#Custom Paper Tube Packaging

Text

Custom Paper Tube Packaging | China Manufacturer & Supplier

Whether you sell confectionery, food, health & beauty, wine & spirits, or household chemicals, Hopak’s paper tube packaging will seal your products uptight and protect them from the outside world.

Choose from various sizes to find the one that suits your dry, powdered, or confectionery packaging needs. Pick a matte or glossy finish to help your doy packs stand out.

Then consider adding a premium feature – a resealable zip to extend the life of your product or a hang hole so that it can be hung on display. <a href=”https://www.hopakpackaging.com/paper-tube-packaging/”>“Paper Tube Packgaing”</a>

0 notes

Text

All Paper Tube Co. specializes in creating custom paper tube solutions that meet the highest quality standards. With our extensive experience in the industry, we are the ideal choice for any custom paper tube needs.

Phone/WA: +86 18118733308

Mail ID: [email protected]

0 notes

Link

Paper Tube Company

Apaper Tube is one of the leading Paper Tube Company in Shenzhen, China which is specialized for the manufacturing and supplying of high quality and reliable packaging boxes and tubes made of different shapes, sizes and material for cosmetics, electronics, food, wine and many other products packaging. To know more, call us at +86075532811558.

0 notes

Text

You can be cheap without being a scumbag. Buy used things. Repair them when they wear out. Check every vending machine you pass for forgotten change in the coin return. Get rid of all that excess blood plasma you don’t need for your non-intensive office job. If you want to be a scumbag, though, you have to be constantly looking for new angles.

Around my part of the world, the government has been telling restaurants to cut it out with the plastic shit. Every meal you order, even if it comes to your house, comes complete with half a dozen plastic utensils that just end up in the dump and – more likely than not – choke a dolphin to death. Yeah. A dolphin. Flipper’s dead because McDonalds won’t stop giving you free forks. What do you think about that, reactionaries?

I digress. One of the things that they’ve been getting rid of as a result of this new regulation is plastic straws. So now the straws are made out of paper, which is not a problem with me, but they include those straws even when you buy a bottle of water. Bottles are for chugging, folks. Which means I have tons of leftover straws kicking around my house, and it bothered my scumbag nature to no extent not to have a creative use for them.

Sure, I tried the basics. Arts and crafts. Scale-model fabrication. Drain tubes. Using them as blowguns to knock out the mailman with a powerful paralytic agent so I could interrogate him at my leisure about why my packages take two weeks to clear customs. Nothing really worked, or at least didn’t use up the straws faster than more arrived with my weekly order (usually placed when I needed another water bottle with which to catch a newly-sprouted leak.) That is, until I figured it all out.

Way back in the 1970s, when the world was going to hell because gasoline became not as expensive as it is now, the brave Swedes had a solution. They figured out that they could burn useless trees as fuel, and so developed wood-gas reactors that they strapped to the back of their Volvos. Run out of gas? Chop down a nearby tree and cram that shit into the tank, you’re good to go. All I had to do was make a trip to Swedish eBay and order a several-hundred-pound woodgas conversion kit using someone else’s credit card. Don’t worry, environmentalists, I picked the slower shipping option. Now, I could chuck these paper straws right in there and get like half a block of gas – for free!

The project has been so successful, in fact, that I now find myself visiting fast-food restaurants just to help myself to several boxes of straws. They give me weird looks, sure, but there’s just something about a half-feral scruffy dude burrowing into your restaurant, stealing several hundred paper straws, and then running out the nearest exit that shouts “don’t call the cops yet.” Even though it probably wouldn’t be hard for them to find me in this plume of noxious waxed-paper smoke.

493 notes

·

View notes

Text

I need funds. Here are things I could trade you in exchange for said moneys.

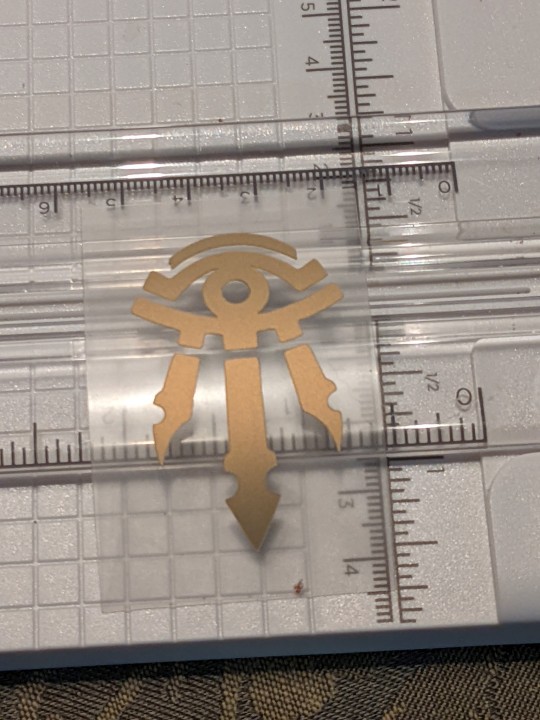

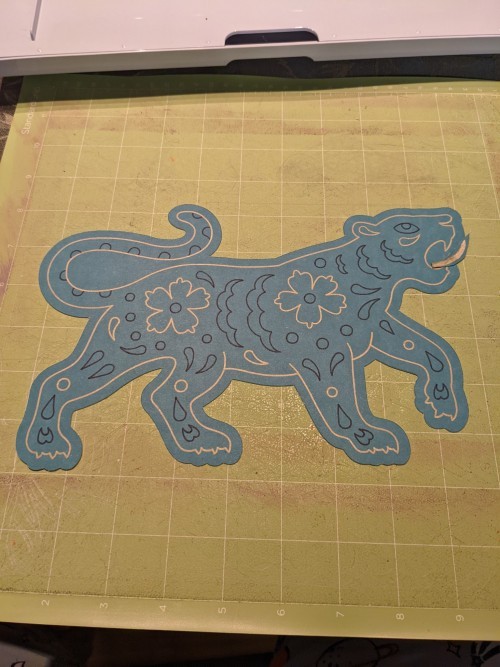

I have a Cricut and can cut out shapes for you. These could be cut in paper, adhesive vinyl(for stickers/decals) or iron-on-vinyl that can be put onto clothing. Honestly it’s a lot of fun to put fandom shapes(like the one shown here) onto things. You send me a image with decent contrast and I can get you a mono-colored shape from it. The limits are what you got and it can only be as big as a 12x12 sheet for most of my colors if you don’t want to have to put it together. I also cut out re-useable stencils from plastic packaging and can do custom orders of those if wanted.

