#Container Liners Suppliers

Explore tagged Tumblr posts

Text

Container Liners: A Versatile Solution for Safe and Efficient Cargo Transport

Container liners have become an indispensable part of modern cargo transportation, ensuring the safe, clean, and cost-effective movement of bulk goods across the globe. These liners are a type of flexible packaging that fit inside standard shipping containers to form a protective barrier between the cargo and the container walls. This article explores the significance of container liners, their manufacturing process, benefits, and the role of leading container liners manufacturers and suppliers, particularly in India.

The Growing Importance of Container Liners in Global Trade

As global trade continues to expand, the demand for bulk transport solutions has surged. Traditionally, bulk goods such as grains, chemicals, fertilizers, and minerals were transported using bags, drums, or even loose inside containers. However, these methods often resulted in spillage, contamination, and wastage. The need for a more efficient and hygienic solution led to the development of container liners.

Container liners not only prevent direct contact between the cargo and the container, thus reducing the risk of contamination, but also offer ease in loading and unloading. These liners are essential in industries that require high standards of cleanliness and safety, such as food, pharmaceuticals, and chemicals. Over the years, container liner manufacturers have developed specialized products that cater to the specific needs of these industries.

Types of Container Liners and Their Applications

Container liners come in various types, each designed to meet specific cargo requirements. Some of the most common types include woven polyethylene (PE) and polypropylene (PP) liners, which are durable and resistant to moisture, chemicals, and abrasion. These liners are ideal for transporting dry bulk cargo like grains, sugar, salt, and plastic resins. Moreover, container liners are also available in specialized forms such as thermal liners, which offer temperature control for sensitive products like food and pharmaceuticals.

Other innovative designs include anti-static liners for transporting chemicals and powders, as well as hermetic liners that provide an airtight seal to prevent moisture and oxygen ingress, thus protecting the cargo from spoilage. The adaptability of these liners makes them suitable for a wide range of industries, further increasing their demand among global Container Liners Suppliers.

Container Liner Manufacturing Process: Precision and Innovation

The production of container liners involves a series of precise and innovative steps to ensure the highest quality and durability. The primary materials used are PE and PP, known for their strength, flexibility, and resistance to harsh conditions. The manufacturing process begins with the extrusion of plastic into thin sheets, which are then woven together to form a sturdy fabric. This fabric is coated with additional layers to enhance its resistance to moisture, UV rays, and chemicals.

Once the fabric is prepared, it is cut and stitched into the desired liner shape, which varies depending on the container size and the specific cargo it will carry. Many container liners manufacturers also incorporate advanced technology such as heat-sealing and ultrasonic welding to ensure leak-proof seams. In India, the container liner sheet industry has seen significant advancements, with manufacturers producing high-quality liners that comply with international standards.

India’s Emerging Role in the Container Liners Market

India has emerged as a key player in the global container liners market, both as a manufacturer and a supplier. The country boasts a growing number of container liners manufacturers that produce a wide variety of liners for domestic and international markets. Indian manufacturers have earned a reputation for offering cost-effective solutions without compromising on quality, making them a preferred choice among global buyers.

Furthermore, the availability of high-quality raw materials and advancements in manufacturing technology have allowed Indian companies to produce container liner sheets that meet the stringent requirements of industries like food processing, chemicals, and agriculture. These sheets are designed to offer superior protection and ensure the safe transportation of bulk goods. As the demand for container liners continues to grow, India’s contribution to the global market is expected to increase further.

Benefits of Using Container Liners

The use of container liners offers a multitude of benefits, making them an essential part of bulk cargo transportation. One of the primary advantages is cost savings. Container liners eliminate the need for expensive bulk packaging, such as bags or drums, reducing material costs. Moreover, they streamline the loading and unloading process, as goods can be poured directly into the container, further saving on labor and handling expenses.

Another significant benefit is the prevention of contamination. Container liners form a barrier between the cargo and the container, ensuring that the goods remain uncontaminated during transit. This is especially important for industries like food and pharmaceuticals, where hygiene is critical. Additionally, container liners protect the cargo from external factors such as moisture, dust, and pests, thus preserving its quality.

Environmental Impact and Sustainability of Container Liners

As industries across the globe shift towards sustainable practices, the use of container liners plays a role in reducing environmental impact. Most container liners are made from recyclable materials such as polyethylene and polypropylene, making them an eco-friendly option. Furthermore, the reduction in packaging waste and the ability to transport bulk goods more efficiently contribute to lower carbon emissions.

Container liners also help prevent spillage and product loss, which can have significant environmental consequences, particularly when transporting chemicals or hazardous materials. By providing a secure containment solution, these liners help minimize the risk of accidents and ensure the safe transport of goods.

The Role of Container Liners Suppliers in Ensuring Quality and Timely Delivery

Container liners suppliers play a crucial role in the global supply chain by ensuring the availability of high-quality liners that meet the specific needs of various industries. Suppliers work closely with manufacturers to offer customized solutions, from selecting the appropriate liner material to designing liners that fit different container sizes and shapes.

In India, suppliers have established a strong network to cater to both domestic and international markets. They ensure timely delivery and provide after-sales services, such as installation guidance and support, to help customers optimize their use of container liners. With the rise of e-commerce and international trade, the role of container liners suppliers has become even more critical in ensuring the smooth flow of goods across borders.

Conclusion: The Future of Container Liners in Global Trade

Container liners have revolutionized the way bulk goods are transported, offering a safe, efficient, and cost-effective solution for industries across the globe. With the growing demand for cleaner and more sustainable transport methods, the importance of container liners is only expected to increase. Indian Container Liner Sheet In India and suppliers have positioned themselves as key players in this market, contributing to global supply chains with their high-quality, competitively priced products.

As the industry continues to evolve, innovations in materials, design, and manufacturing processes will further enhance the performance of container liners, making them an even more integral part of the logistics sector.

Frequently Asked Questions (FAQs)

What are the main materials used in container liners? The primary materials used in container liners are polyethylene (PE) and polypropylene (PP), which are known for their durability, flexibility, and resistance to moisture and chemicals.

Can container liners be reused? While some container liners are designed for single-use, others, especially those made from durable materials, can be reused if properly cleaned and maintained. However, it is important to ensure that reused liners meet hygiene and safety standards, especially in industries like food and pharmaceuticals.

