#gear box manufacturing Ahmedabad

Explore tagged Tumblr posts

Text

Understanding Worm Gearbox Ratios and Their Role in Optimizing Operations

Worm gearboxes are considered an important part of any industrial applications that require large amounts of torsion and accurate control. The ratio in case of a worm gearbox is a most critical specification that bears major influence over speed control, torque magnification, and gearbox effectiveness. This blog will help you understand worm gearbox ratios, how these units work and how they could benefit or affect your operations.

What Are Worm Gearbox Ratios?

The worm gearbox ratio defines how much the input speed is slowed down and vice versa how much the torque is increased. For instance, a 10:1 ratio means that for the [output gear] to make a round the input gear has to make 10 rounds. This results in:

A tenfold reduction in speed.

A tenfold increase in torque.

Such ratios are useful in applications where low-speed high torque operations are desired.

How Gear Ratios Affect Torque

Torque Multiplication

A decrease in speed results in a corresponding increase in torque. For instance:

The compound can adopt a one ratio or one to ten, transforming the input torque to deal with the extensive load.

This makes the worm gearbox well suited in hoists that require high torque, in winches and other mechanical systems.

Why Gear Ratio Matters for Your Operations

A. Efficiency and Power Optimization

Choosing the correct gear ratio means that the motor runs at the right speed to be efficient. Higher LG and TM ratios generate more torque than lower ratios, The Battleship OHP achieves a certain power speed/torque balance that is important for energy efficiency.

B. Precision and Control

Therefore in some areas such as robots, and auto systems, the right gear ratio provides improved control. Higher ratios provide slow and continuous motion required in many applications to offer great precision and product quality.

Choosing the Right Gear Ratio for Your Application

Several factors influence the choice of a worm gearbox ratio:

Load Requirements: Systems handling heavy loads, such as cranes, benefit from higher ratios to ensure smooth operation.

Precision Needs: Applications like conveyor belts or robotic arms require lower ratios (e.g., 3:1 to 5:1) for precise motion control.

Real-World Applications of Worm Gearbox Ratios

A. Material Handling

Conveyor systems often use gear ratios of 5:1 to 20:1, enabling controlled material movement with minimal wear on the system.

B. Precision Machinery

Lower ratios are used in robotic systems and automated lines to ensure smooth, precise operations.

Conclusion

Understanding the appropriate worm gearbox ratio is critical to enhancing the performance and safety of your machinery. The right ratio can improve operational consistency and reduce energy costs by optimising speed reduction and torque multiplication.

Contact us today to find the perfect worm gearbox for your operations!

#worm gearbox repairs#double reduction gear box#decades of gearbox experience#worm gear manufacturer#worm reduction gearbox#reduction gearbox manufacturers#gearbox application in industries#gearbox manufacturer in ahmedabad#worm screw gearbox factory#gearbox repair Ahmedabad#double reduction gearbox ahmedabad#gear box manufacturing ahmedabad#reduction gear manufacturers#gearbox repair cost ahmedabad#gearbox manufacturer#gearbox vertical ahmedabad#gearbox repair services ahmedabad#buy worm reduction gearbox#worm gearbox manufacturer Ahmedabad#worm reduction gearboxes Ahmedabad#worm gearbox manufacturer gujarat#gearbox manufacturer in gujarat#gearbox manufacturer rajasthan#gearbox repair rajasthan#worm gearbox manufacturer Rajasthan#reduction gearbox manufacturer Rajasthan#reduction gearbox manufacturer maharashtra

0 notes

Text

Leading SMSR Gear Box manufacturers in India - Shaft Mounted Speed Reducer Manufacturers In Ahmedabad - Nisuka Industries

Nisuka is a renowned name in the industry as one of the top SMSR gear box manufacturers in Ahmedabad, India and trusted Shaft Mounted Speed Reducer manufacturers. We specialize in providing high-quality, durable, and efficient gearboxes designed to meet the demands of various industrial applications. Our products are known for their superior performance, robust construction, and long service life, making them an ideal choice for industries like mining, quarrying, and material handling. At Nisuka, we are committed to delivering innovative solutions that enhance productivity while ensuring reliability and cost-effectiveness for our clients.

#SMSR Gear Box#Manufacturing#SMSR Gear Box manufacturer#Shaft Mounted Gearbox Manufacturer#Conveyor Gearbox Manufacturer

2 notes

·

View notes

Text

Understanding PE Liners: Applications, Benefits, and Frequently Asked Questions

Plastic Bag Manufacturers in Ahmedabad, or polyethylene liners, are versatile products used in various industries for their durability, flexibility, and cost-effectiveness. These liners are primarily made from polyethylene, a type of plastic known for its chemical resistance and low moisture absorption. In this article, we will delve into the applications, benefits, and common questions related to PE liners.

What are PE Liners?

PE liners are sheets or films made from polyethylene, which can be either low-density polyethylene (LDPE) or high-density polyethylene (HDPE). LDPE liners are known for their flexibility and high impact resistance, making them suitable for applications requiring a softer and more pliable material. On the other hand, HDPE liners are stiffer and offer greater tensile strength and chemical resistance, ideal for more demanding environments.

Applications of PE Liners

1. Agriculture: In agriculture, Plastic Bags Manufacturers in Gujarat are used as pond liners, greenhouse covers, and silage covers. Their impermeability ensures that water stays contained, reducing wastage and enhancing the efficiency of irrigation systems. Additionally, these liners protect crops from pests and weather conditions, promoting better yield.

2. Construction: PE liners play a critical role in the construction industry as vapor barriers and underlayments. They prevent moisture from seeping through floors and walls, thereby protecting buildings from dampness and mold. These liners are also used in landfills as geomembranes to contain waste and prevent leachate from contaminating the groundwater.

3. Packaging: In the packaging industry, PE liners are widely used to line boxes, bags, and containers, ensuring that the contents are protected from moisture and contamination. They are especially useful in the food industry to preserve the freshness of products and extend shelf life.

4. Healthcare: In healthcare, PE liners are utilized in the production of disposable gloves, aprons, and other protective gear. Their chemical resistance and hygiene properties make them suitable for medical environments where contamination control is critical.

5. Environmental Protection: PE liners are essential in environmental protection efforts, such as lining containment ponds for hazardous materials and lining canals to prevent water loss. Their durability and resistance to chemicals ensure that they effectively contain pollutants and protect the environment.

Benefits of PE Liners

1. Durability: PE Bag Manufacturer in Ahmedabad are known for their long-lasting durability. They resist punctures and tears, making them suitable for harsh environments and heavy-duty applications.

2. Chemical Resistance: One of the key advantages of PE liners is their resistance to a wide range of chemicals, including acids, bases, and solvents. This makes them ideal for use in environments where exposure to hazardous substances is a concern.

3. Flexibility: PE liners, especially those made from LDPE, offer excellent flexibility. This makes them easy to install and adapt to various shapes and surfaces, ensuring a tight and secure fit.

4. Cost-Effectiveness: Compared to other lining materials, PE liners are relatively inexpensive. Their longevity and low maintenance requirements also contribute to their cost-effectiveness, providing a high return on investment.

5. Environmental Friendliness: PE liners are often recyclable, reducing their environmental impact. Advances in recycling technologies have made it possible to reuse and repurpose polyethylene materials, contributing to sustainability efforts.

Conclusion

PE liners are a versatile and reliable solution for a wide range of applications across different industries. Their durability, chemical resistance, and cost-effectiveness make them an excellent choice for tasks ranging from agricultural irrigation to environmental protection. By understanding their properties and proper usage, businesses and individuals can effectively utilize PE liners to achieve their goals while maintaining safety and sustainability.

Frequently Asked Questions (FAQ) about PE Liners

Q1: What is the difference between LDPE and HDPE liners?

A1: LDPE (Low-Density Polyethylene) liners are more flexible and have higher impact resistance, making them suitable for applications requiring pliability. HDPE (High-Density Polyethylene) liners, on the other hand, are stiffer and offer greater tensile strength and chemical resistance, ideal for more demanding environments.

Q2: How are PE liners installed?

A2: The installation process for PE liners depends on the application. Generally, the surface must be prepared by cleaning and leveling. The liner is then unrolled and laid out, ensuring it covers the entire area without wrinkles. For larger installations, seams are welded together to create a continuous barrier. It's important to follow manufacturer guidelines for specific installation procedures.

Q3: Are PE liners environmentally friendly?

A3: PE liners can be environmentally friendly, especially when they are made from recycled materials and are recyclable themselves. Their durability also means they do not need to be replaced frequently, reducing waste. Proper disposal and recycling of PE liners contribute to their environmental friendliness.

Q4: Can PE liners be used for potable water storage?

A4: Yes, PE liners can be used for potable water storage. However, it is crucial to ensure that the liner is made from food-grade polyethylene, which is safe for contact with drinking water. These liners must comply with regulations and standards for potable water storage.

Q5: How do you repair a damaged PE liner?

A5: Repairing a damaged PE liner involves cleaning the damaged area thoroughly and using a patch of the same material to cover the tear or puncture. The patch is typically welded or adhered to the liner to ensure a secure and leak-proof repair. It is advisable to consult the manufacturer's guidelines or a professional for repair procedures.

0 notes

Text

Are You Looking For Gear Pumps Manufacturer in India?

If you are Looking for Gear Pumps for you industries. Creative Engineers is leading manufacturer and Supplier Gear Pumps of from Ahmedabad, India. Gear Pumps available in Ahmedabad, Vadodara, Vapi, Gandhinagar, Surat, Rajkot, Halol, Nagpur, Mumbai, Bangalore, Hyderabad, Pune, Pimpri Chinchwad. South Africa, Dubai, Nepal, Sri Lanka.

What is Working of Gear Pump?

A Gear Pump and rotary gear pump is a type of positive displacement pump, It uses two or more gears to move fluids or liquids smoothly. Gears are placed in such a way that it rotates within a casing, then it creates a suction on inlet side of the pump, which draws in fluid, and then pushes the fluid out of the pump on the outlet side. Gear pumps are commonly used in hydraulic systems, lubrication systems, and in the transferring of fuel and other viscous liquids.

Rotary Gear pump are known for their compact design, high efficiency, and the ability to handle a range of fluid viscosities. The can pump transfer viscous fluids at high pressures and are often used in industrial and automotive applications where precise fluid control is required.

Gear pump Advantages

Gear pump has Only two moving parts.

Only one stuffing box.

Non-pulsating discharge.

Excellent for high-viscosity liquids.

Constant and even discharge regardless of all pressure conditions.

For ore Details Click here : https://www.sspumpsindia.com

0 notes

Text

Are You Searching For The Gearbox Manufacturers In India?

Welcome to Ram Industries, the best gearbox manufacturers in Ahmedabad, Bengaluru, Raipur, Kolkata, Orissa, Bombay, Indore, Coimbatore and India etc. places where we specialize in building gearboxes that can handle the toughest challenges.

Our gearboxes are built to last, so you can be confident that your operations will continue to run smoothly. We're not just selling gearboxes; we're selling you peace of mind. Whether you're looking for a reliable gearbox for power generation or use in the cement or mining industries, we have you covered.

Let's work together to find the perfect gearbox solution for you.

What are the top gearbox manufacturers in India?

There are many gearbox manufacturers in India, including Ram Industries, Elecon Engineering, Bharat Gear, and Bonfiglioli.

What are the types of gearboxes manufactured in Coimbatore, India?

Indian gearbox manufacturers in Coimbatore has produce various types of gearboxes, including helical gearboxes, bevel gearboxes, worm gearboxes, planetary gearboxes, and industrial gearboxes.

What is the price range of gearboxes manufacturer in Bombay, India?

The price range of gearboxes manufacturer in Bombay, India varies widely depending on the type of gearbox, size, and quality. Generally, Indian manufacturers offer competitive prices compared to their international counterparts.

What is the quality of gearboxes manufactured in Orissa, India?

Indian gearboxes manufacturers in Orissa, produce that meet international standards such as ISO and AGMA. However, the quality of gearboxes varies among manufacturers, and it is important to research the reputation and track record of a specific manufacturer before making a purchase.

What is the delivery time for gearboxes manufactured in Raipur, India?

Delivery time for gearboxes manufactured in Raipur, India depends on the manufacturer, the type and size of the gearbox, and the quantity ordered. Usually, it might last anywhere from a few days and many weeks.

What are the industries that use gearboxes manufactured in Kolkata, India?

Gearboxes manufactures in Ahmedabad, Bengaluru, Raipur, Kolkata, Orissa, Bombay, Indore, Coimbatore and India are used in a wide range of industries, including power generation, cement, mining, sugar, and steel.

What are the features and benefits of gearboxes manufactured in Indore, India?

Features and benefits of gearboxes manufactured in India may vary depending on the manufacturer and type of gearbox. Generally, they are known for their durability, reliability, and competitive pricing.

How do I choose the right gearbox manufacturer in India?

When choosing a gearbox manufacturer in India, it is important to consider factors such as reputation, quality, delivery time, after-sales service, and price. Conducting research and reading customer reviews can also be helpful.

How can I contact gearbox manufacturers in India for inquiries and orders?

Gearbox manufacturers in India can be contacted through their websites, email, phone, or in-person visits to their offices or factories.

What is the warranty and after-sales support offered by gearbox manufacturers in India?

The warranty and after-sales support offered by gearbox manufacturers in India varies among manufacturers. Generally, they offer a warranty period ranging from 12 to 24 months and after-sales support in the form of repair and maintenance services.

We introducing ourselves as a one of the leading Gearbox manufacturers in Kolkata, Ahmedabad, Orissa, Bengaluru, Raipur, Bombay, Indore, Coimbatore in India worm reduction gear unit and other mechanical reduction gear boxes.

Thank you for considering Ram Industries for your gearbox needs.

We understand that choosing the right gearbox can be challenging, but we're here to help make the process easier for you. Our team of experts is committed to delivering high-quality products and outstanding after-sales support.

We're confident that our gearboxes will meet and exceed your expectations. Contact us today to learn more about how we can help you find the perfect gearbox solution.

#Gearbox Manufacturer in Ahmedabad#Gearbox Manufacturer in Orissa#Gearbox Manufacturer in Raipur#Gearbox Manufacturer in Coimbatore#Gearbox Manufacturer in Kolkata#Gearbox Manufacturer in India#Gearbox Manufacturer in Bombay

1 note

·

View note

Text

Buy High-quality Gear Box At Best Price

Prakash Engineering and Gear Co. is one of the best gear box manufacturers in India. We manufacturer and supplies various type of crusher gear, SMSR gear box, conveyor, and many more with excellent after sale service. Contact us to buy best quality gear box.

#gear box manufacturer#gear box manufacturer in india#gear box manufacturer in ahmedabad#gearbox#gear box

2 notes

·

View notes

Photo

A machine consists of a power source and a power transmission system, which provides controlled application of the power(Gear Box Manufacturer) in Ahmedabad India. The most common use of Gear Box is in motor vehicles, where the transmission adapts the output to drive wheels.

0 notes

Link

#Elevator Amc#Capsule Elevators#Elevator Gear Box Manufacturers#Drum Waiter Mfrs#Passenger Lift Manufacturers In Ahmedabad#Elevator Installation Services In Ahmedabad

0 notes

Link

Nishi Enterprise is an industry leading helical gear box manufacturer in Ahmedabad, India. It offers helical gears with stronger and longer teeth that can be used for effectively carrying large and heavy loads in the construction of cement, plastics, rubber and other types of industries.

#helical gears#helical gearbox#helical gear box manufacturer in Ahmedabad#helical gear manufacturer in Ahmedabad#helical gear manufacturers in India#herringbone gears#helical gear box suppliers

0 notes

Text

High quality Gearbox Supplier in Ahmedabad

JS Gear is the only helical gear manufacturers in India with the in- house R&D facilities that have approved from the government of India. You are surely got the perfect solution with us. We are one of the best designers and manufacturers of industrial gear box suppliers that can be used for a wide range of applications. We regularly deal in different types of gear box products and associated spare parts that are used in wide range of industries. Our experts can also handle repairing contracts for all kinds of gearboxes. We are designing and manufacturing various types of gear boxes and industrial gear based on current industrial standards and norms.

Premium Helical Gearbox Manufacturer

We have an extensive team of professionals who can work on designing and manufacturing different types of helical inline gearboxes and industrial gears based on current industrial standards and norms. We manufacture and supply customize gearbox to the clients as per needs and specification. We pride ourselves on our quality, on-time deliveries and our competitive pricing. We have earned a reputation for providing premium helical gearbox to the Indian market for a wide variety of applications. While widely known by our capabilities for all types of gearbox, we have extensive experience in the production of a wide variety of custom gears that meet the most stringent quality standards.

#helical gear manufacturers#industrial gear box suppliers#helical inline gearboxes#premium helical gearbox

1 note

·

View note

Text

Maximizing Efficiency in Stone Cutting: How Worm Reduction Gearboxes Make a Difference

The nature of the stone-cutting business requires accuracy, dependability, and speed for the value to be added to products. Reduction gearboxes are reportedly worm reductions gear, a pacesetter in stone-cutting across equipment manufacture to help boost performance and control costs. As for this gearbox, this blog seeks to discuss how it assists in operations in the stone cutting industry.

Superior Torque Output for Heavy-Duty Applications

Stone cutting machines deal with hard and massive materials that need high power for operation. Worm reduction gearboxes excel in:

Delivering High Torque: They effectively translate motor speed into the high level of torque essential for carving and other applications on rock like materials.

Managing Heavy Loads: Its construction allows for their stable operation under a significant level of loading.

Compact Design with Multi-Purpose Applications

Industrial applications especially need to get the space optimized to the fullest. Worm gearboxes stand out due to:

Streamlined Design: Originally, they do not occupy a lot of space making it easier to install them on various equipment that possibly can be available.

Flexible Mounting Options: It is available in machine positioning methods including horizontal, vertical and square mounting to suit a host of layouts.

Ensuring Precision and Operational Stability

Precision and stable conditions are important characteristics in operating the stone cutting equipment. Worm gearboxes contribute by:

Providing Controlled Speed Reduction: Due to this, their gear ratio counts allows for blending steady speed and accuracy to make precise cuts all the time.

Dampening Vibrations: The wo mechanism quiets the vibrations ensuring enhanced cut quality as well as smooth functionality.

Energy Efficiency for Cost-Effective Operations

Energy costs are considered one of the main expenses of any organisation and business. Worm reduction gearboxes support:

Minimizing Power Loss: Their design provides maximum conversion of energy, thus minimizing wastage of energy which is not required.

Long-Lasting Performance: Longevity with very little maintenance is usually a plus since it reduces the general cost of operations and reduces on time the machines would be out of service.

Extending Equipment Longevity

Stone-cutting machines remain under great stress continuously. Worm gearboxes protect these machines by:

Reducing Mechanical Stress: They share operational loads evenly hence; they cause little stress or pressure to other parts.

Resisting Harsh Conditions: Made using strong rugged materials, worm gearboxes are able to withstand abrasive operating conditions and usage.

Quieter Operations for a Better Work Environment

Acoustic control is a much neglected area of manufacturing concerns. Worm gearboxes help by:

Smooth Gear Engagement: Its design minimizes backlash hence less operational noise.

Self-Locking Capability: This avoids reversals that are disruptive and damaging to operational stability, thus extending noise reduction measures.

Diverse Applications in Stone Cutting

To cater to the specific needs of the stone-cutting industry, worm gearboxes offer customization options such as:

Bridge Saws: A machine employed in sawing of large stones into various sizes and shapes as may be required.

Block Cutters: Most suitable in breaking huge pieces of stones into smaller chunks.

Conclusion

Worm reduction gearbox plays the most critical role in increasing the performance, reliability and accuracy in stone cutting machines. High quality yet cost effective customized gearboxes will enable enhancement of business operations, low maintenance costs, and high customer satisfaction. These gearboxes are not just parts – they are the soul of today’s stone-cutting industry success.

#worm gearbox repairs#worm gear manufacturer#reduction gearbox manufacturers#worm reduction gearbox#worm reduction gearbox near me#gearbox repair cost ahmedabad#gear box manufacturing ahmedabad#double reduction gearbox ahmedabad#gearbox repair ahmedabad#buy worm reduction gearbox#gearbox repair services ahmedabad#gearbox manufacturer#gearbox vertical ahmedabad#reduction gear manufacturers

0 notes

Text

Types of Electric Motors Most Industries Use

Electric motor manufacturing has evolved over the last few decades. Today, there is one suitable motor available for each variety of industrial requirements. If you are looking for a reputed electric motor manufacturer company, Shri Rang Enterprise can be your one-stop choice at any time. One size fits all has never been the concept for motors.

The industries engage in a wide variety of applications and tasks that require an equally diverse range of electric motors. Hence, the market has an extensive collection of motors featuring different size, shape, and potential to augment the diverse industrial applications. Here are some of the types of motors most industries use.

AC Brushless Motors

If motion control is on your mind, nothing can beat the performance of AC brushless motors. When the motor remains operative, inside the stator, a rotating magnetic field generates. This helps synchronize the stator and the rotor. This variety of motors requires permanent electromagnets to operate.

DC Brushed Motors

So far as this type of motor is concerned, the current flow remains dependent on brush orientation on the stator. Some of the electric motors feature a different functional specification. For these, the relative brush orientation with respect to the bar rotor remains decisive of the current flow. For these motors, the commentator plays a critical role.

Direct Drive

What makes this variety of motors unique and better than the traditional servo ones are its low wear and tear technology and high-efficiency performance? These motors accelerate quickly, which makes these a faster choice. Also, if buying a durable motor is on your mind, these can be a smart choice.

DC Brushless Motors

Inventing motors having high performance in smaller space was the primary motive behind making the DC brushless motors. Therefore, these motors offer high efficiency and feature a precise shape. Especially when compared to the AC models, these seem considerably precise.

Stepper Motors

External magnets electronically manipulate the internal rotor of the stepper motors. The manufacturers use either a soft metal or permanent magnets to make the rotor of the stepper motor. Through the process of winding, the rotor teeth remain aligned with the magnetic field. This helps in flexible point-to-point movement in fixed accelerations.

Servo Motors

To facilitate positioning, these motors come with a feedback sensor. Therefore, in robotics, this variety of motors finds a wide application. This variety of motors uses both linear and rotary actuators. Plenty of applications in several industries deploy low-cost servo motors these days.

Linear Motors

Unrolled stators and rotors are integral to these linear motors. These stators and rotors produce linear force along the length of the device. The flat active section of linear motors features two ends. These are specifically more accurate and faster than the rotatory motors.

Ahmedabad is amongst the most reputed city for supplier of all kinds of induction motors dealers, gear motor, gear boxes, variable frequency drive with all types of mechanical requirement manufacture and available stock of all material spares available.

Our accomplished team of experts are proficient to understand the current modern pattern and deal best administration to achieve our client’s requirements. We additionally offer types of appropriate items and repairing and service of AC Drives, CG Motor and many other types of motors, drives etc.

With an undertaking to expand our business globally, we follow to moral - strategic policies and attempt to complete 100% percent client fulfilment. We can convey great - quality in consistence with industrial and client necessities for their need of Flame Proof Motor, Crane Duty Motor and BBL Motor as dealers and suppliers all over the India.

Our main aim is to provide all types of motor and drive services with great quality in consistence of industrial standard levels and necessities.

The varying range of motors available in the market ensures that you will find something you need for sure. All you have to check before buying one are the specifications that make any motor superior over the other similar options.

Shri Rang Enterprise is a manufacturer of electric motors, and we are also Bharat Bijlee Motors dealers in Ahmedabad. We have all types of electric motors, AC drives, BCH switchgear, and control gears.

1 note

·

View note

Text

Gearbox Manufacturers in Ahmedabad

A gearbox is a mechanical device that transmits power and motion from a source, such as an engine, to a machine or device that uses it. It typically consists of a series of gears and shafts that transmit power and motion by meshing the teeth of the gears together. The gearbox manufacturers in Ahmedabad may be arranged in a variety of configurations to increase or decrease the speed and torque of the transmitted motion.

Gearboxes are used in a wide range of applications, including vehicles, industrial machinery, and power tools. They are designed to transmit power efficiently and smoothly, and may also be used to change the direction of the transmitted motion.

Certainly! There are a few more things that readers might want to know about gearboxes. Such as types of gearboxes available in the market, transmission ratio, efficiency, maintenance application, and various other relevant topics of the gearbox.

Types of gearboxes: There are many different types of gearboxes, including planetary gearboxes, worm gearboxes, helical gearboxes, and bevel gearboxes, among others. Each type has its unique characteristics and is suitable for different applications.

Transmission ratios: The transmission ratio of a gearbox refers to the ratio of the output speed and torque to the input speed and torque. A gearbox with a high transmission ratio will reduce the output speed and increase the output torque, while a gearbox with a low transmission ratio will do the opposite.

Efficiency: The efficiency of a gearbox refers to the percentage of the input power that is transmitted to the output. A highly efficient gearbox manufacturers in Ahmedabad will transmit a large proportion of the input power, while a less efficient gearbox will lose some of the power through friction and other losses.

Maintenance: It is important to properly maintain a gearbox to ensure that it continues to operate effectively and efficiently. This may include regularly lubricating the gears, replacing worn or damaged parts, and checking for any other issues that may affect the gearbox's performance.

Applications: Gearboxes are used in a wide variety of applications, including vehicles (such as cars, trucks, and motorcycles), industrial machinery, and power tools. They are also used in many other types of equipment, including conveyor systems, elevators, and wind turbines.

Ram industries have been working in the niche market to offer quality products to the people.

The company manufactures a variety of products such as helical gear box, worm gearboxes, gearbox Manufacturers in Ahmedabad and worm reduction gear in Ahmedabad.

We manufacture the products by using the latest technology along with highly skilled professionals who are having experience in manufacturing quality products.

0 notes

Text

Extruder Screw Barrel manufacturers in India | Radhekrishnaexports

Extruder Screw Barrel manufacturers in India offered by Radhekrishna exports Machinery Manufacturing, Ahmedabad, Gujarat. Radhekrishna exports renowned engineering company have been serving in the field of the screw – barrel manufacturing company. India's largest size screw barrel manufacturers. We create Screw Barrels, one thing, every day. Designing, processing and manufacturing screws and barrels and gear boxes. For plastic machines. We offer and produce all varieties of machine screws in India at the most competitive prices.

0 notes

Text

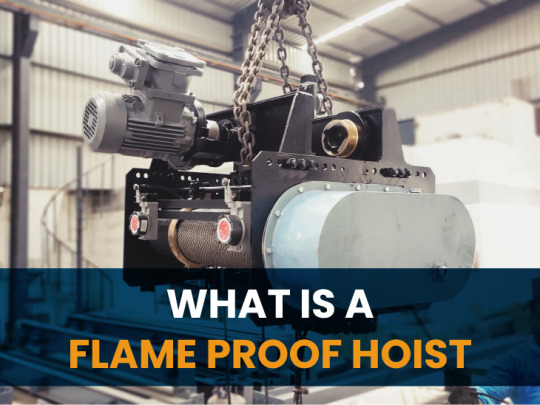

What is flame proof hoist ?

An improved version of the standard electric hoist is the Flame proof electric hoist. Its flame-proof variation utilizes exposed Flame-proof components and is of the Flame-proof variety. Because these components are comprised of non-sparking materials, they are somewhat Flame-proof. The volume and weight of an electric hoist are smaller than those of other lifting devices. Despite being a little lifting device, it has a very strong lifting effect and high lifting efficiency.

What Makes Flame Proof Electric Hoists Crucial For Industries?

One of the crucial lifting tools in manufacturing and industrial production is the electric hoist. The industry is getting increasingly split as the economy and business grow. The demands of working circumstances cannot be met by a standard electric hoist in industries with combustible and explosive qualities. The Flame Proof Electric Hoists were created as a result to address the issue of material handling in these unique working circumstances.

This kind of hoist is useful where combustible liquids, vapours, and gases are present and is employed to stop any unfavourable accidents in your business. The fundamental tenet of flame-proof enclosures is that internal Flames cannot be prevented and that dangerous areas are not completely removed from electrical equipment. 80% of businesses currently work in hazardous environments and with hazardous equipment. According to statistics, almost 70% of injuries and fatalities happened when there was no flameproof wire rope hoist.

Working Principle of Flame Proof Electric Hoists

In addition to the Flame-proof elements, the electrical parts it employs, such as control boxes, control buttons, stoppers, and so on, are likewise self-contained Flame-proof equipment. Additionally, a soft-wrapped power introducer is used. In order to prevent sparks from friction or collision when the Flame Proof Hoist is in use, Flame-proof precautions are also applied to the mechanical components of the entire hoist. Despite the Flame-proof safeguards that have been put in place, it is still important to make sure that the heavy machinery's surface temperature doesn't rise above 110 degrees Celsius while it is in use.

When the covers are securely fastened, an enclosure for electrical machinery and switch gear will be able to bear internal Flame of combustible gas or vapours that may enter or originate inside the enclosure without causing damage and without transmitting the internal Flame to the exterior gas or vapours for which it is intended to be employed through any joints or other structural holes in the enclosure.

Where Should Flame Proof Hoist be used?

Flame Proof Hoist are Specially designed for usage in highly flammable environments. In coal mines, refineries, and chemical processing facilities, a variety of modes are possible.

Many plants handle materials that could explode if they are in close proximity to spark-prone machinery. Such an Flame poses a risk to people's lives, health, and property.

We advised using our Flame proof electric hoists for material handling in this region to reduce the likelihood of a catastrophe.

Conclusion

Flame proof hoist of exceptional quality are offered by many manufacturers in India. Even so, there are several suppliers of Flame Proof Electric hoists in Ahmedabad, with Stalmac Enterprise being one of the top Flame Proof Hoist Producers.

0 notes

Text

Prakash Engineering & Gear Co is one of the best NU worm Gearbox manufacturer. we manufacturer quality product that meets your needs.

#gear box manufacturer in ahmedabad#gear box manufacturer#nu gearbox#nu gearbox manufacturers#Nu Type Worm Gearbox

1 note

·

View note