#Container liners manufacturers

Explore tagged Tumblr posts

Text

Container Liners: The Essential Solution for Bulk Shipping

In the world of logistics and transportation, ensuring that goods arrive safely and in optimal condition is paramount. One effective solution that has gained popularity among shippers is the use of container liners. These liners are designed to provide a protective barrier within shipping containers, safeguarding the contents against contamination, moisture, and damage. This article will explore the features, benefits, applications, and the role of container liners manufacturers in providing high-quality liner solutions.

What Are Container Liners?

Container liners, often referred to as Liner bag containers, are specialized bags made from durable materials such as polyethylene or polypropylene. They are designed to fit snugly within standard shipping containers, providing a protective lining for bulk cargo. Container liners come in various sizes and designs to accommodate different types of products, from food items to industrial materials.

Key Features of Container Liners

Moisture Protection: Container liners are engineered to protect goods from moisture and humidity, which can lead to spoilage or degradation of the cargo.

Contamination Prevention: The liners create a barrier that prevents contamination from external sources, ensuring that the goods remain pure and uncontaminated.

Ease of Loading and Unloading: Container liners are designed for easy filling and emptying, streamlining the logistics process and reducing labor costs.

Cost-Effective: Using liners can reduce the need for additional packaging materials, leading to cost savings for businesses.

Customizable Options: Many manufacturers offer customizable liners, allowing businesses to tailor them to their specific needs regarding size, material, and branding.

Applications of Container Liners

Container liners are versatile and can be used across various industries. Here are some common applications:

1. Food Industry

In the food industry, container liners are essential for transporting bulk food products such as grains, flour, and sugar. They help maintain the integrity and freshness of the food, protecting it from moisture and contamination during transit.

2. Chemical Industry

Container liners are widely used in the chemical industry for shipping powdered and granulated chemicals. The liners provide a safe barrier that prevents leakage and contamination, ensuring compliance with safety regulations.

3. Agriculture

In agriculture, container liners are used for transporting fertilizers, seeds, and animal feed. Their moisture-resistant properties help preserve the quality of these products, protecting them from spoilage.

4. Construction Materials

Container liners are ideal for shipping construction materials like sand, gravel, and cement. They ensure that the materials remain dry and uncontaminated during transportation.

5. Recycling and Waste Management

Container liners are also utilized in recycling and waste management, providing a clean and safe way to transport recyclable materials or waste without risk of contamination.

The Role of Container Liners Manufacturers

Container liners manufacturers play a crucial role in producing high-quality liners that meet the diverse needs of various industries. They focus on utilizing advanced materials and manufacturing techniques to ensure that their products deliver optimal performance.

Quality Assurance

Reputable container liners manufacturers implement stringent quality control measures to ensure that their products meet industry standards. This includes testing for strength, moisture resistance, and durability to ensure they can withstand the rigors of transportation.

Customization

Many manufacturers offer customization options, allowing businesses to tailor the liners to their specific requirements. This could include custom sizes, materials, and branding, helping businesses enhance their brand visibility.

Sustainability Efforts

With the growing emphasis on sustainability, many manufacturers are exploring eco-friendly materials and production processes. This commitment to sustainability helps businesses align with environmental goals and consumer preferences.

Choosing the Right Container Liners

When selecting container liners, it’s essential to consider several factors to ensure quality and reliability:

1. Material Quality

Choose liners made from high-quality materials that offer excellent moisture and contamination resistance. The right material will depend on the specific type of cargo being transported.

2. Size and Fit

Ensure that the liner fits the container snugly to prevent shifting during transport. Accurate sizing is crucial for optimal performance and protection.

3. Customization Options

Consider whether customization options are available to meet your specific branding and operational needs. Custom liners can enhance brand visibility and ensure functionality.

4. Supplier Reputation

Select a reputable container liners manufacturer known for delivering high-quality products and reliable customer service. Research customer reviews and testimonials to gauge their reputation in the industry.

5. Pricing and Value

While cost is an important factor, it’s essential to consider the overall value offered by the liners. Compare prices, but prioritize quality and features that will benefit your operations in the long run.

Benefits of Using Container Liners

Using container liners offers numerous advantages for businesses involved in shipping and logistics:

1. Enhanced Protection

Container liners provide a protective barrier that safeguards goods from moisture, dust, and contamination, ensuring that products arrive in optimal condition.

2. Cost Savings

By reducing the need for additional packaging materials and minimizing product loss, container liners can lead to significant cost savings for businesses.

3. Efficient Handling

The design of container liners simplifies the loading and unloading process, reducing labor costs and increasing operational efficiency.

4. Versatility

Container liners can be used for a wide range of products, making them a versatile solution for various industries.

5. Improved Sustainability

Many manufacturers offer eco-friendly liners, allowing businesses to adopt more sustainable packaging practices.

Summary

Container liners are an essential component of modern shipping and logistics, providing a protective barrier that ensures the safe transport of bulk goods across various industries. With features like moisture protection, contamination prevention, and ease of handling, these liners offer significant advantages for businesses. Understanding the role of container liners manufacturers and selecting the right supplier can help companies optimize their shipping processes and protect their valuable cargo. As sustainability becomes increasingly important, container liners remain a practical and effective solution for businesses looking to enhance their packaging strategies.

FAQs

1. What types of materials are container liners made from?

Container liners are typically made from durable materials like polyethylene and polypropylene. These materials offer excellent moisture resistance and protection against contamination.

2. Can container liners be customized for specific needs?

Yes, many container liners manufacturers offer customization options, allowing businesses to tailor the liners in terms of size, material, and branding to meet their specific requirements.

3. Are container liners suitable for transporting food products?

Absolutely! Container liners are widely used in the food industry to protect bulk food products from moisture and contamination during transportation.

0 notes

Text

Container Liners: A Versatile Solution for Safe and Efficient Cargo Transport

Container liners have become an indispensable part of modern cargo transportation, ensuring the safe, clean, and cost-effective movement of bulk goods across the globe. These liners are a type of flexible packaging that fit inside standard shipping containers to form a protective barrier between the cargo and the container walls. This article explores the significance of container liners, their manufacturing process, benefits, and the role of leading container liners manufacturers and suppliers, particularly in India.

The Growing Importance of Container Liners in Global Trade

As global trade continues to expand, the demand for bulk transport solutions has surged. Traditionally, bulk goods such as grains, chemicals, fertilizers, and minerals were transported using bags, drums, or even loose inside containers. However, these methods often resulted in spillage, contamination, and wastage. The need for a more efficient and hygienic solution led to the development of container liners.

