#Custom Injection Mold Tooling

Explore tagged Tumblr posts

Text

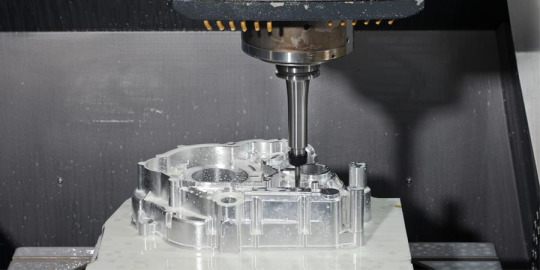

T&R Tooling is a leading provider of plastic injection molding in Northern Texas. With years of experience and a team of skilled professionals, we specialize in delivering high-quality, precision-molded plastic components for a wide range of industries. Our state-of-the-art facility is equipped with advanced machinery and technology to handle projects of any complexity.

T&R Tooling 282 Elm Grove Rd., Valley View, TX 76272 (940) 726–6020

My Official Website: http://www.trtooling.com/ Google Plus Listing: https://www.google.com/maps?cid=1529569677814869897

Our Other Links:

plastic injection tooling in Texas: http://www.trtooling.com/new-tooling/ rapid prototyping Texas: http://www.trtooling.com/3d-printing/

Service We Offer:

Plastic Injection Molding 3d Printing Tool Repair New Tooling Design Services Quality Assurance

Follow Us On:

Twitter: https://twitter.com/ToolingR31294 Pinterest: https://www.pinterest.com/trtoolingtx/ Instagram: https://www.instagram.com/trtooling/

#plastic injection molding northern texas#custom injection mold tools texas#tooling for plastic injection molding texas#plastic injection tooling in texas#prototyping texas

0 notes

Text

How Hands Craft Precision: A Journey through Injection Parts and Molding Services by PTMS

PTMS's injection parts and molding services exemplify the pinnacle of precision engineering and craftsmanship. With a steadfast commitment to excellence and a focus on meeting the diverse needs of clients, PTMS continues to set the standard for innovation and quality in the manufacturing industry.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

1 note

·

View note

Text

Maximize Efficiency in Pressure Die Casting with Our High-Quality Steel!

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry.

Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more : https://www.viratsteels.com/hot-work-steel.html https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any queries feel free to contact us : [email protected] or Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DieCasting#PressureDieCasting#DieCastingProcess#CastingIndustry#AluminumCasting#MoldMaking#hot work steel#h11steel#h13steel#h21steel#din 2344#din2343

2 notes

·

View notes

Text

Vacuum Forming Is a Game Changer in Manufacturing

Innovation in the manufacturing sector is what propels cost-effectiveness, adaptability, and efficiency. Vacuum forming is one such cutting-edge method that has completely changed the way goods are created and manufactured. Due to its many benefits, vacuum forming technique has become more and more common in a variety of sectors.

Production at a Low Cost

The affordability of vacuum forming is one of its main benefits. Vacuum forming uses less expensive machinery and tools than conventional production techniques like die casting or injection molding. Because of this, vacuum forming is a desirable alternative for small- to medium-sized production runs, allowing companies to save costs without sacrificing quality.

Quick Prototyping

Rapid prototyping is made possible by Vacuum Forming China, which enables engineers and designers to test and iterate product concepts fast. It is possible to build several prototypes at a reasonable cost because to the short lead times and inexpensive tooling costs. This quickens the process of developing new products, allowing companies to launch new concepts more quickly and adapt quickly to the needs of their customers.

Flexibility in the Choice of Materials

A large variety of thermoplastic materials may be used with vacuum forming, giving producers the freedom to select the material that is best suited for their particular purpose. Because of their versatility, goods with different levels of flexibility, transparency, and durability may be made. Vacuum forming is a flexible solution for a multiplicity of sectors, accommodating a wide range of material needs from durable automotive components to thin-gauge packaging.

Smooth Customization of the Design

Vacuum forming makes it simple to easily customize complex designs. It is possible to accomplish intricate textures, undercuts, and forms without the requirement for costly tool adjustments. Vacuum forming is a great option for creating aesthetically pleasing and useful items in a variety of sectors, including consumer electronics, car interiors, and signs, because of its adaptability in design customization.

Lightweight Goods

Because vacuum-formed materials by vacuum forming manufacturer are lightweight by nature, they are appropriate for uses where weight is a crucial consideration. This benefit is especially pertinent to the aerospace and automobile sectors, where weight reduction may improve overall performance and fuel economy. Additionally, vacuum-formed items' lightweight design makes handling, shipping, and installation simpler.

Next: Investment Casting Offers Both Versatility and Precision

#Vacuum Forming#Vacuum Forming Process#vacuum forming manufacturer China#vacuum forming manufacturer#Vacuum Forming Companies#Custom Vacuum Forming

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

Waterproofing Services in Hyderabad

Waterproofing Services in Hyderabad by MH Waterproofing: Protect Your Home from Dampness and Leakage

Hyderabad, with its dynamic weather conditions ranging from scorching heat to heavy rains, presents significant challenges in maintaining the structural integrity of buildings. Water seepage, damp walls, and leaky roofs are common issues faced by homeowners and businesses. MH Waterproofing, a trusted name in the industry, offers comprehensive waterproofing services in Hyderabad to protect your property from water damage and enhance its lifespan.

Why Choose MH Waterproofing in Hyderabad?

1. Expertise and Experience

MH Waterproofing has years of experience providing reliable waterproofing solutions. Our team of skilled professionals is trained to tackle a wide range of issues, from minor leaks to extensive water damage.

2. Comprehensive Solutions

We offer a variety of waterproofing services tailored to meet the unique needs of each client. Whether it’s a residential property or a commercial building, we have you covered.

