#Off-road vehicle components manufacturer

Explore tagged Tumblr posts

Text

Metalman Auto Ltd. is a leading OEM automotive parts supplier, specializing in high-quality metal components for various vehicle types. We are a one-stop shop for sheet metal, tubular fabrication, metal finishing, and assembly of components for original equipment manufacturers (OEMs) in both automotive and non-automotive sectors. Established in 1986, we are among India's first companies to offer comprehensive metal fabrication, finishing, and assembly solutions.

Contact us at +91 240 665 2444 (Ext. 500) or

email [email protected].

#Truck parts supplier#Bus components manufacturer#Commercial vehicle engine parts provider#Heavy-duty vehicle parts manufacturer#Commercial vehicle suspension components supplier#Light commercial vehicle parts manufacturer#Fleet vehicle parts supplier#Commercial vehicle transmission parts provider#Agricultural vehicle parts manufacturer#Farm machinery components supplier#Agri-vehicle engine parts producer#Tractor parts manufacturer#Agricultural equipment components provider#Agri-vehicle OEM parts supplier#Farm vehicle chassis components manufacturer#Agri-vehicle transmission parts producer#Construction vehicle parts supplier#Off-road vehicle components manufacturer#Heavy machinery parts provider#Mining vehicle parts supplier#Off-highway equipment components manufacturer#All-terrain vehicle parts supplier#Earthmoving equipment parts provider#Off-highway vehicle engine parts manufacturer#B2B auto parts distributor#Automotive supply chain management#OEM parts supply chain solutions#Automotive parts wholesale supplier#B2B vehicle components supply chain#Supply chain solutions for automotive OEMs

1 note

·

View note

Text

Why Your Porsche Macan Might Vibrate When Accelerating

Have you been experiencing vibration when driving your Porsche Macan at high speeds lately?

Macan is one of the most popular Porsche models… known for its impressive handling and performance. If it is vibrating when you press the gas pedal, it is trying to communicate with you about an issue. An issue that, if left undiagnosed, can translate into expensive repairs. Today’s blog post discusses some of the prominent reasons why such a high-performing vehicle might shudder during acceleration.

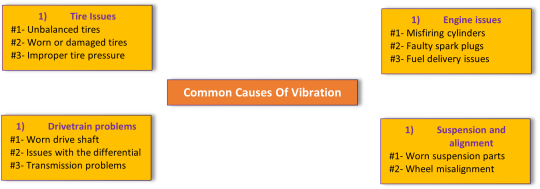

Common Causes of Vibration

Tire Issues

#1- Unbalanced tires: If your Macan’s tires are not properly balanced, you will experience a wobbling sensation when driving at high speeds. The intensity of the sensation will only increase over time. Vibration is the least that you’ll need to be worried about. Unbalanced tires can contribute to an array of drivability issues including decreased handling, increased tire wear, and a rougher ride.

#2- Worn or damaged tires: You might sense vibration as you accelerate your Porsche if there is a bulge in its tire sidewall… It is not safe to drive with such a tire deformity. It can contribute to a bunch of performance-related issues―ranging from traction loss to poor handling. You might also have to deal with issues such as sudden blowouts, premature tire replacement, and suspension malfunctions.

#3- Improper tire pressure: Inflating tires beyond the recommended range can also cause vibration. It is therefore important that you have your Porsche Macan’s tire pressure checked routinely and inflate it according to the manufacturer’s guidelines.

Drivetrain problems

#1- Worn drive shaft: The drive shaft is an essential component of a vehicle’s drivetrain… entrusted with the task of facilitating power transfer from the engine to the wheels. If your Porsche’s drive shaft gets damaged because of corrosion, contamination, or physical impact, you’ll encounter all sorts of drivability issues… including intense vibration under acceleration.

#2- Issues with the differential: The differential is yet another power-distributing component of your vehicle’s drivetrain… responsible for enabling the wheels to turn at different speeds. If there is something off with your Porsche Macan’s differential, you may feel vibration… especially during acceleration. Address the issue promptly if you don’t want the issue to escalate into an expensive repair.

#3- Transmission problems: When was the last time you had your Porsche Macan’s gearbox fluid changed? The gearbox is an important component of any vehicle… the sole purpose of which is to make the engine a controlled source of power. If your vehicle’s transmission system acts up because of low lubricant or a damaged component, its performance will suffer. And your vehicle might shudder under acceleration.

Engine issues

#1- Misfiring cylinders: Your Porsche engine will vibrate violently if some of its cylinders are not firing properly. From ignition system issues to faulty sensors… there can be many reasons why a car engine may misfire. Find out what’s going on with your Porsche and why some of its cylinders are not firing the way they should.

#2- Faulty spark plugs or ignition coils: Electric sparks generated by these tiny components ensure controlled combustion of the air-fuel mixture inside the cylinders. Prolonged exposure to repeated heating and cooling cycles, accumulation of carbon deposits, and improper gap between spark plug electrodes can influence spark plug operation… As a result, the engine might run rough and vibrate violently.

#3- Fuel delivery issues: If your Porsche Macan engine is not getting the correct amount of fuel at the right time, its performance will suffer. It may run unevenly and vibrate during acceleration.

Suspension and alignment

#1- Worn suspension components: The suspension system does much more than just damping road shocks. It distributes the vehicle’s weight across all four wheels. It prevents body roll during turns. Most importantly… it enables better steering response. Your Porsche will vibrate during acceleration if its suspension system is not in good shape.

Wrapping Up

So, there you have it…

A list of reasons why you might experience vibration when accelerating your Porsche Macan. Such an issue should not go undiagnosed… as it could lead to expensive repairs down the road. Have your vehicle checked by certified professionals if it’s wobbling too much under acceleration. Whether the culprit is a faulty suspension part or a defective drivetrain part… have it fixed before its too late.

#porsche macan#porsche service center#porsche maintenance#porsche car mechanic#porsche car suspension

2 notes

·

View notes

Text

As the conspiracy reaches its finale, the Void Hunter joins the fight.

Uncover the Conspiracy in Zenless Zone Zero's All-New Version "A Storm of Falling Stars", S-Rank Agent Hoshimi Miyabi is here! With S-Rank Agent Asaba Harumasa Limited-Time Giveaway! Pre-register to obtain additional rewards.

893 notes

·

View notes

Text

New! RC10CC Classic Clear Edition Kit

THE RC10CC COLLECTOR'S EDITION KIT Own the car that changed RC off-road racing forever. Now, in a crystal-clear collector’s edition!

We have shown you our SLA prototype race cars for years and how we use them for parts fit and testing. Our goal with the RC10CC was to provide you with the same look and feel as our SLA prototype display vehicles but more cost-effective and practical. We took the RC10 Classic and shot many of the molds in polycarbonate clear. While it is stronger than SLA and could be driven, it was manufactured as a display piece for your collection.

The polycarbonate clear components will only be available in the kit. They will not be sold individually.

Available: December 2023. (Pictured: #6004 RC10CC Classic Clear Edition Kit.)

More: https://tinyurl.com/asc6004?utm_source=x&utm_medium=social&utm_campaign=websiteproductsrc10cc

youtube

#Team_Associated#collectables#collectibles#WeAreAE#teamassociated#teamassociatedrc#rccar#rc#hobby#buggy#offroad#ae#rccars#rcbuggy#rchobby#rchobbies#rccollectible#rccollectable#Youtube

8 notes

·

View notes

Text

Maintenance Tips for Leaf Springs: Ensuring Longevity and Performance

Leaf springs play a crucial role in the suspension system of various vehicles, providing stability and support. Regular maintenance is essential to keep them in optimal condition, ensuring a smooth and safe ride. In this comprehensive guide, we'll delve into effective maintenance tips for leaf springs, covering key aspects such as inspection, lubrication, common issues, and practical solutions.

