium Metabisulfite Manufacturers provide this essential compound to the food industry, where it acts as a preservative, preventing oxidation and bacterial growth in packaged food and beverages. In water treatment, sodium metabisulfite helps neutralize chlorine and other harmful contaminants, ensuring safe water quality. The pharmaceutical industry utilizes it in drug formulation and preservation, while the mining sector uses it for extracting precious metals such as gold. With its broad range of applications, sodium metabisulfite remains an indispensable chemical in multiple industries.

Conclusion

The chemical industry plays a vital role in supporting modern industries by providing essential chemicals that drive efficiency and innovation. Liquid Chlorine Gas Manufacturers, Sodium Sulphate Manufacturers, Anhydrous Ammonia Manufacturers, Aluminium Sulphate Manufacturers, and Sodium Metabisulfite Manufacturers contribute significantly to industrial growth and environmental safety. By choosing high-quality chemical manufacturers, industries can ensure a consistent supply of these critical substances while maintaining safety and compliance standards.

0 notes

Text

How to Choose the Best Cotton Fabric Printing Machine for Your Business

Choosing the right cotton fabric printing machine is crucial for businesses in the textile industry. With advancements in digital textile printing, selecting the best machine can significantly impact print quality, production efficiency, and cost-effectiveness. Whether you are starting a new business or upgrading your existing setup, understanding the key factors that influence this decision is essential.

Orange O Tech is a leading brand in textile printing, offering cutting-edge solutions to meet the demands of modern businesses. In this guide, we will walk you through the essential factors to consider when selecting a cotton fabric printing machine that aligns with your business goals.

Understanding Cotton Fabric Printing

Cotton is one of the most widely used natural fibers in the textile industry due to its softness, durability, and breathability. However, printing on cotton requires specialized machines that ensure ink absorption, color vibrancy, and durability. Unlike synthetic fabrics that are compatible with sublimation printing, cotton requires direct-to-fabric (DTF) printing or pigment-based printing for optimal results.

Key Factors to Consider When Choosing a Cotton Fabric Printing Machine

1. Printing Technology

The printing technology you choose will determine the print quality, efficiency, and versatility of your business. Here are the primary technologies used in cotton fabric printing:

Direct-to-Fabric (DTF) Printing: Ideal for natural fibers like cotton, this method provides deep ink penetration and vibrant prints. It is widely used for both small and large-scale production.

Reactive Printing: Uses reactive dyes that chemically bond with the fabric, ensuring long-lasting prints with excellent wash durability.

Pigment-Based Printing: Eco-friendly and cost-effective, this method is suitable for businesses looking for a sustainable printing solution.

2. Production Speed and Capacity

Your production requirements will dictate the type of machine you need. If you are running a large-scale textile business, you need a high-speed cotton fabric printing machine that can handle bulk orders efficiently. Machines like those offered by Orange O Tech can print thousands of meters per day, making them ideal for high-volume operations.

If you are running a smaller business or a custom-printing service, a mid-range machine with moderate production speed may be more suitable.

3. Print Resolution and Quality

High-resolution printing ensures that designs are sharp, detailed, and vibrant. When choosing a machine, consider the dots per inch (DPI) resolution. Machines with advanced printheads, such as Kyocera or Epson, provide superior color accuracy and sharpness, ensuring professional-quality prints on cotton fabric.

4. Ink Compatibility

The type of ink used in your cotton fabric printing machine is crucial for achieving long-lasting, high-quality prints. Some of the best ink options for cotton fabric include:

Reactive Inks: Offer deep color penetration and excellent durability. Ideal for high-end fashion textiles.

Pigment Inks: Require minimal water usage and are environmentally friendly. Best for sustainable printing solutions.

Acid Inks: Used for delicate fabric printing but less common for cotton.

Ensure that the machine you choose is compatible with the ink type that best suits your business needs.

5. Eco-Friendliness

Sustainability is becoming a key factor in the textile industry. Modern cotton fabric printing machines incorporate eco-friendly technologies that reduce water and energy consumption. Orange O Tech offers machines that use minimal resources while delivering high-quality prints, making them a great choice for businesses looking to reduce their environmental impact.

6. Cost Considerations

While investing in a cotton fabric printing machine, consider both the initial purchase cost and the long-term operational expenses. Some key cost factors include:

Machine price: Higher-end machines may have a larger upfront cost but offer better efficiency and durability.