What industries benefit the most from container liners? Industries that transport bulk goods, such as food and beverages, chemicals, pharmaceuticals, and agriculture, benefit significantly from using container liners due to the protection, cleanliness, and cost-effectiveness they offer.

Why is India a leading supplier of container liners? India has a well-developed manufacturing sector that produces high-quality container liners at competitive prices. The availability of raw materials, skilled labor, and advanced manufacturing technologies have contributed to India's growing role as a leading supplier of container liners globally.

0 notes

Text

Container Liners: A Comprehensive Overview

Container liners play an essential role in the transportation of bulk cargo by offering a protective layer within shipping containers. These liners are used extensively across industries for transporting dry, bulk materials like chemicals, food products, minerals, seeds, and other granulated materials. They are designed to keep the contents safe from contamination and damage during transit.

What Are Container Liners?

Container liners are large plastic or textile sheets that fit inside standard containers to create a barrier between the cargo and the walls of the container. This ensures that materials are kept clean, dry, and free from external elements such as moisture or dust. These liners are particularly valuable for bulk materials, as they allow containers to carry loose products without needing intermediate packaging, reducing the overall shipping cost.

Importance of Container Liners in Bulk Shipping

The primary benefit of using container liners is the protection they offer to the materials being transported. Since containers are exposed to various weather conditions and may have been used to carry different kinds of cargo in the past, liners ensure that the new cargo is not contaminated by residue from previous shipments. The container liner also prevents materials from sticking to the walls, simplifying the unloading process.

Container liners also reduce packaging costs by allowing bulk shipping. Instead of shipping materials in smaller packages, companies can load loose materials directly into the container lined with a protective sheet, maximizing shipping efficiency and minimizing waste.

Types of Container Liners

Container liners come in various materials, shapes, and sizes to meet the needs of different industries. Some common types include:

1. Polyethylene Container Liners

Polyethylene (PE) container liners are widely used due to their strength and flexibility. They are suitable for transporting dry goods such as grains, seeds, or chemicals. These liners are made from high-density polyethylene (HDPE), offering excellent protection from moisture and external contaminants.

2. Polypropylene Container Liners

Polypropylene (PP) liners are another popular option. Known for their durability, these liners are ideal for transporting heavier materials such as minerals, ores, and cement. They offer resistance to tearing, making them perfect for more demanding applications.

3. Woven Fabric Liners

Woven fabric liners are made from polypropylene or polyethylene materials and are designed to be strong and durable. They are often used in extreme shipping conditions where there is a risk of the liner being punctured or torn. These liners are ideal for transporting heavy or sharp materials.

4. Bulkhead Liners

Bulkhead liners provide extra reinforcement at the entrance of the container, preventing spillage during the loading and unloading process. They are commonly used in the food and agriculture industries, providing an additional layer of protection against contamination.

Container Liners Manufacturers and Suppliers

The global demand for container liners is steadily increasing, leading to the growth of numerous container liner manufacturers and suppliers. Manufacturers in various regions produce different types of liners based on the specific needs of their customers.

In India, Container liners manufacturers and suppliers have established themselves as key players in the global market, producing high-quality liners for various industries. These manufacturers offer an array of options, from standard liners to customized solutions, to meet the shipping needs of diverse industries.

Indian Container liners suppliers have developed advanced production technologies to ensure that the liners meet international safety and quality standards. Whether it’s transporting food-grade materials or hazardous chemicals, Indian suppliers provide a range of liners to suit the specific needs of their clients.

Container Liner Sheet in India: A Growing Market

The demand for Container liner sheet in India has grown significantly in recent years. As India continues to emerge as a key global player in the export of bulk materials, the need for reliable, high-quality container liners has increased.

India's strong manufacturing base in the plastics and textile industries makes it an ideal location for producing container liner sheets. These sheets are typically made from materials such as HDPE and PP, which provide excellent resistance to environmental factors like moisture, UV radiation, and chemicals.

Many manufacturers in India now offer eco-friendly container liners made from biodegradable materials, reflecting the country’s growing focus on sustainability and environmental protection.

Applications of Container Liners

Container liners are used in a wide range of industries, including:

1. Food and Agriculture

In the food and agriculture industries, container liners are used to transport bulk food items such as grains, cereals, seeds, and sugar. These liners ensure that the cargo remains clean and uncontaminated during transit.

2. Chemicals

Container liners are frequently used for transporting bulk chemicals like powders, fertilizers, and granules. Their protective properties prevent chemicals from reacting with the container’s surface or being exposed to external elements.

3. Mining and Minerals

Industries involved in mining and minerals use durable liners to transport ores, sand, and other raw materials. The liners offer added protection from wear and tear during long-haul transportation.

4. Plastics and Resins

Liners are essential in the plastic and resin industry, where bulk shipments of plastic granules and resins need to be transported efficiently without contamination or moisture exposure.

How to Choose the Right Container Liner

When selecting a container liner, several factors must be considered, including the type of cargo being transported, the environmental conditions, and the loading and unloading processes. The liner should offer protection from moisture, UV radiation, and possible contamination. For hazardous materials, additional safety standards and features, such as reinforced liners or multi-layered sheets, may be necessary.

Working with reliable Container liners manufacturers ensures that the liners meet the specific needs of your cargo. Customized solutions are also available from many suppliers, allowing businesses to choose liners that perfectly fit their containers and materials.

Innovations in Container Liner Technology

As industries become more focused on sustainability and efficiency, manufacturers of container liners are developing eco-friendly and cost-effective options. Some manufacturers are exploring the use of recycled and biodegradable materials, which reduce environmental impact without compromising performance.

Additionally, innovations in liner design, such as anti-static properties for chemical transport or thermal insulation for temperature-sensitive materials, are helping to expand the scope of container liner applications.

Benefits of Using Container Liners

Using container liners offers several advantages, including:

Cost Savings: Container liners allow bulk transportation, eliminating the need for individual packaging and reducing overall shipping costs.

Product Protection: Liners protect cargo from external contaminants, moisture, and damage during transit.

Improved Efficiency: Liners make loading and unloading quicker and easier, enhancing operational efficiency.

Sustainability: Many manufacturers now offer environmentally friendly options, such as biodegradable liners, reducing waste and pollution.

FAQs

1. What types of materials are used to manufacture container liners?

Container liners are typically made from materials like polyethylene (PE), polypropylene (PP), and woven fabrics. These materials provide protection from moisture, contamination, and environmental factors, ensuring the safe transport of bulk cargo.

2. Can container liners be customized to fit specific container sizes?

Yes, many container liner manufacturers and suppliers offer customized solutions to fit containers of various sizes. Businesses can work with manufacturers to create liners tailored to their specific needs, ensuring a perfect fit for their cargo.

3. What are the benefits of using container liners in bulk shipping?

Container liners offer several benefits, including cost savings, product protection, and improved operational efficiency. By allowing bulk transportation, they eliminate the need for individual packaging, reduce contamination risks, and simplify loading and unloading processes.

0 notes

Text

Hazardous waste containment liners US

For More Details Visit https://www.amconky.com/geomembrane-liners

#Hazardous waste containment liners US#Pond Builder in Kentucky#Pond liner suppliers US#Landfill Tarp suppliers US

0 notes

Text

Discover Aastha Enterprises: Pioneering Excellence in Packaging Solutions

In the dynamic and demanding world of packaging, Aastha Enterprises has established itself as a key player, known for its dedication to quality and innovation. With a comprehensive range of products and services, we are your go-to partner for superior packaging solutions.

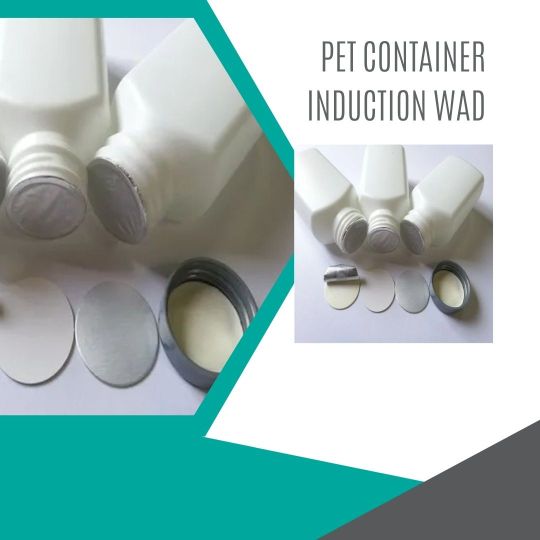

As leading Pet Container Induction Wad Suppliers, we provide advanced induction wads that ensure your containers are sealed securely, preserving product freshness and integrity. Our expertise in this area reflects our commitment to offering solutions that meet the highest industry standards.

Our product lineup includes EP Wad Liners, which are essential for enhancing the effectiveness of your packaging. These liners offer superior protection and reliability, ensuring that your products remain in optimal condition throughout their journey from production to consumer.

Additionally, we offer HDPE Container Mould solutions, designed to meet the rigorous demands of modern packaging. Our moulds are crafted with precision to ensure durability and efficiency, making them a vital component in the packaging process.

As prominent Pet Container Induction Wad Manufacturers, we specialize in producing high-quality induction wads specifically for PET containers. These wads provide secure sealing, preventing leaks and maintaining product quality.

Our role as Vented Induction Wad Suppliers further demonstrates our commitment to catering to a variety of packaging needs. Vented induction wads are crucial for applications requiring controlled pressure release, ensuring optimal performance and safety.

At Aastha Enterprises, we pride ourselves on our ability to deliver innovative and effective packaging solutions tailored to meet your specific needs. Trust us to be your partner in achieving packaging excellence and enhancing your product's market presence.

#Pet Container Induction Wad Suppliers#EP Wad Liners#HDPE Container Mould#Pet Container Induction Wad Manufacturers#Vented Induction Wad Suppliers

1 note

·

View note

Text

How Jumbo Bags Contribute to Efficient and Sustainable Supply Chains

In today's dynamic and demanding world, optimizing efficiency and sustainability in supply chains is no longer a luxury, but a necessity. As a leading Jumbo Bag Manufacturer, Rishi FIBC recognizes this crucial need and dedicates itself to providing innovative solutions that contribute to robust and responsible logistics movements.

Let's delve into how Jumbo Bags, or FIBCs (Flexible Intermediate Bulk Containers), play a pivotal role in shaping efficient and sustainable supply chains:

Why choose Rishi FIBC

Jumbo Bags play a crucial role in shaping efficient and sustainable supply chains. By choosing Rishi FIBC as your Jumbo Bag Manufacturer, you gain access to innovative solutions, unwavering commitment to quality, and a partner dedicated to environmental responsibility. Together, we can build a future where supply chains are not just efficient but also contribute to a healthier planet.

0 notes

Text

Looking for Pre-Hard H13 tool steel with its standard hardness of 460-500 BHN!

The perfect tool steel for hot work and cold work applications… Get in touch with us today to place your requirement! #h13steel #din2344 #aisih13…

The equivalent steel grade H-13 / SKD61 / AISI H13 normally available in the annealed condition but in some specific applications, we provide Pre-Hard H13 with its standard hardness 460-500 BHN. Utilized for ejector pins, apparatus holders and shrink fit chucks.

Application: Dies for Drop Forgings , Aluminum / low Pressure Die Casting, Extrusion, Containers & liner, Punches, Plugs, Holdez , Injection moulds Etc.

Mode of Supply: Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website www.h13steel.in / https://www.viratsteels.com/h13.html

🌐https://www.viratsteels.com 📨 [email protected] 📞 +91-98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#h13toolsteels#h13steel#h13diesteel#din 2344#aisih13

3 notes

·

View notes

Text

FIBC Liners Bags

Alpine FIBC PVT.LTD. is a best manufacturer, exporters and suppliers of high quality FIBC Liners & Container FIBC Liners Bags in India, USA, Germany, France, UK, Italy, Canada, Spain, Netherlands, Portugal, Greece, Sweden, Argentina, Chile, Poland. A bulk bag can be fitted with an inner bag, which we call a liner. This liner provides additional protective properties against air and water vapor migration and the effect of light. Alpine FIBC can manufacture liners in the following materials: LDPE, LLDPE, MDPE, HDPE, PA, EVOH or aluminum. Loose, Glued, Tabbed, Stitched Liners, EVOH Liner, Baffle Liner, Aluminum, Foil liner, Conductive, Antistatic liner.

