#Cad Scanning

Explore tagged Tumblr posts

Text

How CAD Scanning Improves Accuracy in Product Design and Engineering

CAD scanning improves accuracy in product design and engineering by converting physical objects into precise digital models. It enhances design validation, supports reverse engineering, and reduces errors. By capturing exact measurements, CAD scanning streamlines development, improves quality control, and ensures efficient, accurate integration of components in the engineering process.

0 notes

Text

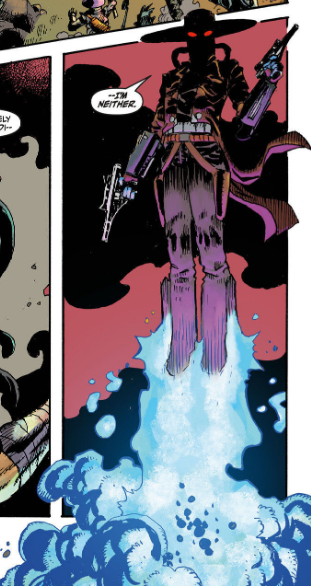

All of Cad Bane's art from the new Star Wars: Hyperspace Stories Vol. 9 (Dark Horse comics).

Some close ups of my favs:

#Cad Bane#Hyperspace Stories#Star Wars#Star Wars Comics#quinlan vos#Bounty Hunter#Jedi#Dark Horse#Duros#my scans

85 notes

·

View notes

Text

The version with just Cad Bane because he deserves all the love in the galaxy

35 notes

·

View notes

Text

Arizona BIM Services - BIMPRO LLC

BIMPRO offers comprehensive BIM services in Arizona to elevate the design and construction projects across Arizona and the surrounding locations of Phoenix metropolitan area.

#BIM Services Arizona#Revit Drafting Services#MEP BIM Services#CAD to BIM Services#Scan to BIM Services

1 note

·

View note

Text

Scan to BIM Services in USA | Point Cloud to Revit by Rvtcad

Rvtcad provides reliable Scan to CAD and Scan to BIM services, successfully delivering over 300 projects annually. We accurately convert Point Cloud data into detailed 3D BIM models and 2D CAD drawings, including high-detail Revit MEP models up to LOD 500. Our experienced team specializes in creating precise as-built documentation, supporting renovation and refurbishment projects worldwide. We work with surveyors, architects, engineers, contractors, and BIM consultants using advanced scanners like Faro, Leica, Matterport, NavVis, Trimble, and GeoSLAM. Our Scan to BIM services are trusted across the USA, UK, Europe, Australia, and over 30 countries globally.

What is Scan to BIM?

Scan to BIM (Building Information Modeling) is the process of capturing existing buildings, structures, or sites through advanced 3D laser scanning technology and converting that data into a highly detailed, intelligent 3D model using software like Autodesk Revit.

The laser scanner collects millions of precise data points — known as a Point Cloud — which forms the foundation for developing an as-built, clash-free, and editable BIM model.

Simply put: Scan to BIM turns real-world spaces into digital models, helping you plan, renovate, manage, and build — smarter.

Why Scan to BIM is a Game-Changer for USA Projects

Across the United States, the demand for precision, speed, and digital workflows is rising in the construction sector. Scan to BIM offers unmatched advantages:

✅ Highly Accurate As-Built Models — Capture exact site conditions to millimeter precision. ✅ Reduced Project Risk — Minimize errors, rework, and costly delays with reliable data. ✅ Streamlined Renovations & Retrofits — Ideal for modifying or upgrading existing structures. ✅ Improved Design Coordination — Centralized models enhance collaboration across teams. ✅ Efficient Facility Management — Maintain and manage buildings using intelligent digital twins. ✅ Faster, Smarter Decision-Making — Empower your team with accurate, real-world insights.

Point Cloud to Revit — What We Deliver

At Rvtcad, we convert Point Cloud data into detailed, intelligent Revit models that meet the highest industry standards. Our models are created to your exact specifications, ensuring:

✔ Architectural Modeling ✔ Structural Modeling ✔ MEP (Mechanical, Electrical, Plumbing) Modeling ✔ LOD (Level of Detail) options: LOD 100 to LOD 400+ ✔ Clash Detection Ready Models ✔ As-Built Documentation

Our Comprehensive Scan to BIM Services (USA)

We offer a full suite of Scan to BIM and Point Cloud to Revit services tailored for the US market:

3D Laser Scanning

On-site laser scanning by expert teams using cutting-edge equipment.

High-density Point Cloud data collection for buildings, infrastructure, and complex sites.

Point Cloud to Revit Conversion

Accurate Revit models for architecture, structure, and MEP systems.

Models developed to client-specific LOD and project standards.

As-Built BIM Modeling

Reliable as-built documentation for renovations, restoration, and facility management.