Ink costs: Some machines consume more ink than others. Choosing a machine with efficient ink usage can save money in the long run.

Maintenance costs: Regular servicing and spare part availability should be factored into your budget.

7. Technical Support and After-Sales Service

Having access to reliable technical support ensures that your business runs smoothly without frequent breakdowns. Orange O Tech provides comprehensive after-sales service, including training, troubleshooting, and maintenance support, ensuring minimal downtime for your business.

8. Versatility and Future Expansion

As your business grows, you may want to expand your printing capabilities. Investing in a versatile cotton fabric printing machine that can handle multiple fabric types, printing techniques, and customization options will help you scale your business without frequent equipment upgrades.

Why Choose Orange O Tech for Your Cotton Fabric Printing Machine?

Orange O Tech is a trusted name in the textile printing industry, offering state-of-the-art cotton fabric printing machines that cater to businesses of all sizes. Here’s why they stand out:

High-Speed Printing: Machines designed for bulk production, reaching up to 15,000 meters per day.

Superior Print Quality: Advanced printhead technology ensures high-resolution, durable prints.

Eco-Friendly Solutions: Machines designed to reduce water and ink wastage.

Comprehensive Support: Training and after-sales service for seamless business operations.

Cost-Effective Machines: Competitive pricing with low operational costs.

Whether you are a startup looking for an entry-level printer or an established textile business seeking high-performance machines, Orange O Tech has the perfect solution for your needs.

Final Thoughts

Selecting the best cotton fabric printing machine for your business is a crucial investment that requires careful consideration. By evaluating factors such as printing technology, production capacity, ink compatibility, cost efficiency, and technical support, you can make an informed decision that ensures long-term success.

Orange O Tech offers a range of high-performance textile printing machines that cater to various business needs, ensuring superior quality, efficiency, and sustainability. If you’re looking to upgrade your printing setup or start a new venture, choosing the right cotton fabric printing machine will set you on the path to success.

1 note

·

View note

Text

Numerous high-quality textile ink manufacturers gathered on May 19-21 Guangzhou ITCPE!

The textile digital printing technology blends fashion with creativity, so its quality is closely related to the aesthetics and durability of the final product. For this technology, the quality of textile digital printing ink undoubtedly plays a crucial role. It not only affects the definition of the print pattern, and color saturation, but also directly affects the wearing experience of the garment and the overall quality.

In recent years, with the rapid development of technology and the wide application of ink in various fields, the market demand for textile digital printing ink shows a trend of continuous growth. According to statistics, in 2023, the global inkjet ink market size has reached a staggering 15.683 billion yuan, and in China, an important consumer market of inkjet ink, the market size has also reached 3.221 billion yuan. This data not only reflects the huge potential of the market, but also predicts that the field will open up a broader prospect.

Some of the exhibitors (The following are in no particular order)

Shenzhen INKBANK Group Inc. — Booth No. T3009

Shenzhen INKBANK Group Inc. is a leading supplier of inkjet ink and digital application solutions in China, specializing in the research, development and manufacture of inkjet ink for 20 years. The company now has a modern R & D and production base of nearly 30,000 square meters, with an annual production capacity of more than 18,000 tons of products sold well at home and abroad in more than 100 countries and regions.

The products developed by the company mainly include: LED-UV curing ink, coating ink, heat sublimation ink, high temperature dispersion ink, reactive dye ink, acid dye ink, water-based pigment ink and water-based dye ink.

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. — Booth No. T4032

Hongsam digital adheres to the “Hongsam +” business philosophy, is rooted in the industry, and is willing to work with more companies to create a new digital life for mankind through extensive links, and in-depth cooperation. Following the value of “Hongsam Service”, we emphasize on channel construction externally, implement process management internally, and connect many channel partners and end-users with Hongsam technology and process services. Guided by the “user thinking” idea, we strengthen our technology and services, and unite upstream and downstream partners in the industry to form a huge network of customers. The “user thinking” idea makes customers and Hongsam connect closely together to become the “Hongsam+” community.

Foshan Kai Yan New Material Co., Ltd. — Booth No. T4017

Kai Yan New Material, a high-tech enterprise in the field of inkjet printing in China, one of the ink manufacturing supplier, owns a plant with an area of nearly 11,000 square feet so far, with the annual production capacity of more than 3,000 tons of UV ink, and more than 2,000 tons of water-based ink. The products are sold at home and abroad in different countries and regions. In just two years, the domestic sales of UV ink rose to rank amongst the top three, creating a miracle of the industry for a single ink product. The company is now in the forefront of the industry. The company focuses on the development of ink in the field of digital inkjet printing applications. We have always been adhering to the vision of “Doing business for well-being, developing ink with devoted will”, to provide customers with professional inkjet printing solutions and services. Our products cover areas such as the textile industry, labeling industry, building materials industry, advertising industry, special applications, and other daily necessities.

Innovation is the vitality of the development of enterprises. “Kaiyan New Material” pays more attention to R & D innovation, and is committed to the concept of “products lead the industry development, business innovation, win-win with partners in the future,” for the individual needs of different customers, the company gives full play to the spirit of innovation, while ensuring product quality.

Fully in accordance with the relevant national laws and regulations, the production of ink products is in line with RoHS, REACH, which marks our products to obtain the peer recognition from all around the world. Talent is the driving force of the enterprise development, so we keep on to establish talent incentive mechanism, and to provide a high-quality platform for capable, ambitious and aspiring talents, as well as a variety of conditions for the enterprise and the staff to grow together. In the future, Kaiyan New Material will always struggle for the goal of “becoming a company with vitality, innovation and faith”, and strive to make itself a bridge for you and me to grow and win together.

Guangzhou Unity Peak Company Ltd. — Booth No. T4009

Guangzhou Unity Peak Company Ltd. was founded in 2009. It is a national high-tech enterprise, and a specialized and sophisticated enterprise of Guangdong Province, located in Guangzhou Nansha Economic Development Zone. Since its inception, the company has been adhering to the “innovation, quality, integrity” business philosophy, and the route of green sustainable development, and focusing on the research and development and production of textile digital printing coating ink. The product has passed the Zurich (Switzerland)-based Oeko-Tex Standard 100, Class 1 certification for 12 consecutive years. The company’s laboratory has been equipped with Malvern particle size meter, ink drop observer, nano-mill and other professional equipment; in 2023, the company’s laboratory passed the CNAS certification, marking that the independent laboratory of Unity Peak new materials has met the international recognized standards in hardware facilities, testing capabilities and management level.

“Macheng” coating ink is the outstanding research and development achievement of the independent laboratory, which is used to research and develop textile digital printing pigment ink to replace imported ones.

After more than ten years of research, the R & D team in the coating ink application program has accumulated rich experience and improved the performance of the coating ink products to make them more in line with the application in Chinese market. At present, Unity Peak has formed a product matrix integrating thermal transfer machine production, coating ink research and development, white ink hot stamping paper and non-sensitive labels, which is a multi-wheel drive to recreate a new textile future. In the future, the company will increase investment in research and development to ensure the stability of product quality and perspectiveness.

Zhuhai Colour Spring Digital Technology Co., LTD — Booth No. T3038a

Zhuhai Colour Spring Digital Technology Co., LTD is located in the beautiful city, Zhuhai. It is a comprehensive enterprise specializing in the research and development, production and sales of digital inkjet ink. Colour Spring adheres to “rigorous attitude, first-class products, first-class service”. Relying on the company’s strong strength and a group of senior R & D, production and sales team, the company has established a number of series of advanced ink product lines, which are sold both at home and abroad.

The company’s products include: textile direct spray coating ink, white ink hot stamping film transfer ink, direct spray white ink, pretreatment fluid, moisturizing fluid, desktop printer compatible cartridge ink, ink tank printer ink, etc.

Zhuhai Colour Spring Digital is committed to providing environmental friendly, economical and high quality inkjet ink products for the global digital printing users. We are willing to build a win-win cooperation with global merchants and counterparts to create a strategic partnership for the future.

