#Automotive Drive Axle Size

Explore tagged Tumblr posts

Text

Automotive Drive Axle Market Likely to Enjoy Massive Growth (2024-2030)

The latest research study released by HTF MI on Global Automotive Drive Axle Market with 123+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know-how of the current market development, landscape, sales, drivers, opportunities, market viewpoint and status. The market Study is segmented by key a region that is accelerating the marketization. Automotive Drive Axle study is a perfect mix of qualitative and quantitative Market data collected and validated majorly through primary data and secondary sources.

Key Players in This Report Include:

American Axle & Manufacturing (United States), Dana Incorporated (United States), ZF Friedrichshafen AG (Germany), GKN Automotive (United Kingdom), Meritor, Inc. (United States), Hyundai Wia Corporation (South Korea), Aisin Seiki Co., Ltd. (Japan), SAF-Holland (Germany), JTEKT Corporation (Japan), Gestamp Automoción (Spain)

Download Sample Report PDF (Including Full TOC, Table & Figures) https://www.htfmarketintelligence.com/sample-report/global-automotive-drive-axle-market

Definition:

An automobile's drive axle is an essential component of the drivetrain system, responsible for transferring power from the engine to the wheels. Axle shaft, differential, and several auxiliary additives make up this system. Movement is made possible by the torque that is transferred to the wheels through the drive axle's connection to the transmission and differential. The force axle in front-wheel pressure motors is the front axle; in rear-wheel pressure automobiles, it is the rear axle. An all-wheel-drive and four-wheel-power configuration typically has a front and a rear pressure axle. Durability is one of the automotive power axles' primary tasks because it must tolerate high torque and rotational forces. They also have joints and bearings that allow for the movement of the suspension, guaranteeing a smooth running system.

Market Trends:

Market Drivers:

Increasing demand for automobiles and transportation services

Technological advancements in vehicle drivetrain systems

Market Opportunities:

Expansion into emerging markets with growing automotive industries

Development of lightweight and high-strength drive axles

Collaboration with automotive manufacturers and suppliers

Major Highlights of the Automotive Drive Axle Market report released by HTF MI:According to HTF Market Intelligence, the Global Automotive Drive Axle market to witness a CAGR of 12% during forecast period of 2024-2030. The market is segmented by Global Automotive Drive Axle Market Breakdown by Application (Heavy-Duty Vehicles, Light Duty Vehicles) by Type (Live Axle, Dead Axle, Tandem Axle) by Vehicle Type (Passenger Vehicles, Commercial Vehicles) by Sales Channel (Original Equipment Manufacturer (OEM), Aftermarket) and by Geography (North America, South America, Europe, Asia Pacific, MEA).

Global Automotive Drive Axle market report highlights information regarding the current and future industry trends, growth patterns, as well as it offers business strategies to help the stakeholders in making sound decisions that may help to ensure the profit trajectory over the forecast years.

Buy Now Latest Report Edition of Automotive Drive Axle market @ https://www.htfmarketintelligence.com/buy-now?format=3&report=11383

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

North America (United States, Mexico & Canada)

South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Objectives of the Report:

-To carefully analyze and forecast the size of the Automotive Drive Axle market by value and volume.

-To estimate the market shares of major segments of the Automotive Drive Axle market.

-To showcase the development of the Automotive Drive Axle market in different parts of the world.

-To analyze and study micro-markets in terms of their contributions to the Automotive Drive Axle market, their prospects, and individual growth trends.

-To offer precise and useful details about factors affecting the growth of the Automotive Drive Axle market.

-To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Automotive Drive Axle market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Have a question? Market an enquiry before purchase @ https://www.htfmarketintelligence.com/enquiry-before-buy/global-automotive-drive-axle-market

Points Covered in Table of Content of Global Automotive Drive Axle Market:

Chapter 01 – Automotive Drive Axle Executive Summary

Chapter 02 – Market Overview

Chapter 03 – Key Success Factors

Chapter 04 – Global Automotive Drive Axle Market – Pricing Analysis

Chapter 05 – Global Automotive Drive Axle Market Background

Chapter 06 — Global Automotive Drive Axle Market Segmentation

Chapter 07 – Key and Emerging Countries Analysis in Global Automotive Drive Axle Market

Chapter 08 – Global Automotive Drive Axle Market Structure Analysis

Chapter 09 – Global Automotive Drive Axle Market Competitive Analysis

Chapter 10 – Assumptions and Acronyms

Chapter 11 – Automotive Drive Axle Market Research Methodology

Get Discount (10-15%) on Immediate purchase 👉 https://www.htfmarketintelligence.com/request-discount/global-automotive-drive-axle-market

Key questions answered:

How feasible is Automotive Drive Axle market for long-term investment?

What are influencing factors driving the demand for Automotive Drive Axle near future?

What is the impact analysis of various factors in the Global Automotive Drive Axle market growth?

What are the recent trends in the regional market and how successful they are?

Thanks for reading this article; you can also get individual chapter-wise sections or region-wise report versions like America, LATAM, Europe, Nordic nations, Oceania, Southeast Asia, or Just Eastern Asia.

About Author: HTF Market Intelligence consulting is uniquely positioned empower and inspire with research and consulting services to empower businesses with growth strategies, by offering services with extraordinary depth and breadth of thought leadership, research, tools, events and experience that assist in decision making. Contact Us: Priyanka Navale (Web Analyst) HTF Market Intelligence Consulting Private Limited Phone: +15075562445 [email protected]

View the Table of Contents and Complete Summary at https://www.htfmarketintelligence.com/report/global-automotive-drive-axle-market

0 notes

Text

Oldsmobile’s Experimental ’66 Toronado Station Wagon

What if Oldsmobile produced a Toronado station wagon? General Motors was intrigued enough by the idea to build a prototype or two.

It’s only natural that General Motors and its Oldsmobile division would seek out additional applications for the advanced front-wheel drive unit designed for the 1966 Toronado. Known internally at GM as the Unitized Power Package or UPP, the powertrain module was a tidy, versatile package, and surely a bundle had been invested in its development. The next application following the Toronado, of course, was the 1967 Cadillac Eldorado. And since one great benefit of the UPP front-drive system was that it allowed a low, flat floor, another use that easily came to mind was a station wagon.

By March of 1966, the GM design had a full-sized studio model ready for display at the Tech Center’s styling court (above). As we can see, this was essentially a European-style shooting brake adaptation of the production Toronado coupe. Sporty, yes, but the two-door wagon didn’t offer much more in the way of useful interior volume over the standard Toronado.

Taking a more practical approach, GM built a full-sized, four-door wagon prototype using the Toronado drive unit and front-end sheet metal. But at the time, Oldsmobile didn’t offer a full-size wagon—its largest wagon was the Vista Cruiser, based on a stretched A-body intermediate platform. So a Pontiac full-sized wagon body shell, from the firewall back, was merged with the Toronado front clip. As the photos show, the Olds/Pontiac mashup was more of a basic proof-of-concept rather than a finished prototype. The tail lamps fit oddly and the front and rear wheel openings don’t match at all.

