#Asphalt Mixing Plant

Explore tagged Tumblr posts

Text

Asphalt Plant | Bitumen Sprayer Manufacturer in India - S.P. Enterprise

S.P. Enterprise is a manufacturer of road construction machinery like asphalt plant, hot mix plant, asphalt drum mix plant, bitumen sprayer in India. We are exporter and supplier of road construction equipments. Call us on +91-9712583240.

#asphalt plant#bitumen sprayer#mobile asphalt plant#asphalt drum mix plant#asphalt mixing plant#asphalt hot mix plant#bitumen pressure distributor

2 notes

·

View notes

Text

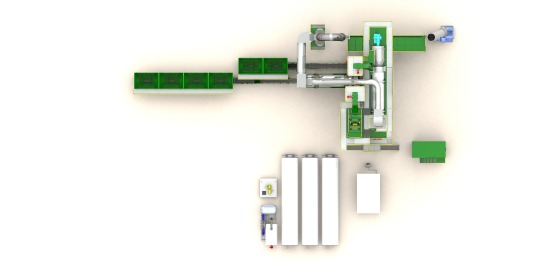

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

Hot Drum Mix Plant Introduction

ot drum mix plant, also known as continuous drum asphalt mixing plant or drum mix asphalt plant, is a kind of asphalt plant that produces asphalt concrete using a continuous process. It realizes the continuous process of heating and drying of aggregate and mixing of mixture through a series of continuous working units. Hot drum mix asphalt plant occupies an important position in road construction projects with its high efficiency and continuous production.

The output of hot drum mix plant varies depending on the model and configuration. Generally speaking, the output of small hot drum mix plant may range from tens of tons/hour to hundreds of tons/hour, while the output of large hot drum mix plant can reach thousands of tons/hour. The specific output needs to be determined according to the model of the hot drum mix plant, production capacity and actual production demand.

Asphalt hot drum mix plant is mainly composed of the following parts: - Batching system: responsible for feeding all kinds of aggregates into the mixing system according to the proportion. - Drying System: Usually consists of drums which are used to heat and dry the aggregates. - Combustion system: Provides heat, which is used to heat the aggregate in the drum. - Mixing system: carried out in the drum to mix the heated aggregate with binder materials such as asphalt. - Hot Aggregate Lifting and Storage System: Lifts the dried hot aggregate to the storage bin for subsequent metering and mixing. - Weighing System: Accurately measures various raw materials to ensure the quality of the mix. - Dedusting system: used to reduce the dust generated during the production process and protect the environment. - Control system: automated control of the whole mixing plant to ensure the stability and efficiency of the production process.

Characteristics of hot drum mix asphalt plant: - Continuous production: The drum hot mix asphalt plant adopts continuous process, which can realize continuous heating and drying of aggregate and continuous mixing of mixture, and improve the production efficiency. - Simple process: Compared with intermittent mixing plant, the process of drum mix asphalt plant is simpler and the structure of the plant is relatively compact. - High degree of automation: modern drum hot mix asphalt plant generally adopts PLC programmable centralized control, touch screen operation, automatic and manual switch freely, which greatly improves the degree of automation of production. - Good environmental performance: Equipped with dust removal system, it can effectively reduce the dust emission in the production process and protect the environment.

Advantages of asphalt hot drum mix plant: - Efficient production: the continuous production process makes the drum hot mix asphalt plant have high production efficiency, which can meet the demand of large-scale road construction projects. - Stable quality: Through precise measurement and continuous mixing, the quality of the asphalt mixture is stable and reliable. - Energy saving and environmental protection: modern drum hot mix asphalt plant emphasizes on energy saving and environmental protection design, and adopts high-efficiency combustion system and dust removal system to reduce energy consumption and emission. - Strong adaptability: can be flexibly configured and adjusted according to the needs of different projects to meet the needs of different types and specifications of asphalt mixture production.

In summary, the hot drum mix plant plays an important role in road construction projects with its high efficiency, continuous and stable production characteristics. With the continuous development of science and technology, the technology and performance of the drum hot mix asphalt plant will be constantly upgraded and improved.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/hot-drum-mix-plant.html Should you be interested in, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

Þ𝗲𝘁𝘁𝗮 𝘃𝗲𝗿ð𝘂𝗿 𝗳𝗿á𝗯æ𝗿𝘁 𝘀𝘂𝗺𝗮𝗿 og við erum til þjónustu reiðubúin til að gera allt fínt og fallegt utan við heimili og fyrirtæki. Starfsfólk BS Verktaka óskar viðskiptavinum sínum og landsmönnum öllum gleðilegs sumar með von um að þið njótið. 📲 551 4000 🌎 https://www.verktak.is/fyrirspurnir/

#asphalt#parking#parking maintenance#asphalt repair#asphalt paving#asphalt shingles#asphalt mixing plant#asphalt contractor#business consulting

0 notes

Text

youtube

260 tph batch asphalt mixing plant video - Atlas Technologies

The plant is heavy and designed to produce quality hot mix asphalt with less maintenance.We are Indian manufacturers and exporters of asphalt mixing plant in different capacities ranging from 60 tph to 260 tph.

0 notes

Text

Negotiating Asphalt Mixing Plant Prices: Strategies for Securing a Competitive Deal

When considering the purchase of an asphalt mixing plant, securing a favorable price is a key objective for many buyers. Negotiating with asphalt mixing plant manufacturers requires tact, preparation, and a clear understanding of your requirements and budget constraints. In this article, we explore effective strategies for asking manufacturers for a good price while ensuring that your needs are met.

Assessing Your Requirements and Budget

Before approaching asphalt mixing plant manufacturers, it's essential to assess your project requirements and budget constraints thoroughly. Determine the desired capacity, features, mobile asphalt plant price, and specifications of the plant based on your project scope and operational needs. Establish a realistic budget range that aligns with your financial resources and investment objectives.

Researching Market Prices and Trends

Conduct comprehensive research to understand prevailing market prices and trends for asphalt mixing plants. Explore pricing information from multiple asphalt mixing plant manufacturers, industry reports, and market analyses to gain insights into pricing dynamics, competitive benchmarks, and pricing strategies. This knowledge will empower you to negotiate from a position of strength and make informed decisions.

Requesting Multiple Quotes

Reach out to multiple asphalt mixing plant manufacturers to request quotes and pricing proposals for the equipment you require. Provide detailed specifications and project requirements to manufacturers to ensure accurate pricing estimates. By obtaining quotes from multiple suppliers, you can compare pricing options, features, and terms to identify the most competitive offer.

Highlighting Competitive Advantages

During negotiations, highlight your interest in the manufacturer's competitive advantages and unique selling propositions. Emphasize factors such as product quality, technological innovations, after-sales support, and reputation for reliability and customer satisfaction. By demonstrating genuine interest and appreciation for the manufacturer's strengths, you can foster goodwill and encourage favorable pricing terms.

Discussing Volume Discounts and Incentives

Inquire about volume discounts, incentives, and promotional offers that manufacturers may offer for bulk orders or long-term partnerships. Discuss the possibility of bundling additional services, such as installation, training, and maintenance packages, into the overall pricing package to maximize value and cost savings.

Negotiating Flexibility and Customization Options

Engage in open dialogue with manufacturers regarding flexibility and customization options for the asphalt mixing plant. Explore opportunities to tailor the equipment specifications, features, and configurations to better align with your project requirements and operational preferences. Negotiate for flexible payment terms, delivery schedules, and warranty provisions that accommodate your needs and mitigate risks.

Building Long-Term Relationships

Approach negotiations with a mindset of building long-term relationships and partnerships with asphalt mixing plant manufacturers. Express your interest in establishing a mutually beneficial collaboration based on trust, transparency, and shared goals. By fostering positive relationships and demonstrating commitment to future cooperation, you may gain access to preferential pricing and priority treatment.

Seeking Clarification and Transparency

Seek clarity and transparency throughout the negotiation process by asking questions, seeking explanations, and requesting detailed breakdowns of pricing components. Understand the factors that contribute to the overall price of the asphalt mixing plant, including materials, labor, overhead costs, and profit margins. Address any concerns or uncertainties upfront to avoid misunderstandings and ensure alignment between parties.

Conclusion

Negotiating with asphalt mixing plant manufacturers for a good price requires preparation, diligence, and effective communication. By assessing your requirements, researching market prices, requesting multiple quotes, highlighting competitive advantages, discussing volume discounts, negotiating flexibility, building relationships, and seeking transparency, you can navigate negotiations successfully and secure a competitive deal that meets your needs and budget constraints. With a strategic approach and collaborative mindset, you can forge partnerships that drive value and propel your asphalt projects to success.

0 notes

Text

Mobile Concrete Batching Plant and Asphalt Mixing Plant

Mobile concrete mixing plant The truck mounted concrete batching plant is a mobile concrete mixing plant equipment. Through ingenious design, the batching system, weighing system, mixing host, material storage, unloading and automatic control system of the batching plant are concentrated in one trailer unit, and the movement of the batching plant is realized by a trailer. The models of mobile…

View On WordPress

0 notes

Text

Asphalt mixing plant video - Atlas Technologies

Atlas asphalt plant working near Ahmedabad, India. Plant is of 160 tph and is fitted with natural gas burner.

0 notes

Text

Asphalt Mixing Plant Price - Atlas Industries

Atlas manufactures different types and categories of asphalt hot mix plants – the basic price or cost will depend on the capacity of the machine selected. It also depends on the type. The capacities that we manufacture start from as low as 20 tph, 40-60 tph, 60-90 tph, 80-100 tph, 120 tph, 160 tph, 200 tph and 260 tph. Visit Us: https://www.atlasindustries.in/blog/asphalt-mixing-plant-price/

0 notes

Video

Support my work, become a Patreon https://patreon.com/alexdehaas | De Langeloop, city of Schagen, The Netherlands. by Alex de Haas Via Flickr: Support my work, become a Patreon patreon.com/alexdehaas

#Aurora HDR#DJI#Dutch#Europa#Europe#HDR#Holland#M2P#Mavic#Mavic 2 Pro#Nederland#Nederlands#Netherlands#Noord-Holland#Ooms Producten B.V.#Schagen#West Frisia#West-Friesland#aerial photography#asphalt mixing plant#avond#drone#evening#fabriek#factory#industrial#industrie#industrieel#industry#landscape

0 notes

Text

Asphalt Drum Mix Plant, Asphalt Mixing Plant, Asphalt Plant Manufacturers in India

S. P. Enterprise is India's reputed manufacturer and supplier of asphalt drum mix plant, asphalt mixing plant, asphalt plant, asphalt hot mix plant etc. Call us on +91-9712583240.

1 note

·

View note

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum: Long service life Energy saving Low emission Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

Asphalt Hot Mix Plant Cost

To know the asphalt hot mix plant cost, we should understand the structure of an asphalt mixing plant. The core of an asphalt mixing plant is a variety of processing equipment, such as crushers, screens, weighing equipment, asphalt mixers, asphalt storage tanks, and generator sets. The cost of the equipment depends on the configuration and brand of the equipment, which generally ranges from millions to tens of millions of dollars. Specifically, the average-sized asphalt hot mix plant cost may range from 2-3 million dollars, while high-end or large-scale equipment may cost tens of millions of dollars.

The overall construction cost of a hot mix asphalt mixing plant includes the following aspects: 1.Land cost: First of all, you need to buy or rent land suitable for building the asphalt hot mix plant, the size and location of the land will directly affect the cost of building the asphalt mixing plant. 2.Equipment cost: Hot mix asphalt plant needs various equipment and machinery for production, including asphalt mixer, asphalt storage tank, hot oil furnace, dust removal equipment and so on. The price of these equipment varies according to the size and brand. 3.Plant construction cost: The hot mix plant needs to build a plant to store the equipment and raw materials, the construction cost includes building materials, labor, design cost, etc. 4.Cost of environmental protection facilities: The asphalt hot mix plant needs to install dust removal equipment and wastewater treatment equipment to meet environmental protection requirements. The purchase and installation cost of these equipments also need to be taken into account. 5.Other costs: These include the costs of approval processing fees, office equipment and personnel training.

Overall, the asphalt hot mix plant cost will be affected by a variety of factors, such as scale, equipment configuration, geographic location and so on. Generally speaking, the cost of building a medium-sized asphalt mixing plant may range from several million to tens of millions of dollars. Before construction, you need to fully consider all factors and make a detailed budget plan.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/asphalt-hot-mix-plant-cost.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

High-Performance Asphalt Hot Mix Plant for Sale

Enhance your road construction projects with an Asphalt Hot Mix Plant from Vishwakarma Engineering Works. Our plants are designed for high productivity and accuracy in asphalt mixing, offering construction companies the reliable equipment they need. Buy Asphalt Hot Mix Plant today and experience efficient, precise, and sustainable asphalt production with our trusted machinery.

Contact Us :- Phone:-9811821123 Email :[email protected] Website :-https://vishwakarmaengworks.com/product/asphalt-hot-mix-plant/

0 notes

Text

Asphalt Mixing Plant in Nashik - Atlas Technologies

See photos of Asphalt mixing plant installed in Nashik. This is a new design and efficient containerized asphalt mixer manufactured by Atlas.

0 notes

Text

Batch Mix or Drum Mix Plant? A Comparison for Your Project

When choosing the right asphalt plant for your construction project, understanding the differences between drum mix and batch mix plants is crucial. Each type of plant has its unique features, benefits, and limitations that can significantly impact your project’s efficiency, cost, and quality. In this blog, we’ll dive into the details of each plant type, compare them, and offer tips to help you make an informed decision.

Asphalt Mixing Plants

Asphalt mixing plants are essential in road construction, providing the asphalt needed for paving. There are two primary types of asphalt mixing plants: drum mix plants and batch mix plants. Each has its own operational mechanisms and use cases.

Asphalt Drum Mix Plant

How It Operates

An asphalt drum mix plant continuously produces asphalt by combining aggregates, bitumen, and additives in a drum. The materials are fed into the drum where they are heated and mixed in a continuous flow process. The mixture is then discharged from the drum and can be used immediately.

Key Components

Drum Mixer: The core component where mixing takes place.

Cold Aggregate Feeder: Feeds aggregates into the drum.

Burner: Heats the aggregates and bitumen.

Control Panel: Manages the operation and quality control.

Bitumen Tank: Stores and supplies bitumen to the mixer.

Advantages

Continuous Production: Allows for constant operation and high output.

Lower Operating Costs: Less fuel and labor compared to batch plants.

Simple Design: Easier to operate and maintain.

Disadvantages

Lower Quality Control: Less precise control over mix quality compared to batch plants.

Limited Flexibility: Harder to adjust mix designs and proportions.

Higher Emissions: Can have a greater environmental impact due to continuous operation.

Ideal Use Cases

Large-Scale Projects: Suitable for projects requiring high production volumes.

Road Paving: Efficient for continuous paving jobs where consistent quality is less critical.

Asphalt Batch Mix Plant

Description and Functionality

An asphalt batch mix plant produces asphalt in batches rather than continuously. The plant mixes a predetermined quantity of aggregates and bitumen at a time, allowing for precise control over the mix.

How It Operates

The batch mix process involves heating and mixing aggregates and bitumen in discrete batches. The process ensures that each batch meets specific quality standards before being discharged for use.

Key Components

Batcher: Measures and batches the aggregates.

Drying Drum: Heats the aggregates before mixing.

Mixing Tower: Combines aggregates with bitumen in a controlled environment.

Control System: Provides precise control over mix formulations and quality.

Cold Aggregate Feeder: Delivers aggregates to the drying drum.

Advantages

Superior Quality Control: Provides more precise and consistent mix quality.

Flexibility: Easier to adjust mix designs and proportions for different projects.

Lower Emissions: Typically more environmentally friendly due to batch processing.

Disadvantages

Higher Initial Cost: More expensive to purchase and set up.

More Complex Operation: Requires more skilled labor and maintenance.

Lower Production Capacity: Generally produces less asphalt compared to drum mix plants.

Ideal Use Cases

High-Quality Pavements: Best for projects requiring stringent quality control and varied mix designs.

Smaller to Medium Projects: Suitable for projects where flexibility and mix quality are critical.

Comparative Analysis

Production Efficiency

Drum Mix Plants: Higher production efficiency due to continuous operation.

Batch Mix Plants: Lower production efficiency as it operates in batches but provides higher quality control.

Mix Quality

Drum Mix Plants: May have more variability in mix quality.

Batch Mix Plants: Offers superior control and consistency in mix quality.

Environmental Impact

Drum Mix Plants: Potentially higher emissions due to continuous operation.

Batch Mix Plants: Generally lower emissions and better adherence to environmental regulations.

Cost Considerations

Drum Mix Plants: Lower operational costs and initial investment but less flexibility.

Batch Mix Plants: Higher initial costs but can result in cost savings through improved quality and reduced waste.

Flexibility and Adaptability

Drum Mix Plants: Less flexible in terms of mix design changes.

Batch Mix Plants: More adaptable to different mix designs and requirements.

Factors to Consider When Choosing a Plant

Project Size and Scope

Consider the scale of your project. Larger projects with high asphalt demand may benefit from the continuous production of drum mix plants, while smaller or quality-focused projects may be better suited to batch mix plants.

Budget Constraints

Assess your budget for both initial investment and ongoing operational costs. Drum mix plants generally have lower initial costs, whereas batch mix plants, though more expensive upfront, can offer long-term savings through quality control.

Environmental Regulations

Ensure that the plant you choose complies with local environmental regulations. Batch mix plants often have an edge in meeting stringent environmental standards.

Quality Requirements

Evaluate the quality standards required for your project. If high-quality, consistent asphalt is critical, a batch mix plant may be the better choice.

Consult a Leading Construction Equipment Manufacturer Today!

Choosing the right asphalt plant can significantly impact the success of your project. For personalized advice and to explore the best options for your needs, consult with a leading construction equipment manufacturer. They can provide valuable insights and recommendations tailored to your specific project requirements.

For more information, read our detailed comparison and make an informed decision that ensures the best outcomes for your asphalt mixing needs.

Visit at: Batch Mix or Drum Mix Plant? A Comparison for Your Project

0 notes