Container liners not only prevent direct contact between the cargo and the container, thus reducing the risk of contamination, but also offer ease in loading and unloading. These liners are essential in industries that require high standards of cleanliness and safety, such as food, pharmaceuticals, and chemicals. Over the years, container liner manufacturers have developed specialized products that cater to the specific needs of these industries.

Types of Container Liners and Their Applications

Container liners come in various types, each designed to meet specific cargo requirements. Some of the most common types include woven polyethylene (PE) and polypropylene (PP) liners, which are durable and resistant to moisture, chemicals, and abrasion. These liners are ideal for transporting dry bulk cargo like grains, sugar, salt, and plastic resins. Moreover, container liners are also available in specialized forms such as thermal liners, which offer temperature control for sensitive products like food and pharmaceuticals.

Other innovative designs include anti-static liners for transporting chemicals and powders, as well as hermetic liners that provide an airtight seal to prevent moisture and oxygen ingress, thus protecting the cargo from spoilage. The adaptability of these liners makes them suitable for a wide range of industries, further increasing their demand among global Container Liners Suppliers.

Container Liner Manufacturing Process: Precision and Innovation

The production of container liners involves a series of precise and innovative steps to ensure the highest quality and durability. The primary materials used are PE and PP, known for their strength, flexibility, and resistance to harsh conditions. The manufacturing process begins with the extrusion of plastic into thin sheets, which are then woven together to form a sturdy fabric. This fabric is coated with additional layers to enhance its resistance to moisture, UV rays, and chemicals.

Once the fabric is prepared, it is cut and stitched into the desired liner shape, which varies depending on the container size and the specific cargo it will carry. Many container liners manufacturers also incorporate advanced technology such as heat-sealing and ultrasonic welding to ensure leak-proof seams. In India, the container liner sheet industry has seen significant advancements, with manufacturers producing high-quality liners that comply with international standards.

India’s Emerging Role in the Container Liners Market

India has emerged as a key player in the global container liners market, both as a manufacturer and a supplier. The country boasts a growing number of container liners manufacturers that produce a wide variety of liners for domestic and international markets. Indian manufacturers have earned a reputation for offering cost-effective solutions without compromising on quality, making them a preferred choice among global buyers.

Furthermore, the availability of high-quality raw materials and advancements in manufacturing technology have allowed Indian companies to produce container liner sheets that meet the stringent requirements of industries like food processing, chemicals, and agriculture. These sheets are designed to offer superior protection and ensure the safe transportation of bulk goods. As the demand for container liners continues to grow, India’s contribution to the global market is expected to increase further.

Benefits of Using Container Liners

The use of container liners offers a multitude of benefits, making them an essential part of bulk cargo transportation. One of the primary advantages is cost savings. Container liners eliminate the need for expensive bulk packaging, such as bags or drums, reducing material costs. Moreover, they streamline the loading and unloading process, as goods can be poured directly into the container, further saving on labor and handling expenses.

Another significant benefit is the prevention of contamination. Container liners form a barrier between the cargo and the container, ensuring that the goods remain uncontaminated during transit. This is especially important for industries like food and pharmaceuticals, where hygiene is critical. Additionally, container liners protect the cargo from external factors such as moisture, dust, and pests, thus preserving its quality.

Environmental Impact and Sustainability of Container Liners

As industries across the globe shift towards sustainable practices, the use of container liners plays a role in reducing environmental impact. Most container liners are made from recyclable materials such as polyethylene and polypropylene, making them an eco-friendly option. Furthermore, the reduction in packaging waste and the ability to transport bulk goods more efficiently contribute to lower carbon emissions.

Container liners also help prevent spillage and product loss, which can have significant environmental consequences, particularly when transporting chemicals or hazardous materials. By providing a secure containment solution, these liners help minimize the risk of accidents and ensure the safe transport of goods.

The Role of Container Liners Suppliers in Ensuring Quality and Timely Delivery

Container liners suppliers play a crucial role in the global supply chain by ensuring the availability of high-quality liners that meet the specific needs of various industries. Suppliers work closely with manufacturers to offer customized solutions, from selecting the appropriate liner material to designing liners that fit different container sizes and shapes.

In India, suppliers have established a strong network to cater to both domestic and international markets. They ensure timely delivery and provide after-sales services, such as installation guidance and support, to help customers optimize their use of container liners. With the rise of e-commerce and international trade, the role of container liners suppliers has become even more critical in ensuring the smooth flow of goods across borders.

Conclusion: The Future of Container Liners in Global Trade

Container liners have revolutionized the way bulk goods are transported, offering a safe, efficient, and cost-effective solution for industries across the globe. With the growing demand for cleaner and more sustainable transport methods, the importance of container liners is only expected to increase. Indian Container Liner Sheet In India and suppliers have positioned themselves as key players in this market, contributing to global supply chains with their high-quality, competitively priced products.

As the industry continues to evolve, innovations in materials, design, and manufacturing processes will further enhance the performance of container liners, making them an even more integral part of the logistics sector.

Frequently Asked Questions (FAQs)

What are the main materials used in container liners? The primary materials used in container liners are polyethylene (PE) and polypropylene (PP), which are known for their durability, flexibility, and resistance to moisture and chemicals.

Can container liners be reused? While some container liners are designed for single-use, others, especially those made from durable materials, can be reused if properly cleaned and maintained. However, it is important to ensure that reused liners meet hygiene and safety standards, especially in industries like food and pharmaceuticals.

What industries benefit the most from container liners? Industries that transport bulk goods, such as food and beverages, chemicals, pharmaceuticals, and agriculture, benefit significantly from using container liners due to the protection, cleanliness, and cost-effectiveness they offer.

Why is India a leading supplier of container liners? India has a well-developed manufacturing sector that produces high-quality container liners at competitive prices. The availability of raw materials, skilled labor, and advanced manufacturing technologies have contributed to India's growing role as a leading supplier of container liners globally.

0 notes

Text

Container Liners: A Comprehensive Overview

Container liners play an essential role in the transportation of bulk cargo by offering a protective layer within shipping containers. These liners are used extensively across industries for transporting dry, bulk materials like chemicals, food products, minerals, seeds, and other granulated materials. They are designed to keep the contents safe from contamination and damage during transit.

What Are Container Liners?

Container liners are large plastic or textile sheets that fit inside standard containers to create a barrier between the cargo and the walls of the container. This ensures that materials are kept clean, dry, and free from external elements such as moisture or dust. These liners are particularly valuable for bulk materials, as they allow containers to carry loose products without needing intermediate packaging, reducing the overall shipping cost.

