#Commercial vehicle suspension components supplier

Explore tagged Tumblr posts

Text

Metalman Auto Ltd. is a leading OEM automotive parts supplier, specializing in high-quality metal components for various vehicle types. We are a one-stop shop for sheet metal, tubular fabrication, metal finishing, and assembly of components for original equipment manufacturers (OEMs) in both automotive and non-automotive sectors. Established in 1986, we are among India's first companies to offer comprehensive metal fabrication, finishing, and assembly solutions.

Contact us at +91 240 665 2444 (Ext. 500) or

email [email protected].

#Truck parts supplier#Bus components manufacturer#Commercial vehicle engine parts provider#Heavy-duty vehicle parts manufacturer#Commercial vehicle suspension components supplier#Light commercial vehicle parts manufacturer#Fleet vehicle parts supplier#Commercial vehicle transmission parts provider#Agricultural vehicle parts manufacturer#Farm machinery components supplier#Agri-vehicle engine parts producer#Tractor parts manufacturer#Agricultural equipment components provider#Agri-vehicle OEM parts supplier#Farm vehicle chassis components manufacturer#Agri-vehicle transmission parts producer#Construction vehicle parts supplier#Off-road vehicle components manufacturer#Heavy machinery parts provider#Mining vehicle parts supplier#Off-highway equipment components manufacturer#All-terrain vehicle parts supplier#Earthmoving equipment parts provider#Off-highway vehicle engine parts manufacturer#B2B auto parts distributor#Automotive supply chain management#OEM parts supply chain solutions#Automotive parts wholesale supplier#B2B vehicle components supply chain#Supply chain solutions for automotive OEMs

1 note

·

View note

Text

Smart Parts Exports: Your Trusted Partner for Genuine and Aftermarket Spare Parts for 2, 3, and 4-Wheelers

Spare parts are crucial to the field of automotive maintenance since they keep cars in optimal operating condition. The performance, safety, and durability of a vehicle can be directly impacted by the dependability of the components you select, regardless of whether you're a distributor, mechanic, or owner. From 2-wheelers like motorcycles and scooters to 3-wheelers like auto rickshaws and tuk-tuks to 4-wheelers like cars, trucks, and commercial vehicles, we at Smart Parts Exports know how important it is to find high-quality original and aftermarket spare parts for all kinds of vehicles.

As one of the top exporters of spare parts, Smart Parts Exports takes pleasure in providing a wide selection of OEM (Original Equipment Manufacturer) and aftermarket spare parts to meet the demands of companies and private automobile owners worldwide. Whether they are looking for high-performance aftermarket spare parts or authentic replacement parts, we make sure that our customers have access to the best goods available thanks to our wide network, in-depth knowledge, and dedication to quality.

The Importance of High-Quality Spare Parts for Vehicle Maintenance

To keep it operating efficiently and safely, all vehicles—regardless of brand, model, or type—need to get regular maintenance. Because they replace worn-out or broken components to restore the vehicle's operation, spare parts are essential to this procedure. Having access to trustworthy original and aftermarket replacement parts is essential for lowering maintenance costs and prolonging the life of all kinds of vehicles, from motorbikes to commercial trucks.

However, how can you tell the difference between aftermarket and original spare parts? Knowing when to employ either can assist businesses, mechanics, and car owners make the best decisions for their requirements. Both have benefits.

Genuine Spare Parts: The Best Choice for Performance and Longevity

Genuine spare parts, sometimes referred to as OEM components, are produced by the original manufacturer or an approved supplier of the vehicle. Perfect fit, performance, and safety are guaranteed since these parts are manufactured to precisely match the vehicle's requirements. You are basically guaranteeing that the item is constructed to the same standards as the original part that came with the car when you select authentic spare parts.

Genuine replacement parts for a large number of car brands are available from Smart Parts Exports. These components include suspension pieces, complex electrical systems, necessary engine parts, and more. You can rely on our products to satisfy the greatest standards of quality and performance, whether you're searching for authentic spare parts for a luxury automobile, a commercial truck, or a well-known motorbike brand.

The key benefits of genuine spare parts include:

Perfect Compatibility: These parts are designed to fit your vehicle precisely, ensuring seamless integration and optimal performance.

Durability and Reliability: Genuine spare parts are built to last and perform under demanding conditions, ensuring a longer lifespan for your vehicle.

Warranty Protection: Many manufacturers offer warranties on genuine spare parts, ensuring peace of mind in case of any issues with the part.

Maintaining Vehicle Value: Using genuine spare parts helps preserve your vehicle’s value, especially for high-end or luxury vehicles.

Aftermarket Spare Parts: A Cost-Effective Alternative Without Compromise

Although many car owners find genuine replacement parts to be a great option, aftermarket spare parts can offer a more cost-effective substitute without sacrificing quality. Often providing similar or even better performance at a fraction of the price of original spare parts, aftermarket spare parts are made by independent manufacturers and are made to fit a wide range of automobiles.

At Smart Parts Exports, we understand that many consumers, particularly those seeking cost-effective solutions or particular performance enhancements, can find great satisfaction in aftermarket spare parts. Every part we export is strong, dependable, and performs on par with original spare parts because our selection of aftermarket spare parts is selected from trustworthy manufacturers who adhere to stringent industry standards.

The advantages of aftermarket spare parts include:

Cost Savings: Aftermarket spare parts are generally more affordable than genuine spare parts, making them an excellent option for budget-conscious vehicle owners and businesses.

Wide Availability: Because aftermarket spare parts are produced by many manufacturers, you’ll often find a wider selection of parts for a specific vehicle model, especially if the original parts are hard to come by.

Performance Enhancements: Many aftermarket spare parts are designed to offer enhanced performance, allowing vehicle owners to upgrade their vehicles with high-performance components.

Variety of Brands: Aftermarket spare parts allow for more options, so you can choose from different brands and manufacturers based on your needs and preferences.

Why Choose Smart Parts Exports for Genuine and Aftermarket Spare Parts?

Being a top exporter of original and aftermarket parts for two-, three-, and four-wheelers makes us at Smart Parts Exports pleased. Customers around the world choose us for the following reasons:

Wide Range of Spare Parts:We offer a comprehensive inventory of parts for cars, trucks, motorbikes, and other vehicle types. We offer anything from electrical systems, filters, suspension parts, engine parts, and more.

High-Quality Standards:We exclusively collaborate with reliable manufacturers and suppliers, regardless of whether you require original or aftermarket spare parts. Every component is carefully examined to make sure it satisfies industry requirements for durability, quality, and safety.

Competitive Pricing: We can provide both original and aftermarket spare parts at extremely affordable costs thanks to our solid ties with suppliers and manufacturers, giving our customers the most value for their money.

Global Reach: We ship spare parts to clients all over the world, from Asia and Africa to North America and Europe. Anywhere in the world, prompt, dependable delivery is guaranteed by our vast shipping network.

Customer Support: We take great satisfaction in offering top-notch client service. Our staff is always available to help with product selection, technical support, and any inquiries you may have regarding our aftermarket or authentic spare parts.

Fast and Reliable Shipping: We recognize the value of prompt delivery, particularly for replacement components. We guarantee prompt and dependable shipping to satisfy your needs, whether you require a part immediately for a repair or to maintain the operation of your company.

Conclusion: Smart Parts Exports is Your One-Stop Shop for Genuine and Aftermarket Spare Parts

In conclusion, Smart Parts Exports can assist you whether you're looking for original or aftermarket spare parts for your two-, three-, or four-wheeler. We are the perfect partner for car owners, mechanics, and businesses worldwide because of our extensive selection, dedication to quality, and outstanding customer service.

Whether you want to keep your car operating at its peak performance with original components or you want to find more affordable options with aftermarket parts, we only provide the best items. No matter what you require, we have the parts, know-how, and worldwide network to guarantee your cars continue to operate dependably and effortlessly.

Get in touch with Smart Parts Exports right now to peruse our selection of replacement parts and learn how we can provide premium original and aftermarket parts to meet your car's maintenance requirements.