Inspection and Lubrication

1. Regular Visual Inspection

Start with a visual examination of the leaf springs for signs of wear, cracks, or deformation.

Check for proper alignment and ensure that the leaves are evenly spaced.

2. Spring Hanger and Shackle Inspection

Examine the spring hangers and shackles for any signs of damage or corrosion.

Tighten loose bolts and replace any worn-out components promptly.

3. Bushings and Bolts

Inspect the condition of the bushings and bolts connecting the leaf springs to the vehicle chassis.

Lubricate these components regularly to prevent friction and reduce wear.

4. Alignment Check

Ensure that the leaf springs are properly aligned to maintain the vehicle's balance.

Misalignment can lead to uneven tire wear and compromise handling.

5. Lubrication Tips

Use a high-quality, lithium-based grease for lubricating the leaf springs.

Apply grease to the ends of the leaves, focusing on pivot points and bushings.

Lubricate at regular intervals, especially after off-road use or exposure to harsh conditions.

Common Issues and Practical Solutions

1. Corrosion Prevention

Combat rust and corrosion by applying a rust inhibitor or anti-corrosion spray.

Keep the leaf springs clean and free from debris to prevent accelerated corrosion.

2. Leaf Fractures and Cracks

Inspect for any fractures or cracks in the leaves, as these can compromise the spring's strength.

Replace damaged leaves promptly to prevent further deterioration.

3. Squeaking Sounds

Address squeaking noises by applying a silicone-based lubricant on the leaf surfaces.

Check for worn-out bushings or shackles, as they may contribute to the noise.

4. Spring Sagging

If your vehicle experiences sagging, consider adding a leaf or replacing worn-out leaves.

Consult the manufacturer's guidelines to ensure proper load capacity.

5. Uneven Wear Patterns

Address uneven wear on the leaf springs by identifying and rectifying the root cause.

Regularly rotate and balance your tires to ensure even distribution of weight.

By implementing these maintenance tips, you can significantly extend the lifespan of your leaf springs and enhance the overall performance of your vehicle. Regular inspections, proper lubrication, and timely resolution of common issues are key to ensuring a safe and comfortable driving experience. Invest time in the care of your leaf springs, and you'll reap the benefits of improved longevity and reliability on the road .

2 notes

·

View notes

Text

Top row: Magazine article and poster from the Splash Grand Prix Middle row: Magazine cover and poster from the California Amphibious Racing Circuit Bottom row: Posters for the Japan Amphibious Endurance Tournament

With the rising popularity in amphibious cars, it only made natural sense to try and push them to their limits, to see just how fast they could go over both land and sea. As a result, several amphibious racing circuits arose all around the world. We've got some advertising material here, as well as some details and descriptions about some vehicles from three of those circuits.

The Splash Grand Prix was started in 1947 by a group of New England amphibious automobile enthusiasts who wanted to see just how fast their boat-cars could go. The result was the Splash Grand Prix, a 5-lap race around a course that takes place on equal amounts land and sea. While not as fast as some of the other circuits, it's been described as more high intensity, shorter-range event, with the winding spaghetti-like roads of the New England area being the perfect challenge for drivers to navigate. The event is a very friendly and humble affair, with people bringing their tents, grills, and coolers in a huge picnic/cookoff style event that culminates into watching the big race. Cars are usually modified or custom-built roadsters, though there have been a few modern-style entries (but nothing too flashy, as there are strict component and weight requirements). The red car in the article to the left is the Hammnicar III, built by John M. Hammond the Fourth in 1982, as a tribute to the then-lost Hammnicar I, and the seldom-seen Hammnicar II. It was used in the Splash Grand Prix in the 1982, 1983, and 1984 seasons, winning the first two, but by 1984, it was out of date. The Hammnicar II was based off of a VW Superbeetle, not unlike the Catfish, but was designed as a tandem-control vehicle, powered by a Chevrolet Corvair Turbo 180 hp turbo motor, rather than the original Volkswagen flat 4. It competed in the super-modified 200 hp class, and was able to achieve speeds on the water of up to 40 knots, while able to do 120 mph on land.

On the other side of the country, we'll find the California Amphibious Racing Circuit. Founded in 1954, you'll find that this event is the polar opposite of the Splash Grand Prix. Loud, bombastic cars with sleek designs and souped-up engines are the stars of the show, and sponsorships litter the sides of the cars like a NASCAR vehicle. Everyone and their grandmother is trying to sell you something at the CARC, and the atmosphere is intoxicatingly overwhelming. The race is televised across the country, with millions tuning in to see these amphibious beasts rip across the sand and surf at speeds that can reach over 130 mph! In 2003, Thompson Hydrosports, a well-known homologation manufacturer, finally decided to dip it's toes into building it's own entry into the 2004 California Circuit season, building the Thompson Tornado (the vehicle on the magazine to the left), powered by the homologation 350 Chevrolet, machined to produce 500 horsepower. The vehicle itself was built from fiberglass and aluminum, and had a top speed on the water of 90 knots, while on land it could achieve 160 mph. The Tornado would become infamous once it entered production in the next year, for being super fast, agile, but most importantly, dangerous. of the 52 built, including the 2 prototypes, 31 of them were damaged beyond repair, or lost in accidents, with a total of 8 fatal accidents killing one or both of the crew. The most notable of the accidents being of the 41st production vehicle, driven by Robert Hall, and James Williams as Navigator, was lost in an 87 knot roll, the vehicle disintegrating around the crew, with nothing of the wreck being recovered, other than two of the wheels.

Crossing the pond, you'll find the Japan Amphibious Endurance Tournament, an affair squarely in the middle of the SGP and the CARC in terms of flashiness. While a little late to the party in 1970, it is nonetheless a beloved event enjoyed by racing enthusiasts across the globe, with events being televised across the world. While CARC vehicles are built for speed, JAET vehicles are built for endurance, boasting innovative designs meant to be efficient and comfortable while still being powerful. Being an endurance tournament, the track usually spans the entire length of Japan in both land and sea, meaning the races can sometimes take over 2 days to fully complete. Pit stops are placed at key points in the race (usually in the transitions between ground and water), but some legs of the race can result in the drivers going for over 8 hours straight! The car featured in the leftmost advertisement is the 1999 ALIAH, developed by the Japanese Hydronautics Committee in 1998. A non-government entity, like the FIA, the JHC built the ALIAH as a successor to Project Kikka, an unbuilt prototype for a 200 mph on road racer, and a 100 knot superboat. ALIAH was built to succeed in nearly as many areas, using a folding wheel mechanism, to allow all 6 wheels to be hidden away to allow for higher speeds on the water. The actual ALIAH travelled up to 185 mph on land, and 83 knots on the water. During testing, however, the vehicle had an engine fire, from it's twin Toyota 1GZ-FE V12 engines, that produced 800 hp each, to the rear 4 wheels, or the hydrojets at the back. Posthumously, the gearbox was found to be at fault, though the EFS (Engine Fire Suppressants) were used, and saved the boat. This Magazine cover shows the post-fire repairs, missing aerodynamic panels, and allowing the internals to be seen. The ALIAH was used to demonstrate the CLASS VI racing series, and CLASS VI is still ongoing, though the current dominant force as of the 2023 season are turbine-electric hybrids, allowing for intense acceleration on land, and intense acceleration on ground. The ALIAH is on display in Karuizawa, at the JHC's headquarters/museum for hydro-racing. It is on display in situ post testing, with the fire damage still visible in places, though repairs had been made after the fire, which are also visible.

