#Best Crusher Plant Manufacturer

Explore tagged Tumblr posts

Text

Best Crusher Plant Manufacturer

When it comes to finding the best crusher plant manufacturer for craftsmen industries, it's important to choose a company that offers high-quality equipment, reliable service, and innovative solutions. Crusher plants are essential in industries that work with rocks and minerals because they help break down large chunks of material into smaller, more manageable pieces. The best manufacturers in this field understand the unique needs of craftsmen industries and design their plants to be efficient, durable, and easy to maintain. They use advanced technology to ensure the crushers work efficiently and can handle various types of materials. Additionally, top manufacturers provide excellent customer support, offering training, maintenance services, and quick responses to any issues that may arise. This ensures that the craftsmen can focus on their work without worrying about equipment failures. Some of the leading crusher plant manufacturers also offer customization options, allowing the equipment to be tailored to the specific requirements of different projects. This flexibility is crucial for craftsmen who often work on unique and varied tasks. By choosing a reputable manufacturer, craftsmen industries can benefit from equipment that not only improves productivity but also ensures safety and reduces operational costs. Whether the need is for a jaw crusher, cone crusher, or impact crusher, the best manufacturers will provide robust machines built to last. This means less downtime and more efficiency, helping craftsmen complete their projects on time and to the highest standards. Therefore, for any craftsmen industry looking to enhance their operations, investing in a crusher plant from a top manufacturer is a smart and beneficial choice.

0 notes

Text

Jaw Crusher Manufacturer and Supplier in Indore Buy the best Stone Crusher Machine Plant, Vibrating Screen, Sand Making Machine, and more at the best price

#jaw crusher manufacturer#best jaw crusher#sand making machine in Indore#stone crusher machine manufacturer#quality stone crusher plant#buy sand making machine

0 notes

Text

Top Stone Crusher Machine Manufacturer in India

The Stone Crusher Machine is a powerful tool designed to crush stones into smaller pieces for various construction purposes. Equipped with robust blades or hammers, it efficiently breaks down large rocks into gravel or sand. With durable construction and reliable performance, the Stone Crusher Machine ensures efficient operation and high productivity. If you are looking for stone crusher machine manufacturers in India? Dhiman Engineering Works stands out as a leading stone crusher machine manufacturer, delivering top-quality products designed to meet your crushing needs. Trust in expertise and innovation to elevate your operations with reliable and efficient stone-crushing solutions.

#Stone Crusher Machine Manufacturer#Stone Dust Machine Plant Manufacturer#Stone Crusher Machine#Stone Crusher Machine Manufacturer in India#Stone Crusher Machine Manufacturer India#Top Stone Crusher Machine Manufacturer#Best Stone Crusher Machine Manufacturer#Top Stone Crusher Machine Manufacturer in India#Best Stone Crusher Machine Manufacturer India

1 note

·

View note

Text

Metal Crusher Machine: The Essential Guide to Efficient Scrap Metal Recycling

In today’s industrial landscape, a metal crusher machine plays an indispensable role in recycling scrap metal. By efficiently breaking down metal waste, these machines contribute to sustainable environmental practices and streamline the recycling process. This guide will walk you through the benefits, working principles, types, and essential maintenance tips for a metal crusher machine.

What is a Metal Crusher Machine?

A metal crusher machine is a powerful device designed to crush metals into smaller, manageable pieces. This machine is essential in metal recycling plants and industries dealing with large quantities of scrap metal, such as automotive, construction, and manufacturing sectors. Metal crushers are also widely used in electronic waste recycling to dismantle electronic components and extract valuable metals.

Benefits of Using a Metal Crusher Machine

Efficient Scrap Metal Processing: Metal crushers can break down large metal parts, simplifying the recycling process.

Environmental Benefits: By recycling metals, these machines reduce the need for mining, helping conserve natural resources and minimize environmental impact.

Cost Savings: Crushing scrap metal reduces storage and transport costs, increasing profitability for businesses.

Energy Efficiency: Processing crushed metal requires less energy in the recycling process compared to whole parts.

How Does a Metal Crusher Machine Work?

A metal crusher machine works on the principle of shredding and hammering metal components.

Loading: Scrap metal is fed into the crusher.

Shredding: Sharp blades, rotors, and hammers break down the metal into smaller fragments.

Sorting and Separating: Some crushers come with magnetic systems to separate non-metallic items.

Crushing: The fragments are compressed into compact pieces, making them easier to handle and transport.

Types of Metal Crusher Machines

Metal crushers come in various types, each designed for specific types of scrap and processing needs.

Jaw Crushers: Ideal for breaking down large pieces of metal like car bodies.

Hammer Crushers: Effective in reducing metal to smaller fragments quickly.

Impact Crushers: Best suited for processing delicate materials without compromising structural integrity.

Shredders: Equipped with rotating blades for finer granulation, shredders are perfect for electronic waste.

Key Features to Look for in a Metal Crusher Machine

When selecting a metal crusher machine, consider the following features:

Capacity: Ensure the machine can handle your volume needs.

Durability: A high-quality machine made of durable materials will last longer.

Energy Efficiency: Energy-efficient models can save operational costs.

Safety Features: Look for models with safety guards and automatic shutdown features to prevent accidents.

Maintenance Tips for Metal Crusher Machines

Proper maintenance can extend the life of your metal crusher and ensure optimal performance. Here are some essential maintenance practices:

Regular Lubrication: Lubricate moving parts to reduce wear and tear

Blade Inspection: Check and replace worn-out blades periodically for smooth operation.

Clean the Machine: Clear metal residues after every operation to prevent buildup.

Monitor Power Consumption: High power usage may indicate a malfunction.

Applications of Metal Crusher Machines

Metal crusher machines are essential in various industries, including:

Automobile: Crushing end-of-life vehicles to recycle metals.

Construction: Processing metal debris from demolished structures.

Electronics: Breaking down electronic devices to extract precious metals.

Manufacturing: Recycling metal scraps to produce new products.

Conclusion

A metal crusher machine is an invaluable tool for industries aiming to reduce waste, promote sustainability, and improve operational efficiency. Investing in a high-quality metal crusher not only enhances your recycling capabilities but also contributes to a more sustainable environment.

0 notes

Text

Choosing the Right Quality Gearbox for Your Applications

An effective gearbox is efficient in performing its functions, especially for fewer downtimes, and increases the equipment’s durability. Thus, this article provides information on how to select an appropriate gearbox, focuses on the issue of quality, and indicates how to find gearbox manufacturers in Ahmedabad when you search for ‘worm reduction gearbox near me’.

Understanding Gearboxes

A gearbox or transmission is a part of a drive system which transmit power from one part to the other altering the speed and the amount of force through which this is achieved. These include; industrial automation applications, automobiles and other vehicular systems, robotics and many more. Selecting the gearbox also depends on the type of needed gearbox and the particular application in which it will be used.

Types of Gearboxes

Following are the types of worm reduction gearboxes-

Worm Reduction Gearbox

Features: These includes; high reduction ratios, compact assembly, self-locking provisions.

Applications: Bearings; Conveyor belts; Lifts and other heavy operating machinery; Boilers; Reaction vessels; Pumps; Fans.

Helical Gearbox

Features: High performance, low noise level, are able to handle loads.

Applications: Belt conveyors, screw conveyors, sprocket conveyors; extruders, crushers.

Bevel Gearbox

Features: Enables a wide-range geometry of both cog gears; enhanced issue of torque transfers.

Applications: Drives that operate on the differential, advertising packaging machinery, presses for printing.

Planetary Gearbox

Features: The benefits are high power density and pack compactness, high efficiency.

Applications: Cars, robots and cutting tools.

Factors to Consider When Choosing a Gearbox

Keep in mind the following points when considering to search ‘worm reduction gearbox near me’-

1. Application Requirements

Determine the requisition need of your application, such as speed, torque, and load at which your application is going to operate. Knowledge of these parameters will assist in filtering the specific kind of gearbox that can be appropriate for the application. 2. Quality and Durability Choose a gearbox whose characteristics are in relation to the characteristics of those available in the market in terms of durability and reliability. The gearboxes should be made of strong materials; in addition to this a gearbox that you are going to purchase should be warrantied.

How to find a Gearbox Manufacturer in Ahmedabad?Just like the proper gearbox, the manufacturer choice also plays a significant role in leading a successful life of the plant.

● Reputation: One should ensure that the manufacturers selected, have a good track record in business. Real customers and their feedback are often informative.● Experience: Select manufacturers that have years of experience in the production of this product. The manufacturers with experience are likely to offer better gearboxes than the relatively new manufacturers.

Gearbox Repair ServicesThere is still need for repair even for the best gearboxes depending on the amount of use that has been accorded to them. This is why accessing quality gearbox repair services is very critical in ensuring that your equipment is well maintained. Key aspects of gearbox repair include:● Inspection and Diagnosis: Proper evaluation to determine the cause of the problem in order to find an appropriate solution.● Component Replacement: Replacing specific components that have gone bad with high-quality components with a view of repairing the product. Conclusion Selecting a gearbox is therefore informed by certain factors, quality of the gearbox, suitability of the gearbox, reputation of the manufacturer among others. Hiring the best and affordable gearbox and also taking time in repairing and maintaining the machinery will ultimately increase the operations of the machinery.

FAQs1. How can I get the best gearbox manufacturer in Ahmedabad?

The price of these products varies and it is important to look for manufacturers who are reputable with long experience, many products, and exceptional after sale services.

2. When should I take my gearbox for service or how frequently should I do that?

They maintenance practices of the equipment which involve inspection, cleaning and lubrication should be carried out at least every 6-12 months to 10-12 months depending with the operating conditions and frequency of use of the equipment.

#gearbox manufacturer#gearbox repair Ahmedabad#worm gearbox manufacturer Ahmedabad#gearbox repair#worm reduction gearboxes Ahmedabad#reduction gear manufacturers#reduction gearbox manufacturers#gearbox manufacturing Ahmedabad#gearbox repair services Ahmedabad#worm reducer gearbox Ahmedabad#gear box manufacturing Ahmedabad#gearbox repair cost Ahmedabad#double reduction gearbox Ahmedabad#horizontal to vertical gearbox Ahmedabad#gearbox vertical Ahmedabad#Top ten Gearbox Manufacturers Ahmedabad#worm gearbox repair ahmedabad#worm gearbox manufacturers#buy worm reduction gearbox#worm gears suppliers#double reduction gearbox

0 notes

Text

Powdered fertilizers require the precise manufacture of fertilizer production machines

Powdered fertilizer, seemingly as fine as dust, contains a huge amount of energy. It quickly dissolves in the soil, providing plants with timely and comprehensive nutrition. Whether it is a large number of elements such as nitrogen, phosphorus, potassium, or a variety of medium and trace elements, powdered fertilizers can meet the growth needs of different crops with their high nutrient content. For those crops that need to be replenished quickly, powdered fertilizer is like a timely rain, bringing vitality and vitality to them.

However, in order to produce high-quality powdered fertilizers, advanced fertilizer production machines are indispensable. First of all, the crusher plays a vital role in the production of powdered fertilizer. It can crush various raw materials, such as ore and organic waste, into fine particles, laying the foundation for subsequent processing. By precisely controlling the particle size of the crushing, the uniformity and stability of the powdered fertilizer can be ensured, making it easier for plants to absorb and utilize.

Then comes the mixer. In the mixer, different fertilizer raw materials are mixed according to precise formula ratios to achieve the best nutrient balance. Advanced mixers can ensure that various raw materials are fully mixed to avoid nutrient imbalance. This is especially important for powdered fertilizers, because only fertilizers with uniform nutrients can provide stable and reliable nutritional support for crops.

In addition, the screening machine is also an important equipment in the production process of powdered fertilizer. It can screen out the particles that do not meet the specifications and ensure that the particle size of the powdered fertilizer meets the requirements. At the same time, the screening machine can also remove impurities and improve the purity of fertilizer. Through the fine screening of the screen, the quality of the powder fertilizer has been further improved.

In short, powdered fertilizer is the delicate nourishment of agriculture, and fertilizer production machines are the precise manufacturing tools to achieve this goal. With the continuous progress of agricultural science and technology, fertilizer production machines will continue to innovate and improve, providing a strong guarantee for the production of more high-quality and efficient powdered fertilizers. Let's look forward to powdered fertilizers playing a greater role in the agricultural field and contributing to the sustainable development of agriculture.

0 notes

Text

MN13 Grade High Manganese Steel Plates

Introduction

MN13 Grade High Manganese Steel Plates are renowned for their high wear resistance and toughness. These steel plates, commonly used in the mining, construction, and heavy engineering industries, are ideal for applications that require a high level of abrasion resistance. The high manganese content in MN13 steel, typically around 12-14%, gives it the unique ability to harden on impact, making it suitable for high-wear environments.

Applications of MN13 High Manganese Steel Plates

Given their unique properties, MN13 Grade High Manganese Steel Plates are widely used across various industries:

Mining and Quarrying: The plates are ideal for manufacturing components like excavator buckets, crusher jaws, and impact hammers that face extreme wear and tear in the mining and quarrying industries.

Railway and Transportation: Due to their high impact resistance, MN13 steel plates are used in manufacturing components like railway crossings and track work that endure constant impact and friction.

Construction and Earthmoving: MN13 plates are utilized in construction equipment, such as bulldozer blades, loader buckets, and dump truck liners, that need to withstand abrasive materials like sand, gravel, and rocks.

Cement and Power Plants: The steel plates are used in cement and power plants for applications such as chutes, hoppers, and liners, where material handling equipment is exposed to high levels of abrasion and impact.

Military Applications: Due to their hardness and resistance to shock, MN13 steel plates are also used in military applications for making ballistic protection equipment and armor plates.

Advantages of MN13 Grade High Manganese Steel Plates

Superior Durability: MN13 plates offer exceptional durability and a longer lifespan than other types of steel, reducing the need for frequent replacements.

Cost-Effective: The reduced need for frequent repairs or replacements lowers operational costs, making it a cost-effective choice for many heavy-duty applications.

Versatility: Suitable for a wide range of industries and applications, these plates provide versatility in design and functionality.

High Impact Resistance: MN13 steel plates withstand extreme impact without deformation, making them ideal for high-impact applications.

Environmentally Friendly: The long lifespan and reduced need for replacement help in minimizing waste and the environmental impact of manufacturing.

Chajed Steel Limited is a victor among the most anticipated Supplier, importers, Exporter in a wide degree of MN13 High Manganese Steel Plates High Yield in India. Broad Ready Stock Inventory Certified to MN13 High Manganese Steel in Warehouse and Processing Facility. Most Trusted Supplier of MN13 High Manganese Steel Plates. Mn13 is to some degree high manganese steel material, which is the best choice for disavowing high impacts, high loads among wear-safe steels.

Mn13 Hot Rolled Steel Plates have shocking properties in restricting strong impacts scratched a territory and high weight scratched zone. In like manner, Mn13 Steel Plates won't be pummelled when in application and are unquestionably not hard to be catted, welded and mutilated when taking mechanical machining works. Stockist and Stockholder of High Manganese Steel Plates to request MN13.

Main feature High Manganese Include

Severe wear on the surface has a work-hardening effect on the austenitic structure of this steel.

This, when combined with the level of carbon in accordance with the international standards, leads

To increase hardness from 200BHN (in as delivered plate) up to an in-service hardness of at least 600BHN.

This work-hardening capability renews itself throughout in-service life. The under layers not work-hardened maintain an excellent resistance to shock and a very high ductility

Chemical Composition

C

Mn

Si

P

S

0.90-1.20

11-14

0.30-0.80

max 0.035

max 0.030

Conclusion

MN13 Grade High Manganese Steel Plates stand out for their excellent wear resistance, work hardening properties, and high toughness. These features make them an ideal choice for industries and applications where components are exposed to severe wear and impact. The ability of MN13 steel to harden under stress, combined with its high ductility and toughness, ensures a high-performance material that meets the demanding needs of modern engineering and industrial applications.

For More Information:

Visit Our Website -https://www.chhajedman.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Sustainable Practices in Indian Limestone Industry

The industry of limestone is a key factor in the development of economics in India as it contributes to projects for infrastructure including cement production as well as a myriad of other industries. Being a significant participant in the world limestone market, India is home to many limestone manufacturers and suppliers who are progressively adopting sustainable methods. This shift to sustainability isn't just important to protect the environment, but to ensure long-term sustainability.

The Importance of Sustainable Practices in Limestone Mining

Limestone mining, although vital to many industries, is also a major environmental issue. The process of extraction can cause destruction of habitats, pollution of water and air quality concerns. As the awareness of environmental concerns rises the urgent necessity for the industry of limestone in order to use more eco-friendly methods to minimize the impact of these activities.

Key Sustainable Practices in Limestone Mining

1. Responsible Mining Techniques

The modern limestone mines are using responsible mining methods to limit the impact on the environment. This includes targeted mining that is focused on removing only the best quality limestone, leaving the lower-quality deposits unexplored. This reduces waste and lessens the impact on the ecosystem.

2. Efficient Resource Management

Effective resource management is an essential element for sustainable mining. Limestone producers in India make use of advanced technology to maximize extraction of resources. For example the utilization in the use of 3D models and satellite imaging assists in accurate estimation of the resources which helps reduce over-extraction and waste.

3. Rehabilitation and Reclamation

The post-mining rehabilitation of land is vital to restore ecological balance. The most reputable lime producers in Jodhpur and the best limestone manufacturers in Rajasthan are at the forefront in the implementation of reclamation programs. The programs are aimed at replanting the plants as well as restoring natural habitats and making sure that the land is able to support the biodiversity of the area after mining operations end.

Innovations by Top Limestone Manufacturers

1. Energy-Efficient Technologies

Energy consumption is a major problem when processing limestone. Leading producers of limestone in Rajasthan have invested in energy efficient methods to decrease the amount of carbon they emit. These breakthroughs include high-efficiency grinders and crushers, in addition to renewable energy sources like wind and solar energy to power operations.

2. Water Management Practices

Water is an essential resource for limestone processing; managing it is crucial to ensure sustainable methods.limestone suppliers in India are currently implementing systems for recycling water that permit the reuse of water used in the process of production. In addition, a few firms have invested in systems for harvesting rainwater to help meet their water requirements and decrease dependence on local water sources.

3. Waste Management and Recycling

A more efficient waste management system is an additional aspect that Indian limestone producers are making progress. A lot of companies are focused on recycling waste products resulting from the processing and mining stages. For instance, limestone fines that are typically regarded as to be waste, can be used to fill the gaps in construction materials, which reduces pollution from garbage disposal.

Case Study: Best Lime Manufacturers in Jodhpur

Jodhpur, the city Jodhpur is famous for its abundant limestone reserves is home to the top lime producers in India. These companies are setting the bar in sustainability practices within the lime manufacturing industry.

One of the most notable examples is [Company Namethat has incorporated many green practices into its work. They have invested in cutting-edge pollution control equipment that reduces emissions. It has also adopted a zero waste policy which ensures that all by-products are reused or recycled. In addition the [Company Name] works with local communities to help support the reforestation of their communities and increase the biodiversity of local communities.

Case Study: Leading Limestone Manufacturers in Rajasthan

Rajasthan is another major region of India's limestone industry, with a number of top companies leading the way in sustainable practices. The company name in Rajasthan is known for its dedication to environmental green practices. The company has embraced modern mining methods that reduce disturbance to the land and has implemented complete environmental management systems to control and reduce environmental impact.

Furthermore the company has created a comprehensive social engagement strategy that is focused on improving the living conditions of the local population. This includes offering jobs and training opportunities, in addition to aiding the local community with infrastructure initiatives.

The Role of Government and Policy in Promoting Sustainability

The government's regulations and policies play an important role in improving green practices within the industry of limestone. In India the government has launched a variety of initiatives to improve the environmental standards of mining operations. They include more stringent environmental impact assessment, regulations on disposal of waste, and incentives for the adoption of green technology.

The Ministry of Environment, Forest and Climate Change (MoEFCC) has established guidelines for sustainable mining practices that are required for all Best Lime Manufacturers in jodhpur. The compliance with these guidelines ensures that mining operations are carried out in a sustainable and ecologically responsible manner.

Challenges and Future Directions

Although substantial advancements have been made, there remain issues to tackle in the pursuit of sustainable development in the limestone industry. The issue of illegal mining, insufficient implementation of regulations on environmental protection and the expense of adopting new technologies present ongoing issues.

To meet these challenges to address these issues, it is crucial for the business to keep making investments in development and research, as well as to collaborate with environmental and government organizations, and increase awareness of sustainable practices among all parties.

Conclusion

It is believed that the Indian lime industry has reached a crucial moment in its progress towards sustainability. The best limestone manufacturers in Rajasthan together with the top lime producers located in Jodhpur and the top limestone producers in Rajasthan are making admirable efforts to adopt eco-friendly methods. From responsible mining practices as well as efficient management of resources to the most innovative water and waste management practices, the business is setting new standards in sustainable development.

#limestone suppliers in india#best Lime Manufacturers in jodhpur#best limestone manufacturers in rajasthan

0 notes

Text

Jaw Crusher Manufacturers - Stone Crusher Machine Plant

KV Metal Gold Crush is engaged in manufacturing industrial Jaw Crusher and Stone Crusher We specialize in providing Best Material Handling, Jaw Stone Crusher Machine

#sand making machine manufacturer#stone crusher machine manufacturer#jaw crusher machine manufacturer#jaw crusher machine#vibrating screen machine manufacturer#jaw crusher manufacturers#single toggle jaw crusher#double toggle jaw crusher#stone crusher manufacturers#jaw crusher plant manufacturers#stone jaw crusher machine#double toggle jaw crusher manufacturers#jaw stone crusher machine#stone crusher machine plant#stone crusher plant manufacturers#single toggle jaw crusher manufacturers#double toggle stone crusher#m-Sand Making Making#100 tph Stone Crusher Plant#50 tph Stone Crusher Plant#200 tph Stone Crusher Plant#250 tph Stone Crusher Plant#500 tph Stone Crusher Plant with cone crusher#105 tph Stone Crusher Plant#two stage plant manufacturer#three stage plant manufacturer#four stage plant manufacturer

0 notes

Text

Best Crusher Plant Manufacturer

Craftsmencrusher stands as the epitome of excellence in the realm of crusher plant manufacturing, revered as the best in the industry. With a relentless dedication to quality, innovation, and customer satisfaction, Craftsmencrusher has established itself as a leader in crafting high-performance and reliable crusher plants. Each plant is meticulously designed and engineered to meet the specific needs and requirements of clients, whether for mining, construction, or recycling applications. Craftsmencrusher utilizes cutting-edge technology and premium-quality materials to ensure the durability, efficiency, and longevity of their crusher plants, setting a new standard for excellence in the industry. Moreover, the company's team of experienced engineers and technicians work tirelessly to provide comprehensive support and assistance to clients throughout the entire process, from initial consultation to installation and beyond. Craftsmencrusher's unwavering commitment to excellence, coupled with their passion for innovation and customer satisfaction, has solidified their reputation as the go-to choice for discerning clients seeking the best crusher plant solutions. Whether for large-scale industrial projects or smaller-scale operations, Craftsmencrusher delivers unparalleled quality, reliability, and performance, making them the undisputed leader in crusher plant manufacturing.

0 notes

Text

Jaw Crusher Manufacturer and Supplier in Indore Buy the best Stone Crusher Machine Plant, Vibrating Screen, Sand Making Machine, and more at the best price

#jaw crusher manufacturer#best jaw crusher#sand making machine in Indore#stone crusher machine manufacturer#quality stone crusher plant#mobile stone crusher manufacturer

0 notes

Text

From Selection to Installation: Your Ultimate Mobile Impact Crusher Buying Guide

Investing in a mobile impact crusher is a significant decision for any construction or mining operation. It's not just about purchasing a piece of equipment; it's about securing a tool that can enhance productivity, efficiency, and profitability. From initial selection to final installation, here's your comprehensive guide to navigating the process smoothly.

Understanding Your Requirements

Before diving into the market, it's crucial to assess your project needs and operational requirements. Consider factors such as the type of material to be crushed, required output size, production capacity, and mobility needs. Understanding your specific requirements lays the groundwork for an informed decision-making process.

Researching Available Options

Once you've defined your requirements, embark on thorough research of available mobile impact crusher plant models. Explore various manufacturers, their reputations, and the technologies they offer. Look for features such as mobility, crushing capacity, fuel efficiency, and ease of maintenance. Compare different models to identify the one that best aligns with your project needs and budget constraints.

Assessing Performance and Reliability

Performance and reliability are paramount when selecting a mobile impact crusher. Look for features that ensure efficient crushing, consistent output, and durability in demanding operating conditions. Evaluate factors such as engine power, crushing chamber design, and hydraulic systems. Opting for a high-performance crusher enhances productivity and minimizes downtime.

Considering Mobility and Transportability

One of the key advantages of a mobile impact crusher is its mobility. Consider the terrain and operating environment where the crusher will be utilized. Evaluate features such as track-mounted or wheeled designs, compact dimensions, and ease of transportation. Choose a crusher that offers optimal mobility without compromising performance or safety.

Ensuring Compliance and Safety

Safety and regulatory compliance are non-negotiable aspects of mobile impact crusher purchases. Ensure that the equipment meets industry standards and safety regulations. Consider features such as remote control operation, safety interlocks, and emergency shutdown systems. Prioritize the safety of operators and maintenance personnel throughout the crusher's lifecycle.

Engaging with Manufacturers and Suppliers

Direct engagement with manufacturers and suppliers provides valuable insights into product specifications and customization options. Schedule consultations to discuss your project requirements and seek recommendations tailored to your needs. Establishing a collaborative relationship facilitates a smooth transition from selection to installation.

Evaluating Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership over the crusher's lifecycle. Factor in maintenance expenses, spare parts availability, fuel consumption, and operational costs. Conduct a comprehensive cost-benefit analysis to assess the long-term viability and return on investment of your purchase.

Finalizing the Purchase Agreement

Once you've identified the ideal mobile crushing and screening plant, finalize the purchase agreement with clarity and diligence. Ensure that all terms and conditions, including warranties, delivery schedules, and payment terms, are documented accurately. Review the contract thoroughly to mitigate potential disputes or ambiguities.

Coordinating Installation and Commissioning

The installation and commissioning phase marks the culmination of the purchasing process. Coordinate closely with the manufacturer or supplier to schedule installation timelines and logistics. Allocate resources for site preparation, equipment assembly, and testing procedures. Prioritize staff training to ensure operational proficiency and safety awareness.

Implementing Maintenance and Service Protocols

Regular maintenance and service are essential to maximize the performance and lifespan of your mobile impact crusher. Develop comprehensive maintenance protocols encompassing routine inspections, lubrication schedules, and component replacements. Establish a relationship with authorized service providers to ensure timely support and spare parts availability.

Embracing Continuous Improvement

The acquisition of a mobile impact crusher represents a significant investment in your operation's efficiency and productivity. Embrace a culture of continuous improvement by soliciting feedback, monitoring performance metrics, and exploring technological advancements. Stay abreast of industry trends and best practices to optimize your crushing operations and enhance overall productivity.

In conclusion, purchasing a mobile impact crusher requires careful consideration and strategic planning. By following the guidelines outlined in this comprehensive buying guide, you can make informed decisions and secure a crusher that meets your operational needs and performance expectations. Remember, the right crusher not only enhances productivity but also positions your operation for long-term success in the competitive landscape of construction and mining industries.

0 notes

Text

Boosting Industrial Efficiency: The Importance of Metal Fabrication in Melbourne

Metal fabrication in Melbourne is crucial for productivity and profitability whether one is in charge of a manufacturing plant, a construction site, or a fleet of heavy machinery. This is something that machining companies are aware of and can handle. If machines' parts are not maintained, they have a reputation for wearing out rapidly, which can lead to costly running expenses from frequent breakdowns. As soon as there are minor flaws, it's crucial to schedule skilled professionals for repairs in order to avoid any failures and to protect the individuals using the device.

An Overview of a Few Important Machining Services

CNC Machining Services: It is a precision machining in Melbourne service and CNC machines are now required for a variety of activities, including laser cutting, turret punching, and tube bending. This type of work should only be assigned to knowledgeable CNC specialists. Leading specialists offer cutting services, CNC turret punching, CNC laser cutting, and other services.

Workshop Services and Capabilities: Top machining service providers provide a wide range of workshop services and capabilities, such as CNC lathes, presses, line boring, heavy equipment, and CNC milling.

Welding Services: To weld different metal pieces, welding is necessary in all industrial buildings, including mills, factories, refineries, and other structures. The top businesses provide a variety of welding services, including TIG, ARC, and aluminium welding.

Plant Design Engineering Services: It is crucial to give careful thought to the industrial facility's design and worker safety. Working with expert businesses can help complete plumbing, structural design, electrical work, procurement, and other associated essential tasks as swiftly and simply as possible.

Install & Commission: Leading engineering service suppliers are also competent in the installation and commissioning of systems in many industries. Among the industries are sand mining, quarrying systems, and paper machine modifications.

Experts are necessary when providing the best solution for industrial issues, such as repairing crusher swing jaws or grinding large-diameter bores. Get the best pricing on solutions to a variety of industrial problems by speaking with reliable machining service suppliers.

Source

0 notes

Text

Shreecom InfoTech-Banking & custom built software Service Provider

Shreecom Infotech is the best software Company. It’s a service provider in the USA, UK, France, UAE, Belgium and other European countries. It’s running successful services since 1992. It Provides software solutions for banking and finance. We also offer marketing management software. These applications are developed in modern platforms with all kinds of computer systems. The software developed by us is user-friendly, comprehensive and flexible. Also these varied in many sectors such as manufacturing, service industries, and mining industry, and all these services are widely applicable. These are competency lies in offering Co-Op Credit Society Software, Pat Sanstha Software, Credit Society Software, Banking Software, Core-Banking Software, and Retail Banking Software. We have a team of software engineers that develop tailored software for our clients. Utility service industry and transportation companies. We ensure that our customers benefit from our best services. We have garnered a huge clientele which includes Hyundai, MNGL, and large mini-banking sectors also we have 27+ experience in the software development area.

We have discussed and planned new projects and have many years of knowledge and experience.

Also, we provide software development and mobile application development services in the UK, USA, Belgium, and France. Expertise in high-quality robust services and these are:

1. Custom Software Development:-

Our Software engineers have converted your business logic into scalable solutions using different technology platforms.

2. Cloud Based Solutions:

We have strong experience in paaS, saaS and laaS of cloud computing services.

3. Mobile Application Development:-

We have a high level of expertise in mobile app development skills.

4. Web Application Development:-

Our development team uses many modern frameworks like JavaScript, angular, and Microsoft tools.

5. Software testing:-

Our team has strong experience in QA automation with expertise in web, mobile and API testing.

6. Data Mining:-

Our database team has many years of experience in designing complex custom database systems for businesses. It is used to find business insight that assists organizations with tackling issues.

We completely customize in high-quality products such as:

1. POS Software:-

It is a complete solution for retail businesses that is easy to use with many modern features.

2. Account payable software:-

Electronic invoice approval system for a paperless office. Large and small companies simply pay bills which is cash flow. It helps to improve the company’s productivity.

3. Utility Billing software:-

It is a self-service web portal solution that integrates billing, online payment etc.

4. Co-operative credit society software:-

This software is commonly used in local languages and used for transactions in the banks.

5. Crusher Billing software:-

This software was specially created for managing stone, and crushed sand at the crusher plant.

It Also Provides POS software, Net banking software, Inventory management software solutions, and Service call management software solutions, Online web development services. We have our in-house talented team with great skills in software product engineering.

#CO-OP CREDIT SOCIETY SOFTWARE#PAT SANSTHA SOFTWARE#EMPLOYEES CO OP CREDIT SOCIETY SOFTWARE#SALARY EARNERS SOCIETY SOFTWARE#GRAMIN BIGAR SHETI SOCIETY Software#MULTI STATE CO OP CREDIT SOCIETY SOFTWARE#PAT PEDHI SOFTWARE#NIDHI SOFTWARE

0 notes

Text

Difference Between Coal Handling and Ash Handling Plant

In thermal power plants, coal is the primary gasoline used to generate electricity. The combustion of coal produces a significant amount of ash, which must be handled and disposed of properly. Coal handling and ash handling are two essential processes in thermal power plants, but they range appreciably in their scope and complexity. We, Intech Engineers, one of the best Ash Handling Plant Manufacturers in Delhi, are here with this blog where you get the clear hints about coal handling and ash handling difference. Let’s have a closure look:

Coal Handling Plant

A coal handling plant is accountable for receiving, unloading, storing, and conveying coal to the boilers. The important additives of a coal handling plant encompass:

Unloading facilities: Coal is typically delivered to the plant via rail or truck. Unloading facilities consisting of rotary car dumpers and truck hoppers are used to transfer the coal from the vehicles to the plant's conveyors.

Storage yards: Coal is stored in open yards or enclosed silos. The storage yards have to be designed to prevent the coal from catching fireplace or being infected by moisture or other substances.

Crushers: Coal is crushed to a uniform length before being conveyed to the boilers. This enables us to make certain that the coal burns flippantly and correctly.

Conveyor belts: Conveyor belts are used to move coal throughout the plant. The belts are designed to face up to the abrasive nature of coal.

Ash Handling Plant

An ash handling plant is chargeable for amassing, conveying, and removing the ash created from the combustion of coal. The predominant additives of an ash handling plant encompass:

Ash collection hoppers: Ash is amassed from the boilers in hoppers placed under the furnace.

Conveyor belts: Ash is conveyed from the gathering hoppers to the ash coping with the device.

Ash conditioning systems: Ash conditioning structures are used to reduce the moisture content material of the ash and make it less difficult to deal with.

Ash disposal systems: Ash is disposed of in quite a few methods, along with landfilling, ponding, or use in production materials.

Key Differences

The key differences among coal handling and ash handling plants are:

Material properties: Coal is a solid cloth that is enormously clean to address. Ash, then again, is the best particulate fabric that can be tough to handle due to its abrasive nature and tendency to shape clumps.

Temperature: Coal is treated at ambient temperature. Ash, on the other hand, is treated at high temperatures. It requires using a special system that can withstand high temperatures.

Environmental impact: Coal handling can generate dirt emissions. Ash handling can generate dirt emissions and water pollution. As a result, ash-handling plant life must be designed to decrease their environmental effect.

Concluding Words Coal handling and ash handling are essential processes in thermal processes plants. While they percentage some similarities, also they fluctuate appreciably in their scope and complexity. Reach us- one of the best Coal Handling Plant Manufacturers in India, we are happy to help!

#Ash Handling Plant Manufacturers#Ash Handling Plant#Ash Handling Plant Manufacturers In India#Ash Handling Plant Manufacturers In Delhi#Best Ash Handling Plant Manufacturers In India#Coal Handling Plant Manufacturers#Coal Handling Plant#Coal Handling Plant Manufacturers In India#Coal Handling Plant Manufacturers In Delhi

0 notes

Text

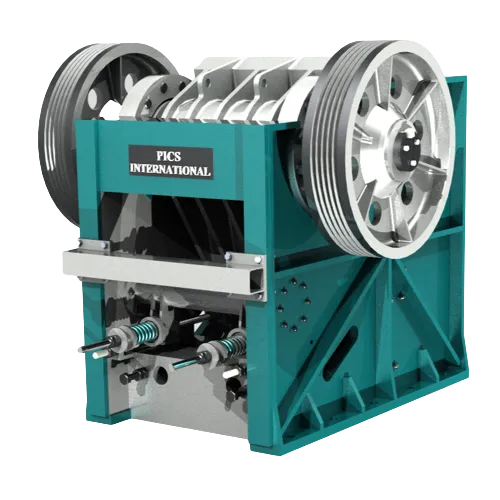

Pics International We Engineer, We Manufacture, We Deliver..... Worldwide

Picson Construction Equipments Pvt. Ltd.

PICS INTERNATIONAL is a leading global engineering and manufacturing unit engaged in supplying cutting-edge crushing and screening equipment for applications in mining, quarrying, and infrastructure projects, Construction and Demolition and waste recycling.

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition waste. These high-quality industrial equipments ensures a fine and precise performance promises an end result which is nothing less than the best.

Our Quality Products

1.CRUSHER

2.IMPACTORS

3.WASHING SYSYTEM

4.SCREENS

5.FEEDERS

6.MIXING

OUR PRODUCTS

1.Single Toggle Jaw Crusher

2 Double Toggle Jaw Crusher

3 Cone Crusher HC Series

4 Cone Crusher GC Series

Our Products

Crusher

Sand Making Machine

C & D Waste Recycling Plant

Washing System

Semi Mobile Series

Applications

Quarrying & Aggregate

Sand Processing

C & D Waste Recycling

Mining

Industrial Sand

Supports

Parts

Service

Operator Training

Dealer Portal

Manuals

Get In Touch

986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat, India.

9081777945

https://www.picsinternational.com/

#Stone Crusher#Cone Crusher#Jaw Crusher#C&D Waste#C&D Waste Recycling#C&D Waste Recycling Plant#C&D Waste Recycling Plant Manufacturer#C&D Waste Recycling Plant Manufacturer in India#Construction & Demolition Waste Recycling#Construction & Demolition Waste#Stone Crusher Manufacturers

0 notes