0 notes

Text

A Comprehensive Guide to Finding Quality Leyland Spare Parts in Delhi and India

Understanding the Importance of Quality Spare Parts

In the world of automobiles, the performance of a vehicle depends heavily on the quality of its components. This is true for both regular passenger cars and commercial heavy-duty vehicles. Spare parts are essential for replacing worn-out or damaged components, ensuring smooth operation, and maintaining the safety standards of the vehicle.

For heavy-duty vehicles, the need for durable and high-quality Leyland spare parts in Delhi becomes even more significant. These vehicles operate under tough conditions, including long hours on the road, heavy loads, and challenging terrains. As a result, having access to superior spare parts can make all the difference in reducing downtime, minimizing repair costs, and ensuring the safety of the driver and cargo.

Where to Find Leyland Spare Parts in Delhi

Delhi, being one of the largest hubs for automobile parts in India, is home to numerous suppliers and distributors offering a wide range of Leyland spare parts in Delhi. The city’s diverse market provides customers with options that cater to various needs, from original equipment manufacturer (OEM) parts to high-quality aftermarket alternatives.

When searching for Leyland spare parts, it's important to consider both the reliability of the supplier and the authenticity of the products. Reputable suppliers often guarantee the quality of the parts they sell, ensuring that each component meets the required standards. It's also beneficial to choose a supplier who offers a variety of parts, from engines and transmissions to suspension systems, brakes, and electrical components.

For those who prefer a hands-on approach, Delhi’s bustling markets, such as Karol Bagh and Bhagirath Palace, are home to several auto parts stores. These markets offer a wide range of spare parts and accessories, making them an excellent place to buy components for commercial vehicles.

Why Choose Delhi for Leyland Spare Parts?

Delhi is not only a national capital but also a commercial powerhouse. The city's strategic location, its well-connected road, rail, and air networks, and its proximity to major manufacturing hubs make it an ideal place to source high-quality Leyland spare parts in Delhi. Additionally, many suppliers in Delhi offer competitive pricing, thanks to the city's status as a commercial center with multiple wholesalers and distributors.

Moreover, Delhi has a skilled workforce and a large number of mechanics who are well-versed in handling heavy-duty vehicles. These mechanics often have direct access to quality spare parts, ensuring that your vehicle is repaired or maintained efficiently. In many cases, you can find mechanics who can source genuine spare parts at reasonable prices, which is another reason why many vehicle owners and fleet managers prefer to buy spare parts in this city.

How to Buy Leyland Spare Parts in India

The process of buying Leyland spare parts in India can be both straightforward and complex, depending on the specific requirements of your vehicle. Fortunately, with the growing number of online platforms and physical stores, purchasing spare parts has never been easier.

When you choose to buy Leyland spare parts in India, the first step is identifying the part you need. It's essential to be precise when selecting the component to avoid costly mistakes. Ensure you know the part number, make, model, and year of your vehicle. This information can usually be found in the vehicle’s manual or on the existing part itself.

Once you’ve identified the required parts, you can explore multiple options for purchasing them. The internet offers an extensive range of suppliers that sell Leyland spare parts in India, allowing you to compare prices, read reviews, and choose the most reliable sellers. Online platforms also provide the convenience of doorstep delivery, which saves time and effort.

Alternatively, physical stores across India offer a more personalized shopping experience. For instance, major cities like Mumbai, Chennai, and Bangalore have well-established automotive markets that cater to both domestic and international customers. It's advisable to visit trusted stores and dealerships that deal with the brand's spare parts to ensure you receive genuine components.

Factors to Consider When Buying Leyland Spare Parts

Choosing the right spare part is crucial, as using substandard or incompatible components can affect the performance of your vehicle. Here are some important factors to consider when buying Leyland spare parts in India:

Authenticity and Quality: Always verify that the parts you are buying are either OEM parts or are produced by certified manufacturers. This ensures the reliability and longevity of the components.

Warranty and Return Policy: Reputable sellers will often offer warranties on their products, allowing you to return or exchange faulty parts. This adds an extra layer of protection for your investment.

Price Comparison: Prices for spare parts can vary between suppliers. It’s a good idea to compare prices and check for any ongoing discounts or promotions to get the best deal.

After-Sales Support: Reliable suppliers offer customer support services, which can be crucial if you encounter issues with the part after installation. Choose a seller who provides assistance and guidance in case of any challenges.

0 notes

Text

TTO Auto Parts: Your One-Stop Solution for Automotive Needs

If you're looking for reliable, high-quality auto parts, TTO.com.ua is your go-to online store. We specialize in providing a wide range of spare parts for various makes and models, ensuring that your vehicle runs smoothly and efficiently. With an extensive inventory, competitive prices, and a commitment to customer satisfaction, we stand out as a trusted partner for all your automotive needs.

Why Choose TTO.com.ua?

Extensive Product Range Our catalog includes everything you need to keep your vehicle in top condition. From engine components and suspension parts to brakes, filters, and electrical systems, we have it all. Whether you drive a passenger car, SUV, or commercial vehicle, TTO.com.ua has the right parts for you.

Guaranteed Quality We collaborate with trusted manufacturers and suppliers, ensuring that every product meets the highest standards of quality and reliability. Whether you’re a professional mechanic or a DIY enthusiast, you can count on our parts to deliver outstanding performance and durability.

Competitive Pricing At TTO.com.ua, we believe that quality should not come at a high cost. That’s why we offer competitive prices on all our products. Regular promotions and discounts make it even more affordable to maintain and repair your vehicle.

User-Friendly Shopping Experience Shopping on our website is simple and hassle-free. Use our intuitive search tools to quickly find the exact parts you need. With detailed descriptions, compatibility information, and high-resolution images, making the right choice is easier than ever.

Fast and Reliable Delivery We understand the importance of timely repairs, which is why we offer quick and reliable shipping across Ukraine. Your order will arrive promptly, so you can get back on the road without delay.

Dedicated Customer Support

Our knowledgeable support team is here to assist you every step of the way. If you have questions about compatibility, installation, or availability, don’t hesitate to reach out. At TTO.com.ua, customer satisfaction is our top priority.

Conclusion

For top-notch auto parts and a seamless shopping experience, look no further than TTO.com.ua. Browse our extensive selection today and enjoy the convenience of finding everything you need in one place. With TTO.com.ua, you can trust that your vehicle is in good hands.

0 notes

Text

Your Trusted Source for Premium Spare Parts for Trucks and Machinery

Heavy-duty vehicles and machinery form the backbone of industries like construction, logistics, and manufacturing. The performance and reliability of these vehicles depend heavily on the quality of their components. This is where premium spare parts play a crucial role. For businesses operating in India, the UAE, the USA, and beyond, finding dependable spare parts for renowned brands such as TATA Motors, Ashok Leyland, JCB, and Caterpillar is essential to ensure uninterrupted operations and maximize efficiency.

The right spare parts can significantly enhance the lifespan and performance of trucks and machinery. High-quality components are designed to withstand rigorous conditions, from heavy loads on construction sites to long hours on the road. When sourced from trusted suppliers, these parts not only meet but often exceed the original manufacturer specifications, ensuring seamless compatibility and optimal performance.

Brands like TATA Motors and Ashok Leyland are synonymous with durability and performance in the commercial vehicle sector. To maintain these standards, it is vital to use spare parts engineered specifically for these vehicles. From engine components and brake systems to suspension parts and gear mechanisms, every piece contributes to the overall performance and safety of the vehicle. With authentic spare parts, businesses can minimize downtime, reduce maintenance costs, and extend the life of their fleet.

In the construction and industrial machinery sectors, brands like JCB and Caterpillar dominate due to their rugged designs and exceptional capabilities. These machines are often exposed to extreme conditions, from heavy excavation tasks to harsh weather environments. Ensuring their peak performance requires spare parts that can endure such demands. For instance, durable hydraulic components, reinforced tires, and advanced filtration systems are crucial for keeping these machines running efficiently.

