#BeltConveyor

Explore tagged Tumblr posts

Video

youtube

DCCD Material Cleaning Equipment Demonstration@DCCD_Group

0 notes

Text

VGA Automation curve belt conveyor is a type of conveyor system used for transporting materials or products around a curved path. Unlike straight belt conveyors that move items in a linear fashion, curve belt conveyors are designed to handle curves, bends, and changes in direction. They are commonly used in industries such as manufacturing, logistics, and warehousing to move items smoothly along a curved route within a facility.

#VGAAutomation#VGApackingmachine#VGAautomationcandypackingmachine#VGA#vgaautomationCurveBeltConveyor#CurveBeltConveyvgaautomation#ConveyorSystems#MaterialHandling#Logistics#Manufacturing#WarehouseAutomation#IndustrialConveyors#CurveConveyors#BeltConveyorTechnology#ConveyorDesign#beltconveyor#MaterialHandlingconveyor#ConveyorTechnology#conveyor#pvcbeltconveyor

1 note

·

View note

Text

Titan material handling pvt. Ltd provide Belt Conveyor at best cost, It Is the best Belt conveyor, Flat Belt Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes

Text

DKT Engineering

Our PVC & PU Conveyor Belt Product line covers genral and food grade bekts that are used in nearly every industry abd come in a variety of sizes and varieties

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#konvey#automation#industry#materialhandling#belts#manufacturing#conveyorrollers#quarry#industrial#beltconveyor#quarrylife#bearing#conveyorbelts#pvcbelt#beltsplicer#vulcanising#r#enduroply#qpiltd#fabrication#quality#conveyoridlers

0 notes

Text

Exporter of Belt Conveyor In Botswana

Exporter of Belt Conveyor In Botswana R Mech Machines LLP established in 2008 in Ahmedabad, Gujarat, India, is a global leader in the manufacture, supply, and export of Belt Conveyors and related products. Our belt conveyors are primarily designed for efficient material handling, offering the flexibility of utilizing side working tables or the conveyor belt for swift assembly. We tailor our conveyors to match specific process requirements, taking into account factors like load weight and the size of transported goods. Types of Belt Conveyors we offer: - Roller Bed Conveyor Belts - Flat Belt Conveyors - Modular Belt Conveyors - Cleated Belt Conveyors - Curved Belt Conveyors - Incline/Decline Belt Conveyors - Sanitary and Washdown Conveyors - Specialty Conveyor Belts Specifications: - Usage/Application: Industrial - Belt Width: 600 mm - Brand: R Mech - Belt Thickness: 10 mm - Features: Heat and Chemical Resistant - Finish: Color Coated - Load Capacity(Kg): 180 kg/Feet - Voltage: 240 V - Automation Grade: Semi-Automatic - Voltage (Volt): 220/380 V - Body Material: Mild Steel - Belt Material: Rubber - Frequency: 50-60 Hz Key Features: - Low energy consumption - High reliability with minimal maintenance - Heavy-duty idlers with anti-friction bearings for extended idler life and reduced horsepower requirements - Robust frames and structural supports for system rigidity - Easy installation - Zero speed switch Our Belt Conveyors are suitable for conveying and elevating various materials, including grains, fertilizer, aggregate, cement, chemicals, and mining products. RMech Machines LLP is Exporter of Belt Conveyor In Botswana and various locations like Gaborone, Molepolole, Maun, Serowe, Kanye, Mochudi, Palapye, Lobatse, Moshupa, Tonota, Tutume, Orapa, Kasane, Nata, Lerala, Shakawe, Kang, Dukwl, Nata, Rasesa, Sojwe, Manyana, Sebina, Morwa, Sowa, Tumasera, Tsao, Mmashoro. If you are interested in our high-quality products, please do not hesitate to reach out to us for further information. Read the full article

#Ahmedabad#BeltConveyor#BeltConveyorInBotswana#Dukwl#Exporter#ExporterofBeltConveyor#ExporterofBeltConveyorInBotswana#Gaborone#Gujarat#India#Kang#Kanye#Kasane#Lerala#Lobatse#Manufacturer#Manyana#Maun#Mmashoro#Mochudi#Molepolole#Morwa#Moshupa#Nata#Orapa#Palapye#Rasesa#RMechMachinesLLP#Sebina#Serowe

0 notes

Text

Belt conveyor manufacturer in India

Sawhney Industries Belt conveyor manufacturer

As one of the leading conveyor belt conveyor manufacturer in India, Sawhney Industries offers a wide range of conveyor belts of unmatched quality and standards.

