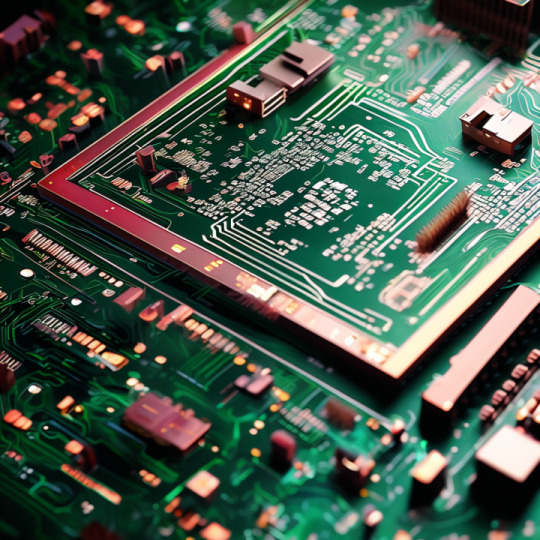

#Copper multilayer pcb

Explore tagged Tumblr posts

Text

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Text

Single layer PCB vs double layer pcb vs multi layer pcb

PCB boards mainly divided into single-layer PCB boards and double-layer PCB boards, as well as multi-layer PCB boards. The most commonly used are single-layer PCB and double-layer PCB boards, and those with more than three layers are called multilayer PCB boards. For applications in different industries, there are different requirements for its shape, size, color, model, number of layers, etc. Now let’s introduce the difference between single layer, double layer and multi layer PCB boards in detail.

The difference in the number of layers: To be simple, the main difference is single-sided wiring, double-sided wiring, and multilayer wiring.

1) single layer pcb: one layer of medium, one side wiring;

2) double layer pcb: one layer of medium, double-sided wiring;

3) multilayer PCB: Usually at least 4 layers, multilayer medium, multilayer wiring.

The difference in structure:The so-called single-sided PCB and double-sided PCB have different copper layers. A double-sided PCB has copper on both sides of the board, which can be connected through vias. However, a single-sided PCB has only one layer of copper, which can only be used for simple circuits, and the holes made can only be used for plug-ins and cannot be connected.

The single-sided printed circuit board is usually a single-sided copper clad laminate. The corroded circuit pattern is made on the copper surface by screen printing or photoimaging, and the excess copper foil is removed by chemical etching to form the conductor pattern. .

The double-sided printed circuit board has upper and lower conductor patterns, and the upper and lower layer are connected by holes. In the printed circuit board processing, the hole wall is plated with a copper layer to make the upper and lower layers conductive. The double-sided printed circuit board usually adopts double-sided copper clad laminates, using screen printing or photoimaging. A corrosion-resistant circuit pattern is made on the copper surface, and the excess copper foil is removed by chemical etching to form a conductor pattern.

The conductor pattern of the multilayer printed circuit board has three or more layers, and the conductor layer is divided into an inner layer and an outer layer. The inner layer is a conductor pattern completely sandwiched inside the multilayer board; the outer layer is a conductor pattern on the surface of the multilayer board. Generally, the inner conductor pattern is processed first during production, and the hole and the outer conductor pattern are processed after pressing, and the inner and outer layers are connected by metalized holes.

The production process of single-sided and double-sided circuit boards is basically similar, and the structure and production are relatively simple, while the multilayer circuit board is different. The requirements for structural design and process production of multilayer pcb are very high, the higher the number of layers, the difficulty is higher.

0 notes

Text

Advancing Technology with Multilayer PCB Manufacturing

Advancing Technology with Multilayer PCB Manufacturing

Printed Circuit Boards (PCBs) are the backbone of virtually all electronic devices, enabling the complex circuitry required for modern technology. Among the various types of PCBs, multilayer PCBs have become essential due to their ability to support advanced electronic designs and high-performance applications. This article explores the process, benefits, and applications of multilayer PCB manufacturing, showcasing their critical role in advancing technology.Get more news about Multilayer PCB manufacturing,you can vist our website!

Understanding Multilayer PCBs A multilayer PCB consists of multiple layers of conductive material separated by insulating layers (also known as dielectric layers). These layers are stacked and bonded together to create a compact, complex structure that allows for the routing of intricate electronic circuits. Multilayer PCBs can have anywhere from three to over 50 layers, depending on the complexity and requirements of the application.

The Manufacturing Process of Multilayer PCBs Design and Layout

The manufacturing process begins with the design and layout of the PCB. Engineers use specialized software to create a detailed blueprint of the circuit, including the placement of components, traces, and vias. This design is then used to create photomasks for each layer of the PCB.

Layer Stacking and Bonding

The individual layers of the PCB are fabricated separately, with each layer consisting of a thin sheet of conductive material (usually copper) laminated onto an insulating substrate. These layers are then stacked in the correct order and bonded together using heat and pressure. This process, known as lamination, ensures that the layers are securely attached and aligned.

Drilling and Plating

Once the layers are bonded, holes are drilled through the stack to create vias, which are used to connect the different layers of the PCB. The drilled holes are then plated with a conductive material, such as copper, to establish electrical connections between the layers.