One of the key factors to consider when sourcing spare parts is quality assurance. Performance-tested components are essential to avoid unexpected breakdowns and costly repairs. Reputable suppliers subject their products to rigorous testing procedures, ensuring that every part meets stringent quality standards. This reliability translates to peace of mind for businesses that rely on these vehicles and machines for their daily operations.

Another significant advantage of partnering with a trusted spare parts supplier is access to a wide range of products. From small fasteners to critical engine components, comprehensive inventory ensures that customers can find everything they need under one roof. This not only simplifies the procurement process but also reduces lead times, allowing businesses to get back to work without delay.

Global shipping capabilities have further revolutionized the spare parts industry. Businesses no longer need to rely solely on local suppliers; they can source high-quality components from trusted providers worldwide. Efficient shipping networks ensure timely delivery, whether the parts are destined for a bustling city in India, a desert site in the UAE, or a remote location in the USA.

Sustainability is another growing concern for businesses across industries. Many suppliers are now offering eco-friendly options, such as remanufactured parts and components made from recyclable materials. These alternatives not only reduce the environmental footprint but also provide cost savings without compromising quality. For companies seeking to align with global sustainability goals, such initiatives are a welcome addition.

The versatility of spare parts extends to customization options as well. Businesses often have unique requirements depending on their operations, and Indianbuilt components can address these specific needs. Whether it’s a specialized part for a unique machinery model or enhanced features to tackle challenging tasks, customized solutions add tremendous value.

Customer support is a cornerstone of any successful spare parts business. Reliable suppliers provide expert guidance to help customers identify the right components for their vehicles or machinery. This ensures compatibility and optimal performance while avoiding the costly mistake of purchasing incorrect parts. Additionally, after-sales support, including installation advice and troubleshooting, enhances the overall customer experience.

When it comes to heavy-duty vehicles and equipment, even the smallest part can make a significant difference. High-performance spare parts ensure that trucks and machinery operate smoothly, safely, and efficiently. By investing in premium components, businesses can reduce downtime, improve productivity, and maintain their competitive edge.

Whether you’re managing a fleet of commercial trucks, overseeing construction projects, or running industrial operations, sourcing reliable spare parts is crucial to your success. With access to top-tier components, advanced technology, and dependable shipping, businesses around the world can keep their operations running at full speed, no matter the challenge.

0 notes

Text

How to Choose the Best Heavy Duty Truck Parts Suppliers for Your Needs

When it comes to maintaining and repairing your fleet of heavy-duty trucks, finding the right Heavy Duty Truck Parts Suppliers is crucial. The quality and availability of the parts directly impact the performance and longevity of your vehicles. Here are key factors to consider when choosing a supplier for your commercial vehicle parts and Truck Parts.

1. Quality and Durability of Parts

The most important aspect of selecting a Heavy Duty Truck Parts Supplier is the quality of the parts. High-quality, durable parts ensure your trucks perform reliably under heavy loads and demanding conditions. Always opt for parts that meet or exceed OEM (Original Equipment Manufacturer) standards to guarantee optimal performance and safety.

2. Comprehensive Range of Products

A reputable supplier should offer a wide variety of commercial vehicle parts, ranging from engine components to suspension, brakes, electrical systems, and more. The availability of diverse Truck Parts ensures you can get everything you need from one supplier, reducing delays and complications in your supply chain.

3. Reputation and Experience in the Industry

Experience matters when it comes to sourcing reliable parts. Choose Heavy Duty Truck Parts Suppliers with a proven track record in the industry. A supplier with years of experience is more likely to offer high-quality products, professional guidance, and superior customer service.

4. OEM and Aftermarket Parts Availability

Look for suppliers who offer both OEM and aftermarket Truck Parts. OEM parts are designed and manufactured by the original truck manufacturer, ensuring perfect compatibility. On the other hand, aftermarket parts can offer more affordable alternatives without compromising on quality. The flexibility to choose between the two allows you to meet your specific needs and budget.

5. Timely Delivery and Quick Turnaround

Minimizing vehicle downtime is essential for your business. Choose Heavy Duty Truck Parts Suppliers who can deliver parts quickly and reliably. A supplier with a strong logistics network and clear communication about lead times will help keep your fleet running smoothly. Ensure they offer expedited shipping options when urgent repairs are needed.

6. Competitive Pricing and Warranty

While pricing shouldn't be the sole factor, it is important to compare prices to ensure you're getting good value for your investment. Suppliers who offer competitive pricing on commercial vehicle parts and clear warranty policies give you peace of mind, knowing you're covered in case of product defects or issues after purchase.

7. Customer Support and Expertise

Good customer support is invaluable, especially when you need expert advice on part compatibility or troubleshooting. Choose suppliers who have knowledgeable support teams available to assist with any queries you may have about the Truck Parts you're purchasing.

8. Certifications and Compliance

Finally, ensure that the supplier complies with relevant industry standards and certifications. This ensures they provide high-quality, safe parts that adhere to regulations, ultimately protecting your vehicles and your business.

Choosing the right Heavy Duty Truck Parts Suppliers is essential for maintaining the efficiency of your fleet. With companies like Supremesales offering a wide range of high-quality commercial vehicle parts and expert support, you can keep your trucks on the road and running at their best.

0 notes

Text

Top 10 Automobile Parts Manufacturers in India

Finding India's top 10 automobile parts manufacturers can be tricky when you don’t know about their quality standards, production, and delivery. This blog will help you find out the top 10 automobile parts manufacturers in India.

Before we deep dive into the blog, Machine Maze can assist you in getting quotations from top automotive parts manufacturers in India. They have a vetted supplier network in India who have attained all the industry-specific certifications.

Now, let’s have a look at the top automobile parts manufacturing companies in India.

01. Samvardhana Motherson International Limited

SAMIL (Samavardhana Motherson International Limited) is established in 1986 and is the leading global supplier of automotive components and systems. The company’s primary products and services are wiring harnesses, vision systems, modules, polymer products, electrical distribution systems, and other automotive components. Products manufactured by SAMIL are used by a wide range of automobile parts manufacturers in India, such as passenger cars, commercial vehicles, and two-wheelers. SAMIL has a strong global presence and a diversified product portfolio.

02. Tata AutoComp Systems Limited

Tata AutoComp Systems Limited is headquartered in Pune, Maharashtra, India, and was established in 1954. It is one of the well-known automobile parts manufacturing companies in India. The company manufactures and supplies a wide range of automotive components and systems, such as engine cooling systems, automotive batteries, rearview mirrors, command systems, HVAC, exhaust and emission control systems, seating systems, battery packs, battery cooling systems, EV charging and electronic solutions for passenger and commercial vehicles, and suspensions for heavy commercial vehicles. These products are used by Indian and global OEMs, including Tata Motors, JCB, and MG Motors.

03. Bharat Forge Limited

Bharat Forge Limited is one of the top 10 companies in automotive parts manufacturing in India. The company was founded in 1961 and it offers a wide range of high-performance, critical, and safety components for diverse applications. The company’s product and service line-up consists of forged and machine components for engines, chassis, and transmissions. These automobile parts are used by General Motors, Ford, and Toyota. Bharat Forge Limited is considered to be an essential member of top automobile parts manufacturers, due to its strong focus on innovation, quality, and customer satisfaction.

04. Bosch Limited

Bosch Limited is a German multinational company that has been operating in India since 1951. In India, Bosch manufactures automobile parts like fuel injection systems, spark plugs, engine control units, and breaking systems. The company’s manufactured parts are used by top OEMs, aftermarket suppliers, and fleet operators. It is considered to be the top automotive parts manufacturer in India, due to its excellence in quality, innovation, and customer service.

05. TVS Motor Company Limited

Headquartered in Chennai, India, TVS Motor Company is a multinational automobile parts manufacturer. The company was founded in 1978 and manufactures automobile parts such as engine, gearbox, suspension system and breaks. These products are used by their customers across 60 countries around the world.