3. Quality Materials

We use high-quality materials and advanced techniques to ensure long-lasting results. Our solutions are designed to withstand Hyderabad’s challenging weather conditions.

4. Affordable Pricing

MH Waterproofing believes in providing top-notch services at competitive prices. We ensure our solutions are budget-friendly without compromising on quality.

5. Customer Satisfaction

Client satisfaction is our top priority. We work closely with our customers to understand their requirements and deliver solutions that exceed expectations.

Our Waterproofing Services in Hyderabad

1. Terrace Waterproofing

Terraces are highly prone to water stagnation and leakage, especially during the monsoon season. Our terrace waterproofing solutions include:

Application of waterproof coatings

Crack sealing and repair

Installation of protective membranes

2. Bathroom Waterproofing

Bathrooms are another area vulnerable to water seepage. We use advanced techniques to prevent leaks and protect your walls and floors from damage.

3. Wall Waterproofing

Damp and moldy walls not only ruin the aesthetics of your home but also weaken its structure. Our wall waterproofing services include:

External wall coatings

Interior damp-proofing solutions

Crack repairs

4. Roof Waterproofing

Flat roofs and sloped roofs are equally susceptible to water damage. MH Waterproofing provides:

Bituminous waterproofing

Polyurethane coatings

Liquid-applied membranes

5. Basement Waterproofing

Basements often face issues like water seepage and dampness due to groundwater pressure. Our basement waterproofing services include:

Drainage system installation

Waterproof coatings

Crack injection techniques

6. Water Tank Waterproofing

Leaky water tanks can lead to significant water wastage and damage to surrounding structures. We offer specialized waterproofing solutions for:

Overhead water tanks

Underground water tanks

Benefits of Waterproofing Your Property

Prevents Structural Damage

Waterproofing protects your building from water infiltration, preventing cracks, corrosion, and weakening of the structure.

Enhances Durability

A waterproofed building has a longer lifespan, as it is better protected against environmental factors.

Improves Indoor Air Quality

By preventing mold and mildew growth, waterproofing ensures a healthier living environment.

Saves Money

Investing in waterproofing services reduces the need for frequent repairs and maintenance, saving you money in the long run.

Increases Property Value

A well-maintained, waterproofed property is more appealing to potential buyers and tenants.

How MH Waterproofing Works

Inspection and Assessment

Our experts conduct a thorough inspection of your property to identify problem areas and determine the best solutions.

Customized Solutions

We provide tailored waterproofing solutions based on the specific needs of your property.

Implementation

Our skilled team uses advanced tools and materials to execute the waterproofing process with precision.

Post-Service Support

We offer post-service support to ensure the effectiveness of our solutions and address any concerns you may have.

Testimonials from Satisfied Clients

"MH Waterproofing did an excellent job waterproofing my terrace. The team was professional and completed the work on time. I haven’t faced any leakage issues since!

"I highly recommend MH Waterproofing. Their bathroom waterproofing service was top-notch and reasonably priced. My walls are now free from dampness.

Why Hyderabad Residents Need Waterproofing Services

Hyderabad’s climate, characterized by intense heat and heavy rains, poses a significant threat to buildings. Prolonged exposure to water can lead to:

Cracks in walls and roofs

Corrosion of reinforcement bars

Mold and mildew growth

Weakening of the building’s foundation

Investing in professional waterproofing services ensures that your property remains protected against these issues.

Tips to Maintain a Waterproofed Property

Regular Inspections

Check your property periodically for signs of water damage, such as damp spots, peeling paint, or cracks.

Keep Drains Clear

Ensure that drains and gutters are free from debris to prevent water accumulation.

Repair Cracks Promptly

Address any cracks or leaks as soon as they appear to prevent further damage.

Use Quality Paints

Opt for waterproof paints and coatings to protect your walls and roofs.

Contact MH Waterproofing Today!

Don’t let water damage compromise the safety and beauty of your property. MH Waterproofing is here to provide the best waterproofing services in Hyderabad.

Let us help you safeguard your property and ensure its longevity. Contact MH Waterproofing today for a free consultation and quote.

Conclusion

Waterproofing is a vital aspect of property maintenance, especially in a city like Hyderabad. MH Waterproofing offers reliable and affordable solutions to protect your home or business from water damage. With our expertise and commitment to quality, you can rest assured that your property is in safe hands. Choose MH Waterproofing and enjoy a leak-free, stress-free living environment.

For More Info visit Our Website,

Or

Feel Free to Calls Us,

Contact Us: + 91-9701048855

Website:https://www.mhwaterproofingservices.com/

Website:https://www.mhwaterproofingservices.com/waterproofing-services-in-hyderabad.html

G-mail: [email protected]

Address: Flat.no:2-6, 615, Nagole Jaipur Colony Main Rd, Ajay Nagar, Nagole, Hyderabad, Telangana 500068.

0 notes

Text

4 Axis CNC Router for Foam, Aluminum, Wood Mold Processing

The 4 axis CNC router has become an indispensable tool in the fields of mold processing and fabrication. Whether working with foam, aluminum, or wood, these machines offer unparalleled precision, versatility, and efficiency.

4 Axis CNC Router

A 4 axis CNC router is a computer-controlled machine that can move along four different axes: X, Y, Z, and an additional rotational axis (A-axis). This additional axis allows for more complex and intricate cuts, making it ideal for mold processing and other detailed fabrication tasks.