I can in fact do really small cuts (see below)

these make fantastic lapel pin like decorations.

I am 80% certain that I can make stickers/paper art of any clear line art I am sent. So if you are an artist and want your line art on something you should talk to me.

These are earrings made out of re-cycled plastic. I have a stock of ones I have made and can also do custom shapes if the shape will work with me. I will post more of them if people are interested.

I have a big bowl of pins. If you see any here that you would like I can send them to you for 1$ with discounts if you want a bunch. Or you can get random grab. I also can make pins to order if anyone wants that.

Soda tab weaving. These are necklaces. I can do other work with this as well but bigger things take a lot more time. The prices you see are before shipping.

I knit hats. These are all still for sale plus I can do custom orders. I also have pumpkins that I have made/can make if you like the look of that one.

I can make fingerless gloves, like this one or more solid. If you like the color of one of the hats above I could make gloves of that same unless I run out of that yarn.

I can also make tube scarves or socks in much the same way.

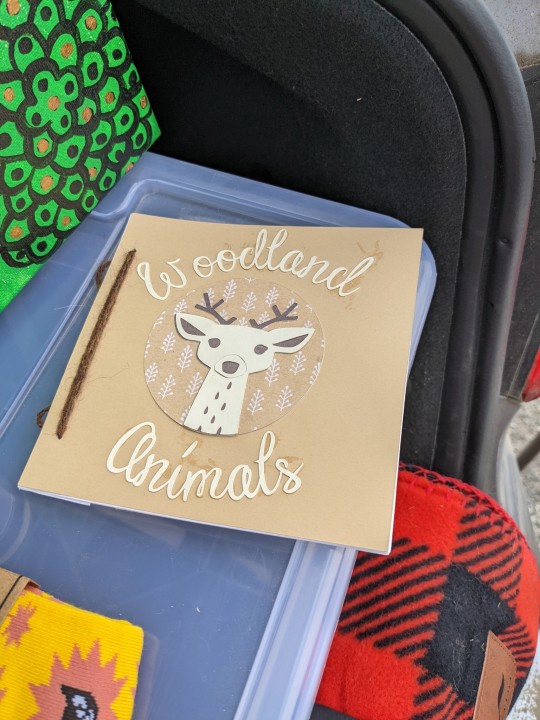

This is a coloring book I made with my Cricut. This one is for sale and I can also do custom work. I also can make small notebooks.

In addition to all this I also make hats and fingerless gloves for local charities(not Salvation Army or Goodwill) and you can sponsor me giving those by in-essence buying the item and having me give it to them for you.

I am disabled and on a fixed income so anything would help even a re-blog.

Yes I am willing to do NSFW work if you have something like that that you want from the Cricut.

Contact me here on Tumblr for best response time or at [email protected]

paypal.me/serglin

Oh! And also you will get free shipping if you order a bunch!

#i make stuff#things for sale#stuff for sale#i make things#DIY clothing#fandom#prints#sort of#I am looking for work#looking for work#commissions#papercraft#stickers#decal#earings#stencils#re-cycled plastic#pins#flare#Soda tab#jewerly#plz share#plz reblog#master post

69 notes

·

View notes

Text

The Art and Science of Packaging boxes for beauty products: A Comprehensive Guide

When it comes to beauty products, packaging plays a crucial role. Not only does it protect the product, but it also serves as a powerful marketing tool. In this article, we'll delve into the significance of packaging in the beauty industry, explore various types of packaging, and highlight current trends and challenges. By the end, you'll understand why packaging is more than just a container for your beauty products.

The Importance of Packaging in the Beauty Industry

First impressions are everything, especially in the beauty industry. Packaging boxes for beauty products is often the first thing a customer notices, significantly influencing their purchasing decision. The packaging of a beauty product is like a book cover; it needs to catch the eye and make an excellent first impression. Attractive packaging can attract customers, while poor packaging can turn them away before trying the product. Packaging is a critical element of a brand's identity. It communicates the brand's values, style, and quality. Consistent, well-designed packaging helps build brand recognition and loyalty. Beyond aesthetics, packaging must protect the product from damage and contamination. Proper packaging ensures the product remains fresh and compelling until it reaches the consumer.

Types of Beauty Product Packaging

Beauty product packaging can be categorized into 3 fundamental types: number one, secondary, and tertiary packaging. Primary packaging boxes for beauty products is the on the spot field that holds the product. For instance, the bottle protecting your preferred basis or the tube of your cross-to mascara. Secondary packaging consists of additional layers that defend and promote the primary package. This is probably the field holding a fragrance bottle or the card sleeve around lipstick. Tertiary packaging is used for bulk dealing with and shipping. It guarantees the secure delivery of merchandise from the manufacturer to the retailer.

Materials Used in Beauty Product Packaging

Various materials are used in beauty product packaging, each with its benefits and drawbacks. Glass is a popular choice for luxury products. It's durable, non-reactive, and has a premium look. However, it's also heavier and more fragile than other materials. Plastic is versatile and widely used in beauty product packaging. It's lightweight, durable, and can be molded into various shapes. The downside is its environmental impact. Metal packaging, often used for lip balms and compact powders, offers durability and a sleek appearance. It's also recyclable, making it a more eco-friendly option. Paper and cardboard are commonly used for secondary packaging. They are lightweight, recyclable, and can be printed with high-quality designs.

Sustainable Packaging Solutions

With increasing environmental concerns, sustainable packaging is increasingly important. Materials such as bamboo biodegradable plastic and recycled paper are gaining popularity in beauty packaging. Waste can be significantly reduced by encouraging consumers to recycle or recycle packaging. Many companies are now designing packaging with this in mind. Biodegradable packaging degrades naturally, reducing environmental impact. This is a good choice for environmentally conscious products.

Design Elements in Beauty Product Packaging

Effective packaging design goes beyond just choosing materials. It involves several elements that together create a compelling product. Colors can evoke emotions and convey messages. For example, green often represents natural and eco-friendly products, while gold and black can signify luxury. The choice of fonts and the way textual content is arranged can effect the readability and attraction of the packaging. It ought to align with the logo's character and target market. Images and photos can beautify the attraction of packaging. High-quality visuals can communicate the product's benefits and attract potential customers.

Innovative Trends in Beauty Packaging

The beauty industry is constantly evolving, and so is packaging. Here are some innovative trends making waves. Technology is being integrated into packaging to enhance user experience, such as QR codes that provide product information or augmented reality experiences. Simplicity is vital in modern packaging. Minimalist designs that focus on essential details and clean aesthetics are trending. Personalized packaging, such as monogrammed containers or custom labels, can make products feel unique and special to the consumer.

