#PCB Layout

Explore tagged Tumblr posts

Text

Die fünf Hauptfunktionen von Lötstopp-Lochverschlüssen

1️⃣ Verhindern des Fließens von Lötzinn durch die Durchkontaktierungen und Vermeidung von Kurzschlüssen während des PCB-Wellenlötens, insbesondere wenn die Durchkontaktierungen auf BGA-Pads platziert sind. Es ist notwendig, die Löcher vor der Vergoldung zu verschließen, um das BGA-Löten zu erleichtern.

2️⃣ Vermeiden von Flussmittelrückständen innerhalb der Durchkontaktierungen.

3️⃣ Nach der Oberflächenmontage und Bauteilplatzierung muss die Leiterplatte auf einer Testmaschine einem Vakuumsaugtest unterzogen werden, um einen Unterdruck für die Fertigstellung zu erzeugen.

4️⃣ Verhindern des Fließens von Lötpaste in die Löcher und Vermeidung von Lötfehlern, die die Lötung während der Montage beeinträchtigen könnten.

5️⃣ Verhindern des Herausspringens von Lötkugeln während des Wellenlötens, was zu Kurzschlüssen führen könnte.

2 notes

·

View notes

Text

[Image 1: PCB layout of an IC surrounded by densely-packed passive components.]

Today's lesson: just because you can pack all the passives neatly around the chip doesn't mean you should. You may not be able to route signals away from the site, or even fit enough vias to break them out on the other side of the board. Let's find out how to strategize the order of operations with this ethernet phy!

Drawing is of a Microchip LAN8720A Ethernet PHY and associated passives, nothing novel. Rings in the top left are test points for power rails.

2 notes

·

View notes

Text

Tips for PCB Stackup Layout

With the continuous emergence of high-speed circuits, the complexity of PCB boards is also getting higher and higher. In order to avoid the interference of electrical factors, the signal plane and the power supply layer must be separated, so it involves the design of multilayer PCB, that is, the design of laminated structure.

1. Avoid Direct Connection of Two Signal Planes

In a multilayer PCB, it usually includes a signal plane (S), a power plane (P) plane and a ground plane (GND). How are the three arranged?

Power and ground planes are usually undivided solid planes that provide a good, low-impedance current return path for current from adjacent signal traces. Therefore, the signal plane is mostly adjacent to the power plane or the ground plane. Moreover, the power supply layer and ground plane use a large area of copper (so the power supply layer and ground plane are also called copper layer), and the large copper film can provide shielding for the signal plane, which is conducive to impedance control and improvement of signal quality.

In addition, should try to avoid two signal planes directly adjacent to each other. Crosstalk is easily introduced between adjacent signal planes, resulting in circuit failure. Adding a ground plane between the two signal planes can effectively avoid crosstalk.

2. Most Top and Bottom Planes are Signal Planes

The top and bottom planes of a multilayer PCB are usually used to place components and a small number of traces, so they are mostly signal planes. Generally, the top plane is the component, and the bottom plane (the second plane) of the component can be set as the ground plane, providing the device shielding layer and providing the reference plane for the top plane wiring.

In addition, note that these signal traces on the top and bottom planes cannot be too long to reduce direct radiation from the traces.

3.Reference Plane Preferred the Ground Plane

Both the power plane and the ground plane can be used as reference planes and have a certain shielding effect.

The difference between the two is that: the power supply layer has a high characteristic impedance, and there is a large potential difference with the reference level; while the ground plane is generally grounded and used as a reference point for the reference level, its shielding effect is much better than that of the power supply layer.

Therefore, when choosing a reference plane, the stratum is preferred.

4. The High-speed Signal Layer is Located in the Middle Plane of the Signal

The high-speed signal transmission layer in the circuit should be the signal intermediate plane and sandwiched between two copper layers. In this way, the copper film of the two copper layers can provide electromagnetic shielding for high-speed signal transmission, and at the same time, it can effectively limit the radiation of the high-speed signal between the two copper layers without causing external interference.

5.The Power Plane and the Ground Plane are Preferably Paired

The power supply layer and the ground plane appear in pairs, shortening the distance between the power supply and the ground plane can reduce the impedance of the power supply, which is beneficial to the stability of the power supply and reducing EMI. In particular, the main power supply should be as adjacent to its corresponding ground plane as possible. In the case of high speed, you can add extra ground planes to isolate the signal plane, but it is recommended not to add more power planes to isolate, because the power plane will bring more high-frequency noise interference.

6.Copper Layer Balance Design

The copper layer, that is, the power plane or the ground plane, is best arranged symmetrically, such as the second plane and the fifth layer of the 6-layer board, or the third layer and the fourth layer should be copper-plated together, which is considered to be flat and horizontal in the process. Structural requirements, as unbalanced copper layers may cause warpage as the PCB expands.

7.Multiple Power Planes away from High-speed Signal Planes

Multiple power supply layers should be kept away from high-speed digital signal wiring. Because the multi-power supply layer will be divided into several physical regions with different voltages, if the signal power is close to the multi-power supply layer, the signal current on the nearby signal layer will encounter an unsatisfactory return path, making the return path A gap appears.

8.Use Even-numbered layers

The classic PCB stack-up design is almost entirely even-numbered, not odd-numbered. Even-numbered layers of printed circuit boards have cost advantages, and even-numbered layers are more resistant to board warpage than odd-numbered layers.

9.Arrange Routing on Adjacent Layers

In order to complete complex wiring, the transition between layers of traces is inevitable. The two layers spanned by a signal path are called a "routing combination". The best routing combination design is to avoid return current flow from one reference plane to another reference plane, but rather to flow from one point (surface) of one reference plane to another point (surface).

Therefore, wiring combinations are preferably arranged on adjacent layers, because a path through multilayers is not clear for return currents. Although the ground bounce can be reduced by placing decoupling capacitors near the vias or reducing the thickness of the dielectric between the reference planes, it is not a good design.

10.The Routing Directions of Adjacent Signal Planes are Orthogonal

On the same signal plane, the direction of most wiring should be consistent, and it should be orthogonal to the wiring direction of adjacent signal planes. For example, the wiring direction of one signal plane may be set to the "Y-axis" direction, and the wiring direction of another adjacent signal plane may be set to the "X-axis" direction.

On the other hand, how to do impedance control is a headache for many users, but Hitech Circuits makes everything so easy. Hitech Circuits will automatically calculate the line width and line spacing corresponding to different impedance controls according to different stacks, so as to do impedance matching for the user, without the need to perform complex impedance calculations manually, saving effort and worry!

0 notes

Text

Understand the key differences between PCB design and PCB layout. Learn how each process plays a critical role in creating efficient printed circuit boards.

