#Blind Bolts Industry

Text

For the Hell of It - Putting on a Show(*)

Characters: Jason Todd x fem!oc

Rating and warnings: NSFW, smut, pre-discussed kink, light bdsm, voyeurism & exhibitionism (discussed, nothing is done in public).

Word count: 1,929

Summary: Jason tries being a little meaner in the bedroom, to delightful results for everyone.

Masterlist

----

In the middle of the night, the bedroom door opened and the Red Hood walked in.

Andy looked up from the book she had been reading. It was a little after three in the morning with the muted sigh of wind rushing past the lofty heights of his apartment. The bedside lamp cast the large industrial-styled room in golden light and murky shadows.

Jason shut the door behind him.

She opened her mouth to ask how patrol went, then found the words dying in her throat. He was standing at the door, mask inscrutable, observing her in silence.

Belatedly it struck her that she had never seen him wear his armour into the bedroom before. She slid her reading onto the bedside table and cocked her head at him.

“Did you wait up for me?” His voice rumbled through the modulator.

“Blame the jet lag.” She shrugged. “Couldn’t sleep. Figured I’d try again once you got back.”

He slowly crossed the space between them.

She pulled her knees up under the blankets. She didn’t know what to make of the way he studied her, but her body already knew how it felt about having his sole focus. The armour only made it worse. She wondered if he knew.

“You remember that talk we had?”

“Which one?” she looked up, only to recall exactly the conversation he was referring to, in the face of blinding white lenses. “Oh.”

Her cheeks warmed. She was very aware of the looming figure standing over her, and anticipation unfurled within her.

“Yes, I remember.”

He pulled his gloves off, loosening finger by finger. He reached down a warm, bare hand and gently traced her cheek. His thumb grazed her lip. He pushed down lightly. She opened her mouth. He slid it in and she curled her lips around it.

He drew his damp thumb back and traced it down her jaw to tilt her chin up.

“The safe word?”

As though it hadn’t been branded onto her mind the moment she agreed to this.

She repeated the word. It came out breathless.

He turned away.

“Take off your clothes.”

Her cotton shirt then her silky bra and matching panties landed on the floor. Her nipples pebbled in the sudden cold. She sat bolt upright, awaiting further instructions. Her heart in its cage beat like the wings of a hummingbird.

Jason reached up to take his helmet off and placed it on the desk.

“Lie down,” he said and he removed his weapons. “Spread your legs, and get yourself warmed up for me.”

A blush rose in her cheeks. He sat in the armchair, facing her. He leaned back, with his legs casually spread wide, and lit up a smoke. He watched her expectantly.

She did as she was told.

She had never put on any kind of performance before, but she wasn’t going to let that stop her now. Most nights Jason relished this part himself. He was an artist with his fingers and she was his sculpture, beauty and pleasure drawn from stoic marble. Tonight he was the audience, and she was artist and art together.

The idea turned from daunting into arousing without her noticing. Her timidity fell away and her pleasure rose.

In the half light the glint of the cigarette reflected in his eyes.

“Do you touch yourself when I’m out?”

She shook her head, mussing her hair against the sheets.”

“No?” he drawled, incredulous.

“No.” It didn’t occur to her to be dishonest. Her role in the scene was not a fabricated one.

“Why not?”

“I… prefer the ache of waiting for you.”

He swore quietly.

“There’s a toy in the bedside table. Get to it.”

She reached out blindly and swiftly found it. Jason enjoyed using it on her, but she had never used it on her own. It let him draw out and build up her pleasure to his own exacting standards without getting distracted by his own ends. He was a wretched tease. She both adored and hated the thing.

He took a long drag of smoke as she adjusted. Her head tipped back against the pillows. Her eyes fluttered shut, but she didn’t want to lose sight of him and kept reopening them. He watched with burning intensity.

Her excitement built and built, far past any notions of simply warming up. He had told her to get ready for him, but he made no move beyond stubbing the cigarette out and attempting to brand her with the heat of his eyes alone.

“Can I… can I climax?” she asked.

“No.”

She withheld her whine.

Normally Jason’s body language was so open and reassuring around her. This was nothing of the sort. The Red Hood, hard and uncompromising, watched her fuck herself on a dildo, and she was more hopelessly turned on than she had ever been under her own touch.

Slowing down was unthinkable as stopping. She had unthinkingly built her pace up, and now she had no off-ramp.

She wasn’t going to ask again.

She wasn’t.

With one hand cast over her face and the other between her legs, she writhed.

Jason let out a harsh breath and stood. Every heavy step towards her felt like salvation and doom both.

He put a hand on her shaking knee.

She squeezed her eyes shut. Despite the calluses and the hardness of his demeanour, his thumb rubbed her skin in a familiar reassurance.

It did not help her predicament. Her breath hitched.

He pushed her hand aside and withdrew the toy. He replaced it with two of his fingers.

She moaned. His touch set her alight and her breath grew thin. His touch was as scorching as his gaze which pinned her down like a lance through the chest.

“I’m-I’m going to cum if you keep doing that,” she said.

So he stopped.

She wanted to cry. She covered her face with her hands and took desperate heaving breaths.

The sound of unbuckling belts cut through her panting.

“Look at me.”

Her eyes snapped open.

Jason lifted her by her hips and impaled her in one blow.

She sang out in relief.

He set a swift pace, slowing only a moment to let her rearrange pillows to support her back, shooting her straight back to the loft heights she had teetered along for so long. He drove her higher still. His thumb rubbed circles over her clit only twice, and her climax slammed into her.

Her whole body shook. He did not slow his pace, relentlessly working her through it.

She breathed hard as she came down, arching her back for him. The relief was short lived but it brought her a moment of clarity.

Jason’s focus was fixed to her entrance, watching himself sink in and out, in and out. So locked up inside his own head tonight.

“Okay?” she asked quietly, breaking character.

His eyes flickered up to hers, and he gave a short nod. His hand on her hip gave a quick squeeze.

Then the hard tilt returned to his jaw and they were back in it.

“Spent the night at a strip club,” he said harshly.

Her eyebrows rose. It was unusual only in that he was telling her about it: his protection extended to sex workers all over the city. She trusted him, it was a non-issue.

“Working out a territory dispute. Negotiations. Should have been done hours ago. But no, they had to keep stopping to watch the girls.” His lip curled and he changed his angle to something deeper. “Made them make out and touch each other. As though we’re there for a good time, as though I have any interest in getting hard with that pack of slavering animals.”

He brushed his sweat slicked hair from his face and swore. She was so helplessly turned on by him even when he was hacked off, she couldn’t come up with any response.

“Waste of my fucking time,” he growled, thrusting with emphasis. “When I have you alone in my bed. Waiting for me. Clenching on nothing. Dripping wet, just for me. Aren’t you, sweets?”

“Yes.”

He pulled out.

She made a needy noise of objection.

“On your knees or in your mouth?”

She rolled over without hesitation.

He chuckled. He ran his hands up her body, possessive and appreciative. He gently pushed her down onto all fours and pushed back in. His pace was more sedate now and his grip softer, having worked out some of his frustrations.

Well, that just wouldn’t do.

“Did you get hard at the club?” she asked.

His pace stuttered. “What?”

She reached back to touch his thigh, a silent reassurance she was still in character.

“Did it turn you on, surrounded by beautiful women making out with each other?”

The snap of his hips picked up. “Yes,” he conceded, arousal and shame and frustration in his voice.

She looked back over her shoulder. Her hair was tousled, her skin flushed, and her lips swollen from where she bit them.

“Were you thinking of me?”

“I–” The look he gave her was a little stunned, a little star struck.

“There, in that red lingerie you bought me, draped over you?” If he wasn’t thinking it before, he was now.

A whispered “yes,” passed his lips. The burning intensity rose in his eyes once more.

“...touching myself?”

He made a hungry noise in his throat.

“Up on the stage, in front of everyone,” she said, as she looked forward again, flicking her hair aside and arching her back. “Putting on a show?”

He growled, then she was pinned to the bed.

“I’d have to kill them all for looking at you,” he said into her ear, bending over her. “And I would–mm–before I’d take you right there.”

He stood tall again, still holding her bent in half with a hand on the back of her neck. His other hand was on the meat of her ass, to drag her back to meet him. He put one leg up on the bed next to her for more power. A thick muscled thigh rippled against her side. Raging waves of need pulled her back down into the depths.

“Trying to upset me, sweetheart?” he asked, back to ruthless and in full control. She was in paradise. “You know only I get to see you like this. That’s why you’re mine.”

She whimpered, so close to the edge.

“Only I can hold you down and fuck you like you deserve. Only I get to watch you writhe… hear you beg.”

“Hnng, please.”

“Please what?”

“Please! Jason, I–I– fuck, Jay, I don’t– I need..”

“That’s my girl,” he said, dark and appreciative. “You know you’re mine before anything else.”

She sobbed a cry.

“You can cum,” he drawled, sneaking a hand around her hip to reach her clit.

Her climax rocked through her violently. Her vision blanked and her body seized up in great wracking jolts. Her mouth hung open, breathing hard against the blanket.

She vaguely heard his voice encouraging her through it, before he followed after her into bliss.

He curled over her back and held her fast against his hips. He growled her name in her ear.

The last of her strength fled her limbs. It felt like her bones had simply melted.

He collapsed on the bed behind her. With shaking, tired arms he gathered her to himself and nuzzled into her neck. He made a soft inquisitive noise. She sighed in contentment in reply. They tangled their legs together, and basked in the afterglow.

Next>>

#jason todd#red hood#jason todd x oc#red hood x oc#jason todd x fem!reader#jason todd x reader#for the hell of it#my fanfic#dc#jason todd x reader smut#buyer beware#sub!reader#dom!Jason#with some light role switching as the mood changes#I wasn't going to post this one but somebody asked for more smut so here we are

307 notes

·

View notes

Text

SS 316 Blind Flange at the Lowest Price

Looking for a durable and corrosion-resistant flange for your industrial applications? The SS 316 blind flange is your go-to choice, offering superior performance in harsh environments. At Udhhyog, we provide the SS 316 blind flange at the lowest price, making high-quality stainless steel products accessible to all industries. In this article, we’ll explore its key features, benefits, and why Udhhyog is your trusted supplier.

What is an SS 316 Blind Flange?

An SS 316 blind flange is a circular steel plate with all the bolt holes but no central opening, designed to seal off the end of a pipeline or pressure vessel. Made from 316-grade stainless steel, it provides enhanced resistance to corrosion, especially in marine and chemical environments. This makes it ideal for industries dealing with highly corrosive substances.

Key Features of SS 316 Blind Flange

Superior Corrosion Resistance: The addition of molybdenum in SS 316 enhances its resistance to chloride pitting and general corrosion.

High Temperature and Pressure Resistance: Capable of withstanding extreme conditions, making it suitable for high-pressure applications.

Versatility: Available in various sizes and pressure ratings to fit different industrial needs.

Benefits of Using SS 316 Blind Flange

Long-Lasting Durability: The robust structure ensures a longer lifespan, even in challenging environments.

Cost Efficiency: At Udhhyog, we offer the SS 316 blind flange at the lowest price, providing excellent value for your investment.

Safe and Secure: Prevents leaks and ensures safe operation of pipelines and pressure vessels.

Applications of SS 316 Blind Flange

Marine Industry: Resistant to saltwater corrosion, making it ideal for shipbuilding and offshore platforms.

Chemical Industry: Suitable for handling aggressive chemicals and acidic environments.

Pharmaceuticals: Used in sterile and sanitary applications due to its hygienic properties.

Why Choose Udhhyog for SS 316 Blind Flange?

Udhhyog is committed to delivering high-quality industrial products at competitive prices. By choosing us, you benefit from:

Top-Quality Products: We source only the best materials to ensure the highest quality standards.

Affordable Pricing: Get the SS 316 blind flange at the most competitive price in the market.

Exceptional Service: Our team is dedicated to providing the best customer experience.

How to Order

Ordering from Udhhyog is simple. Visit our website and click on SS 316 blind flange lowest price to place your order. We ensure timely delivery and hassle-free service.

#SS316BlindFlange#StainlessSteelFlange#IndustrialFlanges#MarineIndustry#ChemicalIndustry#Udhhyog#FlangeSupplier#LowestPriceFlange

2 notes

·

View notes

Text

WILLOW - "RUN!"

youtube

The first time we've covered Willow solo since "20th Century Girl" in 2011!

[6.82]

Joshua Minsoo Kim: A phenomenal parlor trick of a song. It begins enjoyably obnoxious from the jump and spends its entire runtime transforming its needling bassline and insistent drums into something even-keeled. The way everything interlocks at the end is the direct result of Willow’s vocals — she was always the ringleader. There’s even a moment that has the unfurling beauty of Steve Reich’s minimalism. It’s apt; there’s so much joy in hearing the real-time transformations here.

[6]

Nortey Dowuona: Asher Bank, the drummer on this song, has the most difficult job: he has to recede for the vocals to take center stage, emerge in order to provide sharp transitions, settle into a smooth groove for the pre-chorus, then carefully carry the outro. More difficult yet, he leans heavily on the kick/snare/kick/kick/kick/snare pattern, largely keeping the hi-hats on a straight, flat drone with no wild tom runs or heavy drum fills to provide flavor. He stays in the pocket for drum engineer Zach Brown to keep him at a low level for Chris Greatti -- handler of piano/bass/acoustic guitar too!!? -- to record. Then Mitch McCarthy quiets the hi-hats and buries them in the mix, letting the kick and snare take starring roles next to the bass as the electric guitar and Willow's vocals drift high over them, rounded off and cocooned with reverb. Willow's voice is a helpless, frightened cry until she settles into her deeper, lower register as the drums pause, rush back toward the front of the mix, then slowly thump into the last bars of the outro, only the kicks heard. All in all, fine job by Bank. Willow sounds great too.

[8]

Alfred Soto: Listening to "run!" blind I'd have assumed HAIM or somebody were responsible for the freakout-in-real-time vocal. The wonder is drummer Asher Bank, whose unpredictable patterns recall similar work on Fetch the Bolt Cutters. The star is Willow, whose performance complements the rhythm.

[8]

Jonathan Bradley: Willow’s anxious shrieks and paranoid gasps demand stronger accompaniment than one and a half post-punk basslines and an admittedly satisfying clattery drum kit.

[5]

Dave Moore: In the past few years Willow has quietly become the most incredible pop artist that you are begging to hear in a language you don't speak. But, much to my own surprise, I couldn't care less about the dippy poetry and therapyspeak -- the right syllables always seem stick to the right melodies and assemble themselves into the right songs. She's a genius.

[7]

Katherine St. Asaph: Willow's A-list family has, maybe paradoxically, caused their musical career to fall into relative obscurity compared to pop's A-list; casual listeners and jaded industry types have seemingly written her music off as nepo stuff that's safe to ignore. Which is a shame, because they're making more ambitious music, more deserving of being called "artpop," than many of the up-and-coming artists marketed in their stead. "Run!" is striking and angsty in a way that shares more in common with '90s singer-songwriters than '20s nu-pop-punkers. There are places in Willow's vocal where I would believe that someone spliced in a Tori Amos sample instead -- the inflections can be uncannily similar. (Well, OK, half the time who I actually hear is Charlotte Martin; close enough.) Docked a point for the outro, which is the sort of indulgent meandering that the doubters probably expected.

[7]

Jacob Sujin Kuppermann: As with many of the great stars of alternative rock through the decades, it's hard to separate the craft from the shtick here. This annoys me in the nervy first half and still doesn't quite land itself in the repeated phrases of the spacier second half, but I can't help but be charmed by the song taken as a whole. To take big swings and fail interestingly is always more valorous than to just muddle through.

[6]

Taylor Alatorre: Saves the Day had In Reverie, the Get Up Kids had On a Wire, Panic! had Pretty. Odd., and Willow has empathogen. Once you have chosen the path of the Emo Girl, there's no going back; record your self-consciously mature and classicist follow-up album, or perish. This is of course an oversimplification, since not even the sellout-iest of emo bands has a career path remotely comparable to Willow's. "I can't get out" is an appropriate grievance for someone with her profile, whether it's stemming from generalized anxiety disorder or the fact that "Whip My Hair" remains her highest-charting hit. Even while Willow is re-enacting a nervous breakdown, she's still the diligent aesthete, arranging her yelps and squawks in a painterly manner between the gaps in the skittering percussion. Then she suddenly realizes that the song's halfway over and she hasn't said the title yet, prompting a vision of escape that sounds like an extended cut of a sensitive Blink-182 bridge. It's pedestrian, it's predictable after 5 seconds, and it's still evocative enough to make me want to re-evaluate a certain therapeutic mantra. "'Wherever you go, there you are'?" Willow seems to ask. "Actually, dude, I was there, which sucked, and now I am here, which doesn't suck. Take that, mindfulness."

[7]

Ian Mathers: I was one of the few positive outliers when we reviewed "Meet Me At Our Spot," and a lot of that was specifically Willow's vocals, so I'm nonplussed that for the first two-thirds here they don't do much for me at all. Might be the production, because during the last minute's worth of "runrunrunrunrun" bits the song does sound better to me. But instead of that section feeling like catharsis or fixation or something equally powerful, it just feels like they ran out of ideas. Better luck next time!

[5]

Harlan Talib Ockey: One of my favorite under-discussed trends in music was the blues rock boom of the early 2010s. Alabama Shakes, Gary Clark Jr., Rival Sons, Kaleo, Hanni El Khatib, Blues Pills, Curtis Harding and Sinkane occasionally, Cage the Elephant and Royal Blood arguably. “Run!” is a near-perfect throwback to this era. Even the guitar tone sounds like it’s from The Black Keys’ Turn Blue, and Willow’s vocal delivery owes a debt to Brittany Howard and St. Vincent (who appears on this album). I’m biased toward giving “Run!” a good score simply because that was most of what I listened to as a teenager, but here’s the deciding factor: when Willow starts to drift away from the formula, she expertly dissolves the outro into dreamy exhilaration.

[8]

Wayne Weizhen Zhang: Major theater kid vibes (non-pejorative).

[8]

[Read, comment and vote on The Singles Jukebox]

4 notes

·

View notes

Text

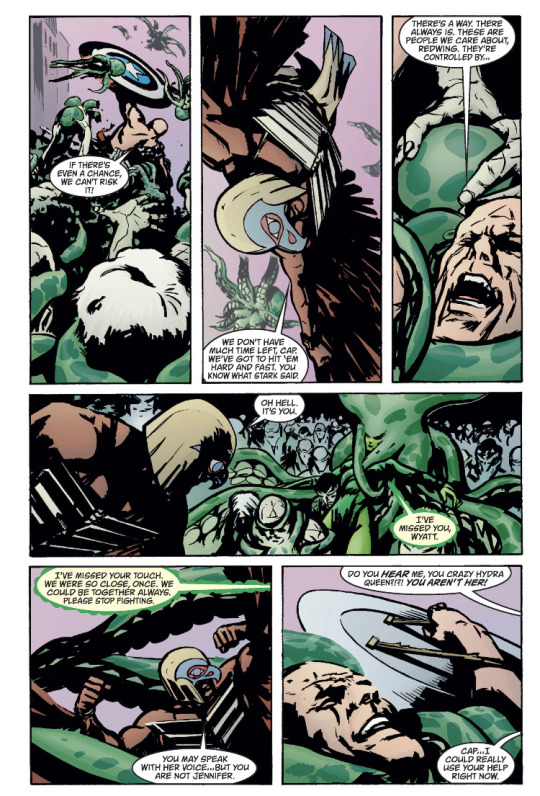

Earth X #1

We’ve recapped billions of years of Marvel Earth history in issue 0, so now we’re ready to get into what’s happened since Uatu was blinded.

As the cover suggests, our focus character for this first chapter is Captain America. His life has gone in such a weird direction that he’s wearing a flag as a toga. With a rope belt.

Also featuring is Wyatt Wingfoot, Cap’s new partner to replace Falcon. But instead of taking on the name Falcon, Wyatt has been named Redwing after Falcon’s pet falcon. Gets named after a pet and with red in the name in case you forget he’s a First Nations guy.

The cover also has a squid, which is very important, and a new Daredevil, who is not important to this issue at all and doesn’t even appear in person.

Even in Bad Future, lying covers.

As Aaron serves as Uatu’s seeing eye robot, he observes the Inhumans returning to Earth.

So the grand tally of Earth X stuff that inspired later Marvel material is at 2. The Inhumans fucking off into space? Earth X did it first.

Black Bolt’s new look with the cowcatcher mouth? Later used as the look for Vox and Vox Supreme, a recent Inhumans and Captain Marvel foe.

The Inhumans are returning to Earth to marry off Luna (daughter of Crystal and Quicksilver) to an unnamed Inhuman prince (son of Black Bolt and Medusa).

Crystal and Medusa are sisters and all the Inhuman royal family are cousins so I guess they’re aiming to recreate the Hapsburg chin.

The Inhumans find Inhuman sanctuary Attilan abandoned. So they figure that the Prince must be hanging out with heroes. So they go to New York, where heroes hang out.

But the world got fucked while they were gone. Everyone in the world was mutated somehow. The Inhumans arrive at a New York that’s weirder than ever.

And elsewhere in the city, Captain America and Wyatt fight a new Hydra. Not neo Nazis in green and yellow uniforms but a mind-controlling space squid hivemind of some kind.

The squids have already assimilated Falcon, She-Hulk, and Sharon Carter.

They can only control you if you give up. Unfortunately, Cap is old and tired and he doesn’t want to fight friends and the world he’s fighting for hardly seems worth it.

According to this issue’s appendix, American democracy is dead. There’s no Congress and President Osborn controls everything. Osborn Industries is basically the economy now.

He is known as the Goblin King so add another tally to things Earth X inspired.

Based on the state of the world being fucked, Cap finds it hard to resist the Hydra’s calls to just give up. But he does find some strength to fight off the squids long enough for Stark’s Purge to start.

Related to the world being fucked? The Avengers are dead. And Tony doesn’t go out anymore.

He’s created the Iron Avengers to replace his dead friends and calls them by the same names.

Add another tally. Iron Avengers is a concept that gets some use in various places. Thanks Earth X.

The Iron Avengers start purging the squids from the streets, causing them to retreat.

But before they left, Cap managed to grab a piece of fabric from them. With a skull on it that looks like the Punisher’s but red. A red skull…

Nobody wants the Red Skull back. As Cap bitterly comments about the Iron Avengers, dead should mean something.

(Steve, what world do you think you live in?)

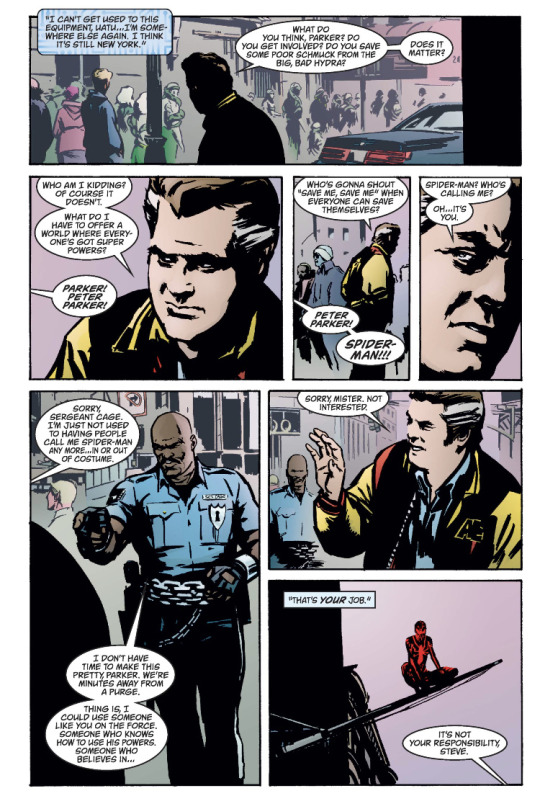

Other heroic cameos in this issue: An older Cyclops rescues a presumed mutant from the squids but the kid freaks and runs away.

Luke Cage is a cop.

Peter Parker is bitter and retired, having decided that a world where everyone has powers means he doesn’t have any great responsibility anymore or possibly rather that he’s not special anymore so why bother.

It’s a very craphole, this Bad Future. With many mysteries to unpack. What fucked the world? Where’s the Inhuman Prince? Who blinded Uatu and why? Why the fuck did Cap decide to wear a flag toga?

The book is a coward if it doesn’t answer that last one.

4 notes

·

View notes

Text

In anticipation of the Ahsoka premiere, I present-

Team GHOST

Kanan Garrus

Color name rule- Kanan is Sanskrit word for "Forest"

Species- Faunus (Wolf ears)

Aura color- Blue

Semblance- Force- A form of telekinesis used to push and pull objects

Weapon- Elegance Dawn- Retractable dustsaber

Misc.

-Has silver eyes

-Went into hiding after Salem's forces found him because of his eyes

-Gets blinded by one of Salem's agents at some point in his story

Hira Syndulla

Color name rule- Hira is Sanskrit word for "Diamond"

Species- Human

Aura color- Green

Semblance- Technopath- Can understand the feelings of, communicate, and bond with technology

Weapon- Pilot's Ace- Dust bolt handgun blaster

Equipment

- The Phantom- A heavily modified Manta-class Atlesian gunship

- The Spector- The Phantom's dropship

- Chopper- An outdated Merlot Industries C1 model maintenance android that Hira rebuilt and reprogrammed. They have a strong bond due to her Semblance

Garazeb "Zeb" Orelia

Color name rule- Orelia is a Latin word for "Golden"

Species- Faunus (Tiger legs)

Aura color- Purple

Semblance- Karabash- Aura energy builds while charging forward for a destructive ramming blow

Weapon- Honor Guard- Collapsible bo rifle

Sabine Wren

Color name rule- A wren is a brown bird

Species- Human

Aura color- Maroon (close enough)

Semblance- Target Lock- Enhanced marksmanship

Weapon- Brush and Canvas

-Brush- Dust infused spraypaint gauntlet

-Canvas- Machine pistol with retractable bayonet

Equipment

- Hard-Light shield vambrace

- Armor forged from the native ore of her village

Misc.

- She's ambidextrous

- Comes from the Vacuan village of Mantle Ore

- Mantle Ore was once an Atlesian mining settlement before being abandoned

Ezra Tandger

Color name rule- Tandger evokes either "tan" or "tangerine"

Species- Human

Aura color- Orange

Semblance- Animal Bond- Can calm animals, sense animals nearby, understand their feelings, etc.

Weapons- Urchin (1st weapon), Rebellion's Spark (2nd weapon)

- Urchin- A bladed vambrace with a high-velocity slingshot

- Rebellion's Spark- A combination handgun and dustsaber

Misc.

- Has silver eyes

- Orphaned at 7 years old

- Hails from Mistral

#rwby#star wars#ahsoka series#ahsoka tano#star wars rebels#sw rebels#sabine wren#hera syndulla#zeb orrelios#ezra bridger#kanan jarrus#rwby ruby

3 notes

·

View notes

Text

Carbon Steel Flanges VS Stainless Steel Flanges

Generally speaking, a flange is a forged or cast ring of steel that is used to connect or join sections of pipe. It also includes flanges that are integral to pressure vessels, pumps, or any other element that utilizes flanges. Bolts connect flanges together and threaded or welded them to the piping system. There are a variety of types of flanges available, including stainless steel flanges (SS flanges), alloy steel flanges, carbon steel flanges, slip-on flanges, blind flanges, weld neck flanges, threaded flanges, lap joints, and orifice flanges. This article discusses stainless steel vs carbon steel.

What are carbon steel flanges?

A flange connects two ends of a pipe or ends a pipe. Various materials are available for them. Flanges made from carbon steel are one such type. This material provides excellent durability, corrosion resistance, and finishing properties. There are several types of them. It is common to use Carbon Steel Blind Flanges to terminate pipes. The raw materials used in the manufacture of these flanges are of high quality. Between 0.25 and 0.60 percent of their carbon content is carbon. In addition to being highly ductile, the product is also excellently fabricated due to its high carbon and manganese content.

What are Stainless steel flanges?

In residential, commercial, and industrial piping systems, stainless steel flanges and fittings are used. Stainless steel is widely used for the transportation of gases or liquids, chemical processing, maritime applications, sanitary applications, and areas requiring corrosion resistance because of its strength, corrosion resistance, and ability to withstand high temperatures, pressures, and flows.

To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us. To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us.

Carbon Steel vs Stainless Steel

Stainless steel has a higher melting point and a lower carbon content than iron-carbon alloys. In appearance and properties, carbon steel is similar to stainless steel, but it contains a higher percentage of carbon.

A common application of engineering and construction materials like carbon steel is in large-scale industrial processes like telecommunications, transportation, chemical processing, and petroleum extraction and refining.

The process used in making Stainless Steel 304 Flanges is essentially two steps consisting mostly of iron and carbon. There are many types of steel that can be called stainless steel 304 flanges. Corrosion resistance can be achieved by adding nickel and chromium to stainless steel.

Flanges in detail:

Pipe Flanges are most often manufactured from forgings produced in grades A-105. There are two grades of A-350 material: LF2 for applications requiring lower temperatures and F42-F70 for applications requiring high yields. It is widely accepted that pipeline service is carried out with high-yield materials due to their increased strength.

Besides having a greater amount of chrome and molybdenum than carbon steel flanges, alloy steel flanges are able to withstand temperatures and pressures that are higher than those of carbon steel flanges. In contrast to conventional carbon steel flanges, they have a higher Chromium content, which makes them more corrosion resistant.

Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Forgings classes can be serviced with trace elements during melting. Aside from this, the 300 Series is not magnetic, whereas the 400 Series is magnetic, as well as has weakened corrosion resistance.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/carbon-steel-flanges-vs-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes

Text

Flanges in the Manufacturing Industry: A Crucial Component

Flanges are essential components in manufacturing industries, providing a means to connect pipes and fittings. These versatile components are used in a wide range of applications, ensuring the efficient and safe operation of manufacturing processes.

Types of Flanges Used in Manufacturing

Various types of flanges are employed in manufacturing, each with its own specific characteristics and applications:

Slip-on flanges: These are the most common type of flange, characterized by their simple design and ease of installation.

Weld neck flanges: These flanges are welded directly to the pipe, providing a strong and reliable connection.

Socket weld flanges: Suitable for smaller pipe sizes, these flanges have a socket that fits over the end of the pipe and is then welded.

Blind flanges: Used to cap off or seal the end of a pipe.

Lap joint flanges: These flanges are joined together using a gasket and bolts.

Applications of Flanges in Manufacturing

Flanges are used in numerous applications within manufacturing facilities, including:

Process Lines: Transporting materials through the manufacturing process.

Utility Lines: Supplying water, steam, and other utilities.

Wastewater Lines: Handling and transporting wastewater.

Compressed Air Lines: Distributing compressed air to various equipment.

Hydraulic Lines: Transporting hydraulic fluids.

Benefits of Using Flanges in Manufacturing

Flanges offer several advantages in manufacturing:

Versatility: Flanges can be used in a wide range of applications and pipe sizes.

Reliability: They provide strong and reliable connections, ensuring the integrity of piping systems.

Efficiency: Flanges can be easily disassembled and reassembled, allowing for maintenance and repairs without disrupting the entire piping system.

Safety: Proper selection and installation of flanges are crucial for ensuring the safety of manufacturing processes.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including flanges. Manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company, Platinex flanges are ideal for the manufacturing industry due to their:

Corrosion resistance: Stainless steel provides excellent resistance to corrosion, making Platinex flanges suitable for various materials and chemicals.

High-temperature resistance: Platinex flanges can withstand high temperatures, making them suitable for processes involving hot materials or fluids.

Precision manufacturing: RMTL ensures precise dimensions and tolerances in Platinex fittings, guaranteeing proper fit and function.

Customizable solutions: Platinex can provide customized flanges to meet specific requirements.

Conclusion

Flanges are essential components in the manufacturing industry, providing reliable and efficient connections between pipes. Platinex piping solutions offer high-quality stainless steel flanges that are well-suited for the demanding requirements of manufacturing processes. By selecting the appropriate flanges and ensuring proper installation, manufacturers can enhance the efficiency, safety, and reliability of their operations.

0 notes

Text

Understanding Flange Standards: ANSI, ASME, and Beyond - Metalica Forging Inc

Metalica Forging Inc, a renowned leader in Flanges Manufacturer in India, offers a wide range of industrial pipe flanges to meet various needs, from 12 inches to 48 inches in diameter. These flanges are essential for seamlessly connecting pipes to other components, such as tees, elbows, reducers, and valves, ensuring a smooth integration within piping systems.

As one of the largest Flange Suppliers in India, we have earned a reputation for its unwavering commitment to meeting the global demands of its clients, who are spread across five continents and nearly 80 countries. This remarkable achievement is a testament to the exceptional quality and durability of the company's products.

We are most trusted name in the Indian flanges market, known for producing ASTM A105 flanges that can withstand high-pressure and high-temperature conditions. As a prominent supplier of JIS Flanges, the company is continuously expanding its service offerings to cater to the changing requirements of its diverse clientele.

Flanges are crucial components in many industries, especially in piping systems. Whether in oil and gas, chemical, power plants, or water treatment facilities, the proper design of flanges can significantly affect the overall performance, reliability, and safety of the system. This blog delves into the secrets of effective flange design, as shared by industry experts, and provides invaluable tips to ensure optimal performance and longevity of flanges in various applications.

Understanding the Basics of Flange Design

A flange is a mechanical part used to connect pipes, valves, pumps, and other equipment into a complete piping system. It is a circular plate with holes for bolts, which allows for a strong connection. Flanges serve both as a structural link and, in many cases, a sealing surface for gaskets to stop leaks.

Key Flange Types

Weld Neck Flange:

This type of product is made for applications that require high pressure. The flange is attached to the pipe by welding the edges together, creating a continuous and smooth connection that spreads the stress across the pipe's wall and the flange's neck. It is well-suited for situations with significant changes in temperature.

Slip-On Flange:

Slip-on flanges are generally used for low-pressure, low-temperature applications and are simpler to install than weld neck flanges. They are positioned over the pipe and welded on the inside and outside to increase their strength.

Blind Flange:

Blind flanges are used to seal off pipelines or valves, which is crucial for testing and maintenance. These flanges have a straightforward design and can withstand high pressure.

Socket Weld Flange:

Socket weld flanges are well-suited for small pipes and high-pressure applications, as they offer exceptional resistance to fatigue.

Lap Joint Flange:

Lap joint flanges paired with stub-end fittings are well-suited for systems that need to be disassembled regularly for inspection or cleaning purposes.

Critical Design Considerations

When designing flanges, various elements must be considered, such as the material type, pressure classification, and surrounding conditions. A properly engineered flange should be capable of enduring the mechanical tensions caused by internal pressure and external forces, while simultaneously preserving a leak-free seal. Here are some expert recommendations to achieve an optimal flange design.

Flange Design Tips from Industry Experts

1. Material Selection: Compatibility is Key

Selecting the right material is crucial when designing flanges. Experts stress the need to pick materials that can withstand the substances flowing through the pipes and the surrounding environment. For example, stainless steel is highly resistant to corrosion, making it a common choice for chemical and water treatment facilities. Conversely, carbon steel flanges are more appropriate for high-temperature settings, such as power plants.

In harsh environments like offshore oil drilling, specialized metal alloys such as Inconel or Monel may be necessary to withstand the intense corrosive effects of seawater. When selecting materials, it's important to consider the temperature and pressure requirements to prevent flange failures during operation.

2. Stress Analysis: Prevent Overstressing the Flange

Analyzing stress is essential to prevent failures, particularly in high-pressure or high-temperature settings. Specialists suggest performing a finite element analysis (FEA) to verify that the flange can withstand the stresses imposed by the system. Excessive stress can result in flange distortion, bolt loosening, and potentially, leakage or catastrophic failure.

3. Flange Face Finish: Achieving a Tight Seal

The surface of a flange, called the flange face, is crucial for stopping leaks. The texture of the flange face should be carefully selected to work well with the gasket material and the specific use. Experts advise using a smoother finish for soft gaskets like rubber or PTFE to get a tight seal, while rougher textures are better with metal gaskets that need more friction to make an effective seal.

The most common finishes for flange faces are:

Raised Face: A higher surface area creates a better seal. This is often used in high-pressure settings.

Flat Face: The flange must be in complete contact with the gasket and the surface it is mating with.

Ring-Type Joint (RTJ): RTJ flanges are designed for use in systems that operate under high pressure and high temperature conditions. These flanges have a groove cut into their face to hold a metal ring gasket in place.

4. Gasket Selection: Proper Sealing is Essential

The type of gasket material and its design are crucial for creating a leak-free seal. The gasket needs to be suitable for the flange material, the substance being transported, and the operating environment, including temperature and pressure.

Metallic gaskets are suitable for high-pressure and high-temperature applications.

Non-metallic gaskets are used in lower-pressure systems and typically include materials like rubber, Teflon, or compressed fiber.

Composite gaskets combine metallic and non-metallic materials, providing a balance between flexibility and strength.

5. Bolt Torque and Tightening Patterns: Ensuring Uniform Pressure

Bolts are essential for keeping the flange assembly intact, and applying the right amount of torque is crucial to prevent uneven pressure, which can cause the gasket to fail. Experts advise using a controlled tightening technique, like a torque wrench, to apply the appropriate amount of force evenly across all the bolts.

Fasteners are essential for securely joining the flanged components, and the appropriate application of twisting force is crucial to prevent uneven pressure, which can result in gasket malfunction. Specialists suggest employing a regulated tightening approach, like a torque wrench, to apply the correct amount of force uniformly across all fasteners.

6. Temperature and Pressure Ratings: Don’t Exceed the Limits

Each flange has particular pressure and temperature limits, often called the "pressure class." These limits define the highest allowed working pressure at a given temperature. Going beyond these limits may result in severe failures.

Experts stress the need to comprehend the system's working conditions and ensure the flange's pressure rating aligns with the maximum anticipated pressure and temperature. For instance, in steam systems, temperature variations can lead to substantial expansion and contraction, necessitating flanges with higher ratings to handle the stress.

7. Corrosion Protection: Guarding Against Environmental Factors

Damage to flanges is often caused by corrosion, particularly in challenging settings like offshore rigs or chemical facilities. Experts advise applying protective coatings, like galvanization or epoxy, to prevent corrosion. In certain situations, using a corrosion-resistant alloy may be necessary to ensure long-lasting performance.

Most Trusted Manufacturer leading flanges in several Indian cities:

MS Flanges Manufacturer In Rajkot

MS Flanges Manufacturer In Ahmedabad

MS Flange Manufacturer In Surat

MS Flange Manufacturer In Pune

MS Flange Manufacturer in Bhavnagar

For More Details

Website: metalicaforginginc.com

0 notes

Text

Carbon Steel ASTM A105 Flanges Manufacturers In India

Carbon Steel ASTM A105 Flanges Manufacturers In India,Supplier In india ,Stockist In India,Exporter In India

Introduction:- Carbon Steel ASTM A105 Flanges Manufacturers In India

India is emerging as a significant hub for the production of Carbon Steel ASTM A105 flanges, catering to a variety of industries such as oil and gas, petrochemicals, power generation, and construction. These flanges are integral to piping systems, providing robust connections that ensure safety and efficiency in high-pressure and high-temperature environments.

Manufacturers in India utilize advanced manufacturing techniques and adhere to stringent quality standards to produce ASTM A105 flanges that meet international specifications. This commitment to quality ensures that their products are reliable and durable, capable of withstanding demanding operational conditions.

The growing industrial landscape in India, combined with an increasing focus on infrastructure development, has led to a rising demand for high-quality flanges. Indian manufacturers are well-equipped to meet this demand, offering a diverse range of flanges, including slip-on, weld neck, threaded, and blind types.

This introduction sets the stage for a closer examination of the features, applications, and leading manufacturers of Carbon Steel ASTM A105 flanges in India, highlighting their role in supporting the

Product Overview:-.

ASTM A105 Flange is a specification for flanges. Specifications can include flanges of various grades made of stainless steel. The flange is made of forged Carbon Steel ASTM and is intended for high temperature use. Shasan Piping Solution is a leading manufacturer and supplier of ASTM A105 flange types.

This material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187.

Specifications:-

Specification Format of SA105N Blind Flange

Specifications

ASTM A182, ASME SA182

Size

1/2″ to 48″

Standards

ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings

Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type

Flate Face, Raised Face, Ring Type Joint

Coating/Surface Treatment

Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

Benefits:-

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding. Please contact us for flange pricing and details.

Conclusions:-

In summary, Carbon Steel ASTM A105 flanges are a vital component in modern piping systems, known for their strength, durability, and versatility. Their compliance with the ASTM A105 specification guarantees high-quality performance in demanding environments, making them a preferred choice in industries such as oil and gas, petrochemical, and construction.

Email Id:- [email protected]

Contact No:-8879709191

0 notes

Text

Inconel 600 Flanges Manufacturers

Inconel 600, a nickel-chromium alloy, is renowned for its exceptional resistance to oxidation and corrosion at high temperatures, making it a popular choice in industries that require durability and reliability. One of the key components made from this versatile alloy is flanges, essential in piping systems for connecting pipes, valves, pumps, and other equipment. This article delves into the characteristics of Inconel 600 flanges, their key properties, specifications, and benefits, offering a comprehensive understanding of their significance in various industrial applications.

Introduction

Flanges are integral parts of many industrial piping systems, providing a means to connect pipes, valves, pumps, and other equipment to form a complete system. Among the various materials used to manufacture flanges, Inconel 600 stands out due to its superior performance in challenging environments. Inconel 600 flanges are widely used in industries such as chemical processing, aerospace, power generation, and marine engineering, where resistance to heat, pressure, and corrosive substances is crucial.

Key Properties of Inconel 600

Inconel 600 is an alloy composed primarily of nickel (72%) and chromium (14-17%), with small amounts of iron (6-10%) and other elements. This combination imparts the following key properties to the material:

High Temperature Resistance: Inconel 600 maintains its mechanical strength and stability at temperatures ranging from cryogenic to over 2000°F (1093°C), making it ideal for high-temperature applications.

Corrosion Resistance: The alloy exhibits excellent resistance to a wide range of corrosive environments, including oxidizing and reducing conditions, making it suitable for use in harsh chemical processing environments.

Oxidation Resistance: Inconel 600 is highly resistant to oxidation at high temperatures, which prevents scaling and surface degradation over time.

Good Mechanical Properties: The alloy possesses high tensile strength and good toughness, making it suitable for applications where mechanical stress and pressure are significant factors.

Non-Magnetic: Inconel 600 is non-magnetic, which can be a critical property in certain applications where magnetic interference must be avoided.

What are Inconel 600 Flanges?

Inconel 600 flanges are specialized components designed to connect pipes, valves, and other equipment in a piping system. They are typically used in applications where the system is exposed to high temperatures, corrosive environments, or both. These flanges come in various types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges, each serving a specific purpose in a piping system.

Specification of Inconel 600 Flanges

Inconel 600 flanges are manufactured according to specific standards and specifications to ensure quality, reliability, and compatibility with other system components. Some of the common specifications include:

Standards: ASTM B564, ASME SB564, DIN, EN, and ANSI standards.

Sizes: Typically ranging from ½” to 48” or as per customer requirements.

Pressure Class: Available in various pressure ratings such as 150#, 300#, 600#, 900#, 1500#, and 2500#.

Dimensions: Adhering to standard dimensions for thickness, diameter, and bolt circle as per ASME B16.5, ASME B16.47, and other relevant standards.

Surface Finish: The flanges may come with different surface finishes, including raised face (RF), flat face (FF), and ring-type joint (RTJ).

Sankalp Alloys Overseas is one of the best exporter, creator and provider of Inconel 600 Flanges in India.Inconel boasts excellent qualities compared to most alloys, including stainless steel. Their higher cost compensates with high mechanical strength and excellent corrosion resistance properties. Generally, Inconel Flanges are used to serve in environments of elevated temperatures. Unlike most alloys that lose dimensional stability and mechanical properties at high temperatures, Inconel retains its performance.

Benefits of Inconel 600 Flanges

Inconel 600 flanges offer several advantages that make them suitable for demanding industrial applications:

Durability: The high strength and toughness of Inconel 600 ensure that flanges made from this material can withstand mechanical stress and pressure over extended periods.

Extended Service Life: Due to its resistance to oxidation and corrosion, Inconel 600 flanges have a longer service life compared to flanges made from other materials.

Versatility: The alloy's ability to perform well in both high-temperature and cryogenic environments makes it suitable for a wide range of applications.

Low Maintenance: The excellent corrosion resistance of Inconel 600 reduces the need for frequent maintenance and replacement, lowering overall operational costs.

Safety: Inconel 600 flanges ensure the safe operation of piping systems, particularly in critical environments such as chemical processing plants and power generation facilities.

Conclusion

Inconel 600 flanges are a critical component in various industrial applications, offering unmatched performance in high-temperature, high-pressure, and corrosive environments. Their exceptional properties, such as resistance to oxidation, corrosion, and mechanical stress, make them a reliable choice for industries where safety and durability are paramount. By understanding the specifications and benefits of Inconel 600 flanges, industries can make informed decisions when selecting materials for their piping systems, ensuring long-term performance and reduced maintenance costs.

Whether in chemical processing, power generation, or aerospace engineering, Inconel 600 flanges continue to play a vital role in ensuring the integrity and efficiency of critical systems.

For More Information:

Visit Our Website - https://www.sankalpalloys.com/

Call Us : +91-88283-69483

E-mail - [email protected]

0 notes

Text

Types of SS 316 Blind Flanges

SS 316 blind flanges are a crucial component in piping systems, known for their durability and resistance to corrosion. These flanges are typically used to seal the end of a pipe, providing a solid barrier to prevent the flow of fluids. Here’s an overview of the different types of SS 316 blind flanges, each tailored to meet specific application needs:

1. Standard Blind Flanges

Description: Standard SS 316 blind flanges are designed according to established industrial standards such as ANSI, DIN, and JIS. They provide a simple and effective way to close off piping systems.

Applications: Commonly used in general piping systems where standard dimensions and pressure ratings are required. Suitable for most industrial, chemical, and water treatment applications.

2. Raised Face Blind Flanges

Description: Raised face blind flanges feature a raised area around the bolt holes, which helps create a better seal between the flange and the pipe.

Applications: Ideal for applications where a tight seal is crucial, such as in high-pressure systems or where leakage could lead to significant issues. Often used in chemical processing and petrochemical industries.

3. Flat Face Blind Flanges

Description: These flanges have a flat sealing surface and are typically used with gaskets that are also flat. The flat face design ensures a large contact area for the gasket.

Applications: Common in lower-pressure applications or where the flange will be used with a gasket that requires a flat surface, such as in water treatment plants and less demanding industrial applications.

4. Spectacle Blind Flanges

Description: Spectacle blind flanges consist of two discs connected by a handle. One disc is a blind flange, and the other is a solid disc that can be used to close the line completely when needed.

Applications: Useful in systems where frequent changes in flow direction or maintenance are required. Often used in pipelines where quick isolation is needed.

5. Slip-On Blind Flanges

Description: These flanges are designed to slip over the end of the pipe before being welded into place. They offer ease of installation and alignment.

Applications: Suitable for applications where ease of alignment and welding are important, such as in construction and repair work.

6. Threaded Blind Flanges

Description: Threaded blind flanges have internal threads that allow them to be screwed onto the end of a pipe. This design eliminates the need for welding.

Applications: Often used in smaller diameter pipes or where welding is not practical. Common in plumbing and smaller-scale industrial applications.

7. Weld Neck Blind Flanges

Description: These flanges have a neck that is welded to the pipe, providing a strong, continuous connection. The neck helps distribute stresses and forces evenly.

Applications: Ideal for high-pressure and high-temperature applications, including in chemical processing and high-stress environments.

8. Blind Flanges with Reinforced Areas

Description: Some SS 316 blind flanges come with additional reinforcement around the bolt holes or flange face to enhance strength and durability.

Applications: Used in high-pressure applications or where additional reinforcement is necessary to withstand extreme conditions.

Choosing the Right SS 316 Blind Flange

When selecting SS 316 blind flanges, consider the following factors:

Pressure Rating: Ensure the flange can handle the pressure requirements of your application.

Temperature Range: Choose a flange that can operate effectively within the temperature range of your system.

Corrosion Resistance: SS 316 is highly resistant to corrosion, but make sure it’s suitable for your specific chemical environment.

Standards and Specifications: Verify that the flange meets industry standards and specifications for your application.

Each grade is selected based on the specific requirements of the application, including exposure to chemicals, temperature, and mechanical stress.

2 notes

·

View notes

Text

Understanding Flanges: Essential Components in Piping Systems

Pipingprojects.us is a well-known Flanges Manufacturer in USA. We manufacture and supply a wide variety of flanges, including lap joint, weld neck, orifice, slip-on, and more. We use a variety of materials to produce high-quality flanges. Common alloy steel flange materials include chromium, molybdenum, and nickel. Chrome Moly flanges are well-known for their superior corrosion and oxidation resistance. We are one of the leading flange supplier in USA.

What Are Flanges?

A flange is a protruding rim, edge, or collar used to connect two sections of piping, allowing for easy assembly, disassembly, and maintenance of the piping system. They are typically round and feature bolt holes around the perimeter, enabling secure connections. Flanges can also join piping to other equipment, such as pumps and valves, making them versatile components in any piping infrastructure.

Types of Flanges

Flanges come in various designs, each suited to specific applications. The most common types include:

Weld Neck Flange: Known for its long tapered hub, this flange is ideal for high-pressure applications. It is welded to the pipe, ensuring a strong connection that can withstand extreme conditions.

Slip-On Flange: As the name suggests, this flange slips over the pipe and is then welded in place. It is easier to install than weld neck flanges but is typically used for lower pressure applications.

Blind Flange: This flange is used to close off the end of a piping system or a pressure vessel opening. It can be easily removed, making it ideal for maintenance and inspection.

Socket Weld Flange: Designed for smaller pipes, this flange has a socket in which the pipe is inserted and then welded around the outside. It is often used in high-pressure, small-diameter piping systems.

Threaded Flange: This flange has internal threads that match the external threads of the pipe. It is typically used in low-pressure applications and systems where welding is not possible or practical.

Lap Joint Flange: Used with a stub end, this flange is not welded or fixed to the pipe, making it easy to assemble and disassemble. It is often used in systems that require frequent maintenance.

We are Flanges Supplier In:

Flanges Supplier in Texas

Flanges Supplier in California

Flanges Supplier in Florida

Flanges Supplier in New York

Flanges Supplier in Los Angeles

Materials of Construction

Flanges are made from a variety of materials, each chosen based on the requirements of the application. Common materials include:

Carbon Steel: Widely used due to its strength and affordability, carbon steel flanges are suitable for high-temperature and high-pressure applications.

Stainless Steel: Known for its corrosion resistance, stainless steel is ideal for applications involving corrosive environments, such as chemical processing and offshore oil and gas.

Alloy Steel: These flanges are used in high-temperature environments, such as in power plants and refineries, due to their enhanced mechanical properties.

Plastic: In situations where weight and corrosion are concerns, plastic flanges offer a lightweight and corrosion-resistant option, commonly used in water treatment and chemical handling.

Applications of Flanges

Flanges are ubiquitous in industries that rely on extensive piping systems. Their applications include:

Oil and Gas: Used extensively in pipelines, refineries, and offshore platforms to connect pipes, valves, and equipment.

Chemical Processing: Essential for handling corrosive substances and ensuring leak-proof connections in chemical plants.

Power Generation: Used in boilers, turbines, and cooling systems to maintain the integrity of high-temperature and high-pressure piping.

Water Treatment: Flanges connect pipes and equipment in water filtration and distribution systems, ensuring reliable and easy-to-maintain connections.

Flanges Manufacturer In USA

We are the top flange manufacturer. These flanges can be made by forging or casting. These components, available from reputable stainless steel flange manufacturers, are used to reinforce or connect beams and columns. When installing stainless steel pipe flanges, a certain flange type is required to provide a precise and secure fit and seamless integration into the piping system.

#Flanges Manufacturer in USA#Flanges Supplier in USA#Flanges Manufacturer#Flanges Supplier in Texas#Flanges Supplier in California#Flanges Supplier in Florida

0 notes

Text

RClassic/M.S Plato: Pipe Fitting Service in Kolkata

Pipe fittings are essential components in any piping system, playing a crucial role in ensuring the efficient flow of liquids, gases, or other materials. Whether you're involved in construction, plumbing, or industrial projects, understanding the different types of pipe fittings and their applications is vital. This guide aims to provide you with an in-depth overview of pipe fittings, their types, materials, and applications, helping you make informed decisions for your next project.

What Are Pipe Fittings?

Pipe fittings are devices used to connect different sections of pipes, redirect flow, or seal a system. They are commonly used in plumbing, heating, cooling, gas, and chemical systems. Fittings come in various shapes, sizes, and materials, each designed for specific applications. The right fitting ensures a secure, leak-proof connection that can withstand the pressure and temperature conditions of the system it serves.

Types of Pipe Fittings

There are several types of pipe fittings, each serving a unique purpose. Understanding these types will help you choose the right fitting for your specific needs.

1. Elbows

Elbows are fittings used to change the direction of the flow in a piping system. They typically come in angles of 90° and 45°, though other angles can be custom-made. Elbows are crucial in systems where pipes need to bend around obstacles or change direction. They are commonly used in plumbing, heating, and cooling systems.

2. Tees

Tee fittings, as the name suggests, are shaped like the letter "T." They are used to combine or split the flow in a piping system. The main flow passes through the straight part of the tee, while the side branch connects to another pipe. Tees are essential in systems where the flow needs to be divided into different directions or combined from multiple sources.

3. Couplings

Couplings are short lengths of pipe used to connect two pipes together. They are typically used to extend the length of a piping system or repair a broken pipe. Couplings come in different types, including full couplings (which connect two pipes of the same diameter), half couplings (which connect a pipe to a fitting or flange), and reducing couplings (which connect pipes of different diameters).

4. Reducers

Reducers are fittings used to connect pipes of different diameters. They help to manage the flow rate and pressure within a piping system by reducing the pipe size from a larger diameter to a smaller one by Pipe Fitting Service in Kolkata. There are two main types of reducers: concentric reducers (which maintain the centerline of the pipes) and eccentric reducers (which offset the centerline to prevent air pockets in horizontal piping systems).

5. Caps and Plugs

Caps and plugs are used to seal the end of a pipe. Caps cover the outside of the pipe, while plugs fit inside the pipe. These fittings are often used in plumbing systems to close off unused pipe sections or to prepare a system for future expansion.

6. Valves

Valves are fittings that control the flow of fluid within a piping system. They can start, stop, or regulate the flow depending on the system's requirements. Common types of valves include gate valves, ball valves, check valves, and butterfly valves. Valves are critical components in systems where precise control of fluid flow is necessary.

7. Flanges

Flanges are fittings used to connect pipes, valves, pumps, and other equipment to form a piping system by Pipe Fitting Service in Kolkata. They provide easy access for cleaning, inspection, or modification. Flanges are usually welded or screwed onto the pipe ends and then bolted together. They come in various types, including slip-on, weld neck, blind, and threaded flanges.

Materials Used in Pipe Fittings

Pipe fittings are made from various materials, each with its own set of properties and applications. Choosing the right material is essential to ensure the longevity and performance of your piping system.

1. Stainless Steel

Stainless steel fittings are known for their durability, resistance to corrosion, and ability to withstand high temperatures. They are commonly used in industrial applications, especially in chemical and food processing plants where hygiene and resistance to corrosive substances are critical.

2. Carbon Steel

Carbon steel fittings are strong and durable, making them ideal for high-pressure applications. They are commonly used in oil and gas, water distribution, and industrial piping systems. However, carbon steel is prone to rust, so it is often coated or galvanized to enhance its corrosion resistance.

3. Copper

Copper fittings are widely used in plumbing and heating systems due to their excellent thermal conductivity and corrosion resistance. They are also relatively easy to work with, making them a popular choice for residential and commercial piping systems. However, copper fittings are more expensive than other materials.

4. Brass

Brass fittings are known for their excellent corrosion resistance, making them suitable for use in water, gas, and steam applications. They are also resistant to wear and tear, making them a durable choice for long-term use. Brass fittings are often used in plumbing, heating, and air conditioning systems.

5. Plastic

Plastic fittings, such as those made from PVC, CPVC, or PEX, are lightweight, affordable, and resistant to corrosion. They are commonly used in residential plumbing, irrigation systems, and chemical processing plants. Plastic fittings are easy to install and maintain, but they may not be suitable for high-temperature or high-pressure applications.

Applications of Pipe Fittings

Pipe fittings are used in a wide range of applications across various industries. Here are some common uses:

1. Plumbing

In residential and commercial buildings, pipe fittings are essential for the installation of water supply and drainage systems. Fittings like elbows, tees, and couplings are used to route pipes through walls, floors, and ceilings, ensuring a continuous flow of water to fixtures and appliances.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on pipe fittings to distribute hot and cold air throughout a building. Fittings like valves, reducers, and flanges are used to control the flow of air and maintain the desired temperature in different zones.

3. Industrial Piping

In industrial settings, pipe fittings are used to transport liquids, gases, and chemicals between different processes. Fittings must be chosen carefully to ensure compatibility with the materials being transported and the operating conditions, such as pressure and temperature.

4. Oil and Gas

The oil and gas industry relies heavily on pipe fittings to connect pipelines, control flow, and manage pressure. Fittings like flanges, valves, and reducers are used to ensure the safe and efficient transport of oil, gas, and other petroleum products.

5. Fire Protection Systems

Fire protection systems, such as sprinkler systems, use pipe fittings to distribute water or other fire-suppressing agents throughout a building. Fittings like elbows, tees, and couplings are used to route pipes to the necessary locations, ensuring coverage in the event of a fire.

Choosing the Right Pipe Fittings

Selecting the right pipe fittings for your project involves considering several factors:

Material Compatibility: Ensure that the fittings are compatible with the pipes and the materials being transported.

Pressure and Temperature Ratings: Choose fittings that can withstand the operating conditions of your system.

Size and Dimensions: Ensure that the fittings match the size and dimensions of the pipes in your system.

Industry Standards: Verify that the fittings meet relevant industry standards and regulations.

When choosing pipe fittings, it's essential to work with a reliable pipe provider who can offer a wide range of high-quality fittings and expert advice. For instance, R classic/Ms Plasto, a trusted pipe provider, offers a comprehensive selection of fittings that meet the needs of various industries, ensuring you get the right components for your specific application.

Conclusion

Pipe fittings are vital components in any piping system, ensuring the safe and efficient transport of fluids, gases, and other materials. Understanding the different types of fittings, the materials they are made from, and their applications will help you make informed decisions for your project. Whether you're working on a plumbing system, an industrial pipeline, or an HVAC installation, choosing the right pipe fittings is essential for the success of your project. Partnering with a reputable pipe provider, like R classic/Ms Plasto, can ensure you get the quality

0 notes

Text

Fasteners Manufacturers In Nigeria

/ Fasteners / By Sachiya Steel International

Nigeria’s dynamic industrial landscape demands high-quality fasteners in various fields such as construction, automotive and infrastructure development. Fasteners serve an essential purpose – mechanically joining or attaching two objects together through mechanical means – with different kinds such as bolts, screws, nuts washers and rivets specifically tailored for specific uses.

Sachiya Steel International Private Limited: Leaders in Fastener Manufacturing

Sachiya Steel International Private Limited of India has become one of the premier producers and exporters of fasteners worldwide. Through dedication to quality, innovation, and customer satisfaction, Sachiya serves global markets including Nigeria with products that adhere to international standards while exceeding customer expectations.

Types of Fasteners Manufactured by Sachiya Steel International Private Limited:

1. Bolts:

Hex Bolts

Carriage Bolts

Eye Bolts

U-Bolts

2. Screws:

Machine Screws

Wood Screws

Self-tapping Screws

3. Nuts:

Hex Nuts

Lock Nuts

Wing Nuts

4. Washers:

Flat Washers

Spring Washers

Belleville Washers

5. Rivets:

Solid Rivets

Blind Rivets

Materials Used:

Sachiya Steel International Private Limited utilizes various materials in manufacturing fasteners, carefully chosen based on their properties and applications:

Stainless Steel: Stainless Steel is known for its corrosion resistance and durability, making it suitable for marine and industrial use.

Carbon Steel: Carbon Steel boasts higher strength and hardness for structural applications as well as machinery purposes.

Alloy Steel: Alloy Steel offers superior mechanical properties such as tensile strength and toughness, making it suitable for critical applications.

Brass: Brass features excellent electrical conductivity as well as aesthetic appeal; often utilized in electrical or decorative applications.

Aluminum: Lightweight with superior corrosion resistance, making this metal an excellent choice for aerospace and automotive applications.

0 notes

Text

How do you choose the right flange for your project? Discuss the factors to consider, such as materi

Material:

○ Corrosion Resistance: Select a material that can withstand the corrosive environment it will be exposed to. Common materials include carbon steel, stainless steel, and alloy steels.

○ Temperature: Ensure the material can handle the operating temperature. For high temperatures, materials like stainless steel or special alloys are preferred.

Pressure Rating:

○ Class Rating: Flanges are rated by pressure classes, such as 150, 300, 600, 900, 1500, and 2500. Choose a flange that matches or exceeds the pressure requirements of your system to ensure safety and performance.

Size:

○ Diameter: The flange diameter must match the pipe or equipment it is connecting. Measure the pipe size accurately and ensure the flange fits properly.

○ Bolt Holes: The number and size of bolt holes should align with the bolt pattern of the connected equipment or pipe.

Type of Flange:

○ Weld Neck: Provides strong, reliable connections and is suitable for high-pressure applications.

○ Slip-On: Easier to align and weld, but may not be as strong under high pressures Flanges .

○ Blind: Used to close off a pipeline or vessel.

○ Socket Weld: Good for small diameters and high-pressure applications.

○ Threaded: Useful for systems where welding is not an option but generally not used for high-pressure applications.

Standards and Specifications:

○ Industry Standards: Follow relevant standards such as ANSI, ASME, or ISO to ensure compatibility and quality Flanges .

Installation Considerations:

○ Accessibility: Ensure there is enough space for installation and maintenance.

○ Gaskets and Seals: Select appropriate gaskets to ensure a proper seal and prevent leaks.

By carefully evaluating these factors, you can select the right flange that meets your project's requirements for safety, performance, and durability.

0 notes

Text

Flanges in the Power Generation Industry: A Critical Component

Flanges are essential components in power generation plants, providing a means to connect pipes, valves, and other equipment. These fittings play a crucial role in ensuring the efficient and reliable operation of power generation systems.

Types of Flanges Used in Power Generation

A variety of flange types are used in power plants, including:

Slip-on flanges: The most common type, characterized by a loose fit over the pipe end.

Weld neck flanges: Welded directly to the pipe for a stronger connection.

Socket weld flanges: Designed for smaller pipe sizes and welded into the pipe end.

Blind flanges: Used to seal off the end of a pipe.

Lap joint flanges: Connected to the pipe using a gasket and bolts.

Applications of Flanges in Power Plants

Flanges are used in numerous applications within power plants, such as:

Steam lines: Connecting steam pipes to turbines for power generation.

Water lines: Supplying water for cooling, boiler feed, and other processes.

Fuel lines: Delivering fuel to combustion chambers.

Coolant lines: Circulating coolant to regulate temperatures.

Piping systems: Connecting various equipment components within the plant.

Benefits of Using Flanges in Power Generation

Flanges offer several advantages in power generation:

Flexibility: They allow for easy disassembly and reassembly of piping systems, facilitating maintenance and repairs.

Reliability: Flanges provide a reliable and secure connection between pipes and equipment.

Versatility: They can be used with a wide range of pipe sizes and materials.

Safety: Proper selection and installation of flanges are crucial for ensuring the safety of power generation operations.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including flanges. These fittings are manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company.

Platinex flanges are ideal for the power generation industry due to their:

Corrosion resistance: Stainless steel provides excellent resistance to corrosion, making it suitable for handling various fluids and chemicals.

High-temperature resistance: Platinex flanges can withstand high temperatures, making them ideal for steam lines and other high-temperature applications.