#Automotive injection mold

Explore tagged Tumblr posts

Text

Automotive injection mold design and mold concept

The most important component of automotive molds is cover mold. This type of mold is mainly a cold stamping mold. In a broad sense, “automotive mold” is a general term for molds that manufacture all parts of a car. For example, stamping molds, injection molds, forging molds, casting wax molds, glass molds, etc.Following mainly analyzes automotive injection mold design and mold concepts: Main…

View On WordPress

#Automotive injection mold#Automotive injection mold design#automotive molds#injection mold design#injection molding#injection molding process#injection molds#mold design#molding process#molding processes#molding structure#plastic design

0 notes

Text

For precision and quality in automotive injection molds We provide custom solutions designed to meet the rigorous demands of the automotive sector. Explore our services and drive your project forward!

1 note

·

View note

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Introducing China Automotive Plastic Mould: Precision and Innovation in Automotive Manufacturing

China Automotive Plastic Mould is a leading provider of high-quality plastic moulds for the automotive industry. Specializing in the design and production of moulds, China Automotive Plastic Mould has become synonymous with precision engineering and cutting-edge technology. Our China Automotive Plastic Mould products are renowned for their durability, reliability, and the ability to meet the stringent demands of modern automotive manufacturing.

Each China Automotive Plastic Mould is crafted with meticulous attention to detail, ensuring that the end product is not only functional but also aesthetically pleasing. Our commitment to excellence is evident in every China Automotive Plastic Mould we produce, as we continuously strive to push the boundaries of what is possible in plastic mould technology.

China Automotive Plastic Mould is dedicated to providing moulds that can withstand the rigors of high-volume production while maintaining the highest standards of quality. Our China Automotive Plastic Mould products are used in the creation of a variety of automotive components, from interior trim to exterior panels, showcasing the versatility of our moulds.

Investing in a China Automotive Plastic Mould means investing in a future-proof solution for your automotive plastic component needs. Our China Automotive Plastic Mould is designed to adapt to the evolving requirements of the automotive industry, ensuring that your production lines remain at the forefront of innovation.

China Automotive Plastic Mould is not just a product; it's a partnership with a company that values long-term relationships and is dedicated to the success of your projects. We are proud of our China Automotive Plastic Mould and the role it plays in shaping the future of the automotive industry. Choose China Automotive Plastic Mould for your next project, and experience the difference that precision and innovation can make.

#China Automotive Plastic Mould#injection molding automotive#auto bumper mould#automobile mould#automotive injection molding company#automotive injection molding suppliers

0 notes

Text

The plastics market in the United States is experiencing robust growth, driven by several key factors. Firstly, the increasing demand for lightweight and durable materials in various industries, such as automotive and packaging, has propelled the plastics market forward. Moreover, the versatility of plastics in design and functionality enhances their appeal, contributing to heightened adoption across diverse applications. Additionally, the escalating need for sustainable and eco-friendly solutions has spurred innovation in bio-based and recycled plastics, creating new avenues for market expansion.

#United States Plastics Market Report by Type (Polyethylene#Polypropylene#Polyvinyl Chloride#and Others)#Application (Injection Molding#Blow Molding#Roto Molding#Compression Molding#Casting#Thermoforming#Extrusion#Calendering#End User (Packaging#Automotive#Infrastructure and Construction#Consumer Goods#and Region 2024-2032

0 notes

Text

Rapid Tooling Services - Prototype Injection Molding by Yakon-Mold.com

In today’s fast-paced manufacturing world, the demand for rapid prototyping and production solutions has grown exponentially. Yakon Mold, a leader in precision molding, offers cutting-edge Rapid Tooling Services and Prototype Injection Molding, catering to industries that require quick, efficient, and cost-effective solutions for product development and manufacturing.

What is Rapid Tooling?

Rapid tooling, often referred to as bridge tooling or prototype tooling, is a process that combines rapid prototyping techniques with conventional tooling to create molds quickly and efficiently. It enables the production of small to medium batches of plastic parts, ideal for testing, validation, and even low-volume production.

With Yakon Mold’s expertise, clients benefit from precision, speed, and reliability, making it possible to iterate and refine designs before moving to full-scale production.

The Role of Prototype Injection Molding

Prototype injection molding is integral to product development, offering an efficient way to create functional prototypes using production-grade materials. It allows manufacturers to test the performance, design, and functionality of a part under real-world conditions. Yakon Mold’s advanced capabilities ensure that these prototypes are produced with exceptional accuracy and detail, providing clients with parts that closely mirror the final product.

Key Benefits of Yakon Mold’s Rapid Tooling Services

Speed to Market: Yakon Mold’s rapid tooling services significantly reduce lead times, allowing businesses to get their products to market faster.

Cost-Effective Solutions: By utilizing prototype molds, companies can save on production costs while maintaining high quality.

Flexibility: Rapid tooling enables easy design modifications, accommodating changes without extensive delays or expenses.

High Precision: Leveraging state-of-the-art machinery, Yakon Mold delivers intricate designs with exceptional dimensional accuracy.

Material Versatility: Clients can choose from a wide range of production-grade materials to ensure the prototype matches the desired end-use requirements.

Applications of Rapid Tooling and Prototype Injection Molding

Yakon Mold’s services are widely used across various industries, including:

Automotive: Creating prototypes for new components, ensuring they meet performance standards.

Consumer Electronics: Testing designs for durability and functionality before mass production.

Medical Devices: Producing accurate prototypes to validate performance and meet regulatory standards.

Aerospace: Manufacturing lightweight and durable parts for high-stress applications.

Why Choose Yakon Mold?

With years of experience and a commitment to innovation, Yakon Mold has positioned itself as a trusted partner for rapid tooling and prototype injection molding. Their customer-focused approach ensures seamless collaboration, from design consultation to final delivery. The company’s state-of-the-art facility and highly skilled team provide unparalleled support and expertise, guaranteeing that every project meets the highest standards.

Conclusion

Whether you’re a startup refining a new product or an established manufacturer exploring design possibilities, Yakon Mold’s Rapid Tooling Services and Prototype Injection Molding are designed to empower your vision. By combining speed, precision, and cost-efficiency, Yakon Mold helps businesses stay ahead in a competitive market.

Explore more about their services and discover how Yakon Mold can bring your ideas to life at yakon-mold.com.

1 note

·

View note

Text

The precision of these new molds is another standout feature. With tighter tolerances and more accurate alignment, the molds can produce parts that fit together seamlessly. This is particularly important in the automotive industry, where the fit and finish of components can affect the performance and safety of a vehicle. The new automotive plastic injection molds ensure that every part is produced to exact specifications, reducing the need for post-production adjustments and rework.

In addition to efficiency and precision, the new molds also contribute to the sustainability of the automotive industry. By reducing waste and improving the recyclability of parts, these molds help manufacturers meet the growing demand for environmentally friendly production methods. The use of advanced materials in the molds also means that they are less likely to wear out or require replacement, further reducing the environmental impact of part production.

The integration of automation and digital technologies into the new automotive plastic injection molds has also been a game-changer. These smart molds can monitor their own performance, alerting operators to potential issues before they become critical. This predictive maintenance not only reduces downtime but also extends the life of the molds, providing a significant return on investment for manufacturers.

0 notes

Text

Leading Plastic Molding Manufacturer for Custom Solutions

Partner with a trusted Plastic Molding Manufacturer for high-quality, custom plastic parts. Our advanced molding technologies and experienced team ensure precision and consistency in every project. Serving various industries, we provide tailored solutions that meet your exact specifications, from concept to production. Rely on us for durable, efficient, and cost-effective plastic molding services.

#plastic injection molding supplier#electronics manufacturing services#automotive mold manufacturers#aluminium die casting

0 notes

Text

Custom Plastic Injection Molding China

Get all automotive, home appliances, and electronics mold now only with Custom plastic injection molding in China. If you are looking for all in one place then visit hsmolds.net. They are the best in the market. They have experts who can assure the quality of the product. Order now!

#Automotive#Custom plastic injection molding in China#Plastic Injection#Molding#Custom plastic injection molding

0 notes

Text

Automotive rubber parts – Driving the automotive industry

The auto sector cannot do without rubber parts. The automotive industry is undergoing a tremendous change, the biggest challenge lies in the supply of value-added products. Here are some new trends in automotive rubber parts. https://alfarubber.home.blog/2023/11/03/automotive-rubber-parts-driving-the-automotive-industry/

#Automotive rubber parts#Gaskets and Seals#Rubber Injection Molding#Seal manufacturer#Bush manufacturer

0 notes

Text

prototype companies near me | injection molding automotive parts

Discover local prototype companies near me that turn your ideas into real products. Whether it's electronics, gadgets, or everyday items, they can help you create and refine your prototypes, turning your vision into a tangible reality.

For top quality injection molding automotive parts, trust Plastic Injection Molds. We deliver precise, high-quality parts tailored to your needs, ensuring excellence in every detail. Your automotive vision, brought to life.

0 notes

Text

Glove Box Assembly Design Guide

Glove box assembly: located in lower middle position of passenger side of dashboard, used to store user manuals, storage items and decorative box assembly.As shown in Figure 1 below. Glove box door: external parts of glove box that can open and close storage function.Glove box lock: A system that locks fixed function when glove box is closed.Glove boxes are classified from form of storage…

View On WordPress

#automotive parts#Glove Box Assembly Design#glove box door welding process#injection molding#plastic parts

0 notes

Text

The Growing Role of Automotive Plastics in Vehicle Design and Manufacturing

Automotive plastics are materials used for the construction of parts and components in automobiles, including the body, interior, and powertrain. These plastics are designed to be lightweight, durable, and cost-effective. Common types of automotive plastics include polypropylene, polyurethane, ABS, and polycarbonate. Automotive plastics are used in many areas of the vehicle, including interior…

View On WordPress

#automotive bioplastic market#automotive injection#automotive injection molding#automotive injection molding companies#automotive plastic additives market#automotive plastic injection molding companies#automotive plastic manufacturers#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#automotive plastics suppliers#COVID 19 impact on Automotive Plastics Market#global automotive plastics market#injection molding in automotive industry#plastic car#plastic car part#plastics for electric vehicle market#polypropylene in cars#use of plastic in automobile

0 notes

Text

Polyolefin Market Will Reach USD 410.4 Billion By 2030

Polyolefin states to a group of polymers produced from an olefin monomer. As thermoplastics, such materials are widespread since they are tremendously simple to meld to shape and can be reformed again and again just by recapping the melding, heating, and cooling process. They array from fluid-like to stiff solids and offer lightweight things that are also flexible, durable, and provide better…

View On WordPress

#Additives Packaging#Catalysts#Construction#Consumer Goods#Extrusion Automotive#Films#Injection Molding#Polymerization#Tapes Blow Molding

0 notes

Text

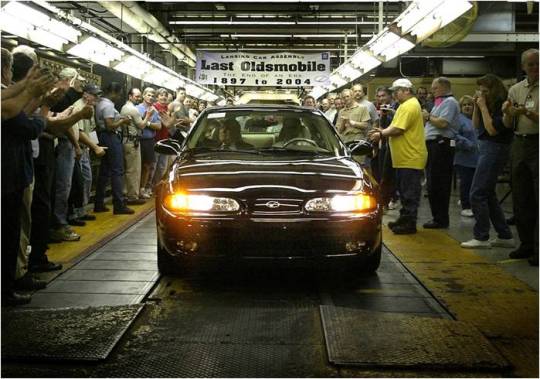

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

93 notes

·

View notes