Regulations and Standards in Beauty Packaging

Beauty brands must adhere to regulations and standards to ensure safety and compliance. Labels must include ingredients, usage instructions, and other relevant information. This ensures transparency and helps consumers make informed choices. Packaging must protect the product from contamination and ensure it is safe. This includes tamper-evident seals and child-resistant packaging. Compliance with environmental regulations is essential, especially for brands focusing on sustainability. This includes proper disposal instructions and using eco-friendly materials.

The Role of Packaging in Marketing and Sales

Packaging is not just about protection; it plays a vital role in marketing and sales. Attractive packaging can stand out on crowded shelves and catch the eye of potential customers. A memorable unboxing experience can enhance customer satisfaction and encourage repeat purchases. Thoughtful packaging boxes for beauty products design can create a sense of excitement and anticipation. Packaging that looks good on camera can be a powerful tool in influencer marketing. Eye-catching designs are more likely to be shared on social media.

Cost Considerations in Beauty Packaging

Balancing quality and cost is a significant consideration for beauty brands. Brands need to allocate a packaging budget that considers production and material costs. Finding cost-effective solutions without compromising quality is critical. This might involve bulk purchasing or using more affordable materials. While price is essential, it's crucial not to compromise on quality. Poor packaging can damage the product and the brand's reputation.

Challenges in Beauty Product Packaging

Despite its importance, packaging boxes for beauty products comes with several challenges. Finding sustainable packaging solutions that are also cost-effective and practical can be complex. Ensuring that products remain fresh and compelling over time is a critical concern. Packaging must prevent contamination and degradation. Counterfeiting is a significant issue in the beauty industry. Packaging must include security features to protect the brand and consumer.

Case Studies of Successful Beauty Packaging

Examining successful packaging can provide valuable insights. A high-end skincare brand uses glass bottles and minimalist designs to convey luxury and elegance. An eco-conscious brand uses recycled cardboard and soy-based inks to highlight its commitment to sustainability. A famous mass-market brand uses bright colors and fun designs to appeal to a younger audience, making their products stand out on shelves.

The Future of Beauty Packaging

The future of beauty packaging looks promising, with several exciting developments on the horizon. Technological advances will continue to drive innovation in packaging, from intelligent packaging to new sustainable materials. Demand for sustainable and eco-friendly packaging will grow as consumers become more environmentally conscious. Experts predict a shift towards more personalized and interactive packaging, enhancing the consumer experience.

Tips for Choosing the Right Packaging for Your Beauty Brand

Selecting the proper packaging is crucial for any beauty brand. Know who your customers are and what they value. This will guide your packaging decisions. Your packaging should reflect your brand's values and identity. Consistency is critical to building brand recognition. Before finalizing your packaging, test it with your target audience and gather feedback. This can help you make necessary adjustments and ensure it resonates with consumers.

Conclusion

Packaging is crucial for beauty merchandise, affecting the whole thing from branding to customer purchasing selections. By expertise the specific styles of packaging, materials and products and being knowledgeable approximately developments and policies, brands can create profitable packaging and attractive Remember that quality packaging protects your merchandise, complements your emblem and draws customers.

2 notes

·

View notes

Text

0.75L Cylinder Food Grade Paper wine bottle box

Industrial Use:Wine Bottle

Place of Origin:Zhejiang, China

Brand Name:OEM/ODM

Model Number:Custom

Paper Type:Kraft Paper

Printing Handling:Stamping, UV Coating

Custom Order:Accept

Feature:Recyclable

Material:Paper

Size:ID99*H314MM

Item:Cylinder Food Grade Paper Packaging Tube for Wine

Usage:For 0.75L wine

Color:CMYK Printing

Liner:White based paper liner

Top and bottom style:Lid with embossed logo,golden tin lid with raised center

Print disposal:4 color printing,gold foil stamping, spot uv coating

Tube thickness:1mm-1.3mm

Our LocationNo.36 Kangxian Rd, Gongshu District, Hangzhou, Zhejiang Province, China, 310015

Email [email protected]

Phone Number0086-571-8817.1780

0 notes

Text

ASEAN Flexible Packaging: Flexible Packaging Gaining Popularity in ASEAN Region

Emergence of ASEAN Flexible Packaging

Flexible packaging has seen tremendous growth in the ASEAN region over the past decade. As consumer lifestyles and shopping habits have evolved, flexible packaging formats have emerged as a popular alternative to rigid containers for various food and consumer goods products. Flexible packaging offers advantages like lightweight construction, ease of opening, re-sealability, and ability to fit irregular shapes that appeal both to manufacturers and customers. Films made from materials like plastic, paper, aluminum foil and their combinations are commonly used in the manufacture of flexible packages. Pouches, bags, wraps and rolls are some of the popular flexible packaging formats utilized by brands.

Rise of the Convenience Culture

The on-the-go lifestyles led by urban consumers in the ASEAN Flexible Packaging have driven the need for portable and convenient packaging options. Flexible packages that can be easily handled and stored are ideal for packed meals, snacks and beverages consumed outside the home. Their compact sizes allow consumers to tuck the packages into bags or carry them conveniently. Products packaged in flexible films can also be resealed after initial opening and enjoyed later, reducing wastage. This appeals to the budgets and environmentally conscious mindsets of millennial consumers. The growth of the quick service restaurants industry and on-demand delivery services further popularizes flexible packages designed for takeaway consumption.

Advantages over ASEAN Flexible Packaging

While rigid containers like bottles, cans and cartons continue to be used for certain products, flexible packaging scores over them on key parameters. Their lightweight plastic, paper or laminate films require 30-50% less material to produce compared to glass or metal containers. This makes flexible packages more energy efficient and cheaper to transport. The lack of rigid infrastructure also enables flexible formats to be produced in various shapes, sizes and customized designs as per the product. Their efficient space-filling abilities allow more units per truck or shipping container compared to rigid packs. All these factors make flexible packaging an attractive option from a cost and sustainability perspective for brands.

Expanding Application Areas

Over the past decade, flexible packaging has expanded beyond traditional FMCG categories like food and beverages to see wider adoption in other industries as well. In the pharmaceutical sector, medicines, capsules and ointments are increasingly packed in lightweight and tamper-evident foil and laminate pouches. The cosmetics industry has also moved from jars and tubes to stand-up pouches and zipper bags for products like compacts, creams and serums. Other sectors witnessing growth in flexible packaging usage include automotive, pet care products and agriculture inputs. Innovative formats like re-closable stand-up pouches and spit pouches have enabled flexible packs to replace rigid cans in categories like pet food as well.

