#Construction : Welded

Explore tagged Tumblr posts

Text

Me when blue collar men uhhhh

11 notes

·

View notes

Text

I think now is a good time to remind people to go into a trade. Whether or not you ever actually use your license for your career, it can be your biggest asset in community organizating. Because if you want to house people, you need people who can build the houses. If you want to bring power or the Internet to areas without, you need people who can run the wire. You want to build a community center? A soup kitchen? You need a construction license. You want to repair busses or your car breaks down on the way to a protest? You need a mechanic license. Hell, you need someone with a CDL license to transport supplies across the country. Going even further, if y'all are actually going to revolt against the government, there has to be people with the skills to keep a community afloat once we separate ourselves from the government.

This goes double for able-bodied or mostly able-bodied people. Because if someone is in a wheelchair and a massive hurricane knocks a tree through their roof, there needs to be people available with the skills to fix it. If someone bedridden relies on their heating system to live through a winter, there needs to be people with the skills to make it happen. We have to learn these skills so we may use them to also lift up those who cannot. Because the reality is, there are a lot of people left behind by the system that will absolutely be decimated by the overturn of that system. We have to be there with organized safety nets intact.

You want to get organized, get skilled. Learn a trade, and use it to build up your community.

#im personally going into welding or construction#and a lot of programs are no longer than a year#a contractors lisense is only 30 days in my state#get organized get skilled#stari wont shut up

7 notes

·

View notes

Text

i hope the girls at the grocery store thought i was pretty wearing my dirty ass welding clothes with shmutz all over my face

#i highly value the opinion of random grocery store girls#i look like a dirty construction worker#i need a shower#girlblogging#girl blogging#just girly thoughts#just girly posts#hell is a teenage girl#girly welding#welding

21 notes

·

View notes

Text

A Morning Weld (December, 2024)

5 notes

·

View notes

Text

iron worker

14 notes

·

View notes

Text

ASTM A234 WPB Pipe Fittings

from @manilaxmifittings

#balancebikes#steel#bike8aerocarbon#carbon#ecosteel#carbonwheels#forgedcarbon#steelbuilding#glosscarbon#carbonfiber#honeycombcarbon#impressivecarbon#steelcontainers#wood#metal#steelware#welding#constructionmachinery#wheels#construction#splitwheels#corimawheels#glass#powermill#concrete#heat#woodart#airsystems#compoundbow#insulation

3 notes

·

View notes

Text

5 notes

·

View notes

Text

#brooklynnewyork#brooklyn#nyc#newyork#newyorkcity#brooklynny#queensnewyork#bronxnewyork#brooklynbridge#brooklynart#brooklynrealestate#queens#bushwickbrooklyn#brooklynnyc#downtownbrooklyn#brooklynblogger#welding#house#construction#rna#welder#casa#rnawelding#shop#repairs#belmontave#homeownerlife#bodega#eastny#brooklynlife

6 notes

·

View notes

Text

Seismic Pallet Rack, Racking, new and used, shelving, cantilever rack (concord / pleasant hill / martinez)

#d uprights#8' long x 4#d#GREEN SEISMIC TEARDROP UPRIGHTS. Ask for the innovative uprights that are knocked down for ease of shipping; and are easily set up with nut#Then we have ORANGE BEAMS that are 6'#8'#9'#10'#12' long with capacities from 2200 lbs./pair to 8204 lbs./pair.#Don't forget about the wire decks made necessary by the fire dept. They want you to have “flow through” decks that allow the sprinklers to#the heat to rise#set off the alarm and activate the vents. Call for prices.#We also sell USED PALLET RACK if it is AMERICAN SEISMIC DESIGN. Chinese made and most of the used pallet rack are not seismic design. Chine#increasing the number of connector rivets on the ends of the beams from 2 to 3#and sometimes requiring backers (double columns) on the upright channels to at least the first beam level.#How do you get your forklift from the ground to your dock or the bed of a truck? Use a MOBILE YARD RAMP. They roll around to various locati#Ground-to-trailer application best served with 36' ramp including a 6' level off. Note the lip on the top end that is welded onto a frame f#000 lbs. capacity as opposed to a flimsy hinged steel plate that doesn't have 20#000 lbs. capacity. Other sizes and capacities available.#All steel welded construction. MADE IN AMERICA. Ramps made in China do not have quality control of their steel. Therefore#the capacities cannot be guaranteed.#Add the full undercarriage with solid 18#or 48“ length of forks. We used to sell used pallet jacks but within a few weeks the customer would come back and want to get a refund beca#WHERE-IS#CASH AND CARRY#NO REFUNDS#CREDITS#WARRANTY#EXCHANGES OR RETURNS#Cash and carry

2 notes

·

View notes

Text

Experience Unmatched Quality of Jindal Spiral Welded Coated Pipes with Tube Trading Co.