06. Varroc Engineering Limited

Established in 1989, Varroc Engineering Limited (VEL) is a global automobile spare parts manufacturer in India. The company designs, manufactures, and supplies an entire range of automotive parts, including exterior lighting systems, plastic and polymer components, electrical-electronics components, and precision metallic components.

07. Endurance Technologies Limited

Endurance Technologies is a automobile parts manufacturer, headquartered in Aurangabad, Maharashtra, India. The company manufactures a wide range of auto components, including alloy wheels, suspension systems, transmissions and breaking systems. It is a Tier 1 supplier to major Indian and global OEMs.

08. Uno Minda Limited

Established in 1958, Uno Minda is a premier Indian manufacturer of automotive component categories, such as switching systems, lighting systems, and alloy wheels. A Tier-1 supplier to more than 500 domestic and international OEMs, it operates 73 global manufacturing facilities, including locations in Indonesia, Vietnam, Spain, and Mexico. Recognized for its innovation, quality, and focus on sustainability, Uno Minda is at the forefront of the automotive industry's shift to electric mobility.

09. Jamna Auto Industries Limited (JAI)

Founded in 1954, JAI is India’s largest and one of the world’s top manufacturers of automotive parts. Its products cater to commercial vehicles, passenger vehicles, and off-highway vehicles, serving OEMs, aftermarket distributors, and replacement parts providers. JAI emphasizes quality, innovation, and customer satisfaction.

10. JMB Group

A diversified conglomerate since 1983, JMB Group specializes in automotive sheet metal components, assemblies, safety systems, and chassis for vehicles. Known for innovation and quality, it collaborates with leading OEMs in India and internationally, solidifying its position as a top player in the automotive components industry.

Conclusion

Machine Maze can help you get in touch with these top automotive parts manufacturers in India. Their team takes control of your contract manufacturing process and assures that top-notch quality is delivered to their clients. Get in touch with Machine Maze and gain access to quotations in 24 hours.

0 notes

Text

Understanding 7075 Aluminum Composition and Its Applications

2024-10-21

7075 aluminum alloy is one of the strongest and most widely used aluminum alloys in high-performance industries, such as aerospace, automotive, and military applications. Known for its incredible strength-to-weight ratio, it is often the go-to material when durability and lightweight characteristics are essential. In this guide, we will delve into the composition of 7075 aluminum, its key properties, common applications, and why Shandong Union Aluminium Co., Ltd. is a leading supplier for high-quality aluminum products, including 7075 aluminum 6061 Aluminium Diamond Plate.

What is 7075 Aluminum Alloy?

7075 aluminum is a high-strength aluminum alloy with zinc as its primary alloying element. It belongs to the 7000 series of aluminum alloys, which are renowned for their strength, toughness, and resistance to corrosion, making them ideal for demanding industrial uses.

The exact composition of 7075 aluminum is as follows:

Zinc (Zn): 5.6-6.1%

Magnesium (Mg): 2.1-2.5%

Copper (Cu): 1.2-1.6%

Iron (Fe): 0.5% (maximum)

Silicon (Si): 0.4% (maximum)

Manganese (Mn): 0.3% (maximum)

Titanium (Ti): 0.2% (maximum)

Chromium (Cr): 0.18-0.28%

Aluminum (Al): Balance (85-90%)

Key Properties of 7075 Aluminum

The 7075 aluminum composition gives it a unique set of characteristics that make it highly desirable in various applications:

1. High Strength

7075 aluminum is one of the strongest commercially available aluminum alloys, comparable to some steels. Its high yield strength makes it ideal for applications requiring strong materials but where keeping weight to a minimum is important.

2. Lightweight

Despite its strength, 7075 aluminum remains lightweight, making it perfect for industries where minimizing weight is critical, such as aerospace and automotive sectors.

3. Excellent Fatigue Resistance

The alloy’s ability to withstand cyclic loading (fatigue) ensures it performs well under conditions where repeated stress is applied, such as in aircraft components.

4. Good Machinability

Although 7075 aluminum is harder than many other alloys, it is still easy to machine, especially in the T6 condition, making it popular in manufacturing processes.

5. Corrosion Resistance

Although it is not as corrosion-resistant as other aluminum alloys like 6061, 7075 aluminum can be treated with protective coatings or anodizing to improve its resistance to corrosion.

Common Applications of 7075 Aluminum

Thanks to its high strength, 7075 aluminum is used in a wide variety of high-performance applications where durability and lightweight properties are essential.

1. Aerospace Industry

7075 aluminum is extensively used in aircraft structures, including wings, fuselage components, and landing gear parts. The aerospace sector relies heavily on its superior strength-to-weight ratio, which helps in improving aircraft performance and fuel efficiency.

2. Automotive Industry

In automotive engineering, 7075 aluminum is used in performance-critical parts such as suspensions, shafts, and other structural components. It helps to reduce the weight of vehicles, thus improving fuel efficiency and performance.

3. Sporting Equipment

High-end sporting equipment, such as bicycle frames, climbing gear, and hockey sticks, are made from 7075 aluminum for its strength and low weight, giving athletes a performance edge.

4. Military Applications

7075 aluminum is used in the military for manufacturing weapons, armor, and other components that require superior strength and durability in harsh environments.

5. Marine and Offshore

Certain parts of boats, marine vessels, and offshore equipment are made from 7075 aluminum due to its strength and ability to handle the cyclic stresses found in marine environments.

Shandong Union Aluminium Co., Ltd.: A Leading Supplier of Aluminum Alloys

Shandong Union Aluminium Co., Ltd. is a trusted supplier of high-quality aluminum products, including 7075 aluminum. Founded in 2011 and located in Gangcheng District, Jinan, the company covers an area of 1.2 square kilometers and boasts a designed production capacity of 360,000 tons.

The company specializes in the Research & Development, production, and marketing of aluminum and aluminum alloy flat rolling products. With advanced technology and high-production capacity, they ensure that clients get premium-quality aluminum products at competitive prices.

Products Offered by Shandong Union Aluminium Co., Ltd.:

Aluminum Ring

Aluminium Sheet

Aluminium Coil

Aluminium Circle

Aluminum Checker Plate

Aluminium Tread Plate

Aluminium Embossed Coil

Aluminium Coating Coil/Sheet

Aluminium Foil

7075 Aluminum vs. Other Aluminum Alloys

When comparing 7075 aluminum with other aluminum alloys, it’s important to consider the following differences:

1. 7075 vs. 6061

Strength: 7075 is much stronger than 6061, making it ideal for structural applications where strength is paramount.

Corrosion Resistance: 6061 is more resistant to corrosion than 7075, making it a better choice for applications exposed to water or moisture.

Cost: 7075 is generally more expensive due to its higher strength properties.

2. 7075 vs. 2024

Strength: Both 7075 and 2024 are high-strength alloys, but 7075 is generally stronger.

Fatigue Resistance: 7075 aluminum has better fatigue resistance, making it a more suitable choice for high-stress applications.

Corrosion Resistance: 2024 is more corrosion-resistant than 7075, though both can be treated to improve corrosion resistance.

Frequently Asked Questions (FAQs)

1. What is the primary use of 7075 aluminum?

7075 aluminum is primarily used in high-performance applications such as aerospace, automotive, military, and sporting goods. Its combination of strength and lightweight properties makes it a go-to material for critical structural components.

2. Can 7075 aluminum be welded?

Welding 7075 aluminum can be challenging due to its high strength and susceptibility to cracking. It is not typically recommended for welding without specific techniques, such as friction stir welding.

3. How does 7075 aluminum compare to steel?

7075 aluminum is comparable to steel in terms of strength but is much lighter. This makes it an attractive option in industries where reducing weight is crucial without compromising strength.

Comparison Table: 7075 Aluminum vs. Other Aluminum Alloys

Property7075 Aluminum6061 Aluminum2024 AluminumTensile StrengthHighModerateHighCorrosion ResistanceModerateHighModerateMachinabilityGoodExcellentGoodWeldabilityDifficultExcellentFairFatigue ResistanceExcellentModerateGoodCommon ApplicationsAerospace, Automotive, MilitaryConstruction, MarineAerospace, Automotive

Conclusion: Why 7075 Aluminum is a Top Choice for High-Performance Applications

In summary, 7075 aluminum composition combines strength, fatigue resistance, and lightweight properties, making it an essential material for high-performance applications. Whether you’re in the aerospace, automotive, or sporting goods industry, this alloy offers unmatched performance for structural components that require both durability and low weight.