Foshan Createtide Digital Tech Co., Ltd. — Booth No. T4033

Guoci Kanglitai has set up more than twenty offices at home, and formed a business layout in foreign markets with seven major sales regions such as China and Africa, Tulsa, India, Middle East and North Africa, Mumbai, Indo-Malaysia-Taiwan, Southeast Asia and Europe, etc. It not only sets up branch offices in India, Turkey and other countries, but also will establish branch offices in the core countries and regions of the world one after another. In Dongying, Shandong Province, Guoci Kanglitai has built a large ink production base with a production capacity that ranks among the top in the world, with dozens of modernized and intelligent production lines, and an annual production capacity of 30,000 tons of ink. With “digital printing materials” as the core business, the company has expanded from ceramic ink to textile ink and other digital printing fields, and in 2024, its subsidiary, Foshan Createtide, newly launched the “COREMAX” digital textile printing ink brand. At present, COREMAX is mainly committed to the development and application of textile hot stamping ink and reactive ink. In the future, COREMAX will provide customers with a complete set of textile digital printing solutions, including but not limited to textile inkjet ink, digital printing process, pre-processing and post-processing of textile fabrics and raw materials, as well as provide customers with efficient and professional pre-sales and after-sales technical services. COREMAX has established several modern intelligent production lines in Sanshui, Foshan, with an annual production capacity of 10,000 tons of textile ink.

Zhuhai Chungkao New Material Tech Co., Ltd. — Booth No. T4025a

We have a strong professional R&D team, professional production team, professional sales team and after-sales service team, advanced laboratory, testing equipment, instruments and so on. The R&D team has more than 15 years of experience in inkjet printing and digital printing industry, and always keeps leading in the industry in R&D technology.

Our complete equipment and facilities and excellent quality control throughout all stages of production enable us to ensure the overall satisfaction of our customers. We insist on technological innovation, efficient production, strict management process and excellent service to provide our customers with perfect inkjet and textile coating ink products and a series of solutions.

We have ISO9001 quality management system certificate. If you are interested in any of our products, or you would like to negotiate customized orders, please feel free to contact us. Welcome to be our win-win partner.

Dongguan Kingjet Printers Consumables Co., Ltd. — Booth No. T3017

Dongguan Kingjet Printers Consumables Co., Ltd., a high-tech enterprise, was founded in 2007 in the “world factory” city — Dongguan. With 10 years of history, we have been focusing on ink research and development, production and sales as a whole. The company’s main operating brands are “Printing color king (印彩王)” and “KINGJET”.

The company now employs more than 50 people, managers and researchers with bachelor’s degree or above, respectively, from the high polymer materials, fine chemicals and business administration and other professions. The company insists on adopting advanced ink production process and formula, together with a series of advanced production inspection and testing equipment such as the laser particle size distribution meter and QUV weathering tester from abroad, as well as printing test equipment for many types of printheads; adopting imported high-grade raw materials and using advanced large-scale specialized production equipment, which guarantees stable quality, high quality and environmental protection of the products.

Kingjet’s products are suitable for Epson, Canon, HP, Brother, Ricoh, Lexmark, Starfire, Kyocera, Konica, Samba and other printheads of wide-format printers, UV flatbed printers, scanning and Single-Pass industrial machines, desktop inkjet printers and other machines and equipment; they can be widely used in digital textile printing industry, advertising printing industry, digital printing industry, digital imaging industry, digital decoration industry, office printing industry, and food industry.

Products applied in the digital textile industry: textile printing heat sublimation ink, textile printing high-temperature dispersion direct spray ink, textile printing paint direct spray ink, textile printing reactive ink, textile printing acid ink, leather odorless weak solvent ink, offset hot stamping ink, cross stitch dye ink.

Products used in the digital imaging industry, digital decoration industry, advertising spray painting industry, and digital printing industry: oil-based weak solvent ink, solvent ink, water-based weak solvent ink, advertising banner ink, UV ink, wide-format pigment ink, pigment ink for coated paper, wide-format dye ink, water-based latex (LATEX) ink, image printing ink, medical film ink, film ink.

Products used in office printing and graphic digital printing industry: desktop printing dye ink, desktop printing thermal transfer ink, desktop printing pigment ink, HP page width printer pigment ink, EPSON page width printing pigment ink.

Products applied in the food industry: food-grade ink.

Products applied to the digital printing industry: POD newspaper and booklet digital printing pigment ink (newspaper and booklet digital printing machine, corrugated digital printing dye ink and pigment ink (EPSON i3200 printhead, HP 970/980/990 printhead corrugated digital printing machine), label digital printing pigment ink (EPSON i3200 label digital printing machine)

High quality is the root of enterprise survival; new products are the source of enterprise advancement and market development. The company’s products have been exported to Southeast Asia, South America, North America, Central Asia, South Asia, Africa, Europe, the Middle East and domestic provinces and cities. Company tenet: excellent quality, reasonable price, reputation first, customer first, integrity-based, continuous innovation.