Leading automotive historian Michael Lamm, writing in the late, great magazine Special Interest Autos (July-Aug 1978) reported that in fact, several of these experimental front-drive wagons were constructed. Mr. Lamm also noted that GM styling vice president Bill Mitchell raved about the flat, unobtructed floors, and he included this awesome Mitchell quote: “With the tailgate down, you could run a motorscooter into it.” But as we now know, the front-drive, Toronado-derived station wagon was never sent into production—though the UPP was later used to power the 1973-78 GMC Motor Home.

There was another Toronado station wagon, not that Oldsmobile had any direct involvement. In 1968-70, American Quality Coach of Blytheville, Arkansas produced the AQC Jetway 707 airport limousine. A Toronado with its wheelbase extended five and a half feet, it sported tandem rear axles, five doors per side, and a Vista Cruiser-ish station wagon roof. Somewhere between 52 and 150 of these behemoths were reportedly built, various sources say, and a number of them are still around.

1968-70, American Quality Coach

#Oldsmobile Toronado Station Wagon#car#cars#oldsmobile toronado#oldsmobile#Toronado Station Wagon#Toronado#station wagon#limousine

68 notes

·

View notes

Text

Automotive Axle and Propeller Shaft Market Revenue Analysis: Growth, Share, Value, Size, Scope, Industry Analsis and Forecast by 2028

"Automotive Axle and Propeller Shaft Market Size And Forecast by 2028

Automotive axle and propeller shaft market is expected to witness market growth at a rate of 3.52% in the forecast period of 2021 to 2028. Data Bridge Market Research report on automotive axle & propeller shaft market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecasted period while providing their impacts on the market’s growth.

the outlook for the Automotive Axle and Propeller Shaft Market remains optimistic, with significant opportunities for growth and innovation. The market’s competitive environment, shaped by leading companies and their strategies, underscores the importance of adaptability and foresight. With a focus on insights, trends, and data-driven analysis, this report serves as a comprehensive guide for stakeholders navigating the complexities of the Automotive Axle and Propeller Shaft Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-automotive-axle-propeller-shaft-market

Which are the top companies operating in the Automotive Axle and Propeller Shaft Market?

The Top 10 Companies in Automotive Axle and Propeller Shaft Market are known for their strong presence and innovative solutions. These include industry leaders. Each of these companies has made significant contributions through cutting-edge products, strategic partnerships, and global reach. Their ability to adapt to market trends and consumer demands has helped them maintain leadership positions in the market, driving growth and setting industry standards.

**Segments**

- By Product Type: - Axle - Propeller Shaft

- By Vehicle Type: - Passenger Vehicle - Commercial Vehicle

- By Material: - Alloy - Carbon Fiber - Others

- By Manufacturing Process: - Forged - Rolled

The global automotive axle and propeller shaft market can be analyzed based on several key segments. Firstly, by product type, the market is segmented into axles and propeller shafts. Axles are a vital component in a vehicle responsible for transmitting power from the engine to the wheels, while propeller shafts are used to transfer torque from the transmission to the differential. Secondly, based on vehicle type, the market is divided into passenger vehicles and commercial vehicles, each having different demands for axles and propeller shafts based on their unique requirements. Thirdly, by material, the market includes alloys, carbon fiber, and other materials, with each offering distinct advantages in terms of strength, weight, and cost. Lastly, based on the manufacturing process, the market is segmented into forged and rolled, with each method influencing the final characteristics of the axle and propeller shaft.

**Market Players**

- American Axle & Manufacturing, Inc. - GKN plc - Hyundai WIA Corporation - JTEKT Corporation - NTN Corporation - Dana Limited - Showa Corporation - Gestamp - Nexteer Automotive - IFA Rotorion

The global automotive axle and propeller shaft market features a competitive landscape with key players driving innovation and growth in the industry. Companies such as American Axle & Manufacturing, Inc., GKN plc, Hyundai WIA Corporation, and JTEKT Corporation play a significant role in the market with their extensive product offerings and strategic initiatives. Other notable market players include NTN Corporation, Dana Limited, Showa Corporation, Gestamp, Nexteer Automotive, and IFA Rotorion, each contributing to the market dynamics with their unique capabilities and market presence. These market players are at the forefront of technological advancements and product developments in the automotive axle and propeller shaft industry, catering to the evolving needs of vehicle manufacturers and customers worldwide.

https://www.databridgemarketresearch.com/reports/global-automotive-axle-propeller-shaft-marketThe global automotive axle and propeller shaft market is poised for significant growth and evolution in the coming years, driven by various factors ranging from technological advancements to shifting consumer preferences. One notable trend in the market is the increasing demand for lightweight materials such as carbon fiber in the manufacturing of axles and propeller shafts. Carbon fiber offers superior strength and reduced weight compared to traditional materials like alloys, aligning with the industry's focus on improving fuel efficiency and reducing emissions. As automakers strive to meet stringent regulatory standards and cater to environmentally-conscious consumers, the adoption of lightweight materials is expected to gain momentum, thereby influencing the market dynamics.

Moreover, the market is witnessing a surge in the adoption of advanced manufacturing processes such as forging and rolling to enhance the structural integrity and performance of axles and propeller shafts. Forging enables the production of components with superior strength and durability, making it ideal for high-performance applications in commercial vehicles and sports cars. On the other hand, rolling offers cost-effective manufacturing solutions with precise control over material properties, appealing to mass production requirements in the passenger vehicle segment. The choice of manufacturing process plays a crucial role in determining the overall quality and performance of axles and propeller shafts, driving manufacturers to explore innovative techniques to gain a competitive edge in the market.

Furthermore, the market players are increasingly focusing on strategic collaborations, mergers, and acquisitions to expand their product portfolio and global presence. By leveraging synergies and complementary capabilities, companies aim to enhance their technological expertise and market reach, fostering innovation and sustainable growth in the automotive axle and propeller shaft market. Additionally, investments in research and development activities to pursue breakthrough innovations in materials science, design optimization, and production efficiency are anticipated to shape the future of the market landscape. With a strong emphasis on sustainability, safety, and performance, market players are poised to deliver cutting-edge solutions that meet the evolving needs of automakers and consumers in the competitive automotive industry.