#Splash Grand Prix#California Amphibious Racing Circuit#Japan Amphibious Endurance Tournament#Fictional Events#ai generated images#human written context#unreality#unfiction

2 notes

·

View notes

Text

modern car design has honestly gone to shit

one reason is that it is now cheaper to put touchscreens, servos, and just screens in general than it is to actually engineer a properly working mechanical system, despite those being around for a literal century now

what's with the "one screen in the middle that controls everything" design philosophy anyways? "we want our drivers to look away from the road" is not. y'know. safe

the futuristic aspect also draws in buyers and (probably) investors, which makes it easier to fund projects. because futurism is better. these cars don't need to last!

and that's another problem: cars, ICE and EV, are not really built to last anymore. yes, all vehicles have a lifetime that they are rated for, but honestly it feels like it's getting shorter. or maybe consumerism has something to do with it: you always need to buy the newer and better car.

driving habits also do have something to do with it though, short commutes with lots of starting/stopping the engine do wear out parts faster. a lot of modern cars have the ability to turn off the engine while at a standstill, which does help increase fuel efficiency at the detriment of the engine

EVs do have drops in battery performance/capacity over time, which doesn't help

shifters are also changing. a lot. i mean, some are definitely cool, and I don't mind things like the BMW shifters that are just an automatic but fancy looking:

but then you have uh. well. tesla. with the touchscreen shifter. ok then

also they have the backup shift buttons. on the ceiling. yeah.

and their turn signals suck. that's enough dunking on tesla for this post. but do continue to dunk on tesla. especially the 6000+ lb. deathtrap called the cybertruck

which actually leads into the next point, big dumb trucks (and the general size increase of cars/the move towards SUVs and crossovers, but mainly the trucks). you know what they are. the giant trucks that have hoods taller than most sedans. that had that beautiful graphic of having worse sight lines than a main battle tank

safe for everyone, you see? they exist because of EPA regulations, after a certain size you're a work truck and less subject to regulations. and also the regulations on small vehicles are much higher than larger ones, in terms of like power to weight. so its a lot easier to make big than make small

most of them are pavement princesses anyways

repeal the chicken tax though, bring in light truck competition from overseas manufacturers. i want my kei trucks/cars (although that's the 25 year import law)

SUVs are painted as being safer, but actually have a higher center of gravity and are more prone to rolling over. they are safer though, cause they have more mass, which means what you hit gets damaged more and you get damaged less.

crossovers are weird cause they kind of can skirt regulations? not sure how they work

you can bypass some regulations with the "SUV overbite." give yourself a good approach angle, and now you're not a passenger vehicles and aren't subject to as many regulations. consequence is you look like this (sorry lexus)

electronic handbrakes. what. it makes sense, somewhat, but also manual handbrakes work perfectly well and are far less prone to failure (also drifting but)

push to start. i mean, it's not all bad, but keys are fun. give me keys. manual is better (although not necessarily for transmissions). don't be constantly emitting a signal that can be copied to steal a car. tesla i'm looking at you. a lot in this

i will say that not all digital displays are created equal. as far as i'm concerned, toyota/lexus have some very beautiful gauge clusters:

spicy, sleek, dare i say sexy, and they trickled down from the lexus LFA, which had a 9k rpm redline and got to that so fast they had to make a new digital cluster just to keep up. wild stuff. plus it's not too in your face and still has some mechanical components. nice

honestly no idea where i was going with this, but:

modern car design is getting worse because of futurism, trying to keep costs down, and poorly written/considered regulations

Touchscreens do not belong in cars

136K notes

·

View notes

Text

As the conspiracy reaches its finale, the Void Hunter joins the fight.

Uncover the Conspiracy in Zenless Zone Zero's All-New Version "A Storm of Falling Stars", S-Rank Agent Hoshimi Miyabi is here! With S-Rank Agent Asaba Harumasa Limited-Time Giveaway! Pre-register to obtain additional rewards.

893 notes

·

View notes

Text

KIO: Leading Automotive Battery Manufacturers Delivering Power and Reliability

Introduction: The Need for High-Performance Automotive Batteries

In the world of automobiles, reliable power sources are crucial to ensuring optimal vehicle performance. Whether for daily commutes or demanding applications, automotive batteries must provide consistent power, durability, and longevity. KIO Battery, a trusted name among automotive battery manufacturers, specializes in crafting high-quality batteries that cater to diverse driving needs. Engineered with cutting-edge technology and premium components, KIO Automotive Batteries are designed to enhance your driving experience and ensure uninterrupted performance.

Why KIO Stands Out Among Automotive Battery Manufacturers

KIO Battery has earned a reputation for excellence by delivering innovative and dependable automotive batteries. Here’s why KIO stands out:

Exceptional Power and Longevity: KIO Automotive Batteries are built to deliver reliable and consistent power. Whether navigating city traffic or taking long drives, these batteries ensure your vehicle performs at its best. Designed with longevity in mind, they reduce the frequency of replacements, offering exceptional value for money.

Advanced Technology: As a leading automotive battery manufacturer, KIO incorporates advanced technology in the design and production of its batteries. From superior cranking power to optimized energy efficiency, KIO batteries meet the demands of modern vehicles equipped with sophisticated electronics.

Durable in Various Driving Conditions: KIO Automotive Batteries are engineered to withstand extreme temperatures, vibrations, and challenging road conditions. Their robust construction ensures uninterrupted performance whether in hot summers, freezing winters, or rugged terrains.

Eco-Friendly Manufacturing: At KIO, we prioritize sustainability by using eco-friendly materials and adhering to responsible manufacturing practices. Our commitment to environmental responsibility makes us a preferred choice among eco-conscious customers.

Applications of KIO Automotive Batteries

Passenger Vehicles: Designed for cars, SUVs, and vans, KIO batteries provide reliable starting power and seamless energy delivery for daily commutes and long drives.

Commercial Vehicles: KIO batteries are ideal for trucks, buses, and other heavy-duty vehicles, ensuring consistent performance under demanding conditions.

Off-Road Vehicles: For adventure seekers and off-road enthusiasts, KIO Automotive Batteries offer durability and power to tackle tough terrains with ease.

KIO’s Commitment to Quality and Customer Satisfaction

KIO Battery takes pride in being a customer-focused company. Every battery undergoes rigorous quality checks to ensure it meets the highest industry standards. Our team of experts is dedicated to providing exceptional support, helping customers choose the right battery for their vehicles and applications.

Why Choose KIO Automotive Batteries?

Unmatched Performance: KIO batteries deliver optimal power and reliability.

Extended Lifespan: Engineered for longevity, they minimize downtime and replacement costs.

Wide Compatibility: Suitable for various vehicle types and applications.

Affordable Excellence: High-quality products at competitive prices.

Conclusion: Trust KIO, a Leader Among Automotive Battery Manufacturers

When it comes to dependable power solutions for your vehicle, KIO Battery is the name you can trust. As one of the premier automotive battery manufacturers, KIO offers a diverse range of batteries tailored to meet your needs, whether for passenger cars, commercial vehicles, or off-road adventures.

Contact KIO Battery Today

Elevate your driving experience with KIO Automotive Batteries. Contact us now to learn more about our innovative battery solutions and find the perfect power source for your vehicle. With KIO, you’re always powered for the journey ahead.

Original Source - https://medium.com/@kiobattery/kio-leading-automotive-battery-manufacturers-delivering-power-and-reliability-f9e7c5dbbc03

0 notes

Text

The Different ATV Types

An all-terrain vehicle (ATV) is а vehicle built to traverse challenging terrain with ease. These handlebar-operated machines come in various types, catering to different power needs, user preferences, and capabilities.

