#Aluminum casting product manufacturer

Explore tagged Tumblr posts

Text

Finding the Best Aluminum Casting Product Supplier: Factors to Consider

Selecting the right aluminum casting product supplier can significantly impact your business. A reliable supplier ensures high-quality products, timely delivery, and consistent performance. Here’s a comprehensive guide to help you identify top-notch aluminum casting product suppliers.

Why Choosing the Right Supplier Matters

Aluminum casting is crucial for many industries, from automotive to aerospace. quality and reliability of cast aluminum products affect your end products' performance and durability. Hence, choosing the right supplier is imperative for maintaining your business’s standards and reputation.

Assessing Supplier Experience

When evaluating potential suppliers, consider their experience in the aluminum casting industry.

Years in Business: A long-standing supplier likely has more expertise and stability.

Client Portfolio: Review the types of clients they serve. Supplying to reputable companies is a good indicator of quality.

Case Studies: Ask for case studies or examples of their past work to gauge their capability in handling complex projects.

Quality of Aluminum Casting Products

Quality assurance is non-negotiable. Make sure the provider adheres to strict quality control guidelines.

Certifications: Check for industry-relevant certifications like ISO 9001, which indicate adherence to high-quality standards.

Quality Control Processes: Inquire about their quality checks at different production stages.

Material Standards: Ensure they use high-grade aluminum and comply with industry standards.

Technological Capabilities

Suppliers using advanced technology deliver better products.

Modern Equipment: Suppliers with up-to-date machinery can provide precise and efficient casting.

R&D Investment: A commitment to research and development suggests innovation and continuous improvement.

Software Utilization: Advanced software for designing and testing can lead to superior castings.

Customization Options

Often, customization is necessary to satisfy project-specific requirements.

Design Flexibility: The supplier should be able to accommodate unique designs and specifications.

Prototype Services: Availability of prototyping services helps ensure the product meets your requirements before full-scale production.

Adaptability: The ability to make adjustments based on feedback is crucial for custom projects.

Production Capacity and Scalability

Assess the supplier’s capacity to fulfill your orders.

Production Volume: Ensure they can handle your order size, whether small batches or large-scale production.

Scalability: The supplier should be able to scale up production if your demand increases.

Lead Times: Check their lead times and ensure they align with your project timelines.

Cost and Pricing Structures

As important as quality is, costs must also be taken into account.

Transparent Pricing: Look for suppliers who offer clear and detailed pricing structures.

Competitive Rates: Compare prices with other suppliers to ensure you're getting a fair deal.

Cost Efficiency: High-quality suppliers can help reduce costs in the long run by minimizing defects and reworks.

Location and Logistics

Supplier location can affect delivery times and shipping costs.

Proximity: Closer suppliers can reduce transportation time and costs.

Logistics Network: Suppliers with a robust logistics network ensure timely and efficient delivery.

Global Reach: If you have international needs, choose suppliers capable of handling global shipments.

Customer Service and Support

Provide excellent customer service to make a huge difference.

Responsiveness: Evaluate how quickly they respond to inquiries and issues.

Technical Support: Access to technical support for troubleshooting and guidance is crucial.

After-Sales Service: Reliable after-sales support indicates a commitment to customer satisfaction.

Sustainability Practices

Eco-friendly practices are increasingly important in today’s business environment.

Sustainable Sourcing: Ensure they source aluminum responsibly and sustainably.

Waste Management: Suppliers should have effective waste management and recycling processes.

Environmental Certifications: Look for certifications that reflect their commitment to environmental stewardship.

Evaluating Supplier Reputation

The reputation of custom aluminum product manufacturer provides insight into their reliability.

Customer Testimonials: Go through other companies' reviews and endorsements.

Industry Reputation: Check their standing within the aluminum casting industry.

Awards and Recognition: Industry awards can indicate exceptional performance and quality.

Partnerships and Long-Term Relationships

Building a long-term partnership with a cast aluminum product manufacturer offers consistency.

Reliability: A dependable supplier ensures consistent product quality and delivery.

Communication: Open and effective communication fosters a healthy business relationship.

Mutual Growth: Choose a supplier interested in growing together with your business.

Innovation and Adaptability

It is essential to be able to innovate and adjust to changes in the market.

Continuous Improvement: Suppliers focused on innovation and improvement can offer better products.

Market Adaptability: The ability to adapt to market trends and customer needs ensures relevance and competitiveness.

Future-Proofing: Partnering with aluminum casting product supplier can help future-proof your business.

0 notes

Text

#Aluminum casting assembly services#Aluminum product manufacturing partner#Aluminum casting product supplier#Aluminum investment casting foundry#Aluminum foundry service

0 notes

Text

Leading the way in Special Steels!