By choosing a reliable supplier like Shandong Union Aluminium Co., Ltd., businesses can ensure they receive top-quality aluminum products, including 7075 aluminum, that meet the most stringent industry standards.

For any business looking to incorporate 7075 aluminum into their products, understanding its properties, comparing it with other alloys, and selecting the right supplier are essential steps in making the most of this high-strength material.

0 notes

Text

Aceforge: Leading the Way as a Tier 1 Automotive Parts Supplier

In the highly competitive automotive industry, Tier 1 suppliers play a crucial role in the supply chain. These companies are directly responsible for delivering complex, high-quality components to original equipment manufacturers (OEMs). Aceforge, a renowned name in the automotive parts sector, has carved out a strong position as a Tier 1 supplier, meeting the demands of global automotive giants.

Understanding the Role of Tier 1 Suppliers

Tier 1 suppliers are the primary vendors for OEMs, providing essential components and systems that go directly into vehicle assembly. Unlike Tier 2 and Tier 3 suppliers, who deal with raw materials or simpler parts, Tier 1 suppliers offer ready-to-install, high-value assemblies such as engine systems, suspension modules, or braking systems. This makes their role pivotal in the overall success of the automotive industry, as they ensure vehicles meet performance, safety, and regulatory standards.

Aceforge’s Position as a Leading Tier 1 Supplier

Aceforge has become a trusted Tier 1 supplier by delivering high-quality, reliable, and technologically advanced components to some of the biggest names in the automotive industry. The company’s commitment to precision manufacturing, cutting-edge technology, and customer satisfaction sets it apart in the competitive automotive parts landscape.

Key Strengths of Aceforge as a Tier 1 Supplier

End-to-End Solutions Aceforge offers comprehensive solutions, from design and development to manufacturing and assembly. This ensures that OEMs receive complete, high-performance systems that are ready to be integrated into vehicles.

Technological Expertise As a Tier 1 supplier, Aceforge employs the latest technologies in manufacturing, including automation, advanced robotics, and Industry 4.0 practices. This allows the company to maintain high production efficiency while ensuring the utmost precision in each component it produces.

Focus on Innovation Innovation is at the core of Aceforge’s operations. The company consistently invests in research and development to stay ahead of industry trends, such as the growing demand for electric vehicles (EVs) and autonomous driving technology. By anticipating these shifts, Aceforge is able to provide OEMs with cutting-edge solutions.

Stringent Quality Control Quality assurance is a top priority for Aceforge. Every component undergoes rigorous testing to ensure it meets OEM specifications and global industry standards. As a Tier 1 supplier, this level of precision is essential to maintaining the trust of automotive manufacturers who rely on consistent quality.

Sustainability and Compliance Aceforge is committed to sustainable manufacturing practices, ensuring compliance with environmental regulations while minimizing waste. By reducing its carbon footprint and adopting eco-friendly processes, Aceforge aligns itself with the evolving expectations of OEMs, which are increasingly prioritizing sustainability.

Products and Systems Offered by Aceforge

Aceforge provides a wide array of automotive systems and components, including:

Engine Components: High-precision engine parts designed to optimize performance, fuel efficiency, and emissions control.

Transmission Systems: Cutting-edge transmission parts that ensure smooth power delivery and long-lasting durability.

Suspension and Steering Components: Advanced suspension and steering systems that enhance vehicle stability, control, and safety.

Braking Systems: High-performance braking solutions that ensure optimal stopping power, reliability, and longevity.

Global Reach and Strategic Partnerships

As a Tier 1 supplier, Aceforge serves a global client base, working with some of the leading automotive brands in the world. The company’s strong supply chain network and manufacturing capabilities allow it to meet the demands of OEMs across diverse markets, from luxury car manufacturers to commercial vehicle producers.

Through strategic partnerships and a customer-centric approach, Aceforge has built long-standing relationships with OEMs that rely on the company’s expertise and reliability.

The Future of Tier 1 Automotive Parts Suppliers

The automotive industry is experiencing a paradigm shift with the rise of electric vehicles (EVs), connected cars, and autonomous driving. These advancements are reshaping the role of Tier 1 suppliers, who must adapt to new technologies and higher standards. Aceforge is at the forefront of this change, investing in innovative solutions to meet the future demands of the industry.

By staying ahead of trends like EV propulsion systems, battery technologies, and lightweight materials, Aceforge ensures that it will continue to be a trusted partner for OEMs in the evolving automotive landscape.

Conclusion

As a leading Tier 1 supplier of automotive parts, Aceforge stands out for its commitment to quality, innovation, and sustainability. The company’s ability to provide end-to-end solutions, coupled with its technological expertise, positions it as a vital player in the global automotive supply chain. As the industry continues to evolve, Aceforge is well-equipped to meet the demands of OEMs and lead the way in delivering the next generation of automotive components.

0 notes

Text

Automotive Drive Axle Market Likely to Enjoy Massive Growth (2024-2030)

The latest research study released by HTF MI on Global Automotive Drive Axle Market with 123+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know-how of the current market development, landscape, sales, drivers, opportunities, market viewpoint and status. The market Study is segmented by key a region that is accelerating the marketization. Automotive Drive Axle study is a perfect mix of qualitative and quantitative Market data collected and validated majorly through primary data and secondary sources.

Key Players in This Report Include:

American Axle & Manufacturing (United States), Dana Incorporated (United States), ZF Friedrichshafen AG (Germany), GKN Automotive (United Kingdom), Meritor, Inc. (United States), Hyundai Wia Corporation (South Korea), Aisin Seiki Co., Ltd. (Japan), SAF-Holland (Germany), JTEKT Corporation (Japan), Gestamp Automoción (Spain)

Download Sample Report PDF (Including Full TOC, Table & Figures) https://www.htfmarketintelligence.com/sample-report/global-automotive-drive-axle-market

Definition:

An automobile's drive axle is an essential component of the drivetrain system, responsible for transferring power from the engine to the wheels. Axle shaft, differential, and several auxiliary additives make up this system. Movement is made possible by the torque that is transferred to the wheels through the drive axle's connection to the transmission and differential. The force axle in front-wheel pressure motors is the front axle; in rear-wheel pressure automobiles, it is the rear axle. An all-wheel-drive and four-wheel-power configuration typically has a front and a rear pressure axle. Durability is one of the automotive power axles' primary tasks because it must tolerate high torque and rotational forces. They also have joints and bearings that allow for the movement of the suspension, guaranteeing a smooth running system.

Market Trends:

Market Drivers:

Increasing demand for automobiles and transportation services

Technological advancements in vehicle drivetrain systems

Market Opportunities:

Expansion into emerging markets with growing automotive industries

Development of lightweight and high-strength drive axles

Collaboration with automotive manufacturers and suppliers

Major Highlights of the Automotive Drive Axle Market report released by HTF MI:According to HTF Market Intelligence, the Global Automotive Drive Axle market to witness a CAGR of 12% during forecast period of 2024-2030. The market is segmented by Global Automotive Drive Axle Market Breakdown by Application (Heavy-Duty Vehicles, Light Duty Vehicles) by Type (Live Axle, Dead Axle, Tandem Axle) by Vehicle Type (Passenger Vehicles, Commercial Vehicles) by Sales Channel (Original Equipment Manufacturer (OEM), Aftermarket) and by Geography (North America, South America, Europe, Asia Pacific, MEA).

Global Automotive Drive Axle market report highlights information regarding the current and future industry trends, growth patterns, as well as it offers business strategies to help the stakeholders in making sound decisions that may help to ensure the profit trajectory over the forecast years.