Utility ATV variants are the workhorses of the off-road vehicle market, engineered for practical, labor-intensive applications, hence dubbed “workhorses.” These machines can traverse hilly, rocky, and rugged terrains due to their robust construction and specialized features, including powerful 250 to 700cc engines that provide the strength and torque needed for pulling heavy loads. The limited but advanced suspension systems in these ATVs provide a smooth ride even on rough ground. Many models feature front and rear storage, making it easy to transport tools and equipment. Leading manufacturers of utility ATVs include Polaris Ranger and Yamaha.

Sport ATVs match the power of utility models but are lighter and more agile. Their engine capacities range between 150cc and 850cc. Lightweight frames make them ideal for high-speed rides on uneven and rugged terrain. Models like the Yamaha YFZ450R boast a fuel-injected engine, an A-arm suspension for aggressive trail raiding, and a steel/aluminum frame for better durability, center of mass, and performance. With top speeds reaching around 55 miles per hour, this ATV type suits thrill-seekers. Other notable brands include Kawasaki and Suzuki, which produce high-performance machines optimized for speed and stability on rugged trails.

For expert riders seeking exceptional power and performance, high-performance quads or ATVs are an excellent choice. These machines are equipped with superior components, such as advanced suspension systems that provide significant ground clearance, and often deliver horsepower surpassing standard ATVs. Leading manufacturers, such as Can-Am with their Outlander and Polaris with their Scrambler model, dominate this segment.

Side-by-side ATVs, or utility task vehicles (UTVs), are famous for delivering enhanced performance, utility, and comfort. These vehicles differ from traditional models in seating configuration and driving controls, featuring two front seats and sometimes an option for rear seating for transporting passengers or cargo. Unlike traditional models, which are handlebar-operated, UTVs have a steering wheel, providing a car-like driving experience. They also come with a rugged frame, sports suspension, and a shorter wheelbase, which makes them agile and well-suited for navigating difficult terrain with ease.

ATVs also cater to various skill levels with entry-level and youth models. Entry-level variants, with engine capacities between 125cc and 250cc, provide enough power for light-duty tasks and recreational riding. These are budget-friendly options for beginners. Youth models designed for children are smaller than the entry-level model and equipped with additional safety features. For instance, they come with an automatic engine shut-off system that prevents the vehicle from running over or dragging a rider in case of a fall or if the ATV tips beyond a safe angle.

Diverging from modern four-wheeled ATVs, the three-wheeled all-terrain cycles (ATC) represent a now-discontinued class of ATVs. These vehicles were notorious for their instability and high rollover risks, requiring riders to possess exceptional skills, such as leaning into turns to maintain balance. Popular in the 1980s, models like the Honda ATC 90 and the Big Red marked an early era of recreational motorized transport.

Given the various choices available today, selecting the right model requires considering various factors. The intended use (whether for recreation, herding, hauling, or racing) should guide buyers toward a suitable category. Rider experience is equally important: beginners may prefer models with automatic transmissions, a lower center of gravity, and smaller engines for easier handling, while experienced riders may opt for high-performance ATVs with larger engines and greater endurance. For eco-conscious users, ATVs that run on electric power or alternative fuels offer a sustainable option.

1 note

·

View note

Text

Brake Repairs in Milwaukee: Why First Rate Auto Is Your Best Bet

When it comes to your car’s safety, there’s no room for compromise. Your brakes are one of the most important systems in your vehicle. Without functioning brakes, even the smallest obstacle can turn into a disaster. That’s why getting regular brake repairs is crucial. But with so many auto repair shops in Milwaukee, how do you choose the right one?

Why First Rate Auto Stands Out in Milwaukee

You’ve probably heard the saying, “You get what you pay for.” When it comes to brake repairs, this couldn’t be more true. So, what sets First Rate Auto apart from the competition? Let’s break it down:

Experienced Technicians Who Know Brakes Inside and Out

At First Rate Auto, we don’t just hire any technician off the street. Our team consists of certified professionals with years of experience. These aren’t just people who can fix cars—they’re brake experts. Whether you’re dealing with squeaky brakes or a more serious issue, we’ve seen it all and know how to fix it.

Brake repair isn’t just about slapping on new pads and calling it a day. It requires a detailed understanding of the brake system, including the master cylinder, brake fluid, rotors, and more. Our technicians take the time to diagnose the problem correctly the first time, ensuring that your car gets the repair it needs without unnecessary work.

Top-of-the-Line Brake Parts for Maximum Safety

We understand that your safety is the top priority, which is why we only use high-quality brake parts. Our brake pads, rotors, and other components are sourced from reputable manufacturers. We won’t skimp on the parts because we want you to have the best.

Whether you drive a small sedan or a heavy-duty truck, we make sure the parts we use are perfectly suited for your vehicle. Cheap parts may save you a few bucks now, but they can lead to costly repairs down the line. We believe in investing in quality because it saves you money in the long run and ensures your vehicle performs optimally.

Fast and Convenient Service

We know that your time is valuable. That’s why we offer fast, efficient brake repairs. At First Rate Auto, we don’t believe in making customers wait for weeks to get their brakes fixed. Our team works quickly without sacrificing quality, so you can get back on the road with peace of mind.

We also understand that life doesn’t always fit into a 9-to-5 schedule. That’s why we offer flexible hours, so you don’t have to worry about taking time off work to get your brakes repaired. Whether you need an early morning appointment or a late afternoon visit, we’ve got you covered.

Affordable Pricing with Transparent Estimates

At First Rate Auto, we pride ourselves on offering competitive prices. We believe that quality brake repair shouldn’t break the bank. When you bring your car to us, we provide clear, transparent estimates—no hidden fees, no surprises.

We take the time to explain the work that needs to be done and the cost involved so you can make an informed decision. We want you to feel comfortable and confident in the service we provide.

Signs Your Brakes Need Repair

Now that you know why First Rate Auto is the best choice for brake repairs, it’s important to recognize when your brakes actually need fixing. Here are some common signs that indicate it’s time to bring your car in for a brake check-up:

Squealing or Grinding Noises

One of the most obvious signs that your brakes need repair is unusual noise. If you hear a high-pitched squeal or a grinding sound when you apply the brakes, it’s a clear indicator that your brake pads are worn down. This could also mean that your rotors are damaged.

When you notice these sounds, it’s essential to get your brakes inspected right away. Ignoring the noise could lead to further damage and more costly repairs down the line.

Vibrations or Pulling

If your car vibrates when you brake, it could mean your rotors are warped or uneven. This can cause the brake pads to grip inconsistently, making it harder to stop your vehicle smoothly. Additionally, if your car pulls to one side when braking, it might indicate an issue with the brake callipers or a fluid imbalance.

Both of these problems can be dangerous, so it’s important to get them checked out as soon as possible.

Warning Lights and Unusual Sounds

Sometimes, your vehicle will let you know when there’s a brake issue before you even notice any physical symptoms. Keep an eye on your dashboard warning lights. If the brake warning light comes on, it’s time to visit a mechanic.

Similarly, if you hear a soft “whooshing” sound, it might indicate low brake fluid levels. This could compromise your braking ability, so it’s crucial to address this quickly.

How First Rate Auto Makes Brake Repairs Easy for You

At First Rate Auto, we want to make your brake repair experience as smooth as possible. Here’s how we do it:

Easy Appointment Scheduling

We know your schedule is packed. That’s why we’ve made scheduling an appointment with us quick and easy. You can either call us directly or use our online booking system to choose a time that works best for you. No long waiting times or complicated scheduling—just simple, hassle-free appointments.

Quick Turnaround Time

We understand that being without your car can be inconvenient. That’s why we aim for quick turnaround times without sacrificing the quality of our work. In many cases, we can complete your brake repair in just a few hours, so you’re not left stranded for long.

Customer Satisfaction Guaranteed

Your satisfaction is our top priority. We stand behind our work with a satisfaction guarantee. If for any reason you’re not happy with the brake repair service you received, we’ll make it right. We believe in building trust with our customers, and that’s why we always go the extra mile to ensure you’re completely satisfied.

Conclusion: Drive Safely with First Rate Auto

When it comes to best auto repairs in Milwaukee, First Rate Auto is the name you can trust. With experienced technicians, top-quality parts, fast service, and affordable pricing, we provide the best brake repair experience in the area. So, the next time you hear that squeak or feel that vibration, don’t hesitate to schedule an appointment with us. We’ll have your brakes back in top shape in no time—keeping you safe on the road and driving with peace of mind.

First Rate Auto

5424 W State St, Milwaukee, WI 53208, United States

+14147743738

Get Direction From Google Map

0 notes

Text

Protecting Lives India’s Premier Road Safety Products Manufacturers

India’s bustling road networks are among the busiest in the world, serving as vital lifelines for trade, travel, and connectivity. However, with high traffic volumes comes an equally significant responsibility—ensuring road safety. Each year, countless lives are impacted by road accidents, underscoring the urgent need for robust road safety devices and solutions. This is where crash barriers and other essential road safety materials come into play. In this blog, we explore the importance of road safety in India and highlight the contributions of leading road safety products manufacturers in India.

Understanding Crash Barriers: The Guardians of Road Safety

Crash barriers are indispensable components of modern road infrastructure. These structures are meticulously designed to reduce the severity of accidents and prevent vehicles from veering off the road. Here are the primary types of crash barriers:

Thrie Beam Crash Barrier The thrie beam crash barrier stands out for its three-wave design, offering enhanced strength and flexibility. It is particularly effective on highways and bridges where high-impact resistance is critical. These barriers are engineered to absorb collision forces, minimizing damage to vehicles and protecting occupants.

Highway Crash Barrier Specifically designed for high-speed roadways, highway crash barriers provide unparalleled safety by preventing vehicles from crossing into opposing traffic lanes or off-road areas. These barriers are a cornerstone of safe and secure highways across India.

Crash barriers not only protect vehicles but also safeguard pedestrians and infrastructure by mitigating accident impacts. Investing in these road safety devices is a proactive step toward reducing road mishaps.

India’s Leading Road Safety Products Manufacturers

India is home to several premier crash barrier manufacturers and road safety products manufacturers that contribute significantly to enhancing road safety standards. These companies produce a wide range of road safety materials tailored to the diverse needs of the nation’s infrastructure. Some of their key offerings include:

Crash Barriers: Durable and rigorously tested for various road conditions.

Road Signages: Providing clear directions and warnings to drivers.

Reflective Road Studs: Enhancing visibility, especially during nighttime.

Safety Cones and Bollards: Organizing traffic flow in construction zones and accident-prone areas.

These manufacturers prioritize quality, innovation, and compliance with international safety standards, ensuring that their products meet the highest benchmarks.

Why Quality Road Safety Devices Matter

The effectiveness of road safety measures depends largely on the quality of the materials and devices used. Here’s why choosing high-quality road safety devices is crucial:

Accident Prevention: Properly installed crash barriers act as lifesavers by preventing vehicles from running off the road or colliding with hazardous obstacles.

Durability: High-quality road safety materials withstand extreme weather conditions and heavy impacts, ensuring long-term performance.

Cost-Effectiveness: While premium materials may involve higher initial costs, their durability and reliability translate into significant savings over time.

Compliance and Trust: Reputable road safety products manufacturers in India adhere to strict regulatory guidelines, providing users with peace of mind and trust in their investments.

Prioritize Road Safety Today

Road safety is not just a collective responsibility but a personal commitment to protecting lives. By investing in top-notch crash barriers, highway crash barriers, and other essential road safety devices, you contribute to a safer environment for everyone. Collaborate with trusted road safety products manufacturers in India to ensure that your roads are equipped with the best safety solutions available.

Take the first step towards safer roads by exploring premium road safety materials from India’s leading manufacturers. Contact us today to learn more about how you can enhance road safety in your community or business. Together, let’s build a safer tomorrow.

#Highway Crash Barriers#road safety products manufacturers#road safety products#roller crash barriers#w beam#crash barriers suppliers#crash barriers#Road Safety Products Manufacturers

0 notes

Text

As the conspiracy reaches its finale, the Void Hunter joins the fight.

Uncover the Conspiracy in Zenless Zone Zero's All-New Version "A Storm of Falling Stars", S-Rank Agent Hoshimi Miyabi is here! With S-Rank Agent Asaba Harumasa Limited-Time Giveaway! Pre-register to obtain additional rewards.

893 notes

·

View notes

Text

The Importance of Regular Alignment Checks for Your Honda Acty

Introduction

The Honda Acty is a compact yet highly dependable vehicle known for its versatility and efficiency. Whether you use it for work or leisure, keeping your Acty in top condition ensures it remains a reliable companion. One often-overlooked aspect of vehicle maintenance is wheel alignment. Regular alignment checks are crucial to maintaining optimal performance and extending the life of your vehicle. In this article, we will delve into why alignment checks are essential and how they can save you money and trouble in the long run. And if you're looking for replacement components, you can find a wide range of Honda Acty parts online to address any alignment-related wear and tear.

What Are Wheel Alignment Checks?

Wheel alignment involves adjusting the angles of your vehicle’s wheels so they align perfectly with the manufacturer's specifications. Proper alignment ensures that the wheels are parallel to each other and perpendicular to the ground. The key elements of alignment include:

Camber: The angle of the wheel when viewed from the front.

Caster: The steering pivot angle.

Toe: The angle of the wheels when viewed from above.

Unlike tire balancing, which focuses on distributing weight evenly around the tire, alignment specifically addresses the positioning of the wheels. Keeping your Honda Acty properly aligned ensures better handling and even tire wear.

Signs That Your Honda Acty Needs an Alignment Check

Spotting alignment issues early can save you from costly repairs. Common signs that your Honda Acty may need an alignment check include:

Uneven or rapid tire wear: Check your tires regularly for uneven tread patterns.

Vehicle pulling to one side: If your car drifts to one side even when the steering wheel is straight, alignment could be the culprit.

Crooked steering wheel: A misaligned steering wheel is a telltale sign of alignment issues.

Decreased fuel efficiency: Poor alignment increases rolling resistance, which reduces mileage.

If you notice these signs, it might be time to search for Honda Acty parts online to replace any worn components and schedule a professional alignment service.

Benefits of Regular Alignment Checks

Regular alignment checks offer several benefits that enhance your driving experience and reduce maintenance costs:

Improved Tire Longevity: Proper alignment reduces uneven wear, extending the life of your tires.

Enhanced Safety: Alignment ensures better handling and stability, especially during sudden maneuvers.

Increased Fuel Efficiency: With wheels properly aligned, your vehicle uses less energy to move forward.

Smoother Driving Experience: Proper alignment eliminates vibrations and ensures a comfortable ride.

By maintaining proper alignment and replacing any damaged components with Honda Acty parts online, you can enjoy these benefits for years to come.

Risks of Ignoring Alignment Issues

Ignoring alignment issues can lead to:

Accelerated Tire Wear: Misaligned wheels wear out tires faster, requiring frequent replacements.

Poor Handling: Misalignment compromises stability and increases the risk of accidents.

Strain on Other Components: Misaligned wheels put extra stress on the suspension and steering systems.

Higher Maintenance Costs: Neglecting alignment can result in expensive repairs down the road.

Don’t let a simple issue escalate; keeping your Honda Acty in good condition is as easy as staying proactive about alignment.

How Often Should You Get an Alignment Check?

Experts recommend getting an alignment check every 6,000 to 10,000 miles or at least once a year. However, the frequency can vary based on factors such as:

Driving Conditions: Rough roads and potholes can knock your alignment out of place.

Terrain: Driving on uneven or off-road terrain affects alignment.

Load: Carrying heavy loads can impact the angles of your wheels.

Additionally, if you’ve recently hit a pothole or curb, it’s wise to check your alignment. Replacing worn-out components with Honda Acty parts online is also a great way to address damage and maintain proper alignment.

Choosing a Reliable Service Provider for Alignment Checks

Selecting the right service provider is crucial for accurate alignment. Consider the following tips:

Look for mechanics or service centers with advanced alignment equipment.

Choose Honda-certified service centers for specialized expertise.

Verify customer reviews and ratings to ensure reliability.

When replacing damaged parts, always opt for genuine Honda Acty parts online to maintain your vehicle’s performance and longevity.

Conclusion

Regular alignment checks are essential for keeping your Honda Acty in peak condition. They improve safety, enhance driving comfort, and save you money by extending the life of your tires and other components. Don’t overlook the importance of addressing alignment issues promptly and sourcing high-quality Honda Acty parts online to keep your vehicle running smoothly. Schedule your next alignment check today and experience the difference it makes!

1 note

·

View note

Text

Stainless Steel Exhaust Systems: Enhancing Performance and Durability for 4x4 Vehicles

In the world of off-road vehicles, particularly 4x4s, performance and durability are key factors in ensuring a successful adventure. One of the most important components that can significantly enhance both aspects is the exhaust system. Stainless steel exhaust systems, in particular, are a top choice for off-road enthusiasts looking to boost their vehicle’s performance while ensuring long-lasting durability. Among the leaders in this field is Outback Exhausts, a brand specializing in high-performance exhaust systems for 4x4 vehicles.

The Importance of a Quality Exhaust System

The exhaust system is an essential part of any vehicle's engine, responsible for directing harmful gases away from the engine and reducing noise. However, the quality of the exhaust system can also influence a vehicle’s overall performance. A high-quality exhaust system can enhance engine efficiency, improve fuel economy, and increase horsepower. For 4x4 vehicles, which often operate under tough conditions, having a reliable exhaust system that can withstand the demands of off-road terrain is crucial.

Why Choose Stainless Steel for Exhaust Systems?

Stainless steel is a superior material for exhaust systems due to its combination of strength, corrosion resistance, and durability. Unlike regular steel, which is prone to rust and degradation when exposed to moisture and harsh weather conditions, stainless steel offers excellent protection against corrosion, even in the most challenging environments. This makes it an ideal material for 4x4 vehicles that are frequently exposed to dirt, water, salt, and extreme temperatures during off-road adventures.

The robust nature of stainless steel ensures that the exhaust system can handle the high temperatures produced by the engine, and its resistance to corrosion guarantees a longer lifespan. Additionally, stainless steel’s ability to withstand mechanical stresses and high-pressure conditions is crucial for off-road vehicles, which often push their limits on rough terrains.

Outback Exhausts: Engineering for Tough Australian Conditions

When it comes to performance exhaust systems designed specifically for 4x4 vehicles, Outback Exhausts stands out as a leading brand. Specializing in high-performance exhaust systems for both newer and older 4x4 models, Outback Exhausts has earned a reputation for engineering systems that are built to last, even in the toughest conditions.

One of the main reasons Outback Exhausts is favored by off-road enthusiasts is its focus on the unique challenges faced by vehicles navigating rugged Australian landscapes. The brand’s systems are engineered to withstand the extreme conditions typical of off-road driving in Australia, including high temperatures, dust, mud, and unpredictable weather patterns.

The Features of Outback Exhausts

Outback Exhausts’ systems are constructed using 409 stainless steel, a material that is specifically chosen for its exceptional corrosion resistance, especially in outdoor conditions. This makes it an excellent choice for off-road vehicles that are frequently exposed to the elements. The 409 stainless steel used in Outback Exhausts systems is known for its ability to endure harsh environmental factors without rusting or degrading over time.

Another key feature of Outback Exhausts systems is the use of mandrel-bent tubing. Mandrel bending is a technique used in the manufacturing of exhaust systems to ensure smooth, unrestricted flow of exhaust gases. The process involves bending the tubing without altering its diameter, unlike traditional bending methods that can lead to restrictions and cause backpressure. This ensures that the exhaust gases flow freely, which can improve engine performance by enhancing the vehicle's power and fuel efficiency.

The smooth flow provided by mandrel-bent tubing reduces exhaust gas turbulence, allowing the engine to expel gases more efficiently. This results in better performance and less strain on the engine, especially during high-demand situations like off-roading or towing.

Heat-Resistant Coating for Extra Durability

In addition to the high-quality 409 stainless steel and mandrel-bent tubing, Outback Exhausts systems are coated with a heat-resistant paint. This coating provides an extra layer of protection, ensuring that the exhaust system can handle extreme temperatures without deteriorating. The heat-resistant paint also helps prevent the build-up of rust and corrosion, which can be a common issue for exhaust systems exposed to high heat and moisture.

The combination of stainless steel, mandrel-bent tubing, and heat-resistant coating ensures that Outback Exhausts systems can handle the most demanding off-road conditions, providing long-term reliability and performance. Whether you are navigating muddy tracks, rocky paths, or dusty trails, Outback Exhausts provides the durability and power necessary for a successful off-road experience.

Outback Exhausts: Designed for Both Newer and Older 4x4 Models

Outback Exhausts understands the needs of 4x4 enthusiasts who may be working with both modern and older vehicles. Their range of exhaust systems caters to a wide variety of 4x4 models, ensuring that even older vehicles can benefit from enhanced performance and reliability. Whether you own a recently purchased 4x4 or a vintage model, Outback Exhausts has a tailored solution to meet your needs.

By choosing an Outback Exhaust system, 4x4 owners not only ensure their vehicle’s longevity but also enhance its ability to perform under tough conditions. The systems are engineered with a focus on both performance and reliability, providing off-roaders with the peace of mind that their exhaust system will hold up under even the most challenging circumstances.

Conclusion

For 4x4 enthusiasts, having a high-quality exhaust system is essential to maximize vehicle performance and ensure longevity. Outback Exhausts delivers on both fronts by offering exhaust systems that are specifically engineered for the tough conditions of off-road driving. Made from durable 409 stainless steel, equipped with mandrel-bent tubing for smooth exhaust flow, and coated with heat-resistant paint, Outback Exhausts systems are built to withstand the demands of off-road adventures, providing enhanced performance, durability, and reliability for both newer and older 4x4 models. For those looking to enhance their 4x4's off-road capabilities, Outback Exhausts is a trusted choice.

0 notes

Text

Waterproof and Dustproof Design of Slide Switches in Extreme Environments

In the context of extreme environments, slide switches must perform reliably despite exposure to elements like moisture, dust, and other contaminants. These switches are crucial components in various outdoor and industrial applications, where reliability and durability are non-negotiable. In this article, we will explore the design considerations for waterproof and dustproof slide switches, focusing on the application of protection ratings such as IP67 and IP68, and strategies to enhance sealing and durability in extreme conditions.