Etching

The next step is etching, where the unwanted copper is removed from each layer to create the desired circuit patterns. A chemical solution is used to dissolve the excess copper, leaving behind the intricate traces and pads that form the PCB's circuitry.

Solder Mask and Silkscreen

After etching, a solder mask is applied to the PCB to protect the copper traces from oxidation and prevent solder bridges during component assembly. The solder mask also gives the PCB its characteristic green color. Finally, a silkscreen layer is added to print component labels, logos, and other markings on the PCB.

Testing and Quality Control

Before the PCB is ready for use, it undergoes rigorous testing to ensure its functionality and reliability. Automated testing equipment checks for continuity, shorts, and other defects. Any issues detected are addressed, and the PCB is re-tested until it meets the required standards.

Benefits of Multilayer PCBs Compact Size and Space Efficiency

Multilayer PCBs allow for more complex circuitry to be accommodated in a smaller footprint. By stacking multiple layers, designers can create compact and space-efficient electronic devices, which is particularly important in applications where size and weight are critical factors.

Enhanced Performance and Reliability

The use of multiple layers enables the separation of different signal types, reducing electromagnetic interference (EMI) and improving signal integrity. This results in enhanced performance and reliability, making multilayer PCBs ideal for high-speed and high-frequency applications.

Increased Design Flexibility

Multilayer PCBs offer greater design flexibility, allowing engineers to implement more complex and sophisticated circuits. The additional layers provide more routing options, enabling the creation of advanced electronic designs that would be challenging to achieve with single-layer or double-layer PCBs.

Improved Thermal Management

The increased number of layers in multilayer PCBs allows for better distribution of heat generated by electronic components. This improved thermal management helps prevent overheating and extends the lifespan of the device.

Applications of Multilayer PCBs Consumer Electronics

Multilayer PCBs are widely used in consumer electronics, including smartphones, tablets, laptops, and wearable devices. The compact size and high performance of these PCBs make them ideal for modern gadgets that require sophisticated functionality in a small form factor.

Automotive Industry

The automotive industry relies on multilayer PCBs for various applications, including engine control units, navigation systems, and advanced driver-assistance systems (ADAS). The reliability and durability of multilayer PCBs ensure the safe and efficient operation of electronic systems in vehicles.

Telecommunications

In telecommunications, multilayer PCBs are used in networking equipment, data servers, and communication devices. The ability to handle high-speed data transmission and reduce EMI makes these PCBs essential for maintaining the performance and reliability of communication networks.

Medical Devices

Multilayer PCBs play a crucial role in medical devices, such as diagnostic equipment, patient monitoring systems, and implantable devices. The precision and reliability of these PCBs are critical for ensuring the accuracy and safety of medical applications.

0 notes

Text

Maximizing Flex PCB Performance: Key Design Strategies and Best Practices | PCB Power

Flexible printed circuit boards (Flex PCBs) are widely used in today’s electronics due to their adaptability and space-saving design. These boards are crucial in industries like wearables, automotive electronics, and medical devices. However, designing Flex PCBs requires a unique approach to ensure durability and functionality. Here are some essential tips and tricks for Flex PCB design, combining insights from the resources available.

Understanding Flex PCBs

Flex PCBs are made from materials like Polyimide and Polyester, which allow them to bend and conform to various shapes. This flexibility makes them suitable for devices where space is limited or the PCB must withstand movement and stress. Flex PCBs offer numerous advantages, but designing them properly is essential to avoid failure during use.

Tips for Flex PCB Design

1. Use a Larger Bend Radius

One of the key aspects of Flex PCB design is maintaining a larger bend radius. A wider bend radius reduces the strain on the copper traces and the dielectric material, which extends the lifespan of the board.

You can calculate the smallest bend radius based on the PCB layers as follows:

2. Opt for Curved Traces

Avoid using sharp, angular traces in your design. Curved traces reduce stress and the likelihood of copper cracking, especially in high-flex areas. Smooth, rounded paths distribute mechanical stress more evenly across the circuit.

3. Stagger Traces on Multilayer PCBs

For multilayer flex PCBs, stagger the traces on different layers to prevent what is known as I-beaming, a situation where stacked copper layers increase stress. Staggering the traces ensures the board remains flexible and strong.

4. Add Tear Stops and Guards

To prevent the board from tearing at bend points, include tear stops or tear guards in areas where the PCB is likely to flex. This strengthens the board and reduces wear over time.

5. Avoid Discontinuities in the Bend Area

Keep vias, holes, and cutouts away from the bending regions. These discontinuities can create weak points that are prone to cracking and breaking. Keep these features outside of high-flex areas to maintain the integrity of the board.

6. Use Stiffeners in High-Stress Zones

In regions where extra support is needed, such as areas with connectors, include stiffeners. Stiffeners reinforce the PCB while still allowing for flexibility in other areas. This can prevent lifting and detachment of copper traces in critical zones.

7. Taper Traces to Avoid Weak Points

Taper-wide traces to prevent stress buildup in transition areas. Narrowing the traces evenly reduces the likelihood of cracks forming, especially in areas where the PCB experiences frequent bending.

8. Optimize Drill-to-Copper Distance

Maintain a proper drill-to-copper distance to avoid damaging the copper during drilling. A minimum distance of 8 mils is recommended to ensure manufacturing tolerances are maintained and the copper is not weakened.

9. Choose a Competent Flex PCB Manufacturer

To ensure success, it's crucial to work with an experienced Flex PCB manufacturer that understands the complexities of flex designs. This ensures that your PCB order meets your design expectations, especially in demanding industries.

Flex PCB Design Techniques

In addition to following these guidelines, use advanced design tools that simulate bending and flexing during the design process. These tools can help detect potential issues early on, ensuring that the final product is robust and ready for manufacturing.

Also, reducing the number of connectors in your design improves reliability and simplifies PCB assembly. Integrated circuits, when possible, can minimize the need for complex connectors, making the design more durable and easier to fabricate.

PCB Power – Your Trusted Flex PCB Partner

At PCB Power, we specialize in providing flex PCB design and PCB fabrication services tailored to meet the specific needs of various industries. Our team ensures that every PCB order is handled with precision and care. We also serve industries globally, including automotive electronics, medical devices, and consumer electronics. Our commitment to excellence is backed by certifications, including ISO 9001 and IPC Class 3 standards.

Conclusion

By following these Flex PCB design tips and tricks, you can ensure that your product is both reliable and durable. Whether you're working on a wearable device or a medical gadget, proper Flex PCB design is key to achieving optimal performance. If you're ready to take your design to the next level, contact PCB Power today for expert guidance and support in bringing your PCB to life. Read More:

0 notes

Text

Understanding Annular Rings in PCB Design | Lion Circuits

In the world of printed circuit board (PCB) design, every detail counts, and one such detail that plays a critical role is the concept of annular rings. These features are essential for ensuring reliable electrical connections and maintaining the integrity of the PCB during the manufacturing process. At Lion Circuits, we recognize the importance of understanding annular rings and their implications for effective PCB design.

What Are Annular Rings?

Annular rings refer to the circular band of copper that surrounds a plated-through hole on a PCB. Essentially, when a hole is drilled into the board and subsequently plated, the copper forms a ring around the hole. This ring is critical because it provides a conductive pathway between the pad and the plated hole, ensuring that electrical signals can pass through without interruption.

Importance of Annular Rings

Electrical Connectivity: The primary purpose of annular rings is to establish a reliable connection between the PCB’s pads and the through-hole components. If the annular ring is too small or improperly formed, it can lead to weak or intermittent connections, which can cause circuit failures.

Mechanical Strength: Annular rings contribute to the mechanical stability of the PCB. A well-formed ring ensures that components are securely anchored to the board, reducing the risk of damage due to thermal expansion or mechanical stress.

Manufacturing Tolerance: During the PCB fabrication process, various factors can affect the integrity of annular rings, such as drilling tolerances and plating processes. Understanding how to design effective annular rings can help mitigate issues during manufacturing, leading to higher yield rates.

Designing Effective Annular Rings

When designing PCBs, it’s crucial to consider the size and dimensions of the annular rings. Here are some guidelines to follow:

Minimum Ring Width: Aim for a minimum width of 0.2 mm for the annular ring to ensure a strong connection. However, this may vary based on specific manufacturing capabilities.

Drill Hole Size: The size of the drill hole impacts the annular ring width. When designing, make sure to account for the drill size and how it will affect the resulting annular ring.

Layer Count: In multilayer PCBs, consider how the annular rings will interface between layers. Proper alignment is crucial for maintaining electrical integrity across layers.

Conclusion

Understanding annular rings is fundamental for anyone involved in PCB design and manufacturing. These features play a vital role in ensuring electrical connectivity, mechanical strength, and overall reliability of the PCB. At Lion Circuits, we emphasize the importance of precise design practices, helping you create high-quality PCBs that meet your specifications. By paying close attention to details like annular rings, you can enhance the performance and longevity of your electronic devices. If you're looking for expert guidance on PCB design or manufacturing, reach out to us today!