Importance of Container Liners in Bulk Shipping

The primary benefit of using container liners is the protection they offer to the materials being transported. Since containers are exposed to various weather conditions and may have been used to carry different kinds of cargo in the past, liners ensure that the new cargo is not contaminated by residue from previous shipments. The container liner also prevents materials from sticking to the walls, simplifying the unloading process.

Container liners also reduce packaging costs by allowing bulk shipping. Instead of shipping materials in smaller packages, companies can load loose materials directly into the container lined with a protective sheet, maximizing shipping efficiency and minimizing waste.

Types of Container Liners

Container liners come in various materials, shapes, and sizes to meet the needs of different industries. Some common types include:

1. Polyethylene Container Liners

Polyethylene (PE) container liners are widely used due to their strength and flexibility. They are suitable for transporting dry goods such as grains, seeds, or chemicals. These liners are made from high-density polyethylene (HDPE), offering excellent protection from moisture and external contaminants.

2. Polypropylene Container Liners

Polypropylene (PP) liners are another popular option. Known for their durability, these liners are ideal for transporting heavier materials such as minerals, ores, and cement. They offer resistance to tearing, making them perfect for more demanding applications.

3. Woven Fabric Liners

Woven fabric liners are made from polypropylene or polyethylene materials and are designed to be strong and durable. They are often used in extreme shipping conditions where there is a risk of the liner being punctured or torn. These liners are ideal for transporting heavy or sharp materials.

4. Bulkhead Liners

Bulkhead liners provide extra reinforcement at the entrance of the container, preventing spillage during the loading and unloading process. They are commonly used in the food and agriculture industries, providing an additional layer of protection against contamination.

Container Liners Manufacturers and Suppliers

The global demand for container liners is steadily increasing, leading to the growth of numerous container liner manufacturers and suppliers. Manufacturers in various regions produce different types of liners based on the specific needs of their customers.

In India, Container liners manufacturers and suppliers have established themselves as key players in the global market, producing high-quality liners for various industries. These manufacturers offer an array of options, from standard liners to customized solutions, to meet the shipping needs of diverse industries.

Indian Container liners suppliers have developed advanced production technologies to ensure that the liners meet international safety and quality standards. Whether it’s transporting food-grade materials or hazardous chemicals, Indian suppliers provide a range of liners to suit the specific needs of their clients.

Container Liner Sheet in India: A Growing Market

The demand for Container liner sheet in India has grown significantly in recent years. As India continues to emerge as a key global player in the export of bulk materials, the need for reliable, high-quality container liners has increased.

India's strong manufacturing base in the plastics and textile industries makes it an ideal location for producing container liner sheets. These sheets are typically made from materials such as HDPE and PP, which provide excellent resistance to environmental factors like moisture, UV radiation, and chemicals.

Many manufacturers in India now offer eco-friendly container liners made from biodegradable materials, reflecting the country’s growing focus on sustainability and environmental protection.

Applications of Container Liners

Container liners are used in a wide range of industries, including:

1. Food and Agriculture

In the food and agriculture industries, container liners are used to transport bulk food items such as grains, cereals, seeds, and sugar. These liners ensure that the cargo remains clean and uncontaminated during transit.

2. Chemicals

Container liners are frequently used for transporting bulk chemicals like powders, fertilizers, and granules. Their protective properties prevent chemicals from reacting with the container’s surface or being exposed to external elements.

3. Mining and Minerals

Industries involved in mining and minerals use durable liners to transport ores, sand, and other raw materials. The liners offer added protection from wear and tear during long-haul transportation.

4. Plastics and Resins

Liners are essential in the plastic and resin industry, where bulk shipments of plastic granules and resins need to be transported efficiently without contamination or moisture exposure.

How to Choose the Right Container Liner

When selecting a container liner, several factors must be considered, including the type of cargo being transported, the environmental conditions, and the loading and unloading processes. The liner should offer protection from moisture, UV radiation, and possible contamination. For hazardous materials, additional safety standards and features, such as reinforced liners or multi-layered sheets, may be necessary.

Working with reliable Container liners manufacturers ensures that the liners meet the specific needs of your cargo. Customized solutions are also available from many suppliers, allowing businesses to choose liners that perfectly fit their containers and materials.

Innovations in Container Liner Technology

As industries become more focused on sustainability and efficiency, manufacturers of container liners are developing eco-friendly and cost-effective options. Some manufacturers are exploring the use of recycled and biodegradable materials, which reduce environmental impact without compromising performance.

Additionally, innovations in liner design, such as anti-static properties for chemical transport or thermal insulation for temperature-sensitive materials, are helping to expand the scope of container liner applications.

Benefits of Using Container Liners

Using container liners offers several advantages, including:

Cost Savings: Container liners allow bulk transportation, eliminating the need for individual packaging and reducing overall shipping costs.

Product Protection: Liners protect cargo from external contaminants, moisture, and damage during transit.

Improved Efficiency: Liners make loading and unloading quicker and easier, enhancing operational efficiency.

Sustainability: Many manufacturers now offer environmentally friendly options, such as biodegradable liners, reducing waste and pollution.

FAQs

1. What types of materials are used to manufacture container liners?

Container liners are typically made from materials like polyethylene (PE), polypropylene (PP), and woven fabrics. These materials provide protection from moisture, contamination, and environmental factors, ensuring the safe transport of bulk cargo.

2. Can container liners be customized to fit specific container sizes?

Yes, many container liner manufacturers and suppliers offer customized solutions to fit containers of various sizes. Businesses can work with manufacturers to create liners tailored to their specific needs, ensuring a perfect fit for their cargo.

3. What are the benefits of using container liners in bulk shipping?

Container liners offer several benefits, including cost savings, product protection, and improved operational efficiency. By allowing bulk transportation, they eliminate the need for individual packaging, reduce contamination risks, and simplify loading and unloading processes.

0 notes

Text

FIBC Liners Bags

Alpine FIBC PVT.LTD. is a best manufacturer, exporters and suppliers of high quality FIBC Liners & Container FIBC Liners Bags in India, USA, Germany, France, UK, Italy, Canada, Spain, Netherlands, Portugal, Greece, Sweden, Argentina, Chile, Poland. A bulk bag can be fitted with an inner bag, which we call a liner. This liner provides additional protective properties against air and water vapor migration and the effect of light. Alpine FIBC can manufacture liners in the following materials: LDPE, LLDPE, MDPE, HDPE, PA, EVOH or aluminum. Loose, Glued, Tabbed, Stitched Liners, EVOH Liner, Baffle Liner, Aluminum, Foil liner, Conductive, Antistatic liner.