0 notes

Text

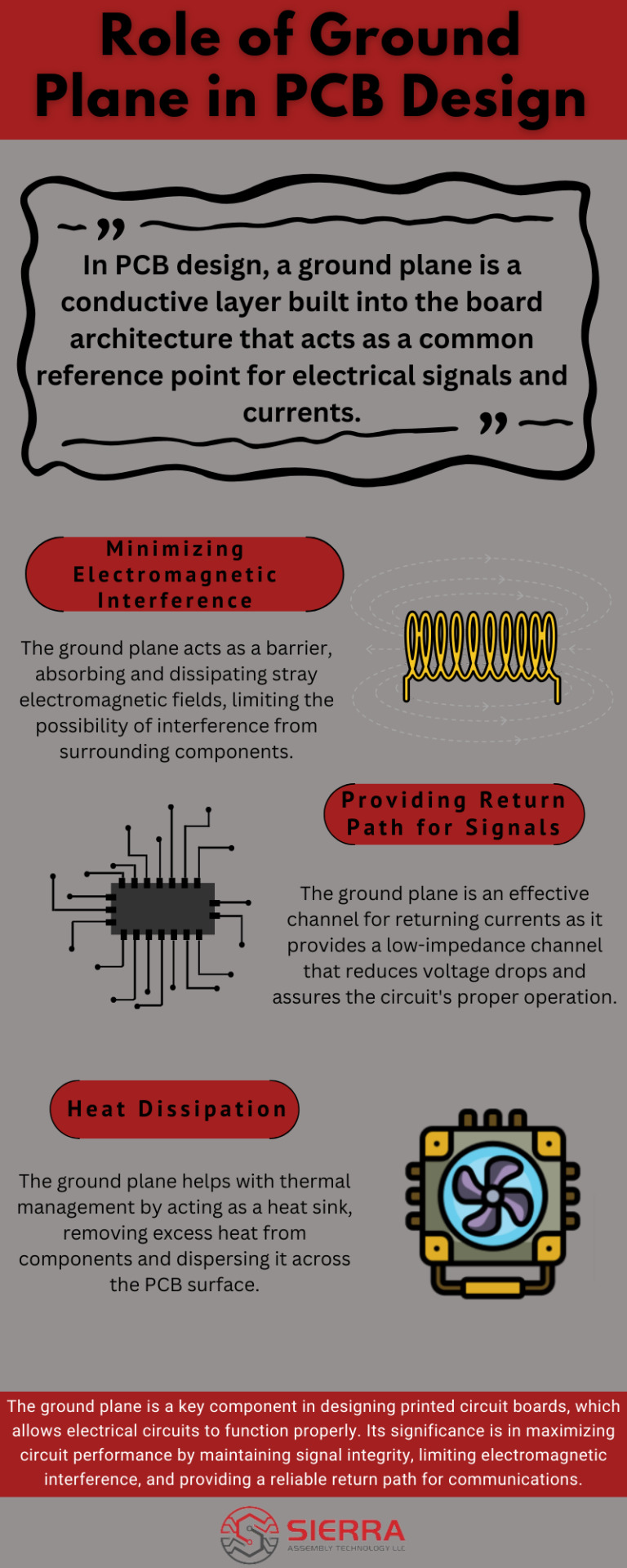

The ground plane in PCB (Printed Circuit Board) design plays a critical role in ensuring the proper functioning of electronic circuits. Primarily, it helps reduce electrical noise and electromagnetic interference (EMI) by providing a low-impedance path for return currents and shielding sensitive components from external EMI sources.

0 notes

Text

From Concept to Reality: Creating Innovative Electronics through Custom PCB Design

0 notes

Text

How PCB Layout Design Contributes to Sustainable Electronics

Sustainable electronics rely on innovative PCB layout design that enhances energy efficiency and reduces electronic waste. By optimizing the layout, like minimizing trace lengths, energy consumption is lowered. Printed circuit boards fabrication now embraces eco-friendly practices, including quick turn PCB fabrication using recyclable materials. Leading manufacturers prioritize sustainable designs, ensuring devices are efficient, durable, and green. Read the complete blog here: https://medium.com/@bayareacircuitsusa/how-pcb-layout-design-contributes-to-sustainable-electronics-59923d28d457

0 notes

Text

at the semiconductor technology conference googling “rram”

#man i dont know whats going on. silicon.#they really let anyone into these things i took a singular pcb layout class and every day after that has been entirely confounding#so much ai talk. expected but man. i think you’re overselling it at this point in time

0 notes

Text

In the bustling tech landscape of Danbury, Connecticut, where innovation and entrepreneurship thrive, the seamless integration of electronics is fundamental to driving progress across industries.

0 notes

Text

PCB Designing Company in Gujarat

Innovative PCB solutions in Gujarat! Leading design company, expert in precision layouts for optimal performance. Elevate your electronics with us.Get more info and contact details in India.

#PCB Designing Company#Printed Circuit Board Design Services#PCB Layout Experts#Electronic Design and Manufacturing#Custom PCB Design Solutions#High-Quality PCB Prototyping#Gujarat PCB Fabrication

0 notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

[Image 1: A collection of decoupling caps arranged around an IC footprint. Most of the pads are linked together, sharing a single via to the 3v3 plane.]

So...is this okay? Or should I be using more vias to supply power, like...

[Image 2: Same layout as image 1, but every 3v3 and ground pad is tied immediately to a via instead of being chained together.]

Is there some happy medium between these? How do we make these decisions?

Drawing is of an Espressif ESP32-Pico-D4 chip and associated passives, nothing novel.