0 notes

Text

$4,200 For A Portable Music Player? — Astell&Kern Offers Latest Audiophile Contender - Notice Today Online https://www.merchant-business.com/4200-for-a-portable-music-player-astellkern-offers-latest-audiophile-contender/?feed_id=193272&_unique_id=66de037acdb44 #GLOBAL - BLOGGER BLOGGER Photo Credit: Astell&KernDigital Products Astell&Kern’s latest audiophile offering comes with a premium price thanks to its 98% copper body. The SP3000T Copper Edition features the same portable audio player that creates a fusion of the best of both worlds for an analog and digital audio experience—now in copper.Astell&Kern’s SP3000T features the integration of a real vacuum tube to create an authentic analog sound, complemented by cutting-edge audio technology such as Teraton Alpha for an immersive auditory experience. This portable audio player features dual Raytheon JAN6418 Mil-Spec vintage vacuum tubes and a triple amp system to allow listeners to select the right tones for their music. The result is an audio player that features separate digital and analog signal processing.The Copper Edition takes that one step further with a body made from 98.8% copper. Copper is known for its excellent sound transmission and resonance properties, enhancing the brightness and richness of musical tones. Astell&Kern has created a specialized multilayer coating that enhances durability to help this limited-edition audiophile accessory maintain its beautiful luster without oxidizing or requiring special maintenance.Due to differences in noise and amplification among original vacuum tubes, Astell&Kern have created a meticulous process to address minute differences in sound quality. Astell&Kern carefully measures and pairs each JAN6418 vacuum tube to minimize deviation between the left and right channels—resulting in a more natural sound reproduction.The SP3000T features an independent modular, flexible PCB design engineered separately from the main PCB. It has a silicone module case designed to absorb primary shocks from the vacuum tube, with silicone tubing perfectly tailored to the vacuum tube to reduce shock transmission along the leads. Finally, it features silicone dampers around the vacuum tube to suspend the tube in the air from both ends—helping to eliminate microphonic noise.Achieving these low noise levels withing the compact confines of the SP3000T body was no easy challenge. The device houses two of AKM’s latest flagship AK4499EX DACs and a separate audio circuit design with the AK4191EQ—which is applied independently to the left and right channels responsible for processing digital signals.With this unique audio circuit configuration, the SP3000T reduces the noise of the input digital signal, while acting as a separate digital delta-sigma modulator. Only analog signals are processed within the DAC AK4499EX, ensuring digital and analog signals are processed separately. http://109.70.148.72/~merchant29/6network/wp-content/uploads/2024/09/pexels-photo-13883855.jpeg Photo Credit: Astell&Kern Digital Products Astell&Kern’s latest audiophile offering comes with a premium price thanks to its 98% copper body. The SP3000T Copper Edition features the same portable audio player that creates a fusion of the best of both worlds for an analog and digital audio experience—now in copper. Astell&Kern’s SP3000T features the integration of … Read More

0 notes

Text

The Role of Multilayer PCBs in Advancing Modern Technology

The Role of Multilayer PCBs in Advancing Modern Technology

In the rapidly evolving world of technology, the demand for more compact, efficient, and powerful electronic devices is ever-increasing. One of the key components driving this advancement is the Multilayer Printed Circuit Board (PCB). These sophisticated circuit boards, which consist of multiple layers of conductive material separated by insulating layers, are integral to the functionality of a wide range of modern electronic devices.Get more news about Multilayer PCB manufacturing,you can vist our website!

What is a Multilayer PCB? A Multilayer PCB is a type of printed circuit board that has more than two layers of conductive copper foil. These layers are stacked and laminated together with insulating layers in between, creating a single, cohesive unit. The primary advantage of this design is the ability to pack more electronic components into a smaller space, which is essential for the miniaturization of modern electronic devices.

Applications in Consumer Electronics One of the most prominent applications of Multilayer PCBs is in consumer electronics. Smartphones, tablets, and laptops all rely on these advanced circuit boards to function. The compact design of Multilayer PCBs allows manufacturers to include more features and functionalities in their devices without increasing the size. For instance, the latest smartphones are equipped with high-resolution cameras, powerful processors, and extensive memory, all of which are made possible by the use of Multilayer PCBs.

Role in Medical Devices The medical field has also greatly benefited from the advancements in Multilayer PCB technology. Medical devices such as MRI machines, pacemakers, and portable diagnostic tools require highly reliable and compact circuit boards. Multilayer PCBs provide the necessary reliability and performance, ensuring that these critical devices operate accurately and efficiently. The ability to integrate multiple functions into a single board also helps in reducing the overall size of medical devices, making them more portable and user-friendly.

Impact on Automotive Industry The automotive industry is another sector where Multilayer PCBs have made a significant impact. Modern vehicles are equipped with numerous electronic systems, including advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs). These systems require complex and reliable circuit boards to function correctly. Multilayer PCBs offer the necessary durability and performance, ensuring that automotive electronics can withstand harsh conditions and provide reliable operation.

Advancements in Telecommunications Telecommunications is yet another field that has seen remarkable advancements due to Multilayer PCBs. The demand for faster and more reliable communication networks has led to the development of sophisticated networking equipment. Multilayer PCBs are used in routers, switches, and other networking devices to handle high-speed data transmission and complex signal processing. Their ability to support high-density interconnections makes them ideal for telecommunications applications.

Future Prospects The future of Multilayer PCBs looks promising, with ongoing research and development aimed at further enhancing their capabilities. Innovations such as flexible Multilayer PCBs and the integration of advanced materials are expected to open up new possibilities in various fields. As technology continues to evolve, the role of Multilayer PCBs in driving innovation and enabling new applications will only become more significant.

Conclusion In conclusion, Multilayer PCBs are a cornerstone of modern technology, enabling the development of more compact, efficient, and powerful electronic devices. Their applications span across various industries, including consumer electronics, medical devices, automotive, and telecommunications. As advancements in PCB technology continue, we can expect even greater innovations and improvements in the performance and functionality of electronic devices.

0 notes

Text

What is a Flex PCB?