The 4 axis machining centre at a good price, provide several configurations to meet different requirement, perfect for several kinds of foam and mould router, the innovation model designed by iGOLDENCNC, combined with a competitive set of configurations. Hot applications include:

>Carving all kinds of non-metal materials processing such as foam, lost foam, automobile foam mold, yacht mold, large ship wooden mold, cast wooden mold, engineering plastic materials, aviation wooden mold, propeller, train wooden mold, etc. >Foam processing of automotive stamping molds, casting wood molds, automotive interiors, processing of engineering plastic materials; >Other industry molds: electrical appliance molds, lighting molds, ceramic sanitary ware, three-dimensional curved surfaces for large musical instruments, instrument molds, home appliance molds, air-conditioning molds, automotive molds, automotive interior molds, automotive bumper molds, automotive instrument table molds, etc.

Benefits of Using a 4 Axis CNC Router for Mold Processing

Precision and Accuracy

4 axis CNC routers offer exceptional precision and accuracy, allowing for the creation of intricate designs and complex shapes. The computer-controlled movements ensure consistent and high-quality cuts.

Versatility

These machines can work with various materials, including foam, aluminum, and wood. This versatility makes them ideal for a wide range of mold processing projects.

Complex Geometries

The additional rotational axis (A-axis) allows for the creation of complex geometries and detailed features that would be difficult or impossible to achieve with traditional 3 axis routers.

Efficiency

4 axis CNC routers can operate at high speeds, significantly reducing production time. The automation of the cutting process allows for continuous operation, increasing overall productivity.

Material Efficiency

CNC routers minimize material waste by producing precise cuts and shapes. This efficiency is particularly beneficial when working with expensive materials like aluminum.

4 Axis CNC Router for Foam Parameter

ModeliGW-MC-2060Working area2000*6000*1100mmSpindleChina HQD 9kw atc air cooling spindle + swing 180 degreeInverterFulingMotorJapan Yaskawa 850W servo motorDriverJapan Yaskawa 1kw servo driverControl SystemSyntec 6MB control system + hand wheelTableVacuum & T-slot table with 7.5kw air vacuum pumpTransmissionXY helical rack, Z Taiwan TBI ball screwGuide railTaiwan linear guideBall screwZ TBI ball screwBodyThick steel tube Welded bodyBeamSteel beamColumnsSteel columnsControl boxIndependent control boxColourCustom madeLubricationAutomatic oilingTool SettingAutomatic Tool Calibration SensorDust collectorDouble bag dust collectorVoltage3 Phase/380V/50HZRotary axisOptional part

Applications of 4 Axis CNC Routers in Mold Processing

4 axis CNC routers are used in various applications within mold processing, including:

Foam Molds: Creating detailed foam molds for casting and prototyping.

Aluminum Molds: Fabricating precise aluminum molds for injection molding and other manufacturing processes.

Wood Molds: Producing custom wood molds for casting, forming, and other applications.

Prototyping: Rapid prototyping of complex designs and geometries.

Custom Tooling: Creating custom tooling and fixtures for specialized manufacturing processes.

Choosing the Right 4 Axis CNC Router for Mold Processing

Consider Your Needs

Identify the specific requirements for your mold processing projects, such as the types of materials you will be working with, the complexity of the designs, and the production volume. Choose a machine that meets these needs.

Machine Size and Capacity

Consider the size of the materials you will be cutting and choose a machine with an appropriate bed size and cutting capacity. Larger machines can handle bigger projects, while smaller machines are suitable for detailed work.

Spindle Power

The spindle power determines the cutting capability of the CNC router. Higher power spindles can cut through thicker and harder materials more efficiently. Choose a spindle power that matches your specific cutting requirements.

Software Compatibility

Ensure the CNC machine is compatible with the CAD and CAM software you plan to use. Compatibility ensures seamless design and toolpath generation.

What is the 4 axis CNC Router?

4 axis CNC router is an automatic computer-controlled machine tool whose spindle rotates 180° along the X-axis or the Y-axis to do 3D arc milling and cutting, which is based on the ordinary 3 axis machine tool. 4th axis CNC router is an automated machine tool kit with computer numerical controller for relief carving and sheet cutting, as well as adding the fourth axis (rotary axis) for 3D cylinders milling.

In addition, the 4-axis CNC machine is divided into four-axis three-linkage and four-linkagel, not to say that the rotation is added, it is a four-axis linkage machine tool, and a computer-controlled system with a rotating axis and a four-axis linkage can be called as a real 4 axis CNC machine. Because of the rotation movement of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.

A real 4-axis machine tool can cut wood, foam, stone, white marble, human body, Buddha statues, sculptures, handicrafts, furniture. 4-axis is refer to X-Y-Z-A, X-Y-Z-B or X-Y-Z-C, 4 axis are linked, the four axis can work at the same time. If the machine has only three feed axes (X, Y, Z), the Y-axis can be manually replaced with a rotating axis, and it can only be three-axis linkage at most. This is a 4th axis CNC machine, and it is also the usual fake four axis. In terms of use, it can process planes, reliefs, and cylinders. If the machine has four feed axes (X, Y, Z, A), it can be processed with four-axis linkage, and can process planes, reliefs, cylinders, non-standard three-dimensional patterns, and corners of 3D patterns.

0 notes

Text

Expert Carpet Cleaning Milton Keynes – Freshen Your Home Now

Carpet cleaning Milton Keynes is the key to keeping your carpets looking pristine and hygienic. Hobbs Cleaning Ltd specializes in professional carpet cleaning services, offering top-quality solutions for both residential and commercial properties. Whether your carpets are stained, dirty, or simply need a refresh, we provide effective cleaning techniques to restore their original beauty.

Why Choose Professional Carpet Cleaning?

While regular vacuuming helps maintain the cleanliness of your carpets, it often isn’t enough to remove deeply embedded dirt and allergens. Professional carpet cleaning services go beyond surface-level cleaning, using advanced tools and techniques to deeply cleanse your carpets.