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA., we are proud to be one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels.

With over five decades of experience, we maintain the biggest steel yards and a high level of inventory from the world’s leading manufacturers like DEW, Vitkovice, Somers Forge, and Villares Metals.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units. The products, we deal in are specifically engineered to extend life service, save time and provide optimal performance to our customers.

You can rely on us for accurate and timely service on our part to process and execute your orders to match your satisfaction.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units as well as these Industries:

Our Serving Industries:

Forging Industry

Pressure Die Casting

Aluminum Extrusion

Automotive Industry

Oil and Gas

Mining and many more..

Our products are specifically engineered to extend service life, save time, and provide optimal performance. Trust us for accurate and timely service to meet your needs.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

youtube

Any further queries feel free to contact us: 🌐www.viratsteels.com 📬 [email protected] 📲+91-98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#SteelIndustry#SpecialSteels#IndustrialSolutions#DB6ToolSteel#H11Steel#H13Steel#DB6Steel#DIN2714#HCHCr#D2Steel#Youtube

2 notes

·

View notes

Text

What are all the types of aluminium fabrication?

Aluminum fabrication design encompasses a myriad of techniques and processes that transform raw aluminum into various finished products. Each method offers unique advantages, catering to diverse applications across industries ranging from aerospace to construction and automotive to electronics.

Extrusion stands as one of the most common aluminum fabrication techniques, involving the shaping of aluminum alloys by forcing them through a die. This process enables the creation of complex profiles with consistent cross-sectional shapes, ideal for applications requiring lightweight yet durable components such as window frames, structural beams, and heat sinks.

Sheet metal fabrication utilizes flat sheets of aluminum, which are cut, bent, and formed into desired shapes and sizes. From precision components for electronics to automotive body panels and aircraft fuselages, sheet metal fabrication offers versatility and efficiency in producing lightweight, corrosion-resistant parts with high structural integrity.

Casting processes, including sand casting, die casting, and investment casting, are employed to create intricate aluminum components with precise geometries. Sand casting is suitable for producing large, complex parts such as engine blocks and transmission housings, while die casting offers fast production of small to medium-sized components with tight tolerances. Investment casting, also known as lost-wax casting, enables the creation of finely detailed parts for aerospace, medical, and jewelry applications.

Welding plays a crucial role in aluminum fabrication, allowing for the joining of aluminum components through various techniques such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and resistance welding. TIG welding ensures precise control over the welding process, making it suitable for thin materials and intricate designs, while MIG welding offers higher deposition rates for thicker sections. Resistance welding methods like spot welding and seam welding are commonly used in automotive assembly and sheet metal fabrication.

The diverse types of aluminum fabrication techniques provide manufacturers and designers with a wealth of options to meet specific performance, cost, and design requirements. Whether it's extrusion, sheet metal fabrication, casting, or welding, each method contributes to the production of high-quality aluminum components for a wide range of applications. With expertise and quality materials from Alugrow Trading, manufacturers can leverage the full potential of aluminum fabrication to bring their designs to life.

Alugrow Trading

2 notes

·

View notes

Text

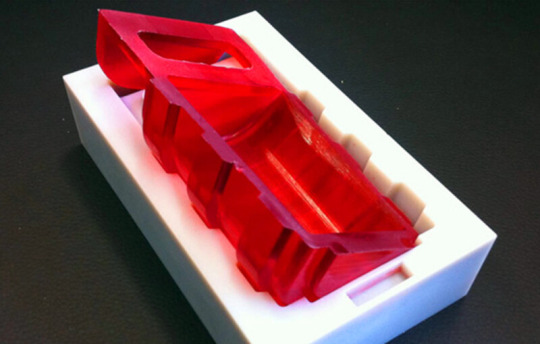

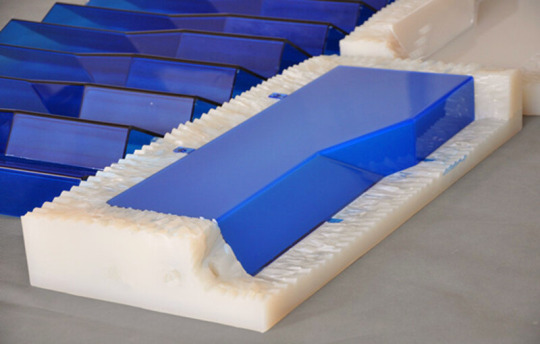

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

#WOODBINE Unveils Prestigious Managing Director's Chairs Redefining Office Luxury

#Revolving Excellence in Seating Craftsmanship

New Delhi, 27.01.2024 – Woodbine, the epitome of furniture elegance, proudly introduces its exclusive line of Managing Director's Chairs, meticulously crafted to elevate office seating to unprecedented heights. These chairs are more than just furniture; they embody a fusion of design, detailing, and workmanship tailored for the discerning executive.

Unveiling the Distinct #Features:

1. Two-Tone PU Leatherette Upholstery:

The Managing Director's Chairs boast a lavish two-tone PU leatherette upholstery, showcasing sophistication in every stitch.

2. Stainless Steel Soft Padded Handles:

Enhanced with soft-padded stainless-steel handles, these chairs provide a touch of luxury and comfort for the modern leader.

3. Aluminum Cast Base with 5 Twin Caster Wheels:

Designed for multitasking excellence, the chairs feature a robust aluminum cast base with 5 twin caster wheels, ensuring smooth mobility for dynamic leaders.

4. Syncro Knee Tilt / Syncro Tilt Mechanism:

Empowering executives with control, the Syncro Knee Tilt / Syncro Tilt mechanism allows seamless back and seat tilting for personalized comfort.

5. #Ergonomically#Designed Ply Seat and Back:

Woodbine prioritizes ergonomic excellence, with ply seat and back cushions designed to provide optimal support and comfort.

6. High-Density Cushioning:

Crafted with hi-density, soft-density, and poly-fil materials, these chairs ensure a comfortable and supportive seating experience throughout the day.

#Exclusivity Personified: The WOODBINE Touch

Woodbine, a master in furniture manufacture, brings forth its signature touch of exclusivity and luxury. Each Managing Director's Chair reflects the brand's commitment to precision crafting and innovative design.

#Unparalleled Reach, Exemplary Comfort

From bustling Delhi to vibrant #Noida, industrial hub #Manesar, and cultural gems like #Jaipur and #Jodhpur, Woodbine's Managing Director's Chairs redefine luxury in executive seating across diverse cities.

#LeadershipRedefined: Your #Signature Chair Awaits

Seize the throne of leadership with Woodbine's Managing Director's Chairs. #Elevate your workspace, enhance #productivity, and make a statement with every swivel. Craft your legacy with Woodbine.

1. Managing Director's Chairs

2. Executive Seating Luxury

3. Office Furniture Elegance

4. Revolving Chairs

5. Woodbine Crafted Chairs

6. Ergonomic Excellence

7. Leadership Seating

8. #WoodbineChairs

9. High-End Office Chairs

10. Executive Comfort Furniture

For media inquiries, please contact:

BARUN KUMAR

Marketing Head

98109 86205

About Woodbine:

Woodbine, synonymous with opulence in furniture design, specializes in crafting bespoke pieces that redefine luxury and comfort. With a legacy of excellence, Woodbine continues to set benchmarks in the world of high-end furniture.

2 notes

·

View notes

Text

Excellence in Non-Ferrous Forging & Casting in India

Non-ferrous forging and casting have emerged as critical processes in the manufacturing landscape, contributing significantly to India's industrial prowess. With a focus on metals like aluminum, copper, brass, and bronze, the country's expertise in non-ferrous forging and casting has reached new heights. Let's explore the excellence that India brings to these essential metallurgical processes.

Non-ferrous forging in India is marked by precision and skill, as manufacturers leverage advanced techniques to shape metals into components with superior mechanical properties. The forging process involves applying heat and pressure to mold metals into desired forms, enhancing their strength and durability. Indian forging facilities are equipped with state-of-the-art technology, ensuring the production of high-quality components that meet international standards.

Casting, another integral part of non-ferrous metal processing, is equally impressive in India. Foundries across the country use advanced casting methods to create intricate and complex shapes from molten non-ferrous metals. The attention to detail in the casting process is evident in the precision components that are vital to various industries.

Industries such as automotive, aerospace, and electronics in India benefit significantly from the excellence in non-ferrous forging and casting. The automotive sector, for instance, relies on these processes for manufacturing engine components, transmission parts, and lightweight structural elements. The use of non-ferrous metals contributes to fuel efficiency and sustainability, aligning with global trends.

In the aerospace industry, where precision and reliability are paramount, non-ferrous forging and casting play a crucial role. Components like aircraft engine parts and structural elements are crafted with meticulous attention to detail, ensuring the highest standards of performance and safety.

The electronics industry in India also reaps the rewards of non-ferrous forging and casting. The superior thermal conductivity of non-ferrous metals makes them ideal for applications such as heat sinks and connectors. The corrosion resistance of these metals ensures the longevity of electronic components in various environments.

As India continues to position itself as a global manufacturing hub, the excellence in non-ferrous forging and casting becomes a cornerstone of its industrial success. The commitment to quality, technological advancement, and sustainability places India at the forefront of non-ferrous metallurgy, contributing to the growth and competitiveness of its industries on the world stage. The journey of excellence in non-ferrous forging and casting in India is undoubtedly a testament to the nation's capabilities in shaping the future of manufacturing.

2 notes

·

View notes

Text

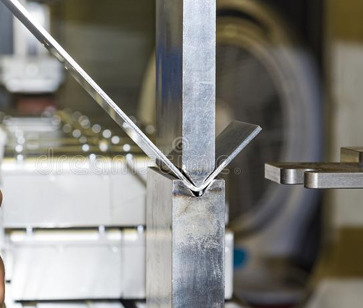

A Deep Dive into Die Casting Varieties, Benefits and Applications

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

Let's appreciate some cases of Xinyiguang's LED floor screen

Stay at home, go shopping, and walk on the road. Our common floor materials include carpet, wood plank, marble, cement road, asphalt and other types, but no matter how fancy, pattern, and color change, they all have a common feature-slightly "dull". Some people say that it is fun and convenient, just change it frequently. It sounds very embarrassing, you can change the carpet every day, but you can't pry the floor every day. Have you heard of Xinyiguang LED floor tile screen? Through the LED display, the visual interactive experience is immersive, giving people: the indoor floor tile screen with the experience of "sitting at home, the world is under the feet"; stepping and jumping, and the intelligent interaction of playing and dancing floor tile screen; waterproof and dustproof, super heavy outdoor floor tile screen. It can be tiled on the ground and displayed slowly, or it can be used to create a dreamy and flashing stair screen that climbs up the steps. Onlooker No. 1: It sounds amazing, do floor tile screens with so many functions really exist? Onlooker No. 2: Need to be powered on? Is it safe? Onlooker No. 3: Will it be crushed? Yes, yes, all of the above! Chinese people don’t lie to Chinese people. The editor of Digital Audio-Video Engineering Network couldn’t stand everyone’s urging, and decided to go to Xinyiguang with everyone to learn about it. It was an eye-opener. Experience the fun of "seeing is owning". 2022 CCTV Spring Festival Opera Gala-P2.976-300 square meters

Shenyang-TV Station-106.25 square meters

Yinchuan-Planning Pavilion-330 square meters

Xinjiang-Museum-P3.91-250 square meters

Zhejiang - Qiandao Lake Tourist Attraction - 240 square meters

Shanghai-Audi Flagship Store-P3.91

Russia - Stavropol - P2.976-288 square meters

Wuhan K11-P6.25 Indoor - 280 square meters

Q&A session

1. Is it safe? Quiet heat dissipation The power box of the LED intelligent interactive floor tile screen box adopts a die-cast aluminum box with good heat dissipation, and a special heat dissipation device is designed by a professional R&D team to achieve a better silent heat dissipation function. 2. Is it waterproof? The bottom case, mask, power cord and signal line of the waterproof and moisture-proof LED floor tile screen module are specially designed and equipped with waterproof and moisture-proof materials. They are made of raw materials with low moisture absorption coefficient. The front and back of the body can reach the waterproof level of IP45. 3. Is it reliable? The anti-slip and wear-resistant LED intelligent interactive floor tile screen mask is made of imported PC materials, which has high wear resistance and flexibility, and good high and low temperature resistance. And designed according to the principle of mechanics, Xinyiguang mask has good anti-slip and load-bearing functions. 4. Is it hard? Super load-bearing Each component of Yiguang LED intelligent interactive floor tile screen, according to different mechanical designs, has an ultimate load-bearing capacity of up to 3 tons per square meter. Onlookers 1, 2, and 3: Awesome! Is that brand okay? Editor: Founded in 2012, Xinyiguang is a professional supplier of global application products and solutions. Xinyiguang has a modern manufacturing plant of 8,000 square meters. The core R&D team has more than 20 years of experience in professional research and development. The company has obtained a number of valid patent certificates and a number of test reports to provide users with high-quality products and services. And in December 2021, it was awarded the "2021 Famous Brand of LED Floor Tile Screen" by Digital Audio Video Engineering Network. The trophy is still warming up, what do you think? Onlooker No. 1: Wow, it's so powerful, I will arrange a basketball court with LED floor tiles for the village immediately, the cubs in our village must not lose to the next village! Low-key arrangement... Onlooker No. 2: I heard it a long time ago! We have 4 in our village, 1 each in the east, west, north, and south. Onlooker No. 3: Tsk tsk tsk, you guys are so naive. I want to arrange a big floor tile screen for the entrance of my house, so that everyone will envy my house! The indoor LED floor tile screens, intelligent interactive floor tile screens, and outdoor LED floor tile screens developed and produced by Xinyiguang have various installation styles of floor tile screens and stair screens. The product cabinets are made of hard materials such as die-casting aluminum, aluminum plates, and iron. Increase the strength of the box, strong and wear-resistant. It's really good, the boss remembers to stock up for the New Year, because it will be a big hit in 2022! Read the full article

2 notes

·

View notes

Text

What is Aluminum Extrusion, and why is it important

Aluminum extrusion is a process where aluminum is forced through a die of the desired cross-sectional shape. The aluminum extrusion process begins with a billet, a rectangular piece of aluminum placed in an oven to be heated to approximately 700 degrees Fahrenheit. Once the billet is heated, it is placed on a loading table and fed into the extruder.

The extruder contains a ram that applies pressure to the billet, forcing it through the die. As the aluminum is forced through the die, it takes on the shape of the cross-section of the die. After the aluminum has been extruded, it undergoes a cooling process before being cut to length. Aluminum extrusion can be used to create a variety of shapes and products, such as pipes, tubing, and window frames.

Aluminum extrusion has many advantages over other manufacturing processes, such as casting and stamping. Aluminum extrusions are stronger than castings and have a higher degree of precision. In addition, aluminum extrusions can be produced in various shapes and sizes. Aluminum sheet panels for cars or aluminum siding for home’s walls and roofs.

Aluminum extrusions are also lightweight yet strong, making them ideal for aircraft and automobiles. Extruded aluminum also has good corrosion resistance and can quickly form complex shapes. These properties make aluminum extrusion an ideal choice for various applications.

Aluminum extrusion is a process by which aluminum is shaped into specific products. The aluminum is placed in a die, and a hydraulic press is used to push the aluminum through the die. This process can be used to create a variety of shapes and products, including pipes, tubing, rods, and more.

Aluminum extrusion has several advantages over other methods of shaping aluminum. For one, it is much faster than other methods. Additionally, it can create products with exact dimensions. The extrusion also allows for much customization, as different dies can create different shapes.

The Benefits of Aluminum Extrusion

There are many benefits to using aluminum extrusion. For one, it is a speedy process. In most cases, the entire process can be completed in just a matter of minutes. Additionally, extrusion allows for exact dimensional control. This means that products made via extrusion will always meet your specifications.

The extrusion also offers a great deal of customization potential. You can create products in nearly any shape or size using different dies. This flexibility makes extrusion ideal for applications requiring precise dimensions, but standard shapes will not suffice.

Finally, aluminum extrusion is relatively inexpensive compared to other methods of shaping aluminum. This makes it an ideal choice for applications where cost is a significant concern.

Conclusion:

Aluminum extrusion is a versatile manufacturing process that offers many advantages over other methods, such as casting and stamping. Aluminum extrusions are solid yet lightweight, precise, and resistant to corrosion. In addition, they can be easily formed into complex shapes. These properties make aluminum extrusion an ideal choice for various applications ranging from plumbing to aircraft construction.

Who are we?

We are an aluminum enthusiast, a surplus aluminum supplier in Canada and the USA.

Furthermore, we have extensive blogs about aluminum metals and their benefits. Some examples are:

Are aluminum canoes good?

Does aluminum help with soundproofing?

How To Make Your Aluminum Product Look Like New Again?

Are aluminum bats better than wood?

What Is The Difference Between Aluminum And Anodized Aluminum?

Additionally, if you ask your device to find “aluminum coil “ near me

or

Find “aluminum sheets “ near me in Toronto; you will find us on Google Maps. Hooray!

Additionally, if you ask your device to find “Aluminum Foil “ near me in Toronto,

Or

Find “Aluminum Wire “ near me in Toronto; you will find us on Google Maps. Hooray!

Call us at 905-764-2245 if you ever need premium aluminum metals in Toronto, Canada and the USA.

6 notes

·

View notes

Text

What Are Cast Aluminum Wheels?

Cast aluminum wheels are a popular choice in the automotive industry due to their unique manufacturing process and material properties. These wheels are created by pouring molten aluminum into a mold, allowing it to cool and solidify. This method results in wheels that are both lightweight and durable, offering a balance of performance and aesthetics.

Characteristics of Cast Aluminum Wheels

Cast aluminum wheels are known for their strength-to-weight ratio, which makes them an attractive option for vehicle manufacturers and enthusiasts alike. They exhibit excellent resistance to corrosion and can be easily customized with various finishes, enhancing the overall appearance of a vehicle. Additionally, these wheels provide good heat dissipation, contributing to improved braking performance.

Advantages of Cast Aluminum Wheels

The primary advantages of cast aluminum wheels include their lightweight nature, which can lead to better fuel efficiency and handling. They also offer design flexibility, allowing for intricate patterns and styles that can complement any vehicle's look. Furthermore, cast aluminum wheels are generally more affordable compared to forged alternatives, making them accessible to a broader audience.

Limitations of Cast Aluminum Wheels

Despite their benefits, cast aluminum wheels do have some limitations. They are more prone to bending or cracking under extreme stress or impact compared to forged wheels. Additionally, while they offer good corrosion resistance, they may still require regular maintenance to prevent damage from road salts or harsh weather conditions.

Why Might Cast Aluminum Wheels Need Straightening?

Cast aluminum wheels might need straightening due to various factors that can lead to deformation over time. Understanding these causes is crucial for maintaining wheel integrity and ensuring safe driving conditions.

Causes of Wheel Deformation

Several factors can contribute to the deformation of cast aluminum wheels. Common causes include hitting potholes or curbs at high speeds, which can result in bends or cracks. Additionally, exposure to severe weather conditions or road debris can also impact the wheel's structure over time.

Signs That Your Wheel Needs Straightening

Detecting signs of wheel deformation early can prevent further damage and ensure vehicle safety. Indicators that your wheel may need straightening include vibrations while driving, uneven tire wear, or visible bends on the wheel rim. If you notice any of these symptoms, it's advisable to seek professional assessment promptly.

Consequences of Ignoring Wheel Damage

Ignoring damage to your cast aluminum wheels can have serious consequences. It may lead to compromised vehicle handling and increased tire wear, which could affect your safety on the road. Over time, untreated wheel damage can also result in more costly repairs or replacements.

For reliable solutions regarding cast aluminum wheel repair or replacement needs, consider exploring Vesteon, where you can find high-quality OEM wheels tailored to your specifications.

To discover more about Vesteon's offerings in cast aluminum wheels, visit their product category.

0 notes

Text

#Aluminum casting supplier#Aluminum casting services#Aluminum casting prototype manufacturer#Aluminum product design and manufacturing

0 notes

Text

WHY VIRAT SPECIAL STEELS? Leading the Way in Special Steels!

Virat Special Steels Pvt. Ltd. INDIA, we are proud to be one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels.

With over five decades of experience, we maintain the biggest steel yards and a high level of inventory from the world’s leading manufacturers like DEW, Vitkovice, Somers Forge, and Villares Metals.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units. The products, we deal in are specifically engineered to extend life service, save time and provide optimal performance to our customers.

You can rely on us for accurate and timely service on our part to process and execute your orders to match your satisfaction.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units as well as these Industries:

Our Serving Industries:

Forging Industry

Pressure Die Casting

Aluminum Extrusion

Automotive Industry

Oil and Gas

Mining

Power Generation

Petrochemical

Aviation

Railways

Agricultural

Hand Tools

Bulk Material Handling

Our products are specifically engineered to extend service life, save time, and provide optimal performance. Trust us for accurate and timely service to meet your needs.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

youtube

Any further queries feel free to contact us: 🌐www.viratsteels.com 📬 [email protected] 📲+91-98140 21775

#ludhiana#viratsteels#india#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#SteelIndustry#EngineeringExcellence#IndustrialSolutions#DB6ToolSteel#SteelTrades#MetalIndustry#Youtube

3 notes

·

View notes

Text

Exploring the Metal Casting Market: Technological Advancements and Industry Outlook

The global metal casting market was valued at USD 136.71 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. Several factors are driving this market growth, with one of the primary drivers being the increasing demand for metal cast products, especially from the automotive sector. Metal casting is a widely used manufacturing process that involves pouring molten metal into molds or dies to create components with complex shapes and large sizes. This process is particularly beneficial for producing parts used in a variety of industrial applications, including automotive, industrial machinery, healthcare, telecommunications, and construction.

A key factor contributing to the growth of the metal casting industry is the regulatory pressure on automakers to improve fuel efficiency and reduce emissions. Governments around the world have implemented stringent pollution control and energy efficiency regulations, particularly in the automotive sector. These regulations are driving the demand for lightweight vehicles, which require casting materials such as aluminum and magnesium alloys to reduce the overall weight of vehicles. This shift toward lightweight vehicles has become an important trend in the automotive industry, as it helps automakers meet fuel efficiency standards while maintaining performance and safety.

Market Growth in the Asia Pacific Region

The metal casting market is expected to witness substantial growth in the Asia Pacific region, largely due to rising demand from end-use industries. Asia Pacific is home to rapidly growing markets in automotive, construction, and manufacturing, making it a crucial region for the industry. In particular, the demand for metal cast products is being driven by growth in the building and construction sector, especially in developing countries like China, India, Malaysia, and Indonesia.

For example, in 2018, Malaysia's residential and non-residential construction sectors grew by approximately 4.4% in real terms, while Indonesia’s construction sector experienced a healthy growth rate of around 7-8%. These growth figures were driven by increasing infrastructure development, government incentives, and favorable market conditions. Governments in these countries have been supporting the construction industry through initiatives such as relaxing mortgage down payment requirements and providing financial incentives for first-time homebuyers. As a result, the demand for metal casting products used in construction and infrastructure projects is expected to continue rising.

The building and construction industry’s growth in these countries is expected to have a significant positive impact on the metal casting market. The demand for cast products used in a variety of construction applications, including infrastructure projects (roads, bridges, and utilities) and residential and commercial buildings, is anticipated to continue expanding. The strong government support for infrastructure development in countries like China and India further supports the sustained growth of this market segment.

Gather more insights about the market drivers, restrains and growth of the Metal Casting Market

Application Segmentation Insights

The automotive sector is the largest consumer of metal cast products, accounting for 59.5% of the market revenue in 2022. The automotive industry's demand for casting products continues to grow as global production increases. For instance, global automotive production saw a modest but consistent rise, with a 2.3% increase in 2017, according to the International Organization of Motor Vehicle Manufacturers (OICA). One of the key trends in the automotive sector is the increasing use of aluminum cast products, which are essential for reducing the weight of vehicles. This trend is expected to continue as automakers focus on achieving better fuel efficiency and complying with stringent emissions standards. The shift to lightweight materials in vehicle manufacturing is, therefore, a major factor fueling the demand for aluminum casting products in the automotive sector.

In addition to the automotive sector, the industrial segment is also expected to experience significant growth. The industrial segment is projected to grow at the fastest CAGR of 5.9% over the forecast period. Products such as decanters, metal valves, gaskets, flanges, air injection tubes, and various industrial components are commonly produced using casting processes. These products are critical in industries such as oil and gas, power generation, and manufacturing. The rapid expansion of manufacturing industries in emerging economies, particularly in China and other parts of Asia, is expected to be a major driver for growth in the industrial segment. The increased need for industrial equipment and infrastructure in these regions will result in higher demand for metal castings used in the production of these components.

The building and construction sector is another key consumer of metal casting products. As governments worldwide increase their investments in infrastructure, including transportation, water supply, telecommunications, and energy networks, the demand for cast products for use in these projects is growing. The construction of large-scale infrastructure, such as bridges, highways, and rail systems, relies heavily on the use of durable metal castings, which provide the necessary strength and resilience for these applications. As infrastructure development continues to be a priority in many developing economies, particularly in the Asia Pacific region, this will further drive the demand for metal casting products in the construction industry.

Key Growth Drivers

Automotive Demand: The automotive sector remains a dominant consumer of metal cast products, particularly in the production of lightweight vehicles to meet fuel efficiency and emission regulations. The continued demand for aluminum cast products in vehicle manufacturing is expected to support the overall market growth.

Industrial Expansion: The industrial segment, driven by the growing manufacturing sectors in Asia and emerging economies, is expected to expand rapidly. The production of industrial components such as valves, pipes, and fittings, all of which are manufactured using casting processes, will continue to drive market growth.

Construction Growth in Asia: The building and construction industry, particularly in developing countries in Asia, is experiencing robust growth. Government initiatives to boost infrastructure investment and residential construction will continue to increase demand for metal casting products, especially in sectors such as transportation, energy, and water infrastructure.

Sustainability and Energy Efficiency: Stringent regulations aimed at reducing carbon emissions and improving energy efficiency are likely to continue driving the adoption of lightweight and energy-efficient materials, particularly in the automotive and aerospace industries. This shift will further elevate the demand for casting solutions.

Challenges

Despite the positive growth outlook, the metal casting industry faces several challenges, including the volatility in raw material prices, environmental concerns related to energy consumption during the casting process, and the need for continuous technological advancements to meet the evolving demands of end-use industries. Additionally, the industry must navigate supply chain disruptions and address concerns about sustainability and waste management practices in the casting process.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Everything You Need to Know About Finding a Reliable Silica Sand Supplier

One of the most widely used sands in many different sectors, supplier of silica sand is an essential raw material because of its high silica content and special physical characteristics. Suppliers of silica sand are essential to maintaining constant quality and availability for a variety of uses, including construction and glassmaking. Here, we explore the definition of silica sand, its applications, characteristics to consider when selecting a provider, and the reasons why having a trustworthy source of silica sand is crucial for businesses all over the world.

What Is Silica Sand?

The main component of silica sand, sometimes referred to as quartz sand, is silicon dioxide (SiO₂). Because of its crystalline form, this material is among the hardest and most resilient sands that can be found. Its high silica content—typically between 95% and 99%—makes it the perfect material for a variety of sectors that need components that are robust and long-lasting. Although silica sand is usually colorless or white, depending on the mineral impurities, it can also appear in yellow, pink, or even black hues.

Key Uses of Silica Sand

Glass Manufacturing: One of the primary uses of silica sand is in the glass industry, where it serves as the main ingredient for producing glass products. The high purity of silica is essential for making quality glass, as impurities can affect the transparency and strength of the final product.

Construction Materials: Silica sand is widely used as a filler in concrete, plaster, and mortar to enhance durability and provide texture. It’s also used in sandblasting applications due to its abrasive properties.

Foundry Casting: Silica sand’s high melting point and durability make it an excellent choice for metal casting, where it’s used to create molds for casting metals like iron and aluminum.

Water Filtration: Silica sand’s granular structure is ideal for water filtration systems, helping remove impurities and contaminants from drinking water. Many industrial and municipal water treatment plants rely on silica sand for efficient filtration.

Paints & Coatings: In paints and coatings, silica sand is added as an extender to improve texture and durability. It is especially popular in textured coatings used for anti-slip surfaces.

Oil & Gas Recovery: Silica sand is used in hydraulic fracturing, where it’s pumped into rock formations to release natural gas and oil. The sand acts as a proppant, holding open fissures created in the rock during extraction.

Why Choose a Reliable Supplier of Silica Sand?

The quality of the supplier of silica sand directly affects the performance of products it’s used in, making the selection of a supplier a critical step for businesses. A reputable supplier offers consistent quality, ensuring that their silica sand meets industry standards and specific requirements.

1. Quality Control:

A reliable supplier performs thorough quality checks to ensure their silica sand meets the necessary specifications. These checks often involve testing for purity, grain size, and particle shape, which are essential factors depending on the end use. For instance, glass manufacturers require silica sand with a high degree of purity, while foundry sand needs precise grain size and distribution.

2. Wide Product Range:

Many industries use silica sand with different specifications. A quality supplier offers a range of silica sands that vary in purity, grain size, and mineral composition, catering to diverse industry needs.

3. Consistency and Availability:

Silica sand suppliers should maintain a consistent supply chain to avoid disruptions. Industries like glass manufacturing and oil extraction rely on regular, uninterrupted deliveries of silica sand, making supplier reliability a key consideration.

4. Competitive Pricing:

A trusted supplier offers silica sand at competitive prices without compromising on quality. Cost efficiency is especially important for industries that consume silica sand in large quantities, like construction and manufacturing.

Factors to Consider When Choosing a Silica Sand Supplier

Selecting a dependable silica sand supplier involves evaluating multiple aspects:

Reputation: Check the supplier’s reputation in the market. Look for customer reviews and feedback that reflect the reliability and quality of the supplier’s products.

Certifications: Reputable suppliers often hold industry certifications that vouch for their quality control processes. These certifications indicate adherence to industry standards and reassure clients of product quality.

Testing and Analysis: Ensure that the supplier performs regular testing on their silica sand products. Testing reports that confirm purity, particle size, and other parameters are essential for industries that rely on specific sand properties.

Environmental Responsibility: Environmentally conscious companies are increasingly prioritizing suppliers who implement sustainable practices. Choosing a supplier who follows responsible mining and processing practices can support eco-friendly business operations.

Pratibha Refractory Minerals – A Trusted Silica Sand Supplier

One of the renowned names in silica sand supply is Pratibha Refractory Minerals. With a focus on quality and customer satisfaction, Pratibha Refractory Minerals provides high-grade silica sand tailored to meet various industrial demands. They are known for their rigorous quality control, timely delivery, and extensive product range, making them a preferred choice for businesses in need of reliable silica sand.

Conclusion

In industries where material quality and consistency are paramount, selecting the right supplier of silica sand can make a significant impact on operations and end products. From construction to water filtration, silica sand plays a vital role, and choosing a reputable supplier, like Pratibha Refractory Minerals, ensures that your operations remain efficient and cost-effective. By focusing on quality, availability, and competitive pricing, businesses can find the right supplier to meet their unique needs, ensuring sustainable success and high-quality output.

0 notes

Text

Aluminum Coils

Marudhar's Aluminum Coils are a premium product for businesses seeking high-quality aluminum for various applications. Their expertise in aluminum manufacturing ensures precise and consistent coil production, available in a range of thicknesses, widths, and lengths to meet specific customer needs. With a focus on quality, innovation, and customer satisfaction, Marudhar's Aluminum Coils are a trusted choice for industries such as packaging, construction, and automotive.

At Marudhar, the key to success is quality control through years of experience and research. With over 40 years of experience, we are a leading national company that can perform all processes of aluminium rolling under one roof, ranging from continuous strip casting to rolling and converting. This has helped us to maintain uniform quality standards and timely delivery for our customers.

0 notes