1. Importance of Waterproof and Dustproof Design for Slide Switches

Slide switches are commonly used in a range of environments, including outdoor equipment, automotive applications, and industrial machinery. These settings often involve exposure to harsh conditions, such as high humidity, dust, dirt, or even submersion in water. Therefore, slide switches need to be designed with robust waterproof and dustproof features to ensure their long-term functionality and reliability.

Common applications that require waterproof and dustproof slide switches include:

Outdoor Lighting Systems: Streetlights and other outdoor lighting solutions that are exposed to rain, dirt, and environmental contaminants.

Automotive Applications: Switches used in vehicles, especially for off-road vehicles, where exposure to dust, water, and dirt is frequent.

Industrial Equipment: Machinery that operates in dusty and wet conditions, such as factories and construction sites.

Marine Applications: Equipment used in marine environments, where exposure to saltwater and humidity is a significant concern.

2. Protection Ratings and Sealing Techniques

To protect the internal components of a slide switch, manufacturers use various sealing technologies and design features to meet specific protection ratings. These ratings, defined by the International Protection (IP) code, indicate the level of protection against dust and water ingress.

IP67 Rating: The "6" in IP67 indicates that the device is completely dust-tight, while the "7" means the device can be submerged in water up to 1 meter for 30 minutes without suffering damage. To achieve this rating, slide switches are typically designed with gaskets, O-rings, or seals made of materials such as silicone or rubber. These seals form an airtight barrier that prevents water and dust from entering the switch’s internal mechanisms.

IP68 Rating: This rating is even higher than IP67, indicating that the device is dust-tight and can withstand prolonged submersion in water deeper than 1 meter. For slide switches that require this rating, more advanced sealing methods are often employed, such as multi-layer sealing systems or the use of corrosion-resistant metals for switch contacts.

3. Key Design Considerations for Waterproof and Dustproof Slide Switches

1. Material Selection

Choosing appropriate materials is critical for ensuring a switch's durability and resistance to environmental factors. For waterproof and dustproof slide switches, materials that offer both sealing and structural strength are essential.

High-Quality Plastics: Materials like polycarbonate, nylon, and PPS (polyphenylene sulfide) are often used for their strength and resistance to environmental factors. These plastics can endure exposure to harsh conditions like UV radiation, moisture, and temperature fluctuations.

Corrosion-Resistant Metals: For switches that require metallic components, corrosion-resistant materials such as stainless steel or coated brass are used to prevent rusting or degradation when exposed to moisture or salty air (e.g., in marine environments).

2. Sealing Technologies

Effective sealing is the cornerstone of waterproof and dustproof slide switch design. In addition to gaskets and O-rings, manufacturers use the following sealing techniques:

Overmolding: This involves molding a rubber or silicone layer around the switch housing to provide a sealed, waterproof barrier.

Double Seals: To increase the level of protection, some slide switches feature dual sealing systems, including both O-rings and gaskets, to ensure that moisture or dust does not enter the internal components.

Potting: In some cases, the switch's internal components are potted (encapsulated) in a protective resin, which further ensures that no water or contaminants can enter.

3. Testing and Certification

To verify the performance of waterproof and dustproof slide switches, manufacturers must conduct rigorous testing according to IP standards. Tests include immersing switches in water for extended periods (to simulate submersion), spraying with dust, and performing vibration tests to simulate real-world conditions.

4. Conclusion

Waterproof and dustproof slide switches are essential for ensuring the reliability and functionality of electronic devices in extreme environments. By integrating advanced sealing technologies, selecting the right materials, and adhering to international protection standards, manufacturers can design slide switches that withstand harsh conditions while maintaining high performance. As industries such as automotive, industrial, and outdoor equipment continue to demand more durable and robust components, the importance of effective waterproof and dustproof designs for slide switches will only continue to grow.

Through continuous innovation and advancements in sealing and material technologies, the next generation of slide switches will be even more resilient and versatile, meeting the needs of high-performance applications in a variety of harsh environments.

en.dghongju.com

0 notes

Text

How Do Brake Pads Work?

Before diving into which brake pads are the best, it’s important to understand their basic function. Brake pads are components in a disc brake system that create friction against the brake rotor (a rotating disc connected to the wheels) to slow or stop the vehicle. When you press the brake pedal, hydraulic fluid is pushed through the brake lines to squeeze the brake caliper, which presses the brake pads against the rotor. This friction generates heat and reduces the rotational speed of the wheel, bringing your vehicle to a stop.

However, not all brake pads are created equal. Different materials are used in brake pad manufacturing, each providing distinct advantages depending on vehicle type, driving habits, and conditions.

Types of Auto Brake Pads

Choosing the right brake pad depends on multiple factors, including friction coefficient, brake feel, and material composition. Below, we’ll break down the most common types of brake pads and discuss their specific characteristics, along with recommendations on the types of vehicles they’re best suited for.

1. Ceramic Brake Pads

Material Composition:

Ceramic brake pads are made from a mix of ceramic fibers, non-ferrous materials, and bonding agents. Some formulations also include small amounts of metal to enhance performance.

Friction Coefficient and Brake Feel:

Friction coefficient: Ceramic pads generally have a moderate friction coefficient, around 0.35-0.45, depending on the specific formulation.

Brake feel: These pads provide a smooth soft and stable braking experience with minimal noise. The gradual friction build-up offers a controlled braking feel, ideal for everyday driving.

Price:

Higher price: Ceramic brake pads tend to be more expensive due to the advanced materials and manufacturing process. They are considered premium products.

Best for drivers who have a higher budget and prioritize comfort, quiet operation, and longevity.

Recommended Vehicles:

Passenger cars, especially luxury vehicles or family sedans, benefit the most from ceramic pads due to their quiet operation, long life, and minimal rotor wear.

These pads are best suited for commuting and city driving but are not ideal for high-performance or heavy-duty applications.

2. Semi-Metallic Brake Pads

Material Composition: These pads consist of a high percentage of metal (30-50%) and are known for their strong braking power.

Friction Coefficient and Brake Feel: With a higher friction coefficient (0.35-0.40), semi-metallic brake pads provide aggressive stopping power, making them ideal for trucks, SUVs, and performance vehicles. However, they tend to produce more noise and brake dust.

Price:

Moderate price: While less expensive than ceramic pads, semi-metallic brake pads are typically more affordable while still offering great performance.

They strike a balance between cost-effectiveness and high performance, making them a solid choice for those who need more aggressive braking without paying top dollar.

Recommended Vehicles: Best for trucks and heavy-duty vehicles involved in towing, off-road, or high-performance driving.

3. Low Metallic Brake Pads

Material Composition: Low metallic brake pads are similar to semi-metallic but contain a lower percentage of metal, making them more balanced in performance.

Friction Coefficient and Brake Feel: These pads offer a moderate brake performance with a friction coefficient between 0.30 and 0.40. They are an affordable option with solid performance for everyday driving.

Price:

Lower price: These pads are generally less expensive than both ceramic and semi-metallic options, making them a cost-effective choice for those on a budget.

They offer a good balance between affordability and performance, particularly for drivers who need reliable braking without the premium cost.

Recommended Vehicles: Suitable for mid-range vehicles, offering a balance of durability, cost, and performance.

4. Organic Brake Pads (NAO - Non-Asbestos Organic)

Material Composition: Made from organic materials, these pads are softer and quieter, with minimal environmental impact.

Friction Coefficient and Brake Feel: Organic pads offer a lower friction coefficient (0.3-0.4), making them suitable for light vehicles and urban driving. They provide a softer braking feel but can wear out faster under heavy use.

Price:

Lowest price: Organic brake pads are typically the most affordable option. They are great for drivers on a tight budget who prioritize comfort and low noise over high-performance braking.

These are an excellent choice for city driving or light-duty vehicles where extreme performance is not required.

Recommended Vehicles: Ideal for compact cars and city vehicles, where low noise and comfort are more important than extreme performance.

0 notes

Text

As the conspiracy reaches its finale, the Void Hunter joins the fight.

Uncover the Conspiracy in Zenless Zone Zero's All-New Version "A Storm of Falling Stars", S-Rank Agent Hoshimi Miyabi is here! With S-Rank Agent Asaba Harumasa Limited-Time Giveaway! Pre-register to obtain additional rewards.

893 notes

·

View notes

Text

youtube

Selecting the appropriate gear oil is crucial for maintaining the performance and longevity of your vehicle's drivetrain components. Among the various classifications, GL-5 gear oil stands out for its specific applications and benefits.

Understanding GL-5 Gear Oil

The American Petroleum Institute (API) classifies gear oils using "GL" ratings, ranging from GL-1 to GL-6, each indicating the oil's suitability for different gear types and operating conditions. GL-5 gear oil is formulated for heavily loaded gear sets, particularly hypoid gears found in automotive axles, operating under high-speed and shock load conditions, as well as low-speed and high-torque scenarios.

Oil Specifications

Key Features of GL-5 Gear Oil

High Extreme-Pressure (EP) Additive Content: GL-5 gear oils contain a higher concentration of EP additives compared to GL-4 oils. These additives form a protective layer on gear surfaces, effectively preventing metal-to-metal contact under heavy loads and extreme pressures.

Protection Against Wear and Corrosion: The robust additive package in GL-5 oils not only reduces wear but also offers protection against corrosion, ensuring the durability of gear components.

Thermal Stability: GL-5 gear oils are designed to maintain their viscosity and protective qualities even at elevated temperatures, which is essential for components subjected to high thermal stress.

Applications of GL-5 Gear Oil

GL-5 gear oils are primarily used in:

Hypoid Differentials: The design of hypoid gears involves significant sliding action, necessitating lubricants with high EP additive levels to prevent wear.

Heavily Loaded Gear Sets: Vehicles operating under severe conditions, such as towing or off-road driving, benefit from the enhanced protection of GL-5 oils.

Considerations When Using GL-5 Gear Oil

Compatibility with Synchronizers: The higher EP additive content in GL-5 oils can be corrosive to yellow metals (e.g., brass, bronze) commonly used in synchronizers of manual transmissions. Therefore, GL-5 oils are generally not recommended for synchronized manual transmissions unless specified by the manufacturer.

Manufacturer Recommendations: Always consult your vehicle's owner manual or manufacturer guidelines to ensure the correct specification of gear oil is used for each component.

Driven Racing Oil's 75W-90 Synthetic Limited Slip GL-5 Gear Oil

For those seeking a high-quality GL-5 gear oil, Driven Racing Oil's 75W-90 Synthetic Limited Slip Gear Oil is a noteworthy option. This synthetic oil is formulated with advanced GL-5 additive chemistry, providing consistent performance in limited-slip differentials. It resists foaming and maintains viscosity under extreme heat and high loads, making it ideal for applications ranging from autocross to track day cars. Additionally, it contains limited-slip additives, ensuring smooth operation of differentials.

Conclusion

Selecting the appropriate gear oil, such as a high-quality GL-5 variant, is essential for the optimal performance and longevity of your vehicle's drivetrain components. By understanding the specifications and applications of GL-5 gear oils, and adhering to manufacturer recommendations, you can ensure that your vehicle operates smoothly under various driving conditions.

0 notes

Text

The Benefits of Buying Restored Defenders for Sale Over New Models

When it comes to owning a Land Rover Defender, enthusiasts are often faced with the choice between buying a brand-new model or opting for a restored version. While both options have their merits, buying restored Defenders for sale has become an increasingly popular choice among off-road lovers, adventure seekers, and collectors alike. In this blog, we’ll explore why purchasing a restored Defender can be more beneficial than buying a new one.

1. Cost-Effectiveness

One of the most significant advantages of buying a restored Defender over a new one is cost. New Defenders can come with a hefty price tag, especially when you factor in additional customization, upgrades, and taxes. Restored Defenders, on the other hand, often offer significant savings while still delivering the performance and durability you expect from a Land Rover. These vehicles are typically priced much lower than their brand-new counterparts, making them a more affordable option for those who want to enjoy the iconic Defender experience without breaking the bank.

2. Classic Design and Timeless Appeal

There’s something special about the classic design of the Land Rover Defender that has captured the hearts of enthusiasts for decades. While new models come with modern technology and updates, the charm of the original design is undeniable. Restored Defenders for sale offer the best of both worlds: you get the iconic, rugged look of the original Defender with the benefit of modern mechanical upgrades. If you’re someone who appreciates the timeless appeal of classic cars, a restored Defender will be more fulfilling than a new, contemporary version.

3. Customization Options

When buying a new vehicle, you might have a few customization options, but they are often limited to factory-standard choices. With restored Defenders for sale, you often have more freedom to choose the modifications and upgrades that suit your personal style. Many restoration shops offer customized interior and exterior designs, bespoke paint jobs, modern tech integration, and off-road enhancements.

4. Sustainability and Eco-Friendliness

Nowadays, a lot of consumers place a high value on sustainability. Buying a restored vehicle is one of the most eco-friendly ways to own a car. Instead of purchasing a brand-new model that requires manufacturing, transportation, and resources that contribute to carbon emissions, buying a restored Defender for sale gives a second life to an existing vehicle. This reduces waste and supports a more sustainable approach to car ownership. Additionally, many restoration shops focus on environmentally conscious practices, further enhancing the sustainability of your purchase.

5. Unique Ownership Experience

Owning a restored Defender for sale offers a unique experience that new models simply can’t match. Restored vehicles have a story to tell. Whether it’s a rare model or one that has been painstakingly rebuilt to perfection, each restored Defender has its own history. For enthusiasts and collectors, owning a piece of history adds a layer of pride and connection that a new model can’t replicate. Additionally, buying a restored Defender from a reputable seller means you can often learn about the restoration process, giving you insight into the work and craftsmanship that went into bringing the vehicle back to life.

6. Durability and Proven Performance

While new cars come with the promise of modern engineering, restored Defenders for sale offer durability that has been tried and tested. The Defender is known for its ruggedness and ability to handle tough terrains. When purchasing a restored model, you’re not just getting a car that looks good—you’re investing in a vehicle that has proven its ability to perform in the most challenging conditions. Moreover, many restoration shops focus on improving the mechanical components of these vehicles, ensuring that you get a reliable and long-lasting off-roader.

7. Value Retention

Land Rover Defenders are iconic vehicles, and they hold their value well over time. A well-restored Defender, especially one that has been carefully cared for and upgraded, is likely to appreciate in value, making it a smart investment. While new cars generally depreciate as soon as they leave the dealership, restored Defenders for sale tend to retain their value better due to their rarity and classic appeal. As classic cars become more desirable, your restored Defender could become a valuable asset in the years to come.

Conclusion

While a new Land Rover Defender offers the latest technology and features, restored Defenders for sale bring their own set of advantages that make them a compelling choice for many buyers. From cost savings and unique customization options to their classic design and proven durability, a restored Defender offers an exceptional ownership experience. Whether you’re a passionate off-roader or a collector seeking a piece of automotive history, a restored Defender is sure to deliver the performance and satisfaction you’re looking for, all while providing a connection to one of the most iconic vehicles ever made.

Also Read : Modern Styling Upgrades: 10 Ways to Refresh Your Restored Defenders

0 notes