#Cargo van loading ramp

Explore tagged Tumblr posts

Text

Tough Loads? Trailer Hire in Nottingham Has You Covered

Nottingham hums with activity, from its medieval roots to its modern industrial estates. Hauling goods is a regular need here. Trailers for rent in Nottingham offer a clever fix. They’re handy. They’re flexible. These towable units, often enclosed or built for specific loads, tackle everything from tools to furniture.

Benefits of Renting Trailers

Shielding Your Gear from Harm

Enclosed trailers are a fortress for your cargo. Nottingham’s drizzly days can’t touch what’s inside. Rain won’t ruin your kit. Sofas stay spotless. This matters for fragile stuff like gadgets or heirlooms. For someone shifting a record collection in Sherwood, a trailer keeps treasures intact. The sealed design also wards off sticky fingers. You can leave it parked without fretting. This protection saves headaches and pricey fixes.

Tackling Tricky Loads

Not every item fits neatly in a van. Trailers come in specialized forms, like low-loaders for hefty gear. These are made for odd-shaped or heavy cargo. Picture generators or garden rollers. A low-loader’s ramp makes loading smooth. For a builder in Carlton lugging a compactor, this is a dream. Unlike regular vehicles, these trailers handle quirky loads without a hitch. You skip the faff of cobbling together transport or making extra runs.

Wallet-Friendly Freedom

Buying a trailer brings upkeep and storage woes. Renting dodges those traps. You pay just for the time you use. No insurance hassles. No, squeezing it into your driveway. Trailers are ready at a moment’s notice, ideal for sudden jobs. For a Nottingham shopkeeper, this keeps costs low. You can grab a trailer for a quick stock run in St Ann’s without tying up funds. This nimbleness lets you meet needs without breaking the bank.

Mastering City and Country Roads

Nottingham’s streets swing from cramped lanes to open fields. Trailers are agile enough for city twists. They glide through tight corners in The Meadows without sweat. They’re also tough for rural treks, like hauls to Ruddington. Most can be towed without a fancy licence. This opens the door for everyday drivers. For a tree surgeon crisscrossing Nottinghamshire, a trailer fits every path without a fuss.

Backing Green Choices

Nottingham’s eco streak runs deep. Trailers help you move goods sustainably. One trailer trip can replace a flurry of car journeys. This trims fuel and fumes. Many trailers are shaped for fuel efficiency, cutting drag. For green-thinking folks in Chilwell, this is a quiet victory. You’re shifting stuff while easing your eco-impact.

Rock-Solid Reliability

A breakdown can throw a spanner in your plans. Rented trailers are kept in top nick to avoid trouble. Mechanics are ready, even at odd hours. For a Nottingham market trader, this is a relief. You can tow a trailer stuffed with wares to a fair in Gedling without fearing a glitch. This dependability keeps your day on track.

Who’s the Perfect Match for Trailer Rental?

Homeowners Making Moves

Nottingham’s homes, from Edwardian gems to new flats, see plenty of turnover. Homeowners are a natural fit for trailers. A move in Clifton might mean lugging beds or fridges. An enclosed trailer keeps them safe from the elements. For DIY relocators, this beats stuffing a car. Even smaller tasks, like clearing a loft in Basford, lean on a trailer’s space. Homeowners save hours and skip the slog of endless trips.

Retailers and Small Business Owners

Nottingham’s markets and indie stores brim with unique goods. Small business owners often need to shift stock. A trailer is perfect for one-off runs. A cafe in Sneinton might haul new tables. A trailer does it in one shot. For shopkeepers, this is cheaper than a full-on lorry. Even stockroom purges in Long Eaton benefit from a trailer’s room. Business owners keep things ticking without splashing out on their own kit.

Tradespeople and Contractors

Nottingham’s building and refit scene is alive with activity. Plumbers, sparks, and chippies need solid transport. Trailers are spot-on for gear and supplies. A job in Radford might call for pipes or plasterboard. A trailer keeps it tidy and secure. Low-loaders suit heavier tools, like scaffolds. For a tiler carting gear across Top Valley, this is a no-brainer. Tradespeople can zero in on their work, not transport tangles.

Gardeners and Landscapers

Nottingham’s green patches, from Victoria Embankment to backyards, need regular TLC. Landscapers shift mounds of soil, shrubs, or slabs. Trailers are made for these hauls. A garden redo in West Bridgford might mean clearing gravel or logs. A trailer takes it all at once. For solo gardeners, this trumps overloading a van. It also keeps clients’ lawns neat, boosting their rep. Landscapers can scale up projects without waste worries.

Market Traders and Event Planners

Nottingham’s Goose Fair and local markets spark transport demands. Traders and event planners lean on trailers. A stall in Victoria Centre needs shelving and stock. A trailer makes the setup a doddle. For gigs in Wollaton Park, trailers shift sound gear or food tents. They’re subtle and fit snug spots. Planners can nail the event without transport woes. Traders save time and keep their goods locked tight.

Landlords and Property Managers

Nottingham’s rental scene, with uni lets and family homes, moves fast. Property managers deal with clear-outs and upgrades. Trailers are a neat solution. A tenancy end in Arboretum might leave sofas or rugs. A trailer clears it in one go. Landlords refitting a house in Bakersfield also win. A trailer keeps flooring or paint cans organised. It’s a thrifty way to tackle one-off jobs without ongoing transport costs.

Slotting into Nottingham’s Streets

Nottingham’s roads range from cobbled nooks to wide avenues. Small trailers fit tight alleys in the Lace Market. Bigger ones suit open plots in Bilborough. Towing is easy with most cars. You might need a permit for kerbside parking, but it’s a simple process. Trailers are dropped off and picked up to suit your diary. This makes them a fit for both city and village jobs. Finding a spot is rarely a snag.

Trailers for rent in Nottingham are more than a way to move stuff. They guard your cargo, handle odd loads, and keep costs down. They bend to the city’s urban and rural quirks while backing green habits. Homeowners, retailers, tradespeople, gardeners, event planners, and landlords all see the upside. Trailers bring ease, security, and efficiency. For anyone shifting goods in Nottingham, a trailer is a sharp pick. It paves the way for smoother projects

1 note

·

View note

Text

My lead flight attendant came to me and said, "We have an H.R. on this flight." (H.R. stands for human remains.)

"Are they military?" I asked.

'Yes', she said.

'Is there an escort?' I asked.

'Yes, I've already assigned him a seat'.

'Would you please tell him to come to the Flight Deck. You can board him early," I said...

A short while later a young army sergeant entered the flight deck. He was the image of the perfectly dressed soldier. He introduced himself and I asked him about his soldier.

The escorts of these fallen soldiers talk about them as if they are still alive and still with us. 'My soldier is on his way back to Virginia ,' he said. He proceeded to answer my questions, but offered no words.

I asked him if there was anything I could do for him and he said no. I told him that he had the toughest job in the military, and that I appreciated the work that he does for the families of our fallen soldiers. The first officer and I got up out of our seats to shake his hand. He left the Flight Deck to find his seat.

We completed our preflight checks, pushed back and performed an uneventful departure. About 30 minutes into our flight, I received a call from the lead flight attendant in the cabin.

'I just found out the family of the soldier we are carrying, is also on board', she said. She then proceeded to tell me that the father, mother, wife and 2-year old daughter were escorting their son, husband, and father home. The family was upset because they were unable to see the container that the soldier was in before we left.

We were on our way to a major hub at which the family was going to wait four hours for the connecting flight home to Virginia . The father of the soldier told the flight attendant that knowing his son was below him in the cargo compartment and being unable to see him was too much for him and the family to bear. He had asked the flight attendant if there was anything that could be done to allow them to see him upon our arrival. The family wanted to be outside by the cargo door to watch the soldier being taken off the airplane.

I could hear the desperation in the flight attendants voice when she asked me if there was anything I could do. 'I'm on it', I said. I told her that I would get back to her.

Airborne communication with my company normally occurs in the form of e-mail like messages. I decided to bypass this system and contact my flight dispatcher directly on a secondary radio. There is a radio operator in the operations control center who connects you to the telephone of the dispatcher. I was in direct contact with the dispatcher. I explained the situation I had on board with the family and what it was the family wanted. He said he understood and that he would get back to me.

Two hours went by and I had not heard from the dispatcher. We were going to get busy soon and I needed to know what to tell the family. I sent a text message asking for an update. I saved the return message from the dispatcher and the following is the text:

'Captain, sorry it has taken so long to get back to you. There is policy on this now, and I had to check on a few things. Upon your arrival a dedicated escort team will meet the aircraft. The team will escort the family to the ramp and plane side. A van will be used to load the remains with a secondary van for the family.

The family will be taken to their departure area and escorted into the terminal, where the remains can be seen on the ramp. It is a private area for the family only. When the connecting aircraft arrives, the family will be escorted onto the ramp and plane side to watch the remains being loaded for the final leg home.

Captain, most of us here in flight control are veterans. Please pass our condolences on to the family. Thanks.

I sent a message back, telling flight control thanks for a good job. I printed out the message and gave it to the lead flight attendant to pass on to the father. The lead flight attendant was very thankful and told me, 'You have no idea how much this will mean to them.'

Things started getting busy for the descent, approach and landing. After landing, we cleared the runway and taxied to the ramp area. The ramp is huge with 15 gates on either side of the alleyway. It is always a busy area with aircraft maneuvering every which way to enter and exit. When we entered the ramp and checked in with the ramp controller, we were told that all traffic was being held for us.

'There is a team in place to meet the aircraft', we were told. It looked like it was all coming together, then I realized that once we turned the seat belt sign off, everyone would stand up at once and delay the family from getting off the airplane. As we approached our gate, I asked the copilot to tell the ramp controller, we were going to stop short of the gate to make an announcement to the passengers. He did that and the ramp controller said, 'Take your time.'

I stopped the aircraft and set the parking brake. I pushed the public address button and said: 'Ladies and gentleman, this is your Captain speaking: I have stopped short of our gate to make a special announcement. We have a passenger on board who deserves our honor and respect. His Name is Private XXXXXX, a soldier who recently lost his life. Private XXXXXX is under your feet in the cargo hold. Escorting him today is Army Sergeant XXXXXXX. Also, on board are his father, mother, wife, and daughter. Your entire flight crew is asking for all passengers to remain in their seats to allow the family to exit the aircraft first. Thank you.'

We continued the turn to the gate, came to a stop and started our shutdown procedures. A couple of minutes later I opened the cockpit door. I found the two forward flight attendants crying, something you just do not see. I was told that after we came to a stop, every passenger on the aircraft stayed in their seats, waiting for the family to exit the aircraft.

When the family got up and gathered their things, a passenger slowly started to clap his hands. Moments later, more passengers joined in and soon the entire aircraft was clapping. Words of 'God Bless You', I'm sorry, thank you, be proud, and other kind words were uttered to the family as they made their way down the aisle and out of the airplane. They were escorted down to the ramp to finally be with their loved one.

Many of the passengers disembarking thanked me for the announcement I had made. They were just words, I told them, I could say them over and over again, but nothing I say will bring back that brave soldier.

I respectfully ask that all of you reflect on this event and the sacrifices that millions of our men and women have made to ensure our freedom and safety in these United States of AMERICA.

Foot note:

I know everyone who reads this will have tears in their eyes, including me. Prayer chain for our Military... PLEASE SHARE THIS! Please send this on after a short prayer for our service men and women.

They die for me and mine and you and yours and deserve our honor and respect.

We have a

http://www.thisblewmymind.com

This Blew My Mind

1 note

·

View note

Text

Deadly Job: 136 File Boxes By Myself

In summer of 1988, I worked at the Georgia Tech Library. Our office was on the 1st floor in the 1955 building. The library includes the 1965 building which is air-conditioned. At the time, the 1955 building was not. The Archives and Records Department included space on the ground floor which was cool, accessible from an elevator in front of the office. When I had a partner working in the department, I could spend 4 hours of my workday down there. But, my partner left, my boss left, and his boss left. I was alone in that office all day. The temperature was often 85 degrees Fahrenheit [29.44 Centigrade] at my desk.

[Photo Credit Wikipedia, see bottom]

On that particular day, I got a call from Accounts Payable. They had 136 file boxes to be picked up and transferred to our storage facility in the sub-basement. It was semester break and I had no student assistants to help me. I was the only one there. Keep in mind that I already had a diagnosis of arthritis in all my leg joints, but I hadn't told my employer. Today's temperature was 95 degrees Fahrenheit [35 C] and 95% humidity. I called my boss' boss and let her know I'd be out of the office, so I had to let Circulation know it would be closed while I did this humongous task.

I got the key from the mail room for the library van.

Accounts Payable was on the 3rd floor of the 1898 building. It doesn't have an elevator. When I leaned on the rail walking up, it nearly fell out of the wall. The stairs had slippery carpet runner all the way up. Needless to say, dragging my heavy hand truck behind me, I was not a happy camper.

At first, I loaded 5 boxes per trip. After several near-falls, I decided to do 4. It's more trips, but I didn't think I could last. My arms and legs were already shaking, and my pain level was climbing.

I got the van loaded for the first time and drove to the sub-basement door. Then, I walked through the library to the elevator. Took it to the ground floor. Then, a freight elevator took me to the sub-basement. There was one more flight of steps down to our storage area. In the building's steam plant. It was brutally hot down there. I walked across in the dark, thick air. Found a light switch. Then I propped the door open with a rock, the only thing we used to keep it open. There wasn't a way to prop it all the way open.

If I had collapsed from heatstroke there, I might not have been found for hours or more. Students didn't walk near the entrance to the sub-basement and there were no other workers around. I easily could have died, and my water cup was back in my office.

The ramp up to where I parked was a steep 45 degree angle, and smooth concrete. My jeans and t-shirt were already soaked with my sweat. Getting my loaded hand truck down to the door without running into it was very hard. It took a lot of trips. The cargo van held between 30-40 of these boxes. It took 4 trips with the van to finally get finished. I was utterly exhausted.

Then I had to turn in the van, get Circulation to unlock the office so I could get my purse and water, and I walked to my car. My house was an hour drive away. Since I was late, my girls were still at daycare, unless my pharmacist husband happened to be off to go get them. I really don't remember which way that was. I had to wait until I was outside the library to gulp my water. It wasn't cold. It was the same water I filled at home before I left that day. If I needed a refill on one of my 2 15-minute breaks, I had to go to the faculty lounge downstairs. The water fountains in the 1955 building all had rusty water. All buildings built before the 70s can have lead solders in water pipes and those from earlier decades can have lead pipes. We warned all the student assistants never to drink from the water fountains, to get it from a cafeteria.

At that job, I may have made a few cents over minimum wage. I always had to worry about whether I would make it in the door of the day care center by 6 sharp. Late fee was $25, but if I was late more than once or twice, they would call DFACS to get my kids [social services] so I always had that stress to worry about. We had flextime at the library, so if traffic made me late, I worked that many minutes over. I didn't have overtime in this job, so if I was over, I probably didn't report it. I don't think we had a time clock in the library. I filled out a paper form every week and turned it in to my boss [or that week, to his boss].

When I did have 4-5 library assistants, we all worked together. As their supervisor, I could have just told them to load the boxes and watched, but I'm not that kind of person. When I supervised people, I did what they did.

I worked for the Georgia Tech Library from May 1988 to late 1989. I had a miscarriage in May 1988. I had another one in Nov 1989, when I worked in the Systems Department. I had to leave for good in 1990 because I had a problem pregnancy. I guess I will always wonder if these jobs had anything to do with my lost babies. After all, in the Archives I had to work on a project in the Fulton Bag and Cotton Collection. This involved taking a tool like a spatula and carefully separating pages of personnel records from rusty paper clips, tedious work that I did 4 hours a day at times. The paper was full of black mold. That year, 1988, I was diagnosed with allergies for the first time in my life.

I was pregnant with my son when I interviewed for the Archival Assistant job. My boss unexpectedly put a full file box in my hands. "Can you lift this much?" I started at the Archives in mid May. On Memorial Day, I lost my son. Was it the lifting I had to do?

As far as suing the library, I would never do that. Any reduction in library funds would only hurt the little over 100 employees there. Most people had roommates, even in the late 80s. Library work is very hard to get without library experience. It took me 6 months to get that job. My genealogy hobby helped me get it.

Don't get me wrong, I loved the people I worked with, and my bosses were not cruel. I blame the GA Legislature for spreading ugly rumors about us state employees being lazy and refusing to vote us pay raises other than a dime or quarter an hour for cost of living. Libraries are underfunded because it's considered a 'female' line of work. I never met a 'lazy' state employee, and I imagine federal employees are just as overworked and underpaid. The Georgia Legislature put a hiring freeze on all state colleges and universities, and that's why I was alone in the Archives and Records Office on that day in Summer, 1988. All the heavy lifting I did probably contributed to the state of my back today. I got disabled at 40. I have moderate arthritis in my neck, and severe arthritis in my lower back. Also, in my 60s after a minor heart attack, my cardiologist discovered a heart problem I have probably had all my life that could have killed me that day. If my doctors had known about that, I might have had an easier time getting Social Security Disability. Or would I?

I also worked in the U of U Library in Utah. People also had to have roommates to pay the bills.

One of my coworkers had a daughter who was dying of heart failure--and she was turned down for disability. This lady really resented me for daring to mention I was considering applying for it. My battle took 4 years and I had to get a lawyer to get Social Security Disability at 40. A lot of people just as disabled as me apply and are turned down, every year. Since that time, I've lived in fear of losing it, because that can happen, too.

This is my testimony, as a former library worker. We are not lazy. We are the victims of politicians, who want you to believe that we are and that we 'really don't need the money'.

While a state employee, I got 11 paid holidays and 1 vacation day plus 1 day of sick leave a month. Most months, I was using that day of vacation for sick leave. I lived in fear of missing too many days and losing my job. My paycheck was docked for any days missed besides these days. If you admit you have disabilities, you might lose your job faster. I knew this and never admitted that I was disabled until it was obvious.

I had many other jobs before I became a state employee. Because of my disabilities, I tried to get jobs where I wouldn't have to lift. Silly me, I thought I wouldn't have to lift many heavy boxes if I worked in an archives. When I moved to Systems, I was lifting 50 lb monitors and 50 lb computer CPUs.

Every job I had, there was something heavy I had to lift on a regular basis. Employers are quick to warn you what not to do because of OSHA [the government agency that protects workers]. Yet, OSHA goes out the window whenever the job's short-staffed. I can only wonder how many people become disabled in the US, only to find out they can't get disability from Social Security. It's not fair that SSDI only applies to lucky folks like me. That co-worker's daughter had medical records that proved she was dying, yet they turned her down.

I am lucky I didn't drop dead that day. My cardiologist said the SCAD I had could've happened any time in my life. I was 30 and had frequent chest pains when lifting boxes. What's SCAD? see

Photo Credit

Georgia Tech Library https://library.gatech.edu/

Georgia Tech Library Wikipedia https://en.wikipedia.org/wiki/Georgia_Tech_Library

https://en.wikipedia.org/wiki/Georgia_Tech English: Tech Tower Date 1 October 2013, 17:44:33 Source Own work Author Mistercontributer Atlanta Georgia (U.S. state) Georgia Tech User: Mistercontributer CC-BY-SA-3.0 Self-published work

More pictures of GT Library from their account

People Watching On Campus Picture Of Atrium https://www.instagram.com/p/DF6bq4tvo1v/?hl=en

2nd picture

Yes, that is me, but from 1981. I used 2 pictures from Pexels for the hand truck

pexels-rdne-7362919.jpg

and the file boxes

pexels-ivan-samkov-8962868.jpg

and a picture of my old van that wasn't orange. I used GIMP to frankenstein these pictures together. I think I did actually get 6 file boxes on the first load.

#working#jobs#work experience#work life#usa#libraries#state employees#government#government employees#government workers#we are not lazy#dangerous working conditions#hazardous work

1 note

·

View note

Text

The Cost-Benefit Analysis of Hiring Professional Packers and Movers in Ranchi

Relocating requires careful planning, time, and work, and it can be both an exciting and difficult process. Whether to employ expert Packers and Movers in Ranchi or do the move yourself is one of the most important considerations to make. A thorough cost-benefit analysis shows that, despite the fact that hiring specialists could appear like an extra investment, the value they provide frequently exceeds the cost. Here's a detailed look at why hiring professional movers can be the best choice you make while moving.

Recognizing the Associated Costs

The Up-front Expenses of Employing Movers and Packers

The price of hiring Ranchi packers and movers usually includes a number of services, such as:

Packing supplies: premium boxes, tape, bubble wrap, and other items to guarantee the security of your possessions.

Labor costs include those associated with loading, packing, moving, unloading, and unpacking.

Transportation Costs: Depending on the distance and amount of cargo, fuel and vehicle expenses are incurred.

Insurance: An optional measure to guard against loss or damage while in transit.

Usually, these expenses are combined into one package, giving a precise estimate up front.

Hidden Fees for Do-It-Yourself Moves

DIY projects may appear more cost-effective at first glance. But there are a number of unstated costs to take into account:

Packing Supplies: Buying supplies on your own can get expensive very fast.

Vehicle Rental: The price of renting a van or vehicle, plus any applicable mileage and fuel charges.

Labor: There may be extra expenses or restrictions associated with hiring helpers or depending on friends or family.

Risk of Damage: Inadequate handling and packing may cause damage that necessitates expensive replacements or repairs.

Advantages of Using Skilled Movers and Packers

Efficiency of Time

Time savings is one of the biggest advantages of working with seasoned Ranchi packers and movers. Movers simplify the entire procedure, from packing your belongings to moving and unpacking them at your new home. This enables you to concentrate on other crucial duties, such establishing utility connections or getting acquainted with your new community.

Knowledge and Experience

With their years of experience, professional movers guarantee that your possessions are packed carefully and moved without incident. They are skilled in carefully handling electronics, heavy furniture, and breakable objects to lower the chance of harm. Their knowledge can be quite helpful, particularly when moving offices or other complicated places.

Obtaining Specialized Equipment

Specialized tools and equipment are needed to move heavy or large things like pianos, sofas, and refrigerators. To handle these objects safely and reduce the possibility of damage or injury, Ranchi packers and movers are outfitted with dollies, straps, and ramps.

All-inclusive Services

The majority of expert movers provide end-to-end services, such as:

Packing and unpacking: They take care of everything, from arranging possessions at your new location to packaging breakables.

Loading and Unloading: Skilled personnel handle heavy lifting, saving you time and minimizing physical strain.

Storage Options: A lot of businesses offer safe places to keep your possessions if you require short-term storage.

Safety and Insurance

The insurance that professional movers offer is among the most comforting features of working with them. Having your belongings insured provides piece of mind in the event of unintentional damage or loss during transit. It is difficult to attain this degree of assurance with a do-it-yourself move.

Cost-Benefit Evaluation: Comparing Prices

Materials for Packing

Packing supplies like boxes, tape, and bubble wrap are necessary for do-it-yourself moves, and they can get pricey. These supplies are usually covered by the service package offered by Ranchi packers and movers, which will save you time and money.

Rent a Car

You will have to rent a car separately for a do-it-yourself relocation, which will cost money for both the rental and gas. Professional movers remove this extra cost by include transportation in their services.

Work

DIY moves can be more expensive and complicated because they sometimes call for hiring additional help or depending on friends and family. A skilled crew is part of the package that professional movers offer, guaranteeing that your possessions are handled with efficiency.

Duration

It takes a lot of time and work to pack, load, and unload during do-it-yourself moves. Because they effectively handle every stage of the procedure, hiring professional movers drastically cuts down on time spent.

Danger of Damage

Due to inexperience with packing and handling, there is a greater chance that your possessions will sustain damage during a do-it-yourself move. Expert movers reduce this risk and frequently offer insurance for further security.

Specialized Tools

Large or heavy objects are more difficult to handle during do-it-yourself moves since they typically lack access to specialized tools like dollies, harnesses, and ramps. All the equipment required for a safe and effective move of your possessions is provided by professional movers.

Analysis of Benefits

Long-Term Financial Savings: Hiring movers may have a greater initial cost, but the potential savings from less damage, better time management, and included services make it a wise investment.

Peace of Mind: Although moving is a difficult process, expert movers take care of the hard lifting, relieving both your physical and emotional stress.

Customization: Packers and Movers make sure you only pay for the services you need by providing solutions that are specifically suited to your needs.

Employing expert packers and movers in Ranchi has several benefits when all the variables are taken into account. The advantages greatly exceed the disadvantages, from the guarantee of a safe and effective transfer to the time and work saved. By putting your trust in knowledgeable experts, you can guarantee a smooth move and concentrate on settling into your new place without having to worry about anything else. Whether you're moving your office or your home, hiring expert movers can ultimately save you money, time, and trouble.

0 notes

Text

How to Choose the Right Vehicle for House Removals?

Selecting the right vehicle for house removals ensures smooth, efficient, and stress-free moving. The right choice can save you time, effort, and even money. Whether you’re moving across town or to a different city, understanding your needs and matching them with the appropriate vehicle will make all the difference in house removals in London. Here’s a comprehensive guide to help you make the best choice.

Assess the Size of Your Move

The first step in choosing the right vehicle is evaluating the size of your move. Consider the following:

Number of Items:

Do you have a few boxes, or are you moving a house full of furniture?

Type of Items:

Larger items like beds, sofas, or appliances may require more space.

Distance:

A larger vehicle is often better for long-distance moves to minimize trips.

Vehicle Recommendations:

Small Moves:

A van, such as a cargo or transit van, is suitable.

Medium Moves:

A box truck or medium-sized moving truck works well.

Large Moves:

A full-size moving truck or large lorry is ideal.

2. Consider Accessibility

Think about the physical layout of your current and future home:

Narrow Streets:

A smaller vehicle might be necessary if either location is in an area with narrow roads.

Parking Restrictions:

Check for parking regulations or permits needed for large vehicles.

Driveway Space:

Ensure the car can fit into your driveway or near your home.

Choosing a vehicle that can easily access your property reduces the risk of delays or added costs.

3. Evaluate Your Budget

The cost of hiring a vehicle for house removals depends on its size, fuel consumption, and rental duration. Professionals provide a package of loading, packing, and transporting. So, it’s always a great decision to hire them and stay relaxed. If you do it separately consider:

Fuel Efficiency:

Smaller vehicles are more fuel-efficient but may require multiple trips.

Rental Costs:

Larger vehicles typically have higher daily rental rates.

Driver Costs:

If hiring a driver, larger vehicles may incur additional fees.

Strike a balance between size and affordability to keep expenses within budget.

4. Check for Professional Drivers

Hiring a professional company that excels in house removals is a wise choice. They have a vast collection of vehicles for relocation. Large trucks and vans can be challenging to manoeuvre, especially on highways or in urban areas. They know that and select the car accordingly.

When hiring a driver:

Ensure they have experience driving the selected vehicle.

Verify the company’s insurance covers driver-related incidents.

Check reviews for trustworthiness and professionalism.

5. Factor in Loading and Unloading Requirements

Ease of loading and unloading is another vital consideration in house removals. Features to look for include:

Loading Ramps:

These make it easier to move heavy furniture and appliances.

Hydraulic Lifts:

Ideal for particularly heavy or bulky items.

Doors and Access Points:

Ensure the vehicle has wide doors and adequate access for more oversized items.

These features can save time and reduce the risk of injury during the move.

6. Account for Fragile and Valuable Items

If you have delicate antiques, artwork, or electronics, ensure the vehicle has appropriate storage capabilities:

Securing Straps:

To keep items stable during transit.

Padding Options:

These are for added protection against bumps and vibrations.

Climate Control:

Necessary for items sensitive to temperature and humidity changes.

A vehicle equipped to handle fragile goods ensures your belongings arrive safely.

7. Think About Multiple Trips

You may have the flexibility to make multiple trips for local house removals. In this case, a smaller vehicle could suffice. However, for long-distance moves, choose a larger vehicle to complete the move in a single trip, saving time and fuel.

8. Consider Professional Moving Companies

Professional relocation companies offer a stress-free alternative. They provide:

Expertly chosen cars based on your move size.

Packing and loading services to optimize space and protect your belongings.

Drivers are experienced in handling large vehicles and tight spaces.

Hiring professional house removals may cost more. However, the convenience and expertise can be worth it.

9. Plan Ahead

The best vehicle for your house removals may not always be available at the last minute. Reserve a reputed moving service in advance to secure the ideal car. Early planning allows you to compare options, get better rates, and avoid the anxiety of last-minute arrangements.

Final Thoughts

Picking the right vehicle for house removals in London requires meticulous consideration of your needs, budget, and the logistical challenges of your move. From evaluating the size of your belongings to ensuring safety and accessibility, each factor plays a role in determining the best option. If in doubt, consult with professional movers from Scope Removal. Their expertise can guide you to the perfect solution, ensuring a smooth, efficient, and stress-free move to your new home.

0 notes

Text

The Essential Tool For Seamless Operations: Why Companies With Home Delivery Vans Need Van Dock Levellers

In the dynamic landscape of logistics and delivery services, efficiency and safety are paramount. If your company relies on home delivery vans, then you will understand the critical importance of streamlined operations to meet your customer demands while ensuring the well-being of your workforce. Amidst the myriad tools and technologies available, one often overlooked yet indispensable asset is the Loading Systems van dock leveller.

In this blog, we delve into the reasons why you should invest in van dock levellers, highlighting how these simple yet effective devices can significantly enhance operational efficiency and safety.

Ensuring Smooth Loading and Unloading Processes

The loading and unloading of goods onto delivery vans can be a labour-intensive and time-consuming process, especially in facilities where the height of the delivery van floor doesn't align perfectly with the dock. This misalignment can lead to delays, increased risk of accidents, and potential damage to goods.

Van dock levellers bridge this gap, literally. They serve as a connecting link between the facility's loading dock and the delivery van, creating a smooth transition for goods to be moved in and out. By eliminating the height differential, van dock levellers facilitate faster and more efficient loading and unloading processes, optimising the use of time and resources.

Enhancing Safety for Workers and Goods

Safety should always be a top priority in any operational environment. Traditional methods of bridging the gap between the loading dock and delivery van, such as using ramps or makeshift solutions, pose significant risks to workers and goods alike. Uneven surfaces, slippery conditions, and manual handling increase the likelihood of accidents, injuries, and product damage.

Van dock levellers provide a safe and stable platform for workers to move goods between the dock and the van. With features like non-slip surfaces, automatic edge barriers, and hydraulic systems for smooth adjustment, they minimise the risk of slips, trips, and falls. Additionally, by ensuring a level surface for loading and unloading, van dock levellers reduce the chances of goods being dropped or damaged during transit.

Improving Operational Efficiency and Cost-Effectiveness

Time is money, especially in the fast-paced world of logistics. Any delays or inefficiencies in the loading and unloading process can have ripple effects throughout the supply chain, impacting delivery schedules, customer satisfaction, and overall profitability.

Van dock levellers streamline operations by minimising downtime and maximising productivity. With faster and safer loading and unloading procedures, you can increase the throughput of goods, reduce waiting times for delivery vans, and optimise the use of available resources. Moreover, by preventing accidents and product damage, van dock levellers help you to avoid costly insurance claims, litigation, and reputation damage.

Adapting to Diverse Delivery Needs

The versatility of van dock levellers makes them suitable for a wide range of delivery scenarios. Whether you are handling small parcels, large packages, or specialised goods, van dock levellers can accommodate different types of delivery vans and cargo vehicles. Adjustable height settings, various weight capacities, and customisable features ensure that you can tailor your loading dock infrastructure to meet your specific requirements.

Stay Ahead of the Curve

In the competitive landscape of home delivery services, you must leverage every available tool and technology to stay ahead of the curve. Van dock levellers may seem like a simple addition to the loading dock, but their impact on operational efficiency, worker safety, and cost-effectiveness cannot be overstated. By investing in van dock levellers, you can ensure seamless loading and unloading processes, mitigate risks, and deliver exceptional service to your customers.

For more information about a Loading Systems van dock leveller contact us now on: 0800 160 1965 or complete the form in the link below:

0 notes

Text

Logistics Advertising: The Future of Advertising

In today's fast-paced digital landscape, where attention spans are fleeting and competition is fierce, businesses are constantly seeking innovative ways to reach their target audiences. Enter the Logistics advertising, a game-changing approach that seamlessly integrates advertising into the supply chain. In this comprehensive blog, we'll explore the intricacies of logistics ads, their impact on the advertising ecosystem, and what the future holds for this dynamic field.

What Are Logistics Ads?

Logistics ads represent a strategic fusion of advertising and supply chain management. Unlike traditional marketing channels, which often operate in isolation, logistics ads infiltrate every stage of the supply chain. From manufacturing to delivery, these ads strategically position themselves to maximize exposure and engagement.

The Supply Chain Ad Network

At the heart of logistics ads lies the Supply Chain Ad Network. This network comprises interconnected businesses collaborating to promote their products and services. Think of it as a web of relationships, where each node plays a vital role. Logistics ads ensure that potential consumers encounter advertisements seamlessly throughout their supply chain journey.

The Role of Logistics Ads

1. Distribution Ad Network

The **Distribution Ad Network** focuses on the efficient movement of goods from manufacturers to retailers. Here's how logistics ads come into play:

Truck Wraps:

Imagine a delivery truck adorned with your logistics company's vibrant ad. As it traverses highways and city streets, it leaves a lasting impression on fellow drivers and potential clients.

Packaging Inserts:

Logistics ads find their way into packaging materials. A simple QR code on a box can lead to personalized landing pages, offering exclusive deals or product information.

2. Transportation Ad Network

The Transportation Ad Network capitalizes on the constant motion inherent in logistics. Consider these scenarios:

Vehicle Branding:

Trucks, vans, and even bicycles become mobile billboards. Your company's logo on the side of a shipping container travels across cities, reaching diverse audiences.

Airport Advertising:

Airports are bustling hubs where logistics intersect. Ads strategically placed in cargo areas or on baggage carts catch the attention of travelers and industry professionals.

Success Stories: Real-World Impact

ABC Logistics: A Case Study

ABC Logistics, a growing player in the industry, recognized the potential of logistics ads. By strategically placing ads on delivery trucks, packaging materials, and collaborating with other supply chain partners, ABC Logistics achieved remarkable results:

1. Brand Awareness

The eye-catching truck wraps increased brand visibility. Commuters and pedestrians encountered ABC Logistics at traffic signals, parking lots, and loading docks.

2. Customer Acquisition

The seamless integration of ads across the supply chain led to new customer inquiries. Shippers, retailers, and manufacturers took notice and engaged with ABC Logistics.

Strategies for Effective Ad Logistics

1 Targeted Placement

Identify key touchpoints in the supply chain where your audience is most active. Tailor your advertisements to resonate with each specific stage.

2. Invest in a Robust Logistics advertising

Streamline the process by using a platform that seamlessly integrates your ads. Look for features like real-time tracking, performance analytics, and dynamic ad placement.

The Future of Ad Logistics

As technology evolves, so does the landscape of advertising. Here are some trends and innovations to watch out for:

1. Retail-Agnostic Media Platforms (RAMPs)

These platforms transcend traditional retail boundaries. They deliver precision-targeted ads across various channels, adapting to consumer behavior and preferences.

2. Personalization

AI-driven algorithms will tailor logistics ads based on individual preferences, location, and context.

3. Immersive Experiences

Augmented Reality (AR) and Virtual Reality (VR) will transform logistics ads into interactive journeys. Imagine unboxing a package and experiencing a 3D ad for the product.

FAQs about Logistics advertising

Q1: What Makes Logistic Ads Different?

Logistics ads go beyond traditional marketing channels. They infiltrate the supply chain, ensuring that your message reaches potential consumers precisely when they are most engaged.

Q2: How Can I Optimize Logistic Ads?

Focus on targeted placement and invest in reliable Logistics advertising. Leverage technology to enhance precision and reach.

Q3: Is Logistic Advertising Cost-Effective?

Yes! By strategically placing ads within the supply chain, you maximize exposure without overspending.

Q4: What’s Next for Ad Logistics?

The future holds exciting possibilities. Expect personalized, immersive, and interactive ads powered by AI, VR, and AR.

In conclusion, Logistics advertising is not just about advertising; it’s about seamlessly weaving your brand into the fabric of the supply chain, leaving a lasting impression on consumers at every turn. As the industry evolves, embracing innovative solutions like Logistic Ads will be essential for staying ahead in the dynamic world of advertising

1 note

·

View note

Text

Apple Car’s Crash: Design Details, Tim Cook’s Indecision, Failed Tesla Deal

By Bloomberg, Mar 6, 2023

Tim Cook shut down plans to acquire Tesla before cycling through a junkyard’s worth of self-driving designs over the past decade. The inside story is a case study in indecision.

Around the beginning of 2020, Apple Inc.’s top executives gathered at a former Chrysler testing track in Wittmann, Arizona, to try out the latest incarnation of the car the technology giant had been trying for years to make. The prototype, a white minivan with rounded sides, an all-glass roof, sliding doors and whitewall tires, was designed to comfortably seat four people and inspired by the classic flower-power Volkswagen microbus. The design was referred to within Apple, not always affectionately, as the Bread Loaf. The plan was for the vehicle to hit the market some five years later with a giant TV screen, a powerful audio system and windows that adjusted their own tint. The cabin would have club seating like a private plane, and passengers would be able to turn some of the seats into recliners and footrests.

Most important, the Bread Loaf would have what’s known in the industry as Level 5 autonomy, driving entirely on its own using a revolutionary onboard computer, a new operating system and cloud software developed in-house. There would be no steering wheel and no pedals, just a video-game-style controller or iPhone app for driving at low speed as a backup. Alternately, if the car found itself in a situation that it was unable to navigate, passengers would phone in to an Apple command center and ask to be driven remotely.

This Canoo electric van gives you a general idea of what the prototype car Apple tested in Arizona looked like. Apple’s was white, with whitewall tires and a sliding door.

In the Arizona desert, Chief Executive Officer Tim Cook, Chief Operating Officer Jeff Williams and senior members of Apple’s design team sat in the prototype as it drove itself around a test track. They loved what they saw. But there was a catch, as the car project’s head, Doug Field, made clear: A lot of work still needed to be done before the autonomous driving system would work in the real world. Field, who’d been hired away from Tesla Inc. to oversee the project, proposed scaling back the self-driving goals to Level 3, which requires a human driver to be ready to take over at a moment’s notice, not watching TV or FaceTiming in a backward-facing seat. But Field’s bosses wanted Level 5.

The next year, Field left Apple to take over the electric-vehicle and software engineering efforts at Ford Motor Co. Under Field’s successor, Kevin Lynch, who also runs Apple’s smartwatch software group, the car’s design continued to evolve. It had become pod-shaped, with curved glass sides that doubled as gull-wing doors, and the company considered including ramps that would automatically fold out to make heavy cargo easier to load. The front and the back were identical, and the only windows were on the sides, a design choice with potentially dire consequences in the event that a human needed to do any driving. (Front and rear windows were later added.) Some people on the project called it the I-Beam.

The I-Beam never made it into production, nor did any of Apple’s other designs. Now, it seems, they never will. On Feb. 27, Apple told staff it was giving up on developing a car. That decision, while abrupt, was not a surprise. Over the past decade, the company toiled away on at least five different major designs, drove prototype self-driving systems for more than a million miles, hired engineers and designers only to lay them off, and weighed partnerships or acquisitions with Tesla, Mercedes-Benz, BMW, Volkswagen and McLaren Automotive, among others. The car program cost, on average, roughly $1 billion annually (or nearly a fifth of Apple’s research and development budget a decade ago), with outside teams for chips, camera sensors, cloud services and software adding hundreds of millions of dollars more to the yearly spend.

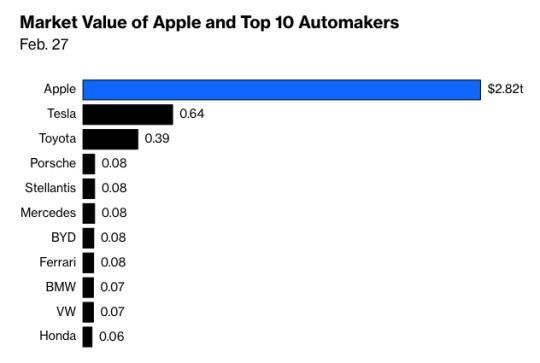

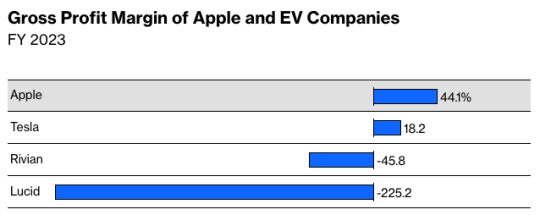

Source: Compiled by Bloomberg. Automakers are the 10 largest companies in the Bloomberg Intelligence Global Automobiles Valuation Peers group

But Apple never got close to realizing its original vision, or any of its subsequent ones. It didn’t get as far as testing a full-scale prototype on public roads. That it didn’t is partly thanks to the enormous technical difficulty of its self-driving goals, as well as the punishing economics of the automaking business. The project was also a failure, at the highest levels of the company, to settle on one thing and do it.

“There are a lot of roads you can take when you have a lot of really smart people and a very big budget,” says Reilly Brennan, a partner at the transportation technology venture fund Trucks VC. “But Apple never had the ability to make a bunch of specific decisions to lead them one way or the other.”

This story is based on conversations with several people involved in the development of the Apple car over the past decade, nearly all of whom asked to remain unnamed because the work was private. According to a longtime Apple executive who worked on the car, it was widely seen within the company as an ill-conceived product that needed to be put out of its misery. “The big arc was poor leadership that let the program linger, while everyone else in Apple was cringing,” they say. Asked what went wrong with the effort, a senior manager involved in the vehicle’s interior design replied: “What went right?”

What emerges is a portrait of the product development process at Apple today. The $2.6 trillion company has a history of hugely ambitious bets, and a track record of upending long-established businesses. It’s been a while since it did that, however. The iPhone is 17 years old and its sales declined last year, and newer products such as Apple’s watch and AirPods, while profitable, exist mostly in its orbit. The jury’s still out on the Vision Pro. Right now, the company is looking for its next big thing, and does not seem sure how to find it.

Cook, Jobs and legendary hardware developer Bob Mansfield, later a steward of Apple’s car project, discuss the iPhone 4 during a Q&A at the company’s headquarters in 2010.

It was Steve Jobs who first floated the idea of a car at Apple. In the late 2000s, in a typically grand pronouncement, the company’s co-founder and CEO declared internally that Apple should have dominant technologies in all of the spaces in which people spent time: at home, at work and on the go. For many Americans, being in transit means being on the road, sometimes for hours a day. “We talked about what would be this generation’s new Volkswagen Beetle,” recalls Tony Fadell, who led mobile device engineering under Jobs. In the wake of the 2008 financial crisis, with American car companies on the brink of failure, the Apple chief executive even floated the idea of acquiring General Motors Co. for pennies on the dollar.

That scheme was quickly abandoned, in part because Apple decided it would be a bad look and in part because of the need to focus on the iPhone. But in 2014, seeking a new multi-hundred-billion-dollar revenue stream, Cook began to focus again on cars. Apple executives weighing whether to enter the market joked with one another that they’d rather take on Detroit than a fellow tech giant: “Would you rather compete against Samsung or General Motors?” The profit margins in cars were far lower than in consumer electronics, but Apple was coming off a stretch during which it had reshaped not only the music industry but the mobile phone market. To its supporters, the idea of getting into automobiles had the potential to be, as one Apple executive puts it, “one more example of Apple entering a market very late and vanquishing it.” While the initial prototypes operated like traditional cars, these supporters eventually pursued more radical redesigns, invoking a transportation technology experience they said would “give people time back.” The ultimate plan was a living room on wheels where people who no longer needed to drive their cars could work or entertain themselves with Apple screens and services instead.

But before sketching out its own designs, Apple considered acquiring Tesla. At that point the electric-car maker’s success was far from assured, and its value was less than $30 billion, or a 20th of what it is today. Adrian Perica, Apple’s head of corporate development, held a series of meetings with Elon Musk. But Cook, who’d succeeded Jobs three years earlier, shut the deal down while negotiations were still at an early stage. Apple’s chief financial officer, Luca Maestri, formerly the General Motors CFO in Europe, argued that the car industry’s low margins were something the tech company couldn’t easily overcome.

Source: Compiled by Bloomberg

Although the Tesla idea was abandoned, the ambitions didn’t go away. Apple’s newly minted hardware chief, Dan Riccio, received approval to start building a car engineering team, and he hired hundreds of engineers from the auto industry for what came to be known as Project Titan. The team working on the car was called the Special Projects Group. Within the company, it was difficult to find spare engineering talent, with attention focused on preparing for the upcoming Apple Watch release and, later, the iPhone X, but Riccio managed nonetheless to poach several dozen engineers from other projects. Early on, Jay Leno gave the team a tour of his garage for inspiration and a minor lesson in automotive history. Around this time, Riccio, rallying his troops, often would close with “Boys, let’s go build a car!”

The infighting began almost immediately. Maestri, the CFO, remained a skeptic, as did Craig Federighi, Apple’s software engineering chief, who had to donate personnel to what he considered a vanity project. Jony Ive, Apple’s design chief at the time, was more ambivalent, pushing for full driving autonomy but also expressing doubts about the wisdom of the endeavor. Some car fans on the Apple leadership team, including the company’s marketing executives, were resistant to building a product that didn’t look and feel like a car. Services head Eddy Cue suggested that it might be more prudent to just try to make a better Tesla rather than invent an entirely new category of machine.

Similar disagreements played out within Project Titan itself. Steve Zadesky, a former Ford engineer and iPhone executive in charge of much of the car effort, imagined the company starting off with limited self-driving features that could then be improved. Others held fast to Level 5. Perica, the mergers-and-acquisitions chief who’d pushed to buy Tesla, told the Apple car team that the company should build “the first bird,” not “the last dinosaur.” When the group first began staffing up in 2015, the goal was to bring something to market by 2020.

Under Ive, the microbus design emerged. The interior would be covered in stainless steel, wood and white fabric. Ive wanted to sell the car only in white and in a single configuration so it would be instantly recognizable, like the original iPod he’d designed. At one point, the group briefly discussed a more traditional SUV-like design, as well. The team’s secret facility in Sunnyvale, California, was packed with car cabin prototypes and simulators. “It looked like you entered Disneyland—it was chock-full of toys,” says someone who worked in the building.

The team played with several different ideas for the interior, including installing a pair of specialized touchscreens suspended with brackets from the ceiling to control the car from both sides of the cabin. It also engineered microphones to be placed outside the vehicle to bring external sounds into the cabin, something passengers in non-Apple cars did by rolling down a window. “They would add all sorts of crazy features to the car and then realize those were bad ideas and pull them back out, leading to another cockpit redesign,” says an Apple executive with knowledge of the frequent changes.

Throughout much of the process, Apple continued exploring partnerships. Riccio and Zadesky, years after Cook shot down buying Tesla, met with Musk to discuss ways they could collaborate, including the possibility of Tesla producing batteries for the Apple car. That prospect didn’t advance. Musk, who didn’t respond to a request for comment for this story, at one point publicly called Apple a “Tesla graveyard” full of engineers he’d fired. A few years later, he tried to restart talks with Cook as Tesla struggled to build the Model 3. Musk has said the Apple CEO wouldn’t meet.

Talks with Mercedes-Benz progressed further. For a few months, Apple and the German automaker actively worked on a partnership similar to the Tesla idea, but with a twist. Mercedes would manufacture Apple’s vehicle, while it would also sell its own cars with Apple’s self-driving platform and user interface. Apple eventually pulled out, in part because the early work gave its executives confidence they could build a car on their own, people involved in the failed deal say.

At other points, Apple held exploratory acquisition talks with car companies beyond Tesla. The closest it got to a deal was with McLaren. Some Apple executives believed that scooping up the British automaker, which makes a few thousand cars by hand each year and sells them to the super rich, would excite Jony Ive, who’d scaled back his involvement at Apple after the launch of the Apple Watch, and reengage him with the company. The proposed deal, before it fell apart, would have provided Ive with a new design studio in London. Other discussions with BMW AG and, much later, Canoo Inc.—an electric-vehicle startup with a decidedly Apple-esque design aesthetic—went nowhere.

By 2016, Apple hadn’t gotten far, and internal advocates of scaling back its car ambitions began to win out. After the board of directors and senior executives began questioning the program’s viability and asking pointed questions about its costs, there were discussions about shutting down the project. But then Riccio convinced Bob Mansfield, a legendary figure at the company for leading the hardware development of the original MacBook Air and iPad, to come out of semi-retirement to shake things up.

Mansfield was among the car skeptics at Apple. His task, as he saw it, was to find out what could be salvaged from the effort. After a few months of evaluation, he decided to focus more attention on the self-driving system than on a car itself. Autonomous software, he argued, could benefit Apple in other areas, even if the company never made an actual vehicle. Other executives, notably Perica, thought Apple could license such an AI system to other carmakers without dirtying its hands in the auto business itself. Over an 18-month period from 2016 to mid-2018, Apple laid off about 120 people, a significant portion of the car project’s head count, according to people with knowledge of the cuts. FieldPhotographer: Ulysses Ortega

Before Mansfield persuaded Field, the former Tesla executive, to take over for him, he and Cook did manage to agree on an interim direction for the company’s autonomous driving efforts: a self-driving shuttle made in collaboration with Volkswagen for Apple employees to use at its new headquarters in Cupertino, California. That project didn’t come to fruition, either. It was seen as a distraction, and Field shut it down. He also eventually shuttered Apple’s work on batteries and other components he felt Apple could just buy off the shelf.

Field - Photographer: Ulysses Ortega

Under Field, full autonomy continued to be a focus even as it grew to seem less attainable. The Arizona demonstration, which the team spent nine months preparing for, was essentially a proof of concept. The team tweaked the prototype software to take turns and curves slower than usual, to make extra sure it wouldn’t injure Cook. “It was well scripted and well laid out,” says someone involved in its creation. “The intent was to show Tim that if we built this product, this is what it would look like for the customer.” (Apple bought the Arizona test track outright a year after the demo.) The team spent a lot of time working on backup controls for such a car so that a driver could extract it from tricky road situations, such as a complex construction zone. The most fully developed steering wheel substitute looked like the controller that comes with an Xbox. “It should have been either all autonomy or a wheel and pedals,” one person involved in the car’s development says, adding that the company spent a lot of time working on ways to mitigate the issue rather than on the hard problem itself.

There were other, smaller dead ends over the course of the project. Apple started planning a multi-acre engineering campus in Silicon Valley where it would design cars, but never broke ground. At one point, Apple and Ford met to discuss a proposal from the American automotive giant to sell Apple cars from its Lincoln brand, an unglamorous make that’s well-represented in rental fleets, to test the self-driving system. The talks didn’t progress past an early meeting.

For Field, Mansfield and others on the team, Cook’s indecision was frustrating. “If Bob or Doug ever had a reasonable set of objectives, they could have shipped a car,” says someone who was deeply involved in the project. “They’d ask to take the next step, and Tim would frequently say, ‘Get me more data, and let me think about it.’” In that setting, it was hard to retain talent: engineers Apple hired for the project would grow convinced things weren’t going anywhere and find jobs elsewhere. After Mansfield retired, the company tried another leadership change to boost the self-driving system. It put Williams, the COO, and John Giannandrea, Apple’s machine learning chief, in charge of overseeing Field and the project. Field left a year later, in September 2021.

Bloomberg News reported on this photo of a Lexus SUV equipped with early Apple self-driving technology back in 2017. Source: Bloomberg

Under Lynch, Apple never got to a streetworthy prototype. The self-driving technology in the company’s fleet of customized Lexus SUVs did show enough promise that there were plans to expand it to more cities in late 2024, according to people with knowledge of the plan. The idea had always been to sell self-driving as a subscription service, as Tesla does with its driver-support features. Other paid add-ons, such as Apple Music and Apple TV+ streamed to the vehicle, would help make up for the uninspiring margins on car hardware. (Some internal estimates pegged Apple’s cost to produce the car at about $120,000, far more than the $85,000 the company had wanted to charge for it.)

Last year, Apple pivoted one last time. Designs were tweaked to move from Level 5 down to Level 2, the level of Tesla’s current Autopilot, which can control both speed and steering but is assistive technology for drivers rather than their replacement. In keeping with that, the new design also incorporated a more traditional automotive interface: a steering wheel and pedals. “They finally smartened up,” says an Apple executive. “I was like, ‘Guys, you could have done this 10 years ago!’”

But the company had ended up where it began a decade earlier, with a product little different from what was already on the market and a basic, not-great self-driving system. “Kevin Lynch is a sensible person,” says an Apple executive involved in the car decision making. “He tried to bring a pragmatic view to it.” When asked, he made clear that true autonomy might be another decade off. He seems to have finally convinced Apple’s leadership that that was a problem without an affordable or reliable solution in the foreseeable future.

Lynch delivering the keynote address at Apple’s Worldwide Developer Conference in 2019.

Recently, members of the Apple car organization were studying how the company would produce the less-advanced car. It considered working with Magna International Inc., which builds some models for Jaguar, BMW and Mercedes. But the indecision at the top of the company filtered down, sapping morale. Apple declined to comment for this story, as did BMW, Ford, McLaren and VW. The former Apple executives named in this story didn’t respond to requests for comment. Neither did Canoo or Mercedes.

Around the beginning of 2024, Cook, who’s known for making decisions based on consensus, began seriously considering shutting down the project. “That’s when you started to see members of the leadership of Titan look for jobs at other companies and within Apple,” says someone with knowledge of the matter. People working on powertrains and other car-related engineering products began to depart.

On the evening of Monday, Feb. 26, the roughly 2,000 employees of Apple’s Special Projects Group received an email announcing a 10 a.m. all-hands meeting the next day. On Tuesday morning, the employees gathered in conference rooms and at desks at Apple’s Silicon Valley offices were told that Project Titan was winding down immediately. Lynch and Williams broke the news on a video call, and they didn’t explain the decision.

The meeting lasted about 12 minutes. Both men thanked the staffers for their work and got straight to the reorg and layoffs. Some employees would immediately get shifted to Apple’s AI division, and some would move over to software engineering. A chunk of the team, though, was immediately without a job. Hardware engineers would have the opportunity to apply for roles in other groups, but there aren’t spots for everyone. Other employees, such as the hundreds of car-specific engineers, test track technicians, self-driving car testers and automotive safety experts, received emails with their severance packages. As for the Arizona track, Apple is already working to sell it.

0 notes

Text

How to Safely and Easily Transport 4X8 Plywood

Transporting 4X8 plywood requires a vehicle with a long cargo bed and securing the plywood with ropes or straps to prevent it from shifting during transport. When it comes to moving 4X8 plywood sheets from one place to another, certain considerations need to be made to ensure a safe and efficient transport. The standard size of plywood sheets is 4 feet by 8 feet, making them too large to fit in a regular car or small truck bed. To transport 4X8 plywood, you need a vehicle with a long cargo bed, such as a pickup truck or a trailer, that can accommodate the full dimensions of the sheets. Additionally, it is crucial to secure the plywood properly using ropes or straps to prevent it from sliding or becoming damaged during transport. By following these steps, you can safely and conveniently transport 4X8 plywood to your desired location.

Preparing For Transportation

Transporting 4X8 plywood can be challenging, but with proper preparation, it can be done safely. Securely tie down the plywood with straps or bungee cords, and ensure it is well-protected from scratches or damage during transportation. Measuring And Planning Before transporting 4X8 plywood, it is crucial to measure and plan the logistics carefully. Having a well-thought-out plan ensures the safe delivery of the plywood and minimizes the risk of damage. Here are the steps to follow: - Measure the dimensions of the plywood sheets accurately. - Calculate the total volume of the plywood to determine the appropriate size of the vehicle required for transportation. - Consider the weight of the plywood and confirm that the vehicle has the necessary capacity to handle the load. - Create a transportation schedule that aligns with your needs and ensures efficient delivery. - Identify any potential obstacles or challenges along the transportation route, such as low bridges or narrow alleys. Securing The Plywood Properly securing the plywood is vital to prevent it from shifting or getting damaged during transport. Here's what you need to do: - Place the plywood sheets inside the vehicle, ensuring they are stacked in a stable and organized manner. - Use straps or bungee cords to secure the plywood by attaching them to anchor points within the vehicle. - Make sure the straps are tightened adequately to keep the plywood in place, but avoid over-tightening as it may cause excessive pressure and damage the sheets. - Consider using wooden braces or dividers to separate the plywood sheets and prevent them from rubbing against each other during transportation. - If transporting the plywood on a roof rack, use foam padding or blankets to protect both the sheets and the vehicle's roof.

Loading And Unloading

Transporting 4X8 plywood can be a daunting task if not properly executed. Loading and unloading the plywood is a crucial step to ensure its safe transportation. By choosing the right vehicle, positioning the plywood correctly, and using ramps or lifts, you can ensure a smooth loading and unloading process. Choosing The Right Vehicle Before you start loading your 4X8 plywood, it's essential to choose the right vehicle. The vehicle should be large enough to accommodate the plywood sheets without causing any damage. A large pickup truck, cargo van, or a utility trailer can be suitable options for transporting plywood. Ensure that the vehicle provides adequate space and is equipped with tie-down points to secure the load. Positioning The Plywood Proper positioning of the plywood sheets is crucial to ensure their stability during transportation. Place the sheets of plywood vertically against the vehicle's interior wall, ensuring an even distribution of weight. Secure the sheets using tie-down straps or bungee cords to prevent them from shifting or falling during transit. By positioning the plywood correctly, you can minimize the risk of damage and ensure a safe and stable transport. Using Ramps Or Lifts When it comes to loading and unloading 4X8 plywood, ramps or lifts can be extremely helpful. If the vehicle is relatively low to the ground, you can use ramps to facilitate the loading and unloading process. Ramps should be sturdy and have a sufficient weight capacity to support the plywood's weight. For heavier loads or vehicles with a higher clearance, a lift or forklift can be used to safely move the plywood sheets onto and off the vehicle. In conclusion, loading and unloading 4X8 plywood requires careful consideration of the vehicle, proper positioning, and the use of ramps or lifts. By following these steps, you can ensure a secure and efficient transportation process, minimizing the risk of damage and ensuring the plywood arrives safely at its destination.

Driving With Plywood

When it comes to transporting 4X8 plywood, proper precautions and techniques are essential to ensure a safe journey. In this section, we will discuss how to securely load and drive with plywood, ensuring peace of mind throughout your trip. From securing the load to taking necessary precautions and employing driving techniques, we have got you covered. Securing The Load Securing the plywood load is crucial to prevent any shifting or flying debris while driving. Follow these steps to ensure a tightly secured load: - Start by selecting a sturdy and reliable vehicle with a flatbed or a trailer that has appropriate dimensions for accommodating the 4X8 plywood sheets. - Place a layer of nonslip material, such as rubber matting or grippy pads, on the bed of the vehicle to prevent the plywood from sliding. - Arrange the plywood sheets in a stack with the edges flush to minimize any gaps. - Using nylon or ratchet straps, secure the stack of plywood tightly to the vehicle or trailer. Ensure that the straps are evenly distributed and tightened to eliminate any movement. - Consider using additional fasteners, such as bungee cords or rope, to provide extra stability and prevent any potential shifting during transit. Taking Precautions Plywood can be susceptible to damage from external factors, so taking necessary precautions is essential. Here are a few precautions to keep in mind: - Protect the plywood from moisture by covering it with a tarp or waterproof sheet in case of inclement weather. - Check the local laws and regulations regarding the transportation of large items like plywood, ensuring compliance with any specific requirements, such as flags or reflective markers. - Inspect the load and securements periodically during the journey to ensure everything remains intact and tightly secured. Driving Techniques Adopting appropriate driving techniques can help maintain stability and minimize risks associated with transporting plywood. Consider the following: - Drive at moderate speeds, avoiding sudden accelerations, decelerations, and sharp turns, which could potentially dislodge the load. - Maintain a safe distance from vehicles ahead, allowing sufficient time to react to any unexpected situations. - Take into account the extra weight and size while maneuvering, such as when changing lanes or passing through narrow spaces. - Be cautious of wind conditions, especially when driving at higher speeds or through open areas. Adjust your driving accordingly to counteract any potential effects on the load. By following these guidelines, you can confidently transport 4X8 plywood while ensuring your safety, the safety of others, and the integrity of the plywood itself during transit.

Frequently Asked Questions For How To Transport 4x8 Plywood

How Do You Transport 4x8 Plywood Safely? To transport 4X8 plywood safely, ensure it is securely strapped or tied down to prevent shifting during transit. Use a truck with a large bed or a trailer to accommodate the size of the plywood. Additionally, consider using support panels to distribute the weight evenly and minimize bending or warping. What Type Of Vehicle Is Best For Transporting 4x8 Plywood? A pickup truck with a long bed or a cargo van is ideal for transporting 4X8 plywood. These vehicles provide enough space and flexibility to handle the size and weight of the plywood sheets. Make sure to secure the plywood properly to prevent any damage or accidents during transportation. How Can I Protect My 4x8 Plywood During Transport? To protect your 4X8 plywood during transport, cover it with a tarp or plastic sheet to shield it from rain or moisture. Avoid placing heavy items on top of the plywood and ensure it is securely fastened to prevent any movement or damage. Consider using edge protectors to prevent the corners from getting chipped or damaged.

Conclusion

In a nutshell, transporting 4X8 plywood can be a daunting task, but with the right techniques, it becomes manageable and stress-free. By ensuring you have the proper equipment, such as a sturdy truck or trailer and secure straps, you can safeguard both your plywood and other motorists on the road. Remember to plan your route, drive with caution, and make sure the plywood is properly secured to prevent accidents or damage. With these tips in mind, you can transport plywood safely and efficiently. Read the full article

0 notes

Text

How to choose the right commercial van for your business?

Choosing the right commercial van for your business is a crucial decision that can impact your efficiency, productivity, and overall success. Whether you're involved in deliveries, service operations, or other commercial activities, several factors should be considered when selecting the ideal van for your business needs.

Define Your Business Needs: Begin by clearly defining the specific requirements of your business. Consider the type of goods or services you'll be transporting, the volume of cargo, the need for passenger space, and any specialized equipment or features required.

Determine Cargo Space and Payload Capacity: Evaluate the cargo space and payload capacity needed for your daily operations. Consider the size and weight of your typical cargo, and ensure that the chosen van can accommodate both the volume and weight requirements. Different vans offer varying cargo capacities, so match the van's specifications with your business needs.

Consider Maneuverability: Assess the maneuverability required for your business environment. If your operations involve frequent stops in urban areas, a smaller and more agile van, like a compact or midsize model, may be suitable. For larger cargo needs, a full-size van with a longer wheelbase might be necessary.

Fuel Efficiency: Factor in the fuel efficiency of the van, especially if your business involves a significant amount of driving. Consider the type of engine, fuel type (gasoline or diesel), and the van's overall fuel economy. Choosing a fuel-efficient van can contribute to cost savings over the long term.