Looking for top-notch spiral welded pipes? Look no further! Jindal Spiral Welded Coated Pipes offer exceptional quality and durability. As the leading distributor in Vadodara, Gujarat, we provide reliable and efficient solutions for all your piping needs.

Trust in our expertise and experience the difference today!

#Jindal spiral Welded Coated Pipes#Jindal Spiral Welded Pipes#Jindal Spiral Welded Pipes Distributor in Vadodara#Gujarat#steel industry#steel companies#industrial#piping material#plumbing industry#construction structure#construction sites#tubetrading

8 notes

·

View notes

Text

The collapsed northern wall of the reactor building of Chernobyl Reactor 4.

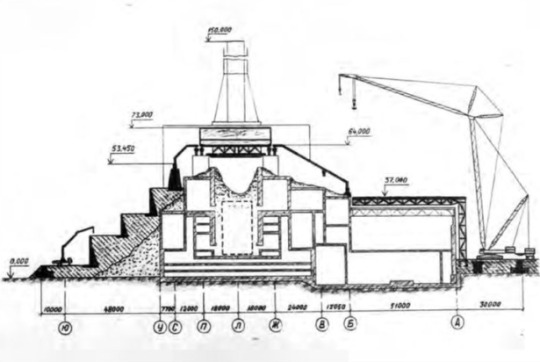

A cross section diagram of the final design of the Sarcophagus.

The Cascade Wall (seen on the left of the diagram above) was one of the most difficult sections of the Sarcophagus to build, but it was one of the most important. It covered the partially collapsed northern wall of the reactor building, as well as the pile of highly radioactive debris left by the explosion. The wall was composed of four stepped tiers, and topped out at 54 meters above the ground.

This was the first part of the Sarcophagus to begin construction. To begin, the men of Sredmesh Unit US-605 installed "Pioneer Walls" (I will make a post on these later) to lessen the gamma radiation at the site. They then filled the space between the Pioneer Walls and the reactor with concrete. On top of this base, they placed huge prefabricated metal wall sections, like the one seen below.

Demag 21 prepares to lift a section of the Cascade Wall into place.

The first tier of the Cascade Wall during installation.

Once the wall sections were all in position, remote controlled concrete pump trucks (seen on the left of the above image) filled the space between the wall and the reactor building, in a similar manner to the area between the Pioneer Walls and the reactor building. This process was repeated until the Cascade Wall was completed.

Crews help to position a section of the third tier of the Cascade Wall before it is lifted into place by crane. These sections weighed more than 120 tons.

Note the white cabin on the crane. These were built similarly to the bathyscaphes used to survey the reactor building during construction of the sarcophagus, with air filters and thick lead sheeting.

The first and second halves of the fourth and final tier of the Cascade Wall, on the left and right respectively.

The men of Sredmash Unit US-605 Shift Four, who installed the fourth tier of the Cascade Wall.

I could not find their names, but I felt compelled to share this photo in their honor.

Without the Cascade Wall, radiation levels would have remained dangerously high and radioactive debris would have been left exposed to the atmosphere. Additionally, it shored up the collapsed northern wall of the reactor building, which had to support some of the weight of the roof section of the Sarcophagus. The men who participated in the project are some of the worst affected amongst the liquidators in terms of sickness.

Men of US-605 fourth shift celebrate the completion of the Cascade Wall with a ceremonial flag raising.

[Image descriptions:

First image: This black and white photo shows the partially destroyed northern wall of the reactor building. Twisted metal and piles of concrete rubble sit on various ledges within the collapsed wall. A network of pipes is visible about three fourths of the way up the wall. The main circulation pumps of the reactor sit partially covered by rubble at the bottom of the wall. Burns cover much of the concrete. An even gravel surface makes up the foreground of the photo, and a large crane is on the right. The striped circular stack of the plant rises in the top left of the image.

Second image: A cutaway diagram of the sarcophagus viewed from the west side of the reactor building. It shows the original structure of the power plant and the plans for the structure of the sarcophagus. From left to right it consists of the four steps of the Cascade Wall, then a slight incline up to the roof section over the reactor hall, then another more gradual slope down to the section covering the turbine hall.