Flex PCB boards or flexible printed circuit boards, as the name suggests, carry out the function of regular PCB boards while being physically flexible. As you must know, PCBs or printed circuit boards carry out the function of establishing connections among various components inside an electrical or electronic device. While rigid PCB boards have ruled the market for so many years now, flex PCB boards emerged and opened the door to new possibilities due to their dynamic nature.

Bare boards of flexible printed circuit boards are made of flexible materials allowing them to bend and be manipulated as per the designer’s requirements. This feature of bendability and flexibility comes in handy while crafting various new-age gadgets such as wearables. To know more about these circuit boards also known as flexible circuit boards, continue reading below.

Classifications of Flexible Printed Circuit Boards

Flex PCB manufacturers can now design, fabricate, and customize PCBs with a wide variety of specifications. While the variations are enormous, flexible circuit boards can broadly be classified into a few types based on their layers and configurations.

By Layers: Single-sided, Double-sided, and Multi-layer flex PCBs

Based on the number of layers present in a flexible printed circuit board, they can be classified into single-sided, double-sided, and multi-layered PCBs. Each type has its advantages and features. While a higher number of layers allows a connection of more components, the complications, and overall costs also increase along with. Therefore, engineers at Hitechpcba study the project requirements carefully to find the best-suited type of flexible printed circuit board for an application.

Single-sided flex PCBs: Single only only have one conductive layer. These are the most commonly used flexible printed circuit boards, with excellent electronic and mechanical properties of flexible material, and also low cost. So they are widely used in consumer electronics.

Double-sided flex PCBs: There are two copper layers which are connected by plated through holes in double-layer flexible circuit boards. It combines high electronic performance and cost-effectiveness and is usually used in high-tech electronic devices with high volumes, such as laptops, cameras, and earphones., etc.

Multilayer flex PCBs: For such very advanced devices, very limited spacing or continuous moving is needed, so we need to use multilayer flexible PCB boards, such as robotics, industrial equipment, and medical applications. Such kind of flex PCB have three or more copper layers. But generally speaking, we do advice using more than four layers in flex PCB which will affect the flexibility.

By Characteristics: Standard flex PCB, Rigid-flex and HDI flexible PCBs

Similarly, based on configuration, flexible circuit boards can be divided into standard flex PCBs, rigid-flex PCBs and HDI flexible PCBs.

Standard flex PCBs: Standard flex PCBs are the most commonly used flexible circuit boards. They are usually produced by polyimide, with one or two conductive layers and stiffeners.

Rigid-flex PCBs: As the name suggests, rigid-flex PCBs are a combination of the features of both rigid and flexible PCBs. In this type of flex PCB board, only the required areas of the PCB are made with flexible materials that help connect the rigid parts of the circuit. This reduces the cost while allowing the PCB to bend as per the requirement.

HDI flexible PCBs: HDI flexible PCBs or high-density interconnect circuit boards can be considered as the advanced version of flexible PCBs. They offer better features and improved performance than regular flexible printed circuit boards.

0 notes

Text

Understanding Gerber PCB Layers

Usually there are layers below in a Gerber:

-Top silkscreen

-Top solder mask

-Top copper

-Bottom copper

-Bottom solder mask

-Bottom silkscreen

-Outline / mechanical

-Drill

-Inner copper

Top Silkscreen (GTO)

The top silkscreen Gerber file contains data to be printed, typically the white or black text on the PCB board, such as part designators, component outlines, logos, polarity indicators, etc. This layer is optional. It is totally OK to have a PCB without silkscreen if that is what you want.

Top Solder Mask (GTS)

Contains data for the protective solder mask which protects the copper. This is typically a green film but can come in a variety of colors. Solder mask layers are negative—meaning filled areas correspond to openings in the solder mask where no solder mask will be applied. These filled areas in the Gerber solder mask layer will leave copper exposed in the final product. This exposed copper is used for component attach and test access points.

Top Copper Layer (GTL)

Contains data for all areas requiring copper, including traces, pads, copper pour, vias, plated through holes, etc. All filled areas correspond to areas with copper plating.

Bottom Copper Layer (GBL)

Identical to top copper, but flipped horizontally around the y-axis. All filled areas correspond to areas with copper plating.

Bottom Solder Mask (GBS)

Identical to the top solder mask, but flipped horizontally around the y-axis. Solder mask layers are negative—meaning filled areas correspond to openings in the solder mask where no solder mask will be applied. These filled areas in the Gerber solder mask layer will leave copper exposed in the final product. This exposed copper is used for component attach and test access points.

Bottom Silkscreen (GBO)

Identical to the top silkscreen mask, but flipped horizontally around the y-axis. This layer is optional. Many single-sided PCBs will not have any silkscreen on the bottom side.

Outline (GKO) and Mechanical Layer (GML)

Contains the board outline, any cut-outs, v-cuts, panel outline, tabs, etc. Without this layer, the manufacturer does not know how to cut out the individual PCBs from the larger panels typically used in manufacturing. Mechanical elements should be included in a single outline layer to prevent some features from being missed unless it makes the outline unclear.

Drill Layer (DRL)

Contains all the drill locations and hole and via sizes. Drill files have numerous file extensions, including .txt or .drl. This layer file must not be confused with the drill drawing or drill map files. Technically not a Gerber file. Some EDA software will export separate files for plated and non-plated holes (vias). This has little meaning, and whether the holes are plated or not will depend on the copper layers.

Inner Copper Layer (GT#)

Multilayer boards may contain additional copper layers for signals or planes (ground or power) between the top and bottom copper layers. Inner plane layers may be in negative format, meaning the filled areas are areas of no copper.

PCB Stencil Gerber Files

Gerber files are also used in the manufacturing of the stencils that are used during the application of solder paste prior to component attachment. Figure 11 highlights a portion of a solder stencil. The solder stencil is aligned to the PCB and placed in direct content. The solder stencil openings are aligned to exposed copper on the surface of the PCB. The solder paste is forced through the openings by a squeegee blade on the stencil printer.

Top Paste (GTP) and Bottom Paste (GBP)

Contains data to make PCB stencils for the boards. Similar to solder mask layers, the data typically contains openings for surface mount parts only. Openings may be slightly smaller than the solder mask openings or partitioned to reduce the volume of solder paste that is applied to the pads. The bottom paste layer is identical in function to the top paste layer but is flipped horizontally around the y-axis.

Understanding Gerber layers doesn't have to be confusing. Familiarizing yourself with the names and functions of each Gerber layer in PCB manufacturing can enhance your design process and streamline communication with your board house. Hitech has professional engineers who can help you design Gerber files. Just share your idea, and we'll take care of the rest. If you have Gerber, you can send it to us for quotation. We will provide you with the best price. Just email [email protected] For more information, please enter https://hitechcircuits.com/

0 notes

Text

PCB Reverse Engineering: Unlocking the Secrets of Electronics

Understanding PCB Reverse Engineering

PCB Reverse Engineering is a critical process in electronics. It involves analyzing and replicating existing circuit boards to understand their functionality. This practice is essential for troubleshooting, product development, and even recreating obsolete hardware.

The Importance of Reverse Engineering in Electronics

Reverse Engineering Electronics helps companies and individuals gain insight into existing designs. This knowledge can lead to innovation, improved performance, and cost-effective solutions. By dissecting the PCB, engineers can identify components, trace connections, and recreate the design.

Steps in PCB Reverse Engineering

1. Visual Inspection and Documentation

The first step involves a thorough visual inspection. Engineers document the board's layout, component placement, and labeling. This documentation serves as the foundation for the reverse engineering process.

2. Component Identification

Identifying each component is crucial. Engineers analyze and catalog resistors, capacitors, integrated circuits, and other elements. This step ensures accurate replication of the original PCB design.

3. Tracing Circuitry Paths

Tracing the circuitry is a meticulous task. Engineers follow the copper traces that connect components. This step reveals the electrical connections and overall structure of the PCB.

4. Schematic Capture

Once the circuitry is traced, engineers create a schematic diagram. This visual representation of the circuit provides a blueprint for replication or modification.

5. PCB Layout Recreation

After the schematic is captured, the next step is recreating the PCB layout. Engineers use software tools to design a new PCB that matches the original. This layout is then ready for manufacturing.

Applications of PCB Reverse Engineering

PCB reverse engineering has diverse applications across industries. It is used in:

• Product Improvement: Enhancing existing designs by understanding and optimizing components.

• Obsolete Hardware Recreation: Reproducing outdated electronics for continued use.

• Troubleshooting: Diagnosing and fixing issues in existing PCBs.

Challenges in Reverse Engineering Electronics

While PCB reverse engineering is valuable, it comes with challenges. These include complex designs, multilayer boards, and proprietary components. Engineers must navigate these hurdles to achieve accurate results.

Future of PCB Reverse Engineering

The future of PCB reverse engineering is promising. As technology advances, so do the tools and techniques used in this field. With the rise of AI and machine learning, reverse engineering will become more efficient, enabling quicker and more accurate replication of complex electronics.

Conclusion

PCB reverse engineering is a powerful tool in the world of electronics. It unlocks the potential to innovate, recreate, and troubleshoot with precision. Whether for product development or preserving legacy systems, reverse engineering remains a cornerstone of the electronics industry.

0 notes

Text

4-layer half-hole multilayer PCB board

Hitech's 4-layer half-hole multilayer PCB, surface immersion gold treatment, made of FR-4 Tg150 halogen-free. Mainly used in consumer electronics, multilayer PCB for any project you need, please feel free to contact us, Cynthia<[email protected]>

Technical Parameters

4L half hole multilayer PCB

Technical description

Material: FR-4 Tg150 Halogen free

Board thickness: 0.8mm

Finished: Immersion gold

Copper thickness: 1 Oz for all layers

Solder mask: TaiYo blue

Min through hole: 0.2mm

Consumer Electronics

0 notes

Text

Multilayer PCB Manufacturer : Definition, Process & Benefits

A PCB is called Multilayer PCB, if it has 3 or more layers(sheets) of copper foil, insulated from each other(by lamination or coating) and joined together to form a single piece. Pcbcircuit is the best multilayer PCB manufacturer In India. Multilayer PCBs are extremely high-density assemblies, incorporating multiple layers into one PCB.

#top 10 pcb manufacturer#pcbcircuit#quick turn pcb fabrication#pcb stencil#pcb manufacturer in india#flex pcb manufacturer#low-cost pcb manufacturer

0 notes

Text

Multilayer PCB Manufacturer : Definition, Process & Benefits

A PCB is called Multilayer PCB, if it has 3 or more layers(sheets) of copper foil, insulated from each other(by lamination or coating) and joined together to form a single piece. Pcbcircuit is the best multilayer PCB manufacturer In India.

#PCB manufacturer#PCB fabrication#custom PCB manufacturing#prototype PCB manufacturing#low-cost PCB manufacturer#high-quality PCB manufacturing#quick turn PCB fabrication#flex PCB manufacturer#multilayer PCB manufacturer#Best pcb manufacturer#Top 10 pcb manufacturer#Pcb manufacturer near me#Pcb manufacturer in Maharashtra#Pcb manufacturer in haryana#Pcb manufacturer in delhi#Pcb manufacturer in india#Pcb manufacturer in Bombay#Pcb manufacturer in jaipur#Best pcb assemble in hyderabad#Low cost pcb assembled in hyderabad#Good pcb assemble in hyderabad#pcb stencils#Two layer pcb stencil#Best pcb stencil maker in hyderabad#SMD pcb board assembly in hyderabad

0 notes

Text

Unraveling the World of Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the seamless integration of electronic components into a compact and efficient system. In this blog post, we'll take a closer look at PCBs, exploring their importance, construction, types, and applications.

Understanding Printed Circuit Boards: Printed Circuit Boards

1. Importance of PCBs: Printed Circuit Boards

PCBs serve as the fundamental building blocks of electronic devices, providing a platform for connecting and mounting electronic components such as resistors, capacitors, and integrated circuits. They offer a reliable and efficient means of interconnecting components while minimizing space and maximizing functionality.

2. Construction of PCBs: Printed Circuit Boards

Substrate: The base material of a PCB, often made of fiberglass-reinforced epoxy resin (FR4), provides mechanical support and electrical insulation.

Copper Layers: Thin layers of copper foil are bonded to the substrate, forming conductive traces that carry electrical signals between components.

Solder Mask: A protective layer of solder mask is applied to the surface of the PCB, covering the copper traces and preventing oxidation.

Silkscreen: Component designators, logos, and other information are printed onto the PCB using a silkscreen layer.

3. Types of PCBs: Printed Circuit Boards

Single-Sided PCBs: Consist of a single layer of copper traces on one side of the substrate, suitable for simple electronic applications.

Double-Sided PCBs: Feature copper traces on both sides of the substrate, allowing for more complex circuitry and higher component density.

Multilayer PCBs: Utilize multiple layers of copper traces interconnected by vias, offering enhanced functionality, signal integrity, and noise immunity.

4. Applications of PCBs: Printed Circuit Boards

Consumer Electronics: PCBs are ubiquitous in consumer electronics such as smartphones, tablets, laptops, and digital cameras.

Industrial Equipment: PCBs are essential components of industrial machinery, control systems, and automation equipment.

Automotive Electronics: PCBs play a vital role in automotive applications, including engine control units (ECUs), infotainment systems, and dashboard displays.

Medical Devices: PCBs are used in medical devices such as MRI machines, patient monitors, and diagnostic equipment.

Conclusion: Printed Circuit Boards

Printed Circuit Boards are the foundation of modern electronics, enabling the seamless integration of electronic components into a wide range of devices and systems. By understanding the construction, types, and applications of PCBs, designers and engineers can leverage this essential technology to create innovative and reliable electronic products that power our interconnected world. Whether you're building a smartphone, a medical device, or an industrial control system, PCBs are the key to unlocking endless possibilities in the world of electronics

0 notes

Text

Printed Circuit Board Market ,Size, Market Statistics and Future Forecasts to 2030

Printed Circuit Board Market Overview

The Printed Circuit Board Market forecast to reach $72.3 billion by 2026, growing at a CAGR of 5.3% from 2021 to 2026. Printed Circuit Board (PCBs) are the foundational building block of most modern electronic devices. PCBs consist of printed pathways which connect different components on the PCB such as transistors, resistors, Programmable Logic Controller (PLCs), Electrolytic capacitors and integrated circuits. The PCB is used in several automotive applications such as power relays, antilock brake systems, digital displays, audio systems, engine timing systems, battery control systems and many more functions. Printed circuit boards are used in many ways in the automotive industry and have changed the way that people drive. The need for PCBs is increasing as vehicle owners and drivers demand more accessories in vehicles. A printed circuit board used in car or truck must be highly reliable and long-lasting.

For More Report Info Click Here : https://www.industryarc.com/Report/110/Printed-Circuit-Board-Market-Analysis-andForecast.html?utm_source=SBM&utm_medium=Social&utm_campaign=NehaM

Report Coverage

The report: “Printed Circuit Board Market– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Printed Circuit Board Market.

By Type – Double-Sided PCB, Multi-Layer PCB, Single-Sided PCB.

By Board Type – Rigid 1-2 Sided, Flex, Rigid Flex, IC Substrate, Standard Multilayer, HDI/Microvia/Buildup.

By Components – Capacitors, Diodes, Integrated Circuits, Resistors and Others.

By Laminate Type – Paper, FR-4, CEM, Polymide and Others.

By End Use Industry – Automotive, Healthcare, Industrial Electronics, Aerospace and Defense, Consumer Electronics Maritime Transport and Others.

By Geography - North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia, Netherlands and Others), APAC(China, Japan India, SK, Australia, Indonesia, Malaysia and Others), South America(Brazil, Argentina, Chile, Colombia and others), and RoW (Middle East and Africa).

Request For Sample : https://www.industryarc.com/pdfdownload.php?id=110&utm_source=SBM&utm_medium=Social&utm_campaign=NehaM

Key Takeaways

The demand for PCBs is high in the forecast period due to growing demand for hybrid electric vehicles (HEV) and Battery electric Vehicles (BEV)

Printed circuit boards are used in several automotive applications like anti-lock brake systems, safety and security features, ECU systems, control engines and GPS navigation systems.

PCBs can be programmed to perform system essential commands irrespective of their sizes.

Asia-Pacific is projected to dominate the market share in the forecast period. Due to economies like China, Japan, South Korea and Taiwan which is witnessing a high surge in automotive production due to availability of low labour and logistical costs.

Printed Circuit Board Market Segment Analysis - By Type

There are three types of printed circuit boards they are single-sided, double-sided and multi-layer PCBs. Multi Layer PCB is projected to grow at the fastest rate from 2021-2026 at 7.2% CAGR. Each type of PCB has various price points and uses and they are widely used in automotive applications. Single-sided PCB is something which comes with only one layer of conducting material on one side of the board and other side is used for incorporating different electronic components such as integrated circuits, programmable logic controllers, electrolytic capacitors and resistors on the board. Double-sided surface mount PCBs are same as single-sided PCBs but the difference is they have two sided traces with top and bottom layer. Multi-layer PCB’s can support a high level of circuit complexity as they are made up of three or more copper layers laminated together.

Printed Circuit Board Market Segment Analysis - By End Use Industry

The various end users assessed include automotive, healthcare, industrial electronics, consumer electronics, maritime transport, aerospace & defense and others. PCB in healthcare is used in various devices which monitor health of a person or assist the doctor in surgical operations. On the other hand PCB in pharmaceutical industry used in manufacturing drugs and other medicines at industry level. PCBA stands for printed circuit board assemblies and they are widely used in the automobile industry. PCB’s have managed to bring a change in the way people drive through increasing complexity of components such as Integrated circuits, programmable logic controllers, electrolytic capacitor and resistors. GPS navigation system, anti-lock brake system, ECU systems that control engines and several safety and security features that all require PCB’s. Aerospace and defense sectors are one of the key consumers of PCB with major application avionics, communication systems, and weapon systems. PCB forms the necessary foundation for packaging and interconnecting in any electronic circuits. PCBs are used in radar signals which set up in military fighter aircraft such as collision avoidance, blind spot detection and adaptive and adaptive cruise control system. Printed circuit boards are commonly used in vehicles these days in passenger cars and commercial vehicles. Passenger Vehicles dominate the automotive market in 2020. The main function of the PCB is to provide mechanical support and electric connection to different components of the vehicle. One of the most common uses of printed circuit boards for vehicles deals with deployment of airbags which is necessary to prioritize safety. The circuit board is incorporated in the airbag deployment rate sensor which helps in dissipating static electricity and triggering the bag when needed. Likewise it is used in in-vehicle infotainment, GPS systems, and power converters and others.

Printed Circuit Board Market Segment Analysis – By Geography

Asia-Pacific is projected to dominate the market share in the forecast period with 45% share in 2020. Economies like China, Japan, South Korea and Taiwan are witnessing a high surge in automotive production as well as across manufacturing sector due to the availability of low labor and logistical costs. Due to enhanced production capacities and the rise of digitalization together driving the PCB in this region. Additionally, China and India are expected to grow much faster due frequent activities in construction, transportation and industrialization contributing to the market growth.

Printed Circuit Board Market Drivers

Growing electric vehicles sales driving the market growth

The demand for electric vehicles is higher in the coming years than petrol and diesel vehicles. Unlike vehicle fuel types, battery electric vehicles have more demand due to increasing concern towards global emissions from vehicles as well as government initiatives to increase the sales of electric vehicles. As the move to electrically powered cars takes place the PCBs will play an important role in production and running of cars, buses and other electrically powered vehicles. Additionally increasing sales of electric vehicles as well as adoption of advanced driver assistance system technology in them are likely to drive the demand for PCB market.

#Printed Circuit Board Market#Printed Circuit Board Market Size#Printed Circuit Board Market Share#Printed Circuit Board Market Trends#Printed Circuit Board Market Growth

1 note

·

View note