In conclusion, the global automotive axle and propeller shaft market present a dynamic and competitive environment with significant opportunities for growth and innovation. The convergence of lightweight materials, advanced manufacturing processes, and strategic partnerships is expected to redefine the market landscape and propel the industry towards a sustainable and technology-driven future. As market players continue to invest in research and development and collaborate to address market challenges and opportunities, the automotive axle and propeller shaft market is poised to witness exciting developments and breakthroughs that cater to the demands of a rapidly evolving automotive ecosystem.**Segments**

Global Automotive Axle & Propeller Shaft Market can be segmented based on various factors including position, type, material, sales channel, vehicle type, propeller shaft type, axle type, and country. In terms of position, axles and propeller shafts can be categorized as front or rear components. The type of axles and propeller shafts can be classified as single piece or multi-piece configurations. When it comes to material, options include alloys and carbon fiber, each offering unique characteristics. Sales channels for automotive axles and propeller shafts can either be OEM (Original Equipment Manufacturer) or aftermarket. Vehicle types such as passenger cars, light commercial vehicles, and heavy commercial vehicles have specific requirements for axles and propeller shafts. Propeller shaft types can vary from front propellers to inter-axles and rear propellers. Axles can be categorized as dead axles, live axles, or tandem axles. Finally, the market can be segmented based on countries across different regions such as the U.S., Canada, Mexico, Brazil, Argentina, Germany, Italy, U.K., Spain, China, India, Japan, South Korea, Australia, Saudi Arabia, U.A.E, South Africa, and many more.

**Market Players**

The major players in the automotive axle and propeller shaft market include ZF Friedrichshafen AG, Melrose Industries PLC, Dana Limited, American Axle & Manufacturing, Inc., Meritor, Inc., SHOWA Corporation, HYUNDAI WIA CORP, Gestamp Automoción, JTEKT Corporation, IFA Group, Automotive Axles Limited, Mark Williams Enterprises Inc., White Technologies Inc., Johnson Power Ltd, Wilson Drive Shafts, Nexteer Automotive, D & F Propshafts, and Bailey Morris Ltd. These players have a significant market presence and contribute to the competitive landscape of the industry. Market share data is available for global regions including North America, Europe, Asia-Pacific, Middle East & Africa, and South America, enabling a comprehensive understanding of the competitive strengths of each player. The market players are actively engaged in strategic initiatives such as mergers, acquisitions, product launches, and partnerships to enhance their product portfolios, expand their global footprint, and drive innovation in the automotive axle and propeller shaft market.

The automotive axle and propeller shaft market is witnessing dynamic growth driven by technological advancements, changing consumer preferences, and regulatory requirements. The increasing demand for lightweight materials like carbon fiber, the adoption of advanced manufacturing processes such as forging and rolling, and the focus on sustainability and performance are key trends shaping the market. With a strong emphasis on innovation, collaboration, and market expansion, the industry is set for exciting developments and breakthroughs that cater to the evolving needs of the automotive ecosystem. As market players continue to invest in R&D and forge strategic partnerships, the automotive axle and propeller shaft market is expected to evolve into a more competitive, efficient, and sustainable sector poised for long-term growth and success.

Explore Further Details about This Research Automotive Axle and Propeller Shaft Market Report https://www.databridgemarketresearch.com/reports/global-automotive-axle-propeller-shaft-market

Key Insights from the Global Automotive Axle and Propeller Shaft Market :

Comprehensive Market Overview: The Automotive Axle and Propeller Shaft Market is growing rapidly, driven by technological advancements and evolving consumer preferences.

Industry Trends and Projections: The market is expected to grow at a CAGR of X% over the next five years, with increasing automation and digitalization.

Emerging Opportunities: New market segments, such as sustainable and eco-friendly solutions, are creating significant growth prospects.

Focus on R&D: Companies are investing heavily in R&D to innovate and improve product offerings, ensuring market leadership.

Leading Player Profiles: Major player dominate the market with strong portfolios and strategic partnerships.

Market Composition: The market is diverse, with a mix of large enterprises and emerging startups driving competition and innovation.

Revenue Growth: The market has witnessed a steady increase in revenue, primarily driven by growing demand and product diversification.

Commercial Opportunities: There are considerable opportunities for business expansion in emerging regions and through technological innovations.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/zh/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/ar/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/pt/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/de/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/fr/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/es/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/ko/reports/global-automotive-axle-propeller-shaft-markethttps://www.databridgemarketresearch.com/ru/reports/global-automotive-axle-propeller-shaft-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Link

0 notes

Text

Revving Up Online Sales: A Deep Dive into the E-commerce Automotive Aftermarket

The global e-commerce automotive aftermarket size was valued at USD 62.12 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 20.5% from 2024 to 2030. The growing usage of online platforms to purchase car parts and accessories is a significant trend driven by consumers seeking convenience, variety, and competitive prices. Enhancements in technology, such as improved logistics and real-time inventory management, improve the overall online shopping process. Moreover, the increasing number of smartphones and internet availability make reaching e-commerce websites easier.

The growing preference for online shopping across various sectors, including automotive parts and accessories drives market growth. Consumers find it more convenient to search, compare, and purchase automotive components online, thanks to the easy accessibility of information, user reviews, and competitive pricing offered by e-commerce platforms. This shift towards digital retail channels has been further amplified by the proliferation of mobile devices, which enable customers to make purchases anytime and anywhere, thus accelerating the demand for online automotive aftermarket services.

E-Commerce Automotive Aftermarket Report Highlights

The lighting segment is expected to register the fastest growth over the forecast period. The growth can be attributed to the ongoing trend of automobile owners to customize and install new and personalized lighting equipment for interiors and exterior uses

The business to customer segment is expected to register the highest CAGR over the forecast period owing to the rising acceptance of DIY innovation in automobiles, thereby promoting automobile users to order automotive parts replacement and self-installation

The Asia Pacific region is expected to dominate the market over the forecast period. This can be attributed to rising economic activity in China and India. The presence of several automotive parts manufacturers in China and their ability to provide affordable and attractive products are offering an impetus to market growth

E-Commerce Automotive Aftermarket Segmentation

Grand View Research has segmented the global e-commerce automotive aftermarket based on replacement parts, end use, and region:

E-Commerce Automotive Aftermarket Replacement Parts Outlook (Revenue, USD Billion, 2017 - 2028)

Engine Parts

Piston and Piston Rings

Engine Valves and Parts

Fuel Injection Systems

Power Train Components

Transmission and Steering

Clutch Assembly Systems

Gearbox

Axles

Wheels

Tires

Braking Systems

Brake Calipers

Brake Pads

Rotor and Drums

Brake Disk

Lighting

Headlamps

Tail lamps

Others

Electrical Parts

Starter Motor

Spark Plugs

Battery

Others

Suspension Systems

Wipers

Others

E-Commerce Automotive Aftermarket End-use Outlook (Revenue, USD Billion, 2017 - 2028)

Business to Business

Business to Customer

E-Commerce Automotive Aftermarket Regional Outlook (Revenue, USD Billion, 2017 - 2028)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Asia Pacific

China

India

Japan

South America

Brazil

MEA

Order a free sample PDF of the E-commerce Automotive Aftermarket Market Intelligence Study, published by Grand View Research.