#FIBC Liners Bags#FIBC Liners Bags Manufacturers#FIBC Liners Bags in India#Container FIBC Liners Bags

2 notes

·

View notes

Text

High Density Polyethylene (HDPE) Prices Trend | Pricing | News | Database | Chart

High-Density Polyethylene (HDPE) is one of the most widely used thermoplastic polymers, prized for its strength, durability, and versatility. It finds applications in a wide range of industries, from packaging to construction, automotive to consumer goods. As a key polymer in global markets, HDPE prices are subject to fluctuation, influenced by a variety of factors such as raw material costs, production capacities, supply and demand dynamics, and geopolitical events. Over the years, HDPE pricing has seen considerable volatility, which can impact production costs, profitability, and the final pricing of goods across sectors. The price trends of HDPE are of particular interest to manufacturers, suppliers, and buyers looking to optimize costs and make informed purchasing decisions.

One of the primary factors driving the prices of HDPE is the cost of its raw material: ethylene. Ethylene, which is primarily derived from natural gas or petroleum, is the building block for HDPE production. As such, fluctuations in global oil prices or changes in the availability of natural gas can significantly affect the cost of producing HDPE. In periods when crude oil prices rise due to geopolitical tensions, supply disruptions, or changes in global demand, the price of ethylene also increases, which, in turn, raises the price of HDPE. Conversely, when crude oil prices decrease, manufacturers may see lower HDPE production costs, leading to more favorable pricing in the market.

Get Real Time Prices for High-Density Polyethylene (HDPE) : https://www.chemanalyst.com/Pricing-data/hdpe-7

Another factor influencing HDPE prices is the global supply and demand balance. Demand for HDPE is strong in many sectors, including packaging, construction, agriculture, and automotive, as its chemical properties make it resistant to moisture, chemicals, and impact. It is used in a wide array of products, such as plastic bottles, pipes, and containers, as well as plastic films and liners. Any fluctuations in demand from these key industries can lead to price changes. For example, during periods of increased consumer demand for packaging or construction materials, the demand for HDPE can outstrip supply, leading to price hikes. Conversely, during periods of slower economic growth or reduced demand from key markets, prices may stabilize or fall.

The production capacity of HDPE manufacturers also plays a key role in determining price fluctuations. Overcapacity in the production of HDPE can lead to lower prices, as manufacturers compete to sell their products. However, when production is limited or reduced due to maintenance, plant closures, or capacity restrictions, the reduced supply of HDPE can cause prices to rise. In addition, factors such as the availability of feedstock, transportation costs, and infrastructure limitations can also influence the production costs associated with HDPE, thus affecting overall pricing trends.

Geopolitical factors and trade policies can further impact HDPE pricing, as these can affect the availability of raw materials, the cost of production, and the price of shipping. Trade tariffs and sanctions, for example, can increase the cost of importing or exporting HDPE, leading to higher prices in certain regions. Additionally, political instability in key HDPE-producing regions can disrupt supply chains, resulting in price hikes due to supply shortages. On the other hand, trade agreements and favorable policies may help stabilize prices by improving access to resources and reducing trade barriers.

Regional variations in HDPE prices are another important consideration. While the global price of HDPE can be influenced by many of the aforementioned factors, local market conditions can cause price differences in different regions. For example, regions with higher production capacities may see lower prices due to a more abundant supply, while regions with limited access to raw materials or production facilities may experience higher costs. The cost of labor, energy, and logistics in different regions also plays a role in determining local pricing trends. These regional disparities highlight the importance of keeping track of both global and local market developments when assessing the price of HDPE.

The rising demand for sustainable and eco-friendly materials has also impacted the pricing of HDPE in recent years. As environmental regulations tighten and consumer preferences shift toward more sustainable products, the cost of recycling HDPE and producing eco-friendly alternatives can drive prices up. The demand for recycled HDPE (rHDPE), in particular, has grown, as it is seen as an environmentally responsible alternative to virgin HDPE. However, the cost of processing and recycling HDPE can be higher, which can result in price increases for rHDPE products.

In addition to these fundamental factors, market speculation and trading in commodity markets can also contribute to short-term price fluctuations. Investors and speculators who trade HDPE futures contracts may drive prices higher or lower based on anticipated supply and demand conditions, geopolitical events, or broader economic trends. While these price swings are typically short-term in nature, they can still have a significant impact on the day-to-day pricing of HDPE in global markets.

For businesses that rely on HDPE as a key material in their production processes, staying informed about price trends is essential for making informed purchasing decisions. By closely monitoring market developments, raw material prices, and production capacities, companies can better anticipate price movements and adjust their purchasing strategies accordingly. Strategic sourcing, long-term contracts, and hedging strategies can all help mitigate the impact of price fluctuations and secure stable pricing for HDPE.

In conclusion, the prices of High-Density Polyethylene are influenced by a complex interplay of factors, including raw material costs, production capacities, supply and demand dynamics, geopolitical events, and regional market conditions. As a vital material used in a variety of industries, HDPE pricing can experience significant volatility, which affects the cost structure of many products. Understanding the factors that drive HDPE prices is crucial for businesses and consumers looking to navigate the ever-changing landscape of this essential polymer.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#HDPE Price#HDPE Prices#HDPE Pricing#High Density Polyethylene Price Monitor#High Density Polyethylene Price

0 notes

Text

Bulk Bags' Crucial Function in Industrial Packaging

Finding the best FIBC bags supplier is essential when looking for bulk packaging solutions for businesses that need long-lasting, effective, and safe storage and transportation solutions. Flexible Intermediate Bulk Containers, or FIBC bags, are the preferred option for managing a variety of materials, including industrial chemicals and agricultural products. These multipurpose bags are renowned for their durability, adaptability, and capacity to transport heavy loads, which makes them the perfect choice for a variety of industries.

FIBC Bags: What Are They?

Weaved polypropylene, a sturdy material that offers strength without adding undue weight, is used to make FIBC bags. These bags are ideal for industries that need to move or store large, heavy items because they can hold materials weighing up to thousands of kilograms. With a variety of sizes, liners, and spouts for controlled filling and emptying, FIBC bags can be customized to meet the demands of a particular industry.

The affordability of FIBC bags is one of their main benefits. Businesses can reduce storage and transportation expenses while maintaining safe handling by using fewer containers to move large quantities. FIBC bags are also recyclable and reusable, which makes them an environmentally friendly option for packaging.

Businesses That Gain from FIBC Bags

FIBC bags are used in many different industries because of their versatility. Here's a closer look at their applications in various industries:

Agriculture: Bulk amounts of grains, seeds, and animal feed are frequently stored and transported in agriculture using FIBC bags. Agricultural products are kept safe from spoiling during storage and transportation thanks to their sturdy design and moisture-resistant qualities.

Construction: Sand, gravel, and other building supplies are perfect for transportation in FIBC bags. They are an effective way to move materials because of their durability, which guarantees that they can tolerate the weight and rough treatment frequently found on building sites.

Chemical Industry: Packaging that can securely hold powders, granules, and hazardous materials is frequently needed in the chemical industry. Both the supplier and the end user can rest easy knowing that FIBC bags offer a safe solution that stops contamination and leaks.

Pharmaceuticals: To store and transport sensitive goods, pharmaceutical companies use FIBC bags made with strict hygienic requirements. To satisfy the exacting standards for quality and cleanliness in this sector, specialized liners and coatings are available.

Recycling: The recycling sector also makes extensive use of FIBC bags for the collection, storage, and transportation of recyclables. Because of their strength and capacity, they are a cost-effective waste management solution that aids recycling facilities in effectively running their businesses.

Advantages of FIBC Bags

FIBC bags are a popular option for bulk packaging in these industries due to a number of advantages:

High Capacity and Cost-Effectiveness: FIBC bags lower storage and transportation expenses by enabling the transportation of large amounts of materials in fewer containers. Businesses that deal with large quantities of bulk materials will particularly benefit from this.

Strength and Durability: FIBC bags are made of premium polypropylene and are intended to endure challenging circumstances and heavy loads. Because of their durability, they continue to function well even after being handled roughly or stored for a long time.

Why Work with a Trusted Supplier of FIBC Bags?

Selecting a trustworthy FIBC bag supplier is crucial to guaranteeing that your packaging requirements are satisfied with consistency and quality. A reliable supplier can offer industry knowledge and help you choose the ideal bag specifications for your particular needs. Working with a seasoned supplier also gives you access to strong, long-lasting FIBC bags that enhance productivity and safeguard your goods.

Sudarshan Add Pack: Your Reliable Supplier of High-Grade FIBC Bags

Sudarshan Add Pack is a reputable brand for companies in need of dependable FIBC bags. Sudarshan Add Pack provides a large selection of FIBC bags that are appropriate for a range of industrial requirements, with an emphasis on quality and client satisfaction. Sudarshan Add Pack, which is well-known for its dedication to offering long-lasting, customizable products, guarantees that each bag satisfies exacting quality standards and is made for effective, secure handling. The product line and experience of Sudarshan Add Pack can support your company's bulk packaging needs, whether you need standard or custom FIBC bags. For premium FIBC bags that offer dependability and value, collaborate with Sudarshan Add Pack.

0 notes

Text

0 notes

Text

Introduction to Container Liners

Container liners play an essential role in transporting bulk materials, particularly in industries where cleanliness, safety, and protection from contamination are paramount. A container liner is a protective barrier placed inside shipping containers to facilitate the transportation of dry bulk cargo, liquids, or even chemical products. They offer a cost-effective and efficient solution for transporting goods in a manner that prevents spillage, contamination, or exposure to external elements. This article delves into container liners, their applications, and the significance of container liner manufacturers and suppliers, especially in India.

Types of Container Liners

Container liners come in various types based on the material and the application for which they are used. Some of the most common types include woven polypropylene (PP) liners, polyethylene (PE) liners, and specialized liners for liquids. PP container liners are often favored for their durability and resistance to wear and tear, making them ideal for transporting abrasive goods. PE liners, on the other hand, are more suitable for food-grade applications, offering a smooth surface that prevents contamination. Many container liner manufacturers also produce specialty liners for chemical or liquid goods, equipped with additional features such as multiple layers or specific resistance properties.

Applications of Container Liners

Container liners are widely used across various industries due to their versatility and efficiency. Their primary application is in the bulk transportation of dry goods such as grains, seeds, sugar, and chemicals. In the food industry, container liners ensure that products remain uncontaminated by external particles or other goods previously shipped in the same container. In the chemical industry, they are used to transport sensitive materials that require protection from moisture, contamination, and other environmental factors. The use of Container liner sheet in India has gained traction due to its effectiveness in bulk handling, particularly in agricultural and industrial sectors.

Importance of Container Liners in Global Trade

With the growth of global trade, container liners have become increasingly important for logistics and supply chain efficiency. They allow companies to transport large quantities of goods without the need for expensive, specially designed containers. By using container liners, businesses can utilize standard containers while ensuring that the goods are safe from damage or contamination. Additionally, liners can help reduce turnaround times since they are easy to install and remove. For many companies, working with Container liners suppliers is a strategic move to ensure that they always have access to reliable liners that meet the specific needs of their cargo.

Benefits of Using Container Liners

Container liners offer several benefits that make them an ideal choice for businesses dealing with bulk materials. Firstly, they significantly reduce the risk of contamination, ensuring that goods arrive at their destination in optimal condition. Secondly, they help minimize wastage, as the liner prevents goods from adhering to the walls of the container. This is especially beneficial for transporting powders, granules, or other fine materials. Thirdly, container liners are cost-effective. They eliminate the need for cleaning containers after every use, reducing downtime and increasing the efficiency of the supply chain. Container liner manufacturers continue to innovate by developing liners with improved sealing and easy installation methods to enhance these benefits further.

Container Liner Sheet in India

In India, container liners are gaining significant popularity due to the country’s expanding industrial and agricultural sectors. Container liner sheet in India is now a crucial element in bulk transportation, helping industries like agriculture, pharmaceuticals, and chemicals to optimize their supply chains. Indian manufacturers produce a wide range of container liner sheets, catering to different needs. From food-grade liners to heavy-duty industrial liners, the products meet international standards and are widely exported. As India's logistics and transportation infrastructure continue to evolve, the demand for high-quality, cost-efficient container liner sheets is expected to rise.

Key Features of Container Liners

When selecting container liners, several key features should be considered to ensure optimal performance. These include durability, resistance to tearing, moisture resistance, and ease of installation. Depending on the cargo being transported, liners may also need to offer specific features such as UV protection, chemical resistance, or food-grade certification. Container liners suppliers offer a variety of liner options, making it essential for businesses to select liners that are compatible with the type of container being used and the nature of the cargo. For example, transporting chemicals may require a liner with multiple layers or specialized coatings to prevent leaks or contamination.

Role of Container Liner Manufacturers

Container liner manufacturers play a pivotal role in the supply chain by ensuring that businesses have access to high-quality liners that meet the stringent requirements of their industries. These manufacturers are continuously innovating, developing liners that offer better protection, easier installation, and longer life spans. Indian manufacturers, in particular, are known for producing liners that meet global standards while remaining competitively priced. With the rise of e-commerce and globalization, the demand for bulk transportation solutions has grown, leading manufacturers to expand their product offerings to meet the diverse needs of industries around the world.

How to Choose the Right Container Liner Supplier

Selecting the right container liners suppliers is crucial for ensuring the safety and efficiency of your logistics operations. When choosing a supplier, it's important to consider their track record, the range of products they offer, and their ability to deliver products that meet industry standards. Additionally, reliable suppliers should provide liners that are easy to install, durable, and cost-effective. In India, many container liner suppliers offer customizable solutions tailored to specific industry needs, which can be a key differentiator when handling sensitive or high-value cargo. Ensuring that your supplier has the right certifications and follows international guidelines is also vital for maintaining product quality and safety.

Environmental Considerations and Sustainability

As the world moves toward more sustainable practices, the production and use of container liners are also being scrutinized. Many Container liners manufacturers are now focusing on creating eco-friendly liners made from recyclable or biodegradable materials. These sustainable options are especially important in industries like food and agriculture, where the use of environmentally friendly materials aligns with broader sustainability goals. In India, the shift toward greener practices is becoming more pronounced, with manufacturers offering liners that are both functional and less harmful to the environment.

Conclusion: The Future of Container Liners

The demand for container liners is expected to grow as industries continue to seek cost-effective, reliable solutions for bulk transportation. In India, container liner sheet in India will play an increasingly important role as the country’s industrial and agricultural output expands. The growing importance of sustainability will also drive innovations in liner materials and designs, with manufacturers focusing on creating products that are both durable and environmentally friendly. For businesses looking to optimize their logistics operations, partnering with reputable container liners suppliers and manufacturers will be essential for staying competitive in a global market.

FAQs

1. What are the main uses of container liners?

Container liners are used primarily for transporting bulk goods such as food products, chemicals, grains, and powders. They protect the cargo from contamination and make it easier to load and unload goods.

2. Can container liners be reused?

While some container liners are designed for single-use, others can be reused depending on the material and the type of goods being transported. Reusable liners are often made of more durable materials and can be cleaned and reinstalled.

3. What factors should be considered when choosing a container liner supplier?

When selecting a container liner supplier, businesses should consider the supplier’s track record, product range, ease of installation, compliance with industry standards, and the ability to offer customized solutions based on the nature of the cargo being transported.

0 notes

Text

The Importance of High-Quality Hazardous Waste Containment Liners in the US

Inside the usa, supervising hazardous waste is an essential regular and prospering endeavor. Hazardous waste control liners play a vital cutoff in preventing the spillage of perilous materials into the soil and groundwater. These liners go about as hindrances, guaranteeing that risky materials are securely contained and do at certainly no point later on address a bet to the environment or human achievement. The reliability of those liners is fundamental for safeguarding secure and fulfilling waste control practices.

Picking the right hazardous Waste Rule Liners:

Picking Hazardous waste containment liners US is crucial for solid waste affiliation. Those liners are open in different substances, which joins HDPE (high-Thickness Polyethylene) and LLDPE (Direct Low-Thickness Polyethylene), each giving groundbreaking levels of attestation from created compounds and tremendous strain. Miles essential to pick liners in shape the specific necessities of the waste being contained, guaranteeing they can struggle with limit made reactions and regular conditions.

Hazardous waste containment liners US

The spot of trade dependably cowl suppliers:

further to administer liners, trade normal cowl (ADC) is another significant inquiry of landfill control. ADC materials are used to cowl waste expectedly to reduce smell, control wreck, and cutoff the effect of wind. The choice of an Alternate Daily Cover supplier US can overall affect the exhibit of landfill undertakings. ADC materials can chip away at the playfulness of risky waste control with the partner of giving additional layers of safety and rule.

Why charming subjects in each liner and ADC?

Splendid liners guarantee that dangerous substances are contained legitimately, even strong regions for as substances assist control with wasting profitably, reduce typical effect, and stay aware of landfill capacity. The two portions work everything considered to make significant solid areas for a control structure that defends the environment and general achievement.

Conclusion:

In outline, the significance of Hazardous waste containment liners US can not be misrepresented appearing differently in relation to safeguarding the organic parts and general flourishing. Likewise, boss is the constraint of picking serious solid areas for an Alternate Daily Cover supplier US to make unequivocal complete waste control. With all that considered, these components add critical strong regions to regularly fit waste discharge practices. Zeroing in on exceptional in every district guarantees that risky substances are controlled limit and carefully, offering expanded term gifts for the regular parts and society.

#Hazardous waste containment liners US#Best Geosynthetics Installer in Kentucky#Pond Builder in Kentucky#Pond liner suppliers US

0 notes

Text

The Versatility and Advantages of PP Jumbo Bags: A Comprehensive Guide

In the modern world of packaging and transportation, PP jumbo bags, also known as polypropylene jumbo bags, have emerged as essential tools for various industries. These large, flexible containers are designed to hold bulk materials, making them an ideal choice for businesses in sectors like agriculture, construction, chemicals, and food. This article will explore the features, benefits, applications, and environmental considerations associated with Jumbo Jumbo Bag, highlighting why they are the go-to choice for bulk packaging solutions.

Understanding PP Jumbo Bags

PP jumbo bags are made from polypropylene, a thermoplastic polymer that is widely used for its durability, lightweight properties, and resistance to chemicals. These bags are constructed using woven polypropylene fabric, which gives them strength and flexibility. Typically, a jumbo bag can hold between 500 kg to 2000 kg of material, making them an efficient solution for transporting large quantities of products.