Texca New Printing Materials Co., Ltd. — Booth No. T4026b

Texca New Printing Materials Co., Ltd. is a foreign (Canadian) joint venture, now located in High-tech Industrial Park, Daguan District, Anqing, Anhui Province, with a registered capital of 6.4 million U.S. dollars.

After the completion of the company, the printing ink project annual output reached 6,000 tons.The construction is completed in two phases, the first of which has an annual output of 3,000 tons of printing ink and 1,000 tons of digital printing ink.

Our company adheres to the development concept of “safe development, green environmental protection”, and will vigorously develop water-based ink, which is a nationally encouraged project, in the next five years. The company adheres to the enterprise spirit of “honesty, diligence, refinement, progress”, pursues the enterprise business philosophy of “quality is vital, service is essential”, and meets the market demand with first-class products and high-quality service.

Guangzhou SAVEN Technology Co., Ltd. — Booth No. 3001, 3002, 3003, 3004

With years of development experience, SAVEN has formed a good symbiotic relationship with many upstream material suppliers, and works closely with printer manufacturers and printhead manufacturers. 4200D, 4203D, 4203L, 4205 and fluorescent hot stamping inks are very popular, and the latest launches in 2022 are the breathable hot stamping ink 6040-1 and the permanent white anti-sublimation ink YB-12D. SAVEN would like to present the best products and development solutions to the customers.

Dongguan Shinycolor Tech Co., Ltd. — Booth No. T4004b

Eastern Tech Company — Booth No. T043C

Eastern Tech Company, founded in 1995, is a specialty ink & coatings manufacturer, headquartered in Milford, CT. Our experienced team of chemists and production technicians have researched, developed, and produced the highest quality ink products for various industries in the United States and worldwide.

Eastern Tech works directly with OEM partners, developing solutions for market. We target Ink Innovations in everything that we do.

With a stream-lined production facility, Eastern Tech has a production capacity of over 500 million yuan CNY or more of ink annually.

With the evolving digital print industry, Eastern Tech has innovated piezoelectric-compatible inkjet inks.

Since 2008, Eastern Tech has manufactured water-based pigmented ink for inkjet printing directly onto t-shirts and other textiles. Our chemists have effectively improved color vibrancy, washability, and maintenance of use. Along with specially formulated pretreatment and cleaning solution products, Eastern Tech offers the complete solution for the Direct-To-Garment (DTG) industry.

Eastern Tech has invested millions in R&D, production, and quality control equipment to further ink innovations.

0 notes

Text

How Does Chiffon Printing Differ from Other Fabrics?

Chiffon is a lightweight, sheer fabric that has gained immense popularity in the fashion industry. Whether used in elegant evening gowns, scarves, or formal wear, chiffon’s delicate nature requires specialized printing techniques to achieve high-quality results. Unlike other fabrics, chiffon printing involves a unique process that enhances its beauty while maintaining its softness and flow.

1. The Nature of Chiffon and Its Printing Challenges

Chiffon is made from silk, polyester, or nylon, giving it a soft, airy feel. Unlike cotton or linen, chiffon has a delicate weave that makes it more challenging to print on. The lightweight and sheer nature of the fabric requires precision in ink application to avoid smudging or distortion of designs. Advanced printing methods like digital sublimation and screen printing are commonly used to ensure intricate patterns appear crisp and vibrant.

2. Ink Absorption and Color Vibrancy

Compared to other fabrics, chiffon does not absorb ink the same way as cotton or wool. Since the fabric is translucent, colors must be carefully applied to maintain their vibrancy without bleeding. Digital and heat transfer printing are preferred for chiffon, as they allow for detailed designs without compromising the fabric’s texture.

3. Durability and Washability

Fabrics like cotton and polyester have a higher resistance to frequent washing, while chiffon requires gentle care to preserve printed patterns. Unlike heavier textiles, chiffon prints may fade if washed improperly. This is why fabric printing specialists use high-quality dyes and fixatives to ensure that the designs remain vibrant even after multiple wears.

4. Printing Techniques Best Suited for Chiffon

Unlike fabrics such as denim or canvas that can withstand traditional screen printing, chiffon benefits more from sublimation or reactive dye printing. These techniques allow the design to bond with the fabric fibers without affecting its softness or causing stiffness. The result is a breathable, lightweight material with flawless prints.

Conclusion