0 notes

Text

How Rubber Seals and O-Rings Drive Reliability in the Automotive Industry

In automotive engineering, even the smallest components play critical roles in vehicle performance and safety. Among these are rubber O-rings and other sealing components, which, despite their size, are vital to the proper functioning of many automotive systems. This guide delves into the significance of rubber O-rings, their applications, and how sealing components produced by leading manufacturers keep vehicles running smoothly and reliably.

The Vital Role of Rubber O-Rings in Automotive Sealing

Rubber O-rings, small donut-shaped elastomer rings, are essential for preventing fluid and gas leaks in automotive systems. Used widely across vehicles, they are crucial in engine and fuel systems. In engines, O-rings prevent oil leaks by creating seals between parts, thus ensuring that oil is contained within the system, supporting efficient performance and preventing potential breakdowns. In fuel systems, these O-rings provide secure seals that prevent dangerous and costly fuel leaks.

Leading rubber parts manufacturing companies produce O-rings designed to withstand high temperatures, pressures, and exposure to harsh chemicals. Such durability ensures they perform reliably even in the challenging conditions typical of automotive environments.

High-Performance Features of Rubber O-Rings

Not all O-rings are suitable for automotive use. High-performance O-rings must be crafted from durable materials such as nitrile, EPDM, silicone, or fluorocarbon rubber, each with specific properties that suit different applications. Nitrile, for example, resists oil and fuel, while silicone performs well in high-temperature environments.

Top rubber parts manufacturers adhere to strict standards, often following ISO certifications, to ensure quality and durability. This commitment is crucial for developing O-rings that withstand the wear and tear of dynamic automotive environments, such as engines with constantly moving parts. Without these high-quality seals, automotive systems would be prone to leaks, resulting in breakdowns and expensive repairs.

Other Key Sealing Components in Automobiles

O-rings are not the only essential sealing components in vehicles. Gaskets and oil seals are equally important for preventing fluid leaks and maintaining system integrity.

Gaskets: Gaskets are commonly found in engines, creating secure seals between engine parts to prevent fluid leaks. Located in areas like the engine block, cylinder heads, and exhaust systems, gaskets withstand high temperatures and pressures without degrading, ensuring the vehicle operates smoothly.

Oil Seals: These seals are designed to prevent oil leaks in key areas, such as axles, crankshafts, and gearboxes. Oil seals contain lubricants while keeping out dust and debris, helping to maintain the performance and longevity of components.

Manufacturers like GB Rubber utilize advanced techniques to produce these components, enhancing the reliability, efficiency, and lifespan of vehicles.

Advancements in Sealing Technology by Leading Rubber Parts Manufacturers

In addition to producing high-quality parts, top rubber parts manufacturers are at the forefront of sealing technology innovation. These companies heavily invest in research and development, constantly developing new materials and production processes that improve the performance and durability of automotive components.

As sustainability becomes a focus, leading manufacturers are exploring eco-friendly alternatives such as thermoplastic elastomers, which offer similar performance to traditional rubber but are more recyclable. Companies like GB Rubber are driving this shift, creating sealing solutions that balance high performance with environmental responsibility.

Choosing a Reliable Rubber Parts Manufacturer for Your Needs

Rubber O-rings and other sealing components are small parts with a big impact on vehicle safety and functionality. Manufacturers of these components play a crucial role, ensuring that vehicles stay on the road safely and efficiently. As the automotive industry advances, especially with electric and hybrid vehicles, rubber parts manufacturers are evolving to meet new demands, developing the next generation of sealing technology.

0 notes

Text

Slide Sledge Hammer: Enhancing Industrial Safety and Efficiency

The Slide Sledge Hammer is a revolutionary tool designed to improve safety and efficiency in industrial applications. Traditional sledgehammers pose risks such as injuries due to missed strikes and flying debris, while the Slide Sledge Hammer addresses these safety concerns with an innovative design that minimizes impact-related hazards. This blog discusses the key features, benefits, and applications of the Slide Sledge Hammer for industrial use. For more information on the Slide Sledge Hammer, visit RAAH Safety.

1. Key Features of the Slide Sledge Hammer

Controlled Impact Technology The Slide Sledge Hammer utilizes a unique sliding mechanism that delivers a controlled force directly to the target. The energy is transferred in a straight line, reducing the risk of glancing blows and improving precision. This design minimizes the chances of missed hits or off-angle strikes, making it safer than traditional hammers.

Interchangeable Tips The tool comes with a variety of interchangeable tips for different applications, such as driving out pins, breaking seals, or performing precision work. The versatility allows the Slide Sledge Hammer to be used across various tasks without the need for multiple tools.

Heavy-Duty Construction Built from high-quality materials, the Slide Sledge Hammer is durable and capable of withstanding harsh industrial conditions. Its robust design ensures long-term use while maintaining reliable performance.

Variety of Lengths and Weights Available in different lengths and weights, the Slide Sledge Hammer can be customized to fit the needs of specific tasks, whether it is for confined spaces or heavy-duty operations. The choice of different sizes provides flexibility in selecting the right tool for the job.

2. Benefits of Using the Slide Sledge Hammer

Enhanced Safety By eliminating the traditional swinging motion, the Slide Sledge Hammer reduces the risk of injuries associated with missed strikes and flying debris. Its controlled impact technology ensures that energy is applied precisely, resulting in fewer accidents.

Improved Accuracy The sliding action delivers a direct force, allowing for greater accuracy when working on delicate or precision tasks. The tool's design helps workers perform tasks more effectively, reducing the chances of damaging surrounding components.

Reduced Fatigue The Slide Sledge Hammer minimizes the physical exertion needed compared to traditional sledgehammers. The controlled impact reduces the need for excessive swinging, which can decrease worker fatigue and improve productivity during long shifts.

Versatility Across Applications The availability of interchangeable tips makes the Slide Sledge Hammer suitable for various tasks, such as maintenance, repair, and demolition work. It can be used in industries like construction, automotive, mining, and oil and gas.

Durable and Long-Lasting Constructed from durable materials, the Slide Sledge Hammer can withstand tough industrial environments. Its longevity reduces the need for frequent replacements, making it a cost-effective tool for long-term use.

3. Applications of the Slide Sledge Hammer in Industrial Use

Pin Driving The Slide Sledge Hammer is ideal for driving out stubborn pins from machinery, trucks, or heavy equipment. The precise force ensures that the pins are removed without causing damage to the equipment.

Automotive Repairs In automotive applications, the tool can be used for tasks like breaking loose rusted bolts, pushing out axles, or separating components. The controlled impact makes it perfect for working on sensitive vehicle parts.

Mining and Heavy Equipment Maintenance The Slide Sledge Hammer is frequently used in the maintenance of mining and heavy equipment to remove pins, bolts, or other components that are difficult to dislodge. Its ability to deliver powerful, controlled impacts ensures safety and efficiency.

Construction and Demolition For demolition tasks, the Slide Sledge Hammer can help break up concrete, brickwork, or other materials. The tool's design minimizes the risk of injuries while providing the force needed for heavy-duty tasks.

