#Compact Valve

Explore tagged Tumblr posts

Text

Habonim C25 Sr-3 Met Pneumatic Actuator Compact Valve | Auto2mation

The Habonim C25 SR-3 MET Pneumatic Actuator Compact Valve is a high-performance valve designed for efficient control in industrial automation systems. Featuring a robust pneumatic actuator, it ensures precise control of fluid and gas flow in a variety of applications. The compact design allows easy installation in space-restricted environments, while its durable construction guarantees long-lasting operation. Ideal for use in industries such as chemical processing, power generation, and marine automation, this valve provides reliability and superior performance. The Habonim C25 SR-3 MET is a trusted solution for enhancing automation and optimizing control systems in complex operations.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Separator#Marine equipment#control valve#Habonim#Compact Valve

0 notes

Text

Buy Close Valves | Compact Valve | Svarrnim Forgings

Svarrnim Forgings' Compact Self Close Valves are designed to provide reliable and efficient flow control. With the ability to close valves automatically, these valves ensure safety and prevent leaks.

0 notes

Text

(i'm procrastinating) (apropos nothing) Käärijä is sooo sexy. ugh. i can't stop watching his videos.

#the compactness. the nails. the joy.#*chefs kiss*#don't mind me i just try this as a release valve so maybe i can finally get back to writing#mmmmm statistics#blergh

2 notes

·

View notes

Text

Discover Tecnik Valves' multiple spring pneumatic actuators—compact, field-reversible, and engineered for high thrust and precise control in throttling, modulating, and on-off applications across industrial processes.

#Multiple spring actuators#pneumatic actuators#high-thrust actuators#Tecnik Valves#linear valve actuators#industrial valve automation#field-reversible actuators#diaphragm actuators#control valve actuators#compact actuator design

0 notes

Text

Maximising Efficiency through Size Reduction Solutions

In today’s fast-paced world, manufacturing efficiency is essential for businesses to not only retain their market share but to expand as well. Companies in all sectors are always on the lookout for ways to streamline processes, minimise waste, and ultimately increase profits. One area that holds promise for improvement is size reduction solutions. These solutions involve a variety of technologies and tools aimed at breaking materials down into manageable particles. Let’s delve into how size reduction can enhance efficiency in certain areas.

0 notes

Text

Industrial dampers manufacturer in Pune

Pune, a bustling hub of industrial activity in India, is home to numerous manufacturing companies, including Parth Valve & Hoses Pvt. Ltd, a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation, quality, and customer satisfaction, Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs

A Legacy of Excellence

Founded with a vision to deliver top-notch industrial solutions, Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a reputation for producing some of the best Industrial Dampers manufacturer in Pune market. The company’s dedication to maintaining high standards is evident in every product they manufacture.

Industrial Dampers

Cutting-Edge Technology and Innovation

Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize state-of-the-art machinery and employ advanced manufacturing techniques to ensure their products meet the highest quality standards. By continuously investing in research and development, Parth Valve stays ahead of the curve, delivering innovative solutions that cater to the evolving needs of their clients.

Industrial Dampers

Comprehensive Product Range

Parth Valve, the Industrial Dampers manufacturer in Pune, offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:

Butterfly Dampers: Known for their compact design and efficient operation, butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.

Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment, providing a reliable seal even in high-temperature environments.

Louver Dampers: Designed for precise airflow regulation, louver dampers are used in various industrial applications to control ventilation and exhaust systems.

Multi-Louver Dampers: These dampers offer superior control over airflow, making them suitable for complex ventilation systems in industrial settings.

Quality Assurance

Quality is at the core of Parth Valve’s manufacturing process. Each product undergoes rigorous testing and quality checks to ensure it meets the stringent industry standards. The company is ISO certified, which reflects its commitment to delivering products that are not only reliable but also durable and efficient.

Customer-Centric Approach

Parth Valve’s success can be attributed to their customer-centric approach. They work closely with clients to understand their specific needs and provide customized solutions that best fit their requirements. Their dedicated customer support team ensures that clients receive prompt assistance and support throughout their engagement with the company.

Sustainability and Environmental Responsibility

In addition to their focus on quality and innovation, Parth Valve is committed to sustainability and environmental responsibility. They implement eco-friendly manufacturing practices and strive to minimize their environmental footprint. By doing so, they contribute to a greener future while maintaining their competitive edge in the industry.