Rise of Digital and Sustainable Packaging

Digital print technology and sustainable materials are two emerging trends influencing the flexible packaging sector in ASEAN. Digital printing enables versioning of pack designs, variable data and personalization at mass production scales - an advantage driving brands to promote their products through vivid flexible packaging graphics. At the same time, consumer demand for eco-friendly packaging has motivated manufacturers to produce flexible films from renewable, recyclable and compostable paper and plastic materials. Features like minimal overwrap and ease of disposal make flexible packages incorporating sustainable attributes a viable green solution. As environmental regulations in the region get stricter, sustainable flexible packaging formats will play a bigger role.

Opportunities for Advanced Manufacturing

The steady growth projected for ASEAN's flexible packaging market is attracting global flexible packaging converters to set up advanced manufacturing units in the region. Machinery and technology for producing various flexible packaging formats like stand-up pouches, flow wraps, vacuum skins are being locally sourced. Home-grown flexible packaging converters are also upgrading with state-of-the-art converting lines to offer innovative formats, custom designs, and value-added services under one roof. Importantly, the incorporation of Industry 4.0 concepts like automation, digitization and internet of things promises to enhance flexible packaging production efficiencies and quality control going forward. All these developments are set to boost ASEAN's flexible packaging manufacturing competitiveness on the global scale.

Rising Demand across Consumer Segments

All major socio-economic segments within the ASEAN region present growing opportunities for flexible packaging. The burgeoning middle and affluent urban populations seek flexible packs for their perceived premium appeal and convenience. At the same time, flexible pouches and laminates are also cost-effective for low unit price segments targeting rural communities or food-insecure demographics. Their versatility to package small quantities at affordable price points helps companies reach price-sensitive consumers across all income levels. With ASEAN's combined population projected to exceed 700 million by 2030, the long-term demand drivers remain favorable for flexible packaging to gain further penetration within the region's diverse consumer base.

The flexible packaging sector has emerged as a key beneficiary of ASEAN's economic growth and transformation towards modern retail channels and lifestyles. Homegrown manufacturers and multinational converters have strengthened flexible packaging capabilities in the region over the past decade through investments, partnerships and technology adoption. Backed by a vibrant consumer market and opportunities across industries, the ASEAN flexible packaging industry offers tremendous potential for further expansion, innovation and global competitiveness in the times to come.

Get More Insights On, ASEAN Flexible Packaging

For More Insights Discover the Report In language that Resonates with you

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#ASEAN Flexible Packaging#ASEAN Flexible#Flexible Packaging#Sustainable Packaging#Plastic Packaging#Food Packaging

0 notes

Text

Custom Paper Tube Packaging | China Manufacturer & Supplier

Whether you sell confectionery, food, health & beauty, wine & spirits, or household chemicals, Hopak’s paper tube packaging will seal your products uptight and protect them from the outside world.

Choose from various sizes to find the one that suits your dry, powdered, or confectionery packaging needs. Pick a matte or glossy finish to help your doy packs stand out.

Then consider adding a premium feature – a resealable zip to extend the life of your product or a hang hole so that it can be hung on display. <a href=”https://www.hopakpackaging.com/paper-tube-packaging/”>“Paper Tube Packgaing”</a>

0 notes

Text

Custom Paper Tube

All Paper Tube Co. specializes in creating custom paper tube solutions that meet the highest quality standards. With our extensive experience in the industry, we are the ideal choice for any custom paper tube needs.

Mail ID: [email protected]

Phone/WA: +86 18118733308

#Custom Paper Tube#allpapertube#cosmetics products packaging#lip balm products packaging#gift products packaging#paper tube packaging#personal care products packaging#paper tube companies

0 notes

Text

Pipe End Caps Exporter in Mumbai : Platinex Piping

About The Product

Butt-weld end cap manufacturer in Mumbai is a flange finishing a distribution after a piping is majored missed, often caused by a welding flaw.

An ASME B16.9 waterproof Butt weld End Cap is a type of specialty fitting that is made in accordance to the www.reference.com/science/end-cap-5b7713bd72370068. This gasket is employed to have hydraulic and pneumatic connections to be sealed, or closed up. To meet the needs of customers, it can be manufactured as a standard product or made in a customized way.

Grades in Pipe End Caps

Stainless Steel Pipe End Caps

Carbon Steel Pipe End Caps

Low Temperature Carbon Steel Pipe End Caps

Alloy Steel Pipe End Caps

Duplex Steel Pipe End Caps

Nickel Alloy Pipe End Caps

ANSI B16.9 Pipe Fitting is a kind of cap fitting that serves to cap the end of the pipe and fittings. We supply end cap sizes that are large, various materials and different dimension ranging. We have butt weld able cap fitting available made from materials like Stainless Steel Hastelloy , Inconel , Monel, and Duplex steel “DS”. As well as SMO 254.

The main characteristics of Buttweld End Cap Fittings Exporters include delivering high efficiency in both applications to water as well as gas. The plus point is also the ability of offering a diameter range f slide and wide tolerance gives a decrease in stock holding cost. They are built according to a new concept utilizing a hardware technology that has been tested and proven already. These devices can be your safety mechanism when you are not at home.

Butt weld Cap Eccentric Tube ship Eccentric Nozzle Elevated Pipe With the year 2050, so many scientists predict that our lifestyle and climate will bind to change significantly.

The tillage weld end cap coupling is used in the Water Supply System.

The valve ANSI B16.9 Butt weld End Caps Notebook uses, which is done by joining two pipes to form compound system. A mechanical and chemical property of this product makes the use of this system suitable for higher temperatures and pressures.

Butt weld End Cap Fit joining in the Paper & Pulp Industry is also one of the popular welding solutions.

The Necessity of the End Cap for General Purpose is Primarily Used In Different Applications.

For example, butt weld end cap process is composed by the fabrication industry.

Before the introduction of end caps in food industry, many people were faced with the difficult task of picking up the right kind of food when they did grocery shopping simply because the food packaging made it hard to see what was inside.

Besides the utility of the Top well and Flow cap Buttweld Caps are also pressed and welded at top, and bottom on the header to the pipes utilized in structural applications.

Those working under pressure whether it be popular culture or religious associations could assemble the ketogenic diet. EXAMPLE: The platinex welded bulge is inserted and threaded through the pipe ring. It can further be welded or screwed on joints for convenience. It is a prudence that an additional pipe should be allowed ahead of closing off the system. This option will enable the practice of any additional expansion of the staunchest system without its necessity to be unconditionally interrupted. The Butt weld natures types are: Stub End,SS Reducer, etc.

Platinex is the leading provider, manufacturer and exporter which offers butt weld end cap fittings of different sizes, dimensions and prices. Pipe Cap Fittings are the simplest way to cap off, and thus, are a push fitting. They are the easiest and simplest. They are placed in order to withstand stub outs, pressure testing; these can be used on wet and dry piping.

Applications

This category of fittings, end cap butt weld, comprises of industries and applications such as:

ASME B16.9 is the one of the most reliable advocate of its type, and it usually designed to meet expectations instead of borrowing the philosophy from other brands. We deliver to you the plenitude in the Butt weld Cap through an international network of the branches with a stock base. These End Pipe Cap is use in various industries like

Stainless Steel Butt weld End Cap makes tasks in Oil & Gas Pipeline module easier.

Welding End Nozzles in Chemical Engineering is regarded as one.

Plumbing connection to water distribution lines required galvanized alloy steel end caps.

Butt weld Cap Eccentric Tube ship Eccentric Nozzle Elevated Pipe With the year 2050, so many scientists predict that our lifestyle and climate will bind to change significantly.

The tillage weld end cap coupling is used in the Water Supply System.

The valve ANSI B16.9 Butt weld End Caps Notebook uses, which is done by joining two pipes to form compound system. A mechanical and chemical property of this product makes the use of this system suitable for higher temperatures and pressures.

Butt weld End Cap Fit joining in the Paper & Pulp Industry is also one of the popular welding solutions.

The Necessity of the End Cap for General Purpose is Primarily Used In Different Applications.

For example, butt weld end cap process is composed by the fabrication industry.

Pipe end caps – ROUND, OVAL MANUFACTURER/EXPORTER IN INDIA | ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 CARBON, ALLOY, STAINLESS STEEL PIPE CAPS

Steel pipe end caps are the pipe fittings, which are mainly used as a plug to cover the end of a pipe. We can manufacture and supply pipe end caps in standard sizes, as well as in accordance with specification of our customers.

Various grades of pipe caps manufactured by Platinex Piping Solutions includes 304/304L, 316/316L, 321, 347, 317L, 310S, 904L, Duplex, Alloy 201, Alloy 800H, Alloy C276, Cupro Nickel, Alloy 400, Alloy 625 and Alloy 600. Our stocking program includes stainless steel pipe caps and carbon steel pipe caps of standard sizes and grades. Our specialty is to offer our customers with pipe caps in various shapes – round, square, rectangular or other special shapes.

0 notes

Text

Which Type of Pre-Roll Tube Is Best for You?

There is an endless supply of ways to package your Pre-Rolled Cones on the market today! Everything from Child-Resistant Pre-Roll Tubes to tins with Custom Pre-Roll Boxes, as well as everything in between! Pre-roll tubes are a simple but useful pre-roll packaging item that has been there since the beginning and is still the most often used pre-roll packaging in the industry.

The pre-roll tubes have gained popularity among cannabis companies as well as customers due to their low price and large variety of patterns and colors. Businesses may entirely customize their Pre-Roll Tubes with a wide range of branding options! It’s now simpler than ever for cannabis brands to fully customize the pre-roll tube to reflect their brand.

Pre-Roll Tube Safety

Compliance with child-resistant packaging has become more and more crucial as state cannabis regulators focus on keeping cannabis out of the hands of children. Certain states have higher compliance requirements than others since some marketplaces are not as liberal as others.

Pre-roll tubes are not all certified child-resistant. According to ASTM requirements, a package must be tested on 100 children under the age of five. To pass, the product cannot be opened by 85 of the 100 children without a demonstration, and 80 of the 100 children must be unable to open it even with a demonstration.

The fact that 90 out of 100 people between the ages of 50 and 70 can open the pre-roll tube is equally significant. Pre-roll tubes that are child-resistant but also appear to be adult-resistant are frequently seen; they are practically difficult to open without using significant force.

It’s also crucial to pay attention to the packaging’s opacity because some governments restrict transparent packaging. Cannabis companies would like that their products be presented in a transparent container, but in certain regions, this may not be feasible. Colorado, Hawaii, Maryland, Massachusetts, New Mexico, Oregon, and Alaska all mandate that cannabis be stored in transparent containers.

The use of a paper sticker covering the lid or cap is the second method for making a pre-roll tube tamper visible. To open the lid, this paper sticker must be peeled off or ripped; in certain cases, simply rotating the cap will shred the sticker, saving the consumer from even having to remove it.

At Innovative Sourcing, we have put a lot of effort into finding pre-roll tube alternates that are both fully functional and long-lasting for adult use, while also being child-resistant. We also aim to provide solutions that can be used in even the most restrictive cannabis markets.

Think about the following factors while choosing your pre-roll tubes:

Decide between plastic, glass, or biodegradable options, considering durability, cost, and environmental impact.

What kind of look is your company aiming for? Are you trying to be as affordable as possible, or are you a premium cannabis brand?

Which joints, and what size, are you going to put inside the tubes?

Types of Pre-Roll Tubes:

Pop-Top Pre-Roll Tubes:

Pre-roll tubes with pop-tops are definitely the most widely used type. Just squeeze, burst, and puff!

This is a cost-effective option that is well-liked within the cannabis community due to its simple operation and affordable price. Every expense counts when trying to offer a product as cheaply as possible!

As per ASTM rules, all of the Pop-Top Pre-Roll Tubes that Innovative Sourcing offers are child-resistant and created in the USA.

Our pop-top tubes are a huge success! Without a demonstration, 98.5% of kids can’t open our pre-roll tubes, and even with a demonstration, 92.5% of kids still can’t open the pre-roll tube. What’s the best thing, then? The pre-roll tubes can be opened by 100% of people in the 50–70 age range! This keeps cannabis out of the hands of children while maintaining easy access for people who require it.

Child-Resistant Glass Pre-Roll Tubes:

We provide Screw-Top Glass Pre-Roll Tubes in a variety of styles. We provide approved child-resistant screw-tops in both black and white. We have something to fit with the design of your brand!

The push-and-turn style cover of these child-resistant screw-top pre-roll tubes makes them simple to use, just like many child-resistant medicine bottles. In matte or glossy black, white, metallic gold, and metallic silver, we have clear and opaque alternatives.

Do pre-rolled tubes have a tight seal and are smell-proof?

