#CNC And Laser Machine

Explore tagged Tumblr posts

Text

Lock it in at a glance! This is definitely a 5-axis CNC processing artifact, with superb precision, and it's so exciting to watch! 🚀✨ #CNCProcessing #5-axisartifact #precisionmanufacturing

#Home CNC Machine#Milling CNC Machine#Miniature CNC Machine#Training CNC Machine#What Are CNC Machines#CNC And Laser Machine#CNC Definition Machining#CNC Drilling Machine#CNC Machine G Code#CNC Machine Programmer Salary

0 notes

Text

Upgraded Snapmaker 2.0 A350T Review: 3D Printer, Laser, CNC

'After a few years, my A350T 3-in-1 now has a quick swap upgrade, reducing discipline switch time from 20 minutes to seconds. Snapmaker does its best to upgrade existing technology where applicable.'

13 notes

·

View notes

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF: TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada: Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic: Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak: Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser: Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD: LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India CNC punching services in pune Best MIG Welding Machine Pre-Treatment for Surface Preparation in pune Best CNC bending services India Best SS fabrication services in India Best spot welding services in pune Best tube, pipe, and angle cutting services in pune Best automotive manufacturers in pune Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

https://berlin-machineries.com/

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

It is our Pleasure to introduce our company HITZE ENGINEERING PVT LTD., Which has been incorporated as manufacturing of sheet metal components Since 2019.

7 notes

·

View notes

Text

High Quality Laser Cutting and Services in london

London, a hub of innovation and technology, has witnessed a surge in the utilization of laser cutting services across various industries. Laser cutting has revolutionized manufacturing processes, offering unparalleled precision, speed, and versatility. In this article, we will explore the significance of laser cutting services in London and delve into the benefits they bring to businesses and…

View On WordPress

#cnc cutting london#CNC cutting Shoreditch#CNC Machining London#CNC routing London#High Quality Laser Cutting Services#Laser cutting#Laser cutting east London#laser cutting london#laser cutting services#Laser Cutting Services in London#laser cutting shoreditch

3 notes

·

View notes

Text

Shaping the Road Ahead: 30 kW Lasers in Automotive Innovation

In recent years, 30 kW fiber laser cutting machines have emerged as a revolutionary technology in the automotive manufacturing industry. These machines utilize advanced fiber laser technology to achieve high-power cutting capabilities, enabling precise and efficient fabrication of automotive components. The impact of these machines on the industry has been profound, leading to improved productivity, cost-saving benefits, and enhanced customization opportunities.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines are state-of-the-art tools that use fiber lasers to cut through various materials, including metals, with remarkable precision. The core of these machines is the fiber laser source, which generates an intense laser beam guided through an optical fiber. This highly focused and coherent laser beam is then directed onto the material to be cut, melting and vaporizing it with exceptional accuracy.

Advantages of fiber laser cutting machines over traditional cutting methods are numerous. Firstly, they offer higher cutting speeds and increased productivity, making them ideal for mass production in the automotive industry. Secondly, fiber lasers consume significantly less energy compared to CO2 lasers, reducing operating costs and environmental impact. Additionally, these machines are known for their excellent beam quality, resulting in smooth, burr-free cuts and minimizing post-processing requirements.

The key components of a fiber laser cutting machine include the laser source, optical fiber, cutting head, and CNC (Computer Numerical Control) system. The CNC system allows for precise control of the cutting process, ensuring accurate and repeatable results. The machine's software plays a crucial role in generating cutting patterns and nesting layouts to optimize material usage and minimize waste.

Transformation

The adoption of 30 kW fiber laser cutting machines has brought about a transformative impact on automotive manufacturing processes. One of the most significant advantages is the improved precision and speed of cutting operations. These machines can cut complex shapes and intricate patterns with unparalleled accuracy, leading to tighter tolerances and higher quality components. The enhanced speed allows for faster production cycles, reducing lead times and increasing overall manufacturing efficiency.

Moreover, fiber laser cutting machines offer exceptional versatility, capable of cutting a wide range of materials used in automotive manufacturing. From steel and aluminum to composites and plastics, these machines can handle various automotive-grade materials with ease, expanding the possibilities for design and innovation.

youtube

Benefits for Automotive Manufacturers

The utilization of 30 kW fiber laser cutting machines provides several compelling benefits for automotive manufacturers. One of the most notable advantages is cost-saving. Due to their high cutting speeds and reduced energy consumption, these machines lead to lower production costs, making them cost-effective for large-scale manufacturing.

Furthermore, fiber laser cutting machines result in minimal material waste. Their precise cutting abilities allow for optimized nesting layouts, maximizing material utilization and minimizing scrap. This reduction in waste not only saves costs but also contributes to a more sustainable and environmentally-friendly manufacturing process.

Another advantage is the level of customization and flexibility these machines offer. With their ability to cut intricate shapes and patterns, automotive manufacturers can cater to customer demands more effectively. Additionally, the adaptability of these machines enables rapid prototyping and quick design iterations, accelerating the product development cycle.

Several leading automotive manufacturers have successfully implemented 30 kW fiber laser cutting machines in their production processes. Hyundai Motor Company for instance, increased their production output by 40% after integrating fiber laser cutting machines into their assembly line. This efficiency gain allowed them to meet rising market demands while maintaining high product quality.

Another example is Volkswagen Group, which achieved significant cost savings by minimizing material waste through precise cutting patterns generated by fiber laser cutting machines. This reduced their overall material expenses and made their operations more sustainable.

In conclusion, 30 kW fiber laser cutting machines have revolutionized automotive manufacturing, offering increased precision, speed, and material versatility. These machines are driving the industry towards enhanced productivity, cost-effectiveness, and customization opportunities, making them a pivotal technology for automotive manufacturers in the 21st century.

2 notes

·

View notes

Video

youtube

STARMA cnc setting manual CCD camera of co2 laser cutting machine

#youtube#STARMA cnc setting manual CCD camera of co2 laser cutting machine This video to show how to setting the parameters of the CCD camera of Co2

2 notes

·

View notes

Text

#Fibre laser Cutting machine in mumbai#cnc laser router dealers in mira road#acrylic manufacturers in mira bhayandar#laser cutting machine suppliers in vasai#laser metal marking machine supplier in mumbai

2 notes

·

View notes

Text

2 notes

·

View notes

Text

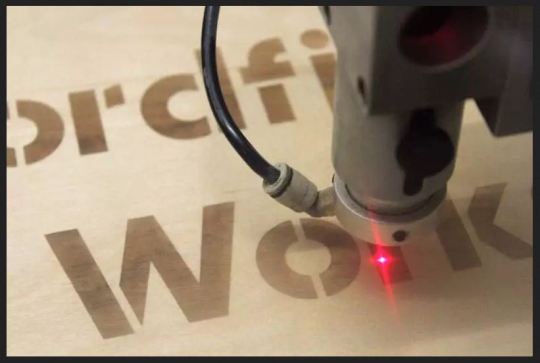

Once upon a time I was the operator of a CNC Laser. We cut die board made of Baltic Birch plywood. The laser head was stationary and the 6x10 foot table below it moved. My boss was kind of manic about having it run as much as possible- to have this wonderful machine pay for itself ASAP. It really was fun to operate and work on.

I had noticed the char and resin collecting in the table one day and told my boss, ‘We need to shut down for an hour to clean that out. It’s a real fire hazard.” He would always say, “Not now, not today.”

One morning ,maybe a month later, I was waiting for a taxi to take me to the airport. Going home to see my fam for Christmas. My boss called screaming and yelling that his million dollar laser was on fire and it was all my fault and I had to come in right now.

I reminded him of my persistent appeals to clean it for the last month. He shut up. I went on vacation. The guy I trained on the laser had gotten a literal trial by 🔥! They got the fire out. Cleaned the table. Not only was the laser stopped - ALL production in the whole shop was down for most of the day.

Shortly after I came back I turned in my two weeks notice.

They'll notice when it impacts profits. 🤷♂️

12K notes

·

View notes

Text

Enhancing Precision Cutting with Oxy-Fuel Cutting Machines

Oxy-fuel cutting machine Manufacturers, also known as oxy-acetylene cutting, is a process that uses a combination of oxygen and fuel gases (typically acetylene) to cut through metal. The process works by heating the metal to its ignition temperature and then directing a high-pressure stream of oxygen onto the heated area. The reaction of the oxygen with the metal causes it to oxidize and burn away, leaving behind a clean cut.

While oxy-fuel cutting was once overshadowed by plasma and laser cutting technologies, it remains one of the most reliable and cost-effective methods for precision cutting, particularly when dealing with thick or heavily oxidized materials.

The Benefits of Oxy-Fuel Cutting Machines

Cost-Effectiveness One of the standout advantages of oxy-fuel cutting is its affordability. Oxy-fuel machines are generally less expensive than their plasma or laser counterparts. The process also requires relatively low maintenance, making it a cost-effective choice for businesses that need precision without breaking the bank.

Versatility Oxy-fuel cutting machines are highly versatile and can be used to cut a wide variety of metals, including carbon steel, stainless steel, and aluminium. Additionally, they are perfect for cutting thick materials, something that other cutting methods like plasma may struggle with.

Precision and Control Modern oxy-fuel cutting machines are equipped with advanced controls that allow for highly precise cuts. With adjustable torch settings and the ability to fine-tune the oxygen flow, operators can achieve cleaner cuts with minimal distortion. This level of control is particularly important for industries that require intricate cuts, such as aerospace and automotive manufacturing.

Ability to Cut Thick Materials Oxy-fuel cutting machines excel when it comes to cutting thick sections of metal, especially those thicker than 1 inch. The ability to cut through heavy materials, such as steel plates used in shipbuilding or construction, makes oxy-fuel machines invaluable in industries that deal with large, heavy components.

Portability Oxy-fuel cutting equipment is relatively portable, especially compared to other cutting technologies like laser cutters. This portability is a huge advantage in industries like construction or shipbuilding, where cutting needs may arise in remote locations or on-site.

Applications of Oxy-Fuel Cutting

Oxy-fuel cutting machines are used across a broad range of industries, thanks to their precision and versatility. Here are some of the sectors that benefit from this technology:

Construction: Oxy-fuel cutting machines are commonly used to cut through steel beams, plates, and other construction materials.

Shipbuilding: The ability to cut thick metal sheets makes oxy-fuel machines a key tool in shipbuilding.

Automotive: For the manufacturing of automotive parts, precision cutting is crucial, and oxy-fuel machines are well-suited to cut through both thick and thin metal components.

Heavy Machinery: Oxy-fuel cutting is ideal for creating precise cuts in large parts used in industrial equipment and machinery.

Aerospace: Aerospace industries require precise cuts for various components, and oxy-fuel cutting ensures a high degree of accuracy.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

How CNC Laser Cutting Machines Improve Metal Work

0 notes

Text

CNC Laser Cutting Machine Manufacturers: Revolutionizing the Manufacturing Industry

In today’s rapidly advancing world, precision and efficiency are at the forefront of industrial manufacturing. One of the most groundbreaking technologies in this space is CNC laser cutting. Manufacturers across various industries rely on CNC laser cutting machines manufacturers to achieve precise cuts, reduce waste, and enhance production speed. For businesses looking for quality and reliability, choosing the right CNC laser cutting machine manufacturer is essential.

What is CNC Laser Cutting? CNC (Computer Numerical Control) laser cutting is a high-tech process used to cut or engrave materials with exceptional precision. The process uses a focused laser beam to melt, burn, or vaporize material, typically metal, plastic, or wood. Controlled by a computer, CNC systems allow for the creation of intricate designs with high repeatability, making them a preferred choice for industries that require high-quality cuts.

The technology offers unmatched accuracy, speed, and flexibility, enabling manufacturers to work with a variety of materials and thicknesses. Whether it’s creating detailed components for the automotive industry or custom designs for the aerospace sector, CNC laser cutting is a game-changer. CNC Laser Cutting Machine Manufacturers: Revolutionizing the Manufacturing Industry

Key Features of CNC Laser Cutting Machines Precision: One of the key reasons manufacturers opt for CNC laser cutting machines is their unparalleled precision. The computer-controlled system allows for consistent and exact cuts, reducing errors that could arise in manual processes.

Speed: CNC laser cutting machines are significantly faster than traditional cutting methods, which results in quicker turnaround times. This speed helps manufacturers meet tight deadlines and enhances productivity.

Minimal Waste: The highly accurate nature of laser cutting minimizes material wastage, which not only saves costs but also makes the process more environmentally friendly.

Versatility: CNC laser cutting machines can handle a wide range of materials, from metals like stainless steel and aluminum to non-metal materials like acrylic and wood, offering versatility for different applications.

Low Maintenance: These machines require minimal maintenance compared to other traditional cutting tools. Their long lifespan and high reliability make them a smart investment for manufacturers looking for consistent performance over time.

Finding the Right CNC Laser Cutting Machine Manufacturer When looking for a CNC laser cutting machine manufacturer, it’s important to consider several factors to ensure you’re getting the best value for your investment:

Experience: Choose a manufacturer with years of experience in the industry. Experienced manufacturers are more likely to produce high-quality machines that are built to last and perform consistently.

Technology: The world of CNC laser cutting is constantly evolving, so it’s important to choose a manufacturer that utilizes the latest technology and offers machines with advanced features.

Customization Options: Different industries have unique needs. The best manufacturers offer customization options to tailor the CNC laser cutting machine to specific requirements, ensuring it’s suited for your production needs.

Customer Support: Look for manufacturers that offer excellent customer support, including installation, training, and ongoing technical assistance. A manufacturer that supports your needs long after the purchase is essential for ensuring your machine operates smoothly.

Quality Assurance: Ensure that the manufacturer adheres to strict quality control processes. The best CNC laser cutting machines are built to withstand the demands of industrial use and deliver reliable performance over time.

Why Choose Fine Cutting Solution? At Fine Cutting Solution, we take pride in being one of the leading CNC laser cutting machine manufacturers. With years of experience in the industry, our team is dedicated to providing cutting-edge technology and high-quality solutions to meet your manufacturing needs. We offer a range of customizable CNC laser cutting machines designed for precision, efficiency, and durability. Our expert team is committed to ensuring your satisfaction through unmatched customer support and tailored solutions.

When it comes to CNC laser cutting, trust the experts at Fine Cutting Solution to provide the precision and reliability you need to stay ahead in the competitive market.

Also Reader:https://finecuttingsolution.in/fiber-laser-cutting-machine-manufacturers/

0 notes

Text

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

CNC Laser Cutting Machine Supplier

Golden Machinery stands as a leading CNC laser cutting machine supplier in India, offering cutting-edge technology for precision cutting in various industries. With advanced CNC controls and high-powered lasers, these machines provide intricate cutting for metals, plastics, and other materials. Whether for intricate designs or bulk production, Golden Machinery’s CNC laser cutting machines ensure precision, speed, and excellent cost-effectiveness.

#cnc laser cutting machine#laser cutting machine suppliers in India#laser cutting machine#laser cutting machine price#Industrial machine tool suppliers#Machine tool suppliers in India

0 notes