Hobbs Cleaning Ltd uses high-quality, eco-friendly cleaning products that are safe for both children and pets. Our team of trained professionals uses a combination of hot water extraction and powerful suction to remove dirt, dust, stains, and bacteria, leaving your carpets spotless and sanitized.

Benefits of Carpet Cleaning Milton Keynes

Enhanced Appearance: Over time, dirt and stains can make your carpets look worn and unattractive. Our carpet cleaning services will restore the vibrancy and color of your carpets, making them look as good as new.

Improved Air Quality: Carpets trap dust, pollen, and allergens that can affect the air quality in your home. Professional cleaning removes these harmful particles, leading to better indoor air quality.

Extended Carpet Life: Regular cleaning helps to maintain your carpets' quality and extend their lifespan. By removing dirt and debris that cause wear and tear, your carpets will last longer.

Healthier Home Environment: Dirty carpets can harbor bacteria, mold, and dust mites, all of which can trigger allergies and asthma. Carpet cleaning Milton Keynes removes these harmful elements, promoting a healthier living space.

Our Carpet Cleaning Process

At Hobbs Cleaning Ltd, we follow a meticulous cleaning process to ensure the best results for your carpets:

Pre-Inspection: We start by assessing your carpets to identify any stains or areas requiring special attention.

Vacuuming: Our team thoroughly vacuums your carpets to remove loose dirt and debris before the cleaning process begins.

Stain Treatment: We apply stain removers to target specific spots and tough stains.

Hot Water Extraction: Our powerful machines inject hot water and eco-friendly cleaning solutions deep into the carpet fibers to break down dirt and grime.

Drying: After extraction, we use high-powered drying equipment to remove excess moisture, leaving your carpets dry and ready to use.

Final Inspection: Our team ensures that your carpets are clean, dry, and free of any stains before we complete the job.

Why Hobbs Cleaning Ltd?

We understand that your home or business in Milton Keynes is important to you. That’s why we are committed to providing exceptional carpet cleaning services. With years of experience and a dedication to customer satisfaction, Hobbs Cleaning Ltd is the trusted name for carpet cleaning Milton Keynes.

Our technicians are fully trained and use the latest cleaning technologies to deliver outstanding results every time. We pride ourselves on offering a hassle-free, professional service that guarantees your carpets are cleaned to the highest standards.

Ready to restore your carpets to their former glory? Contact Hobbs Cleaning Ltd today for the best carpet cleaning Milton Keynes has to offer!

0 notes

Text

With years of experience in the industry, T&R Tooling has built a strong reputation for delivering reliable and durable custom injection mold tools Texas. Their state-of-the-art facility is equipped with advanced machinery and equipment, allowing them to produce tools that meet even the most demanding specifications.

T&R Tooling 282 Elm Grove Rd., Valley View, TX 76272 (940) 726–6020

My Official Website: http://www.trtooling.com/ Google Plus Listing: https://www.google.com/maps?cid=1529569677814869897

Our Other Links:

plastic injection tooling in Texas: http://www.trtooling.com/new-tooling/ 3D Printing Texas: http://www.trtooling.com/3d-printing/ Service We Offer:

Plastic Injection Molding 3d Printing Tool Repair New Tooling Design Services Quality Assurance

Follow Us On:

Twitter: https://twitter.com/ToolingR31294 Pinterest: https://www.pinterest.com/trtoolingtx/ Instagram: https://www.instagram.com/trtooling/

#custom injection mold tools texas#plastic injection molding service texas#injection molding tooling texas#3D Printing Texas#prototyping texas

0 notes

Text

Elevate Your Production: Expert Injection Mold Tooling in China

Discover the pinnacle of precision and efficiency with PTMS injection mold tooling services in China. As industry leaders, we leverage cutting-edge technology and vast expertise to deliver top-quality molds tailored to your exact specifications. Whether you require prototypes or high-volume production molds, we have the solutions to optimize your manufacturing process. Trust us to exceed your expectations and streamline your production workflow. Learn more about our services at injection mold tooling china.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

0 notes

Text

Looking for the Best Tool & Die Steel Supplier in Hyderabad?

Look no further! Virat Special Steels Pvt. Limited is your go-to supplier for all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel.

Virat Special Steels Pvt. Limited stands out as one of the premier Tool & Die Steels Suppliers in Hyderabad. Let’s explore why they’re a top choice:

Wide Range of Materials: Virat Special Steels deals in various steel types, including:

Tool Steel: DB6 / DIN-1.2714 / AISI L6, essential for cutting, shaping, and forming tools.

Die Steel: DIN 2343, 2344 / AISI H11, H13, crucial for molds, dies, and precision components.

Plastic Mold Steel: DIN 2738, 2311 , AISI P 20, tailored for plastic injection molding.

High-Speed Steel: DIN 3243 , 3343 / AISI M2 , M35, ideal for high-speed machining.

Alloy Steel: Versatile and robust for diverse applications.

Value-Added Services: They go beyond supplying raw materials. Their services include: - Material Machining: Precision shaping and customization. - Cut Pieces: Ready-to-use segments for efficiency. - Tailor-Made Material: Customized to specific requirements.

Metallurgical Expertise: Virat Special Steels provides metallurgical advice to ensure optimal material selection and performance. Their team understands the nuances of steel properties and applications.

Quality Assurance: Quality is non-negotiable. They adhere to stringent standards. Ultrasonic inspection ensures material integrity.

State-of-the-Art Facilities: Their Gurugram and Ludhiana plants boast cutting-edge technology. Consistent quality and timely delivery are their hallmarks.

Strong Distribution Network: Virat Special Steels reaches across India, ensuring accessibility. Whether in Hyderabad or beyond, their steel is within reach.