Scan to 2D Drawings

Generation of precise floor plans, sections, and elevations from Point Cloud data.

MEP BIM Modeling

Comprehensive MEP models for accurate coordination and clash detection.

Industries We Serve Across the USA

Our BIM expertise supports a wide range of projects, delivering accurate Scan to BIM, CAD, and MEP modeling solutions for:

🏢 Commercial Buildings 🏠 Residential Developments 🏗 Infrastructure, Highways & Bridge Projects 🏛 Historic Preservation & Heritage Buildings ⛪ Church & Religious Structures 🏭 Industrial & Manufacturing Facilities 🏥 Healthcare & Hospital Projects ✈ Airports & Transportation Hubs 🏫 Education & Institutional Buildings 🔧 MEP Systems, Coordination & As-Built Modeling

Why Rvtcad is a Trusted Scan to BIM Partner in the USA

✔ Deep USA Market Knowledge — We deliver models that align with American building codes and standards. ✔ Experienced BIM Specialists — Our team combines technical precision with project expertise. ✔ Tailored Solutions — Every project receives a customized approach based on your needs. ✔ Rapid Turnaround Times — Fast, efficient service without compromising quality. ✔ Competitive, Transparent Pricing — High-quality BIM services that respect your budget. ✔ Strict Data Confidentiality — Your project data is protected with top-level security protocols.

Our Process — Seamless, Efficient, Reliable follow a proven, client-friendly workflow to ensure project success:

Step 1: Site Survey & Laser Scanning experts conduct precise 3D laser scans of your building or site.

Step 2: Point Cloud Generation Raw scanned data is processed into a usable, high-density Point Cloud format.

Step 3: Revit Model Development BIM team transforms the Point Cloud into a highly accurate, clash-free Revit model.

Step 4: Quality Control & The final model undergoes rigorous quality checks before secure delivery.

Applications of Scan to BIM in the USA. Our Scan to BIM solutions support:

✔ Renovation & Retrofitting ✔ New Construction Planning ✔ Historic Building Preservation ✔ Clash Detection & Coordination ✔ Facility & Asset Management ✔ Space Optimization & Interior Design ✔ Infrastructure Upgrades ✔ Construction Documentation

Partner with Rvtcad — Your Scan to BIM Experts. You need reliable, accurate, and efficient scan-to-BIM or Point cloud-to-Revit services in the USA Rvtcad is your go-to partner. With our technical expertise, USA project experience, and commitment to excellence, we help you deliver projects on time, on budget, and without surprises.

#scan to bim#point cloud to bim#3d laser scanning#scan to revit#bim laser scanning#point cloud to cad#as-built drawing#bim services#as-built drawings#scan to cad

0 notes

Text

Why Electrical BIM modeling California is Essential for Modern AEC Projects

If you’re in the AEC (Architecture, Engineering, and Construction) industry in California, chances are you’ve already heard the buzz about BIM. But let’s get specific: what does Electrical BIM modeling mean for California-based projects? And why are more MEP firms, contractors, and developers making the switch?

Let’s see what this technology is doing for the Golden State.

What is Electrical BIM Modeling?

BIM is a digital process that creates 3D representations of a building’s physical and functional characteristics. Now, when we talk about Electrical BIM modeling, we’re zooming in on everything from conduit runs and panel boards to lighting layouts and low-voltage systems.

This isn’t just drafting in 3D, it’s smart, data-rich modeling that allows for real-time collaboration between design, engineering, and construction teams.

Why California Needs Electrical BIM

California presents some unique challenges and opportunities for construction and infrastructure. With its strict building codes, push for sustainable energy systems, and complex zoning regulations, the state demands precision. That’s where Electrical BIM modeling comes in.

Here’s why it’s gaining momentum:

Code Compliance from the Start California has some of the toughest energy and building codes in the country. With Electrical BIM modeling, engineers can simulate and verify compliance during the design phase reducing delays and rework.

Sustainability is Not Optional With the state pushing for all-electric buildings and a transition to solar, electrical systems are more complex than ever. Electrical BIM helps teams design and coordinate renewable energy systems, EV charging infrastructure, and energy storage early on.

Labor Shortages Demand Efficiency Let’s be honest: California’s skilled trades are stretched thin. BIM allows contractors to pre-plan installations with precise coordination, reducing field conflicts and saving on labor costs.

Urban Density Calls for Tight Coordination Whether it’s a new commercial high-rise in Los Angeles or a hospital retrofit in San Francisco, tight spaces mean every inch of conduit and cable tray matters. Electrical BIM modeling ensures spatial accuracy and minimizes clashes with structural and HVAC systems.

Who’s Using It?

More firms are moving from 2D CAD to BIM platforms like Revit and Navisworks. Developers building high-rise mixed-use spaces in downtown San Diego. Design-build firms tackling mission-critical facilities in the Bay Area. Even public sector projects in Sacramento are adopting Electrical BIM modeling as the standard.

For GCs and subcontractors bidding on large-scale jobs, BIM isn’t just a nice-to-have, it’s a must. Owners want deliverables that go beyond PDFs and blueprints. They want data they can use for maintenance and operations for years to come.

The Competitive Edge

Here’s the real kicker: companies leveraging Electrical BIM modeling in California are winning more bids, completing jobs faster, and delivering higher-quality work. They avoid costly clashes and change orders by solving problems before crews even hit the site.

That’s not just tech, it’s ROI.

Future-Proofing Your Business

California isn’t slowing down. From electrified schools to grid-resilient hospitals, electrical systems are only getting more complex. Investing in Electrical BIM modeling today means being ready for tomorrow’s requirements.

Whether you’re an MEP engineer, a GC, or a developer it’s time to rethink how you approach electrical design and coordination.

Where Clove Technologies Comes In

If you’re looking to streamline your project and improve coordination, Clove Technologies offers highly efficient Electrical BIM modeling services in California. Their team of BIM specialists helps bridge the gap between design intent and real-world execution saving you time, money, and headaches on your next project.

Check out this new blog on Why MEP BIM modeling is changing USA’s AEC industry.

Contact Clove Technologies today to schedule a free BIM consultation and discover how our innovative solutions can power your project’s success.

Email: [email protected] BIM modeling, Mechanical BIM modeling in Texas, Fire Protection BIM modeling in Texas, Low Voltage BIM modeling in Florida, Plumbing BIM modeling in Georgia, Mechanical BIM modeling in Illinois, Fire Protection BIM modeling in Illinois, Electrical BIM modeling California, Low Voltage BIM modeling, California BIM modeling in Georgia, Scan to BIM, Scan to BIM in Georgia, H.V.A.C 3D Modeling in US / USA, Plumbing 3D Modeling, H.V.A.C 3D Modeling.

0 notes

Text

Why Aerial Drone Surveying and 2D CAD Services Are Essential for Modern Engineering Projects

In today’s engineering landscape, accuracy, speed, and adaptability are non-negotiable. As project scopes expand and demand for digital transformation grows, two technologies are proving indispensable: aerial drone surveying and 2D CAD services. Together, they are reshaping how modern projects are planned, documented, and delivered — from the initial site analysis to final as-built records.

While each technology holds its value, its combined application provides a significant advantage to industries that rely on real-time insights and detailed engineering documentation.

What Aerial Drone Surveying Brings to the Table

Aerial drone surveying uses unmanned aerial vehicles (UAVs) equipped with high-resolution imaging systems and LiDAR to collect precise data from above. Unlike traditional ground-based surveying, drones capture comprehensive topographical and structural data quickly and with minimal disruption to ongoing operations.

Speed and Efficiency: Drones can cover large, complex, or hazardous areas in a fraction of the time it takes for manual surveys.

Safety and Accessibility: Surveying hard-to-reach or dangerous terrain is conducted safely from the air, minimizing risks to personnel.

Data Depth: High-resolution imagery and LiDAR scanning offer engineers accurate terrain models, elevation data, and volumetric analysis critical to infrastructure and site planning.

This data forms the foundation for further planning and is especially valuable for industries like construction, logistics, and industrial engineering where exact site measurements drive downstream design and layout decisions.

The Importance of 2D CAD Services in Engineering

While drone surveys provide raw spatial data, 2D CAD services translate that information into usable design formats. These services involve the creation of technical drawings and schematics used for construction plans, mechanical layouts, and facility documentation.

Precision in Design: 2D CAD drawings are essential for detailing dimensions, tolerances, and spatial relationships in engineering layouts.

Ease of Collaboration: CAD files can be easily shared across departments and teams, streamlining communication and approvals.

Modifiability: Design changes are inevitable. CAD platforms allow for easy revisions and version tracking without compromising project timelines.

In many projects, 2D drawings serve as the formal record of design intent and are often required for regulatory or construction documentation.

A Powerful Combination: Drones and CAD Working Together

The real value emerges when drone surveying and CAD services are combined in a single workflow. Aerial survey data can be imported directly into CAD software, allowing engineers to build designs that reflect real-world site conditions with a high degree of accuracy.

This integration reduces the risk of dimensional errors, helps avoid conflicts during construction, and ensures that every decision is grounded in reliable data. It also supports faster project startup, better stakeholder alignment, and smoother implementation.

PMC’s Expertise in Integrated Engineering Solutions

Production Modeling Corporation (PMC) brings a comprehensive understanding of drone surveying and CAD design to engineering and industrial projects. Leveraging decades of experience, PMC provides high-precision aerial drone surveying services and 2D CAD drafting tailored to real-world applications in manufacturing, construction, and logistics.

Their team works closely with project stakeholders — from engineers to plant managers — to ensure that the data collected and the documentation delivered are aligned with operational goals and compliance standards.

Final Thought

The integration of aerial drone surveying with 2D CAD services represents a new standard in modern engineering. It’s no longer just about collecting data — it’s about transforming that data into insights that drive better decisions, more efficient planning, and higher-quality outcomes.

For organizations looking to streamline workflows, reduce rework, and future-proof their projects, PMC delivers the tools, expertise, and support to make that transformation a reality.

0 notes

Text

What Is Reverse Engineering and When Should You Use It?

In today’s competitive and innovation-driven manufacturing landscape, companies are continually searching for methods to optimize designs, streamline production, and gain deeper insight into existing products. One of the most powerful yet often misunderstood tools that supports these objectives is reverse engineering.

Reverse engineering enables organizations to deconstruct a product or system to understand its components, functions, and design principles. This process is not only used to replicate products but also to analyze their structure, improve upon them, or integrate them into new applications.

This article offers a comprehensive explanation of reverse engineering—what it is, how it works, the technologies involved, its applications across industries, and the scenarios where it proves most valuable.

Defining Reverse Engineering

At its core, reverse engineering is the process of disassembling or analyzing an object to understand how it was designed and manufactured. It involves extracting design information from existing products, often in the absence of technical documentation or original design files.

Unlike traditional engineering, which moves from concept to product, reverse engineering starts with the finished item and works backwards to deduce the original specifications. The insights gained are often used to:

Create 3D models and CAD files

Improve product design

Develop compatible components

Diagnose failures or weaknesses

Reproduce obsolete or legacy parts

Reverse engineering does not necessarily imply copying or duplication. Rather, it is a legitimate and valuable practice in modern product development, maintenance, and innovation.

How Reverse Engineering Works

The reverse engineering process varies depending on the object, industry, and intended outcome, but it generally follows a consistent sequence:

1. Data Acquisition

The first step involves capturing detailed information about the object’s geometry, dimensions, and features. This is typically done using advanced 3D scanning technologies such as:

Laser Scanners: Emit laser beams to detect surface contours.

Structured Light Scanners: Project light patterns and measure distortions to determine surface geometry.

Computed Tomography (CT) Scanners: Capture both internal and external features using X-ray technology.

Coordinate Measuring Machines (CMMs): Use touch probes to precisely measure specific points.

These tools collect millions of data points, forming a comprehensive digital representation of the object known as a point cloud.

2. Data Processing and Mesh Generation

The raw point cloud data is cleaned, aligned, and processed to remove noise and inconsistencies. The next step is to convert the point cloud into a polygonal mesh—a 3D surface composed of interconnected triangles.

This mesh is then optimized to ensure it accurately reflects the physical object’s shape while maintaining a manageable file size for further use.

3. 3D Modeling and CAD Conversion

Once a high-quality mesh is obtained, it is used to reconstruct the object in a computer-aided design (CAD) environment. Engineers develop a fully parametric or feature-based CAD model that replicates the part’s geometry.

At this stage, material specifications, tolerances, and functional features may also be analyzed and documented. The final CAD model can be edited, shared, or integrated into larger assemblies.

4. Analysis and Application

The finished model is then used for various purposes, including design improvements, simulation, tooling development, or manufacturing reproduction. Engineers may also perform stress tests, fit checks, and other simulations using the digital model.

Key Technologies in Reverse Engineering

Advances in digital manufacturing and metrology have significantly expanded the capabilities of reverse engineering. The following technologies are essential:

3D Scanning

High-resolution 3D scanning tools rapidly capture the surface geometry of physical objects, forming the foundation for all subsequent steps. These scanners vary in accuracy, speed, and suitability depending on the object's size, complexity, and material.

CAD Software

CAD platforms such as SolidWorks, Autodesk Inventor, Siemens NX, and others play a crucial role in interpreting scanned data and creating usable design files. These models are often parametric, allowing engineers to modify features and dimensions easily.

Simulation Tools

Finite Element Analysis (FEA) and other simulation tools are used in conjunction with CAD models to evaluate a product’s performance under various conditions. These insights support design optimization and failure analysis.

3D Printing and Prototyping

Rapid prototyping allows teams to test modifications derived from reverse engineering efforts. By printing physical models, engineers can assess fit, function, and ergonomics quickly and affordably.

When Should You Use Reverse Engineering?

Reverse engineering is applicable in a wide range of situations across multiple industries. It is especially useful when dealing with legacy components, product innovation, or systems integration. Below are the most common scenarios that justify the use of reverse engineering.

1. Recreating Obsolete or Legacy Parts

One of the primary uses of reverse engineering is to reproduce discontinued components for machines, vehicles, or systems that are no longer supported by the original manufacturer. With no access to original drawings or tooling, reverse engineering provides a reliable way to maintain critical assets and extend their lifecycle.

This is particularly valuable in aerospace, defense, rail, and heavy industries, where replacing entire systems is impractical or cost-prohibitive.

2. Product Improvement and Optimization

Reverse engineering enables manufacturers to analyze existing products and identify opportunities for improvement. Engineers can assess design weaknesses, material inefficiencies, or manufacturing complexities and apply innovative solutions to enhance performance, durability, or cost-effectiveness.

The process often leads to

Lighter and stronger designs

Reduced manufacturing steps

Better ergonomics or aesthetics

Improved energy efficiency

3. Competitive Analysis

Organisations often use reverse engineering to examine competitor products and gain insights into their features, performance, and manufacturing techniques. This helps in benchmarking, identifying intellectual property challenges, and driving innovation.

While care must be taken to respect legal and ethical boundaries, competitive reverse engineering is a legitimate practice used for market intelligence and strategic planning.

4. Integrating New Components with Existing Systems

In cases where new parts or systems need to work seamlessly with older components, reverse engineering ensures dimensional compatibility and functionality. By modeling the existing hardware accurately, engineers can design new components that align perfectly without trial and error.

This use is common in:

Automotive retrofits

Industrial equipment upgrades

Electronic system integration

5. Quality Control and Inspection

Reverse engineering is sometimes used as a validation tool in quality assurance. By scanning and modeling a manufactured part, teams can compare it to the original design and detect any deviations or defects.

This process enhances dimensional verification, especially for complex geometries that are difficult to measure with traditional tools.

6. Digital Archiving

Preserving the design data of critical components through reverse engineering creates a digital archive for future reference. This is important in museums, aerospace restoration, and asset management, ensuring that data is never lost even if physical components degrade or disappear.

Industries Benefiting from Reverse Engineering

The versatility of reverse engineering means it is widely applicable across a variety of sectors:

Aerospace

Airplane components, many of which have long service lifecycles, often require replacement or refurbishment after the original manufacturing data is lost. Reverse engineering ensures structural integrity and regulatory compliance.

Automotive

Classic cars, custom vehicles, and prototype parts benefit greatly from reverse engineering. It enables part reproduction, modification, and even digital recreation of entire vehicle systems.

Medical Devices

Medical implants, prosthetics, and surgical instruments are reverse-engineered to improve functionality, ensure anatomical fit, or replicate discontinued designs.

Consumer Electronics

Electronics companies often disassemble products to understand PCB layouts, circuitry, and design logic. This enables repair, customization, or the development of compatible accessories.

Industrial Manufacturing

Reverse engineering supports tooling design, process improvement, and machine maintenance. It is also used to digitize old parts or machinery for integration into modern workflows.

The Role of Reverse Engineering in Innovation

Beyond its practical applications, reverse engineering fosters innovation by bridging the gap between legacy knowledge and modern capabilities. It encourages experimentation, cross-functional learning, and iterative improvement.

By understanding the details of how a product works, engineers can:

Identify underutilized features

Explore alternative materials

Develop more efficient manufacturing methods

Combine legacy and modern technologies

This approach is particularly important for companies striving to remain competitive in rapidly evolving markets. It allows them to leapfrog development stages, reduce R&D costs, and bring products to market faster.

Ethical and Legal Considerations

While reverse engineering is a powerful tool, it must be practiced within ethical and legal boundaries. It is important to respect patents, copyrights, trade secrets, and intellectual property (IP) rights.

Organizations using reverse engineering must ensure their efforts do not infringe on protected designs. In many jurisdictions, reverse engineering for interoperability or repair purposes is legal, but copying patented elements without permission is not.

Working with professional providers of reverse engineering services in Australia ensures that all procedures are carried out in compliance with local laws and international IP standards.

Choosing the Right Reverse Engineering Partner

The effectiveness of reverse engineering relies heavily on the skill, experience, and tools used. Partnering with specialists who understand materials science, digital modeling, and manufacturing processes ensures accurate, high-quality results.

Providers offering reverse engineering services in Australia are equipped with advanced scanning systems, robust CAD platforms, and cross-industry expertise. They help clients navigate complex engineering challenges, from legacy part digitization to modern product development, while maintaining confidentiality and regulatory compliance.

Conclusion

Reverse engineering is a powerful, multi-purpose process that enables organizations to derive valuable design and manufacturing data from existing physical products. Whether used for reproduction, enhancement, integration, or analysis, it offers significant advantages across the product lifecycle.

By turning physical objects into digital intelligence, reverse engineering allows industries to move forward while learning from the past. It supports innovation, sustainability, and precision in a world where adaptability and speed are crucial to success.

As industries increasingly adopt digital technologies and advanced manufacturing techniques, reverse engineering will play an even more integral role—especially when executed by trusted professionals who offer comprehensive reverse engineering services in Australia and beyond.

#reverse engineering#product development#3D scanning#CAD modeling#engineering services#component analysis#design replication

1 note

·

View note

Text

Cad Scanning

Nel Pretech Corporation offers top-tier CAD Scanning services, converting physical objects into accurate digital models. Their advanced scanning technology and expertise ensure precise data capture, aiding in design, analysis, and quality control processes across various industries.

0 notes

Text

Top Architectural Scan to BIM Services | Accurate BIM & CAD Services

Looking for professional Architectural Scan to BIM services? We provide high-accuracy Architectural BIM Modeling and Scan to CAD services to transform point cloud data into detailed 3D models. Our expertise ensures precision, efficiency, and seamless integration into your architectural and construction projects. Whether you need BIM models for renovation, restoration, or new builds, our services guarantee high-quality results. Improve your workflow with our Scan to BIM and Scan to CAD services tailored to your needs.

#Architectural Scan to BIM#Architectural Scan to BIM services#Architectural Scan to CAD Services#Architectural BIM modeling service

0 notes

Text

Scan to CAD Conversion Services

Exciting news! We've revolutionized our Implementation of 3D Scan to CAD Conversion Services provider. Say goodbye to manual measurements and hello to precision and efficiency! Unlocking endless possibilities in design and engineering. Experience seamless transition from physical to digital models with our cutting-edge Architectural PDF to CAD Conversion Services in USA. Accelerate your projects with accurate data capture and streamline your design process.

0 notes

Text

Scan To CAD Technology is a process that converts physical objects into precise digital 3D models using 3D scanning technology and CAD software. It captures real-world geometry, generating a point cloud, which is then transformed into an editable CAD file. This technology is widely used in engineering, manufacturing, architecture, and healthcare for reverse engineering, quality control, and prototyping. Scan-to-CAD streamlines design workflows and enhances innovation across industries by improving accuracy and efficiency.

0 notes

Text

Accurate 3D Laser Scanning Services in Italy | Scan to BIM by Rvtcad

Italy is a land of iconic architecture, ancient structures, and modern construction projects. From historical monuments in Rome to smart buildings in Milan, accurate data is essential to preserve, plan, and build efficiently. That’s where 3D laser scanning and Scan to BIM services come in — and Rvtcad is proud to be a trusted name in delivering high-quality digital solutions across Italy.

What is 3D Laser Scanning?

3D laser scanning is a cutting-edge method for capturing the exact physical dimensions of a building or space. The technology uses laser beams to scan the environment and collect millions of data points. These points form a point cloud, which is the base for creating accurate 3D models or 2D drawings.

Scan to BIM – Bringing Real Spaces into the Digital World

Scan to BIM (Building Information Modeling) is the process of converting point cloud data into a detailed, intelligent 3D BIM model. These models represent a building’s architecture, structure, and MEP (Mechanical, Electrical, and Plumbing) systems. BIM allows project teams to plan, manage, and maintain buildings more effectively.

Whether it's a cathedral in Florence, a residential villa in Tuscany, or a commercial tower in Milan — Rvtcad transforms your physical space into a fully-digital BIM environment.

Why Choose Rvtcad in Italy?

At Rvtcad, we combine technology with expertise. Our team includes certified laser scanning professionals, experienced Revit modelers, and BIM specialists. We bring precision, speed, and clarity to every project.

Here’s why Rvtcad stands out:

✅ Highly Accurate Scanning

We use FARO, Leica, and Trimble scanners to capture exact measurements with millimeter precision.

✅ Expert BIM Modeling

We create clean, clash-free BIM models in Revit, customized to your Level of Detail (LOD 100–500).

✅ Italy-Wide Service

From Rome to Naples, Venice to Sicily — we provide on-site scanning and remote BIM services throughout Italy.

✅ Fast Delivery

We understand project timelines. That’s why we deliver high-quality models within committed deadlines.

✅ All-In-One Solutions

From scanning and CAD drafting to full BIM coordination, we provide end-to-end support for your project.

Our Key Services

3D Laser Scanning for Buildings & Infrastructure

Scan to BIM (Architectural, Structural, MEP)

Revit Modeling from Point Cloud

2D Floor Plans, Sections & Elevations

As-Built Documentation

BIM for Facility Management

Why Scan to BIM is Important for Italy

Italy is rich in architectural diversity. Renovating or maintaining old structures requires accurate data to avoid damage. That’s why laser scanning and BIM are becoming standard tools for architects, engineers, and builders in Italy.

Benefits include:

Zero guesswork – real measurements every time

Fewer site visits – data is captured once and shared digitally

Better planning – know what exists before you build

Easy collaboration – share BIM files with stakeholders

Long-term use – models for future repairs, upgrades, or inspections

Serving Architects, Engineers, Surveyors & Contractors

Whether you’re an architect designing a renovation, a contractor verifying construction work, or a facility manager handling maintenance – Rvtcad is your reliable Scan to BIM partner.

We ensure that every model we deliver meets your expectations, your project needs, and your software compatibility.

🔧 Software Expertise

Autodesk Revit

AutoCAD

Recap

ArchiCAD

SketchUp

Navisworks

Let’s Build Smarter with Rvtcad

If you’re looking for accurate, affordable, and fast 3D laser scanning services in Italy, Rvtcad is ready to help. From detailed site scanning to BIM-ready models, we bring quality and commitment to every project.

#scan to bim#point cloud to bim#3d laser scanning#bim services#as-built drawing#bim laser scanning#scan to revit#scan to cad#as-built drawings#point cloud to cad

0 notes

Text

0 notes

Text

Why Fire Protection BIM modeling in Illinois is Essential for Modern AEC Projects

Building Information Modeling (BIM) is already revolutionizing the way projects are designed, coordinated, and managed. When applied specifically to fire safety systems, BIM modeling becomes a powerful tool to design and document sprinkler layouts, fire suppression systems, smoke alarms, emergency lighting, and other life-saving infrastructure with unmatched precision.

Using 3D digital models, engineers and contractors can visualize and coordinate fire safety systems early in the design process, reducing conflicts and change orders during construction. It also ensures compliance with the National Fire Protection Association (NFPA) codes and Illinois fire codes.

Why Fire Protection BIM Modeling Matters in Illinois

Illinois, home to both dense urban cores like Chicago and sprawling suburban developments, requires a tailored approach to fire safety. Local authorities have stringent fire codes, especially in high-rise construction, commercial spaces, and health care facilities.

Fire Protection BIM Modeling in Illinois plays a pivotal role in satisfying both design and safety requirements. The ability to run clash detection simulations, ensure sprinkler head clearance, and coordinate with architectural and MEP systems before construction begins reduces costly rework and shortens project timelines.

Key Benefits for Illinois-Based Projects

Code Compliance: Ensures adherence to Illinois fire codes and NFPA standards.

Early Detection of Conflicts: Identifies design issues before they reach the construction phase.

Increased Collaboration: Streamlines communication between architects, engineers, and contractors.

Facility Management: Post-construction, BIM data supports maintenance and emergency preparedness.

Who Needs This?

If you’re a general contractor working on commercial developments in Chicago, a design engineer on a hospital project in Springfield, or a building owner updating an old warehouse in Rockford — you’ll benefit from integrating Fire Protection BIM Modeling into your project.

It’s especially useful for:

Healthcare facilities with strict evacuation route standards

Education institutions needing fire suppression for lab buildings

Warehouses with automated fire systems

High-rise residential towers requiring multi-zone protection

What Sets BIM Apart from Traditional Fire Protection Design?

Traditional 2D drawings and spreadsheets can’t capture spatial relationships or system interdependencies. BIM models, however, bring a level of intelligence and collaboration unmatched by older methods.

By implementing BIM for fire safety systems, you’re not just complying with regulations you’re actively optimizing safety, cost, and time efficiency.

Where Does This Fit in the Construction Workflow?

Fire Protection BIM Modeling fits best during the design development and pre-construction phases. This timing allows fire system designers to work closely with MEP consultants and structural engineers, ensuring coordinated and compliant installations.

It also integrates with 4D (time) and 5D (cost) simulations to help project stakeholders understand not only how systems will be built, but also how long they will take and how much they will cost.

Choosing the Right Partner

If you’re considering Fire Protection BIM Modeling in Illinois, it’s essential to work with specialists who understand Illinois fire codes, construction workflows, and Building Information Modeling technologies.

Clove Technologies stands out in this space. Their team delivers highly accurate, code-compliant fire safety systems tailored to the needs of Illinois construction. Whether it’s a large commercial project or a specialized facility, Clove Technologies ensures that fire safety is engineered right from the start.

Check out this blog on Electrical BIM Modeling in Florida

Contact Us now : [email protected]

Keywords : Plumbing BIM modeling, Mechanical BIM modeling in Texas, Fire Protection BIM modeling in Texas, Low Voltage BIM modeling in Florida, Plumbing BIM modeling in Georgia, Mechanical BIM modeling in Illinois, Fire Protection BIM modeling in Illinois, Electrical BIM modeling California, Low Voltage BIM modeling, California BIM modeling in Georgia, Scan to BIM, Scan to BIM in Georgia, H.V.A.C 3D Modeling in US / USA, Plumbing 3D Modeling, H.V.A.C 3D Modeling.

0 notes

Text

Transforming Reality into Precision: The Power of 3D Laser Scan to CAD

In the world of design, construction, and engineering, accuracy is paramount. Whether you're working on a large-scale infrastructure project or a complex architectural renovation, having precise measurements and data is essential to success. One of the most revolutionary technologies to impact these fields is 3D laser scanning. When combined with Computer-Aided Design (CAD) software, it allows for the creation of highly detailed, accurate digital models of real-world environments. This process, known as "3d Laser Scan To Cad," has transformed industries by improving efficiency, reducing errors, and enhancing collaboration.

What is 3D Laser Scanning?

3D laser scanning is a process that uses laser beams to capture a physical environment or object and convert it into a digital 3D model. The laser scanner emits laser pulses that bounce back after hitting a surface, measuring the distance to the surface with incredible precision. This data, often referred to as "point clouds," can be used to represent the exact shape and dimensions of the scanned object or environment in 3D space.

The technology is capable of capturing millions of data points per second, making it possible to document complex structures, both large and small, with unparalleled accuracy. Unlike traditional measurement methods, 3D laser scanning does not require physical contact with the object, allowing for safer and faster data collection.

The Process: From Laser Scan to CAD Model

The transition from a 3D laser scan to a usable CAD model involves several key steps:

Data Capture: A laser scanner is placed in strategic locations around the object or environment to collect data from different angles. This results in a set of point clouds that represent the scanned surfaces.

Point Cloud Registration: If multiple scans are taken, they need to be aligned and combined into a single, unified point cloud. This process, known as registration, ensures that all scan data fits together seamlessly, even when gathered from different positions.

Point Cloud Processing: The raw point cloud data may contain noise or irrelevant points that need to be cleaned up. Software tools are used to refine the data, ensuring that only the necessary information remains for further processing.

Model Creation in CAD Software: The cleaned point cloud is imported into a CAD program, such as AutoCAD, Rhino, or Revit, where it serves as a reference for creating accurate 3D models. Engineers, architects, or designers can use this reference to create detailed representations of the object or space, including dimensions, geometry, and spatial relationships.

Final Design & Integration: Once the CAD model is created, it can be modified, analyzed, and integrated into broader design plans. The model can be used for simulations, structural analysis, or visualizations, depending on the project’s requirements.

Benefits of 3D Laser Scan to CAD

The integration of 3D laser scanning with CAD software brings several advantages to a variety of industries:

Accuracy and Precision: The level of detail captured by laser scanners is far superior to traditional manual measuring techniques. This results in highly accurate CAD models that reflect real-world conditions.

Speed and Efficiency: Laser scanning is significantly faster than manual measurement, allowing for rapid data collection in a fraction of the time. This is especially beneficial for large, complex environments that would otherwise take days or weeks to measure.

Reduced Errors and Rework: With accurate data at the outset, the likelihood of errors in the design phase is minimized. As a result, costly rework due to design mistakes or inaccuracies is significantly reduced.

As-Built Documentation: In renovation or retrofit projects, 3D laser scanning provides accurate "as-built" data, which is essential for understanding the current state of a structure. This ensures that design modifications fit seamlessly with existing conditions.

Improved Collaboration: 3D models can be easily shared across teams, improving communication and

collaboration between architects, engineers, contractors, and clients. The digital models can be reviewed, annotated, and modified in real-time, streamlining the design process.

Better Decision-Making: Accurate data and detailed models provide stakeholders with a clearer understanding of the project, enabling better decision-making and more effective project management.

Applications of 3D Laser Scan to CAD

The applications of 3D laser scan to CAD are vast and varied, spanning across multiple industries:

Architecture and Construction: In both new builds and renovations, 3D laser scanning captures every detail of a structure, making it easier to create accurate blueprints and identify potential design challenges before construction begins.

Manufacturing: Manufacturers can use 3D scanning to reverse-engineer existing parts or create prototypes with precise measurements, reducing the time spent on design iterations and prototyping.

Heritage Preservation: Historical sites and monuments can be digitally preserved through 3D scanning, allowing for restoration or replication with an unprecedented level of detail and accuracy.

Aerospace and Automotive: Engineers in the aerospace and automotive sectors use 3D scanning to capture precise measurements of parts and assemblies, ensuring that designs fit together perfectly during the production process.

Civil Engineering: Large infrastructure projects, such as bridges, tunnels, and highways, benefit from 3D laser scanning to create detailed models of the existing environment, aiding in design, analysis, and construction.

Conclusion

The integration of 3d Laser Scanner To Cad technology is a game-changer for industries that rely on precise design and measurement. By transforming physical spaces into highly accurate digital models, it not only improves the efficiency and accuracy of design work but also reduces the risk of costly errors and delays. As technology continues to evolve, the combination of 3D laser scanning and CAD will only become more essential for driving innovation and precision across a wide range of industries. Whether you're designing a new building, renovating a historical landmark, or developing complex machinery, 3D Laser Scan to CAD is the future of accurate, efficient, and collaborative design.

0 notes