#FIBC Liners Bags#FIBC Liners Bags Manufacturers#FIBC Liners Bags in India#Container FIBC Liners Bags

2 notes

·

View notes

Text

In today’s globalized economy, brand integrity is vital for businesses aiming to establish a solid reputation. As companies expand their reach and enter international markets, the complexities of shipping logistics become more pronounced. Products must be transported safely, efficiently, and in a manner that reflects the quality and reliability of the brand. This is when the use of container liners is necessary. These specialized protective coverings not only safeguard products during transit but also play a significant role in maintaining brand integrity.

0 notes

Text

Discover Aastha Enterprises: Pioneering Excellence in Packaging Solutions

In the dynamic and demanding world of packaging, Aastha Enterprises has established itself as a key player, known for its dedication to quality and innovation. With a comprehensive range of products and services, we are your go-to partner for superior packaging solutions.

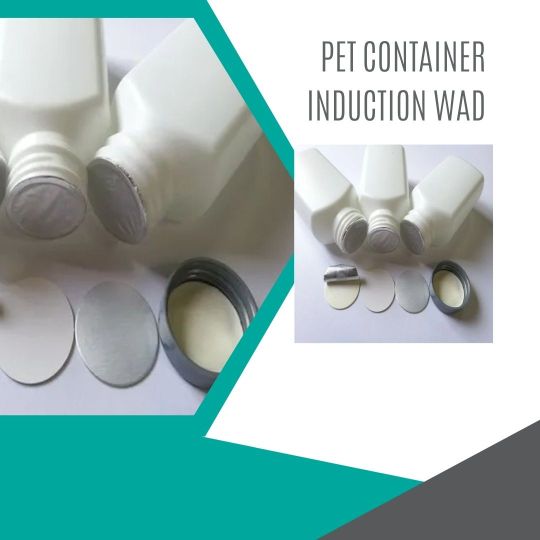

As leading Pet Container Induction Wad Suppliers, we provide advanced induction wads that ensure your containers are sealed securely, preserving product freshness and integrity. Our expertise in this area reflects our commitment to offering solutions that meet the highest industry standards.

Our product lineup includes EP Wad Liners, which are essential for enhancing the effectiveness of your packaging. These liners offer superior protection and reliability, ensuring that your products remain in optimal condition throughout their journey from production to consumer.

Additionally, we offer HDPE Container Mould solutions, designed to meet the rigorous demands of modern packaging. Our moulds are crafted with precision to ensure durability and efficiency, making them a vital component in the packaging process.

As prominent Pet Container Induction Wad Manufacturers, we specialize in producing high-quality induction wads specifically for PET containers. These wads provide secure sealing, preventing leaks and maintaining product quality.

Our role as Vented Induction Wad Suppliers further demonstrates our commitment to catering to a variety of packaging needs. Vented induction wads are crucial for applications requiring controlled pressure release, ensuring optimal performance and safety.

At Aastha Enterprises, we pride ourselves on our ability to deliver innovative and effective packaging solutions tailored to meet your specific needs. Trust us to be your partner in achieving packaging excellence and enhancing your product's market presence.

#Pet Container Induction Wad Suppliers#EP Wad Liners#HDPE Container Mould#Pet Container Induction Wad Manufacturers#Vented Induction Wad Suppliers

1 note

·

View note

Text

Secure and Efficient Bulk Transport with Polyethylene (PE) Container Liners

Polyethylene (PE) container liners are a versatile packaging solution for transporting bulk goods like minerals, powders, seeds, and food. These liners create a barrier between the container and the product, ensuring safe and efficient shipping. Made from virgin polyethylene, PE liners come in various configurations – single, double, or triple layer – to suit specific needs. Whether you require standard liners for typical shipping containers or custom liners for specialized cargo, PE liners can be tailored to your exact requirements.

The benefits of PE liners are numerous. Their ease of installation and minimal handling during transport make them a time-saving option. Food-grade virgin polyethylene ensures safe food transport, free from contamination and moisture. PE liners are also cost-effective, protecting against cargo spillage and reducing cleaning costs. Additionally, their certification by ISP 9001-2000 and ISO 22000 guarantees quality and safety in food management. Overall, PE container liners offer a reliable and economical way to transport bulk goods.

0 notes

Text

Are you looking for the Best Professional Braille Carton Manufacturer in Noida, and then Vishal Box is your ideal choice to get the higest quality packaging boxes. We offer you a beautiful, high quality and durable Braille Carton. This box is suitable for packing materials and goods. We are involved in manufacturing and supplying such excellent cartons and a full range of packaging boxes like liner box, Mono carton, Laminated Packaging Boxes, Luxury Packaging Boxes, New Innovative Boxes, Best Paper Boxes, Clamshell Packaging Boxes, Rigid Packaging Boxes, Best Printed Corrugated Boxes, Food Container Boxes, Tray Boxes and more.

To know more info about our products you can directly contact us at +91-8499879631 or visit the website: https://vishalbox.com/

#Braille Carton Manufacturer Noida#printed corrugated box#manufacturers of liner & mono carton#laminated packaging boxes manufacturer in noida#braille carton manufacturer#best corrugated box in noida#food containers boxes in noida

0 notes

Text

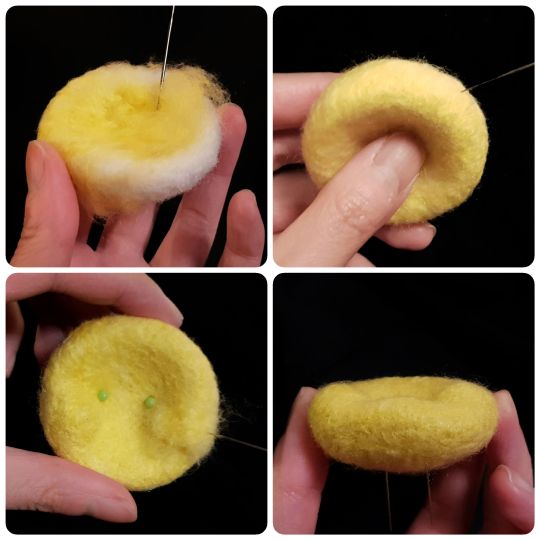

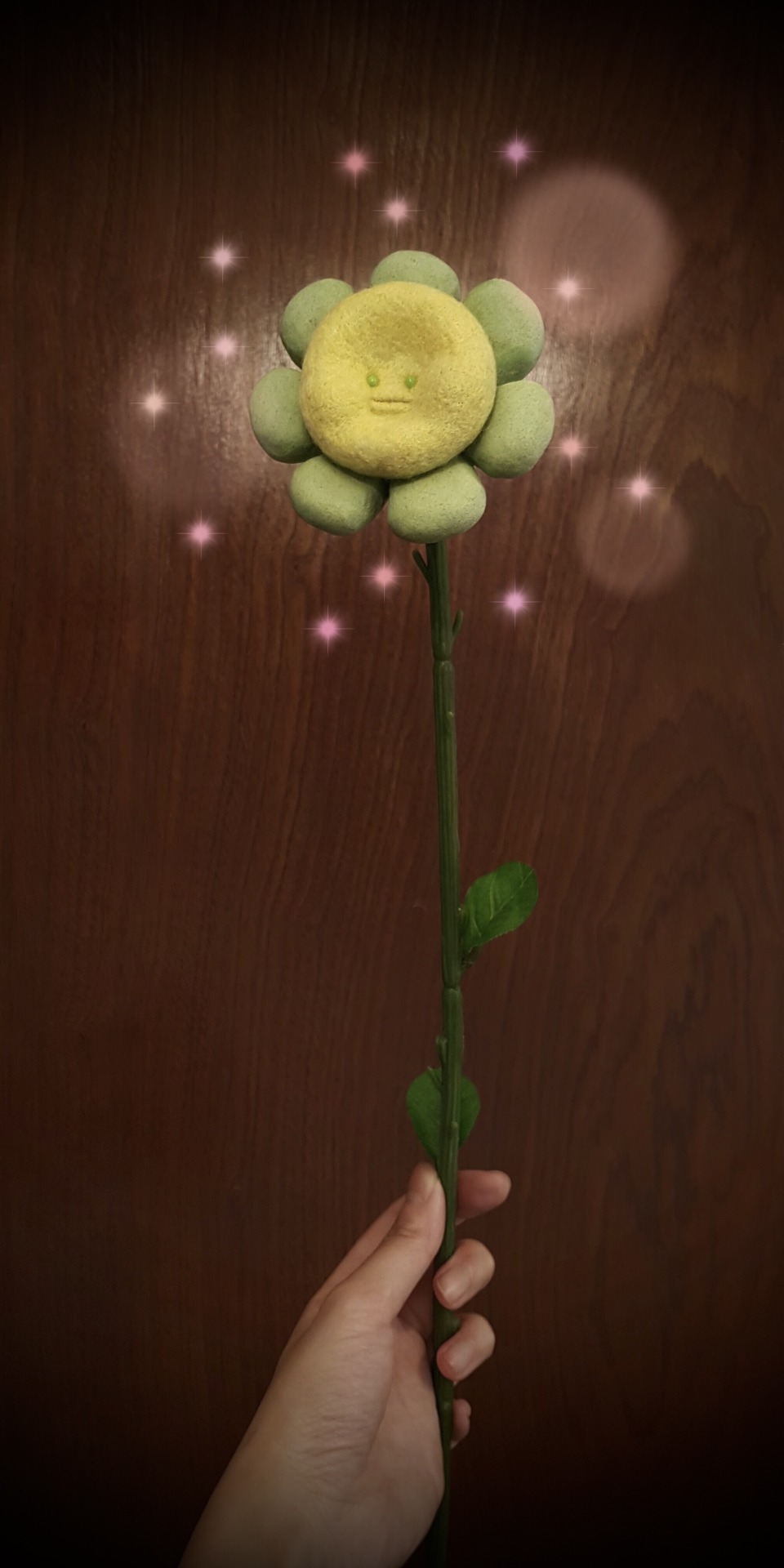

Odd Flower Friend

Mixed media figure made with felt, paper clay, and recycled plastic flower stem. Great gift for someone you feel uncertain of. It will watch them, day and night, without a blink.

Materials we used:

Plastic flower stem (scavenged from our dungeon of dross)

Green and wood air dry clay for petals

Polyester batting as base fiber (scavenged from grocery delivery padding)

Soft yellow acrylic / nylon yarn as top fiber (hand unraveled with pet brush)

Glass head sewing pins in green

Wood glue

Tools we used:

Felting needles

Wire cutter

Smooth sculpting stick

Some water in a small bowl

Toothpick

Pet carding brash (only to unravel yarn with)

Notes:

Yarn can be cheaper than roving and provides much more variety in colors and fabric content. We wanted this project to use synthetic fiber only and it is much easier (while tedious) and cheaper to unravel yarn than to scour the earth for non-animal based roving.

Plenty of abandoned plastic flower at thrift stores. Consider salvaging before buying newly manufactured materials whenever possible.

Always pay attention to inorganic trash, and find ways to recontextualize them as materials. e.g. The polyester batting is from grocery deliveries by a company called Renewliner that made wrong claims that their liner is recyclable. But not many places recycle PET in this form, so it practically is polyester fluff that is trash to most households. Ask friends and family around to collect them. They are great as base fiber for needlefelting.

Cut poly batting into circles.

Stab them to a loose disc shape.

Continue to stab as you bend the disc into a bowl shape.

Marvel at your felted bowl shaped dish base.

Put a mesh of top fiber on felted base.

Evenly stab top fiber on.

Cut glass pins to length.

Put glass pins at roughly where eyes best be.

Stab in more top fiber where cheeks best be.

Stab in the undercheek area, (sideways) towards chin, to make chin more prominent.

Roll a little top fiber into a loose ellipsoid and stab it where the top lip best be.

Repeat the same step for the lower lip. Make sure the corner of the mouth sinks into the edge of cheeks. Leave a defined gap in between lips.

Stab the gap in between lips to deepen it.

Stab the area below lower lips to deepen, but not as much as lip gap.

Stab any loose fiber from the back of face back in. Make sure to not stab through the other side and keep the fiber contained within the face.

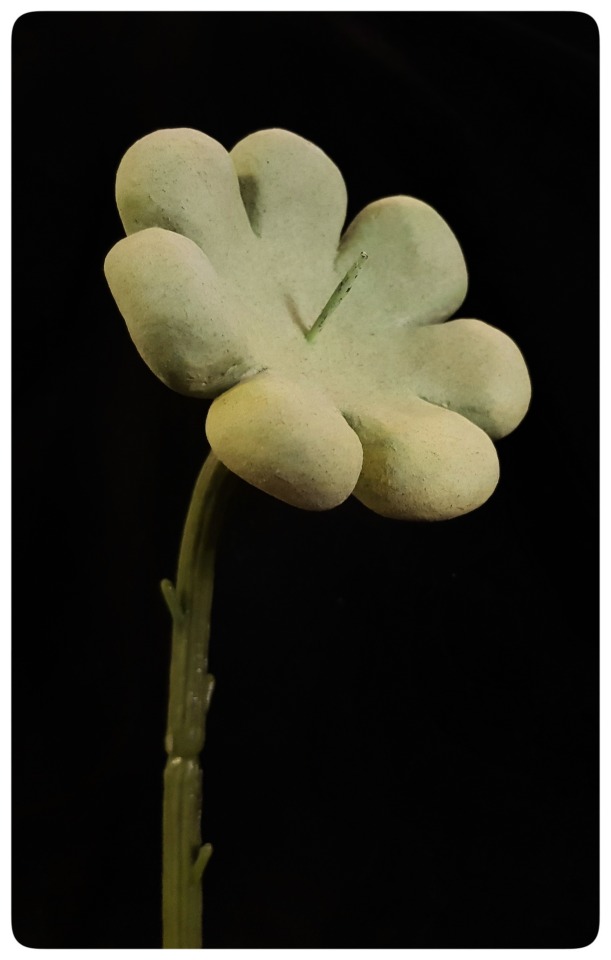

Mix a bit of green clay with wood clay for a desaturated natural soft green.

Make a thick round disc.

Cut 7 slits evenly at edge.

Round the corners with wet fingers with small bowl of water.

Bend it to a slight bowl shape like we did with the felted face.

Let dry on a domed surface.

Poke a hole through the petals with the plastic flower stem tip when the petals are dry to the touch but still moist inside.

Let petal dry completely.

Once dry, take out the petals, use wood glue diluted with water to seal petals. Make sure it is sealed just enough without looking too glossy. Dap finger on glossy parts to make them matte.

Let petal dry completely.

Once dry, put wood glue at the tip of the flower stem (the base of the stem needle). Our cupped shaped head held a good amount of glue.

Insert petals on the flower stem through the hole to desired position.

Let dry again for at least a day.

Once dry, trim off any excess stem needle that would be too long for the face’s thickness with wire cutter.

With a toothpick slowly drill a hole into the back of the face at where the stem needle would be best inserted.

Insert the flower face onto flower stem tip.

And you have yourself a good enough new flower friend.

#crafts#crafting#cute art#upcycle#art#upcycling#needlefelt#needlefelted#needle felting#needlefelting#fantasy art#fantasy creature#diy#spooky crafts#kawaii art#weird art#felt art#arts and crafts#creature#character design#character art#witchcrafts#dreamcore#surreal

16 notes

·

View notes

Text

Nike InfinityRN 4

Nike Running has its latest answer in delivering high-level performance while reducing environmental impact: Nike ReactX foam, which is debuting in the new Nike InfinityRN 4.

Compared to Nike React foam, ReactX is engineered to cut down its carbon footprint in a pair of midsoles by at least 43% due to reduced energy in the manufacturing process, and increase energy return by 13%.

The resulting balance between performance and environmental impact in ReactX foam is a feat of sport performance engineering. The industry has two traditional methods of making foam, which can be summarized as either injection or compression molding. The overall process for injection is simpler, and thus carries a lower carbon footprint — but it also tends to have lower energy return, and a lower performance benefit. On the other hand, compression molding delivers more responsive foams with higher energy return, but also creates more waste and uses more energy to make it.

ReactX foam was researched, developed and tested over five years to craft a formulation that hits the sweet spot between performance and environmental impact. In putting the material through an injection process, rather than through compression molding, the new foam delivers a higher energy return without creating a higher carbon footprint.

The new shoe pairs ReactX foam with an all-new Nike Flyknit upper that allows maximum airflow, breathability, flexibility, and containment, with a soft, supportive foam collar. The lightweight fabric uses an average of 60% less waste than traditional footwear-upper manufacturing. The updated upper also features increased volume in the toe, a midfoot support system and a water-resistant liner.

The Nike InfinityRN 4 launches globally July 13 on nike.com and at select retailers.

2 notes

·

View notes

Text

A Complete Guide to the Plastic Recycling Process

The plastic recycling process is a vital solution to the global plastic waste crisis. It helps reduce environmental pollution, conserve resources, and promote sustainability. With billions of tons of plastic produced annually, understanding how to reduce plastic waste through recycling is more important than ever. This guide explores the key stages of recycling, types of plastics, and its overall benefits.

Why Recycle Plastic?

Plastic is versatile and durable but poses significant environmental challenges due to its slow decomposition. Recycling offers a way to:

Reduce Plastic Pollution: Keeps plastic out of landfills and oceans.

Conserve Resources: Saves raw materials like petroleum and natural gas.

Lower Energy Consumption: Recycling plastic uses less energy than manufacturing new materials.

Protect Ecosystems: Reduces harm to wildlife caused by plastic waste.

Stages of the Plastic Recycling Process

Collection

Plastic waste is gathered from homes, businesses, and public recycling bins.

Collection systems vary by region and can include curbside pickup or drop-off points.

Sorting

Plastics are sorted by type and color, often using automated systems like infrared scanners.

Sorting ensures only recyclable plastics enter the next stage of the process.

Cleaning

Contaminants like food residue, labels, and adhesives are removed.

Clean plastics are shredded into smaller pieces for easier processing.

Shredding and Resizing

Plastics are shredded into flakes or pellets, which can be used in manufacturing.

This step improves material handling and prepares the plastic for melting.

Melting and Reforming

Plastic flakes are melted and reformed into new products or raw materials.

Advanced technologies allow for the creation of high-quality recycled plastics.

Manufacturing New Products

Recycled plastics are used to create new items, such as bottles, clothing, or construction materials.

Types of Plastics Commonly Recycled

PET (Polyethylene Terephthalate)

Found in water bottles and food containers.

Easily recyclable and turned into fibers or new containers.

HDPE (High-Density Polyethylene)

Used in milk jugs, detergent bottles, and pipes.

Recycled into durable goods like benches and bins.

LDPE (Low-Density Polyethylene)

Found in shopping bags and packaging films.

Often recycled into trash bags and liners.

PP (Polypropylene)

Used in food containers and automotive parts.

Recycled into industrial materials or storage solutions.

How to Reduce Plastic Waste

Choose Reusable Products: Opt for reusable bottles, bags, and containers instead of single-use plastics.

Recycle Correctly: Follow local guidelines to ensure your plastic waste is properly sorted and recycled.

Support Recycled Products: Buy items made from recycled plastic to encourage demand.

Spread Awareness: Educate others about the importance of the plastic recycling process and reducing waste.

Benefits of the Plastic Recycling Process

Reduces Environmental Impact

Recycling prevents tons of plastic from entering ecosystems.

Saves Energy

Recycling plastic uses 88% less energy than producing new plastic.

Creates Jobs

The recycling industry generates employment opportunities in collection, sorting, and processing.

Supports a Circular Economy

Promotes a sustainable system where materials are continuously reused.

The Future of Plastic Recycling

Innovations in technology are making plastic recycling processes more efficient. Chemical recycling, for example, can break down plastics to their original molecules, creating higher-quality recycled materials. Governments and industries worldwide are investing in ways to reduce plastic waste and improve recycling rates.

By participating in plastic recycling and adopting habits to reduce plastic use, we can make a significant impact on the planet's health.

0 notes

Text

0 notes

Text

High Density Polyethylene (HDPE) Prices Trend | Pricing | News | Database | Chart

High-Density Polyethylene (HDPE) is one of the most widely used thermoplastic polymers, prized for its strength, durability, and versatility. It finds applications in a wide range of industries, from packaging to construction, automotive to consumer goods. As a key polymer in global markets, HDPE prices are subject to fluctuation, influenced by a variety of factors such as raw material costs, production capacities, supply and demand dynamics, and geopolitical events. Over the years, HDPE pricing has seen considerable volatility, which can impact production costs, profitability, and the final pricing of goods across sectors. The price trends of HDPE are of particular interest to manufacturers, suppliers, and buyers looking to optimize costs and make informed purchasing decisions.

One of the primary factors driving the prices of HDPE is the cost of its raw material: ethylene. Ethylene, which is primarily derived from natural gas or petroleum, is the building block for HDPE production. As such, fluctuations in global oil prices or changes in the availability of natural gas can significantly affect the cost of producing HDPE. In periods when crude oil prices rise due to geopolitical tensions, supply disruptions, or changes in global demand, the price of ethylene also increases, which, in turn, raises the price of HDPE. Conversely, when crude oil prices decrease, manufacturers may see lower HDPE production costs, leading to more favorable pricing in the market.

Get Real Time Prices for High-Density Polyethylene (HDPE) : https://www.chemanalyst.com/Pricing-data/hdpe-7

Another factor influencing HDPE prices is the global supply and demand balance. Demand for HDPE is strong in many sectors, including packaging, construction, agriculture, and automotive, as its chemical properties make it resistant to moisture, chemicals, and impact. It is used in a wide array of products, such as plastic bottles, pipes, and containers, as well as plastic films and liners. Any fluctuations in demand from these key industries can lead to price changes. For example, during periods of increased consumer demand for packaging or construction materials, the demand for HDPE can outstrip supply, leading to price hikes. Conversely, during periods of slower economic growth or reduced demand from key markets, prices may stabilize or fall.

The production capacity of HDPE manufacturers also plays a key role in determining price fluctuations. Overcapacity in the production of HDPE can lead to lower prices, as manufacturers compete to sell their products. However, when production is limited or reduced due to maintenance, plant closures, or capacity restrictions, the reduced supply of HDPE can cause prices to rise. In addition, factors such as the availability of feedstock, transportation costs, and infrastructure limitations can also influence the production costs associated with HDPE, thus affecting overall pricing trends.

Geopolitical factors and trade policies can further impact HDPE pricing, as these can affect the availability of raw materials, the cost of production, and the price of shipping. Trade tariffs and sanctions, for example, can increase the cost of importing or exporting HDPE, leading to higher prices in certain regions. Additionally, political instability in key HDPE-producing regions can disrupt supply chains, resulting in price hikes due to supply shortages. On the other hand, trade agreements and favorable policies may help stabilize prices by improving access to resources and reducing trade barriers.

Regional variations in HDPE prices are another important consideration. While the global price of HDPE can be influenced by many of the aforementioned factors, local market conditions can cause price differences in different regions. For example, regions with higher production capacities may see lower prices due to a more abundant supply, while regions with limited access to raw materials or production facilities may experience higher costs. The cost of labor, energy, and logistics in different regions also plays a role in determining local pricing trends. These regional disparities highlight the importance of keeping track of both global and local market developments when assessing the price of HDPE.

The rising demand for sustainable and eco-friendly materials has also impacted the pricing of HDPE in recent years. As environmental regulations tighten and consumer preferences shift toward more sustainable products, the cost of recycling HDPE and producing eco-friendly alternatives can drive prices up. The demand for recycled HDPE (rHDPE), in particular, has grown, as it is seen as an environmentally responsible alternative to virgin HDPE. However, the cost of processing and recycling HDPE can be higher, which can result in price increases for rHDPE products.

In addition to these fundamental factors, market speculation and trading in commodity markets can also contribute to short-term price fluctuations. Investors and speculators who trade HDPE futures contracts may drive prices higher or lower based on anticipated supply and demand conditions, geopolitical events, or broader economic trends. While these price swings are typically short-term in nature, they can still have a significant impact on the day-to-day pricing of HDPE in global markets.

For businesses that rely on HDPE as a key material in their production processes, staying informed about price trends is essential for making informed purchasing decisions. By closely monitoring market developments, raw material prices, and production capacities, companies can better anticipate price movements and adjust their purchasing strategies accordingly. Strategic sourcing, long-term contracts, and hedging strategies can all help mitigate the impact of price fluctuations and secure stable pricing for HDPE.

In conclusion, the prices of High-Density Polyethylene are influenced by a complex interplay of factors, including raw material costs, production capacities, supply and demand dynamics, geopolitical events, and regional market conditions. As a vital material used in a variety of industries, HDPE pricing can experience significant volatility, which affects the cost structure of many products. Understanding the factors that drive HDPE prices is crucial for businesses and consumers looking to navigate the ever-changing landscape of this essential polymer.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#HDPE Price#HDPE Prices#HDPE Pricing#High Density Polyethylene Price Monitor#High Density Polyethylene Price

0 notes

Text

#FIBC Liners Bags#FIBC Liners Bags Manufacturers#FIBC Liners Bags in India#Container FIBC Liners Bags

2 notes

·

View notes

Text

How Container Liners Can Save You Money in the Long Run?

Businesses are continuously looking for methods to save expenses and increase efficiency in the cutthroat market of today. One often-overlooked solution that can significantly impact your bottom line is the use of container liners. These protective barriers serve multiple purposes in shipping and storage, and they can lead to substantial long-term savings. This article explores how container liners can save you money, focusing on their benefits and the insights from leading Container liners manufacturer.

Understanding Container Liners

Container liners are specialized bags made from durable materials such as polyethylene or polypropylene, designed to fit inside shipping containers or bulk transport vessels. Their primary purpose is to protect the cargo from moisture, contaminants, and physical damage. By creating a barrier between the cargo and the container walls, these liners help maintain product integrity, making them essential for various industries, including agriculture, chemicals, and food production.

Reducing Product Loss and Damage

One of the most significant ways container liners save money is by minimizing product loss and damage during transport. When goods are exposed to moisture or contaminants, the risk of spoilage increases dramatically. For instance, agricultural products like grains or seeds can deteriorate if not properly protected. A high-quality Liner bag container acts as a moisture barrier, ensuring that products remain in optimal condition from the moment they are loaded until they reach their final destination.

Case Study: Agricultural Shipping

Consider a company that ships grains without using container liners. If even a small amount of moisture enters the container during transport, it can lead to significant losses due to spoilage or mold. By investing in quality container liners, the same company can protect its goods, ultimately saving thousands of dollars in lost revenue.

Lowering Cleaning and Maintenance Costs

Using container liners also reduces cleaning and maintenance expenses associated with shipping containers. Contaminants such as dust, dirt, and moisture can build up in containers over time, requiring costly cleaning efforts before the next load. With a liner in place, the container’s interior remains clean and dry, reducing the frequency of cleaning and prolonging the lifespan of the container itself.

Long-Term Savings on Container Lifespan

By protecting containers from the wear and tear associated with various cargo, container liners help extend the life of shipping containers. This means businesses can avoid the cost of premature replacements and maintenance, leading to additional savings.

Streamlining Loading and Unloading Processes

Container liners facilitate smoother loading and unloading operations. Since they are designed to fit the container precisely, they allow for easy access to the cargo, making the process quicker and more efficient. This reduction in handling time can significantly lower labor costs, especially in high-volume shipping operations.

Improving Operational Efficiency

When workers can load and unload cargo more quickly, it reduces the time containers spend in port or at distribution centers. This efficiency not only leads to cost savings but also improves overall operational performance, allowing businesses to handle more shipments in the same timeframe.

Enhancing Safety and Compliance

Safety is a crucial consideration in the shipping industry, and container liners can contribute to a safer working environment. By preventing spills and leaks, they help mitigate risks associated with transporting hazardous materials. This is particularly important for companies that deal with chemicals or other potentially dangerous substances.

Avoiding Regulatory Fines

Using container liners can also help businesses comply with industry regulations regarding safety and contamination. A company's reputation may suffer, substantial fines may result, and legal problems may arise from noncompliance. By investing in quality liners, businesses can avoid these costs and ensure they meet all necessary safety standards.

Customization Options for Specific Needs

Many container liners manufacturers offer customization options to meet specific business needs. Businesses can choose from various sizes, materials, and features, allowing them to optimize their packaging solutions. Custom liners can be tailored to protect specific types of cargo, further reducing the risk of damage and loss.

Increased Versatility in Applications

The versatility of container liners means that they can be used across multiple sectors, from food and agriculture to chemicals and pharmaceuticals. This adaptability allows companies to standardize their packaging solutions, reducing the complexity and cost associated with managing multiple types of packaging.

Environmental Benefits Leading to Cost Savings

Using container liners can also contribute to sustainability efforts, which can yield long-term cost savings. Many manufacturers produce eco-friendly liners made from recyclable materials, allowing companies to reduce their environmental footprint. Implementing sustainable practices can enhance a company's reputation and appeal to environmentally conscious consumers.

Reducing Waste Management Costs

By minimizing product loss and spoilage, container liners help reduce waste management costs associated with disposing of damaged goods. This reduction not only saves money but also contributes to a more sustainable business model.

The Importance of Quality in Container Liners

Investing in high-quality container liners is crucial for maximizing savings. While it may be tempting to choose cheaper options, low-quality liners may fail to provide the necessary protection, leading to increased losses and costs down the line. Working with reputable container liners manufacturers ensures that you receive durable, reliable products tailored to your needs.

Building Long-Term Relationships with Suppliers

Establishing relationships with trusted suppliers can also lead to better pricing and terms. As businesses build loyalty with their container liners supplier, they may benefit from bulk discounts or early access to new products, further enhancing cost savings.

Conclusion

Incorporating container liners into your shipping and storage operations is a smart investment that can yield significant long-term savings. By reducing product loss and damage, lowering cleaning and maintenance costs, streamlining loading processes, and enhancing safety, container liners offer a comprehensive solution for businesses across various industries. Collaborating with reputable container liners manufacturers and suppliers ensures that you select high-quality liners that meet your specific needs, ultimately leading to greater efficiency and profitability.

If you’re looking to maximize your savings and improve your operational efficiency, consider implementing container liners in your logistics strategy. The benefits are clear: by protecting your products, minimizing costs, and ensuring compliance, container liners are an essential component of a successful and sustainable business model.

FAQs About Container Liners

1. What are container liners?

Container liners are protective bags made from materials like polyethylene or polypropylene, designed to fit inside shipping containers. They safeguard cargo from moisture, contaminants, and physical damage.

2. What industries benefit from using container liners?

Container liners are widely used in agriculture, food production, chemicals, and pharmaceuticals. They are ideal for packaging grains, powders, and bulk liquids.

3. How do container liners help reduce product loss?

By creating a moisture barrier, container liners prevent spoilage and contamination, ensuring that products remain intact and usable throughout transport.

0 notes

Text

How Jumbo Bags Contribute to Efficient and Sustainable Supply Chains

In today's dynamic and demanding world, optimizing efficiency and sustainability in supply chains is no longer a luxury, but a necessity. As a leading Jumbo Bag Manufacturer, Rishi FIBC recognizes this crucial need and dedicates itself to providing innovative solutions that contribute to robust and responsible logistics movements.

Let's delve into how Jumbo Bags, or FIBCs (Flexible Intermediate Bulk Containers), play a pivotal role in shaping efficient and sustainable supply chains:

Why choose Rishi FIBC

Jumbo Bags play a crucial role in shaping efficient and sustainable supply chains. By choosing Rishi FIBC as your Jumbo Bag Manufacturer, you gain access to innovative solutions, unwavering commitment to quality, and a partner dedicated to environmental responsibility. Together, we can build a future where supply chains are not just efficient but also contribute to a healthier planet.

0 notes