For more information, visit Virat Special Steels. Trust in their expertise for all your steel needs! 🛠️🔥

Consultation: For further assistance, consult their #Gurugram office. Learn more https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-hyderabad/

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#Hyderabad#SteelSupplier#MetalTraders#db6 steel#h13toolsteels#h11steel#din 2714#din2344#din3343

2 notes

·

View notes

Text

Top Crack Repair Services in Kansas City: Ensuring Structural Integrity and Aesthetic Appeal

Cracks in walls, floors, or foundations can compromise the safety and appearance of your property. Whether caused by natural settling, weather changes, or external damage, addressing these issues promptly is crucial. In Crackology Kansas City stands out as the go-to resource for crack repair services. With a skilled and experienced team, they ensure precise and long-lasting solutions for all types of cracks.

Why Crack Repair is Essential

Cracks are more than cosmetic issues; they often signal deeper structural concerns. Ignoring them can lead to significant problems like:

Foundation Weakening: Cracks in the foundation can compromise the stability of your building.

Water Leakage: Cracks allow water to seep in, leading to mold, mildew, and further structural damage.

Reduced Property Value: Visible cracks can lower the aesthetic appeal and market value of your property.

Timely crack repair not only addresses these concerns but also prevents future issues, protecting your investment.

Common Causes of Cracks

To effectively repair cracks, it’s vital to understand their root causes. Some common factors include:

Soil Movement: Shifting soil can exert pressure on foundations, causing cracks.

Weather Conditions: Freeze-thaw cycles expand and contract materials, creating fissures.

Poor Construction: Subpar materials or techniques can lead to early cracking.

Aging Infrastructure: Over time, natural wear and tear weaken structures.

By identifying the cause, Crackology101.com ensures tailored solutions for every repair.

Types of Crack Repair Services Offered

Crackology101.com specializes in a wide range of crack repair services to cater to both residential and commercial properties in Kansas City.

Foundation Crack Repair Foundation cracks demand immediate attention to prevent further structural damage. The team uses advanced techniques like epoxy injections and polyurethane foam to seal and reinforce the foundation.

Wall Crack Repair From hairline fractures to deeper fissures, wall cracks are treated with precision. The team ensures a seamless finish that restores the structural integrity and visual appeal of your walls.

Floor Crack Repair Cracks in concrete floors not only look unsightly but can also pose tripping hazards. Crackology101.com employs state-of-the-art methods to level and seal floor cracks, ensuring safety and durability.

Driveway and Pavement Crack Repair Outdoor surfaces like driveways and pavements are prone to cracking due to weather exposure. Specialized materials are used to withstand heavy traffic and changing weather conditions.

What Sets Crackology101.com Apart?

Choosing the right service provider is essential for effective and lasting crack repair. Crackology101.com is renowned in Kansas City for:

Expert Team: Their skilled professionals bring years of experience and industry knowledge.

Advanced Techniques: They use cutting-edge equipment and materials for precise repairs.

Custom Solutions: Every crack is unique, and the team provides tailored solutions to address specific problems.

Affordable Pricing: High-quality repairs are offered at competitive rates, ensuring value for money.

Customer Satisfaction: Crackology101.com prioritizes customer satisfaction, maintaining open communication and delivering exceptional results.

The Crack Repair Process

Crackology101.com follows a meticulous process to ensure thorough and effective repairs:

Inspection: The team conducts a detailed assessment to identify the type, size, and cause of the cracks.

Preparation: The affected area is cleaned and prepped to ensure the repair materials adhere properly.

Repair Application: Using specialized materials and tools, the cracks are carefully sealed and reinforced.

Finishing Touches: The surface is smoothed and restored to its original appearance.

Quality Check: Every repair undergoes a final inspection to ensure durability and precision.

Preventing Future Cracks

While professional repairs address existing issues, proactive measures can help prevent future cracks:

Regular Maintenance: Keep an eye on your property for early signs of damage.

Proper Drainage: Ensure that water is directed away from the foundation to avoid soil movement.

Soil Stabilization: Strengthen the soil around your property to minimize shifting.

Temperature Regulation: Use insulation to reduce the impact of extreme temperature changes.

By combining quality repairs with preventive care, your property can remain crack-free for years to come.

Trust Crackology101.com for All Your Crack Repair Needs

When it comes to crack repairs in Crackology Kansas City, MO is a name you can trust. Their skilled team ensures that every repair is handled with care, precision, and expertise. From minor cosmetic fixes to major structural reinforcements, they deliver results that stand the test of time.

For reliable and efficient crack repair services, visit Crackology101.com today. Let their experts restore the safety, beauty, and value of your property with unparalleled professionalism and dedication.

0 notes

Text

The Complete Guide to Wing Nuts Manufacturers

Introduction

Wing nuts are an essential part in a number of industries, saving time and hassle by allowing quick attachment and detachment of parts without the need for specialized tools. These versatile fasteners are so popular among applications that require frequent adjustments or disassembly. Do you know where these small yet indispensable components come from? This blog delves into the world of wing nut manufacturers, how significant they are, production processes, and tips on how to choose the right wing nut manufacturer.

What are Wing Nuts?

A wing nut is a nut with two large metal "wings" on either side that can be easily turned and tightened by hand. They are commonly used in applications where a tool-less, quick assembly or disassembly is desired. Common materials used for the production of wing nuts include steel, stainless steel, brass, or plastic. Wing nuts are offered in various sizes and styles for different applications.

Role of Wing Nuts Manufacturers

Wing nuts manufacturers are companies that produce fasteners that serve the requirements of industries that include construction, furniture assembly, aerospace, and automotive. They make sure wing nuts meet specific durability, functionality, and safety standards. Here is what goes into their production:

Material Selection

The choice of material is dependent on the application. For instance:

Stainless steel for corrosion resistant applications outdoors and in the marines.