Oil and Gas Industry In the oil and gas sector, the Slide Sledge Hammer is used for the maintenance of drilling rigs, pipelines, and other equipment. Its durable construction ensures it can handle the demanding conditions of the industry.

4. Safety Guidelines for Using the Slide Sledge Hammer

Wear Appropriate Personal Protective Equipment (PPE) Always use suitable PPE, such as safety glasses, gloves, and hearing protection, when using the Slide Sledge Hammer. This helps protect against potential hazards like flying debris or loud noise.

Inspect the Tool Before Use Check the Slide Sledge Hammer and its tips for any signs of wear or damage before starting a task. Replace any damaged components to maintain safe and effective operation.

Secure the Work Area Make sure the work area is clear of any bystanders or obstacles. Properly secure the item you are working on to avoid shifting or movement during the impact.

Select the Correct Tip for the Task Choose the appropriate tip for the specific application. Using the correct tip ensures that the force is applied correctly and reduces the chances of damaging the tool or the workpiece.

Use the Tool as Intended Follow the manufacturer’s instructions on how to use the Slide Sledge Hammer. Avoid modifying the tool or using it for tasks it is not designed for.

5. Maintenance Tips for the Slide Sledge Hammer

Regularly Clean the Tool Keep the Slide Sledge Hammer clean by wiping it down after use. This helps prevent rust and ensures the tool remains in good condition.

Lubricate Moving Parts Apply lubrication to any moving parts to ensure smooth operation. Regular lubrication reduces wear and tear, prolonging the life of the tool.

Store in a Dry Environment To avoid corrosion, store the Slide Sledge Hammer in a dry place when not in use. Consider using a protective case to prevent accidental damage.

Conclusion

The Slide Sledge Hammer is a versatile and safer alternative to traditional hammers, providing controlled impact, increased accuracy, and improved worker safety. Its wide range of applications in industrial environments makes it an essential tool for maintenance, repair, and demolition work. For more information on the Slide Sledge Hammer, visit RAAH Safety.

0 notes

Text

0 notes

Video

youtube

2013 T-Rex Aero 3S by Anibal Automotive Design - Peel Paddock 2013 - Mon...

This is 200 horsepower and its light it's like 1300 lbs. And it can handle 800 pounds and the suspension is rock solid. It's very good. In the middle looks like a race car if you fill in the two voids it looks just like a race car and it's intense. We'd have to change a few things because the speed would be enormous. This is stock it goes about 190 miles an hour with two people with one president's 220 mph like a motorcycle behavior. But if you do the kit and you put the front end on and you close up the vents on the wheel well and it fits in nice and solid and the intakes are already there for the engine and you put on wheel wells and back end to it and you take the panel out above the motor and you put a new one in it really does not a ton of work it's not much money I gotta take that weird looking fishtail off the top of it. They have strange people in China and their gangs are weird and yeah they're kind of out there OK. To watch out when you go to China not to end up on the plate. They don't like people there who are foreigners they even nervous about our friend and just kept asking him questions so he started telling jokes and it calmed everyone down then they got real fast at the period but here's the deal we are watching trump fault the pieces and people are backing off until his statues and caches are gone and he is starting to realize he's doomed so you're acting like an **** to everybody including me but this is the car that the empire has picked and they have picked the conversion to happen a solid rear end they think and people say that independent suspension is safer and it is if it's not that hard so they'll probably go with that and it's not that much more as a matter of fact it's more prevalent and easier to get so I probably go with it and yeah it is safer you don't bounce off the road when you're doing a corner and everybody's gonna do it that is go fast around the corners it seems like it can. I've had this with my kit on it with this 200 horsepower version and it is a 490CC Motor and it's a lot of horsepower you have to super cool it and cool the transmission I've had it up to about 280 mph and I think you can go faster some are saying about 320 mph and he doesn't need to go that fast then it will hold his weight and kens And yeah that guy needs to lose weight but he's gonna get bigger and it might not fit him anymore but he can sell it and buy a new one and he'll probably might even go and get a vader kit those are a full size car. Grandpa has one and he likes it and it's a good idea. So I'm gonna go ahead and start making these kits I have it already and it looks really really hot and the rear end is completely done up and I do have it as 4 wheel independent suspension and it works really easy off the motor with a shaft drive. And yeah you put it in the middle and the And yeah you put it in the middle and the wheels only go up and down they don't go anywhere else so it's not that hard to do it's a strange trans axle and you have rear wheel drive on both into limited slip box. So I'm pretty good at this and this is a great idea. Will probably sell for 5 grand you can get a used one of these for about 4 grand or five grand. But not to 200 horsepower version. Start selling and they'll sit around by the time he gets around to it 3 months is plenty of time for that phenomena. And then they'll find out about my kit. I will get help on this i'm gonna start putting together and do testing and make several prototypes and after a prototype is done I take it apart. We don't we don't want any chicanery we said to take pictures that's all I get that we're going to go ahead with this this is a great car it's really inexpensive and a lot of people can buy it and use it as a regular car. Brand new it's like $8000 or less and it's Chinese. there's tons of people that can make these parts and we have cities of people that can do it and they're sitting around doing nothing these would be awesome in those cities and they make great fly vehicles and people are smaller and they look like they're loaded with the sports car. And it's really cheap it'll be 8000 for a new one plus five grand for the kit and a $1000 for extra stuff if you want it $14,000 and you have a brand new Lotus and it goes faster than the Lotus and it's probably safer it has a real cage. Now I've said my piece and I want people to see tell me if you want one of these

bg

we shall print now

Olympus

your great ok kid and yes good a mission and it is a mini vaydor good

Thor Freya

and the name and it is Arrow and tons say it ok and we mean it too.

Hera and h e had me no i did he said im pooped and will hold off now no

tons will fight me for it. and die. and tons see macs hold it. and want teh new iron man power source. and trump wil die. needs to that fn loser

bg

0 notes

Text

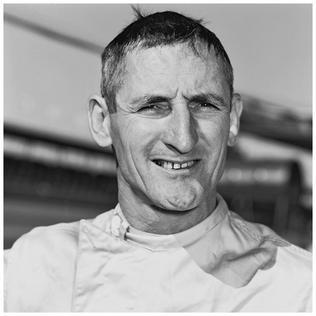

• Ken Miles was born on November 1st of 1918 in Sutton Coldfield, England. During his early life he apprenticed at a British car manufacturer. During World War II, he worked in various duties that dealt with machinery and utilized his mechanical skills. He began motorcycle racing while in the service and this would continue after his tour. After World War II, he returned to the automobile industry and to automotive racing. He acquired a Frazer-Nash racer and installed a Ford V8-60 engine. It had mile success in local and club competition.

• In 1952 Ken Miles came to the United States where he accepted a position as service manager for an MG distributor in California. Later, he would became involved with a wide range of teams and races and have a profound influence on early American road racing. His skills as a driver and fabricator quickly evolved and he became legendary on the West Coast with his competitive Specials.