Conclusion

Parth Valve & Manufacturing Co. is the best choice for Industrial Dampers manufacturer in Pune. Their unwavering commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation. As industries continue to evolve, Parth Valve is well-equipped to meet the challenges of the future, providing top-tier solutions that drive efficiency and reliability in industrial operations.

For more information on Parth Valve’s products and services, visit their website or contact their customer support team. With Parth Valve, you can be assured of the best in Industrial Dampers technology and unparalleled service.

#Industrial Dampers in Pune#Industrial Dampers#Importance of industrial dampers#Pune#a bustling hub of industrial activity in India#is home to numerous manufacturing companies#including Parth Valve & Hoses Pvt. Ltd#a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation#quality#and customer satisfaction#Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs#A Legacy of Excellence#Founded with a vision to deliver top-notch industrial solutions#Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a r#Cutting-Edge Technology and Innovation#Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize s#Parth Valve stays ahead of the curve#delivering innovative solutions that cater to the evolving needs of their clients.#Comprehensive Product Range#Parth Valve#the Industrial Dampers manufacturer in Pune#offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:#Butterfly Dampers:#Known for their compact design and efficient operation#butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.#Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment#providing a reliable seal even in high-temperature environments.#Louver Dampers: Designed for precise airflow regulation#louver dampers are used in various industrial applications to control ventilation and exhaust systems.#Multi-Louver Dampers: These dampers offer superior control over airflow

0 notes

Text

Daihatsu Fellow 90, 1989. Presented at the 28th Tokyo Motor Show, a concept for a T-roof 2-door 16 valve 1600cc compact hardtop.

#Daihatsu#Daihatsu Fellow 90#concept#prototype#design study#T-roof#pillarless hardtop#1989#28th Tokyo Motor Show#Daihatsu Fellow#16 valve

268 notes

·

View notes

Text

This idea came from someone asking me about V’s internal organs and gastro/intestinal workings. I delved into a bit of bio/mechanical research that might make sense in the Cyberpunk world. Follow the jump below!

↓

SomaTek specializes in manufacturing synthetic organs designed to transcend our organic limitations.

SomaTek GastroPro™

In a world ravaged by toxic food chains, tainted water supplies, and unreliable agriculture, the GastroPro™ synthetic stomach- amply nicknamed “the iron gut”- is a feat of mechanical organ replacement. Capable of digesting virtually any hazardous or non-nutritive substance without harm, while mimicking and surpassing the core functions of a natural biological system.

The GastroPro™ environment utilizes a stabilized industrial-grade acidic solution (SomaTek’s trademarked confidential blend of fluorinated superacids exceeds the hydrochloric acid and pepsin present in an organic stomach) that is non-corrosive to internal components due to reactive smart hydrogel linings. This acid bath breaks down everything: from your home cooked dinner, to food past its expiration, to actual garbage- designed to adapt to a full range of ingested toxicity. After processing, the liquified matter proceeds to a secondary chamber which is programmed with enzymatic nano filters to separate and neutralize indigestible items versus actual processable materials. *Note that the GastroPro™ is incapable of operating in isolation. The following organic systems are required to be enhanced or replaced:

Esophagus (GastroLine™) is equipped with reinforced smart hydrogel lining to withstand both caustic substances and abrasive matter. Peristaltic actuators move matter regardless of shape or size, while micro-blade emulsifiers begin compacting particularly dense or fibrous materials. Anti-reflux valves prevent acid from backing up.

Liver, Pancreas, Gall Bladder (GastroTox™ Subsystem) further supports the GastroPro™ by processing even rarer or complex toxins, capable of converting them into an array of energy for the body dependent on specific inputs. For example: chemical, electrical, first and second generation biofuel, etc. (Optional but highly recommended)

Intestines & Appendix (GastroTract™) serves as the primary absorption and release unit. Lined with nutrient-binding nanites to extract usable calories, vitamins, minerals, or chemicals. Absorption channels direct these throughout the body via embedded villi structures to the bloodstream and lymphatic system. In users with further modifications, waste may be redirected to a bypass port location of their choosing. The most popular choice being via a urinary tract.

Oral Cavity (OraPro™ Subsystem) is a customizable sum of parts that further supports the GastroPro™ with an artificial tongue embedded with gustatory receptors, reinforced cheek/gum lining, and teeth strong as chrome. (Optional but highly recommended)

Brain Chemistry (CraveShard™) the neural implant designed to be installed into the cyberdeck to simulate, regulate, or even suppress cravings. (Optional but highly recommended) The user may override urges based on their schedule and preferences, as well as control serotonin and dopamine feedback. The implant works harmoniously with receptors built into the GastroPro™ to recognize the identity of consumed materials. It can even reproduce the effects caused by ingested alcohol, hallucinogenics, opioids, narcotics, etc.

