#Carbon Steel Market Market Research

Explore tagged Tumblr posts

Text

#Carbon Steel Market Market#Carbon Steel Market Market Share#Carbon Steel Market Market Size#Carbon Steel Market Market Research#Carbon Steel Market Industry#What is Carbon Steel Market?

0 notes

Text

Activated carbon filters are porous materials used to purify air and water by trapping and removing contaminants through adsorption. They consist of activated carbon particles with a high surface area, providing an effective means of removing impurities such as chemicals, gases, odors, and organic compounds.

The activated carbon filters market size is projected to grow from USD 267 million in 2020 to USD 330 million by 2025, at a CAGR of 4.4%. The activated carbon filters market has been gaining significance with its major application in water treatment and air purification; the duo being its major applications. Stringent government regulations implying directives for industrial water pollution and quality drinking water have led to fast growth and acceptance of activated carbon filter products. These regulations are being implemented in the regions of Europe and North America and also gaining importance in the APAC region. The policies and regulations implemented by different authorities for supporting the use of activated carbon filters are attributing to the growth of activated carbon filters market.

#Activated Carbon Filters Market#Activated Carbon Filters Price#Activated Carbon Filter Manufacturers#Stainless Steel Shell#Carbon Steel Shell#carbon filter air purifier#activated carbon water filter#activated charcoal filter#activated charcoal water filter#air purifier with activated carbon filter#filter activated#granular activated carbon filter#catalytic carbon filter#activated carbon filters#carbon water filter#water filter charcoal#carbon air filter#blueair 411 filter#Activated Carbon Filters Market Analysis#Activated Carbon Filters Market Size#Activated Carbon Filters Market Share#Activated Carbon Filters Market Trends#Activated Carbon Filters Market Growth#Activated Carbon Filters Market Research#Activated Carbon Filters Market Revenue#Activated Carbon Filters#Global Activated Carbon Filters market#Activated Carbon Filters Market Overview#Activated Carbon Filters Research Report#Activated Carbon Filters research insights

0 notes

Text

I was born and raised in Gary, Indiana, so this story resonates deeply with me. Way too many of my high school friends died young from heart and lung diseases easily traceable to the crud in the air we all breathed for years.

Excerpt from this story from the Chicago Tribune:

The “Dirty Steel, Dangerous Air” report details the national and local health and economic costs of steel industry pollution. Industrious Labs released the report on Monday.

Industrious Labs is an environmental organization focused on cleaning up industries through network and capacity building, research and analysis, and data-driven campaigns, according to its website.

The 44-page report found that coal-based steelmaking contributes to an estimated $13.2 billion in health costs, 892 premature deaths and almost 100,000 lost school and work days annually, according to a news release from the organization.

“Steel communities have been sounding the alarm on harmful air pollution for years, and this report quantifies just how devastating and far-reaching the consequences are,” Hilary Lewis, steel director at Industrious Labs, said in the news release. “The EPA has consistently failed to safeguard the health of these communities from the dangers of coal-based steelmaking. It’s time for stronger regulations that recognize the opportunity of cleaner steelmaking technologies and tougher enforcement of penalties on polluters to truly protect public health.”

The report focuses on 17 facilities nationwide, including four plants in Northwest Indiana, each of which are owned by U.S. Steel or Cleveland-Cliffs.

In addition to steelmaking, the report looks at the harmful effects of coke, a processed form of coal used in steelmaking.

The steel industry accounts for more than 90% of the market demand for coke, according to the report, which called coke a “very dirty fossil fuel.”

The product is made by mixing coal with oil or water and heating it at 2,000 degrees for many hours. Coke requires dozens of large ovens to be made as well, according to the report.

Industrious Labs’ report also found that most residents in Gary are in the top 10% of U.S. residents most at risk for developing asthma and at risk of low life expectancy.

The city is home to U.S. Steel’s Gary Works facility, which could potentially receive $300 million for its blast furnace if a deal between the company and Nippon Steel is approved.

The $300 million investment will allow for higher steel production and reduced emissions, Gary Mayor Eddie Melton said in a statement. The furnace should have its life extended by up to 20 years.

Some residents, including those who are members of Gary Advocates for Responsible Development, have concerns about the investment.

Carolyn McCrady, member of GARD, said the only way for the steel industry to grow in “a healthy way” is to get rid of blast furnaces. McCrady believes in the use of direct reduction furnaces, which she calls more environmentally and economically friendly.

Direct reduction furnaces could reduce carbon dioxide emissions by half and produce about 20% of steel nationwide, McCrady said.

5 notes

·

View notes

Text

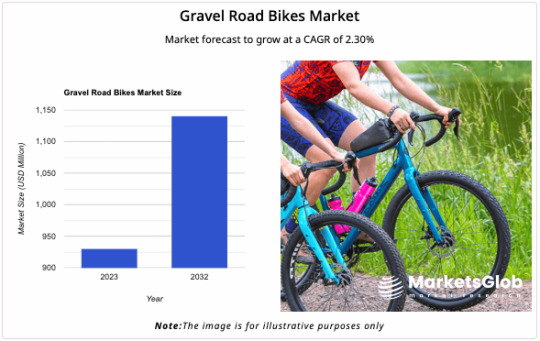

Gravel Road Bikes Market to Hit USD 1,141 Million by 2032

The global Gravel Road Bikes Market was valued at USD 930 million in 2023, and it is expected to grow to USD 1,141 million by 2032, as projected by MarketsGlob. This represents a compound annual growth rate (CAGR) of 2.30% from 2024 to 2032. The increasing demand for gravel bikes is being driven by rising fitness trends, adventure cycling, and the growing preference for eco-friendly transportation solutions.

What is a Gravel Road Bike?

A gravel road bike is a type of bicycle designed to perform well on mixed surfaces, such as gravel paths, dirt roads, and traditional paved roads. These bikes typically feature wider tires for better grip and stability, a more relaxed geometry for comfort over long rides, and durable frames made from materials like steel, aluminum, carbon, or titanium. Gravel bikes are favored for their versatility, allowing riders to switch between on-road and off-road cycling with ease, making them ideal for adventure cyclists, commuters, and long-distance riders alike.

Key Players Driving the Market

Several key players contribute significantly to the growth and development of the Gravel Road Bikes Market. These companies are recognized for their innovative products, market influence, and dedication to meeting the needs of cyclists worldwide. Some of the major players include:

Specialized Bicycle Components

Trek

Giant

Cervelo

Cannondale

Vitus Bikes

Merida Bikes

Fuji Bikes

Cube Bikes

Santa Cruz Bicycles

SCOTT Sports

Liv Cycling

Salsa Cycles

Bianchi

Diamondback Bicycles

GT Bicycles

Lauf Cycles

Ribble Cycles

(Note: This list is not final. Please request a sample report for the latest information on key market players.)

Market Segmentation

The Gravel Road Bikes Market is segmented into different product types, applications, sales channels, and regions. This segmentation provides a comprehensive view of the market and helps understand various consumer needs.

Product Types Analysis

Steel Gravel Bikes

Aluminum Gravel Bikes

Carbon Gravel Bikes

Titanium Gravel Bikes

Applications Analysis

Men

Women

Kids

(Note: This segmentation is not exhaustive. We can further customize the data based on your specific requirements. Request a sample report for deeper insights.)

Sales Channel Analysis

Direct Channel

Distribution Channel

Regional Insights

The Gravel Road Bikes Market is segmented into key regions, providing insights into geographic demand and market trends:

North America (United States, Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, Spain, Benelux, Poland, Austria, Portugal, Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, Australia, Taiwan, Rest of Asia Pacific)

South America (Brazil, Argentina, Colombia, Chile, Peru, Venezuela, Rest of South America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East & Africa)

As the global demand for adventure and fitness-oriented cycling continues to rise, the Gravel Road Bikes Market is set to expand steadily. With a projected market value of USD 1,141 million by 2032, key players and innovative products will continue to drive this growth. For customized insights and further details, it is recommended to request a sample report. In-Detail Scope of Research: https://marketsglob.com/report/gravel-road-bikes-market/9425/

2 notes

·

View notes

Text

Aluminum Market: Products, Applications & Beyond

Aluminum is a versatile element with several beneficial properties, such as a high strength-to-weight ratio, corrosion resistance, recyclability, electrical & thermal conductivity, longer lifecycle, and non-toxic nature. As a result, it witnesses high demand from industries like automotive & transportation, electronics, building & construction, foil & packaging, and others. The high applicability of the metal is expected to drive the global aluminum market at a CAGR of 5.24% in the forecast period from 2023 to 2030.

Aluminum – Mining Into Key Products:

Triton Market Research’s report covers bauxite, alumina, primary aluminum, and other products as part of its segment analysis.

Bauxite is anticipated to grow with a CAGR of 5.67% in the product segment over the forecast years.

Bauxite is the primary ore of aluminum. It is a sedimentary rock composed of aluminum-bearing minerals, and is usually mined by surface mining techniques. It is found in several locations across the world, including India, Brazil, Australia, Russia, and China, among others. Australia is the world’s largest bauxite-producing nation, with a production value of over 100 million metric tons in 2022.

Moreover, leading market players Rio Tinto and Alcoa Corporation operate their bauxite mines in the country. These factors are expected to propel Australia’s growth in the Asia-Pacific aluminum market, with an anticipated CAGR of 4.38% over the projected period.

Alumina is expected to grow with a CAGR of 5.42% in the product segment during 2023-2030.

Alumina or aluminum oxide is obtained by chemically processing the bauxite ore using the Bayer process. It possesses excellent dielectric properties, high stiffness & strength, thermal conductivity, wear resistance, and other such favorable characteristics, making it a preferable material for a range of applications.

Hydrolysis of aluminum oxide results in the production of high-purity alumina, a uniform fine powder characterized by a minimum purity level of 99.99%. Its chemical stability, low-temperature sensitivity, and high electrical insulation make HPA an ideal choice for manufacturing LED lights and electric vehicles. The growth of these industries is expected to contribute to the progress of the global HPA market.

EVs Spike Sustainability Trend

As per the estimates from the International Energy Agency, nearly 2 million electric vehicles were sold globally in the first quarter of 2022, with a whopping 75% increase from the preceding year. Aluminum has emerged as the preferred choice for auto manufacturers in this new era of electromobility. Automotive & transportation leads the industry vertical segment in the studied market, garnering $40792.89 million in 2022.

In May 2021, RusAl collaborated with leading rolled aluminum products manufacturer Gränges AB to develop alloys for automotive applications. Automakers are increasingly substituting stainless steel with aluminum in their products owing to the latter’s low weight, higher impact absorption capacity, and better driving range.

Also, electric vehicles have a considerably lower carbon footprint compared to their traditional counterparts. With the growing need for lowering emissions and raising awareness of energy conservation, governments worldwide are encouraging the use of EVs, which is expected to propel the demand for aluminum over the forecast period.

The Netherlands is one of the leading countries in Europe in terms of EV adoption. The Dutch government has set an ambitious goal that only zero-emission passenger cars (such as battery-operated EVs, hydrogen FCEVs, and plug-in hybrid EVs) will be sold in the nation by 2030. Further, according to the Canadian government, the country’s aluminum producers have some of the lowest CO2 footprints in the world.

Alcoa Corporation and Rio Tinto partnered to form ELYSIS, headquartered in Montréal, Canada. In 2021, it successfully produced carbon-free aluminum at its Industrial Research and Development Center in Saguenay. The company is heralding the beginning of a new era for the global aluminum market with its ELYSIS™ technology, which eliminates all direct GHG emissions from the smelting process, and is the first technology ever to emit oxygen as a byproduct.

Wrapping Up

Aluminum is among the most widely used metals in the world today, and is anticipated to underpin the global transition to a low-carbon economy. Moreover, it is 100% recyclable and can retain its properties & quality post the recycling process.

Reprocessing the metal is a more energy-efficient option compared to extracting the element from an ore, causing less environmental damage. As a result, the demand for aluminum in the sustainable energy sector has thus increased. The efforts to combat climate change are thus expected to bolster the aluminum market’s growth over the forecast period.

#Aluminum Market#aluminum#chemicals and materials#specialty chemicals#market research#market research reports#triton market research

4 notes

·

View notes

Text

youtube

Marine Energy Wales

The coast of Wales, with over 1,200km of coastline and up to 6GW of generating capacity has a significant wave and tidal stream climate. The Welsh Government has commissioned the Marine Renewable Energy Strategic Framework for Wales, a million-pound project mapping resource and potential constraints which provides developers with an online tool. Pembrokeshire has the highest concentration of wave resource in Wales, making it a perfect location for testing technology and attracting investment.

The marine sector in Wales has received 37 million pounds in research projects over the last decade to support the development of the sector. This has been used to undertake world class research which provides developers with excellent support and resources. Marine Energy Wales has links to all the research projects being carried out in Wales with research project managers who are part of the MEW working group.

Increasing renewable energy generation is essential to the decarbonization of electricity generation, and increasingly important to the necessary shift to a low carbon economy. With the right regulatory and economic conditions, marine energy has the potential to meet ten per cent of the European Union’s power demand by 2050. It is also possible that by then, power generated by the marine energy sector in Europe could avoid the equivalent of 276M tonnes of carbon dioxide emissions every year.

There is also the potential for significant commercial reward through the development of a new indigenous industry focused on marine energy and its associated supply chain. With the right support, Europe, with Wales leading the initiative - could maintain leadership in a global wave and tidal stream market worth a potential 460bn.

I chose to talk about Marine Energy Wales, as it seems to contribute to several of the Sustainable Development Goals. MEW contributes to climate action; affordable and clean energy, establishing a sustainable city and community; creating partnerships with others nationally and internationally to achieve the goals, and generating economic prosperity in the industry along with innovation and infrastructure.

Most projects managed under MEW are based in Pembrokeshire, a county famous for beautiful beaches and countryside. Not only is Pembrokeshire a beautiful place, where many people choose to go on holiday, it is also already home to an energy sector supply chain and workforce, which supplies 25% of the UK’s petrochemicals; 30% of the UK’s requirements and includes steel fabricators, marine and other engineering specialisms, boat builders and ship repairers. These skills can be transferable and will be of benefit to the renewables industry who base their projects near an abundant marine energy source.

In the podcast above, I talk about Marine Energy Wales and how they contribute towards the Sustainable development goals and how projects like the Pembroke Dock marine centre, Selkie and Bombora are enabling technology that will not only generate a low cost renewable energy source, but also create employment; economic prosperity and opportunity to my county and many other areas in Wales.

2 notes

·

View notes

Text

Southeast Asia Hydrogen Generation Industry: Market Trends, Drivers, and Future Outlook

1. Market Overview

The Southeast Asia hydrogen generation market is projected to be valued at USD 8.94 billion in 2025 and is expected to grow to USD 9.94 billion by 2030, reflecting a compound annual growth rate (CAGR) of 2.14% during the forecast period (2025-2030).

The Southeast Asia hydrogen generation market is expanding, as nations within the region seek to diversify their energy sources and reduce their carbon footprints. Hydrogen, as a clean and versatile energy carrier, is increasingly seen as a promising alternative to traditional fossil fuels. The market is primarily driven by the potential of hydrogen in various applications, including transportation, industrial processes, and power generation.

Southeast Asia is home to a number of countries that are heavily reliant on fossil fuels, but at the same time, there is growing recognition of the need to transition to cleaner energy sources. As a result, the hydrogen generation industry is becoming an integral part of the region's efforts to meet climate goals and reduce greenhouse gas emissions.

2. Key Market Trends

A. Government Support and Policy Initiatives

Governments in Southeast Asia are actively promoting the use of hydrogen through various policy measures, incentives, and collaborations. Countries like Japan, South Korea, and Australia are already pioneers in hydrogen production, and Southeast Asia is following suit with its own set of national strategies and roadmaps for hydrogen development. In 2021, Singapore launched the "Singapore Hydrogen Strategy" as part of its broader Green Plan 2030, outlining plans for hydrogen infrastructure and innovation in the energy sector. Similarly, Thailand, Malaysia, and Indonesia have expressed interest in adopting hydrogen technology to power their industries and transportation systems.

These policies aim to create a conducive environment for hydrogen development, including funding for research and development, subsidies for hydrogen infrastructure, and long-term goals to integrate hydrogen into the region's energy system.

B. Hydrogen as a Key Component of Decarbonization

One of the biggest drivers of the hydrogen generation market in Southeast Asia is the push toward decarbonization. The region has committed to reducing its carbon emissions under international climate agreements like the Paris Agreement, and hydrogen is increasingly seen as a critical tool to achieve these goals. Hydrogen can be used to decarbonize a variety of sectors, including heavy industries like steel, chemicals, and cement, as well as transportation and power generation.

For example, countries like Thailand are exploring the use of hydrogen in the manufacturing of green steel, while Indonesia has been focused on utilizing hydrogen as a means of decarbonizing its power generation and industrial sectors. This trend is expected to accelerate as countries look for cost-effective and efficient ways to achieve net-zero emissions by mid-century.

C. Rise of Green Hydrogen

Green hydrogen, produced from renewable energy sources such as wind, solar, and hydropower, is gaining momentum in Southeast Asia. The region’s vast renewable energy potential—especially in countries like Indonesia, the Philippines, and Vietnam—makes it an ideal location for the development of green hydrogen production. Unlike traditional hydrogen production methods, which rely on fossil fuels, green hydrogen is produced through electrolysis, using renewable electricity to split water molecules into hydrogen and oxygen.

This shift toward green hydrogen aligns with Southeast Asia’s commitment to reducing its reliance on coal and natural gas, as well as decreasing its overall carbon emissions. Green hydrogen is seen as a long-term solution to not only decarbonizing the region but also positioning Southeast Asia as a key player in the global hydrogen economy.

D. Regional Collaborations and Investments

The hydrogen generation market in Southeast Asia is benefiting from growing international and regional collaborations. Countries are working together to share knowledge, expertise, and investments in hydrogen technologies. The development of hydrogen hubs in key Southeast Asian cities is also fostering collaboration between governments, industry players, and academia.

Major international players, including oil and gas companies, energy utilities, and clean tech startups, are increasingly investing in Southeast Asia’s hydrogen sector. This includes partnerships focused on scaling up hydrogen production technologies, improving storage and transportation methods, and exploring innovative uses of hydrogen in various industries.

3. Challenges Facing the Industry

A. Infrastructure Development

One of the biggest hurdles to the growth of the hydrogen generation market in Southeast Asia is the lack of infrastructure to support the production, storage, and transportation of hydrogen. Hydrogen is a challenging substance to handle and requires specialized storage and transportation systems, especially for large-scale applications. The development of hydrogen refueling stations, pipelines, and storage facilities is crucial for enabling the widespread adoption of hydrogen.

B. High Production Costs

Despite the growing potential of hydrogen as a clean energy source, its production—especially green hydrogen—remains costly. The process of producing hydrogen through electrolysis requires substantial amounts of renewable energy, which can be expensive. As a result, the cost competitiveness of hydrogen compared to other energy sources like natural gas or coal is still a challenge. However, as renewable energy costs continue to decline and economies of scale in hydrogen production are realized, the cost of green hydrogen is expected to become more competitive.

C. Market Uncertainty and Policy Risk

The hydrogen generation market in Southeast Asia is still in its nascent stages, and uncertainty around government policies, subsidies, and long-term commitments can impact investment decisions. The availability of financial support and the introduction of stable policies will be key in shaping the market’s future trajectory. Moreover, market players must navigate regulatory challenges related to the adoption of hydrogen technologies and ensure compliance with safety standards.

4. Growth Opportunities

A. Expanding Renewable Energy Capacity

Southeast Asia's abundant renewable energy resources provide a significant opportunity for hydrogen generation, particularly green hydrogen. Expanding solar, wind, and hydropower infrastructure can lower the cost of renewable electricity, which is key to making green hydrogen economically viable. Countries like Indonesia, the Philippines, and Vietnam are well-positioned to capitalize on this opportunity, with large-scale renewable energy projects already underway.

B. Hydrogen in Transportation

Hydrogen-powered vehicles, particularly in the heavy-duty and long-distance transport sectors, offer a major growth opportunity in Southeast Asia. With its relatively low carbon footprint compared to fossil fuel-powered vehicles, hydrogen can play a transformative role in the transportation sector. The development of hydrogen-powered buses, trucks, and trains is gaining traction in countries like Singapore and Malaysia, where the push for cleaner urban transport solutions is strong.

C. Industrial Applications

Hydrogen has a vast range of industrial applications, including its use in refining, chemicals, and steel manufacturing. As Southeast Asian countries continue to develop their industrial sectors, hydrogen can be used to decarbonize energy-intensive processes. This presents an opportunity for hydrogen to play a pivotal role in driving sustainable industrial growth in the region.

5. Conclusion

The Southeast Asia hydrogen generation market is on the cusp of significant growth, driven by the region's commitment to sustainability, the rise of green hydrogen, and government support for clean energy initiatives. While challenges related to infrastructure, production costs, and regulatory frameworks remain, the potential for hydrogen to contribute to Southeast Asia's energy transition is immense.

For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence

0 notes

Text

From Ore to Infrastructure: Key Insights into the Iron and Steel Market

The global iron and steel market size is expected to reach USD 2,253.52 billion by 2030, according to a new report by Grand View Research, Inc. expanding at a CAGR of 3.8% from 2023 to 2030. Rising demand for heavy machinery and growth in the construction industry is expected to augment market growth over the forecast period.

Over 98% of the total iron ore transforms into pig iron, which is a crucial component in the production of steel. Finished steel products are used in various industries, such as heavy industry, construction, automotive, and consumer goods. In heavy industry, steel is a strong material that can handle heavy weights and tough conditions. It provides stability and safety to heavy machinery, equipment, and infrastructure by maintaining their structural integrity. Thus, it is widely used in heavy industries such as shipbuilding, defense products manufacturing, and oil & gas.

Investment in the oil & gas industry is expected to drive the demand for steel over the forecast period. For instance, in April 2022, Cairn Oil & Gas, a Vedanta Group subsidiary, announced investing USD 700.0 million in oil & gas exploration projects in India. The company plans to invest in 100 exploratory wells, including the project in the Barmer region of Rajasthan, India.

Despite the rising penetration in various end-use industries, the product faces hindrances in the automotive industry. Electric vehicles prefer to use aluminum because of its lightweight and robust characteristics. This lightweight property helps reduce fuel consumption and lowers carbon emissions. As a result, aluminum is increasingly being used as a substitute for steel in electric vehicles, and this trend is expected to negatively affect the global market growth in the foreseeable future.

Region-wise, Asia Pacific is projected to undergo substantial revenue growth with a CAGR of 3.6% across the forecast period. This growth can be attributed to substantial investments in the region's construction and infrastructure sectors of developing economies. For instance, The Indonesian parliament approved the Capital City Bill in January 2022, paving the way for constructing a new capital city in the East Kalimantan province. The country has plans to invest USD 35 billion in the project, which is projected to be finalized by 2024.

In terms of competitive rivalry, the global market is characterized by intense competition and fragmentation. Major market players are implementing strategies such as mergers and acquisitions to strengthen their positions to expand their capacities. For instance, in January 2022, POSCO agreed with Adani Group, an Indian multinational conglomerate, to set up a mill worth USD 5.0 billion in Gujarat, India. The new mill utilizes green hydrogen and renewable energy sources for steel production. Furthermore, the companies agreed to collaborate in various industries, including logistics, renewable energy, and hydrogen.

Iron And Steel Market Report Highlights

Based on iron ore application, the steel segment is expected to register a growth rate of 2.0% in terms of revenue over the forecast period. The production of steel is expected to increase over the forecast period on account of rising investments in the construction of smart cities, led by increasing urbanization rates.

For example, Saudi Arabia’s NEOM project is anticipated to consume the largest amount of iron and steel. Further, at a capacity of 650 tons per day, the NEOM project will commence hydrogen production in 2026, which will be used by green steel and cement industries, for the city to run at 100% renewable energy.

Based on steel end-use, the building & construction segment captured the largest revenue share of the market, with over 45.0% in 2022. Rising investment by emerging economies to modernize their infrastructure is expected to propel the demand for the product.

Based on region, the Middle East & Africa is expected to achieve a revenue growth rate of 4.3%, over the forecast period. This growth is primarily driven by the emergence of infrastructure projects in the Middle East, which in turn is boosting the demand for products in the region.

Iron And Steel Market Segmentation

Grand View Research has segmented the iron and steel market report on the basis of product, iron ore application, steel end-use, and region.

Iron & Steel Product Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

Iron Ore

Steel

Iron Ore Application Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

Steel

Other

Steel End-Use Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

Building & Construction

Automotive & Transportation

Heavy Industry

Consumer Goods

Other

Iron & Steel Regional Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Spain

Italy

Russia

Turkey

Asia Pacific

China

Japan

India

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Iran

Order a free sample PDF of the Iron And Steel Market Intelligence Study, published by Grand View Research.

0 notes

Text

Pipe Fittings Manufacturer in India

Emerging India the new leader for industrial manufacturing marketplace Pipelines: The prime category pipe fitting has been developed productive foundation within Emerging India owing to that fact of this marketplace having proper infrastructure along with a high level of demandingness within products For Indian manufacturers and across the same, for the Country market, there are able successfully as well to produce supply on demand those said products by simply catering to huge levels of mass production Industries while fulfilling all roles on as domestic player.

This holds the piping wherein, in connection, control, and diversion of fluid, there will be an assembling that can also be called a pipe fitting. Pipe Fittings Manufacturer in India alter their directions depending on how fluids flow in them, and in doing so, they may become quite involved, especially when one has been exposed to corrosion or destruction. In point of fact apart from these one has the elbows, tees, reducers couplings unions and flanges that are considered amongst the most essential ones. Other than that it may also be available in a wide variety of others, such as stainless steel and carbon steel, PVC, copper, amongst many more.

Many of the best Indian firms of pipe fitting manufacturing companies have now finally committed toward quality and innovation that finally pays the output in some improved forms toward their customers while investing much more for research and developmental activities wherein such products should change themselves and cater to every type of need ranging from customized which matches up and stands out at something special toward that particular kind of application pertaining to those relevant industries.

This also is the future of pipe fitting sales in India, with a bright outlook and the wake of fast-speed industrialization in India along with the governmental "Make in India" initiative, thus bright is the future. With the growth of infrastructures, there is a great concern toward the pursuit of renewable and green energy throughout the spectrum, and in this background the industry is seen to take that extra edge on.

It would be maximum efforts toward placing the customer first through best efforts of Pipe Fittings Manufacturer in India toward the aspects of innovation, quality, and affordability along with a commitment toward excellence for all such needs within the global market. This will be achieved together with unmatched solutions toward all of the demands towards a specific requirement of a high-quality, reliable firm within the Indian market.

0 notes

Text

Steel Market Spotlight: High-Growth Opportunities for Market Leadership

The latest study released on the Global Steel Market by Straits Research, Research evaluates market size, trend, and forecast to 2032. The Steel Market consider covers noteworthy inquire about information and proofs to be a convenient asset record for directors, investigators, industry specialists and other key people to have ready-to-access and self-analysed study to help understand market trends, growth drivers, openings and up and coming challenges and approximately the competitors.

The steel market refers to the global industry involved in the production, processing, distribution, and consumption of steel, one of the most widely used materials in construction, manufacturing, automotive, energy, and infrastructure development. Steel, an alloy primarily composed of iron and carbon, is valued for its strength, durability, malleability, and versatility. It plays a critical role in modern economies, serving as a foundational material for industrial and consumer goods.

Get Free Sample Report PDF @ https://straitsresearch.com/report/steel-market/request-sample

The titled segments and sub-section of the market are illuminated below:

By Product Type

Carbon steel

Alloy steel

Stainless steel

Tool steel

Structural Steel

Prestressing Steel

By Application

Industrial Structures

Building and Construction

Automotive

Electrical Appliance

Tools and Machinery

By Steel Type

Flat

Long

Some of the key players profiled in the study are:

Nucor Corporation

Shougang Group

Hyundai Steel Co. Ltd

ArcelorMittal SA

Kingspan Group

Jiangsu Shagang Group

POSCO, Shangdong Iron and Steel Group Co.Ltd

Gerdau S.A

Tata Steel

Maanshan Iron and Steel

Hesteel Group

Nippon Steel

Wuhan Iron and Steel Cor

Baosteel Group

Thyssenkrupp Steel Europe AG

Get Detailed Segmentation @ https://straitsresearch.com/report/steel-market/segmentation

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

• The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

• North America (United States, Mexico & Canada)

• South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

• Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

• Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Objectives of the Report:

•To carefully analyze and forecast the size of the Steel Market by value and volume.

• To estimate the market shares of major segments of the Steel Market

• To showcase the development of the Steel Market in different parts of the world.

• To analyze and study micro-markets in terms of their contributions to the Steel Market, their prospects, and individual growth trends.

• To offer precise and useful details about factors affecting the growth of the Steel Market

• To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Steel Market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered:

• How feasible is Steel Market for long-term investment?

• What are influencing factors driving the demand for Steel Market near future?

• What is the impact analysis of various factors in the Global Steel Market growth?

• What are the recent trends in the regional market and how successful they are?

Buy Steel Market Research Report @ https://straitsresearch.com/buy-now/steel-market

Region Included are: Global, North America, Europe, APAC, South America, Middle East & Africa, LATAM.

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

At long last, Steel Market is a important source of direction for people and companies.

Thanks for reading this article; you can also get region wise report version like Global, North America, Europe, APAC, South America, Middle East & Africa, LAMEA) and Forecasts, 2024-2032

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Steel Market Market#Steel Market Market Share#Steel Market Market Size#Steel Market Market Research#Steel Market Industry#What is Steel Market?

0 notes

Text

Hydrogen Energy Storage Market Size, Share & Growth | Forecast 2025-2032

The hydrogen energy storage market is emerging as a critical component in the global transition to renewable energy, driven by increasing demand for clean energy solutions, technological advancements, and supportive government policies. According to SkyQuest Technology, the Hydrogen Energy Storage Market size is poised to reach to USD 22.60 Billion by 2032, growing at a CAGR of 4.4% during the forecast period. This market offers innovative solutions to meet energy storage demands while addressing environmental concerns.

Market Size and Growth Projections

The hydrogen energy storage market is witnessing significant growth as industries and governments focus on decarbonization and clean energy. Hydrogen's ability to store energy over long periods and its role in balancing supply and demand are pivotal in accelerating its adoption.

Request a Sample of the Report here: https://www.skyquestt.com/sample-request/hydrogen-energy-storage-market

Key Market Drivers

Global Push for Clean Energy Increasing pressure to reduce carbon emissions is driving investments in hydrogen energy storage technologies.

Energy Resilience and Grid Stabilization Hydrogen storage solutions provide critical support for grid balancing, enabling consistent energy supply.

Government Policies and Incentives Policies aimed at promoting green hydrogen production and usage are accelerating market growth.

Integration with Renewable Energy Sources Hydrogen enables efficient storage of surplus energy generated by solar and wind systems, enhancing their viability.

Market Segments

The hydrogen energy storage market is segmented based on storage type, end-user, and application:

By Storage Type:

Liquid Hydrogen

Gas Hydrogen

Solid Hydrogen

By End-User:

Industrial

Commercial

Residential

By Application:

Transportation

Stationary Power

Portable Power

Speak with an Analyst for More Insights: https://www.skyquestt.com/speak-with-analyst/hydrogen-energy-storage-market

Regional Insights

North America: The region dominates the market, driven by government initiatives and investments in green hydrogen technologies.

Europe: Europe's commitment to achieving net-zero emissions is fostering the adoption of hydrogen energy storage solutions across various sectors.

Asia-Pacific: The region is experiencing rapid growth due to rising industrialization, urbanization, and investments in renewable energy.

Latin America & Middle East: These regions are leveraging hydrogen to address energy security challenges and support sustainable development.

Buy the Report to Get the Full Analysis: https://www.skyquestt.com/buy-now/hydrogen-energy-storage-market

Top Players in the Market

Key players in the hydrogen energy storage market are investing in research and development to offer advanced and cost-effective solutions. Prominent companies include:

Air Liquide

Linde PLC

Cummins Inc.

Nel ASA

Plug Power Inc.

Ballard Power Systems

ITM Power PLC

Hydrogenics Corporation

McPhy Energy S.A.

Chart Industries, Inc.

View Full ToC and List of Companies here: https://www.skyquestt.com/report/hydrogen-energy-storage-market

Emerging Trends

Advancements in Electrolyzer Technology Innovations in electrolyzers are reducing costs and enhancing hydrogen production efficiency.

Green Hydrogen Adoption The growing preference for hydrogen produced from renewable sources is transforming the market landscape.

Expansion of Hydrogen Refueling Infrastructure Development of hydrogen refueling stations is supporting the adoption of fuel cell electric vehicles (FCEVs).

Industrial Applications of Hydrogen Hydrogen is increasingly being used in industries such as steel production, chemical manufacturing, and ammonia synthesis.

The hydrogen energy storage market holds immense potential as the world shifts toward sustainable and clean energy solutions. By focusing on technology, scalability, and integration with renewable energy systems, companies can leverage significant growth opportunities in this dynamic market.

#Hydrogen Energy Storage Market#Hydrogen Energy Storage Market Size#Hydrogen Energy Storage Market Share#Hydrogen Energy Storage Market Trends#Hydrogen Energy Storage Market Growth#Hydrogen Energy Storage Market Outlook#Hydrogen Energy Storage Market Key Players#Hydrogen Energy Storage Market Overview#Hydrogen Energy Storage Market Competitor#Hydrogen Energy Storage Market Insights#Hydrogen Energy Storage Market Forecast#Hydrogen Energy Storage Market Analysis#Hydrogen Energy Storage Market Statistics#Hydrogen Energy Storage Market Data#Hydrogen Energy Storage Market PDF#Hydrogen Energy Storage Market Excel#Hydrogen Energy Storage Market Strategy#Hydrogen Energy Storage Market Innovations

0 notes

Text

Raw Materials for Screw Manufacturing in India: Trends and Sources

India's screw manufacturing industry relies on a range of raw materials to meet growing domestic and export demands. High-quality steel, such as carbon steel, alloy steel, and stainless steel, is the primary material used due to its strength, durability, and corrosion resistance. Emerging trends highlight a shift towards environmentally sustainable and lightweight materials, such as titanium and aluminum alloys, driven by industries like automotive and aerospace. India sources raw materials from domestic suppliers and global markets, with hubs like Maharashtra and Gujarat playing a pivotal role. Innovations in raw material processing and recycling are further boosting efficiency. As India’s industrial growth continues, the focus on quality, cost-effectiveness, and eco-friendly practices is reshaping the screw manufacturing sector.

Introduction to Screw Manufacturing in India

Screw manufacturing in India has seen exponential growth, fueled by industrialization, infrastructure development, and increasing demand in sectors like construction, automotive, and electronics. The raw materials used in the production process play a critical role in determining the quality, durability, and functionality of screws. This article delves into the trends and sources of raw materials for screw manufacturing in India.

Key Raw Materials for Screw Manufacturing in India

Steel is the primary raw material for screw production in India, with low-carbon, medium-carbon, and stainless steel varieties being commonly used. Brass, aluminum, and titanium are also utilized, especially for specialized applications such as corrosion resistance and lightweight screws. The quality of these materials determines the screws’ strength, hardness, and resistance to wear.

Emerging Trends in Raw Material Procurement

In recent years, the screw manufacturing industry in India has witnessed significant shifts in raw material sourcing. With a focus on sustainability, many manufacturers are opting for recycled steel and eco-friendly alloys. Additionally, the adoption of advanced material grades like alloy steel and high-strength stainless steel is gaining momentum to meet global standards and diverse industry requirements.

Major Domestic Sources of Raw Materials in India

India has a robust steel industry that caters to the needs of screw manufacturers. Leading producers like Tata Steel, JSW Steel, and Steel Authority of India Limited (SAIL) supply high-quality raw materials. States such as Odisha, Jharkhand, and Chhattisgarh are major hubs for steel production, while brass and aluminum are sourced from regions like Gujarat and Maharashtra.

Import of Raw Materials for Screw Manufacturing

Despite a strong domestic base, India imports a significant portion of high-grade steel, brass, and titanium for specialized screw manufacturing. Key suppliers include countries like China, Japan, and South Korea, known for their superior material quality and cost competitiveness. The import of raw materials is critical for meeting the rising demand for precision screws in high-tech industries.

Challenges in Raw Material Sourcing for Screw Manufacturing

Screw manufacturers in India face challenges like fluctuating raw material prices, supply chain disruptions, and inconsistent quality. Global economic uncertainties and geopolitical tensions further complicate import dependencies. Manufacturers must navigate these challenges while maintaining cost-efficiency and product quality to stay competitive in both domestic and international markets.

Future Outlook: Innovations and Sustainability in Raw Materials

The future of screw manufacturing in India lies in innovation and sustainability. Research and development efforts are underway to explore lightweight and high-strength materials like carbon composites and nanomaterials. Additionally, initiatives to reduce the carbon footprint of raw material production and increase the use of recycled materials are gaining traction in the industry.

Conclusion

The screw manufacturing industry in India is poised for growth, driven by advancements in raw material quality and sourcing strategies. By leveraging domestic resources, importing high-grade materials, and embracing sustainable practices, manufacturers can meet the evolving demands of various industries. The focus on innovation and adaptability will ensure India remains a key player in the global screw manufacturing sector.

0 notes

Text

The Role of Material Testing Labs in Supporting UAE’s Construction Boom | +971 554747210

The UAE’s rapid urbanization and ambitious infrastructure projects have propelled the country into a global hub of innovation and development. From iconic skyscrapers to sprawling residential communities, the construction boom in the UAE demands top-tier materials that ensure safety, durability, and compliance with international standards. At the heart of this growth lies the critical role of material testing labs, which provide essential services to maintain the quality and integrity of construction projects.

This blog explores how material testing lab support the UAE’s construction boom and contribute to the nation’s economic and infrastructural success.

Understanding the UAE’s Construction Boom

The Scale of Development

The UAE’s construction sector is a cornerstone of its economy, with megaprojects such as Expo City Dubai, the Museum of the Future, and Abu Dhabi’s cultural district showcasing the nation’s ambition. These developments demand cutting-edge materials and engineering solutions.

The Challenges

With such rapid growth, the industry faces challenges including:

Ensuring the quality and safety of materials.

Adhering to international and local building codes.

Managing environmental and sustainability goals.

Material testing labs play a pivotal role in addressing these challenges, ensuring that projects meet the required standards and deliver lasting value.

Ensuring Material Quality and Durability

Comprehensive Testing

Material testing labs in the UAE conduct a wide range of tests to assess the quality and durability of construction materials. These include:

Concrete Testing: Ensuring compressive strength, mix design, and performance under load.

Steel Testing: Verifying tensile strength, elasticity, and corrosion resistance.

Soil Testing: Assessing soil stability, compaction, and load-bearing capacity.

Preventing Structural Failures

By identifying weaknesses or defects in materials, these labs help prevent costly delays and ensure the safety of construction projects.

Compliance with International Standards

Regulatory Adherence

Material testing labs ensure that construction projects comply with international standards such as ISO, ASTM, and BS. They also adhere to local regulations set by authorities like the Dubai Municipality and Abu Dhabi Quality and Conformity Council (ADQCC).

Benefits of Compliance

Facilitates smooth project approvals.

Enhances the credibility of developers and contractors.

Mitigates risks of non-compliance penalties.

Driving Innovation in Construction Materials

Exploring New Materials

The UAE’s ambitious projects often require innovative materials, such as lightweight composites, high-strength alloys, and eco-friendly alternatives. Material testing labs play a vital role in:

Evaluating the performance of new materials.

Conducting research and development for enhanced applications.

Supporting the adoption of sustainable materials in line with green building initiatives.

Examples of Innovation

Projects like the Burj Khalifa and Louvre Abu Dhabi have relied on advanced materials tested and certified by UAE labs, showcasing their indispensable role in achieving engineering marvels.

Supporting Sustainability Goals

Environmental Responsibility

Sustainability is a core focus of the UAE’s Vision 2030. Material testing labs contribute by:

Testing recycled and renewable materials.

Ensuring compliance with environmental standards.

Assessing the carbon footprint of construction materials.

LEED Certification

By partnering with material testing labs, developers can achieve green building certifications such as LEED, which enhance the environmental profile and market value of projects.

Risk Mitigation and Safety Assurance

Identifying Potential Risks

Material testing labs conduct rigorous evaluations to identify:

Material fatigue and wear.

Resistance to extreme weather conditions.

Vulnerabilities to fire, corrosion, and seismic activity.

Ensuring Worker and Public Safety

By guaranteeing the integrity of materials, testing labs play a direct role in safeguarding workers, occupants, and the general public.

Enhancing Efficiency and Cost-Effectiveness

Reducing Waste

By testing and certifying materials before construction, labs help reduce material waste, ensuring only high-quality resources are used.

Avoiding Costly Delays

Timely identification of defects or non-compliance ensures that projects remain on schedule and within budget.

Fostering Collaboration Across Stakeholders

Bridging Gaps

Material testing labs serve as a bridge between developers, contractors, and regulatory bodies. They facilitate:

Transparent communication.

Streamlined project approvals.

Harmonized efforts to meet project goals.

Long-Term Partnerships

Many developers and contractors establish long-term partnerships with UAE labs to ensure consistent quality and reliability across multiple projects.

Leveraging Advanced Technology

State-of-the-Art Equipment

Material testing labs in the UAE are equipped with advanced technology, including:

Non-destructive testing (NDT) tools.

X-ray diffraction (XRD) for material composition analysis.

Thermal imaging for insulation and energy efficiency testing.

Benefits of Technology

Faster and more accurate testing results.

Enhanced ability to meet complex project requirements.

Conclusion

Material testing labs are the unsung heroes of the UAE’s construction boom. By ensuring material quality, supporting innovation, driving sustainability, and mitigating risks, they are indispensable partners in the nation’s ambitious development journey. From iconic landmarks to everyday infrastructure, their contributions underpin the success of projects and the safety of communities.

For developers and contractors aiming to deliver world-class projects, partnering with a trusted material testing lab in the UAE is not just an option—it’s a necessity. Choose wisely and build a foundation of excellence that stands the test of time.

#material testing#material testing lab#material testing uae#testing lab near me#testing lab uae#testing labs

0 notes

Text

Specialty Polyamides: Unlocking Opportunities in Advanced Materials

The global specialty polyamides market size is expected to reach USD 4.31 billion by 2030, registering a CAGR of 7.0% during the forecast period, according to a new report by Grand View Research, Inc. Rising concerns regarding automotive fuel efficiency and favorable government regulations regarding the use of polyamides in the automotive, textile, and consumer goods industries are expected to drive the global market over the forecast period. With the increasing focus on green technologies and sustainability, the use of specialty polyamide in the automotive industry is expected to increase over the forecast period.

Globalization, coupled with an increase in consumer disposable income, is projected to drive the global automotive sector, which is further expected to augment market growth. Moreover, the high strength-to-weight ratio of the product has made it popular in other transportation industries, such as aerospace & defense. It is majorly used in the components of military aircraft and helicopters to reduce their overall weight to a large extent. Based on the product segment, high-temperature polyamide demand is anticipated to advance at a significant growth rate over the forecast period. Long-chain specialty polyamides are traditionally used to produce monofilaments, which are further used in a broad range of high chemical resistance and good dimensional stability applications.

Some of the key applications of long-chain specialty polyamides include cooler hoses, fuel lines, transmission oil, corrugated tubes, sensors & solenoids, oil & gas transportation, hand-held devices, and hydraulic applications. The electrical & electronics application segment is projected to witness substantial growth during the forecast period. Polyamides are used in display technologies, home electronics, mobile electronics, smart devices, and electrical components. Electronic devices and assemblies are getting smaller and hence, dissipate high amounts of heat. In addition, the demand for thermally conductive plastics for household applications has risen sharply in recent years.

This trend is expected to continue driving product demand over the coming years. Specialty polyamide filled with electrically conductive materials provides resistance to Electrostatic Discharge (ESD), Electromagnetic Interference (EMI), and Radio-frequency Interference (RFI) shielding in electronic equipment, as well as for conveyor systems and trays used to manufacture semiconductor chips. Common fillers in this application include carbon powder, carbon fiber, stainless steel fiber, and nickel-coated carbon fiber. Other application areas include wiring & associated devices, batteries, switches, industrial connectors, and mobile parts.

Specialty Polyamides Market Report Highlights

Asia-Pacific is estimated to record the fastest growth rate during the forecast period. India is the fastest-growing country in the Asia Pacific region on account of the growing automotive industry

The long-chain specialty polyamides product segment is potentially fueling the industry growth owing to its rising demand in various end-use industries

Various strategic initiatives were recorded over the past few years that have supported industry growth

For instance, in November 2021, BASF SE launched an R&D center in Ansan, South Korea’s Engineering Plastics Innovation Center

The new building houses the integrated R&D team and capabilities of Solvay’s polyamide business, other new capabilities, and the Consumer Electronics Competence Center

In South Korea, its R&D capabilities include reinforcement materials, technical skills, innovations, and parts testing services

Moreover, materials testing, including polyoxymethylene, polyamide, and polybutylene terephthalate can be conducted in South Korea

Specialty Polyamides Market Segmentation

Grand View Research has segmented the global specialty polyamides market based on product, end-use, and region:

Specialty Polyamides Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Long Chain Specialty Polyamide

High Temperature Specialty Polyamide

MXD6/PARA

Specialty Polyamides End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Automotive & Transportation

Electrical & Electronics

Consumer Goods & Retail

Energy

Industrial Coatings

Others

Specialty Polyamides Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Netherlands

Italy

Poland

Spain

Asia Pacific

China

India

Japan

Hong Kong

Taiwan

Thailand

South Korea

Central & South America

Middle East & Africa

Order a free sample PDF of the Specialty Polyamides Market Intelligence Study, published by Grand View Research.

0 notes

Text

Innovative Soap Dispenser Solutions with Jumbo Roll Toilet Paper Dispenser Suppliers in China

If there is one item that cannot be done without in commercial areas, especially where there is a high traffic flow in restrooms, then it would be the jumbo roll toilet paper dispensers. These basic installations help guarantee availability, cleanliness, and economics at the workplace. The Jumbo Roll Toilet Paper Dispenser Suppliers in China have risen to the task by offering quality dispensers in the market to meet international market demand. Their products include furniture that is durable, modern, and economic, making their products popular in business space.

Why Choose Suppliers from China?

Chinese manufacturers are known to offer quality products at a relatively lower cost as compared to their competitors. They use high-tech production techniques that can meet the demands of consumers as they develop dispensers. Whether the application is for airports, shopping centers, offices, or healthcare facilities, these suppliers make sure a variety of designs and possibilities are appropriate for different spaces.

Moreover, customization can also be provided by the suppliers. The dispensers themselves can be branded, have a specific color, or have other options that would fit perfectly in any restroom environment. The firms have adopted strict quality assurance policies that make buyers confident in the quality of products with regard to safety and performance. The considered commitment to the quality and affordable price of Chinese suppliers takes the leadership in the global market.

Characteristics of Quality Dispensers

The leading suppliers thus focus on functionality and how these can make life easier for the user. High-quality dispensers are considerate of paper wastage but at the same time have to be easy to use. Some common features include:

Durability: Most dispensers are built using strong and durable materials such as ABS plastic or medical-grade stainless steel for durability under difficult use.

Ease of Maintenance: Its designs have incorporated features such as rapid access and clear view paper-shield windows to minimize paper charges.

Safety: Rounded corners and tamper-proof designs give users protection and increase security and are appropriate for use in public areas.

Environmentally Friendly Options: A large number of suppliers have models that utilize environmentally friendly materials for companies that are trying to decrease their carbon footprint.

Apart from these features, some suppliers have included more sophisticated elements like sensors that perform touchless operations and are very useful in view of the current pandemic concerns on hygiene.

Competitive Advantages

China has a vibrant manufacturing industry compared to many other countries in the world, and this is an added advantage for those seeking jumbo roll toilet paper dispensers. The last two factors relate to order industry volume and order industry expenses; high rates of volume and expense allow bulk industry orders to be met by suppliers and timely delivery in international markets.

Furthermore, Chinese suppliers are also fulfilling the expectations of global buyers in terms of value-added services. Most offer guarantees, servicing plans, and support in case the customer is not satisfied with what they have bought. Some also invest in research and development by bringing in new products through product differentiation, such as bringing in antimicrobial coatings or designing for smaller restrooms.

Choosing Your Supplier

Supplier selection is an important factor that needs to be carefully worked out to ensure that the right supplier is selected for buying high-quality goods. Begin by assessing their certifications, which may be ISO 9001, which proves compliance to international quality standards. Requirements concerning the environmental and safety aspects must also be met and checked periodically as well.

This enables one to gauge the quality of the dispenser, especially on the kind that they manufacture, usefulness, and looks. Moreover, Jumbo Roll Toilet Paper Dispenser Suppliers in China with positive responses from the clients and a good rating can also be considered. Another area that encourages clarity is communication regarding your needs, your time frames of delivery, and your service provision in the aftermath of a sale.

Visit now:: https://www.bosin-industry.com/

0 notes

Text

Liquid Organic Hydrogen Carriers Market Fueled by Efficient and Stable Hydrogen Solutions

The Liquid Organic Hydrogen Carrier (LOHC) market is poised to revolutionize the hydrogen economy, with its valuation forecasted to rise from USD 0.89 billion in 2023 to over USD 1.6 billion by 2030. With a compound annual growth rate (CAGR) of 5.4% between 2024 and 2030, this market holds immense potential to change the energy landscape. Let’s delve into what’s driving this growth and why LOHC is the key to the future of clean energy.

What Are Liquid Organic Hydrogen Carriers (LOHC)?

LOHCs are organic chemical compounds capable of absorbing and releasing hydrogen through chemical reactions. These carriers offer a stable, safe, and efficient method for storing and transporting hydrogen, making them ideal for large-scale hydrogen distribution systems.

Download Sample Report @ https://intentmarketresearch.com/request-sample/liquid-organic-hydrogen-carrier-market-3042.html

Key Features of LOHCs

Stability: Unlike gaseous hydrogen, LOHCs are stored in liquid form at room temperature, reducing storage risks.

Efficiency: They provide a high hydrogen density, optimizing transportation efficiency.

Safety: LOHC technology eliminates the risks associated with high-pressure hydrogen storage systems.

The Rising Demand for Hydrogen as Clean Energy

As the world seeks to reduce its carbon footprint, hydrogen is emerging as a leading contender for clean energy solutions. Here’s why:

Global Carbon Emission Goals: Nations are setting ambitious goals to achieve net-zero emissions.

Industrial Applications: Hydrogen is being adopted in steel production, ammonia synthesis, and refineries.

Transportation Fuel: Hydrogen-powered vehicles, including fuel-cell electric vehicles (FCEVs), are gaining traction.

Why LOHC Technology?

While hydrogen holds promise, its adoption depends on efficient storage and transport solutions. LOHC technology addresses these challenges by:

Simplifying Infrastructure Needs: It uses existing liquid fuel infrastructure for transportation.

Enhancing Safety: Hydrogen stored in LOHC is non-explosive and less hazardous.

Reducing Costs: It minimizes the need for expensive cryogenic tanks.

Market Segmentation in the LOHC Industry

By Carrier Type

Toluene-Based LOHC: Widely used due to its availability and performance reliability.

Perhydro-Dibenzyltoluene: Offers improved storage capabilities.

N-Ethylcarbazole: Known for high hydrogen absorption efficiency.

By Application

Stationary Applications: Power plants and industries rely on LOHC for hydrogen storage.

Transportation Sector: Supports hydrogen fuel delivery systems for automobiles and aviation.

Regional Analysis of the LOHC Market

North America

Leading the transition to hydrogen economy.

Strong government support and investments in green technologies.

Europe

Accelerated hydrogen adoption due to stringent climate regulations.

Active research in LOHC technologies by nations like Germany and the Netherlands.

Asia-Pacific

Rapid industrialization and growing focus on clean energy.

China, Japan, and South Korea are prominent contributors.

Access Full Report @ https://intentmarketresearch.com/latest-reports/liquid-organic-hydrogen-carrier-market-3042.html

Technological Advancements in LOHC

Catalyst Innovation: Developing better catalysts to enhance hydrogen release and absorption efficiency.

Material Advancements: Exploring alternative LOHC compounds for improved performance.

Integration with Renewable Energy Sources: Aligning LOHC technology with solar and wind energy for sustainable hydrogen production.

Challenges in the LOHC Market

High Initial Investment Costs: Technology adoption requires substantial infrastructure development.

Energy Losses: Efficiency drops during hydrogen absorption and release processes.

Limited Awareness: Many industries lack a clear understanding of LOHC potential.

Future Outlook for the LOHC Market

With ongoing technological advancements and increasing adoption across sectors, the LOHC market is expected to overcome current challenges. Industry collaborations, regulatory support, and public awareness campaigns will likely expedite the integration of LOHC technologies into mainstream energy systems.

FAQs

1. What are the primary advantages of LOHC over traditional hydrogen storage?

LOHC offers safety, stability, and scalability, making it more suitable for hydrogen transport and storage compared to high-pressure or cryogenic systems.

2. Which industries are driving LOHC adoption?

Industries such as energy, automotive, and manufacturing are major adopters, with significant applications in hydrogen fuel distribution and industrial processes.

3. How does LOHC compare to other hydrogen storage methods?

Compared to methods like metal hydrides or compressed hydrogen, LOHC provides safer handling, cost-effective infrastructure utilization, and high energy density.

4. What is hindering LOHC adoption in emerging markets?

Challenges include high initial investment costs, energy inefficiencies during conversion, and limited awareness of its potential applications.

5. What regions offer the highest growth potential for the LOHC market?

Regions like Asia-Pacific, North America, and Europe, driven by industrialization and green energy policies, exhibit the highest growth potential.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes