#Automatic filter press in india

Explore tagged Tumblr posts

Text

Exporter of Spin Flash Dryer in Morocco

Drytech Engineering Systems is a trusted Exporter of Spin Flash Dryer in Morocco. Our Manufacturing Unit is located in Ahmedabad, Gujarat, India. Drytech Engineering Systems material to be dried is fed into the drying chamber in a fine, dispersed form through the feed mechanism. The high-speed rotor creates intense agitation, ensuring thorough mixing of the material and hot air. As the moisture evaporates, the air stream carries the dried particles toward the cyclone separator for collection. What is a Spin Flash Dryer? A Spin Flash Dryer is an industrial drying system that uses hot air and mechanical agitation to dry moist materials quickly. The equipment has a cylindrical chamber with a high-speed rotor that disintegrates and dries fluid-based materials. Available various types of spin flash dryer Fully Automatic Spin Flash Dryer and semi-automatic Spin Flash Dryer. Spin Flash Dryer Features: Efficient Drying System: Uses hot air to rapidly dry materials and a high-speed rotor for mechanical agitation. Collection System: Equipped with a bag filter and cyclone separator for collecting dry powders. Energy-Efficient: Operates efficiently with high output levels while minimizing energy consumption. Cohesive and Non-Cohesive Materials: Suitable for both cohesive and non-cohesive pastes, cakes, and viscous products. Chemical and Thermal Resistance: Constructed from high-quality stainless steel, resistant to corrosion and high temperatures. No Sticking or Accumulation: Ensures smooth operation without material buildup or sticking. Voltage Level: Operates at 440V/50HZ for optimal performance. Applications of Spin Flash Dryer: Wet Cakes and Moist Powders High Viscosity Fluids Filter Press Wet Cakes FAQs. Q1: What types of materials can be dried using a Spin Flash Dryer? A1: Spin Flash Dryers are ideal for drying moist powders, wet cakes, filter press wet cakes, high-viscosity fluids, and thick pastes. Q2: How does a Spin Flash Dryer work? A2: A Spin Flash Dryer works by feeding material into a drying chamber where it is exposed to hot air and mechanical agitation. The moisture evaporates quickly, separating the dried particles from the air through a cyclone separator. Drytech Engineering Systems is a trusted Exporter of Spin Flash Dryer in Morocco, including the following locations Fes, Rabat, Marrakesh, Casablanca, Meknes, Tangier, Chefchaouen, Essaouira, Ouarzazate, Tetouan, Agadir, Khenifra, Errachidia, Larache, Oujda, Ksar el-Kebir, Beni-Mellal, El Jadida, Tinghir, Guelmim, Azrou, Al Hoceima, Midelt, Kenitra, Nador, Taroudant, Tiznit, Safi, Skhirat, Sefrou, Salé, Asilah, Fquih Ben Salah, Oulad Teima, Ben Guerir, Fnideq, Province of Ouezzane, Lqliâa, Tantan, Tiflet, Sidi Slimane, Taourirt, Beni Ansar, Khouribga, Ben Slimane, Taza, Martil, Berrechid, Berkane, Khemisset, and Oued Zem. For more details or inquiries about our Spin Flash Dryers, contact Drytech Engineering Systems. View Product: Click here Read the full article

#Agadir#Ahmedabad#AlHoceima#Asilah#Azrou#BenGuerir#BenSlimane#BeniAnsar#Beni-Mellal#Berkane#Berrechid#Casablanca#Chefchaouen#ElJadida#Errachidia#Essaouira#Exporter#ExporterofSpinFlashDryer#ExporterofSpinFlashDryerinMorocco#Fes#Fnideq#FquihBenSalah#Guelmim#Gujarat#India#Kenitra#Khemisset#Khenifra#Khouribga#Ksarel-Kebir

0 notes

Text

Supplier of HDPE Nutsche in Tamil Nadu

Sunfiber is a leading Manufacturer and Supplier of HDPE Nutsche in Tamil Nadu, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. An HDPE Nutsche is a filtration system commonly used in industrial applications to separate solids from liquids. It is a type of filter press, where a porous medium (such as a filter cloth) is used to separate solid materials from liquid. HDPE material ensures excellent resistance to chemical corrosion, making it perfect for industries that deal with aggressive chemicals or high temperatures. The Nutsche filter typically consists of a large tank or vessel with a filtration medium that allows liquid to pass through while trapping solid particles. This process is crucial in several industries for achieving high purity and efficiency in the separation process. Specifications of HDPE Nutsche: Material: High-Density Polyethylene (HDPE), providing exceptional chemical resistance and durability. Capacity: Available in a range of capacities from small-scale laboratory units to large industrial models, ensuring versatility across different needs. Pressure Rating: Suitable for use in both low and high-pressure applications. Temperature Range: Designed to withstand a wide range of temperatures, typically between 0°C to 90°C. Filter Area: Customizable filter areas, depending on the filtration requirement. Sealing System: Advanced sealing systems ensure leak-proof operation and reliable performance. Applications of HDPE Nutsche: Chemical Industry Pharmaceutical Industry Food and Beverage Industry Water Treatment Mining and Metallurgy Environmental Engineering FAQs: What are the advantages of HDPE material in nutsche? HDPE offers superior chemical and corrosion resistance, ensuring long-lasting durability and reliability in harsh environments, making it ideal for filtration processes involving aggressive chemicals. What types of HDPE Nutsche filters are available? We offer manual, automatic, batch, and continuous HDPE Nutsche filters, catering to different scales of operation, from laboratory use to large-scale industrial applications. Are the filters customizable? Yes, Sunfiber offers customization options for filter sizes, pressure ratings, and configurations to meet specific requirements in various industries. Sunfiber is a Supplier of HDPE Nutsche in Tamil Nadu, India including Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#HDPENutsche#HDPENutscheinTamilNadu#Kallakurichi#Kanchipuram#Kanniyakumari#Karur#Krishnagiri#Madurai#ManufacturerofHDPENutsche#ManufacturerofHDPENutscheinTamilNadu#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur#Pudukkottai#Rajapalayam#Ramanathapuram#Ranipet#Salem

0 notes

Text

Top features to look in for a modern chai machine

Convenience and beverage quality are two aspects that should go together, when you are brewing the perfect cup of chai. Whether you are running a cafe, managing an office, or want a reliable tea machine for your area, it is essential to choose the right chai machine.

With Pradeep iBrew, a leading tea machine manufacturer, you get innovative solutions designed to meet your specific needs. Let’s explore the top features to look for in a modern chai machine.

1. Automation and Efficiency

Modern chai machines, like the automatic tea coffee vending machines, offer unparalleled ease of use. With just a press of a button, these machines can brew authentic chai or coffee in minutes, saving time and effort for both customers and employees.

2. Versatility

A versatile chai machine should cater to various preferences. Pradeep iBrew’s machines can prepare everything from traditional chai to karak tea, and even act as a coffee tea machine for cafes, ensuring a diverse menu for users.

3. Fresh Milk Integration

Machines like the fresh milk tea chai machines elevate the tea-drinking experience by using fresh milk, ensuring a rich and creamy texture that’s hard to beat.

4. Filter Coffee Compatibility

India loves its filter coffee! Look for machines that double as filter coffee machines or the best filter coffee maker machines in India to deliver authentic South Indian coffee with ease.

5. Durability and Build Quality

When investing in a chai machine, durability is key. Machines from trusted manufacturers like Pradeep iBrew are designed with high-quality materials, ensuring longevity even with regular use.

6. Energy Efficiency

Energy-saving features in chai machines help reduce operational costs, making them an ideal choice for both offices and cafes.

7. Hygiene and Maintenance

A modern chai machine should be easy to clean and maintain. Features like automated cleaning cycles and minimal manual intervention ensure hygiene and hassle-free operation.

8. Customizable Options

Pradeep iBrew offers machines that allow customization of ingredients, sweetness, and strength, enabling every user to enjoy their beverage just the way they like it.

9. Advanced Brewing Technology

State-of-the-art coffee tea filter machines and tea maker machines from Pradeep iBrew ensure consistent flavor with every brew, maintaining the traditional taste of chai and coffee.

10. Compact and Stylish Design

Modern chai machines are not just functional but also aesthetically appealing, fitting seamlessly into any space. With these features, a chai machine from Pradeep iBrew becomes an indispensable part of your café, office, or home. Invest in advanced tea and coffee brewing solutions today and redefine the way you enjoy beverages.

#automatic tea coffee vending machines#chai machine#coffee tea machine for cafes#filter coffee machines#fresh milk tea chai machines#tea machine manufacturer

0 notes

Text

How automation transformed newspaper production at India’s ABP

“Adapting to changing consumer preferences and leveraging new technologies is crucial for survival and growth of the newspaper printing industry,” Pradyumna Mitra, general manager – engineering, ABP, told participants at Wan-Ifra's recent Indian Printers Summit.

Mitra’s presentation focused on the benefits of automation for newspaper printing.

“We must adapt to new challenges. Recent wars and global disruptions have only contributed to increased production costs, particularly through supply chain issues,” he said during the summit.

The impacts on the industry have been significant.

Increased printing costs, higher newsprint prices, and logistical challenges have emerged as key issues. Additionally, the growing adoption of digital news consumption has led to negative growth in print revenue, making it clear that traditional methods of production are no longer sustainable in their current form.

The shift towards automation in newspaper production is crucial for survival, Mitra said.

Leveraging automation in prepress to enhance efficiency

ABP, which publishes popular dailies such as Anandabazar Patrika (Bengali) and The Telegraph, has taken significant steps towards automation, particularly in the prepress segment. Mitra highlighted some of the tools they have implemented to streamline operations.

Pro Image OnColor plugin: It provides editorial teams with the ability to process images faster in an automated mode, without human intervention. OnColor can process a high volume of images quickly to meet publishing standards within tight deadlines. The tool’s workflow provides fast and consistent results, significantly reducing ABP’s time to press, Mitra said.

AI-powered Retouch4Me plugin in Adobe Photoshop: The plugin automates the photo-editing process with minimal manual intervention. It applies machine learning models to analyze images and make retouching decisions based on skin tones, texture, and lighting patterns.

Adobe Generative AI: This tool is integrated into ABP’s workflow to automate image editing tasks such as removing unwanted objects and adjusting exposures in real-time. Mitra described how tools such as Generative Remove, Camera Raw Filter, and Parametric Filters, help optimize tasks such as image retouching and adjustment.

Automated tools in production and press

Beyond prepress, ABP has leveraged automation in production and press operations.

Automation of advertisement file processing, which ABP implemented about a year and a half ago using OneVision Asura pre-flight software, has allowed ABP to efficiently manage a high volume of ads.

“We also implemented script-based PDF content validation, which helps us ensure accuracy in text elements such as dates and metadata,” Mitra said.

In terms of press operations, automation is helping ABP reduce waste. The Auto Fan Out correction software has been integrated into the Pre-Press NewsX workflow to improve overall print quality. The system automatically adjusts offset values based on individual print unit behavior to improve consistency and reduce material waste.

Automation tools can manage complex files with more than 10,000 images, reducing delays and waste during peak production hours, Mitra said.

Cutting costs with automated energy management solution

Energy management is another area where automation is helping ABP cut costs and improve efficiency.

Frequent grid power interruptions had previously resulted in mechanical failures and downtime during press operations, causing loss of critical production time at night.

“To avoid this, we had to run generators continuously at night during high production periods. This led to high fuel costs and frequent servicing of the generators,” Mitra said.

“We installed a dynamic UPS system with PLC-based automation to ensure seamless power transitions, which helped us reduce fuel costs and eliminate unnecessary stoppages,” he added.

Integrating energy meters and real-time data acquisition systems has helped the publisher better monitor its power consumption from solar, diesel generators, and grid systems. This approach allows ABP to identify non-critical areas and reduce energy waste.

Electricity costs are a major concern for any printing plant. In most cases, HVAC systems account for 40% to 50% of the overall electricity bill, depending on weather conditions. Continuous HVAC operation also shortens the lifespan of rotating components such as pumps, chiller compressors, and H-U motors. However, with the help of IoT-based sensors and data analytics, ABP now collects real-time data to monitor system performance more effectively.

Waste management using IoT-enabled solutions

Automation has proven beneficial for ABP in waste management as well.

“Traditionally, waste copies are collected manually, weighed, and sold to agencies,” Mitra said. “However, this process is labor-intensive and inefficient.”

To address this, ABP is in the process of implementing an automated system to streamline the logistics of waste handling. The proposed system will involve a conveyor connected to a compacter, reducing human intervention and improving the sale value of waste.

ABP is also evaluating IoT-enabled smart containers for further reduction in manual handling. Additionally, the publisher is conducting a feasibility study to automate its 48,000-sqft warehouse at the Barasat plant in Kolkata, for incorporating automated guided vehicle (AGV) technology.

“This system ensures error-free operation, reduces waste, and improves efficiency with minimal human intervention. Real-time tracking of material flow allows warehouse personnel to make informed decisions about stock levels and optimize operations,” Mitra said.

‘Automation is key to our journey towards sustainability’

Mitra highlighted the role of predictive maintenance in extending spare serviceability and preventing unplanned breakdowns.

“We have conducted a pilot project using IoT sensors and AWS cloud data analytics to acquire real-time temperature and vibration data from our print couple motors,” he said. “This pilot has yielded encouraging results, and we are optimistic about the potential for predictive maintenance using AI and machine learning.”

However, Mitra acknowledged there are challenges in setting up a robust data acquisition infrastructure and managing the large volumes of data required.

“We must take advantage of the latest developments in IT and electronics hardware,” he said. “Automation is key to our journey towards sustainability.”

He concluded by highlighting the potential for collaboration between technology users and suppliers to develop cost-effective, smart, and customized solutions.

“In this era of connectivity, automation can play a critical role in helping us achieve long-term sustainability in the newspaper industry,” he said.

(First published on Wan-Ifra)

0 notes

Text

Multi Column Distillation Plant - MCD Manufacturer in India

Manufacturer, Supplier of Multi Column Distillation Plants - MCD, Produce distilled water by separating impurities through multiple distillation columns, India.

Vacuum Tray Dryer, Zero Hold Up Filter Press, Filter Press, Colloid Mill, Multi Mill, Blender, Double Cone Blender, Octagonal Blender, Vibro Sifter, Double Deck Vibro Sifter, Single Deck Vibro Sifter, Dryer, Fluid Bed Dryer, Tray Dryer, Vacuum Tray Dryer, Liquid Manufacturing Plant, Liquid Filling Line, Automatic Liquid Bottle Filling Machine, Automatic Rotary Bottle Washing Machine, Manual Inspection Machine With Bw Hood, Turn Table, Mumbai, India.

0 notes

Text

Discover the Best Polypropylene Filter Press Manufacturers in India

Polypropylene filter presses are an essential part of any industrial process involving filtration of water, chemicals, or other liquids. Finding the right polypropylene filter press manufacturer is key to getting the best products that meet your needs. India is home to numerous polypropylene filter press manufacturers, and knowing which ones provide the best quality and value can help you find the right supplier for your needs. In this blog, we’ll explore the top polypropylene filter press manufacturers in India, and what sets them apart from other suppliers.

The leader in polypropylene filter press manufacturing in India is amikon blowers Industries amikon blowers Industries has been producing top-quality polypropylene filter presses since 1985, and their products are renowned for their quality and value. Their presses come in a wide range of sizes and configurations, making them suitable for a variety of industrial applications. They also offer a wide range of accessories, such as water recirculation systems and automatic cake discharge systems, making them a great choice for any filtration needs.

Another great polypropylene filter press manufacturer in India is Star Filtration Systems. Star Filtration Systems has been producing top-quality filter presses since the early 1980s. They have a wide range of products, including manual and automated systems, and their presses are designed to meet the exact needs of their clients. They also offer a variety of accessories, such as water recirculation systems, cake discharge systems, and more.

Last but not least, we have amikon blowers. Amikon Blowers is one of the leading manufacturers of polypropylene filter presses in India. Their presses come in a wide range of sizes and configurations, making them suitable for a variety of industrial applications. Additionally, they offer a wide range of accessories, such as water recirculation systems and automatic cake discharge systems, making them a great choice for any filtration needs.

These are just a few of the top polypropylene filter press manufacturers in India. With so many suppliers to choose from, it’s important to do your research and find the one that best meets your needs. Whether you’re looking for a manual or automated system, or need a wide range of accessories, the right supplier can help you find the perfect solution for your filtration needs. So don’t hesitate to start your search today and discover the best polypropylene filter press manufacturer in India for your needs

Amikon Engineers & Consultant

Registered Office:

Plot No - 194, Block-k, Vijay Vihar, Phase-2, Sector-4, Rohini, Delhi -110085, India

Corporate Office:

Office No.148,1st Floor, Vardhmaan Grand Plaza, Sector-3, Rohini, New Delhi - 110085 (INDIA)

Call Support:

Tel: +91 11 41516313

Mobile : +91 9311108295, +91 9311108296

0 notes

Text

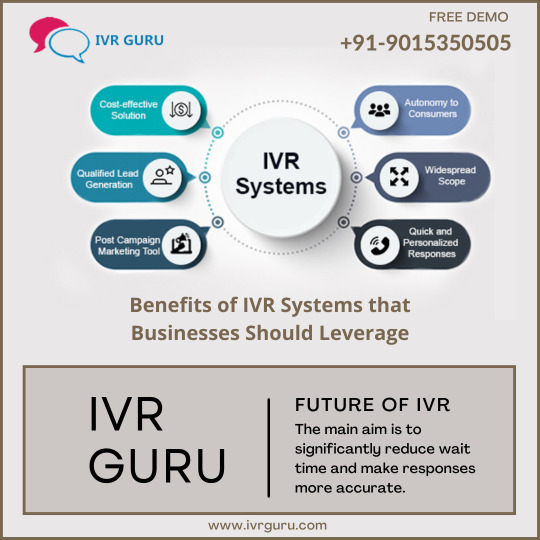

Why IVR Guru for IVR Services

What is IVR?

Interactive Voice Response (IVR) is an automated phone system that interacts with the callers and assembles the information by giving them choices through a pre-recorded voice response system. If necessary, they can resolve their enquiry by speaking to the mapped agents in the IVR system.

Is your Business not growing?

Every business wants to grow their business but due to lack of time and tracking, it gets difficult to increase productivity/revenue. There are some common factors due to which businesses are not able to grow, whereas there are all commoditized (Office space, good staff, etc.) available.

Punctuality

Negligence

Non-Tracking

Low Productivity

No Records

Others

Solution - A quality IVR Service provider is the only solution for all problems related to IVR System. When you implement IVR Service in your business, all the problems will resolve automatically.

Check out how!

When a customer calls on your business number (IVR No.), a pre-recorded welcome tone plays like “Welcome to ABC Private Limited, press 1 for sales/marketing department, press 2 for the HR department, press 3 for accounts department” and so on. It makes a better brand image of your company in the caller’s mind.

Every incoming call on IVR is recorded in the IVR panel, which means your staff will talk to the customer without delay and efficiency. If the employee missed the call, then the record is saved in the IVR panel’s database. You can track every call in the IVR panel, and you can download the report as well.

There is a filter provided in the call record with which you can filter the data according to your requirement and download it for further process of reporting. Punctuality is built up automatically in the staff and there is no space for negligence. If the system runs in such a proper way, then productivity and revenue automatically increase.

There are many more features of an IVR System that make the system more effective and transparent.

IVR features list:

You can make your mobile number/ toll-free number a virtual number and map executives to it.

You can add ‘n’ number of executives against a Virtual Number.

No Call Drop.

You can track your calls with a single click.

You can set priority for answering calls according to you for the Sales Team.

You can provide access to the employee so that they can see their self-call record.

You can access your call tracking panel anywhere, anytime online.

100% voice recording of each answered call with play/download option.

User-Friendly Control Panel.

2-way prompt message notification. After the call disconnects, both executive and client get the message showing the name and mobile number of the other.

You can download reports into excel from the panel with a single click.

Stick Agent Facility is also available.

100% data security.

It is also important to choose the best IVR Service provider to get the best experience and better productivity. IVR Guru has been a leading company in providing IVR Services. We have been increasing productivity and growth for different companies and we will do the same it comes to your company as well.

Increase your business awareness all over India through quality voice call campaigning with the most trusted IVR Service provider in Delhi, Noida, Mumbai, etc. IVR Guru an Interactive Voice Response (IVR) which is simple, can process over a million calls an hour, usable, voice-driven, Voice XML IVR platform, cloud hosting services, and developer solutions. There are lots of IVR services Provider in Delhi NCR but how can you find the best service provider… Don’t worry no need to find them because IVR Guru Give you complete information, Manage your business calls easily with an IVR and 24X7 availability to your customers

Related - https://ivrguru.com/virtual-number-provider-india

Source - https://medium.com/@deepakivrguru/why-ivr-guru-for-ivr-services-e963739d3c72

#ivr service provider india#best ivr system#virtual mobile number#toll-free number#vocie call service#Why IVR Guru for IVR Services#Best IVR Service Provider in India

0 notes

Photo

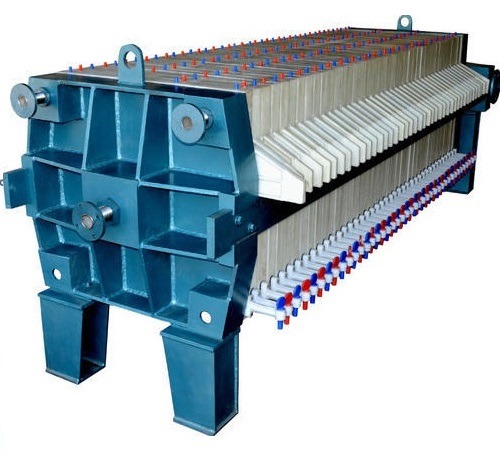

A Automatic filter press is a fixed volume machine that separates liquid and solid. A solution is added to the filter press and dew is applied under pressure. So that solid and liquid can be separated. And it is used for water treatment in the municipality.

0 notes

Text

Filter Plates Manufacturers in Coimbatore - Hydro Press Industries

Hydro Press Industries are one of the best filter plates manufacturers in South India. With expert mechanism and efficiency the filter plates from Hydro Press delivers quality and performance. We manufacture a wide range of filter plates in-house. We make use of high molecular polypropylene. Our filter plates are recognised for their excellent chemical resistance even at high temperatures, long working life, zero problems of leakage, crack and corrosion and enhanced filtration and washing efficiency.

In house manufacturing

100 % virgin polypropylene filter plates

Excellent quality, High machining accuracy and good finishing

Extended life

Available in wide range of sizes and configuration

Plates available with design pressure ranging from 4 bar up to 30 bar pressure

Discharge : Open and closed discharge

Feed : Centre feeding , Top / bottom Corner feeding, Top Centre

To know more https://www.hydropressindustries.com/filter-plate.php

Stellar Performance of Hydro Press Filter Press across Industries

Hydro Press Industries is one of the leading manufacturers and exporters of various types of filter presses with different sizes and configurations. Our filter presses are installed and working successfully in various types of Industries such as Effluent / Sewage / Water Treatment plants, Paper industries, Edible oil industries, Leather tanneries, Food processing, Chemical, Mineral and Ceramic industries in India and overseas.

Waste Water Treatment plants

Our filter presses find application in effluent treatments plans, municipal sewage works, industrial purification plants and industrial acid waste neutralisation.

Chemical Industries

Efficient and effective filtration is required in the chemical industry. Filter presses are used as part of the production process to filter pigments, dyes, catalysts, detergents, bio-fuels and other intermediate products.

Sewage Treatment Plants

Our water treatment systems are used to control waste water from industries, sewage odour control, BOD reduction, aeration, clarification and nitrogen removal.

Effluent Treatment Plants

In effluent treatment plants, automatic and fully automatic presses are used for liquid and chemical waste, soil decontamination, liquid electroplating waste and special waste incineration plants.

Tannery Industries

The tannery sector uses a lot of chemicals to obtain the end product. The chemicals are dissolved in water and sludge is created. The filter presses reduces the moisture content, volume and weight of the solid residue

Textile Industries

The water waste from the textile industry contains contaminants such as dyes, surfactants and heavy metals. With the use of a filter press, the problem of sludge bed is eliminated and overflow is controlled.

Food Processing Industries

Filter presses are used to filter and purify finished products such as sugar, wine, beer, yeast for baking and brewing and pectin.

Edible oil industries

Filter press machines and refinery machines are used as oil purifiers in the edible oil processing industry. It is used to refine rice bran oil, coconut oil, sunflower oil, sesame oil, mustard oil, gingerly oil, and peanut oil.

Pharmaceutical Industries

Filter presses are commonly used in the pharmaceutical and biotechnology industry. It is mainly used to filter agar-agar, blood plasma, algae and other various intermediate pharmaceuticals.

#Filter Press Manufacturer#Automatic Filter Press Manufacturers#Hydraulic Filter Press Manufacturers#Filter Plate Manufacturers in India#Plate Filter Press Manufacturers#Filter Cloth Suppliers

0 notes

Text

New MG Cars | Up coming SUV Cars | Features

Upcoming SUV Cars

Here is the rundown of all upcoming SUV cars which are required to dispatch in India in the year 2021-2022. The famous forthcoming SUV vehicles incorporate MG ZS, Force Motors Gurkha, Volkswagen Tiguan 2021 and Audi e-tron. Select a vehicle to know the normal value, dispatch date, determinations and Images.

📷

Upcoming SUV Cars in 2021

Model Expected Price

MG ZS Rs. 12 Lakh

Force Motors Gurkha Rs. 10 Lakh

Volkswagen Tiguan 2021 Rs. 28 Lakh

Audi e-tron Rs. 1 Crore

Hyundai Palisade Rs. 40 Lakh

Mitsubishi Eclipse Cross Rs. 18 Lakh

MG ZS Latest Updates

MG Motor India uncovered the interior ignition motor emphasis of the ZS SUV at Auto Expo 2020. It includes new plan components like more honed projector headlamps, updated LED DRLs, a sparkle dark MG grille, and more honed LED taillamps. Indeed, even the 17-inch combination wheels include a sportier plan. Inside features incorporate front and back driver's touch power windows, voyage control, a 6-speaker sound framework, just as a 8-inch touchscreen infotainment framework with Apple CarPlay and Android Auto.

In the engine, it is fueled by two petroleum motors. The principal petroleum plant is a 1.5-liter normally suctioned engine creating 120PS/150Nm, with the other alternative being a 1.3-liter turbocharged motor putting out 163PS/230nm. Transmission choices incorporate a 5-speed manual, CVT, and 6-speed programmed gearbox.

Expect a dispatch not long from now, with costs liable to be a bit less expensive than the all-electric ZS, what begins at Rs 23.71 lakh (ex-display area India).

Details of MG ZS

MG ZS is at present accessible in Petrol motor. MG ZS is accessible in Automatic transmission as it were.

Features:

Solace and Convenience

Downpour Sensing Front Wiper

Press Button Start Stop With Smart Entry

6 Ways Power Adjustable Driver Seat

Electronic Gear Shift Knob

Active Energy Recovery System(KERS) – 3 Levels

Auto Headlamp

Driving Modes : Eco, Sport and Normal

Journey Control

Double Pane Panoramic Sky Roof

PM 2.5 Filter

PM 2.5 Filter

MG ZS EV comes outfitted with an inbuilt PM 2.5 Air Filter to give sound air inside your SUV lodge. Which means regardless of whether PM 2.5 estimation outside is 200-300, the level inside the vehicle will be protected, under 30 AQI, in just shy of 5 minutes. You inhale unadulterated as your ZS EV inhales unadulterated. One could securely say that you roll up the windows for a much needed refresher.

CO2 Savings

Save CO2 and decrease your carbon impression each time you drive the MG ZS EV - welcome a positive effect on the climate around you.

20.32cm Infotainment Touch screen

Your vehicle is an expansion of you. Also, MG Motors launching a vehicle like MG ZS EV is considerably more so. To keep you associated and consistently in contact, it accompanies a 20.32cm HD Touch Screen controlled by the I-SMART EV 2.0, to guarantee you generally have a finger on your vehicle's heartbeat.

Sky Roof

20.32cm Infotainment Touch screen Your vehicle is an expansion of you. What's more, a New MG Cars like MG ZS EV is considerably more so. To keep you associated and consistently in contact, it accompanies a 20.32cm HD Touch Screen controlled by the I-SMART EV 2.0, to guarantee you generally have a finger on your vehicle's heartbeat.

#best 7 seater suv in india#7 seater suv cars in india#best selling suv in india#New Car Brands in India#MG Hector Company#mg hector company

1 note

·

View note

Text

Exporter of Spin Flash Dryer in Mauritius

Drytech Engineering Systems is a leading Manufacturer, Supplier, and Exporter of Spin Flash Dryer in Mauritius. We are Based in Ahmedabad, Gujarat, India. Drytech Engineering Systems offers spray dryers, flash dryers, spin flash dryers, and multi-effect evaporators. We provide two types of the spin flash dryer like Fully Automatic Spin Flash Dryer, Semi-Automatic Spin Flash Dryers. Features of Spin Flash Dryer: Disintegration System: Breaks down wet cakes for effective drying. Hot Air Injection: Pre-heated air is used to dry materials quickly. Cyclone Separator and Bag Filter: Collects dry powder efficiently. Energy-Efficient Operation: Operates at a voltage of 440V/50HZ. High Output Level: Rapid drying of paste and fluid-based substances. Chemical and Thermal Resistance: Durable design for various applications. No Sticking or Accumulation: Ensures smooth operation. Working Principle: Material Introduction: Materials are fed into the drying chamber in a fine, dispersed form. Hot Air Injection: We inject hot air at high velocity, promoting rapid moisture evaporation. Drying and Separation: A high-speed rotor creates agitation, mixing materials with hot air. Dried particles are carried to the cyclone separator for collection. What materials can be dried using a Spin Flash Dryer? Suitable for filter press wet cakes, fluids with high viscosity, and thick pastes. What are the energy requirements? Operates at 440V/50HZ, ensuring energy-efficient performance. How does the drying process work? The drying process involves material introduction, hot air injection, and drying/separation in a cyclone. What are the advantages of a fully automatic dryer? Enhanced efficiency, reduced manual intervention, and precise process control. Can I customize the drying parameters in a semi-automatic dryer? Yes, operators can adjust feeding rates, temperature, and drying times as needed. Drytech Engineering Systems is an Exporter of Spin Flash Dryer Mauritius covering locations such as Port Louis, Plaines Wilhems, Vacoas-Phoenix, Beau Bassin-Rose Hill, Curepipe, Quatre Bornes, Rivière Noire, Pamplemousses, Savanne, Grand Port and Flacq. Contact us today for more information, pricing, and availability. View Product: Click Here Read the full article

#Ahmedabad#BeauBassin-RoseHill#Curepipe#DrytechEngineeringSystems#Exporter#ExporterofSpinFlashDryerMauritius#Flacq#FlashDryers#GrandPort#Gujarat#India#Manufacturer#ManufacturerinAhmedabad#MultiEffectEvaporators#Pamplemousses#PlainesWilhems#PortLouis#QuatreBornes#RivièreNoire#Savanne#SpinFlashDryerMauritius#SpinFlashDryers#SprayDryers#Supplier#Vacoas-Phoenix

0 notes

Text

Coffee Machine Market Players Sharpens Cost Cutting to Gain Sales Recovery

Latest Research Study on Global Coffee Machine Market published by AMA, offers a detailed overview of the factors influencing the global business scope. Coffee Machine Market research report shows the latest market insights with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors, Challenges and Current Scenario Analysis of the Coffee Machine. This Report also covers the emerging player’s data, including: competitive situation, sales, revenue and global market share of top manufacturers are Keurig green mountain (United States),Panasonic (Japan) ,Nestle nespresso (Switzerland) ,Jarden (United States),Delonghi (Italy) ,Electrolux (Sweden) ,Melitta (Germany) ,Morphy richards (United Kingdom) ,Philips (Netherlands) ,Hamilton beach (United States),Illy (Italy) ,Bosch (Germany) ,Krups (Germany) ,Jura (Switzerland).

Brief Summary of Coffee Machine: Coffee machine is an appliance used to brew coffee, widely used in coffee shops and canteens. Over the years, drinking coffee has evolved from being a simple dining routine to energy boosting agents. Whether it is a trend or long term practice, drinking coffee has been adopted with reflecting modern lifestyle and sophistication which has gained considerable growth around the globe. Considering the rising café culture and working millennial attraction towards coffee, the market for a coffee machine is expected to gain traction in the near future Free Sample Report + All Related Graphs & Charts @ : https://www.advancemarketanalytics.com/sample-report/10750-global-coffee-machine-market-2 Coffee Machine Market Report offers a detailed overview of this market and discusses the dominant factors affecting the growth of the market. The impact of Porter's five armies on the market over the next few years has been discussed for a long time in this study. We will also forecast global market size and market outlook over the next few years. Types of Products, Applications and Coffee Machine Market Report Geographical Scope taken as the Main Parameter for Market Analysis. This Research Report Conducts an assessment of the industry chain supporting this market. It also provides accurate information on various aspects of this market, such as production capacity, available production capacity utilization, industrial policies affecting the manufacturing chain and market growth. The Global Coffee Machine Market segments and Market Data Break Down are illuminated below: by Type (Drip coffee machine, Steam coffee machine, Capsule coffee machine, Bean-to-cup coffee machines, Other coffee machine (Traditional Espresso Machines, Filter Coffee Machines, Capsule/Pod Coffee Machine)), Application (Commercial coffee machine, Office coffee machine, Household coffee machine), Sales Channel (Direct sales channel, Specialty retailers, Department stores, Hypermarkets and supermarkets, Online distributor channel), Function (Semi-automatic, Fully automatic), End user (Coffee Specialty Stores, Full Service Restaurants, Quick Service Restaurants, Food Junctions, Hotels/Café’s, Lounge, Residential Sector) What's Trending in Market: Growing Demand for Fresh Coffee for Across Corporate Offices

Increasing Use in Public Functions and Gathering

Challenges: Low Adoption in Rural Areas Owing to Prevalence of Alternate Coffee Making Techniques

Manufacturing Coffee Machines Which Requires Minimum Maintenance

Restraints: High maintenance cost may restraint the global coffee machines market in some aspects

Market Growth Drivers: Rise in Number of Shops and Cafe Offering Coffee

Growing Consumption among Working-Class Millennial

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc. Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/10750-global-coffee-machine-market-2 Strategic Points Covered in Table of Content of Global Coffee Machine Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Coffee Machine market

Chapter 2: Exclusive Summary – the basic information of the Coffee Machine Market.

Chapter 3: Displaying the Market Dynamics- Drivers, Trends and Challenges & Opportunities of the Coffee Machine

Chapter 4: Presenting the Coffee Machine Market Factor Analysis, Post COVID Impact Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Coffee Machine market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2021-2026)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source Finally, Coffee Machine Market is a valuable source of guidance for individuals and companies in their decision framework. Data Sources & Methodology The primary sources involves the industry experts from the Global Coffee Machine Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects. In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age. Get More Information: https://www.advancemarketanalytics.com/reports/10750-global-coffee-machine-market-2 What benefits does AMA research studies provides?

· Supporting company financial and cash flow planning

· Latest industry influencing trends and development scenario

· Open up New Markets

· To Seize powerful market opportunities

· Key decision in planning and to further expand market share

· Identify Key Business Segments, Market proposition & Gap Analysis

· Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Asia. About Author:

Advance Market Analytics is Global leaders of Market Research Industry provides the quantified B2B research to Fortune 500 companies on high growth emerging opportunities which will impact more than 80% of worldwide companies' revenues.

Our Analyst is tracking high growth study with detailed statistical and in-depth analysis of market trends & dynamics that provide a complete overview of the industry. We follow an extensive research methodology coupled with critical insights related industry factors and market forces to generate the best value for our clients. We Provides reliable primary and secondary data sources, our analysts and consultants derive informative and usable data suited for our clients business needs. The research study enable clients to meet varied market objectives a from global footprint expansion to supply chain optimization and from competitor profiling to M&As. Contact Us:

Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 (206) 317 1218

Connect with us at

https://www.linkedin.com/company/advance-market-analytics

https://www.facebook.com/AMA-Research-Media-LLP-344722399585916

https://twitter.com/amareport

3 notes

·

View notes

Text

Top Reasons to Choose an Automatic Tea Coffee Machine for Your Office

Creating a comfortable and productive work environment is vital for any successful office setup. Providing your employees with a quick and easy way to enjoy their favorite beverages can significantly enhance their productivity and satisfaction. This is where an automatic tea coffee machine for offices from Pradeep iBrew becomes essential.

Effortless Convenience

An automatic tea coffee machine simplifies the process of preparing beverages. With just the press of a button, employees can enjoy perfectly brewed tea, coffee, or filter coffee without the need for manual effort or expertise.

Versatile Options

Pradeep iBrew’s machines cater to diverse preferences, offering everything from refreshing tea to the rich taste of South India’s favorite filter coffee. Whether you want a tea maker machine or the best filter coffee maker machine in India, Pradeep iBrew delivers unmatched versatility.

Cost-Effective Solution

Investing in an automatic machine reduces dependency on external vendors, saving money in the long run. Plus, it minimizes the time spent by employees away from their desks, boosting efficiency.

Hygienic and Reliable

Automation ensures beverages are prepared in a clean, hygienic environment, maintaining consistent taste and quality every time.

Enhance Office Culture

A shared coffee corner becomes a hub for social interactions, brainstorming sessions, and team bonding. With Pradeep iBrew’s filter coffee machine, you can create a welcoming atmosphere that fosters collaboration and creativity.

Upgrade your office setup today with a Pradeep iBrew automatic tea coffee machine – the perfect blend of convenience, taste, and reliability!

#automatic tea coffee machine for offices#best filter coffee maker machine in India#Filter coffee machine#Tea maker machine

0 notes

Photo

GROUNDNUT FULLY AUTOMATIC OIL MILL PLANT

We at CHETAN AGRO INDUSTRIES Rajkot Gujarat, One of the leading manufacturer and exporter of Oil mill machinery and its related products from India specialized in manufacturing all types of Oil Expeller, Filter press, Baby Boilers, Decorticators and other Agro machinery products. Our Oil mill machinery is design and developed by experienced and qualified engineers of Chetan Agro Industries to work soundless and to give more output with extra percentage to oil from any type of oil seeds.

Mail - [email protected] Address - 11-BHAKTINAGAR STATION PLOT, GONDAL ROAD, OPP. BOMBAY PETROL PUMP, RAJKOT, GUJARAT, INDIA. Facebook - https://www.facebook.com/chetanagroindustries

#OilMillMachinery#mustardoilexpeller#oilexpeller#oilmakingmachine#oilpressmachine#minioilmill#healthyfood#HomeOilMaker

1 note

·

View note

Text

Multi Column Distillation Plant, Manufacturer, Supplier, Mumbai, India

We are best dealer, Manufacturer, Supplier of Liquid Manufacturing Plant, Get more details of Liquid Manufacturing Plant in mumbai, India.

Vacuum Tray Dryer, Zero Hold Up Filter Press, Filter Press, Colloid Mill, Multi Mill, Blender, Double Cone Blender, Octagonal Blender, Vibro Sifter, Double Deck Vibro Sifter, Single Deck Vibro Sifter, Dryer, Fluid Bed Dryer, Tray Dryer, Vacuum Tray Dryer, Liquid Manufacturing Plant, Liquid Filling Line, Automatic Liquid Bottle Filling Machine, Automatic Rotary Bottle Washing Machine, Manual Inspection Machine With Bw Hood, Turn Table, Mumbai, India.

0 notes

Text

A Simple Explanation of Important Washing Machine Parts & Functions

Washing machines aren’t built like they was once (thank goodness!), and today they’re truly very dependable kitchen appliances that rarely pass wrong. This is outstanding information for busy mums who don’t have the time to sit down and study the person manual from start to complete, learning approximately all the specific washing device elements.

However, for us matic moms, knowledge a touch about some of the greater essential functions may want to keep lots of hassles have to we ever stumble upon a chunk of issue using the system. Also check: Best front load washing machine

As you in all likelihood already understand, there are lots of various varieties of washing machine in India, and each washing system is unique to the subsequent. The format and functionality of a Samsung version may be quite unique to that of an Electrolux , as an example. This isn’t something to fear about. While there can be small differences, the primary washing machine elements and function buttons are quite a whole lot the equal across the board.

The Most Important Washer Parts Let’s neglect about all the complex, internal components of a showering device – we’re now not inquisitive about the mechanics or the inner workings of the device. All we really need to realize is how the principle parts and mechanisms work, so that ought to something go wrong, we've got pretty a solid idea about how to fix it without having to name a repairman.

Detergent Dispenser On a front-loading device, your detergent dispenser will commonly be a pull out drawer, or (usually with a pinnacle-loading system) it may be a part of the agitator. This drawer is quite sincere – it’s wherein you put your liquid or powdered detergent , whichever you pick to use, and your material softener. It’s nicely really worth giving your detergent drawer a clean each every so often.

Sometimes, no longer all of the detergent is pulled into the machine at some point of a wash, and the remnants can begin to clog up the drawer. Luckily, a brief wash with warm water is all you want to preserve this part of your washing machine walking easily.

Controls, Dials & Buttons The variety of buttons and dials on specific washing system models may be the stuff of nightmares for lots mums, mainly in case your new system in no manner resembles your antique one. What button do you press? Which manner need to you point this dial? Don’t worry! In many instances, you’ll have a temperature putting (e.G. 30 tiers celsius), a cycle placing (e.G. Pre-wash cycle, rinse cycle and so on) and a cloth setting (e.G. A wool putting and a synthetics setting) – you’ll generally most effective want to consciousness on these three control panels, and they’re quite self explanatory.

For special washes, together with in case you need to use a hand wash putting or a sanitisation setting, you may need to delve a touch deeper into the guide, however it’s no longer tough to understand. If you notice your buttons and dials are starting to paste, provide the outside of your washing device a wipe with a moist fabric and your favorite kitchen purifier to get rid of any dust.

Safety Lock

If you’ve were given a top-loading device, then you could slip this part. The protection lock applies handiest to front-loading machines – the kind that small hands may additionally try to force open whilst you’ve got your lower back turned for only a 2nd!

Your kids pay greater interest in your normal chores than you might imagine, and that they understand thoroughly what button to press to open the system, which can be disastrous if it’s mid-cycle.

The Bosch Serie 2 Classixx includes a baby lock, which could render the open button vain while the machine is strolling to prevent your kitchen or utility room from being flooded.

The Drum The drum is the big, open location you load your dirty laundry into. It’s a relatively easy element to appearance after, because it’s essentially self-cleaning, however it doesn’t harm to run a cloth across the inside of the drum every now and then to take away any pieces of lint. Unfortunately, in case your drum isn’t spinning it’s quite tough to realize why, as there are many motives for a non-running drum, including worn brushes or a defective motor. You may additionally have to call a repairman if this is the case.

The Agitator If you’ve were given a front-loading washing gadget, you don’t need to fear about this at all, because the drum alone agitates the garments. If, however, you've got a pinnacle-loading machine, the agitator is one of the maximum crucial washing system components. The agitator is the pole-like attachment that rises up in the center of the drum, and its activity is to move the garments across the drum, using small blades to make certain each item of laundry is saturated and washed thoroughly.

The agitator sits on a rotating ‘coupler’, which slots into the bottom and makes it spin. In time, the enamel that slot collectively can start to wear down, and that they don’t suit together as properly any more. If you discover your agitator stops spinning, it’s probably you may need to install a new coupler.

Water Hose Semi automated washing device parts are slightly distinctive to the elements in completely automatic machines. This sort of device requires more guide input than its absolutely automated counterparts, along with the want for water to be delivered and tired by way of hand. While all machines incorporate a water hose for draining water, you’ll emerge as a great deal more familiar with this hose in case you’re the usage of a semi automated machine.

It’s quite simple to apply: it just includes angling the hose into the bucket to get rid of the water. If you experience any issues along with your water hose, a blockage is the maximum probably alternative. Remove the hose, push thru any lint or hair that’s end up stuck, and also you need to see a huge distinction.

For more recommendation on the usage of a semi automated washing machine, take a look at out this accessible manual.

Tips from Our Matic Moms about Different Washing Machine Parts Our Matic Moms have plenty of helpful pointers about using a showering gadget and searching after distinct parts.

Final Parts:

“Don’t leave your clothes for your washer for more than 24 hours – they may get musty and moldy.”

“To prevent color stains, earlier than washing clothes put 1/2 bucket water in a bucket with one spoon salt and soak garments for five minutes.”

“Always use easy water for every wash; it's going to assist you to easy your washing machine.”

“Always cross for maintenance and checking of device in every three months. This will help for longer stay.”

“Clean the drum of your washing machine once in each 15 days.”

“Always cast off the clear out and clean it as soon as in whilst, to apply washing system cleaning to its fullest.”

“Understand why manuals are written and study them carefully.”

“I continually dispose of completed masses without delay and do now not permit damp garments sit in the system. Also use right quantity of detergent. I additionally preserve the gadget clean.”

“Nowadays, even pinnacle loading machines come with infant lock. Filters are any other very vital a part of washing machines.”

1 note

·

View note