The design of a PP Jumbo Bags often includes a square or rectangular shape, with an open top and a bottom that can be easily closed. Many bags feature additional components, such as discharge spouts, lift loops, and inner liners, which enhance their usability and versatility.

Key Features of PP Jumbo Bags

Durability: The woven structure of polypropylene provides exceptional strength, allowing jumbo bags to withstand heavy loads and rough handling. They are resistant to tearing, puncturing, and abrasion.

Lightweight: Compared to traditional packaging materials, PP jumbo bags are significantly lighter. This characteristic helps reduce shipping costs and makes handling easier.

Versatile Sizes: Jumbo bags come in various sizes and configurations, allowing businesses to choose the most suitable option for their specific needs. Custom sizes can also be produced to meet unique requirements.

Moisture and Dust Resistance: Many PP jumbo bags are designed to be moisture-resistant, which is essential for protecting products like grains and chemicals from damage. Additionally, they can be lined to provide added protection against dust and contaminants.

Eco-Friendly Options: While traditional polypropylene bags are not biodegradable, some manufacturers offer biodegradable or recyclable variants, contributing to more sustainable packaging solutions.

Advantages of Using PP Jumbo Bags

Cost-Effective: One of the primary reasons businesses opt for PP jumbo bags is their cost-effectiveness. They are less expensive than rigid containers and can be reused multiple times, reducing overall packaging expenses.

Space-Efficient: When empty, jumbo bags can be flattened and stored easily, saving valuable warehouse space. This feature is particularly beneficial for businesses that require efficient inventory management.

Easy Handling: PP jumbo bags are designed with features like lift loops, making them easy to load and unload with forklifts or other machinery. Their lightweight nature also simplifies manual handling.

Bulk Packaging Solutions: These bags are ideal for bulk shipping and storage, allowing companies to minimize the number of individual containers required for transporting large quantities of products.

Protection from Environmental Factors: The robust design of PP jumbo bags protects the contents from environmental factors such as moisture, dust, and UV rays, ensuring product integrity during transport and storage.

Applications of PP Jumbo Bags

PP jumbo bags are used across various industries, reflecting their versatility:

Agriculture: Farmers and agricultural suppliers use jumbo bags to store and transport grains, seeds, fertilizers, and animal feed.

Construction: The construction industry employs PP jumbo bags for carrying sand, gravel, and other bulk materials.

Chemicals: Chemical manufacturers utilize these bags for packaging powders, granules, and other bulk chemical products, ensuring safety and compliance with regulations.

Food Industry: Many food manufacturers and distributors use PP jumbo bags for bulk packaging of products like sugar, flour, and rice, as these bags can be designed for food safety.

Recycling: PP jumbo bags are also used in the recycling industry for collecting and transporting recyclable materials, providing a sustainable solution for waste management.

Environmental Considerations

While PP jumbo bags offer numerous advantages, it is essential to consider their environmental impact. Polypropylene is a petroleum-based product, which raises concerns regarding its sustainability. However, many manufacturers are taking steps to produce eco-friendly variants that are recyclable or biodegradable.

Businesses can also contribute to sustainability by reusing PP Jumbo Bag whenever possible and ensuring proper disposal at the end of their life cycle. Some companies have implemented recycling programs to recover and repurpose used bags, promoting a circular economy.

Conclusion

PP jumbo bags have become an indispensable part of the packaging landscape due to their strength, versatility, and cost-effectiveness. Their applications across various industries showcase their adaptability to meet the demands of bulk packaging. As businesses continue to prioritize efficiency and sustainability, the use of PP jumbo bags is likely to grow, solidifying their place as a preferred solution for bulk transportation and storage needs. With ongoing innovations in materials and designs, these bags will continue to evolve, providing even greater benefits for users and the environment.

Frequently Asked Questions

1. What are PP jumbo bags made of? PP jumbo bags are made from woven polypropylene, a durable thermoplastic polymer that is lightweight and resistant to moisture, chemicals, and tearing.

2. How much weight can a PP jumbo bag hold? Typically, PP jumbo bags can hold between 500 kg to 2000 kg (approximately 1,100 to 4,400 lbs), depending on the bag’s design and specifications.

3. Are PP jumbo bags reusable? Yes, PP jumbo bags are designed for multiple uses. Many businesses reuse them for transport and storage, which enhances their cost-effectiveness.

4. Can PP jumbo bags be customized? Yes, PP jumbo bags can be customized in size, shape, and design to meet specific requirements. Features like discharge spouts and lifting loops can also be added.

0 notes

Text

Customizing U Panel Bulk Bags: Tailoring Solutions for Your Industry

U panel bulk bags, also known as U panel FIBC bags, have become an essential packaging solution across multiple industries. The versatility and durability of these bags make them the preferred choice for transporting bulk materials. With the ability to customize the U panel bag to specific industrial needs, companies can optimize their logistics and storage operations. In this article, we will explore the advantages of U panel bulk bags, their customization options, and how a reliable U panel bulk bag manufacturer can help businesses find the perfect solution for their requirements.

Understanding U Panel Bulk Bags

A U panel bulk bag is designed with three panels of fabric that are sewn together, creating a "U" shape. This construction provides the bag with its characteristic strength and shape retention, allowing it to hold large quantities of bulk material without sagging or tearing. The design ensures even distribution of weight, making it ideal for industries dealing with heavy or dense materials.

For industries like agriculture, mining, chemicals, and construction, the U panel FIBC bag is indispensable due to its ability to safely store and transport powders, granules, or coarse materials. However, what sets U panel bulk bags apart from other flexible intermediate bulk containers (FIBCs) is their high degree of customizability. Depending on the industry, manufacturers can tailor these bags to meet specific requirements, enhancing both efficiency and safety.

Why Customization Matters in U Panel Bulk Bags

When selecting packaging solutions, one size does not fit all. Customizing U panel bulk bags ensures that a business’s unique demands are met, whether it’s handling hazardous materials, optimizing storage space, or enhancing the ease of transport. A quality U panel bulk bag manufacturer will offer various customization options that cater to the specific needs of different industries. These can include:

Size Adjustments: U panel bags come in various sizes to accommodate the storage or transportation of different material volumes. Customizing the size allows businesses to optimize space in warehouses or during shipping.

Weight Capacity: Depending on the material, the weight capacity of the bag can be adjusted. Industries dealing with heavy materials can opt for reinforced U panel FIBC bags that ensure the bags remain stable and do not tear under pressure.

Filling and Discharge Options: U panel bulk bags can be customized with different filling and discharge mechanisms, such as spouts, duffel tops, or open tops, and discharge options such as flat bottoms or spout bottoms, making the process of loading and unloading materials more efficient.

Lifting Loops: Custom lifting loops can be designed to allow for easy handling of the U panel bags with forklifts or cranes, essential for industries requiring quick and secure transportation of bulk goods.

Liners: For industries dealing with moisture-sensitive materials or hazardous chemicals, a U panel bag can be customized with internal liners. These liners provide an additional barrier that protects the contents from contamination, moisture, or leaks.

Industries Benefiting from U Panel FIBC Bags

Many industries rely on U panel FIBC bags for their day-to-day operations. Some of the industries that benefit the most from these customized bags include:

Agriculture: Farmers and agricultural suppliers use U panel bulk bags to store and transport grains, seeds, and fertilizers. Customization options like UV-resistant fabric, breathable materials, or added liners help preserve the quality of agricultural products and ensure that they arrive at their destination in optimal condition.

Mining: The mining industry frequently transports heavy materials like ores, minerals, and rocks, requiring bulk bags that can withstand considerable weight. Customized U panel bag with reinforced seams and durable lifting loops ensure that these materials are moved safely.

Construction: Construction sites need bulk bags for storing and moving sand, gravel, cement, and other building materials. U panel FIBC bags provide a reliable solution, especially when customized for heavy-duty usage.

Chemicals and Pharmaceuticals: For industries handling sensitive chemicals or pharmaceutical ingredients, U panel bulk bags can be customized with liners and anti-static materials to prevent contamination, ensure product safety, and maintain compliance with safety regulations.

Food Industry: U panel bags used in the food industry can be tailored to meet strict hygiene standards, ensuring that food-grade materials like flour, sugar, and starch are kept safe during transport. These bags can be customized with food-safe coatings, ensuring the safety and quality of the contents.

U Panel FIBC Bags in India: Meeting Global Standards

India is emerging as a significant player in the global U panel bulk bag market, with numerous manufacturers offering high-quality, customized solutions. The U panel FIBC bag in India is manufactured in compliance with international standards, ensuring that businesses across the world receive bags that meet their specific needs.

Indian manufacturers have honed their production processes, focusing on quality control, sustainability, and customization. Many U panel bulk bag manufacturers in India offer eco-friendly options, including bags made from recycled materials or those designed to be reused multiple times, reducing the environmental impact of bulk packaging.

Indian manufacturers also offer competitive pricing, making them a cost-effective choice for companies looking to import customized bulk bags. Whether a business needs UV-resistant bags for agriculture, chemical-resistant liners for hazardous materials, or extra-strong lifting loops for construction, Indian manufacturers provide a wide range of options to meet the demands of different sectors.

The Role of a Reliable U Panel Bag Manufacturer

Choosing the right U panel bulk bag manufacturer is crucial for businesses looking to tailor packaging solutions to their specific requirements. A reputable manufacturer will offer more than just a standard bag; they will provide guidance on the best customization options for the industry. Key factors to consider when selecting a U panel bag manufacturer include:

Experience and Expertise: A manufacturer with extensive experience in producing U panel FIBC bags for various industries will understand the unique challenges of each sector. They will be able to recommend the most suitable materials, designs, and custom features.

Quality Control: Look for manufacturers that prioritize quality control, ensuring that every bag meets strict safety and durability standards. This is especially important for industries dealing with hazardous materials or food products, where contamination risks are high.

Customization Options: The best manufacturers will offer a wide range of customization options, from bag size and weight capacity to specialized liners and lifting loops, ensuring that each bag meets the client’s specific needs.

Sustainability: As environmental concerns become increasingly important, manufacturers that offer sustainable solutions, such as biodegradable materials or reusable U panel bags, will be the preferred choice for businesses looking to reduce their carbon footprint.

Conclusion

Customizing U panel bulk bags allows businesses to find solutions that fit their unique requirements, enhancing the efficiency of their operations. Whether you need a U panel FIBC bag in India or anywhere else in the world, a reputable U panel bulk bag manufacturer will help you design the perfect packaging solution. With a range of customization options available, businesses can ensure they are using the most suitable bulk bags to transport and store their materials, while also benefiting from durability, cost-efficiency, and safety.

Frequently Asked Questions (FAQs)

How is a U Panel Bulk Bag different from other bulk bags? The U Panel design provides greater stability and strength, making it ideal for handling heavier loads compared to some other FIBC designs.

Can U Panel Bulk Bags be customized? Yes, U Panel Bulk Bags can be fully customized in terms of size, fabric type, liners, spouts, and printing to meet the specific needs of various industries.

Which industries use U Panel Bulk Bags? U Panel Bulk Bags are used in a wide range of industries, including agriculture, construction, mining, chemicals, and pharmaceuticals, due to their durability and flexibility.

0 notes

Text

Looking for Pre-Hard H13 tool steel with its standard hardness of 460-500 BHN!!

The perfect tool steel for hot work and cold work applications… Get in touch with us today to place your requirement! #h13steel #din2344 #aisih13…

The equivalent steel grade H-13 / SKD61 / AISI H13 normally available in the annealed condition but in some specific applications, we provide Pre-Hard H13 with its standard hardness 460-500 BHN. Utilized for ejector pins, apparatus holders and shrink fit chucks.

Application: Dies for Drop Forgings , Aluminum / low Pressure Die Casting, Extrusion, Containers & liner, Punches, Plugs, Holdez , Injection moulds Etc.

Mode of Supply: Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website www.h13steel.in / https://www.viratsteels.com/h13.html

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#h13steelmanufacturer#h13steel#h13steelbarexporter#din2344#aisih13#hot work steel#SteelTrades#MetalTraders#DieSteels#ToolSteel

3 notes

·

View notes

Text

#FIBC Liners Bags#FIBC Liners Bags Manufacturers#FIBC Liners Bags in India#Container FIBC Liners Bags

2 notes

·

View notes