0 notes

Text

Understanding Gerber PCB Layers

Usually there are layers below in a Gerber:

-Top silkscreen

-Top solder mask

-Top copper

-Bottom copper

-Bottom solder mask

-Bottom silkscreen

-Outline / mechanical

-Drill

-Inner copper

Top Silkscreen (GTO)

The top silkscreen Gerber file contains data to be printed, typically the white or black text on the PCB board, such as part designators, component outlines, logos, polarity indicators, etc. This layer is optional. It is totally OK to have a PCB without silkscreen if that is what you want.

Top Solder Mask (GTS)

Contains data for the protective solder mask which protects the copper. This is typically a green film but can come in a variety of colors. Solder mask layers are negative—meaning filled areas correspond to openings in the solder mask where no solder mask will be applied. These filled areas in the Gerber solder mask layer will leave copper exposed in the final product. This exposed copper is used for component attach and test access points.

Top Copper Layer (GTL)

Contains data for all areas requiring copper, including traces, pads, copper pour, vias, plated through holes, etc. All filled areas correspond to areas with copper plating.

Bottom Copper Layer (GBL)

Identical to top copper, but flipped horizontally around the y-axis. All filled areas correspond to areas with copper plating.

Bottom Solder Mask (GBS)

Identical to the top solder mask, but flipped horizontally around the y-axis. Solder mask layers are negative—meaning filled areas correspond to openings in the solder mask where no solder mask will be applied. These filled areas in the Gerber solder mask layer will leave copper exposed in the final product. This exposed copper is used for component attach and test access points.

Bottom Silkscreen (GBO)

Identical to the top silkscreen mask, but flipped horizontally around the y-axis. This layer is optional. Many single-sided PCBs will not have any silkscreen on the bottom side.

Outline (GKO) and Mechanical Layer (GML)

Contains the board outline, any cut-outs, v-cuts, panel outline, tabs, etc. Without this layer, the manufacturer does not know how to cut out the individual PCBs from the larger panels typically used in manufacturing. Mechanical elements should be included in a single outline layer to prevent some features from being missed unless it makes the outline unclear.

Drill Layer (DRL)

Contains all the drill locations and hole and via sizes. Drill files have numerous file extensions, including .txt or .drl. This layer file must not be confused with the drill drawing or drill map files. Technically not a Gerber file. Some EDA software will export separate files for plated and non-plated holes (vias). This has little meaning, and whether the holes are plated or not will depend on the copper layers.

Inner Copper Layer (GT#)

Multilayer boards may contain additional copper layers for signals or planes (ground or power) between the top and bottom copper layers. Inner plane layers may be in negative format, meaning the filled areas are areas of no copper.

PCB Stencil Gerber Files

Gerber files are also used in the manufacturing of the stencils that are used during the application of solder paste prior to component attachment. Figure 11 highlights a portion of a solder stencil. The solder stencil is aligned to the PCB and placed in direct content. The solder stencil openings are aligned to exposed copper on the surface of the PCB. The solder paste is forced through the openings by a squeegee blade on the stencil printer.

Top Paste (GTP) and Bottom Paste (GBP)

Contains data to make PCB stencils for the boards. Similar to solder mask layers, the data typically contains openings for surface mount parts only. Openings may be slightly smaller than the solder mask openings or partitioned to reduce the volume of solder paste that is applied to the pads. The bottom paste layer is identical in function to the top paste layer but is flipped horizontally around the y-axis.

Understanding Gerber layers doesn't have to be confusing. Familiarizing yourself with the names and functions of each Gerber layer in PCB manufacturing can enhance your design process and streamline communication with your board house. Hitech has professional engineers who can help you design Gerber files. Just share your idea, and we'll take care of the rest. If you have Gerber, you can send it to us for quotation. We will provide you with the best price. Just email [email protected] For more information, please enter https://hitechcircuits.com/

0 notes

Text

Common Challenges in PCB Design and Manufacturing and How to Overcome Them

Modern electronics’ skeleton is made up of printed circuit boards (PCBs), which allow different parts to be connected and enable the operation of everything from smart phones to heavy machinery. Engineers and manufacturers, however, must cross several obstacles on the way from PCB design to effective manufacturing. To know more visit at https://livearticlez.com/common-challenges-in-pcb-design-and-manufacturing-and-how-to-overcome-them/