Advantages over natural digestion include immunity to internal poisoning, pathogens, parasites, and contaminants. Zero indigestion, zero allergic reaction. Accelerated enzyme breakdown. And multi-source nutrition: users can derive sustenance from otherwise indigestible materials.

Please be aware the GastroPro™ is not without its complications. Over-reliance can result in malabsorption issues if the user abuses the capabilities of the GastroPro™. Care should be taken to continuously ingest products with beneficial properties. In the event of nutrient deficits, the user’s deck will receive periodic warnings regarding nutritional supplementation to prevent systemic decline. Psychosomatic disorders may also emerge as a result of losing sensory pleasure of consumption (“digestion dissonance'”- disconnect with satiety) if the recommended OraPro™ Subsystem and CraveShard™ are not installed.

Regular care encompasses monthly detox flushes, filter replacements, nanite reseeding, and pH rebalancing treatments. All of which can be accomplished via a doctor licensed to administer Somatek devices.

116 notes

·

View notes

Text

I got a bit hyperfixated and now all my free time is suffering for it.

Facts nobody asked for ✨✨.

1-

-I like to think that Peeps being made of Volcanium X (basically, magma) is naturally warm despite being a robot.

-He can control his temperature, more so when he's not attacking or using battle functions.

-Wander often cuddles close to him on cold nights to feel his warmth, or if Peepers himself notices that Wander may be cold he doesn't hesitate to change his body to an ideal temperature.

Wander takes advantage of this characteristic to ask him to use it to cook or heat up food or other things for him.

2-

-Peepers has three forms.

The base form that he mentally molded based on his physical form when he was organically alive (only a bit taller xd).

His true, teeny tiny, compact form (based on the 2012 bible design) to which he is forced to turn back when he's running out of Volcaium X in the tank to save energy.

And the Dombot form that he only uses when he feels truly threatened or obfuscated by something or someone (it makes him terribly tired).

-Peepers could simply refill his tank mechanically and conventionally, injecting himself into those mechanical, artificial veins with the much-needed substance in a rather boring process.

It is Wander who took it upon himself to design a metal thermos specially for him.

From subtly and unsuspectingly asking him what kind of material would hold the powerful substance to weaving him a custom, knitted case with glitter, cute star patches and the legend "World's Greatest Robo-Boyfriend" embroidered on the side.

Although Peepers has no need to drink liquids or ingest things by any means other than absorbing or consuming them through a valve, he still sips from that straw every time he needs to recharge with VX.

There is no other way, just that and that's it.

#wander over yonder#woy#wander#woy wander#commander peepers#disney#wandering eye#wander x peepers#stargazing#immortal AU#robo peepers#old man Wander#lol#sketches#my art

107 notes

·

View notes

Note

You know how tech seems to always be getting smaller and sleeker? Apply that to transformers. Young bots with cute little smooth spikes and older ones with big hefty textured spikes. Young bots flocking to the older ones for a chance of the valve rearranging "ribbed for their pleasure" experience...

Young bots showing off their cute little spikes, "look how compact mine is" "but look how much smoother mine is!"... All teasing the older bots for their chunky, textured spikes... Don't worry, the old mechs will have those brats panting and drooling all over the nearest table pretty soon! Teach those bots how clunky and useless their spike really is.

36 notes

·

View notes

Text

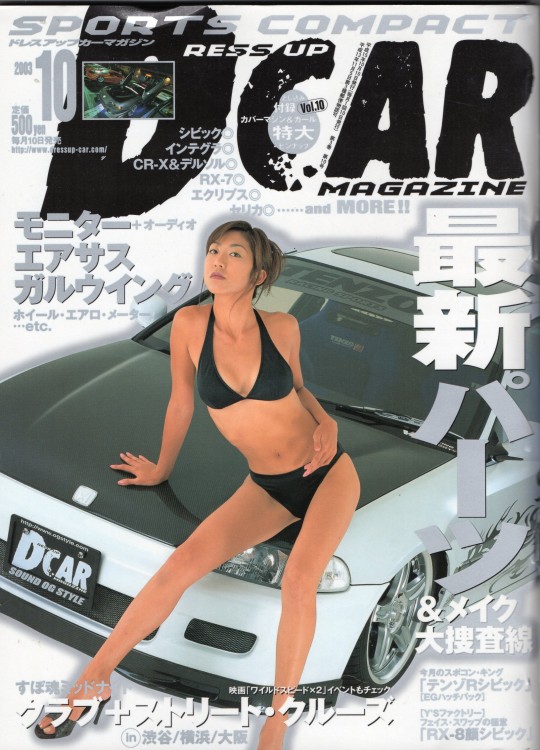

Taking it back to 2003 with this Tenzo R sponsored Civic EG. Tenzo R was a US company that popped up during the early tuner days that specialized in knock-off parts. They made wheels, valve covers, seats, and more. What's funny is that these parts became popular in Japan during the Spocom (sport compact) boom. Oh, the EG is on air suspension, I forgot to mention that.

📚: D-Car 2003

29 notes

·

View notes

Text

Compact valve manufacturer | Svarrnim Forgings

Svarrnim Forgings are a leading compact valve manufacturer that ensures you and your loved ones are always protected from gas leakages. Svarrnim Group has been a symbol of quality, reliability, and integrity for nearly four decades in the field of manufacturer. The proprietorship venture, Svarrnim Forging, promises to continue the legacy in the valve manufacturing sector.

#Compact valve manufacturer#Close valves manufacturer#compact valves manufacturers#self-closing valve manufacturers#compact valve

0 notes

Text

Mazda Familia GT-R review

Mazda Familia/GT-R

This is Mazda's cash cow Familia's WRC entry machine!

This Familia GT-R is also a rally model. By distributing the driving force unevenly between the front and rear, it has eliminated the disadvantage of 4WD vehicles when driving around curves. Of course, it also ensures practicality as a compact two-box vehicle at an above-average level.

Vehicle configuration

-What is the positioning of this car?

Positioned as Familia's top-of-the-line car

Familia is a popular car that has established a solid market share. The GT-R is the top-of-the-line model. The GT-R is a sports car developed from Familia with the aim of participating in rally races. It is difficult to demonstrate technical features in this class, but Mazda is asserting the uniqueness of the GT-R by equipping it with a full-time 4WD system exclusive to the GT-R.

Naturally, the GT-R is only available with one engine: the 1800cc inline 4-cylinder DOHC turbo, which produces a maximum output of 180 horsepower in the GT-X but increased to 210 in the GT-R. The body is only available as a 3-door hatchback.

Equipment & Mecha

Here are the noteworthy equipment and mechanisms!

Improved driving performance by changing torque distribution between front and rear wheels

In addition to the GT-R, the Familia also has other full-time 4WD models available, but Mazda classifies the GT-R and GT-X as sports 4WDs, and the other 4WD models as lifestyle 4WDs.

Naturally, the full-time 4WD system used in the GT-R is different from other 4WD vehicles, and mechanically it has a center differential with a viscous coupling-type LSD which distributes driving force unevenly between the front and rear wheels at 43:57.

The engine is a 1800cc inline 4-cylinder DOHC 16-valve turbocharged engine with a horsepower output of 210. The figures may seem a little ordinary, but when you use it to its full potential, it still feels thrilling to drive.

The appeal of 4WD driving!

The compact body and crisp driving are appealing

The uneven torque distribution of 45:57 between the front and rear is exactly the same as that used by Lancia, the multiple-time rally champion, in its Delta. The main advantage of this is that it makes it easier for the car to turn around curves, and this is also evident in the Familia GT-R.

In any case, the Familia GT-R shows a finish that doesn't make you feel any datedness when it first debuted when it comes to its movement around curves. There is no impression that it has any particularly advanced mechanisms, but when you turn the steering wheel, the car changes direction instantly and faithfully.

This feeling of being able to ride a bike is likely to be hard to give up for those who are still strongly sport-oriented.

The DOHC 16 valve + turbo engine also shows easy-to-handle characteristics. As expected, the feeling at low revolutions is a little inferior compared to the turbo engines that have appeared in the past few years, but the powerful feeling after the turbo starts to work is very stimulating.

The compact body, powerful engine, and full-time 4WD system, which is no longer innovative but delivers an outstanding driving experience, all of these elements come together perfectly to give the Familia GT-R a performance that still feels like it can compete at the front line.

PIC CAPTIONS

→The engine's distinctive feature is that it runs smoothly up to high speeds.

←1800 DOHC turbo that delivers a maximum output of 215 horsepower.

Check the room!

The interior design shows signs of age.

The age of the design is most evident in the interior. The design around the instrument panel, which skillfully combines straight lines and curves, certainly left a sophisticated impression when it was first released, but unfortunately it is difficult to be satisfied with it today, both in terms of design and texture.

The comfort around the rear seats is not particularly satisfactory, not only in this GT-R, but in all Familia cars.

PIC CAPTIONS

→Design aside, the instrument panel is highly practical.

↑The driver's seat is firm and comfortable, so you won't get tired easily.

rival

This is the rival car in terms of driving!!!!!

The company is losing ground to new rivals.

The Lancer and other models are the first cars that should be mentioned as rivals, but the differences in design are obvious. The Familia GT-R's driving is certainly sporty enough to stir the spirit of sport, but it can no longer compete with the Lancer in terms of ultimate punch, and it also cannot compete with the Familia in terms of quietness and vibration.

The GT-R's DOHC turbo engine is far ahead of the competition.

Even though it is a full-time 4WD system, the Familia GT-R's center differential system gives a rough driving feel when compared to the many sports 4WD cars currently on the market. The car's greatest appeal was its crisp and natural handling on curves, but the reason for this is that so many sports 4WDs that surpassed it have appeared in a short period of time. Unfortunately, when trying to enjoy serious sports driving, there are many dissatisfaction points with the body rigidity and suspension design. With the Familia itself due for a full model change soon, it seems a bit harsh to ask for such things, but it is a shame that the car's basic design was not fully developed.

PIC CAPTIONS

↑Compared to newer cars like the Lancer, the age of the design is obvious overall.

8 notes

·

View notes

Text

Zoeller Sump Pumps: Are They Worth the Hype?

When it comes to providing reliable basement protection, Zoeller sump pumps have made a name for themselves. Homeowners often find themselves at a crossroads when deciding on the best pump for their needs, especially following incidents of flooding or water intrusion. This article aims to explore the efficacy and value of Zoeller sump pumps while addressing common concerns about their operation and maintenance.

What Makes Zoeller Sump Pumps Stand Out? Quality Engineering and Reliability

One of the most significant aspects that sets Zoeller sump pumps apart is their reputation for quality engineering. These pumps are designed with durable materials such as cast iron and thermoplastic, ensuring longevity in even the most demanding conditions. Whether you're dealing with heavy rainfall or simply want to mitigate potential water damage in your home, you can trust that a Zoeller sump pump will perform reliably.

Moreover, Zoeller's commitment to quality is backed by various certifications, including being UL Listed and CSA certified, which assures homeowners that they are investing in a product that meets high safety standards.

youtube

Versatile Options for Various Needs

The range of options available from Zoeller allows homeowners to select a model tailored to their specific circumstances. From the compact Zoeller M53, perfect for small basements or crawl spaces, to more robust models like the Zoeller M98, there is an option suitable for every need. The choice between a submersible and pedestal design also adds flexibility; submersible units are ideal for deeper pits, while pedestal pumps excel in tighter spaces.

Innovative Features Enhance Performance

Incorporating advanced technology into their designs, Zoeller offers features like automatic float switches and thermal overload protection. These elements contribute to efficient operation, ensuring that your pump only activates when necessary. Additionally, some models come equipped with battery backup systems, making them invaluable during power outages—an essential feature for regions prone to severe weather.

Installation Considerations: Setting Up Your Zoeller Sump Pump Understanding Installation Costs and Requirements

When contemplating installing a sump pump, understanding the financial implications is crucial. The average cost of putting in a sump pump can vary widely based on factors like labor costs and additional equipment needed (e.g., check valves or discharge pipes). Generally speaking, homeowners can expect installation prices ranging from $1,000 to $2,500 depending on their specific setup.

It's worth noting that while you may be tempted by cheaper options from competitors like Liberty Pumps or Wayne Water Systems, investing in a reputable brand like Zoeller through Plumbing Supply And More ensures https://www.plumbingsupplyandmore.com/ you get superior service and support throughout your purchase journey.

DIY vs Professional Installation: What’s Best?

For those who consider themselves handy, installing a sump pump can be a rewarding DIY project. However, if you're feeling overwhelmed by technical jargon—like understanding terms

2 notes

·

View notes

Note

Okay hear me out. Megatron fragging Rosie after that exchange. Wanting to mark her up. Him being a tad insecure because Ratchet hit nerves. Give. Now.

I can do that. Because I agree it probably hit a few nerves. -Rosie It'll be under the cut as usual. Warnings: Mass Displacement, Creampies, Possessive Megatron, Human and Bot Sticky Interfacing. IDW Continuity Technically.