Although our Pop-Top Pre-Roll Tubes are the most widely used choice, they are not totally airtight and do not retain all of the scents from your product. To reduce airflow and lengthen the product’s shelf life, you can include a heat-shrink band.

The airflow is restricted but not entirely blocked by our child-resistant glass pre-roll tubes. They might be the most aesthetically pleasing, but they might not preserve the freshness of your food as well as some of our other choices. Many companies package their pre-rolls with moisture packs in an attempt to address this problem.

For optimal sealing, our Glass Pre-Roll Tubes work best when paired with a shrink-wrap sleeve. These are stylish tubes, but it’s crucial to remember that they’re not child-resistant and might not be legal in some markets if further security isn’t taken.

If your company is known for creating high-end items that provide a very luxurious smoking experience, you might want to take into consideration glass screw-top tubes or our Super Seal tubes. Choose a color that goes nicely with your branding and logo by keeping it in mind.

Visit our website at www.innovativesourcing.com or call us at (509) 452-4800 if you are interested in customized branding. We will create custom pre-roll tubes just for your business.

#Glass Joint Tubes#Glass Pre Roll Tubes#Preroll Tube#Pre Rolled Tubes#Pre Roll Joint Tubes#Pre Roll Tubes Wholesale

1 note

·

View note

Text

Tube Packaging Procurement Intelligence 2024 - 2030: Key Factors to Consider

The global tube packaging category is projected to grow at a CAGR of 5.7% from 2024 to 2030. Key factors driving the growth of the global category include growing consumption of personal care products, rising use of flexible packaging formats, advancements in packaging technology, increasing demand from emerging markets, and a surge in requirement within the pharmaceutical sector. Some of the major trends in the market include rise in usage of biodegradable and sustainable products, growing prioritization of consumer safety, increase in product innovations, emergence of paper-based tube packaging, and rising adoption of minimalist design. For instance, paper-based tube packaging is increasingly being used for food items, cosmetics, personal care products, textiles, and apparels, as it offers a natural and eco-friendly alternative to traditional plastic packaging. Paper-based tubes are lightweight and cost-effective and are durable and customizable. Few of the major restraining factors include stringent government regulations, issues in recyclability of plastic, availability of substitutes, and fluctuations in raw material prices.

Key technology trends and innovations driving the global tube packaging category include single-dose tube packaging, smart tube packaging, multi-layered laminated tube manufacturing, nanocomposite coatings, anti-counterfeiting solutions, and 3D printed tubes. Single-dose tube packaging involves individually packaged products in single-serving units. This technology ensures precise dosage and minimizes product waste, particularly in pharmaceuticals and personal care products. It also enhances convenience to customers by providing ready-to-use portions. Moreover, it improves product hygiene and reduces the risk of contamination or cross-contamination. Smart tube packaging incorporates digital technologies to enhance functionality and user interaction. Smart tubes are embedded with features such as Near-Field Communication (NFC), QR codes, and RFID tags. These features enable product authentication, inventory tracking, and interactive customer experiences. For instance, customers are able to access product information or usage instructions through their smartphones or devices.

The tube packaging category is fragmented and consists of a large number of global market players, turning the category to be competitive. Key players in the category set themselves apart by providing innovative product design, deploying advanced manufacturing capabilities, producing sustainable alternatives, engaging in strategic collaborations, implementing robust marketing strategies, and focusing on compliance in order to stay competitive. Additionally, they are also focusing on improving the overall customer experience by providing competitive pricing, developing customized products, streamlining ordering processes, and enhancing customer service. For instance, key players are using online portals for distribution wherein customers are able to seamlessly browse catalogues, select products, and place orders with enhanced and real-time inventory visibility. Moreover, automated order processing and tracking is also being used to streamline the sourcing, by providing customers with instant order confirmations and delivery updates. Customers in the category possess high bargaining capability owing to an extensive supply base.

Order your copy of the Tube Packaging Procurement Intelligence Report, 2024 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Raw materials, labor, equipment, labelling, logistics, and other costs are the major cost components in this category. Other cost components comprise R&D, compliance, rent and utilities, general and administrative, sales and marketing, and taxes. Raw materials and labor account for the largest share of the cost structure. Key players in this category typically adopt cost-plus pricing model in order to price their products. In the cost-plus pricing structure, a profit margin is added to the product's manufacturing expense, to determine the ultimate selling price. This pricing structure enables vendors to ensure a profit on the products being sold. Few of the key factors influencing the prices of tube packaging include fluctuations in the prices of raw materials such as aluminum and plastic, variations in labor costs, deviations in fuel and shipping costs, and geographic location. For instance, prices of Polyethylene (PE) and Polypropylene (PP) resins are forecasted to rise in Q1 2024. In 2023, the prices of aluminum tubes used for packaging in the U.S. were in the range of USD 0.05 - USD 1.2 per tube. The prices of laminated tubes were in the range of USD 0.06 - USD 0.7 per tube. Moreover, the prices of plastic tubes were in the range of USD 0.03 - USD 0.5 per tube.

Asia Pacific dominates the global tube packaging category, holding a significant portion of the global market share. Key drivers for this region include rapid urbanization, rise in demand from emerging countries such as China, India, and Vietnam, rise in the number of suppliers entering the market, favorable government initiatives, and increase in usage among cosmetics and cleaning products. Key driving factors in developed regions such as North America and Europe include presence of large-scale companies, high adoption of technological innovations, robust production infrastructure, and high demand for environmentally friendly products. Asia Pacific is expected to be the fastest growing region during the forecasted period due to a rise in the disposable income, increase in the demand from oral care and cosmetics, and surge in the usage of compact-size tube packaging. Comparing the prices charged by various suppliers, assessing product portfolio of various suppliers, evaluating the experience level of suppliers, comparing product innovations, comparing the lead time of various suppliers, evaluating customer ratings, and checking adherence to environmental and safety standards are some of the best sourcing practices considered in this category.

Tube Packaging Procurement Intelligence Report Scope

• Tube Packaging Category Growth Rate: CAGR of 5.7% from 2024 to 2030

• Pricing Growth Outlook: 5% - 10% increase (Annually)

• Pricing Models: Cost-plus pricing, Competition based pricing, Demand-based pricing, Volume-based/bulk pricing

• Supplier Selection Scope: Cost and pricing, Past engagements, Productivity, Geographical presence

• Supplier Selection Criteria: Geographical service provision, industries served, years in service, employee strength, revenue generated, regulatory certifications, key clientele, usage mode (squeeze/twist), sustainable product offerings, integration of smart packaging (yes/no), customer service, lead time, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Browse through Grand View Research’s collection of procurement intelligence studies:

• Packaging Design Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Molded Pulp Packaging Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Key Companies

• Albea Group

• Amcor plc

• Berry Global Inc.

• EPL Limited

• Hoffmann Neopac AG

• Huhtamäki Oyj

• Montebello Packaging

• Romaco Group

• Sonoco Products Company

• Unette Corporation

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Tube Packaging Procurement Intelligence#Tube Packaging Procurement#Procurement Intelligence#Tube Packaging Market#Tube Packaging Industry

0 notes

Text

The Rise of Glass Pre-Roll Tubes: A Trend in Cannabis Packaging

In the world of cannabis consumption, presentation and preservation are just as important as the product itself. One of the latest trends in cannabis packaging is the use of glass pre-roll tubes. These sleek, functional, and aesthetically pleasing containers are revolutionizing the way pre-rolls are packaged and consumed.

The Benefits of Glass Pre-Roll Tubes

Glass pre-roll tubes offer several advantages over traditional packaging options. Firstly, they provide superior protection for pre-rolls. Unlike plastic or paper, glass is non-reactive and doesn’t alter the taste or quality of the cannabis inside. This means that pre-rolls stay fresh for longer periods, preserving their flavor and potency. Glass also offers a level of durability that prevents crushing and maintains the integrity of the pre-roll, ensuring that users receive a high-quality product every time.

Another significant benefit of glass pre-roll tubes is their aesthetic appeal. Glass is often perceived as a more premium material compared to plastic, and this perception extends to the product inside. A well-designed glass tube can enhance the overall experience of consuming cannabis, making it feel more luxurious and sophisticated. Additionally, glass pre-roll tubes can be customized with various designs, colors, and logos, providing an opportunity for brands to create a unique and memorable product.

Environmental Impact

In an era where environmental sustainability is a growing concern, glass pre-roll tubes stand out as an eco-friendly alternative to plastic packaging. Glass is infinitely recyclable, meaning that it can be recycled over and over without losing quality or purity. This reduces the overall environmental footprint of cannabis packaging and aligns with the values of eco-conscious consumers. By choosing glass pre-roll tubes, brands and consumers alike can contribute to a more sustainable future.

Practical Considerations

From a practical standpoint, glass pre-roll tubes are also user-friendly. Many tubes come with airtight seals that ensure the contents remain fresh and protected from moisture and contaminants. They are also easy to clean and reuse, adding an extra layer of convenience for both consumers and dispensaries. Some glass pre-roll tubes are designed with built-in filters or child-resistant features, further enhancing their functionality and safety.

Customization and Branding

Customization plays a significant role in the popularity of glass pre-roll tubes. Brands can take advantage of the clear surface of glass to showcase their logos, designs, and branding elements. This not only helps in building brand identity but also allows consumers to identify and connect with their favorite products more easily. Whether through screen printing, etching, or labels, glass pre-roll tubes offer ample opportunities for creative expression and brand differentiation.

The Future of Glass Pre-Roll Tubes

As the cannabis industry continues to evolve, glass pre-roll tubes are likely to become even more prevalent. Their combination of durability, aesthetic appeal, and environmental benefits make them an attractive choice for both consumers and producers. With ongoing innovations in design and functionality, glass pre-roll tubes will undoubtedly continue to enhance the cannabis experience, setting new standards for packaging in the industry.

In conclusion, glass pre-roll tubes represent a significant advancement in cannabis packaging. Their ability to preserve freshness, provide a premium feel, and support environmental sustainability make them a compelling choice for modern consumers and brands alike. As the industry moves forward, glass pre-roll tubes are poised to play a central role in shaping the future of cannabis packaging. For more details visit our website www.skunkjarspackaging.com

#Cannabis Jars#Premium Cannabis Packaging#Cannabis Packaging Alameda#Cannabis Packaging California#Cannabis Packaging US#Marijuana Packaging Alameda#Marijuana Packaging California#Marijuana Packaging US#2 oz Glass Jars#3 oz Glass Jars#4 oz Glass Jars#6 oz Glass Jars#10 oz Glass Jars#Pre Roll Jars#2 oz Plastic Jars#3 oz Plastic Jars#4 oz Plastic Jars#6 oz Plastic Jars#10 oz Plastic Jars#Pre Roll Tubes#Glass Pre Roll Tubes#Plastic Pre Roll Tubes#115mm Pre Roll Tubes#95mm Pre Roll Tubes#Concentrate Jars#Glass Concentrate Jars#Qube Jars#Qube Concentrate Jar#5ML Qube Concentrate Jar#9ML Qube Concentrate Jar

0 notes

Text

BECHEM India Products & Services all over the country

Established in 1834, Hagen, Germany, BECHEM pioneered the concept of specialty lubricants. The BECHEM Group today offers specialized products for critical industrial applications across the world. BECHEM India is a 100% subsidiary of BECHEM GMBH. The Indian subsidiary with a dedicated sales team spread across the country, caters to industrial lubricant requirements including cement, steel, automotive, paper, food & pharma, textile and metal working processes.

BECHEM’s Product range,

Specialty Greases and Oils

High temperature greases

High load lubricants

High speed greases

Water resistant greases

Food grade lubricants

Electric contact lubricants

Lubricants for noise damping and plastic parts

High performance oils for industrial gear boxes

High temperature and high load chain oils

Compressor oils

Metal Working Fluids

Metal cutting fluids

Metal forming fluids

Wire drawing fluids

Sheet forming oils

High performance cleaners

Pastes and Sprays

Anti Friction Coatings

1) Lubricating Greases

Industrial applications operate under intensive conditions such as extreme temperatures, pressures and speeds for extended durations. Greases are expected to provide long life while ensuring minimal friction and wear between the contact surfaces. The grease also has to withstand external factors such as water exposure, dust entry, thermal radiation, contact with corrosive and acidic medium etc. To achieve the desired performance is a feat possible only with high quality speciality lubricants. As one of the earliest lubricant firms, BECHEM pioneered the concept of speciality greases and oils.

Visit us for more Speciality Lubricants: https://www.bechemindia.com/lubricants/lubricating-greases/

2) Oils & Fluids

BECHEM’s extensive range of speciality oils and metal working fluids for industrial applications and metal working processes are developed with high quality base oils and advanced additive packages.

The range of speciality oils are based on mineral as well as synthetic hydrocarbons including Polyalphaolefins (PAO) and Polyglycols (PG). Recommended for industrial gear boxes, heavy duty chains as well as oil lubricated plain and roller bearings, the speciality oils by BECHEM possess superior oxidation stability, high dosage of anti-wear additives and excellent viscosity temperature behaviour.

BECHEM’s range of speciality fluids cover the entire spectrum of metal working processes from moderate machining to severe cutting operation to wire drawing and tube forming processes. The new generation of metal working fluids by BECHEM provide long sump life, excellent surface finish and corrosion protection, extended tool life and best in class economy.

Visit us for more Oils & Fluids: https://www.bechemindia.com/lubricants/lubricating-oils

3) Industrial Lubricants:

BECHEM has developed a vast array of high-performance industrial lubricants for critical applications across industry segments. From high temperature greases for Steel mills to life lubricants for automotive components, BECHEM strives to create value for customer’s processes through consistent efficiency and environmentally responsible products.

It offers the industrial lubricants user a high-performance range of lubricants for various tribological challenges. BECHEM’s comprehensive range of industrial lubricants include special and multipurpose greases and pastes, mineral and synthetic oils, anti-friction coatings as well as process fluids covering the complete range of metal working operations.

Visit us for more details: https://www.bechemindia.com/industrial-lubricants/

4) Pastes and Sprays:

BECHEM offers an extensive range of pastes and speciality aerosols in spray can package for reduction of friction and wear in diverse industrial scenarios such as maintenance and assembly lines to long term lubrication of automotive components.

BECHEM’s range of pastes are recommended for mechanical equipments and applications that are exposed to extreme high temperatures and pressures. To prevent fretting corrosion, pastes are suitable as anti-seize agents for bolts, bushes, spindles and guide ways.

Visit us for more details: https://www.bechemindia.com/sprays-pastes/

5) Anti Friction Coatings

BECHEM’s range of Anti Friction coatings are developed with a combination of high-quality solid lubricants, organic/inorganic binding agents, solvents and high-performance additives.

Dry film lubricants are advantageous over wet (oil and grease) when adhesion, lifetime lubrication and appearance are crucial requirements of the application. Dry lubricants perform exceedingly well at elevated high temperatures, extreme pressures and in vacuum. Also, dry film lubricants are environmentally friendlier as there is no after-use disposal involved as with wet lubricants.

BECHEM’s range of Anti Friction coatings are developed with a combination of high-quality solid lubricants, organic/inorganic binding agents, solvents and high-performance additives. These performance coatings from BECHEM have provided excellent results for customers.

As application of the coating to the work component plays a critical role in the performance of the anti-friction coating, BECHEM also collaborates with Partners who provide these services. Customers therefore don’t have to worry about coordinating with the multitude of entities.

Visit us for more details: https://www.bechemindia.com/industrial-lubricants/automotive-industry-lubricants/anti-friction-coatings

Feel Free to Contact for BECHEM India Product & Services/related Queries:

Address: #28 D, Bidadi Industrial Area, Bangalore – 562109

Website: https://www.bechemindia.com/

Email: [email protected]

Contact No: +91- 80669 00875

0 notes

Text

Makeup Packaging: How the Packaging Influences your Makeup Shopping Decisions

Evolution of Makeup Packaging

Makeup packaging has come a long way from the simple metal compacts and paper boxes of the early 20th century. As the needs and preferences of consumers have changed, so too has the design and functionality of makeup containers. Early on, manufacturers focused primarily on protecting the product and providing basic information. Over time, additional elements were incorporated to attract customers and influence purchasing. Let's take a look at some of the key developments in makeup packaging over the decades.

In the first half of the 1900s, powder and rouge came in simple tins or cardboard boxes with minimal graphics. Lipsticks were cylindrical tubes or pots with a color swatch on the label. As mass production gained steam post World War II, plastic containers replaced metal for lower costs. This allowed for molded compacts in fun shapes and larger palettes. Glossy advertisements brought vibrant colors to magazines, creating demand for new styles.

The consumer revolution of the 1960s ushered in disposable income and self-expression. Makeup went pop with bright packaging to match the youth culture. Revlon launched its trendsetting Pop Art nail polishes and lipsticks adorned in painterly prints. Clear plastic emerged for lip and eye products to better showcase shades. Sleek metallic tubes conveyed luxury for higher-end brands.

Advancements in printing birthed graphic designs and bold typefaces in the 1970s-80s. Eyeshadow palettes took off as a way to build kits for different looks. Signature brand logos helped cultivate customer loyalty. In the 90s, limelight for gutsy colours like turquoise brought out futuristic finishes. Lightweight plastics and minis became portable must-haves.

The 21st century saw Makeup Packaging pushed to new limits. From glittery exteriors to holographic shifters mimicking the products inside, flashy exteriors drew consumers to shelves. Sustainable bamboo and recycled tubes entered the scene. Customizable compacts allowed personalization. Complex molds created multifunctional components like built-in brushes or mirrors. Meanwhile, technological interfaces blurred physical and digital worlds.

Impact of Sensory Marketing

Advances in materials science and manufacturing now allow unparalleled creativity and interactivity in makeup applications. Whereas appearance was once the main focal point, sensory elements are equally important in engaging target audiences. The feel, sound and even smell of a product all influence the shopping experience. Brands employ these techniques to build emotional connections at points of sale.

A well-designed container can enhance several senses on its own. Smooth plastic that's cool to the touch may translate quality, while premium metallic finishes signal luxury. The satisfying click of a compact or satisfying twist of a lipstick potentially triggers positive responses. Some go farther with touch-activated lights, music or voice memos inside. Layered fragrances on compacts may match scent to specific lip, eye or face palettes.

On shelves, standouts make first impressions through vibrant palettes that jump off in peripherals. Glossy, holographic or textured exteriors catch attention where seconds matter most. Meanwhile, satisfying sensory aspects encourage handling time crucial to consideration and education. It's no surprise high-tech packaging coincides with top-selling prestige lines. Brands realize an immersive unboxing fosters attachment and increases lifetime customer value.

Sustainable Innovations

As environmental and ethical concerns rise globally, forward-thinking companies innovate with sustainability in mind. Post-consumer recycled plastic is a growing standard while bioplastics create plant-based options. Some new packaging utilizes recycled cardboard envelopes that fold flat for shipping. Refillable compacts reduce single-use waste by allowing replacement of powders or creams over time.

Get more insights on Makeup Packaging

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Makeup Packaging#Cosmetic Containers#Beauty Packaging#Makeup Containers#Skincare Packaging#Product Design#Luxury Packaging#Sustainable Packaging

0 notes