Buy Now Latest Report Edition of Automotive Drive Axle market @ https://www.htfmarketintelligence.com/buy-now?format=3&report=11383

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

North America (United States, Mexico & Canada)

South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Objectives of the Report:

-To carefully analyze and forecast the size of the Automotive Drive Axle market by value and volume.

-To estimate the market shares of major segments of the Automotive Drive Axle market.

-To showcase the development of the Automotive Drive Axle market in different parts of the world.

-To analyze and study micro-markets in terms of their contributions to the Automotive Drive Axle market, their prospects, and individual growth trends.

-To offer precise and useful details about factors affecting the growth of the Automotive Drive Axle market.

-To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Automotive Drive Axle market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Have a question? Market an enquiry before purchase @ https://www.htfmarketintelligence.com/enquiry-before-buy/global-automotive-drive-axle-market

Points Covered in Table of Content of Global Automotive Drive Axle Market:

Chapter 01 – Automotive Drive Axle Executive Summary

Chapter 02 – Market Overview

Chapter 03 – Key Success Factors

Chapter 04 – Global Automotive Drive Axle Market – Pricing Analysis

Chapter 05 – Global Automotive Drive Axle Market Background

Chapter 06 — Global Automotive Drive Axle Market Segmentation

Chapter 07 – Key and Emerging Countries Analysis in Global Automotive Drive Axle Market

Chapter 08 – Global Automotive Drive Axle Market Structure Analysis

Chapter 09 – Global Automotive Drive Axle Market Competitive Analysis

Chapter 10 – Assumptions and Acronyms

Chapter 11 – Automotive Drive Axle Market Research Methodology

Get Discount (10-15%) on Immediate purchase 👉 https://www.htfmarketintelligence.com/request-discount/global-automotive-drive-axle-market

Key questions answered:

How feasible is Automotive Drive Axle market for long-term investment?

What are influencing factors driving the demand for Automotive Drive Axle near future?

What is the impact analysis of various factors in the Global Automotive Drive Axle market growth?

What are the recent trends in the regional market and how successful they are?

Thanks for reading this article; you can also get individual chapter-wise sections or region-wise report versions like America, LATAM, Europe, Nordic nations, Oceania, Southeast Asia, or Just Eastern Asia.

About Author: HTF Market Intelligence consulting is uniquely positioned empower and inspire with research and consulting services to empower businesses with growth strategies, by offering services with extraordinary depth and breadth of thought leadership, research, tools, events and experience that assist in decision making. Contact Us: Priyanka Navale (Web Analyst) HTF Market Intelligence Consulting Private Limited Phone: +15075562445 [email protected]

View the Table of Contents and Complete Summary at https://www.htfmarketintelligence.com/report/global-automotive-drive-axle-market

0 notes

Text

Reliable Spare Parts for Heavy Vehicles in India

The Importance of Quality Clutch Plates

Among the critical components of a vehicle, clutch plates play a pivotal role. A well-functioning clutch plate ensures smooth gear transitions, optimal power delivery, and prolonged vehicle life. The demand for reliable and durable clutch plates is particularly high in the commercial vehicle sector. For those seeking the best options, Bharat Benz clutch plate in India stands out as a preferred choice. Designed for durability and efficiency, these clutch plates cater to the rigorous demands of heavy-duty vehicles, providing a seamless driving experience.

Why Choose Genuine Spare Parts?

The benefits of choosing authentic spare parts for vehicles go beyond just performance. Genuine components are designed to meet the exact specifications of the vehicle, ensuring a perfect fit and reliable operation. When you buy Signa spare parts, you invest in quality and peace of mind. Genuine spare parts are tested for durability and compliance with safety standards, making them the best option for maintaining the reliability of your vehicle.

Clutch plates, in particular, are a component where quality cannot be compromised. A substandard clutch plate can lead to significant issues, including transmission problems, reduced fuel efficiency, and premature wear and tear. Opting for a trusted Bharat Benz clutch plate in India ensures that you’re equipping your vehicle with a component that meets the highest standards of quality and performance.

Where to Buy Reliable Spare Parts?

Finding a trusted supplier for heavy vehicle spare parts is crucial. Whether you need to buy Signa spare parts or replace your clutch plate, it’s essential to choose a supplier that guarantees authenticity and quality. Many suppliers in the market offer competitive prices, but not all can provide genuine products. Ensuring that the supplier has a good reputation and offers a warranty on their products is key to making an informed purchase.

Enhancing Vehicle Longevity with Proper Maintenance

Regular maintenance is as important as choosing quality spare parts. A combination of timely servicing and genuine parts can significantly extend the lifespan of your vehicle. When considering a replacement for critical components like clutch plates, opting for a trusted Bharat Benz clutch plate in India ensures optimal functionality and reduces the risk of recurring issues.

Additionally, maintaining other essential systems, such as the engine, suspension, and brakes, becomes easier when you have access to genuine spare parts. The reliability of parts sourced from trusted suppliers helps maintain the vehicle’s integrity, ensuring safe and efficient operations.

The Cost-Effectiveness of Genuine Spare Parts

While genuine spare parts may come with a slightly higher price tag compared to aftermarket alternatives, their long-term benefits outweigh the initial cost. Authentic parts offer superior durability, reducing the frequency of replacements and repair costs. When you buy Signa spare parts, you invest in the long-term health of your vehicle, ensuring lower maintenance costs over time.

Similarly, choosing a high-quality Bharat Benz clutch plate in India helps avoid frequent breakdowns and enhances the overall driving experience. The upfront investment in genuine parts leads to improved vehicle performance and reduced operational costs, making it a cost-effective choice in the long run.

Ensuring Safety and Compliance

Using genuine spare parts not only benefits the vehicle but also ensures compliance with safety standards. Substandard parts can compromise vehicle safety, putting drivers, passengers, and other road users at risk. By opting to buy Signa spare parts from a trusted source, you ensure that your vehicle adheres to safety regulations and performs optimally in all conditions.

When replacing clutch plates, choosing a Bharat Benz clutch plate in India guarantees that you’re using a component designed to handle the demands of heavy-duty vehicles. These clutch plates undergo rigorous testing to ensure their reliability and safety, giving you confidence in your vehicle’s performance.

0 notes

Text

Premium Honda Acty Parts for Maintenance and Upgrades

The Honda Acty, a staple in the world of mini trucks and vans, has long been cherished for its reliability, versatility, and efficiency. Whether used for commercial purposes, personal transportation, or recreational adventures, maintaining and upgrading a Honda Acty is crucial to ensure its longevity and optimal performance. For enthusiasts and owners looking to keep their vehicles in top condition, accessing premium Honda Acty parts is essential. This article delves into the importance of high-quality parts, offers insights into sourcing them, and highlights Oiwa Garage as a top recommendation for purchasing Honda Acty parts online.

The Importance of Premium Honda Acty Parts

1. Ensuring Reliability and Performance

Premium parts are designed to meet or exceed the original equipment manufacturer (OEM) specifications. This means they fit perfectly and function seamlessly within the vehicle’s systems. Using high-quality parts ensures that the Honda Acty operates reliably, maintaining its performance standards and minimizing the risk of breakdowns.

2. Enhancing Safety

Safety is paramount when it comes to any vehicle. Premium Honda Acty parts contribute significantly to the overall safety of the vehicle. Whether it's brake components, suspension parts, or engine elements, using reliable and durable parts helps in preventing potential failures that could lead to accidents.

3. Longevity of the Vehicle

Investing in premium parts not only enhances the immediate performance of the Honda Acty but also contributes to its long-term health. High-quality components are less likely to wear out prematurely, which means fewer replacements and repairs over the vehicle's lifespan.

4. Maintaining Resale Value

A well-maintained vehicle with high-quality parts retains its value better than one that has been repaired with substandard components. For owners looking to sell or trade their Honda Acty in the future, maintaining it with premium parts can result in a higher resale value.

Common Honda Acty Parts for Maintenance and Upgrades

Maintaining and upgrading a Honda Acty involves a range of parts. Some of the most commonly sought-after components include:

1. Engine Components

The heart of the Honda Acty, the engine, requires regular maintenance with high-quality parts to ensure it runs smoothly. Commonly needed engine parts include:

Oil filters

Spark plugs

Timing belts

Fuel injectors

2. Suspension and Steering

For a smooth and controlled ride, the suspension and steering systems must be in top condition. Key parts in this category include:

Shock absorbers

Struts

Control arms

Tie rods

3. Brake System

Safety-critical, the brake system must be maintained with precision. Essential brake parts include:

Brake pads

Rotors

Brake lines

Calipers

4. Transmission Components

To ensure seamless gear shifts and efficient power transfer, high-quality transmission parts are necessary:

Clutch kits

Gearbox components

Transmission fluid

Shift cables

5. Electrical and Lighting

Electrical components and lighting are crucial for the vehicle's functionality and safety:

Alternators

Batteries

Headlights

Tail lights

Finding Honda Acty Parts Online

In today's digital age, finding Honda Acty parts online is more convenient than ever. However, with the plethora of options available, it's important to choose reputable suppliers to ensure you get premium quality parts. Here are some tips for sourcing Honda Acty parts online:

1. Check for Authenticity

Ensure that the online store offers genuine or high-quality aftermarket parts. Look for certification and detailed product descriptions that confirm the parts' authenticity and compatibility with your Honda Acty.

2. Read Reviews and Ratings

Customer reviews and ratings can provide valuable insights into the quality of parts and the reliability of the supplier. Look for consistent positive feedback and high ratings.

3. Compare Prices

While premium parts might come at a higher price, it's still important to compare prices across different platforms. This ensures you get the best deal without compromising on quality.

4. Verify Return and Warranty Policies

A reputable online store will have clear return and warranty policies. This provides assurance that you can return or exchange parts if they do not meet your expectations or if they are defective.

Why Oiwa Garage is Your Best Bet for Honda Acty Parts Online

Among the many options available, Oiwa Garage stands out as a top choice for sourcing premium Honda Acty parts online. Here’s why:

1. Extensive Selection of Premium Parts

Oiwa Garage offers a comprehensive range of Honda Acty parts, from essential maintenance components to specialized upgrade parts. Their extensive inventory ensures that you can find exactly what you need for your vehicle.

2. Quality Assurance

At Oiwa Garage, quality is a top priority. They provide only the highest quality parts that meet or exceed OEM standards. This commitment to quality ensures that every part you purchase will perform reliably and last longer.

3. Expertise and Customer Support

With a team of knowledgeable experts, Oiwa Garage provides excellent customer support. Whether you need advice on selecting the right part or assistance with a technical issue, their team is always ready to help.

4. Competitive Pricing

Oiwa Garage offers competitive pricing on all their Honda Acty parts. They understand the importance of affordability without compromising on quality, making them a cost-effective option for maintaining and upgrading your vehicle.

5. Positive Customer Reviews

Oiwa Garage has garnered numerous positive reviews from satisfied customers. Their reputation for reliability, quality, and excellent service makes them a trusted source for Honda Acty parts.

6. Convenient Online Shopping Experience

Their user-friendly website makes it easy to find and purchase the parts you need. With detailed product descriptions, clear images, and easy navigation, shopping at Oiwa Garage is a hassle-free experience.

Conclusion

Maintaining and upgrading your Honda Acty with premium parts is essential for ensuring its reliability, performance, and safety. By choosing high-quality components, you can enhance the longevity of your vehicle and maintain its value over time. For those looking to source Honda Acty parts online, Oiwa Garage emerges as a highly recommended option. With their extensive selection, commitment to quality, competitive pricing, and excellent customer service, Oiwa Garage is the ideal destination for all your Honda Acty parts needs.

1 note

·

View note

Text

Thermo king tripac apu

Premium Quality Heavy-Duty Truck Parts in The U.S at Truckpartsline

In the expansive world of heavy-duty trucks and commercial vehicles, ensuring top-notch performance and reliability is paramount. Truckpartsline.com stands out as a trusted and comprehensive online resource for premium-quality truck parts in the United States. Whether you're a fleet manager, an independent truck owner, or a mechanic, accessing high-quality parts is essential to keeping vehicles running smoothly and efficiently. Let's delve into what makes Truckpartsline.com a go-to destination for heavy-duty truck parts.

A Comprehensive Selection of Parts

Truckpartsline.com boasts an extensive inventory of heavy-duty truck parts, covering a wide range of makes and models. From engines and transmissions to braking systems, suspension components, and electrical parts, they offer everything needed to maintain, repair, or upgrade commercial trucks. Whether you're working on a freight hauler, a construction vehicle, or a specialized truck, you're likely to find the parts you need at Truckpartsline.com.

Premium Quality and Reliability

One of the standout features of Truckpartsline is its commitment to providing premium quality parts from reputable manufacturers. Each product offered undergoes rigorous quality control measures to ensure durability, performance, and compatibility with various heavy-duty truck applications. This dedication to quality gives customers peace of mind, knowing that the parts they purchase will meet or exceed industry standards.

Ease of Navigation and Ordering

Navigating the Truckpartsline website is intuitive and user-friendly. Customers can easily search for specific parts by category, brand, or part number, streamlining the shopping experience. The website is designed to provide detailed product descriptions, specifications, and compatibility information, enabling informed purchasing decisions.

Competitive Pricing and Value

While offering premium-quality truck parts, Truckpartsline.com remains committed to competitive pricing. They understand the importance of cost-effectiveness for fleet operators and independent truck owners alike. By maintaining strong relationships with suppliers and optimizing their operations, Truckpartsline.com strives to offer excellent value without compromising on quality.

Customer Service Excellence

At Truckpartsline, customer satisfaction is a top priority. Their team of knowledgeable and experienced professionals is dedicated to assisting customers with their inquiries, providing technical support, and ensuring a smooth purchasing process. Whether you have questions about a specific part or need assistance with an order, the customer service team is readily available to help.

Convenience and Nationwide Shipping

Truckpartsline.com offers the convenience of online shopping with nationwide shipping services. No matter where you are in the United States, you can have high-quality truck parts delivered directly to your doorstep or preferred service location. This flexibility allows customers to access essential parts without the hassle of visiting multiple suppliers or stores.

Building Trust Through Reliability

In the competitive world of heavy-duty truck parts, Truckpartsline.com stands out as a trusted source for premium-quality components. Their commitment to reliability, customer service, and value has earned them a loyal customer base within the trucking industry. Whether you're in need of routine maintenance parts or specialized components for repairs or upgrades, Truckpartsline.com offers a dependable solution.

Conclusion

Truckpartsline is more than just an online retailer of heavy-duty truck parts; it's a reliable partner for individuals and businesses striving to maintain and optimize their fleets. With a commitment to quality, competitive pricing, and exceptional customer service, Truckpartsline.com continues to be a leading choice for truck owners and operators across the United States. Explore their comprehensive inventory and experience the difference that premium-quality parts can make in keeping heavy-duty trucks performing at their best.

0 notes

Text

LED Headlight and Spare Parts Suppliers: Vinayak Automotive

In the fast-paced world of automotive innovation, the demand for high-quality LED headlights and spare parts continues to grow. Whether you're an individual car owner or part of a business seeking premium automotive supplies, Vinayak Automotive is your trusted partner. With a strong reputation as a LED headlight supplier and spare parts provider, Vinayak Automotive ensures you never have to compromise on quality or performance.

Why Choose LED Headlights for Your Vehicle?

LED headlights have become the go-to choice for many vehicle owners. They offer several advantages over traditional halogen or HID lights:

Energy EfficiencyLED headlights consume less power, reducing the strain on your vehicle's battery and enhancing fuel efficiency. This makes them a smart and sustainable choice.

Enhanced Brightness and VisibilityWith their powerful illumination, LED headlights provide superior visibility during nighttime drives, foggy conditions, or heavy rain.

Longevity and DurabilityLED lights have an impressive lifespan, often lasting up to 50,000 hours or more. Their robust construction ensures resistance to vibrations and wear.

As a LED headlight supplier, Vinayak Automotive provides a diverse range of headlights that cater to different vehicle models and customer preferences. The products are carefully curated to meet the highest standards of safety and performance.

Comprehensive Spare Parts Solutions

In addition to being a leading LED headlight supplier, Vinayak Automotive takes pride in its extensive collection of spare parts. The right spare parts are essential for maintaining a vehicle's efficiency and longevity. Here are some key highlights of what makes Vinayak Automotive stand out as a spare parts supplier:

Wide Product RangeVinayak Automotive offers a vast inventory of spare parts, including brake pads, filters, spark plugs, suspension components, and more. Whether you're working on a routine replacement or a specialized repair, you can find what you need.

Quality AssuranceEvery product at Vinayak Automotive undergoes stringent quality checks. This ensures customers receive only top-notch parts that guarantee reliability and durability.

Affordability and AccessibilityCompetitive pricing and an efficient supply chain make it easy for customers to access the parts they need without breaking the bank.

Vinayak Automotive: A Name You Can Trust

What sets Vinayak Automotive apart in the automotive supply industry? Here are a few reasons why customers consistently choose this brand for their LED headlights and spare parts:

Expertise and ExperienceWith years of experience in the automotive industry, Vinayak Automotive has honed its ability to deliver quality products and services.

Customer-Centric ApproachCustomer satisfaction is at the heart of everything Vinayak Automotive does. From offering guidance on the right products to ensuring timely delivery, the team goes above and beyond to meet client expectations.

Commitment to InnovationBy keeping up with the latest trends and technologies, Vinayak Automotive ensures its products align with modern vehicle standards and consumer needs.

Applications of LED Headlights and Spare Parts

Whether you're an individual, a garage owner, or part of a fleet management team, partnering with a reliable LED headlight supplier and spare parts provider is crucial. Vinayak Automotive caters to diverse needs, including:

Personal VehiclesUpgrading your car’s headlights or replacing worn-out parts has never been easier with Vinayak Automotive’s extensive range of products.

Commercial VehiclesFor businesses that rely on a fleet of vehicles, Vinayak Automotive ensures you have access to dependable spare parts and lighting solutions.

Repair and Service WorkshopsWorkshop owners can depend on Vinayak Automotive for consistent supply and premium quality products.

Final Thought

When it comes to sourcing premium automotive solutions, Vinayak Automotive is a name you can rely on. As a trusted LED headlight supplier and spare parts supplier, the brand continues to set industry benchmarks with its commitment to quality, innovation, and customer satisfaction. Whether you're upgrading your vehicle’s headlights or sourcing spare parts for maintenance, Vinayak Automotive ensures you’re covered with products that enhance performance and safety.

0 notes

Text

Top Heavy Duty Truck Parts Suppliers You Should Know

When it comes to maintaining and servicing heavy-duty truck parts suppliers, selecting the right supplier is crucial for ensuring your fleet operates efficiently and reliably. Whether you’re in need of OEM parts or aftermarket solutions, understanding the key players in the industry will help you make informed decisions. Below are some essential aspects of the commercial vehicle parts market and the suppliers who stand out in providing quality truck parts.

1. Global Industry Leaders in Heavy Duty Truck Parts

Leading heavy-duty truck parts suppliers like Supremesales offer top-notch products that ensure the longevity and optimal performance of heavy-duty trucks. These suppliers specialize in a variety of components, ranging from truck parts like engines, brake systems, and transmissions to more specialized elements like suspension systems and steering components. Choosing a supplier with global reach ensures that you can access parts from trusted manufacturers no matter where you are.

2. Wide Range of Product Offerings

Top heavy-duty truck parts suppliers provide a diverse selection of commercial vehicle parts designed for various truck models and functions. From engine parts to electrical systems and cooling components, these suppliers cover all the essential areas needed to keep trucks running smoothly. Whether you need OEM or aftermarket parts, having access to a full catalog can save time and reduce operational costs.

3. Quality and Durability You Can Trust

When dealing with truck parts, durability and performance are paramount. Heavy-duty truck parts suppliers ensure that their products are built to withstand the toughest conditions, including extreme temperatures and heavy loads. High-quality materials and stringent quality control processes are standard in the industry to ensure each part meets the required standards for commercial vehicle performance.

4. Aftermarket Parts for Cost-Effective Maintenance

For fleet operators looking to cut costs without compromising quality, aftermarket truck parts offer a practical solution. Many heavy-duty truck parts suppliers provide aftermarket options that meet or exceed OEM specifications. These parts allow for cost-effective repairs and replacements while maintaining the performance and safety of the truck.

5. Strong Distribution and Availability

One of the key advantages of working with top commercial vehicle parts suppliers is their robust distribution network. This allows for quicker delivery times and better accessibility of parts, helping reduce downtime for truck owners and fleet operators. Suppliers with extensive warehouses and distribution channels can provide a steady flow of parts wherever they’re needed.

6. Technological Advancements in Truck Parts

In response to the increasing demand for fuel efficiency and sustainability, heavy-duty truck parts suppliers are investing in advanced technologies. Innovations in sensor systems, automation, and eco-friendly materials are becoming increasingly common in commercial vehicle parts. These advancements help trucks run more efficiently, reduce emissions, and enhance overall performance.

Conclusion

Choosing the right heavy-duty truck parts suppliers is crucial for keeping your trucks in top condition and ensuring your business runs smoothly. Suppliers like Supremesales offer a wide range of high-quality truck parts and commercial vehicle parts that meet the demands of the industry. By considering factors like product variety, quality, and customer service, you can make better decisions for your fleet’s maintenance and longevity.

0 notes

Text

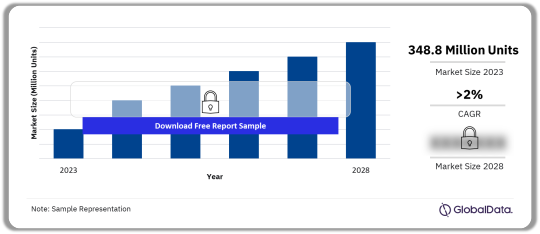

Global Automotive Suspension Systems Market: Regional Growth and Market Dynamics

The global automotive suspension systems market exhibits regional variations in growth and dynamics influenced by factors such as economic conditions, vehicle demand, regulatory environment, and technological advancements.

Buy the Full Report for Additional Automotive Suspension Systems Market Forecast Insights or Download a Free Sample Report

Here's an overview of regional growth and market dynamics:

1. North America:

Market Size: North America holds a significant share of the global automotive suspension systems market, driven by the presence of major automotive manufacturers and a large vehicle parc.

Technological Advancements: The region is characterized by a strong focus on technological innovations, including the adoption of advanced suspension systems with features such as adaptive damping, air suspension, and electronic controls.

Demand for SUVs and Trucks: High demand for SUVs, pickup trucks, and light commercial vehicles in North America drives the growth of suspension system suppliers catering to these vehicle segments.

Regulatory Environment: Stringent safety and emissions regulations influence the design and manufacturing of suspension systems, with a focus on improving vehicle dynamics, stability, and occupant protection.

Aftermarket Opportunities: The aftermarket for suspension components is significant in North America, with consumers often upgrading their vehicles with aftermarket suspension kits for enhanced performance and customization.

2. Europe:

Market Dominance: Europe is a major hub for automotive technology and manufacturing, with leading suspension system suppliers headquartered in the region. It holds a substantial share of the global market.

Focus on Comfort and Handling: European consumers prioritize vehicle comfort, handling, and performance, driving the adoption of advanced suspension technologies such as adaptive dampers and multi-link suspensions.

Electric Vehicle Adoption: European countries are leading the transition towards electric mobility, which influences the development of specialized suspension systems tailored for electric vehicles (EVs) and plug-in hybrids.

Stricter Emissions Standards: Stringent emissions regulations in Europe encourage the use of lightweight materials and energy-efficient suspension systems to improve fuel efficiency and reduce environmental impact.