0 notes

Text

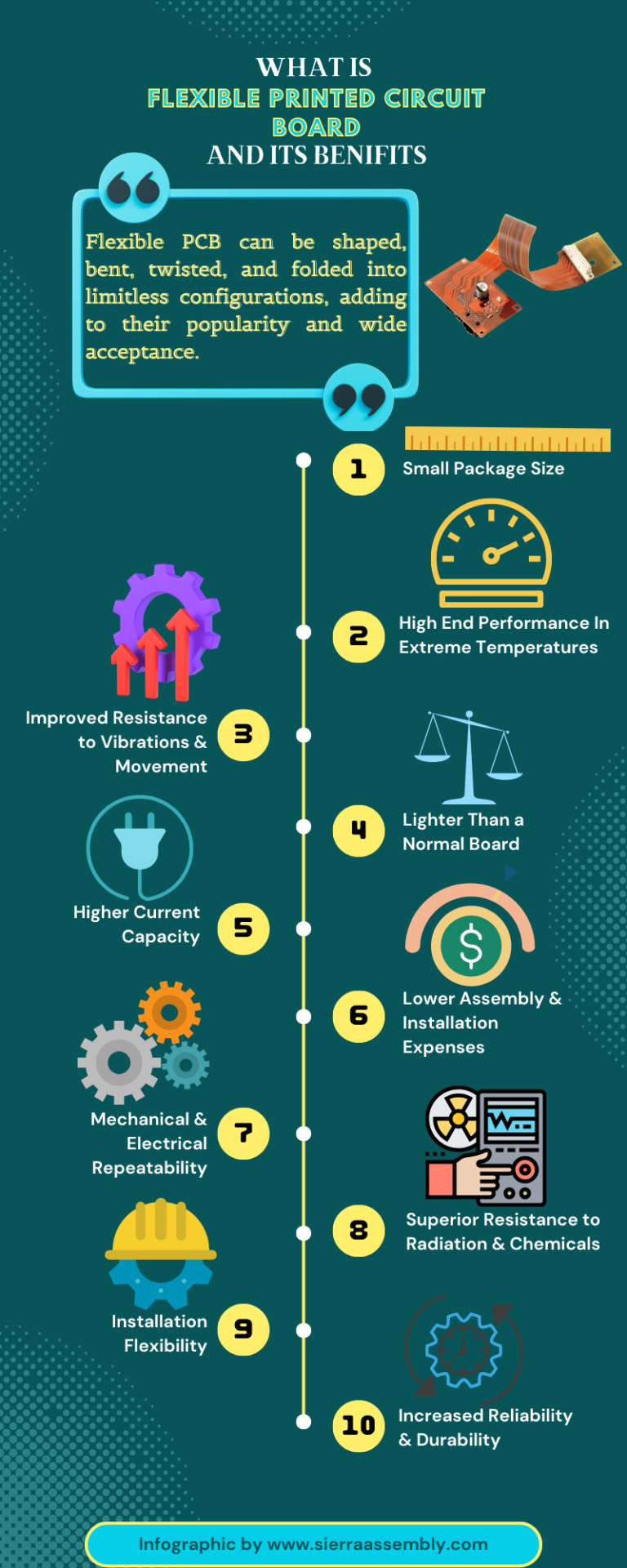

A Flexible Printed Circuit Board (FPCB), often referred to as a flex PCB, is a type of printed circuit board designed to be flexible and conform to various shapes. Unlike traditional rigid PCBs, which are made of inflexible materials like fiberglass or epoxy, flexible PCBs are constructed using flexible materials that allow them to bend, twist, and flex without damaging the electrical connections.

0 notes

Text

Innovations in PCB Layout Design by Leading Printed Circuit Boards Manufacturers

Stay ahead in the electronics industry with innovative PCB layout design from leading printed circuit boards manufacturers. By combining cutting-edge manufacturing techniques and advanced printed circuit board design software, they ensure precision, efficiency, and reliability. Perfect for creating compact, high-performance devices, these services bring your technology to life with flawless quality. Read the complete blog here: https://www.tumblr.com/bayareacircuitsusa/763936269318455296/innovations-in-pcb-layout-design-by-leading?source=share

0 notes