Belt conveyors are used in many industries. All industries use different types of belt conveyors depending on their specifications and requirements.

With the belt conveyors, materials, or goods are moved in bulk from start to finish while maintaining quality. Imagine how much time we would lose without a belt conveyor. In short, belt conveyors are a proven choice as they are lightweight and reliable.

Sawhney Industries is one of the leading Belt conveyor manufacturer in India, manufacturing and supplying a wide range of high-quality conveyor belts. As a renowned material handling equipment manufacturer in India, we also provide customized solutions for the specific requirements of our customers around the world. We use high quality raw materials to manufacture products that are of the highest quality combined with the highest industry standards. Our products are used for various purposes in various industries.

How does it work?

Conveyor belts are simply thick, wide and strong belts that are attached to the conveyor in a circle. Belts are mounted on two or more pulleys, rotors or drums driven by a motor. The part of the loop is known as the conveyor belt and is usually made up of several layers of material depending on the application. The first layer given the belt its shape, and the second layer helps transport the material.

When the engine is running, discs, rotors, or drums rotate. Due to this rotation, the conveyor begins to rotate in one direction due to friction with the belt. When belt conveyors are used to transport large or bulky items, typically long or long distances, the rollers are mounted on a support surface. They hold things in place and protect the harness from weakening.

Product Benefits

Sawhney Industries has the largest manufacturing capability and equipment to produce machines with the highest performance, unrivaled durability and reliability, easy installation, easy maintenance, affordable and many other benefits.

Call us:

Rajeev Sawhney: +91-9810197254

Karan Sawhney: +91-9999950064

Mail us- sawhneyindustriesindia@gmail.com

Address: B-71/7, Mayapuri Industrial Area Phase-I, New Delhi-110064

#SawhneyIndustries#BeltConveyor#ConveyorManufacturer#IndustrialConveyors#MaterialHandling#ConveyorSystems#MadeInIndia#Manufacturing#Engineering#Automation#ConveyorBelt#QualityConveyors#InnovationInConveyors#Logistics#SupplyChain#FactoryAutomation#IndustrialEquipment#ConveyorSolutions#BulkMaterialHandling#IndiaManufacturing

0 notes

Text

The Importance of Food Grade Turning Belt Conveyors

Food grade turning belt conveyors enhance efficiency and hygiene in food processing. They navigate tight spaces, ensuring safe transport of products while minimizing contamination risks. Ideal for various applications, they are essential for modern food production facilities.

For more information

visit our website https://justpaste.it/6n442

Or Contact Us; 9520989666

0 notes

Text

Mechanical Conveying Systems that Excel: Prochem's Expertise Unleashed

Discover unparalleled efficiency with Prochem's Mechanical Conveying Systems, where expertise meets innovation. Our cutting-edge solutions redefine material handling, ensuring seamless and precise transportation of goods. From robust belt conveyors to flexible screw conveyors, Prochem's expertise is unleashed to optimize your processes. Trust in our commitment to excellence as we elevate your operations with advanced technology and reliable mechanical conveying systems designed to excel in every application. Elevate your material handling experience with Prochem – where expertise meets unparalleled performance.

#ProchemInnovation#MechanicalConveyingExcellence#MaterialHandlingSolutions#InnovativeTechnology#EfficientTransportation#BeltConveyors

0 notes

Text

5 Key Advantages Of Belt Conveyors For Maximizing Efficiency

If you have ever had a job that required you to carry heavy goods all day, you're aware of some of the advantages of belt conveyors. You might have back pain to prove it! It takes a lot of time and effort for human beings to move minerals and rocks or boxes and food supplies. And the right conveyor belt can make your company's task much easier. Plus, belt conveyors lower labour expenses while increasing production. So, let's go over all the benefits and advantages of adopting conveyor systems and how they will affect your work.

What is a Conveyor System?

A conveyor system is a mechanical handling device used in the industry to transfer various commodities, cargo, and products. This technique drops workforce, hazards, and labor expenses in the workplace. These are quite useful for transporting large objects from one location to another. This method employs a belt, roller, and wheels to transfer goods or big loads. An electric motor can be used to power these systems. Material handling systems, such as belt conveyors, vary depending on the materials or goods transported.

Conveyor systems, or mechanical handling devices, are used in various sectors to convey goods and loads from one location to another within a given space. There are many conveyor systems, such as belt conveyors, chain conveyors, screw conveyors, roller conveyors, slat conveyors, drag chain conveyors, overhead conveyors, and Powered Roller Conveyors!

5 Advantages of Belt Conveyors for Industries

When moving a product, a conveyor makes the operation much faster and easier. Even in extreme environments, heavy-duty belt conveyors can continue transporting heavy, jagged objects. You can unwind knowing that your manufacturing process will not be disrupted.

What’s more? Let’s take a look!

They Lower Costs:

With a conveyor in place, you will require fewer human resources, which will help you save money in the long term. Conveyors also work quickly, which helps you reduce manufacturing hours. The faster the products move down the assembly line, the fewer hours are required to keep the lights on. Conveyors consistently boost efficiency by 15% across a wide range of industries.

They Reduce Downtime:

Another advantage of a conveyor system is that it decreases downtime. Even if your factory has a truck or forklift, human resources are still required to load and unload the vehicle and drive it. You can keep a conveyor running continuously, enabling continuous loading and unloading, with the flip of a switch – as long as it doesn’t break down. When you choose a high-quality conveyor system, you will have to fix it less frequently.

They Give you an Edge Over Competitors:

Conveyors are now ubiquitous in many sectors. With a high-quality automated mobility strategy, your company may stay caught up in the competition. It improves productivity, quality control & customer service. Customers can count on your organisation if your conveyor consistently delivers the same product every time. When customers use your services, they know what they're getting.

You Can Move Back and Forth:

Many chain conveyors can move in both directions. It is especially useful if your products must pass through many lines before they are ready to ship. All you need is someone to operate the controls. Slowing down the conveying system at any point during production is also possible.

They Make the Workplace Safer:

A happier workplace is safer. A conveyor reduces the likelihood of an operator being injured by a worker pushing, hauling, or lifting a large load. Whether you've been delivering things by hand or forklift, a conveyor system minimises collisions, making your workplace safer!

Find The Best Conveyor System For Your Company!

Apart from all the benefits above, conveyor systems are extremely adaptable. They are easily adaptable to different industries, functions & various systems. Also, the ability to adapt to diverse produce sizes and weights is an added benefit to an installation.

Want to reap all the advantages of belt conveyors? Delta Stark can help. We are the leading manufacturer of belt conveyors who can help you find the exact conveyor system you need!

Reach out to us today!

0 notes

Text

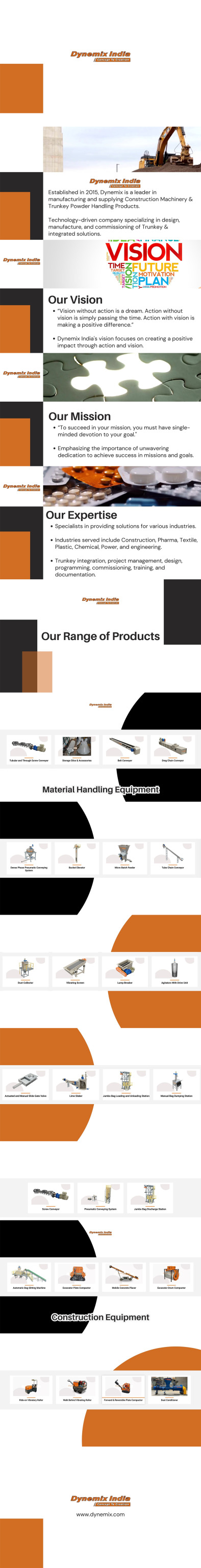

Dynemix India Engg. Pvt. Ltd - Transforming Industries with Innovation

Welcome to Dynemix India Engg. Pvt. Ltd., a rapidly growing company dedicated to revolutionizing the construction industry. With a strong commitment to personalized creative engineering services, we've been designing and manufacturing a wide range of cutting-edge equipment since our inception.

About Us: At Dynemix, our overriding commitment is to provide you with the most effective equipment in the construction industry. Our comprehensive product range, coupled with deep technical knowledge and a wealth of experience, ensures that you get top-notch solutions for your construction needs.

Quality Commitment: Our commitment to quality is deeply ingrained in our core values of innovation and tradition. This unique blend allows us to maintain a futuristic vision, ensuring that the products we deliver are not just of high quality but also at the forefront of technological advancement. We take pride in our success, driven by a relentless focus on delivering quality in every aspect of our operations.

Know about Bulk Bag Unloader visit - https://dynemix.com/products/material-handling-equipments/bulk-bag-unloader/

#ConstructionEquipment#DuplexVibratingRoller#RideOnVibratoryRoller#MobileConcretePlacer#ExcavatorDrumCompactor#ExcavatorPlateCompactor#ForwardandReversiblePlateCompactor#MobileConcreteBatchingPlant#TruckMountedBatchingPlant#ConcreteReclaimer#AutomaticBagSlittingMachine#MaterialHandlingEquipment#BulkBagLoader#BulkBagUnloader#BeltConveyors#ScrewConveyors#LumpBreaker#Delumper#BucketElevators#DensePhaseSystem#Agitators#DustCollectors#LimeSlacker#RibbonBlender#ActuatedSlideGateValve#DragChainConveyor#ManualBagDumpingStation#MicroBatchFeeder#PneumaticConveyingSystem#TubeChainConveyor

0 notes

Text

Power Your Operations with Conveyors Joint Belt Industrial

Are you looking to revolutionize your industrial operations and enhance productivity? Look no further than Conveyors Joint Belt Industrial! We are proud to introduce our cutting-edge conveyor systems designed to streamline your processes, increase efficiency, and maximize your output.

Why Choose Conveyors Joint Belt Industrial?

Unparalleled Durability: Our conveyors are built to withstand the toughest industrial environments. With premium-quality materials and robust construction, they ensure long-lasting performance, minimizing downtime and maintenance costs.

Customizable Solutions: We understand that every operation is unique. That's why we offer a wide range of conveyor options tailored to your specific requirements. From belt conveyors to roller conveyors, we have the perfect solution to optimize your workflow.

Efficient Material Handling: Our state-of-the-art conveyor systems excel at moving materials of all sizes and shapes with precision and reliability. Whether you need to transport heavy loads, fragile items, or bulk materials, our conveyors deliver unmatched efficiency.

Advanced Automation: Stay ahead of the competition with our conveyor systems integrated with cutting-edge automation technologies. From automated sorting to barcode scanning, we provide intelligent solutions that streamline your operations and increase throughput.

Safety First: At Conveyors Joint Belt Industrial, safety is our top priority. Our conveyors are equipped with advanced safety features such as emergency stop buttons, protective guards, and automated fault detection, ensuring a secure working environment for your personnel.

Industries We Serve

Our versatile conveyor systems cater to a wide range of industries, including:

Manufacturing: Optimize your production line with our efficient conveyors, reducing manual labor and boosting overall output.

Warehousing: Streamline your warehousing operations by automating material handling, order fulfillment, and inventory management.

Logistics and Distribution: Enhance your logistics operations with our conveyor solutions, enabling faster and more accurate shipment processing.

E-commerce: Power your e-commerce business with our conveyor systems, facilitating smooth order fulfillment and timely shipping.

0 notes

Video

youtube

Detailed Process of Ceramic Insert Lagging Welding and Installation@DCCD...

#youtube#dccd factory bulkmaterialhandling cement beltconveyor powerplant rubberlagging solutions coal port conveyorsystems#conveyormanufacturer

0 notes

Text

22日、大阪の四貫島PORTにて行われる上映イベント「Calling」に参加します。自分はAプログラムで『Dan Chi Gai』、Bプログラムにて『Taphophobia』を上映させていただく他、座談会にも参加予定です。千鳥橋駅周辺・此花地区では関連の1ヶ月に渡る大型アートイベント「ニュ〜パライソ別世界編」が開催中ですのでよろしくお願いします。

Calling in KONOHANA 2025

2019年より活動を続けている自主上映団体 Callingですが、今回5年ぶりとなる有観客の上映会を行います。今回は、東京を中心に活動する映画上映団体 グランド・レベル・シネマにもご参加いただきます。劇映画、実験映画、アニメーション、と多彩なジャンルの作品と様々な世代の映像作家との交流をお楽しみいただけます。ぜひお越しください。 モリトラコーヒーとDONEによるフード出店もあります。

■Introduction 自主上映団体 Calling は、京都、大阪、神戸の京阪神間に在住し活動する4名の映像作家により立ち上げられた上映団体である。 様々なジャンル、スタイル、場所に対してCalling(呼ぶ)し、交流していく活動を通じて新たな映像の在り方を希求している。

前身企画として2019年2月9日から11日の3日間に京都五条lumen galleryにて平成生まれの映像作家のための自主上映会「平成Calling」を企画。 日本全国の地域で活動する若い世代の映像作家の作品を集め上映を行なった。

以降、東京(渋谷 イメージフォーラム)・大阪(此花 FIGYA)・韓国 釜山(釜山国際映画祭 招待企画)など様々な地域で上映活動を意欲的に行い活動している。

Calling is an independent screening organization founded by four filmmakers living and working in the Kyoto-Osaka-Kobe area. Through activities to call and interact with various genres, styles, and places, we are seeking a new way of presenting the moving image works.

As a predecessor project, we organized a voluntary screening event, "Heisei Calling" for filmmakers born in Heisei era (1989-2019) at the Gojo lumen gallery in Kyoto from February 9th to 11th, 2019. The event gathered and screened the works of young filmmakers from all over Japan.

Since then, we have been enthusiastically conducting screening programs in various places such as Tokyo (Shibuya Theater Image Forum), Osaka (Konohana FIGYA), and Busan, South Korea (Busan International Film Festival Invited Project).

■日時 2/22(土)14:30〜18:00 開場 14:30

■料金 1プログラム ¥1,000- 2プログラム ¥1,800- 1プログラム(大学生以下):¥500-

■会場 PORT 〒554-0014 大阪府大阪市此花区四貫島1丁目6−6 阪神電車千鳥橋駅より徒歩2分 JR西九条駅より徒歩15分

■プログラム 15:00〜16:00 Aプログラム 『Iconological Vision』 - Yüiho Umeoka 『或るひのまぼろし』 -柴原直哉 『BeltConveyor』 - 片岡拓海 『had lived』 -さとうゆか 『Children/wars』 - 丹羽彩乃 『花グループエイリアンライターケース・エイリアンアナルお香立てCM』 - へねちぇん 『「運幸・エイリアン阿永琉お香たて」ご紹介ムービー』 -へねちぇん 『いちょうの森のなかで』-松本玲果 『Study of Steenbeck スティーンベックについて』-藤井アンナ 『Astigmatism 乱視』-藤井アンナ 『Where | Was Born』 - ニシノユキコ 『Haru』 - 大熊誠一郎 『Dan Chi Gai』 - ムラカミロキ

16:10〜16:50 参加作家による座談会

17:00〜18:00 Bプログラム 『ManipulatedColorbars』 - Yüiho Umeoka 『思洞』 - 柴原直哉 『書動一口(くにがまえ)一』-片岡拓海 『在』-さとうゆか 『21:00』 - 丹羽彩乃 『れもんがひえてるれいぞうこ』 -松本玲果 『グランス Glanced』 - 藤井アンナ 『グラウンド・ゼロ』 -ニシノユキコ 『1億光年キロ』-大熊誠一郎 『Taphophobia』 - ムラカミロキ

※上映終了後、来場作家による作品解説あり

■フード モリトラコーヒー DONE

■クレジット 主催 Calling 共催 グラウンド・レベル・シネマ 協力 PORT / ニュ〜パライソ別世界篇 / KONOHANANEST

Facebook Event Page https://www.facebook.com/events/502568836207013/

Calling https://callingcinematheque.jimdofree.com/ X(Twitter): @Calling66920143 https://x.com/Calling66920143 Instagram: @calling_cinematheque https://www.instagram.com/calling_cinematheque/ Facebook Page https://www.facebook.com/CallingCinematheque/ YouTube Channel https://www.youtube.com/@calling7347

グラウンド・レベル・シネマ https://www.groundlevelcinema.com/ X(Twitter): @groundlevel2020 https://x.com/groundlevel2020 Instagram: @ground_level_cinema https://www.instagram.com/ground_level_cinema/

四貫島 PORT https://shikanjima-port.jp/ Instagram: @port.jp https://www.instagram.com/port.jp/ Facebook Page https://www.facebook.com/p/PORT-100063276875043/ Tel. 090-9860-2784 〒554-0014 大阪府大阪市此花区四貫島1-6-6 PORT 阪神なんば線「千鳥橋」駅より下車徒歩2分 JR環状線・阪神なんば線「西九条」駅より下車徒歩20分 千鳥橋駅から改札を出て右側。道路に出てまた右側に進みます。 ファミリーマートを右折して商店街を進み、左手角に歯医者さんのある路地に入ると、路地を抜けたところ右手角がPORTです。

モリトラコーヒー Instagram: @moritora_coffee https://www.instagram.com/moritora_coffee/ X(Twitter): @morinagi1 https://x.com/morinagi1

DONE Instagram: @done_jpn https://www.instagram.com/done_jpn/

ニュ〜パライソ別世界編

開催期間 2/1 - 3/2 VENUE 阪神なんば線 千鳥橋駅 周辺 JR環状線 西九条駅 徒歩約10分 大阪市此花区 梅香、四貫島エリア 「Infomation さぼてん堂」11:00~18:00

「あたらしくて、いつもどおり。いつもどおりで、別世界。」 今年三回目の開催となるニュ〜パライソは、前二回の開催形式とは全く違う形、一ヶ月間の長期で開催することになりました。 今年のテーマは「あたらしくて、いつもどおり。いつもどおりで、別世界。」 一ヶ月間、人々の生活するまちの一つである「千鳥橋」という町の中で、アート作品、音楽、踊り、さまざまな形の表現が紛れ込み、人々がそれぞれの「ニュ〜パライソ」と出会うための導線を作ります。

「ニュ〜パライソ」って? 「ニュ〜パライソ」は直訳すると「あたらしい楽園」となります。 でも、今回わたしたちが行うイベントにおける「ニュ〜パライソ」は単にその言葉通りのものではありません。 当たり前のようにある日々や生活、風景の裏側に、いつも想像の及ばないことがとてつもない数蠢いていて、私たちはそれらに出会って感動したり、時にあえて忘れたり無視したりしながら過ごしている。 そうして見えなくなっているものを、さまざまな視点から見つけ直していこう、新しく見つけてもいこう、という試み、そうしてみつけた視点や風景こそが、「ニュ〜パライソ」だと定義しています。 町の魅力、表現の魅力はさることながら、それぞれの魅力をひとつひとつのトリガーとして、その向こう側に何かを見つけるきっかけにしてほしいと思っています。

私たちは、逃げてみても出迎えてみても同じにやってくる今を皆揃って生きている。 生きていることは、人であっても、猫であっても、魚でも、虫でも、土でも、ミジンコでも、皆おなじ。 愛する者でも、敵でも、罪人でも、賢者でも、皆おなじ。 そんないつもどおりのことも、隣をみたり、足元をみたり、後ろを見たり空を見上げたりするだけで、全く違って見えたり、くっきり見えたり、全く見えなくなったりするのだということを、みんなで思い出したいな、という思いです。

ニュ〜パライソ実行委員会

【主催】ニュ〜パライソ実行員会、さぼてん堂 【助成】一般財団法人おおさか創造千島財団

ニュ〜パライソ https://newparaiso.com/ X(Twitter): @newparaiso https://x.com/newparaiso Instagram: @newparaiso.fes https://www.instagram.com/newparaiso.fes/ note https://note.com/newparaiso/ YouTube Channel https://www.youtube.com/@%E3%81%AB%E3%82%85%E3%81%B1%E3%82%89%E3%81%84%E3%81%9D Shop(stores) https://newparaiso.stores.jp/

さぼてん堂 〒554-0013 大阪府大阪市此花区梅香1-18-19 黄色いお家 X(Twitter): @saboten_dou https://x.com/saboten_dou Instagram: @saboten_dou https://www.instagram.com/saboten_dou/

0 notes

Text

Exporter of Belt Conveyor In Sudan

Exporter of Belt Conveyor In SudanR Mech Machines LLP established in 2008 in Ahmedabad, Gujarat, India, has emerged as a global leader in manufacturing, supplying, and exporting Belt Conveyor and other related products.The main purpose of our belt conveyors is material handling.You can use either the side working tables or the conveyor belt for quick assembly.We construct conveyors based on process requirements, considering the load weight and size of the commodities that need transport.The Types of Belt ConveyorsRoller Bed Conveyor Belts Flat Belt Conveyors Modular Belt Conveyors Cleated Belt Conveyors Curved Belt Conveyors Incline/Decline Belt Conveyors Sanitary and Washdown Conveyors Specialty Conveyor BeltsSpecificationUsage/Application: Industrial Belt Width: 600 mm Brand: R Mech Belt Thickness: 10 mm Features: Heat, Chemical Resistant Finish: Color Coated Load Capacity(Kg): 180 kg/Feet Voltage: 240 V Automation Grade: Semi Automatic Voltage (Volt): 220/380 V Body Material: Mild Steel Belt Material: Rubber Frequency: 50-60 HzFeaturesLow energy consumption High reliability and less maintenance Heavy duty idlers with anti-friction bearings to increase idler life and reduce horsepower requirements Heavy duty frames and structural supports to provide system rigidity Easy to install Zero speed switch Our Belt Conveyors are used for grains, fertilizer, aggregate, cement, chemical, mining conveying and elevating.RMech Machines LLP is Exporter of Belt Conveyor In Sudan and various locations like Khartoum, Omdurman, Khartoum North, Port Sudan, Kassala, Al-Ubayyid, Al-Fashir, Wad Madani, El Geneina, Atbara, Dongola, Rabak, Sennar, Kaduqli, Ed Damer, El Obeid, Medani, Kosti, El Fasher.If you are interested in our high-quality products, please do not hesitate to reach out to us for further information. Read the full article

#Al-Fashir#Al-Ubayyid#Atbara#BeltConveyor#CurvedBeltConveyors#Dongola#EdDamer#ElFasher#ElGeneina#ElObeid#Exporter#ExporterofBeltConveyorInSudan#FlatBeltConveyors#Incline/DeclineBeltConveyors#Kaduqli#Kassala#Khartoum#KhartoumNorth#Kosti#Manufacturer#Medani#Omdurman#PortSudan#RMechMachineLLP#Rabak#Sennar#Sudan#Supplier#WadMadani

0 notes

Text

What are the different media options available for airport branding in the Madurai Airport?

Madurai Airport Advertising

Airport Ad Media for Brand Promotion

1

3

2

01

LUGGAGE TROLLEY

Luggage Trolley ads play important role in airport advertising.

02

CONVEYOR BELT

Conveyor Belt ads at Airport.

03

AIRPORT BILLBOARDS

Airport Billboards in India.

AWhat is the passenger traffic handled by the Madurai Airport on an average basis per month?

The passenger traffic experienced by the Madurai airport on an average is around 8.5 lakh people per month.

AWhat are the different media options available for airport branding in the Madurai Airport?

The various media branding options available for airport advertising at the Madurai Airport are:

Airport Baggage Trolley Advertising

Airport digital screen advertising

Conveyor Belts Advertising

Security Tray Advertising

Wifi Package Advertising

Newspaper Sticker Advertising in the Times of India newspaper

Newspaper Sticker Advertising in the Economic Times newspaper

Advertising in the Interior of a tarmac coach

Advertising in the Exterior of a tarmac coach

Advertising in the waiting/ lounge area of the airport

Advertising in the Security Area Hold of the airport

Advertising in the outside area of the airport

Advertising in the arrival area; and

Advertising in the departure area of the Madurai Airport.

AWhat are the available options for airport advertising in the lounge area of the Madurai Airport?

The available options for airport advertising in the lounge area of the Madurai Airport are:

Digital Vertical Standees

Tabletop Display

LCD with Sponsored Content

Mobile/ laptop charging stations, etc.

AHow many flights are catered to by the Madurai Airport on a monthly basis?

The average number of flights which fly in and out of the Madurai Airport are 9600 per month.

AWhat is the rate of advertising on the digital illuminated screen in the lounge of the Madurai Airport?

The lounge of the Madurai Airport has a provision of Airport digital screen advertising. The rates of advertising on one such screen is 31000 INR per screen per month.

AWhat are the rates of the other media branding options in the Madurai Airport for airport advertising?

To know about the rates of the other media branding options in the Madurai Airport for airport advertising, get in touch with us by calling us at (+91) 99538 47639 or by writing to us at business@myhoardings.com.

AIs there a lounge in the Madurai Airport?

Yes, there is a lounge facility for the flyers in the Madurai Airport.

AIs the Madurai Airport an international one?

Yes, the Madurai Airport does have an international terminal. Besides connecting the city to the other major Indian cities, the airport is also connected to a few other international cities too like Colombo, Dubai, Singapore, etc.

AAre there other charges involved in the interior branding of the tarmac coaches in the Madurai Airport?

Yes, there is an additional printing and mounting charge in the interior branding of the tarmac coaches in the Madurai Airport which is not included in the rate chart of this media branding option.

AWhat are the branding options available in the interior of the tarmac coaches in the Madurai Airport?

The branding options available in the interior of the tarmac coaches in the Madurai Airport for airport branding are:

25-30 grab handles; and

8 static panels.

AHow can I advertise my brand on the exterior of the tarmac coaches in the Madurai Airport?

The advertisement of your brand can be wrapped on both the sides of the tarmac coaches including even the windows of the coaches. The advertisement will be in full display for the entire duration of its operation which is 18 hours.

AWhat is the lead time for the exterior branding of the tarmac coaches in the Madurai Airport?

The lead time for the exterior branding of the tarmac coaches in the Madurai Airport is longer than the usual lead time for the other media branding options which is around 1 weeks’ time in general.

AWhat are the dimensions of these wrap ads on the exterior of the tarmac coaches in the Madurai Airport?

The dimensions of these wrap ads on the exterior of the tarmac coaches in the Madurai Airport will be provided to you at the time of the confirmation of the airport advertising deal with MyHoardings.

AWhat are the dimensions of the design layouts to be pasted on the 3 sides of the luggage trolleys for airport baggage trolley advertising at the Madurai Airport?

The dimensions of the design layouts to be pasted on the 3 sides of the luggage trolleys for airport baggage trolley advertising at the Madurai Airport will be provided at the time of the confirmation of the airport advertising deal with MyHoardings.

AWhat is the minimum time for booking an airport advertising campaign at the Madurai Airport?

The minimum time for booking an airport advertising campaign at the Madurai Airport is 1 month, unless otherwise mentioned or stated.

AHow much tax am I required to pay for booking an airport advertising deal at the Madurai Airport?

For booking an airport advertising deal at the Madurai Airport, you are required to pay an additional GST of 18% on the rates of the different media options that you opt for branding purposes in the airport.

AWhat are the creative design formats for the submission of the design layouts for airport advertising of your brand in the Madurai Airport?

The creative design formats for the submission of the design layouts for airport advertising of your brand in the Madurai Airport are .cdr, .ai and .pdf.

AWhat are the guidelines followed by the Madurai Airport for airport advertising?

The guidelines followed by the Madurai Airport for airport advertising are:

The Madurai Airport authorities follow a strict code of rules for the design layouts of the advertisements. You are to follow each and every one of them closely, failing of which can lead to the rejection of the whole campaign altogether.

For a branding campaign to go live in the Madurai Airport, it takes around 3 weeks of time.

ACan multiple brands advertise in a single ad space in the Madurai Airport?

Yes, the Madurai Airport has the provision of allowing multiple brands to advertise in a single ad space.

AWhen am I required to make the payment for the airport advertising deal in the Madurai Airport?

You are required to pay in advance for the airport advertising campaign after the campaign is designed effectively, the availability of the ad spaces verified and your ad deal confirmed with MyHoardings.

AHow will I know about the successful completion of the airport branding campaign in the Madurai Airport?

As proof of execution, MyHoardings will share pictures of the ad spaces in the Madurai Airport with you which have been graced with your brand’s advertisement within 2 days.

AWhat is the passenger profile of the Madurai Airport?

The Madurai Airport is mainly visited by the corporate employees, the people form the MNCs, entrepreneurs from the small and medium enterprises and professionals from the Public Sector Units. Tourists also form a sizeable portion of the passenger traffic in the Madurai Airport, making it one of the busiest airports in the southern part of the country and thus, a suitable place for advertising your brand to capture the fancy of the highly captive audience.

AWhy indulge in an airport branding campaign in the Madurai Airport?

The Madurai Airport is expanding its services and its operations with each year. With the extension of the airport, not only will you get greater opportunities to engage in regional branding but also, invest in national branding at the same time. Investing in an airport advertising campaign in the Madurai Airport will expose your brand to the most affluent and influential people of the city and the state, ensuring a sizeable revenue generation and popularity for the brand from the southern-most state of the country.

How will MyHoardings help me in an airport advertising campaign in the Madurai Airport?

As an airport advertising agency, MyHoardings (Jugnoo Media Private Limited) enjoys nationwide popularity and confidence in airport advertising. The authorities of the Madurai Airport have given us the provision of exclusive rights to the ad spaces of the airport and thus, as an airport hoardings company, we enjoy a special status in the Madurai Airport due to our diligence and our professionalism. Our team at MyHoardings will assist you in each step of the way for airport branding at the Madurai Airport, curating your advertising campaign, and giving you the best solution that will be appropriate for your budget. Along with providing our clients with the most affordable rates and the best deals for airport advertising, we offer professional assistance and guidance from the scratch. Get your brand noticed to the right audience to get the desired sales and revenue generation from the airport advertising campaign at Madurai Airport. Just write to us at business [at] myhoardings.com or talk to us directly at (+91) 99538 47639.

0 notes

Photo

Belt Conveyors are one of the many types of Conveyor system. They are continuous moving strips that are used for carrying different materials from one place to another. Belt Conveyors has several applications such as Coal Handling for power plants, Rail Unloading, Raw materials for Cement plants, etc.

Contact Us - +91-9871374601 , +91-9540945514

Mail - contact@innovativepacktech.com

1 note

·

View note