"R-ight there, fuck, ahhh..." she was singing again. Just for him.

His encounter with Ratchet had him overcompensating. He couldn't believe the nerve of that mech. His vents heated the air around them as his digits dug into that spot inside of Rosie. He was greedy, he trusted very few around his human.

"Don't stifle yourself. I want to hear you." he said leaning over her small frame, "No need to be shy."

He wanted to be rougher, so much rougher. He wanted her to be so sore and exhausted she couldn't make it to the med bay. But, he was being as gentle as he could for her in the moment. Enjoying the fact only he could make her feel like this. Only he could make her sing like this. He shifted her legs and pressed even deeper. He watched as her head fell back. His spike would be in her soon enough. He had grabbed some energon earlier just so he could do this. He couldn't be satisfied by just tasting her today. He needed to be inside of her.

"Megatron~" she whined as his digit brushed a sensitive spot few could reach inside of her.

He smirked, "Again." he said wanting the validation it was his name she was moaning. And he was blessed with his request being answered. His other digit idly played with her enlarged clit, some humans were very similar in some aspects and he took advantage of it.

"What do you want?" his engine revved as he vented again, hot air filling the room.

"I to cum... overload... please I-I can't take this much more." she begged almost sobbing from over-stimulation. "Not so f-aaast." He smirked licking her lubricant from his digit. He let her rest for the moment as he focused his form. Compacting down with mass displacement was never easy and it had it's limits. He could only get down to perhaps a bit smaller than Starscream's size, but focused on his Spike and valve to being just large enough so she could take him without worry.

He chuckled moving the hair from her face, "I waited too long for this." he hummed.

He had never taken this sort of action with her. He was always worried about hurting her. But, today he needed to mark her. He needed to make damn sure other mechs knew who her cybertronian partner was.

"Y-you're smaller." she watched as she caught her breath.

"Mass displacement dearspark. You deserve a proper night with me."

He watched as her eye lit up and she nodded. Her enthusiasm helped his nerves, he had never displaced in such a way. So, he was glad it would not be wasted. He gently brought her to his face and kissed her gently. His panel retracted and revealed his pressurized spike. He left bite marks along her shoulders as he began to position her in his servos. And in one careful movement he buried himself inside of her.

"F-fuck. Frag... " she gasped and grabbed onto whatever part of him that she could.

He had done his job well if it was that easy. And he took pride in it. He watched as she arched into the berth below her and moaned. He noted the small bulge in her abdomen and smirked. He bent over her as they found their pace. Only shifting when her legs finally gave up and she begged him for more. He pressed her legs over into a press so he could press himself deeper into her valve. No, pussy that's the term she had used before.

"I waited so long for this. Primus... mine. Mine." he felt his resolve slip. His insecurities falling out of his intake, "My Rosie. Frag."

"Please, harder, I'm so close already, frag please." her voice sang out.

A thought crossed his circuits, but he decided to hold back on that for now. He would approach that subject of sparkbonding later. He focused instead on pounding into her poor pussy and making her feel good. He could feel the sensation building in his bipedal cord and he held it back.

"Overload for me. Show me I'm the only mech who can make you feel this way." his voice dropped low as he growled.

He felt her flutter around his spike and smirked, that was new. He kissed her where he could. His massive frame overshadowed hers as he pulled her hips in more.

"I'll make them question how you're not sparked." he breathed as his vents hissed again, "Come on dearspark."

In the moment he watched her come undone her pussy clamping around his spike. She practically screamed out his name. And in a few more rushed thrusts he overloaded in her. He felt another orgasm hit her as she milked him of all his transfluid. He caught his breath for a moment before immediately checking in on her. His digits caressed her face gently. He watched her blissed out face come back to this reality and smirked.

"Mmmm so good. Full..." she managed to breathe out, "I love you..."

His spark throbbed violently and he leaned in to kiss her face, "I love you too."

He smiled as he felt his insecurities melt. Those words meant more than anything else. He carefully pulled his depressurized spike from her and carefully cleaned the mess they had made. He watched as she fully came to and sit up.

She smiled at him as he returned to his original size and scooped her up in a blanket. He knew she would need a bath and started to walk the direction it was.

"Ratchet give you trouble?" she murmured as she ran her hands over the marks he left.

Megatron chuckled, "It doesn't matter. Not anymore."

#Valveplug#maccadam#megatron#megatron x rosie#megatron x human#rosie writes#hes in love your honor#robot x human

42 notes

·

View notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes