#CNC Turning Factory

Explore tagged Tumblr posts

Text

CNC Turning Parts: Precision Engineering for Every Industry

In the world of manufacturing and precision engineering, CNC turning parts play a pivotal role. From aerospace to automotive, and from medical devices to consumer electronics, CNC turning parts are the unsung heroes behind countless products we use every day. In this comprehensive guide, we will delve deep into the world of CNC turning parts, CNC Turning Factories, and Turned Parts, shedding light on their importance, manufacturing process, and applications.

The Basics: CNC Turning Parts Unveiled

CNC Turning Parts: The Heart of Precision Machining

CNC turning parts are the fundamental building blocks of precision machining. They are components produced through the CNC (Computer Numerical Control) turning process. These parts are essential in creating the intricate and specialized components required in various industries.

CNC Turning Factory: Where Precision Meets Innovation

A CNC Turning Factory is where the magic happens. These facilities are equipped with state-of-the-art machinery and skilled technicians who transform raw materials into finely crafted CNC turning parts. The combination of advanced technology and human expertise results in parts that meet the most exacting standards.

The Significance of Turned Parts

Turned parts are the outcome of CNC turning, and they come in a vast array of shapes, sizes, and materials. Their significance lies in their ability to make complex and precision-driven products possible. From tiny screws in medical devices to large components in aerospace applications, turned parts are ubiquitous.

CNC Turning Parts in Action

Aerospace: Where Precision is Paramount

The aerospace industry relies heavily on CNC turning parts for the creation of critical components. Aircraft engines, landing gear, and avionics systems require precision turning parts to function flawlessly. These parts must withstand extreme conditions and maintain high levels of performance and reliability.

Automotive: Driving Innovation

In the automotive industry, CNC turning parts are found throughout the vehicle. From the engine block to the transmission system, these parts ensure the optimal operation of the vehicle. Precision is crucial for safety, fuel efficiency, and overall performance.

Medical Devices: Life-Saving Precision

When it comes to medical devices, precision is a matter of life and death. CNC turning parts are instrumental in the production of devices such as pacemakers, surgical instruments, and prosthetics. These parts must meet strict quality standards to ensure patient safety.

Consumer Electronics: A World of Miniaturization

In the realm of consumer electronics, CNC turning parts are responsible for the miniaturization of technology. From the tiniest components in smartphones to intricate connectors in laptops, these parts make our gadgets sleek, efficient, and user-friendly.

The CNC Turning Process

Turning Raw Materials into Masterpieces

The CNC turning process involves the removal of material from a workpiece using computer-controlled machinery. The workpiece is rotated while a cutting tool shapes it into the desired form. This process is highly precise, allowing for intricate and complex shapes to be created with utmost accuracy.

Materials Matter

CNC turning parts can be made from various materials, including metals, plastics, and composites. The choice of material depends on the specific requirements of the part, such as strength, heat resistance, and conductivity.

Precision at its Finest

One of the standout features of CNC turning is its ability to produce parts with incredible precision. Tolerances in the range of micrometers are achievable, ensuring that parts fit perfectly and perform as intended.

Efficiency and Speed

CNC turning is not only about precision but also efficiency. These machines can work at high speeds, making them suitable for high-volume production. This combination of precision and efficiency is what makes CNC turning an indispensable process.

CNC Turning Factories: Where the Magic Happens

State-of-the-Art Machinery

CNC Turning Factories are equipped with cutting-edge CNC machines. These machines are capable of turning, milling, and drilling, making them versatile for a wide range of parts.

Expertise and Skill

While machines are crucial, it's the expertise of the technicians that truly sets CNC Turning Factories apart. Skilled operators program the machines, monitor the process, and ensure that the final parts meet the highest standards.

Quality Control

Quality control is a non-negotiable step in CNC Turning Factories. Every part undergoes rigorous inspections to ensure it conforms to the required specifications. This commitment to quality guarantees that only the best parts reach the market.

Turned Parts: Versatile and Essential

Diverse Applications

Turned parts find their way into countless applications. They are used in hydraulics, pneumatics, automotive systems, and even in everyday products like bicycles and furniture. The versatility of turned parts is truly remarkable.

Customization Possibilities

CNC turning allows for a high degree of customization. Manufacturers can produce turned parts that are tailor-made for specific applications, ensuring optimal performance and efficiency.

Sustainability Matters

In today's environmentally conscious world, turned parts play a role in sustainability. The precision they offer minimizes material waste, and their use in energy-efficient systems contributes to a greener planet.

0 notes

Text

CNC milling and turning machining

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc machining parts#cnc parts#cnc parts company#cnc parts factory#cnc precision machining#cnc milling#cnc turning

4 notes

·

View notes

Text

Turned parts

Turned parts are machined by rotary motion between workpieces and linear or curvilinear motion between tools to change the shape and dimensions of the blank into a part that meets the requirements of the drawing.

0 notes

Text

Cosmos Impex: Leading CNC Machine Tools Manufacturer & Supplier in India

Established in 1987, Cosmos Impex excels in Leading CNC Machine Tools Manufacturer & Supplier in India. We offer cutting-edge machining centers, including vertical and horizontal turning centers, 5-axis and die-mould machining centers, and imported machines from Taiwan and Japan. Our commitment to innovation, quality, and customer service ensures top performance and reliability for manufacturers across India.

#cnc machine manufacturer india#cnc machine suppliers in india#cnc machine manufacturers in vadodara#cnc machine cost in india#cnc machine manufacturer in gujarat#cnc vertical machining centers#best vmc machine in india#vertical milling machine cnc#cnc drilling tapping machine#cnc turning machine manufacturers in india#cnc vertical turning lathe#vertical turning lathe#Digital factory solution iot cnc#surface grinder machine manufacturer#surface grinding machine price#cnc lathe machine manufacturer in india#cosmos vmc#cosmos vmc 1160#cosmos vmc 800#cosmos cvm 1370 price in india#cosmos cvm 1160 price#cosmos cvm 640 price in india#cosmos cvm 800 specifications#cosmos cvm 1370#cosmos cvm 1160

0 notes

Text

Revolutionizing Precision by CNC Components Manufacturers

CNC (Computer Numerical Control) is a machining technology. Products are created by removing material from a so-called workpiece using various cutting tools. At the same time, the production process is automated by software – the tool or workpiece moves according to the code, and the machine operator performs only auxiliary operations, such as changing tools or setting the workpiece. CNC machining by CNC components manufacturers makes it possible to produce high-precision parts from a CAD (computer-aided design system) file with excellent physical and mechanical properties. Due to the high level of automation, CNC machining is competitive for single pieces & short runs, as well as for serial and mass production.

CNC manufacturing process

The CNC manufacturing process of a product can be broken down into four main steps:

1. An engineer designs a CAD model.

2. A technologist based on CAD/CAM software prepares a control program for the CNC machine.

3. The operator inserts the tool, and workpiece into the CNC machine and starts the control program.

4. The CNC machine performs all the processing operations – material removal.

CNC Machine Applications Industries

Aerospace

The aerospace industry encompasses all modes of air transport, from massive Airbus A380 aircraft that carry hundreds of passengers to spacecraft designed to fly to the International Space Station, the Moon, and even Mars. Aerospace technology is characterized by incredible precision that is difficult to achieve with conventional tools, which is why CNC machines by CNC-turned parts manufacturers were the perfect solution.

CNC in Aviation

The CNC machine plays a crucial role in the fast and accurate production of the parts that are used in the operation of every component of the aircraft. Such tools are used to create engine parts, cockpit equipment, aircraft skin, wings, and other parts.

CNC in the space industry

CNC is used at NASA, SpaceX, and Roscosmos enterprises to provide rockets with parts of any size and shape with incredibly high fitting accuracy. They produce spare parts for engines, computer equipment, parts for various systems, and spacecraft hulls.

Car

Car shop manager Rocky Helms has a lot of work to do. He oversees the workshop of the world-famous racing team Richard Childress Racing (RCR). The company's 24 employees work two shifts a day to produce the 170,000 parts needed to service the RCR.

The workshop itself occupies 7,000 square meters on a 210,000 square meter campus. Since its inception in 1969, RCR has played 17 championships and won more than 200 times in three NASCAR Major Series, including three Daytona 500 races (1998, 2007, 2018) and three Brickyard 400 races (1995, 2003, 2011).

To increase the production of cars and maintain maximum productivity in the workshop, the RCR is equipped with the latest material handling technologies, including the Roland MODELA MDX-540 benchtop mill.

According to Helms, the machine can do the work in 10 minutes that a person does in 10 hours. RCR uses Roland to mill engine and brake parts, wheel discs, and shock absorbers. The device is also used to create carbon fiber parts & to engrave identification numbers on parts.

Medical

In the space industry, it is customary to say: "There is no repair shop in space." The quality, precision, and reliability of each part must be impeccable because once it leaves the planet, it just has to work. The same applies to the medical field. If the prosthetic implant does not work properly, it affects the health and well-being of the patient. When the operation is complete, the part simply needs to function.

Global trends indicate that the need for medical implants will increase, as will the competition in the market. According to Seco Tools, about five major suppliers are vying for 85 percent of the orthopedic parts market, with more than 200 companies vying for the remaining 15 percent.

The manufacturing process of orthopedic implants includes cutting, grinding, 3D printing, and other operations on CNC devices by CNC machining parts factory. The machine performs roughing, finishing, milling, T-slot machining, chamfering, and deburring. The goal is to achieve the required surface finish, reducing the need for time-consuming manual processing. Five-axis milling and grinding machines provide advantages when working with complex shapes and contours of prosthetic implants. Thanks to CNC, the production time is significantly reduced & the accuracy is increased. Modern technology is capable of processing almost any material, including titanium and ceramics.

0 notes

Note

Cali Cali bo-bali banana fana fo-fali me my mo mali! Cali!

I'm three Budweisers in and got an itch for alpha Price with a sudden need to breed (yay! Surprise rut!), and there's his sweet smelling omega neighbor who he's been keeping at arm's length because he's a professional dammit and has complete control of his urges, thank you very much.

Honestly, I just wanna see Mr. "I'm Married to My Job" lose it and show back up on base abashed and mated, and also ridiculously proud of his lil omega's claiming bite, because "she turned into a wildcat, lads. I couldn't stop her." *wink-wink*

Or not. I'm happy with any smutty Price fic you bestow on us, really. I'm just being weirdly specific because— alcohol = horny thots. 🍺😏🥴🫠

Drunken hugs 🫂 from Random Thot

RTG!! You are the most amazing person, and every time I see your pfp on AO3 or tumblr, I just get all gooey inside. Thank you for the ask! I wrote (and fully deleted) this fic three times because I wanted to get it right. I just pray that I could deliver. <3 <3 Hope this is what you were hoping for!!

MDNI/NSFW -- TW: damsel in distress, ABO dynamics, knotting, fuck-or-die scenarios, CNC, fluids, PIV sex, female OC

Glory, Glory

It was his last beer of the night, and he was ripping it apart. Curling, soggy shards of the torn label were stuck under his thumbnail, darkening the translucent edge and making it look dirty. They littered the sticky, lacquered bartop like ugly snow, falling in a tiny, chaotic mess. His hands were more than just dirty, the captain thought to himself as he used his wide thumb to itch at the glue-covered glass, rolling little, paper shards away from the smooth surface to reveal the amber liquid swirling within. The captain’s hands; they were covered in blood. Not innocent blood, but blood all the same. They’d never be clean again.

But, that was the job, and he was good at it. His hands were a direct reflection of his hard work. Killing evil bastards kept the world safe. Some poor sob in a factory could clean out the glue-painting machine that pasted these fuckin’ labels on all of these bloody beer bottles because of one unshakable truth: John Price was good at killing evil bastards.

Unfortunately, the killing would need to wait until after the mandated leave window closed again. His argument with Kate still grated inside of his head. He could almost hear her harsh, Yank accent in his ears.

“What do you want me to tell payroll, John? You can’t be here. You’ve got too many days. Go home. See your mom.”

“I see her plenty, Katie. Let me run that ops gig with Keller. C’mon. I’ll do overwatch,” he tried his best to weasel his way back into a bit of active duty.

“You’d be the world’s most expensive overwatch. Hell no. Here’s your ticket,” she shoved an envelope in his hands, “...and your money,” another envelope, “Go the fuck home, Captain. That’s an order.”

An order. More like a toothless threat.

But, alas, here he was, staring at a freshly shaved, buzzcut version of himself in a filthy pub mirror, undressing bottles left and right.

“Another, mate?” The barkeep pointed to his almost-empty drink, making a slight grimace at the paper graveyard that was sprinkled across his bar.

“No,” John sighed, pulling out a few notes from his wallet, “I’m off.”

“Happy Christmas,” the barkeep took the bills and didn’t bother to look up again, setting himself to sweeping the torn strips off of the surface, preparing for the next paying customer.

“You, too,” John muttered, tugging his black wool beanie over his ears before braving the classic cold, wet, and windy Liverpudlian night.

He didn’t live far. John’s mum had kept up his loft down by the docks, but it certainly didn’t feel like home. Home wasn’t real. Not anymore. As he walked along the Mersey’s edge, he peered into the black water, wondering if he’d ever truly go home again.

All of a sudden, he heard a shrill scream. Every sense that had been dulled by his lager was now as sharp as a blade and set on its edge. Again, a high-pitched shout pealed through the night air, beckoning him back to his heroism. That keening was the sound of some evil that needed stamping out, and he was hungry for it.

He sprinted through the warehouse district, chasing the noise of scuffling, ducking behind alleys and abandoned garages, looking for the source. Finally, there was a flash of red that caught his eye, so he ran towards it, his mind making sense of the scene in front of him.

Voices were jumbled and mashed up together, barely registering in his mind.

“Out here in a fuckin’ heat. Dumb bitch! C’mere.”

“She’s got a knife!”

“C’mere, you little slag. Get –”

In the middle of three huge, stinking Alphas, a tiny Omega was struggling, arm outstretched, brandishing her knife at them to keep them at bay. John came up behind the biggest one, some bald fuck with a dirty coat, and dropped him, cracking his spine in two places with well-placed fists, and breaking his jaw on his way down to the ground, leaving him groaning on the concrete.

One of his mates, a older man with thick, black eyebrows, lunged at Price, a look of indignant surprise on his face. The Omega screamed, her red coat yanked back over her face by the third man, her knife clattering to her feet. Price focused on Mister Eyebrows, dodging a lazy haymaker before popping him twice in the nose, drawing out his blood and knocking out at least two of his front teeth. Then, John grabbed him by the collar, pulling his jaw into his raised knee and listening to the satisfying splash as he fell into a murky puddle.

Finally, he set his sights on the last Alpha of the pack whose ropey arm was looped across the Omega’s neck, choking the air from her lungs. He growled at Price, his scent turning to rancid fear,

“Stay back! She’s mine, you big bastard.”

The captain had nothing to say. With a practiced ease, he side-stepped her assailant, breaking the elbow that controlled her throat, making him release her immediately. The evil bastard stumbled back, hand outstretched, bargaining for his life,

“Wait, wait. I’ll share her with you, how’s that? I’ll even let you have first go!”

A deafening howl came out of his mouth as Price’s boot heel made contact with his kneecap, forcing it to snap at a terrible angle. John’s hand shot out and grabbed the man by the hair on the crown of his head, tugging cruelly at his scalp. Without mercy, John slammed his face into a nearby bollard, and the howling stopped.

It was quiet again aside from the Omega’s trembling breaths. She had recovered the knife and was now pointing it towards John with shaking hands and wide, determined eyes.

“You alright, love?” Price asked, holding his hands up in a sign of peace, edging towards her in gentle, predictable steps.

“Y-yeah… Stay! Stay right there,” her voice was bright and clear, and he could hear her strength laced through her words. He stopped in his tracks, respecting her wishes.

“What are you doin’ all the way out here, darlin’?”

“They dragged me over here from Baltic Fleet,” she straightened up, getting her bearings, wiping the blood from a small cut in her cheek, “Fuckin’ bastards. Thank you, by the way.”

“Jus’ doin’ my job,” Price shrugged, waiting for her to lower the knife even further before he continued his approach.

“Police?” She asked, a little confused.

“Not exactly,” Price smiled, offering a hand out to her, “John Price, Captain of His Majesty’s RAF service.”

“Oh,” she studied him for a moment, and then her eyes fell to the hand, ready to bite but deciding to shake it instead.

When he touched her skin, Price felt her fever. Shocked, he tightened his grip, not meaning to startle her but too surprised by her temperature to ignore it.

“Christ, love. You’re burnin’ up.”

As quick as a flash, she yanked her hand out of his grasp and retreated back towards the wall of the warehouse behind her, scooting her way towards the corner to get out of his range, ready to bolt. She didn’t respond, but John watched as she wiped her brow, dotted with sweat and covered in concern.

“Hey,” he moved forward again protectively, “You can’t be out here alone. Not like this. At least let me walk with you. I’ll stay ten paces behind. It’s not safe.”

“I’m fine,” she said with more strength in her voice than what she was ready to produce.

“You’re not. You’re in a bloody heat. When did it start?” He watched as her knees began to tremble, and against her obvious wishes, he helped her sit on the warehouse deck, letting her keep the knife so she could feel safe.

“Yesterday…” She closed her eyes, trying to shake it off, “It’s… I’m fine. It’s never this bad.”

Now that he was close to her, Price was smothered by the scent of her body. The Omegan glands in her neck smelled like thick, wild honey, and her heat was mixing with her aroma, turning an already sweet smell into a lucious, decadent gourmand, pulling him in like quicksand.

“C’mon,” he helped her up, “Where’s your place? I’ll get you close.”

The clang of her knife made him glance up to see her eyes closed and her mouth slack. She was out, too weak to withstand the fever and the physical exertion.

Price felt his body react to her need. He was filled with rage, white and hot, at her situation. Those goddamn monsters were trying to take advantage of her in this vulnerable state. She should be home in her nest, being taken care of by her Alpha, covered in soothing oils and cool compresses, her needy little cunt stuffed full of his knot, staving off these symptoms and enduring them for her. Instead, she’d been hunted, chased, made to fight for her dignity out here in the middle of the docks. Something else inside Price’s chest curled around his anger.

Possession.

He tried to shake it off, knowing it came from being unmarked, but it had been so many years as a lone Alpha that he knew how to control it. Or, at least he thought he did.

Now, though, he found himself pulling at the neck of her coat as he held her in his arms, invading her privacy to check for a bite. He felt the shame wash over him as he covered her skin back up. He had no business searching for a mating bite. She was not his Omega, and he was not her Alpha.

After a few minutes out in the chilled wind, he made it to his apartment. Thankfully, it was late enough that his neighbors weren’t outside to witness what looked like a literal kidnapping, and he shuffled her inside without much trouble. Price lay her down on his long, leather sofa, careful to rest her head on the soft arm. He went to the kitchen to retrieve a cold rag and pressed it to her forehead, hoping to hold back the fever for as long as he could.

“C’mon, pretty girl. Wake up,” he whispered, trying to gently shed her coat and sweater, peeling her layers off to bring her temperature down to a more manageable level.

She moaned, her eyes wrenching shut even tighter, her face twisted in pain,

“My head…” She sighed, desperate for some relief.

“I know, love. C’mon,” John propped her up a bit, moving the rag so that the coldest parts would be against her skin, “What’s your name? I can find an address. Do you have your purse?”

“They… took it? I don’t… I dunno…” She muttered, obviously having a hard time stringing her thoughts together, “I don’t feel so good.”

This was not ideal. Price knew what came next. A high fever, exhaustion, fatigue, nausea, increased heart rate, and then…

“Alpha?” Her eyes were open, glassy and dark, the pupils fully blown, looking up at him with an outpouring of unfathomable need. Her scent rolled off of her in mind-altering waves, shoving Price’s carefully-built walls out of the way and sending shocks of desire straight to his heart and his fat, growing cock.

“No, baby. I’m not your Alpha. Who is he? Can you give me a name?” John asked, checking her coat pockets in a rushed panic. He was running out of time.

“Alpha, please… I need… Help me, please,” her shaking hands reached under his jacket and shirt, her knuckles rubbing against his furry belly, her strong fingers digging around for his belt buckle, getting right to the point.

Price felt the room flex around him, and he tried to breathe in air that wasn’t saturated by her vanilla spice, searching in the deepest recesses of his mind for some semblance of his self control.

“Easy, love. I can’t m–mmngh!” Her mouth slotted over his as he tried to protest, stopping his heart and his words at the same time.

She was heaven. Her smell was making his skin tingle all over his body, down his arms and up his legs, rushing to his central, sacral core. And her taste was even better. His little cinnamon roll, so sweet and warm, burning for him like a flame, hot and ready to scar him for life.

“Mngh… Love, mmm… Wait…” Price held her back, using more force than he thought he should need, surprised by her sudden power.

“John…” He met her eyes and found a particular clarity within them. She was coming out of her haze. But, it wouldn’t last. This was his final chance to keep her from doing something she would regret.

“Darlin’, I can’t. I’m not your Alpha.”

“You smell like you are,” she mewled, rubbing her wounded cheek across his engorged neck gland, spreading his scent all over herself.

“I can’t,” he moved away from her, trying to hold her in his arms for comfort rather than to bask in her expressive heat, “My work… I can’t leave you here, pretty girl.”

She sobbed out, trying to hold back from writhing against his body, doing everything she could not to make it harder for him to turn her down. Her eyes were rimmed red and pink from exhaustion, and she was staring down at her own hands, vibrating with tremors, slurring her words,

“Just lock me in the bath. I’ll run cold water. I’ll be fine…”

Something ancient and feral snarled in Price’s mind.

No.

“No,” he said, involuntarily, the voice in his head escaping from his throat.

“Please… I can’t stop myself… I want your knot, Alpha. Lock me up before I do something to you… Something you don’t want…” She could barely put two words together. Every thought was a struggle. He was losing her again.

He grabbed her and held her to his chest, clutching her like water in his palm, using all his strength to keep her with him,

“I want you, love. I want… Fuck, I need you.”

All of a sudden, the energy around their bodies stilled. That cracking, sparking electricity that bound them together was roiling just beyond John’s consciousness, ready to surge. But, he stayed perfectly still, waiting to see what she did next. She locked eyes with him and leaned in close, as if she would kiss him. But, she didn’t. She dipped her head down until she found his Alphic gland, swollen and bruised purple from him holding back his lust, nuzzling at it with the tip of her nose, rooting against him, testing his patience, checking to see if his temperament was true. Then, when he let her sniff him in his most potent spot, when she knew his soul was as pure as his scent, that he was true, she sucked his flesh between her lips, drawing his musk onto her tongue.

She’d accepted him. He reeled from it, unable to hold back a groan, his cock jerking against his zipper, thrashing to escape, flooding with hot blood and threatening to fill his knot before he’d even had a chance to taste her.

John pulled her mouth off of him and stared at her eyes again, in awe of her beauty, his mind swirling and yet perfectly sharp, begging her darkly,

“Give me your neck, Omega.”

The ritual had begun, and as she swept her hair away from her shoulder, pulling it around her back, she bent for him, arching her head down in a submissive bow, revealing her Omegan mating line. It looked like a keloid scar, the raised skin swollen and painful, like a pounding vein that ran from below her earlobe down to the top of her shoulder, full of her hormones and thick with her magic. One bite, and he would be in her thrall, pliant to her every whim, beholden to her needs until her heat had run its course.

Price had never given his bite to anyone. It had been easy to abstain. In fact, in his youth, he had a hard time understanding his mates’ commitments to their Omegas, scoffing at their lack of duty to their stations, doubting their commitment, and - moreover - doubting their loyalty. He remained a captain through and through, and he’d never made room for anyone or anything else. But, here he was, his teeth aching in his jaw, bigger and sharper than they should’ve been, his every sense heightened and taking her in like a drug, compelling him to punch through her delicate flesh and suck her nectar deep into his belly.

The feeling of her skin against his lips was enough to send a chill through his body. He was cooling from the inside out, and his body needed her heat. She was forcing a rut to take hold in him, and he could feel himself changing for her. Then, he bit down as hard as he could, breaking the thin seal of her mating line with ease, feeling the searing mixture of her oil and her blood filling his mouth and throat like a ripe plum, wet and sweet, and promising pleasure if he chose to swallow her.

He drank from her for as long as he dared, taking her in long, slurping gulps, letting her essence coat his throat, feeling the hot fluid burn inside of his chest and down into his stomach where it pooled and lingered, warming him up from the inside out.

“Alpha…” She moaned, raising her hand to cup his cheek as he sucked her life into himself, rubbing her thumb so softly over his shut eyelashes that he barely felt it.

John pulled away from her, his eyes fluttering open, her bright orange blood iridescent with her mating oil, making the red cells burn bright like a fresh-cracked yolk, gleaming, trapped between his teeth like gold. He watched it drip down her chest, staining her clothes, and he began to tear them off of her. She let him, limp and mute as he peeled her open, making her naked and pulling her into his arms.

He carried her into his bedroom, kicking open the door and busting the bolt through the strike, splintering the wood and not giving a shit about the damage. John lay her in the middle of the mattress and set to surrounding her with whatever softness he could find; his shirts, his blankets, even his scarves. Anything warm and comfortable was added to the nest, giving her as much support as he could before standing back to admire his work.

She eyed him from her recumbent throne, commanding him with her gaze. John stripped off his shirt for her, raking it up his back and over his shoulders, feeling as if he was moving his body for her and only for her. All of his motions, even his ragged breaths, were only escaping from his lungs because she wanted them to. His buckle clattered apart, and he popped open the button of his jeans, lowering the zipper in a sharp, metallic rip.

Once free, his heavy prick flagged, leaping forward and pulsating for her, proudly showing her his gleaming head. He was drooling an unrelenting stream of iridescent precome, his balls tight and full of Alphic oil, ready to coat her warm insides with his shining sex.

John climbed onto the bed, his face focused on her wet mound, admiring the plumpness of her, imagining her - in every delicious way - like a tender peach. He crawled to her, his mouth still stained neon orange from her gland, and he smeared her wet quim all over his lips and tongue. He wasn’t licking her so much as he was wearing her like warpaint, moving his nose and cheeks through her to ensure he was soaked in her heady slick, his body making wild, unbridled choices purely on instinct.

“Yes, baby, please…” Her voice went straight through him like a bullet, tightening his cockhead to an uncomfortable degree, and it jerked against the mattress in protest. Her hands were in his hair, scratching through his scalp, encouraging him to sink his tongue deep inside of her hole.

John obeyed, helpless to her desire, his mind wiping clean and being rewritten by her will. He was swimming in her scent, drenched in her slick, and gasping against her pussy, his eyes fixated on her form as it writhed above him. When she met his eyes, she bit the inside of her lip, crying out for him, rewarding him for his prostrated fealty. Then, she began to rock her hips against his jaw, fucking herself on his face, and he let her use him to her heart’s content, staying strong and sure, allowing his body to be used, objectified and glorified by it.

When she began to come, it was the most beautiful thing he’d ever seen. He followed his tongue inside of her with two of his thick fingers, pressing against her walls, pushing her over the edge. She bolted upright, wrapping her thighs around his face, smothering him with her body, trapping him breathless between her legs. Her whole being trembled for him. He could feel the shimmer of her very soul, rattling and writhing with her siren-like keening. And just when he started to see spots in his vision, needing air just a little less than he needed to please her, she lay open for him, blooming outward like a flower, releasing him from a limbo he longed to return to, oozing with a stream of rainbow-tinted come, the Omegan oil within her womb escaping to advertise its promises to her mate.

Without knowing why, John found himself lapping it up from her pulsing hole like a hound, swallowing mouthful after mouthful and grunting with each pass of his broad tongue.

“John, I need... Please, put your knot inside me. I’ll be good…” She begged, tears shining at the corners of her eyes from her come-drunk bliss, her hands plucking at her nipples and trying to soothe herself down from her high.

“My pretty girl wants this knot, yeah?” John grinned devilishly, dipping his finger into her over and over and licking it clean like she was a jar of endless honey, “Wants me to breed this gorgeous cunt…”

At that comment, she spread her legs even wider for him, opening up for him like a blossom for the sun, ready to take whatever he had to give her. It was mesmerizing for John to see her like this. Everything about her was filled with intoxication and need. He was just a vessel for her pleasure, pouring himself into her to make her full again. Dizzy and drunk with adoration, he notched his girth at her entrance, struggling to fit even his cockhead within her.

“Fuck… so bloody warm…”

Her body was burning him with every millimeter he sank into her, the heat of her tight sex in such high contrast with his cool rut. It felt like he was swimming in a roiling pot of sugary caramel, clinging and cloying and sticking to every part of him, and yet it was not enough. He needed more. His hips thrust forward, savage yet steady, reaching deep inside of her like an anchor, rushing to settle himself within her darkness.

The way his Omega cried out this time was different, and it snapped him to her attention, his mind immediately sensing a new need.

“Love, tell me what you need.” He purred, his mouth kissing her lips and her neck, lapping at the now-healing wound his own fangs had made, talking to her between long licks of his tongue, “Tell me, and it’s yours.”

“You’re so big. I’ve never…” She sounded ashamed.

Price slowed to a creeping pace, focused fully on her face,

“Never had a knot before?”

She shook her head, her eyes full of worry. John wrapped her up in his arms, dragging himself out of her slowly before filling her up again as carefully as he could.

“Tha’s alright, baby. You’re mine, and I’ll keep you safe. I promise.”

“Feels like I’m burning alive,” she sighed, her brow furrowing with distress, “John, I need… I don’t know how…”

“Look at me, alright?” He helped her focus her eyes on his, “Don’t… Just stay with me, right here. You’re gonna come for me, and then… I’ll give you what you need.”

“Please,” she whimpered, her voice so small.

Price set himself on a path with a purpose. He used his hand to rub small, rhythmic circles beside the rigid body of her clit, coaxing her pussy to drop even more slick around him, using every ounce of willpower he had left not to let his knot slip inside of her prematurely. His thrusts were jerky and restrained, but he felt her begin to rock back and forth with his hand’s movements, bringing her closer and closer to her glowing joy.

“Good girl,” he praised her, watching her as she began to fall apart around him, “Tha’s my good little Omega. Come for your Alpha just like that. Just… mmf-fuck! Like that! Holy fuck.”

The feeling of her slick pussy clenching and twisting around his cock’s tugid body was enough to make him see stars. He felt almost sick with pleasure, his whole core lighting up like a roaring fire, spitting and aching to bury himself within her.

At the end of her crescendo, he felt himself let go of the chain, and he rutted his knot inside of her, humping himself forward ruthlessly, his body contorting itself to fit her needs. His knot sealed him within her, and although he was not yet orgasming, he was filling her with his come, the creamy flow of it spilling out of his tip, filling her hole and coating his prick from inside of its hungry little sheath.

“Your come… I can feel it inside of me. Oh, my God,” she sighed with some sort of relief, her eyes rolling inside of her head, her arms losing their strength, and her back arching towards him, lifting up as if she would float right into Heaven.

And just like that, her fever began to abate. With his knot stuffed inside of her, locking his seed within her hole, his Alphic oils could soothe her heat, bringing her back to the realm of consciousness and delivering her from her wild state.

“John,” she lay back, her hand pressed to his cheek.

He didn’t answer her. Instead, he bent forward on his elbows and kissed her mouth, chastely at first, and then languidly, exploring her taste. When he did finally pull away, she was awake and alert, sated and happy. He smiled down at her,

“Hey, pretty girl,” he whispered, wiping her hair back from her face.

“Hey,” she smiled back at him, wrapping her ankles around his back for comfort, not knowing that it was just enough to set his cock on edge again, his Alphic instinct rejoicing at the feeling of being trapped by his mate.

“You alright?” John asked, a tinge of worry at the edge of his voice.

“I am now, thanks to you,” she sighed, tucking herself in beneath him, rubbing her hands along his ribs and the soft fur of his back and arms, feeling every bit of him as if she was seeing him with her touch, “You saved me, Alpha.”

“Aye,” he nudged her jaw with his nose, asking her wordlessly to give him the vulnerable softness of her neck. She obliged, and he spoke to her between sucking kisses, “All mine. My Omega. Innit that right, baby?”

She was practically lambent beneath the scrutiny of his possession, rolling in it like a wave in the sand, captured by it and surrendering to the riptide of his unbreakable grip. She nodded, humming her ascent, her expression turning a little rueful right at the end of his kisses. The sorrowful timbre of her voice broke his heart,

“I’m grateful. But, I know this isn’t what you wanted, and I’m so sor–”

“No,” he kissed her words away, feeling his length throb inside of her, urging him to kiss her again, “No, love.”

“I won’t bite you,” she promised, her gaze still full of apology, “You won’t be stuck with me.”

“Bite me, Omega,” he bent his head and buried his face in her shoulder, giving her his gland in total surrender, “Go on. I’m yours.”

“John…” She hesitated, but he could feel her body flood her hole, excited beyond measure at the thought of binding him to her as her mated Alpha.

“Go on,” he commanded in his smoky growl, holding her tighter and bracing for the ecstasy of her teeth.

He felt her lips first, and his balls tightened, ready to fling him into a messy orgasm as soon as he felt his gland shatter in her mouth. Her Omegan teeth wouldn’t break the skin, but he knew she was strong enough to crack the shell around his swollen node. The anticipation of her bite was wrecking his mind, and he was gasping for breath by the time he felt her jaw set itself against him.

“Baby, please…” He whined in her ear, his hips thrusting in short, jerking thrusts, unable to move much with his knot still trapped up inside of her, holding his gushing come in her hole, pushing it into her womb from the sheer volume of it.

Her teeth connected, and he could hear his unbroken shell give way beneath her strength, the hormones inside of it rushing through his system like wildfire, burning through his veins and making him scream for her. At the same time, John felt his core throw him into a raw orgasm, his whole body trembling above her, wringing himself from the inside out.

“Alpha,” she sighed, licking his neck to comfort him, “My Alpha…”

“Yours, baby. All yours.”

— — — — —

The new trainees filed out of the gym, sweaty, bloody, and eager to be out of the captain’s sight. Price had run them ragged, forcing them to spar with practice weapons, pitting them against each other in a strained, exhausting competition. Ghost and Soap sat with Gaz as they eyed their commander, their eyes glued to the fresh bite mark on his neck, shocked into a silent stupor.

“I cannae believe it. Mated? To which lassie?” Soap asked, dumbfounded.

“I didn’t think he’d ever take a mate,” Gaz marvelled.

“I thought he was savin’ himself for marriage,” Ghost quipped, earning himself a scuff from Soap.

Price made his way across the mat, pulling his sweaty shirt off his back to trade it for a clean one. The red welts and nail-marks across his shoulders and down his belly made Gaz let out a low whistle. But, his commander’s glare stopped him mid-note.

“Wha’s that, Garrick?”

“Nothin’, sir. Just… admirin’ your battle scars,” Gaz smiled, wishing his two teammates would stop snickering so loudly.

“Looks like a hell’uva fight, Cap,” Ghost added, looking everywhere but into Price’s icy eyes.

“Wha’s her name?” Soap asked outright, skipping over the double entendres and going right for the point.

Their captain sighed, zipped up his gym bag, and stood in front of his three officers, glaring down at them with a look that was on the border of dead-seriousness,

“If I told you that, lads, I’d have to kill you.”

#ilysm rtg!#cali answers asks#but like very slowly#call of duty fanfic#captain john price#call of duty#cod mw2#cod#john price#cod mwii#captain price#captain johnathan price#price#cod price#john price smut#john price x female oc#x fem!oc#x female oc#cod smut#by the californicationist

350 notes

·

View notes

Note

Do you just really enjoy the idea that all art-making by humans will cease to exist (except for the very rich)? Do you and the people like you have some other pathological need to jump to the defense of the moustache-twirling capitalists (and their useful idiots) behind AI design? Do you realize you *are* such a useful idiot? I'm curious.

I'm going to mostly focus on your point that "art-making by humans will cease to exist" because it's. Confusing.

Art, famously a thing that is only made when it's profitable.

It's important to point out that (in a non-pejorative way) that this is the Luddite situation. The Luddites were 100% correct that mechanisation would take their jobs and fuck up their lives. At the same time, it would be patently ridiculous to solve the issue by mandating that you can't mechanize factories, and it is missing the point to say that AI will destroy the concept of art from human culture.

Art has never been like, a stupendously profitable enterprise that you get into because it pays well. It sucks! It sucks that being commercially successful as an artist has basically for centuries meant working odd jobs doing whatever while you try to scrape enough together to turn a living on your passion and most of the time failing. The Starving Artist is a character archetype going back centuries.

At the same time, it's hard to argue that there's something unique about the artist's desire to make a living from their craft. Many people will not get to do their passion for a living. Artists aren't in a unique situation here, there's no doubt thousands of people working boring desk jobs who really want to be field biologists, or journalists, or video producers. I would love to make my living building specialist sensing hardware for postgrads all year round, but that's basically a nonexistent job. Most people are just working to get paid.

Photography absolutely killed the shit out of the professional advert painter. Digital music production shrunk the music studio crew by a huge factor. CNC machining eliminated machinist jobs in factories. This always sucks for the people who are put out of work but it's not unique or special. Much ink has been spilled on the topic of automation, it's just hitting a group of people who we all thought wouldn't have to contend with automation.

It's frustrating that already not everyone can make a living doing the thing they believe is their calling, but I find it hard to believe that art itself will be killed by AI. It's very easy to feel like doing art is the highest moral calling for all people and so we should reward it, but it's just a thing you do.

As for being a useful idiot, I must once again stress that if you think there are mustache twirling villains secretly directing the flow of the economy with the goal of hurting specific people then you believe things that are wrong because you have a fundamentally dysfunctional way of understanding the world that will lead you to incorrect conclusions. There's no head you can cut off the snake.

109 notes

·

View notes

Text

Something completely different: Some model railroad thoughts. I do have a bit of an odd conundrum: For a model railroading project I'd like a lathe in 1:160 scale. Not working, just for putting inside a factory building. Ideally some other machinery too, but the lathe is distinctive and large and would be fun. At that scale it would be just a couple of millimetres tall and wide, maybe 1-2 cm long, so really tiny. That sounds kind of difficult. At that scale you can't see much at all, so the supply of N scale building interiors used to be very limited, because few people were mad enough to demand it. Is there any chance of getting this lathe?

Well it turns out the problem is choosing which one, because there are two I can buy literally right now:

The Modellbahn-Union design is clean and clearly polished and comes with a cart. I can actually get this one painted (order number MU_N-A50006) or unpainted (MU_N-A00006), but I'm definitely going with painted. They also sell way more equipment, which is really nice to really fill out my factory. Great! I thought it was crazy that I could even find a lathe in that scale at all, let alone that it was painted.

The other option is from British company Langley Models (set A143). It's a set with a CNC lathe, a drill press and I think a bandsaw… and I don't like it. This is cast zinc, and it comes unpainted, so I'd have to paint it all by hand. That seems annoying. Or maybe I get it anyway just so I have some machinery at hand if I need to fill more space? The more complex surface does look nice, if I'm being honest.

Two different lathes in unreasonably tiny scales. That's really cool.

But that's not enough.

Right now all the model railroad manufacturers in Europe are announcing their new items, and besides trains, locomotives, freight cars and the like to preorder, that also includes accessories. And German company Noch uses color 3D printing to provide entire scenes with people and equipment, like this (set 35904):

Look at that. People! Table! A drill press! Grinders! Welding cart! Anvil! And in the middle, a nice-looking lathe! Should I buy one of the existing lathes, or pre-order that set? The official announcement just says "2025", I might be waiting until December for this, which would be annoying.

And then a few days later dutch company Artistic released their news, including set 316.143:

Look at that. A giant lathe, with an operator, and a drill press and a cart as well. Artitec's stuff is all hand-painted and looks gorgeous and full of detail, and this is no exception. Fewer people and equipment, but it looks better.

And so at the start of this quest I thought, "hm, will I ever be able to find a tiny lathe in 1/160 scale for my model railroad?", and now I'm wondering, "which tiny lathe(s) should I buy and/or pre-order, there are way too many to choose from". I don't have a moral to this story, it's just interesting the kind of stuff you can find to buy for model trains.

(But the DB class 643.2 in Euregiobahn livery, which I see daily on my way to work? No chance. The base model hasn't been made since the early 2000s, and never in this paint scheme, which is interesting considering it's the only paint scheme they've worn for most of their lives. Urgh.)

3 notes

·

View notes

Text

My manager can't drive from a 3rd DUI and her friend showed up to give her a lift home and it happened to be a guy that I worked closely with at the aerospace factory when I was a machinist. He yells "Dave *last name*!"

She side-eyed me and has no idea that we worked closely for five years. "How does he know your full name?!?" (I haven't seen this guy since 2010)

He said "Give him a raise immediately. He's smart as hell!"

She said "I've kinda been gathering that." and I probably turned a little red. It was a dead Thursday, so the three of us chatted for about an hour. He kept telling her "Dave knows his shit. He can do anything."

He's a goofball. He was 1st shift and I was 2nd shift on the same CNC machine.

He's 67 and retired but just as bombastic as ever. He was forced into retirement for peeing positive for marijuana. But I'll take that third party recommendation for a raise.

7 notes

·

View notes

Text

I know I've mentioned in the past the irony that "fancy computer whoozit" devices that weird retro-fetishists like to complain about have actually made modern equipment, especially military equipment, a lot more reliable than their predecessors (i.e., it turns out robotically-assisted precision fabrication, computer-controlled fuel-injection systems, and fly/drive-by-wire controls make for a much more reliable main battle tank than a supertractor that may or may not have the rough edges sanded off) but it's also interesting to note that modern manufacturing techniques have made those same devices cheaper as well.

Like, the "good ol' simple" M1 Garand had a unit price of over $1400 in today's money, and the "make this thing as cheap as humanly fucking possible" M3 grease gun ran for almost $250 by the same metric. The M4, using aircraft-grade aluminum and polymer, making heavy use of fancy CNC milling techniques, and running through the layered gauntlet of MIC price-gouging between factory floor and armory door, has a unit cost of $700.

I'm not sure I have a real moral here beyond "luddites btfo once again" but it's interesting to take note of.

4 notes

·

View notes

Text

youtube

Nick Newman helped design a modular construction system so anyone with just a mallet and a drill can build their own home. Since co-founding U-Build in 2020, he has built— and watched others build— furniture, garden sheds, tiny homes, and full-sized houses, so it makes sense he’d use the flat-pack box system to turn the company work van into his full-time home.

[Watch our first video featuring Nick's U-Build universal home-build system, a CNC-cut flat-pack design anybody can assemble to make a home: • U-Build hands-on:... ]

According to Newman, "the U-Build construction system is something like if IKEA and LEGO had a baby. So, it's these big boxes that can be assembled with a mallet and a screwdriver. Effectively, you start out with your individual panels, which are cut with precision using a CNC machine, and it's designed with this kind of locking system so you can basically put the pieces together: it would always be on the 'right' configuration." Watch it at 25:45.

[Video timeline]

— Nick Newman out in London on his electric campervan: 00:10

— Explaining EV's lack of congestion charge in London: 00:20

— Charging the van in central London: 00:50

— Thunderstorm: 2:20

— Stealth setup: 03:00

— EV van conversion into vanlife camper: 3:30

— Conversion with U-Build boxes ("building blocks") timelapse: 3:42

— Explanation of a U-Build minimum unit of construction, the box: 03:50

— Kirsten interviews Nick Newman: 04:20

— U-Build's modularity put to the test inside a van: 05:10

— Locking system for drawers (inspired by the ones on commercial aircraft): 06:30 and 14:50

— Festival build out of U-Build blocks: 07:15

— Sink: 0832

— Current van living interior: 11:30

— Adapting working straps to vanlife: 12:00

— Folding clothes: 13:05

— Hammock setup: 19:28

— At Stroud, Gloucestershire: 20:45

— U-Build's workshop under construction on an old empty factory: 21:30

— Describing U-Build as a self-build system: 25:45

— On using empty buildings: 22:10

— "People could stay in a house like this for really cheap": 22:15

— Warehouse spaces to solve housing emergencies? 22:30

— Out in Herefordshire: 36:28

— Student-built house with U-Build: 36:35

He started using the fully-electric Sprinter van as a temporary home while on overnight work trips. The U-Build system involves assembling CNC-cut, formaldehyde-free plywood boxes as building blocks which then bolt together to create a rigid frame for a structure.

The conversion cost him less than £2,000 (about $2,400, or €2,300). The system is entirely demountable, so the boxes can be reused over and over: it was easy for Newman to take the boxes he was working with daily and rearrange them in the van to build a bed, kitchen (U-Scrub), storage, and toilet (U-Poo).

Newman left a shared warehouse where he was paying £800 for a tiny, windowless bedroom for vanlife in central London, and because the van is electric, he doesn’t pay congestion charges (£15/day). He has tricked out the van to appear in drive mode so he can use the vehicle’s battery and air conditioning and heating while parked.

The U-Build (and Studio Bark) team recently bought an abandoned warehouse in Stroud (Gloucestershire) for less than the price of a tiny studio in London. While they decide what to do with the space, they have installed U-Build dwellings (built in a half day) to use as bedrooms and private offices. It’s the same model as the SHED Project, where they worked with a London-based guardian company to provide quick-build homes from U-Build kits to provide housing for those in need in exchange for building surveillance.

https://u-build.org/

https://www.instagram.com/ubuild/

Nick's YouTube channel: / @electric.vanlife

Here's our story covered by Autoevolution: https://www.autoevolution.com/news/th...

On *faircompanies: https://faircompanies.com/videos/u-bu...

#kirsten dirksen#solarpunk#building#house#sustainable architecture#sustainable building#architecture#Nick Newman#U-Build#electric vehicles#sustainable housing#electric van#London#uk#england#Studio Bark#Stroud#Gloucestershire#Youtube

6 notes

·

View notes

Text

CNC turning and milling services

#design#autos#business#prototyping#cnc machining#prototype#prototype machining#rapid prototyping#precision machining#cnc turning#cnc milling#cnc precision machining#precisionmanufacturing#machining parts#cnc machining center#cnc part#cnc parts company#cnc parts factory

3 notes

·

View notes

Text

SHENCHONG sheet bending follower is working with CNC press brake in our Korea customer's factory. This is a CNC press brake bending follower device that assists workers in turning up during the bending process. Save labor, fast and flexible, mass production. All factories that need to reduce labor intensity and improve production efficiency can use it.

2 notes

·

View notes

Text

The boss’s latest business destroying idea; replacing the stocks and blowpipes on the blackwood sets with plastic ones so that only the fringe bodies and tops are made of wood. He said he’s doing this to save him work at the factory... the factory where everything’s done by CNC machine and all he needs to do is hit the run button.

Since making this the standard he’s already had one trade order cancelled over it because when people buy a blackwood instrument they want a complete instrument in blackwood. He’s even put the price way up because the manager suggested doing that instead of making this Black and Tan monstrosity of an instrument... so the boss has just done both?

Every American who comes into the shop to buy only wants blackwood, and pretty much turns around and walks back out when all we have is full delryn sets.

He’s even tried this before and it failed! Apparently a few years ago he made “less than ten” sets like this and it took nearly a year before they were all sold.

He’s doing this again after but making any widen wooden sets at all for months because he couldn’t be bothered.

How in the fuck is this place still in business?!

4 notes

·

View notes

Text

2023 KTM 1290 Super Duke RR - Limited Numbers, Unlimited Fury

Following the roaring success of the KTM 1290 SUPER DUKE RR in 2021, 500 units of the 2023 KTM 1290 SUPER DUKE RR will go into production, promising the same levels of ferocity but with a meaner, darker look. The KTM 1290 SUPER DUKE RR will once again rip into the Tarmac, leaving a deep, lasting impression as the ultimate limited-edition Hyper Naked motorcycle in the KTM stable. The numbers tell the story – 1,301 cc, 180 hp, 180 kg and 140 Nm, with a phenomenal 1:1 power-to-weight ratio, making it every bit as beastly as its predecessor, but with a darker shadow. Sporting a gloss black and matt carbon base, contrasting white graphics and striking orange accents, the 2023 KTM 1290 SUPER DUKE RR casts an ominous shadow with menacing intentions. This is further exaggerated with a collection of unique custom-made components which are specific to the RR, adding more aggression and attitude. With the KTM 1290 SUPER DUKE RR being 11 kg lighter than a standard KTM 1290 SUPER DUKE R EVO, it is equally at home decimating lap times as it is carving up mountain roads, providing riders with the ultimate Hyper Naked package. However, it’s the collection of WP Suspension’s finest components worn by the 1290 SUPER DUKE RR that take it from a backroad brawler to accomplished track day terror. Upfront, a fully adjustable WP APEX PRO 7548 closed cartridge fork has been tailored specifically for the RR, while a custom-made WP APEX PRO 7746 shock takes charge of the rear. The WP APEX PRO 7117 steering damper keeps things in check, offering 30 clicks to dial it into your specification. Carbon fibre is used extensively, with the subframe also receiving the lightweight carbon treatment, creating a unique single-seat unit. The LED taillights are incorporated into the LED turn signals, as well as KTM’s adaptive brake light as standard. As an added extra to enforce the KTM 1290 SUPER DUKE RR exclusivity, owners will be presented with a bespoke carbon fibre box containing the keys to their new BEAST. For the absolute power-hungry, an Akrapovič EVO line full exhaust system is available as an optional extra, which adds even more bite to THE BEAST.

Notable features on the KTM 1290 SUPER DUKE RR include: - 1:1 power-to-weight ratio - WP APEX PRO COMPONENTS Suspension - Akrapovič Slip-on exhaust - Exclusive carbon fiber bodywork - Lightweight lithium ion battery - Ultra-lightweight forged wheel - Carbon fibre subframe with a single seat - New, black CTG - Limited to only 500 units - Unique, branded carbon key box - Factory triple clamp - Adjustable CNC-machined rearset

Not only impressive when it comes to hardware, the KTM 1290 SUPER DUKE RR boasts the most complete track-orientated electronics pack ever seen on a KTM motorcycle as standard, adding advanced TRACK and PERFORMANCE MODE. While the KTM 1290 SUPER DUKE RR already boasts a full range of exclusive components and bodywork, riders looking for more ferocity can browse a full range of specially developed KTM PowerParts, along with a dedicated range of KTM PowerWear. This includes a custom leather race suit, uniquely finished KTM 1290 SUPER DUKE RR branding and matching design.

The 2023 KTM 1290 SUPER DUKE RR will only be available in Europe and the United Kingdom. Orders open today, 13 March and can only be secured through a select number of authorised KTM dealers. For more KTM Motorcycles UK news check out our dedicated page KTM Motorcycles UK News or head to the official KTM Motorcycles UK website www.ktm.com/en-gb.html Read the full article

2 notes

·

View notes

Text

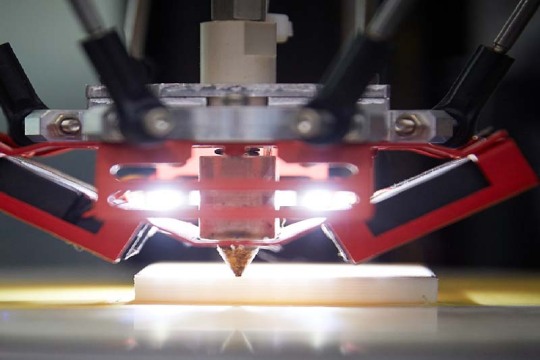

⚡In a flash, the laser moves like a paintbrush! Watch the metal take shape in an instant under the beam, the magic of technology that is accurate to the millimeter - it turns out that manufacturing can be so cool! ✨ #IndustrialAesthetics #HardcoreTechnology

SheetMetalProcessing #LaserCutting #SmartManufacturing #IndustrialTechnology #PrecisionManufacturing #MetalArt #ManufacturingBlackTechnology #Flash #TechAesthetics #ProductionMoment

0 notes