Third image: A black and white photo showing a large crane on the right preparing to lift a large section of metal wall on the ground in front of it. The wall has a small section to help it stand on its own protruding at ninety degrees at its bottom, with angular pipes bracing it against the wall. The crane is lifting it via its hook, which is attached in the shape of an uppercase A. A large metal brace holds the two halves of the lifting section apart above the wall section.

Fourth image: A black and white photo showing the early construction of the cascade wall. The collapsed northern wall sits above the newly placed first section of the cascade wall. The wall is on a raised embankment, below which sit a concrete pump truck sticking its spindly white boom into the wall to add concrete and help build the structure.

Fifth image: The same large crane is lifting another section of the cascade wall just off of the ground. The first and second tiers of the wall can be seen in place in the background of the photo. Nine men, dwarfed by the section of wall they are working on, pull on ropes attached to the wall to angle it correctly for placement on top of the previous sections. The heavy protective cabin of the crane can be seen mounted on the crane chassis, a large white metal box with thick windows to protect the driver from radiation.

Sixth and seventh images: these twin images show the lifting of the two final sections of the cascade wall into place. These sections are both shown in the air on the way to their destination.

Eighth image: A group photo of about forty men in front of the destroyed reactor during the construction of the cascade wall. The wall is only partially finished, but the men are posing in two rows for a photo (crazy!). The men are dressed in dark khaki/deep blue clothes, and white sanitary caps that cover their hair and prevent contaminated. Some of them are also wearing masks or respirators.

Ninth image: this color image shows another gathering of liquidators around a blue concrete pump with a red banner attached to the end of its pump arm. The arm is fully extended about a hundered feet into the air. The group is a lot more informal. The cascade wall is seen fully completed behind the men, but several white and orange concrete pumps still work on other parts of the Sarcophagus. The large yellow crane used to lift the wall sections into place sits idle on the right of the image. Also in this image is the iconic red and white striped chimney of the plant.

#chernobyl#chernobyl hbo#nuclear#nuclear power#radiation#accidents and disasters#history#reactor#autism#disaster#concrete#remote control#concrete pump#construction equipment#construction#welding#heavy lifting#chernobyl disaster#collapse#explosion#cleanup#soviet#soviet union#ussr (former soviet union)#ussr#ussr history#reactor 4#sarcophagus#chnpp#nuclear disaster

8 notes

·

View notes

Text

How do potholes form?

Is there anything worse than driving down a road riddled with potholes? Not just these potholes are an annoyance but they can also be quite dangerous. These potholes are dreading and plaguing drivers ever since the construction of the first paved road.

While these potholes seem harmless at the first look, they can cause substantial damage to your vehicle. As these potholes pose potential hazards, we are sure you want to know the causes, the ways to minimize them and something about pothole repairs in Sydney.

How these potholes are formed?

Essentially, a pothole is a dip or deviation in a paved road’s smooth surface. They are formed when groundwater seeps underneath the pavement. As the water freezes underneath, it expands, the pavements swells, and starts cracking. As the ice melts, the gaps become present underneath the paved surface and as a result, the pavement weakens.

To make the matters worse, every time a car drives over this weakened surface, the pavement continues to break. After some time, the pieces of the roadway become dislodged and displaced completely. And so, you officially have a pothole now.

These potholes should be repaired on time. While we know all the civil work in Sydney is taken care of by the civil authorities, the civilians can also take voluntary roles in at least taking care of the roads. To get pothole repairs in Sydney at affordable costs, reach out to us. We will be glad to assist you.

6 notes

·

View notes

Text

It's supposed to be an okay day today but if the noise won't fucking stop I'm gonna have to resort to violence—

#I don't mind the construction but their music is fucking ECHOING in this godawful way and I'm going to vomit#and the chainsaw and welding??? GO TO HELL#ALSO THE MOTHERFUCKING NEVERENDING LATO LATO I'M GONNA BASH YOUR MISSHAPEN GEADS IN IF YOU KEEP AT IT#holy FUCK I have a headache and migraine all at once#blog#personal stuff

3 notes

·

View notes

Text

mid day doing a little mini-jog out back to my car to grab my welding hood fast as hell before the foreman comes back and finishes the job himself bc i want to weld so bad

#its been SO FUCKING LONG since i last mig welded its so relaxing#construction welding is usually stick and my most recent union welding class was flux core cuz i was already stick certified#i should try to get more certifications over the summer when im not welding tbh

6 notes

·

View notes

Photo

2 notes

·

View notes