• Miles first racer (that he constructed) was in 1953, while working for Gough Industries. He had been racing MG TD's for Gough, but they were often outclassed by the competition. Gough helped Miles with creating a racer, though he was unable to provide cash. What Gough did provide was use of any MG or Morris and any stock spare part.

• Miles began work on the MG R-1. The frame was created from mild steel tubing and attached to MG Series "Y" independent front suspension. The rear was comprised of a live axle. Alfin aluminum drum brakes with two-wheel cylinders were used to provide the stopping power while a Morris Minor rack-and-pinion kept the vehicle in the drivers control.

• Under the hood was an experimental racing engine that had a 1466cc displacement size. The engine would later be used by MG for their MG TF 1500. The engine had twin SU carburetors and a 10.5:1 initial compression ratio. The compression ratio was later increased to 11.6:1. The 83 horsepower engine was mated to a stock MG TD transmission which sent the power to the rear wheels.

• The car was clothed in a hand-formed aluminum body. The overall weight of the vehicle was less than 1,230 pounds. The car made its inaugural appearance in 1953 at a rainy Pebble Beach. The car had not been tested but this did not seem to matter, as it emerged victorious. Throughout the next year, the car would win all of the races it was entered, except for two. Its racing career came to an end in 1954 at Pebble Beach, when it suffered mechanical difficulties and failed to finish the race. The flywheel bolts fractures which allowed the flywheel to come loose. This resulted in the engine over-revving and it threw a rod. The R-1 Miles Special's racing career had come to an end.

• The second Miles Special racer was constructed in similar fashion to the first, but incorporated many key mechanical and design changes. Many MG components were still utilized, such as the gearbox and 1466cc MG XPEG engine. The space frame chassis was constructed from one-inch steel tubing which was lighter than its predecessor, but still retained the structural rigidity. To reduce frontal area, the driving position was lowered by nearly four inches. Other techniques were used to reduce the frontal area. The engine was tilted down in the front which did much to achieve this goal.

• The car was narrow and low, which meant changes were needed to fit all the engine components in the engine bay. The MG intake manifolds were installed upside down which allowed the carburetors to be angled and fit under the hood. The design of the vehicle was similar to the MG TF. This was done for brand recognition and to help promote the MG line of vehicles. There were differences; the R-2 had an envelope body with fenders that flared up, and over, the front and rear wheels. In the front was an MG style grille with headlights on either side. The car was finished in British racing green.

• The car was given the nickname, the Flying Shingle. Its inaugural race was in 1955 at Willow Springs. It failed to finish the race. Many of the other races in which it entered, it emerged victorious. Among its accomplishments were first place finishes at Pebble Beach and Torrey Pines. Miles was doing well in small-bore racing, but the competition was consistently keeping pace. Soon, a new machine was needed.

• Miles acceptable a position at Johnny Von Neumann's Porsche dealership. He raced during the 1956 season in a Porsche 550 Spyder and began work on a new racing Special. With von Neumann providing a generous budget, and Porsche providing ample stock components, Miles was able to construct a proper, large-budget racer. Power came from a Porsche Carrera four-cam engine that displaced 1500cc. The chassis was a Cooper Bobtail with a modified nose. The suspension was an independent setup with drums in the front and rear. The body shell was constructed of aluminum which aided greatly in the vehicles low weight of just under 950 pounds.

• Near the close of 1956, the newly created Special was brought to Pomona where it was piloted by Miles to a second place finish. At Paramount Ranch, the car was driven to a class win in the 1500cc class, and beat-out the big-bore modified class as well. The car was raced in 1956 and for part of 1957 before the von Neumann dealership was given the break they had been desperately searching for - a Porsche 550A. The car was supplied from the factory with orders to sell the R-3 Pooper Special. The R-1, R-2, and R-3 are still in existence in modern times. They are used in vintage competition and are shown at events.

• Ken Miles life came to a tragic end on August 17th, 1966 while driving a Ford J-car prototype. The car was traveling at 175 mph on a back-strech. Ken began preparing for a corner, slowing the vehicle down, but it went out of control and over an embankment. Ken was thrown from the car as it spun and went end-over-end. This tragedy brought an end to a brilliant career that began during the very early 1950s.

16 notes

·

View notes

Link

0 notes

Text

Stainless Steel Round Bar Market Size, Share, Analysis, Growth, Key Players, Trend and Forecast to 2034

In 2023, the global Stainless Steel Round Bar market was estimated at around 31 million tonnes. The market is expected to experience steady growth, with a projected Compound Annual Growth Rate (CAGR) of 4.2% during the forecast period through 2034.

Introduction:

Stainless steel round bars are essential components in various industrial applications due to their remarkable strength, corrosion resistance, and versatility. In South Africa, the demand for these robust materials is on the rise as industries seek durable and high-performance solutions. This article explores the dynamics of the Stainless Steel Round Bar Market in South Africa, highlighting its applications, market trends, and impact on industrial development.

Industrial Applications and Demand:

Stainless steel round bars are used extensively across multiple industries, including construction, automotive, manufacturing, and aerospace. Their superior mechanical properties make them ideal for applications requiring durability, precision, and resistance to harsh environments. The increasing industrialization and infrastructural development in South Africa drive the demand for stainless steel round bars in various sectors.

Click Here: https://www.chemanalyst.com/industry-report/stainless-steel-round-bar-market-4172

Construction Industry:

In the construction industry, stainless steel round bars are utilized for structural support, reinforcement, and fabrication of components such as beams, columns, and railings. Their strength and corrosion resistance make them suitable for both indoor and outdoor applications, ensuring long-lasting performance. As South Africa invests in building and infrastructure projects to support urbanization and economic growth, the demand for stainless steel round bars is expected to increase significantly.

Automotive Sector:

The automotive industry relies on stainless steel round bars for manufacturing critical components like axles, engine parts, and fasteners. These bars offer high strength, durability, and resistance to wear and tear, making them ideal for vehicle parts that require long-term reliability. With South Africa's automotive sector focusing on innovation and sustainability, the adoption of high-quality materials like stainless steel round bars is anticipated to rise, supporting the production of more efficient and durable vehicles.

Manufacturing and Heavy Industries:

Stainless steel round bars play a crucial role in manufacturing and heavy industries, including machinery, equipment, and tool production. Their versatility allows for precise machining and fabrication, making them indispensable in creating components that demand exact specifications and high performance. The expansion of South Africa's manufacturing base, driven by both domestic demand and export opportunities, fuels the growth of the stainless steel round bar market.

Aerospace and Defense:

In the aerospace and defense sectors, stainless steel round bars are used for producing high-strength, corrosion-resistant parts and components. Their reliability under extreme conditions is critical for aerospace applications, including aircraft frames, landing gear, and engine components. As South Africa aims to enhance its aerospace capabilities, the demand for advanced materials like stainless steel round bars is set to grow, contributing to the sector's development and innovation.

Market Trends and Growth Drivers:

The Stainless Steel Round Bar Market in South Africa is influenced by several trends and growth drivers. These include the increasing need for durable and high-performance materials in industrial applications, advancements in production technologies, and the push for sustainable and eco-friendly solutions. The growing focus on infrastructure development, automotive innovation, and industrial modernization also drives the adoption of stainless steel round bars across various sectors.

Click Here: https://www.chemanalyst.com/industry-report/stainless-steel-round-bar-market-4172

Significant players in the Global Stainless Steel Round Bar market are Universal Stainless & Alloy Products, Carpenter Technology Corporation, Tsingshan Holding Group, ThyssenKrupp Materials, Shri Bhagavati Bright Bars, Dongbei Special Steel, Crucible Industries, J. H. Stainless, ArcelorMittal, Garelick Steel, WalsinLihwa, ATI Allvac, Outokumpu, and Others.

Challenges and Strategies:

Despite its advantages, the Stainless Steel Round Bar Market in South Africa faces challenges such as fluctuating raw material prices, competition from alternative materials, and technical complexities in production. To address these challenges, strategic initiatives such as investing in research and development, enhancing local production capabilities, and fostering partnerships with global suppliers are essential. These strategies can help stabilize supply, reduce costs, and drive innovation in the market.

Conclusion:

The Stainless Steel Round Bar Market in South Africa represents a vital component in the country's industrial and infrastructural development. With its exceptional properties and wide-ranging applications, stainless steel round bars support key sectors like construction, automotive, manufacturing, and aerospace. By leveraging market opportunities, addressing challenges, and fostering innovation, South Africa can harness the full potential of the Stainless Steel Round Bar Market, driving industrial growth, technological advancement, and economic development in the region.

0 notes

Text

In the bustling automotive market of Kuala Lumpur, the Aruz 1.5X from SUASA SURIA SDN. BHD dealership stands out as a compelling choice for families and adventure seekers alike. Boasting a perfect blend of performance, spaciousness, and reliability, this SUV promises an exhilarating driving experience on both urban streets and off-road terrains. Equipped with a robust 1.5L Petrol Engine featuring 4 cylinders and 16 valves DOHC, the Aruz 1.5X delivers a spirited performance with 101 hp of power at 6000 RPM and 133 Nm of torque at 4200 RPM. Its Direct Injection fuel supply system ensures optimal fuel efficiency, making it an economical choice for long journeys. Step inside the Aruz 1.5X, and you'll be greeted by a cavernous cabin capable of accommodating seven passengers comfortably. With ample cargo volume of 213 liters and flexible seating arrangements, this SUV effortlessly adapts to your lifestyle needs, whether it's a weekend getaway or daily commutes. Built on a sturdy chassis with a ground clearance of 220 mm, the Aruz 1.5X conquers challenging terrains with ease while providing a smooth and stable ride. Its advanced safety features, including ventilated discs front brakes, MacPherson Strut front suspension, and Live Axle rear suspension, ensure optimum control and stability in various driving conditions. Designed for utmost convenience, the Aruz 1.5X comes loaded with features like electric power steering with tilt adjustment, rack & pinion steering gear type, and adjustable steering column. The 4-speed automatic gearbox and 2WD drive type offer seamless handling and maneuverability, whether you're navigating city streets or exploring the great outdoors. Sporting sleek alloy wheels measuring 17 inches and radial tires of size 215/60 R17, the Aruz 1.5X exudes a commanding presence on the road. Its aerodynamic design, coupled with distinctive styling cues, makes it a head-turner wherever it goes. In summary, the Aruz 1.5X from SUASA SURIA SDN. BHD dealership represents a perfect fusion of style, performance, and versatility. With its spacious interior, robust performance capabilities, and advanced safety features, it redefines the standards of SUV excellence in Kuala Lumpur's automotive landscape. Whether you're embarking on a family adventure or navigating through the urban jungle, the Aruz 1.5X is your ideal companion for every journey. Experience the thrill of driving with confidence—explore the Aruz 1.5X today!

0 notes

Text

Automotive Drivetrain Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Drivetrain Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Drivetrain Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Drivetrain Market is experiencing robust growth driven by the expanding globally. The Automotive Drivetrain Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Drivetrain Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

The global automotive drivetrain market size was USD 183.26 billion in 2020. The market is projected to grow from USD 191.50 billion in 2021 to USD 311.43 billion in 2028 at a CAGR of 7.2% in the 2021-2028 period

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/106409

Key Strategies

Key strategies in the Automotive Drivetrain Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Drivetrain Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Drivetrain Market.

Major Automotive Drivetrain Market Manufacturers covered in the market report include:

BORGWARNER INC (Michigan, U.S.) Aisin Seki Co., Ltd. (Aichi, Japan) American Axle & Manufacturing, Inc. (Detroit, U.S.) Melrose Industries PLC (London, U.K.) ZF Friedrichshafen AG (Friedrichshafen, Germany) Magna International Inc (Aurora, Canada) Dana Limited (Ohio, U.S.) JTEKT Corporation (Aichi, Japan) SHOWA CORPORATION (Saitama, Japan) Schaeffler AG (Herzogenaurach, Germany)

The rising developments in all wheel drive (AWD) for upcoming passenger cars and SUVs are driving the growth of the market. The important shift in consumer demand will eventually impact the driveline business offered by different OEMs.

Trends Analysis

The Automotive Drivetrain Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Drivetrain Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Drivetrain Market Solutions.

Regions Included in this Automotive Drivetrain Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Drivetrain Market.

- Changing the Automotive Drivetrain Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Drivetrain Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Drivetrain Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Automotive Drivetrain Market?

► Who are the prominent players in the Global Automotive Drivetrain Market?

► What is the consumer perspective in the Global Automotive Drivetrain Market?

► What are the key demand-side and supply-side trends in the Global Automotive Drivetrain Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Drivetrain Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Drivetrain Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

#Automotive Drivetrain Market#Automotive Drivetrain Market Share#Automotive Drivetrain Market Size#Automotive Drivetrain Market Trends#Automotive Drivetrain Market growth#Automotive Drivetrain Market outlook#Automotive Drivetrain industry

0 notes

Text

Unleashing Power and Precision: Square Drive Hydraulic Torque Wrenches Revolutionize Fastening

In the realm of industrial bolting and construction, the demand for tools capable of delivering immense torque with precision is paramount. Traditional tools often fall short when faced with monumental torque requirements, leading to inefficiencies and potential complications in critical applications. Enter the square drive hydraulic torque wrench – a powerhouse tool designed to conquer the toughest fastening challenges across diverse industries.

**ABS Group: Pinnacle Models for Unrivaled Performance**

Within ABS Group's inventory, the pinnacle of square drive hydraulic torque wrench models is on display, each offering unique features catering to specific needs:

1. **MXT+:** Integrating the strengths of the original MXT with advancements.