Brass for the aesthetic purpose

Plastic when the need for light and non-conductive applies.

Design and Engineering

Ergonomic designs are incorporated for wing nuts in order to ease handling. Manufacturers generally use computer aided design software where they come up with precise designs and tailor them towards specific applications.

Manufacturing Process

Casting: Used mainly for creating intricate shapes. Mainly used with plastic or massive metal wing nuts.

Stamping: Cheap on metal wing nuts, with pressing of the metal sheet into a desired shape.

Injection Molding: Applied more to plastic wings, enabling mass-produced parts with good quality.

Machining: The fabrication process of more precision wing nuts. It is used where high-grade aerospace and industrial needs are considered.

Quality Control:

The processes guarantee that the wing nuts meet the industry standards as indicated by the ISO, DIN, or ANSI specifications. There may also be tensile strength tests, corrosion resistance checks, and dimensional accuracy test.

Uses of Wing Nuts

Wing nuts are used for various applications that include:

Assembly of Furniture: Tool-less, fast assembly for shelves, tables, and chairs.

Plumbing: Fixing of fixtures and fittings in households and commercial locations.

Aerospace: Wing nuts are used which are light weight and corrosion resistance in aircraft interior.

Automobile: Used in securing battery terminals, clamps, and many other parts of an automobile.

DIY projects: It is one of the favorite items used by hobbyists and crafters.

How to Choose the Right Wing Nuts Manufacturer

Selecting the right manufacturer is crucial to ensure quality, reliability, and cost-effectiveness. Here are some factors to consider:

Experience and Expertise:

Look for manufacturers with a proven track record in producing wing nuts for your specific industry. Experienced manufacturers are more likely to understand your needs and deliver consistent quality.

Material Options:

A good manufacturer should offer a wide range of materials to suit different applications.

Customization Capabilities:

Whether you require specific sizes, designs, or materials, choose a manufacturer that can provide customized solutions.

Certifications and Standards:

Ensure the manufacturer adheres to international quality standards, such as ISO 9001, to guarantee product reliability.

Production Capacity and Lead Times:

Assess whether the manufacturer can meet your volume and timeline requirements without compromising quality.

Cost Efficiency:

While cost is important, it shouldn't be a sacrifice for quality. Compare quotes from multiple manufacturers to get the best value.

The Future of Wing Nuts Manufacturing

The wing nuts industry continues to evolve with advancements in materials science and manufacturing technologies. 3D printing and automation are becoming increasingly prominent, enabling manufacturers to produce high-quality wing nuts with greater efficiency and customization capabilities. Moreover, sustainable manufacturing practices are gaining traction, with an emphasis on recycling and eco-friendly materials.

Conclusion

Wing nuts may be small in size, but their role in ensuring the safety and functionality of countless applications is immense. Thus, the proper choice of manufacturer would ensure that one gets high-quality, reliable products. Understanding production processes, material options, and critical factors in choosing a manufacturer is what will enable you to make an informed decision that meets your specific needs.

Whether you are looking for wing nuts for industrial purposes or for your next DIY project, the information contained here will help you make informed decisions in finding the right wing nuts manufacturers.

FAQ

1. What materials are commonly used to manufacture wing nuts?

Wing nuts are typically made from materials like steel, stainless steel, brass, and plastic. The choice of material depends on the application, such as stainless steel for corrosion resistance or plastic for lightweight needs.

2. How are wing nuts made?

Wing nuts are produced using methods such as casting, stamping, injection molding, or machining. The manufacturing process depends on the material and required precision.

3. What industries use wing nuts the most?

Industries like furniture assembly, plumbing, aerospace, automotive, and DIY projects commonly use wing nuts for their ease of assembly and disassembly.

4. Can wing nuts be customized?

Yes, many manufacturers offer customization options, including specific sizes, materials, and designs tailored to unique applications.

5. How do I choose a reliable wing nuts manufacturer?

Look for manufacturers with extensive experience, a wide range of material options, adherence to quality standards, and the capacity to meet your production and timeline requirements.

#ananka#fasteners#linkedin#article#blog#anankafasteners#wingnuts#nuts#nutmanufacturer#manufacturer#fastenersmanufacturer#wingsnutmanufacturer#mumbai#supplier#hex#bolt#usa#uk

0 notes

Text

How Custom Plastic Injection Molding is Transforming Product Design

In today’s rapidly evolving manufacturing landscape, custom plastic injection molding plays a pivotal role in revolutionizing product design and development. This advanced manufacturing process allows companies to create high-quality, precise components that are used across various industries, from automotive to consumer electronics. One company that exemplifies the benefits of this technology is L-D Tool & Die, a leader in delivering tailored solutions for their clients’ complex design needs.

The shift toward High-Quality Custom Plastic Injection Molding has enabled designers and engineers to push the boundaries of product innovation. With the ability to produce complex shapes and geometries with exceptional precision, businesses can now create components that were once impossible to achieve with traditional manufacturing methods.

The Basics of Custom Plastic Injection Molding

At its core, custom plastic injection molding involves injecting molten plastic into a precisely designed mold. The plastic then cools and solidifies, taking the shape of the mold to create a finished product. The process is highly versatile and capable of producing a vast range of products, from small and intricate parts to large, durable components.

What sets high-quality custom plastic injection molding apart is the ability to create highly accurate parts with consistent tolerances, which is essential for industries where precision is key. This is where custom precision machined components come into play. These components are critical for applications where the highest standards of accuracy, performance, and functionality are demanded.

How High-Quality Custom Plastic Injection Molding Enhances Product Design

One of the biggest advantages of custom plastic injection molding is the ability to produce parts in large quantities while maintaining high standards of quality. This is ideal for mass production scenarios, where each part must meet exact specifications without deviation. In addition to efficiency, the process reduces material waste and ensures that the final product is both durable and functional.

The flexibility of custom plastic injection molding also allows for a wide range of materials to be used. Whether it’s thermoplastics, elastomers, or specialized materials, manufacturers can choose the right plastic for the job, depending on factors like strength, flexibility, heat resistance, and appearance. This means that product designers are no longer limited by material constraints and can push the envelope when conceptualizing new products.

Custom Precision Machined Components in Plastic Injection Molding

In many cases, the need for custom precision machined components arises when a product requires parts with intricate features or tight tolerances. These components are often integrated into plastic injection molded products, allowing for enhanced performance and functionality. The precision involved ensures that the end product meets the highest standards, making it suitable for industries like aerospace, medical devices, and automotive, where even the slightest defect could lead to catastrophic consequences.

Custom precision machined components are typically crafted using advanced CNC machines, which offer the ability to produce parts with exacting specifications. These components are then incorporated into the injection-molded parts, where they work together to deliver superior performance. The combination of injection molding and precision machining is what makes modern product design so versatile and capable of meeting demanding industry requirements.

The Role of L-D Tool & Die in Modern Manufacturing

L-D Tool & Die is a prime example of a company that has harnessed the power of custom plastic injection molding and precision machining to meet the evolving needs of their clients. Their commitment to providing high-quality custom plastic injection molding ensures that each product is produced with the utmost care and attention to detail. By offering tailored solutions and using state-of-the-art equipment, L-D Tool & Die helps businesses bring their product ideas to life, regardless of complexity.

L-D Tool & Die’s expertise in Custom Precision Machined Components is also integral to their success. They offer precision manufacturing services that ensure all components meet the tightest tolerances, enabling designers to create intricate, high-performance products with confidence. With a customer-centric approach, L-D Tool & Die collaborates with clients from the initial design phase through to production, ensuring that the final product is exactly as envisioned.

Benefits of Using Custom Plastic Injection Molding in Product Design

Cost-Effectiveness: While the initial tooling costs for custom plastic Injection Molding can be higher, the overall production costs are typically lower for large runs of parts. This is because the process is highly efficient, and the parts produced are uniform, reducing the need for rework or waste.

Design Flexibility: The precision of custom plastic injection molding means that designers have more freedom when it comes to product design. Complex shapes, textures, and even multi-material parts can be easily incorporated into the final product.

Improved Product Quality: With custom plastic injection molding, manufacturers can achieve higher levels of consistency and quality control. This ensures that each part performs as intended, leading to better overall product reliability.

Speed to Market: The fast turnaround time of custom plastic injection molding allows companies to bring their products to market quicker, providing a competitive edge in industries where time-to-market is critical.

Sustainability: The ability to reuse molds and reduce material waste makes plastic injection molding a more sustainable manufacturing option compared to other processes.

Custom Plastic Injection Molding in Various Industries

Custom plastic injection molding is utilized in a wide range of industries, thanks to its ability to produce cost-effective, high-quality parts with precision. In the automotive industry, it’s used to create components such as dashboard parts, bumpers, and interior panels. In the medical field, custom molded plastics are used in devices and instruments that require strict compliance with hygiene standards and precise performance.

The versatility of custom plastic injection molding is also evident in consumer electronics, where it is used for creating parts like housings, buttons, and connectors. Its use in the aerospace industry allows for the creation of lightweight yet durable components that must withstand extreme conditions. The flexibility of the process and the precision of custom components make it the perfect solution for these demanding industries.

The Future of Custom Plastic Injection Molding

As technology continues to evolve, custom plastic injection molding will only become more advanced. Innovations in mold design, materials, and automation will continue to improve the process, making it more efficient and cost-effective. The integration of 3D printing technology with injection molding also holds the potential to further expand the possibilities for product designers, offering even greater flexibility in design and manufacturing.

L-D Tool & Die remains at the forefront of these developments, consistently pushing the boundaries of what can be achieved with custom plastic injection molding and custom precision machined components. Their ability to adapt to new technologies and stay ahead of industry trends ensures that they are able to provide their clients with cutting-edge solutions that help transform product designs.

In conclusion, custom plastic injection molding has transformed product design by offering unparalleled precision, design flexibility, and efficiency. The combination of high-quality custom plastic injection molding and custom precision machined components provides manufacturers with the tools they need to create innovative products that meet the highest standards of quality and performance. With companies like L-D Tool & Die leading the way, the future of product design looks more exciting than ever.

0 notes

Text

How to Choose the Best Basement Wall Repair Contractors in North Carolina

A solid foundation is crucial for the safety and longevity of any home, and basement walls play a vital role in maintaining structural integrity. If you're facing issues like cracks, bowing, or water damage in your basement walls, finding experienced basement wall repair contractors is essential. For homeowners near North Carolina, selecting the right contractor can save you time, money, and stress.

Signs You Need Basement Wall Repairs

Basement wall issues often start small but can escalate quickly. Here are some common signs that indicate you need professional repair services:

Visible Cracks: Horizontal or stair-step cracks are a clear indication of foundation stress.

Bowing or Bulging Walls: This can be caused by hydrostatic pressure or shifting soil.

Water Seepage: Moisture entering through basement walls can lead to mold and structural damage.

Uneven Floors: This can be a symptom of shifting basement walls.

Foundation Settlement: Signs include sinking walls or gaps between walls and floors.

If you’re noticing any of these issues, it’s time to consult with trusted basement wall repair contractors.

Why Choose Professional Basement Wall Repair Contractors

DIY fixes might seem tempting, but basement wall repairs often require specialized tools and expertise. Professional contractors ensure:

Accurate Diagnosis: Identifying the root cause of the problem.

Tailored Solutions: Techniques like wall anchors, carbon fiber reinforcement, or drainage systems based on your specific needs.

Long-Term Results: Ensuring structural integrity and preventing future issues.

For homeowners near North Carolina, partnering with local experts like Atlantic Foundation provides peace of mind and high-quality results.

Key Considerations When Choosing a Contractor

To find the best basement wall repair contractors near North Carolina, keep these factors in mind:

Experience and Expertise: Look for contractors with extensive experience in handling basement wall repairs. They should be familiar with the soil and weather conditions in North Carolina.

Licenses and Certifications: Ensure the contractor is licensed and certified to perform structural repairs.

Customer Reviews: Check online reviews and testimonials to learn about their reputation.

Comprehensive Services: Opt for contractors who offer a range of solutions, such as wall stabilization, crack repairs, and waterproofing.

Warranty: A reliable contractor provides a warranty on their work to guarantee long-term results.

Atlantic Foundation, a trusted name in North Carolina, meets all these criteria and offers exceptional basement wall repair services.

Techniques for Basement Wall Repairs

Modern contractors use a variety of methods to address basement wall issues, including:

Wall Anchors: Effective for stabilizing bowing walls by counteracting pressure.

Carbon Fiber Reinforcement: Strengthens cracks and prevents further damage.

Epoxy Injection: Repairs cracks and restores wall integrity.

Interior and Exterior Waterproofing: Prevents water infiltration to protect the structure.

Foundation Piering: Stabilizes sinking walls and foundations.

Discuss these options with your contractor to determine the best approach for your home.

Why North Carolina Homeowners Trust Atlantic Foundation

When it comes to basement wall repair contractors near North Carolina, Atlantic Foundation stands out for its:

Experienced Team: Decades of expertise in basement wall repair and foundation services.

Custom Solutions: Tailored repairs to meet your specific needs.

Transparent Pricing: No hidden fees, just honest and competitive pricing.

Exceptional Customer Service: Dedicated to providing a stress-free experience.

Visit their basement wall repair page for more details on their services.

Conclusion

Basement wall issues should never be ignored. By choosing the right basement wall repair contractors near North Carolina, you can ensure the safety and stability of your home. Don’t wait until minor problems turn into major structural concerns—consult experts like Atlantic Foundation today to safeguard your home’s foundation.

For more information, visit Atlantic Foundation’s website or contact their team to schedule an inspection.

0 notes

Text

Choosing the Right Custom Injection Mould Manufacturer for Your Needs

In today’s competitive manufacturing industry, finding the right custom injection mould manufacturer is crucial for businesses aiming to create high-quality plastic components. The process of injection molding has become a staple in industries ranging from automotive to consumer goods, thanks to its efficiency, precision, and scalability. Partnering with a reliable injection molding maker can make all the difference in meeting production goals and ensuring customer satisfaction.

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten plastic into a mould cavity. The material cools and solidifies into the desired shape, resulting in durable and precise components. This process is highly versatile, enabling manufacturers to produce everything from small, intricate parts to large, robust products. Given its versatility, working with an experienced injection molding maker is essential to ensure quality results.

Why Work with a Custom Injection Mould Manufacturer?

Every project is unique, and a custom injection mould manufacturer offers tailored solutions to meet specific requirements. Customization ensures that your moulds are designed with the exact specifications, materials, and features you need. This is particularly important for industries like medical, aerospace, and electronics, where precision and reliability are non-negotiable.

Some benefits of choosing a custom injection mould manufacturer include:

Precision Engineering: Custom manufacturers use advanced technology and expertise to design moulds that meet your precise requirements.

Material Expertise: They can guide you in selecting the best materials for your application, ensuring durability and cost-effectiveness.

Streamlined Production: Custom moulds are optimized for efficiency, reducing cycle times and production costs.

Scalability: Whether you need a small batch or high-volume production, a custom manufacturer can adapt to your needs.

Key Factors to Consider When Choosing an Injection Molding Maker

Selecting the right injection molding maker is a critical decision that can impact the success of your project. Here are some factors to consider:

Experience and Expertise: Look for manufacturers with a proven track record in your industry. Experienced providers understand the complexities of various applications and can deliver superior results.

Technological Capabilities: Ensure the manufacturer uses advanced machinery and software for precision mould design and production. Technologies like 3D printing and CAD/CAM tools are invaluable in modern injection molding.

Material Selection: A good injection molding maker will offer a wide range of material options and help you choose the best one for your product’s requirements.

Quality Assurance: Check if the manufacturer has rigorous quality control processes in place to ensure consistent and defect-free products.

Customization and Flexibility: Your chosen manufacturer should be able to provide tailored solutions and adapt to changing project needs.

The Future of Injection Molding

As technology advances, the injection molding industry continues to evolve. Custom injection mould manufacturers are leveraging innovations like automation, AI, and sustainable materials to stay ahead of the curve. These developments not only improve production efficiency but also align with the growing demand for eco-friendly manufacturing practices.

Conclusion

Partnering with the right custom injection mould manufacturer is essential for businesses looking to achieve excellence in plastic component production. By selecting a reputable and experienced injection molding maker, you can ensure that your products meet the highest standards of quality and performance. Whether you’re launching a new product or scaling up production, the right partner can help you navigate the complexities of modern manufacturing and achieve your goals with confidence.

#plastic chocolate molds#injection molding solutions#plastic injection mold design#technology#science#best injection molding company#plastic injection molding manufacturer

0 notes