2. **Avanti:** Featuring a remarkable peak output exceeding 1,76,307 Nm.

3. **Edge S:** Standing as the stalwart for tasks involving high torque requirements in routine maintenance.

**Precision Bolting with Hydraulic Torque Wrench Square Drive Rental Services**

To empower industries with the latest in bolting technology, ABS Group proudly announces the availability of Hydraulic Torque Wrench Square Drive Rental Services. This offering ensures that businesses can access cutting-edge tools for precision bolting without the need for a significant upfront investment.

Explore the product inventory and delve into essential technical details by visiting ABS Group's Square Drive Hydraulic Torque.

**Unveiling the Powerhouse: Square Drive Hydraulic Torque Wrenches**

*Details:*

- **Brute Force:** Hydraulic pressure generates precise torque exceeding thousands of foot-pounds (ft-lbs), effortlessly handling tasks beyond manual or impact tools.

- **Squarely Embraced:** Compatible with standard impact sockets featuring square drives, offering versatility and convenience.

- **Pumping Up the Power:** Models with hand-held hydraulic pumps, electric, and pneumatic options cater to varying preferences.

- **Precision Dialed In:** Adjustable torque settings for optimal control and minimized overtightening risks.

- **Confined Spaces Conquered:** Compact design and optional features like reaction arms and swivel heads allow access to tight corners and awkward angles.

*Applications:*

- **Industrial Behemoths:** From engine assemblies and turbines to generators and heavy machinery.

- **Construction Marvels:** Secure structural beams, braces, and anchor bolts for buildings that stand the test of time.

- **Oil and Gas Lifeline:** Maintain pipelines, valves, and flanges for uninterrupted energy flow.

- **Keeping Trains on Track:** Ensure wheel bearings and track components are fastened to perfection.

- **Automotive Finesse:** Tighten suspension components, axles, and engine parts with precision.

**Why Choose Square Drive Hydraulic Torque Wrenches?**

- **Unmatched Muscle:** High torque capabilities for tackling the toughest fastening challenges.

- **Precision Control:** Adjustable torque settings prevent overtightening and safeguard components.

- **Maneuverability in Tight Spaces:** Compact design and optional features enhance accessibility.

- **Reduced Operator Fatigue:** High torque without the muscle strain of manual tools.

**Temporary Muscle Boost: Hydraulic Torque Wrench Rental**

For those occasional high-torque needs, ABS Group provides Hydraulic Torque Wrench rental services in India, offering a cost-effective solution without compromising on performance.

*Remember:*

- **Additional Equipment:** Hydraulic torque wrench pumps, hoses, and specific sockets might be required.

- **Maintenance Needs:** Hydraulic systems require proper care and servicing – ABS Group has got you covered!

**Selecting the Right Wrench: A Quick Guide**

- **Match Torque Range:** Align the torque range with specific requirements.

- **Choose Drive Size:** Select the compatible drive size for your application.

- **Consider Power Source:** Evaluate the preference between hand-held hydraulic pumps, electric, or pneumatic options.

- **Evaluate Features:** Consider optional features and accessories for enhanced functionality.

- **Set a Budget:** Determine your budget and explore rental options with ABS Group in India.

**Conclusion: Tackle Any Challenge with Confidence**

Square drive hydraulic torque wrenches offer unparalleled power and versatility, making them the go-to choice for demanding fastening tasks. With readily available rental options from ABS Group, businesses can confidently tackle any challenge, knowing they have the support of cutting-edge technology and expertise.

Visit Square Drive Hydraulic Torque Wrench to explore the complete range and elevate your bolting capabilities to new heights.

0 notes

Text

Automotive E-axle Market Industry Forecast and Competitive Landscape Reports | Global Insight Services

Global Insight Services has recently updated its global market reports, now including the latest data for 2024 and projections through 2033.

An automotive e-axle is a complete, integrated electric drive system that replaces the traditional engine, transmission, and differential in a vehicle. The e-axle contains an electric motor, transmission, and differential all in one unit. This allows for a more compact design and lighter weight, which improves fuel economy and reduces emissions. The e-axle also provides superior torque and power delivery, which results in better acceleration and handling.

Key Trends

The automotive industry is increasingly looking for ways to electrify vehicles in order to meet stringent emissions regulations. One key area of focus is the development of electric axle technology, which can help improve vehicle efficiency and performance.

To Know More@ https://www.globalinsightservices.com/reports/automotive-e-axle-market/?utm_id=Pranalip

Some of the key trends in automotive e-axle technology include:

Increased use of electric motors: Electric motors are becoming increasingly common in automotive applications, and e-axles are no exception. Electric motors offer a number of advantages over traditional internal combustion engines, including higher efficiency, lower emissions, and quieter operation.

Improved battery technology: As electric motors become more prevalent, so too does the need for improved battery technology. E-axles typically rely on batteries to store energy, which can then be used to power the electric motor.

Increased use of regenerative braking: Regenerative braking is a key technology for electric vehicles, and e-axles are no exception. Regenerative braking captures energy that would otherwise be lost as heat, and uses it to recharge the vehicle’s batteries.

Improved thermal management: Thermal management is a critical consideration for electric vehicles, as they generate a lot of heat when operating. E-axles need to be designed with effective thermal management in mind to ensure that the electric motor and batteries are kept at their optimal operating temperature.

Key Drivers

There are a few key drivers of the automotive e-axle market. Firstly, the e-axle market is being driven by the need for more fuel efficient vehicles. With the rising cost of fuel, consumers are increasingly looking for ways to save money at the pump. One way to do this is to purchase a vehicle with an e-axle, which can offer better fuel economy than a traditional gasoline or diesel engine.

Another key driver of the e-axle market is the increasing stringency of emissions regulations. In order to meet these regulations, automakers are turning to e-axles to power their vehicles. E-axles can help to reduce emissions by up to 90% when compared to traditional gasoline or diesel engines.

Lastly, the e-axle market is being driven by the need for more powerful and efficient vehicles. E-axles can offer up to twice the power and efficiency of a traditional gasoline or diesel engine. This is especially beneficial for electric vehicles, which require a lot of power to operate.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS21538/?utm_id=Pranalip

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS21538/?utm_id=Pranalip

Market Segments

The automotive e-axle market report is bifurcated on the basis of type, vehicle, and region. On the basis of type, it is segmented into all-wheel drive, front wheel drive, and rear wheel drive. By vehicle, it is categorized into battery electric vehicle and plug-in hybrid electric vehicle. Region-wise, it is studied across North America, Europe, Asia-Pacific, and the rest of the World.

Key Player

The automotive e-axle market report includes players such as Dana Incorporated, Melrose Industries PLC, Robert Bosch GmbH, Schaeffler AG, Magna International Inc., Borgwarner Inc., GKN plc, Nidec Corporation, AVL GmbH, and Linamar Corporation.

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS21538/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

About Global Insight Services:

lobal Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes