#Aluminium Cast

Text

Mark - pedal

obviously an industrial pedal - any ideas about the pedal or the brand are welcome!

facebook.com/Carlo Zoccola

20 notes

·

View notes

Text

Rockman: Casting Aluminum for EV parts since two decades

Core of Rockman Services

Quality Management

Safety Protocols

Environmental Sustainability

For More Information Click here : https://www.rockman.in/aluminium-die-casting/

0 notes

Text

Dining Table by Gerard Mannoni Circa 1970,

Cast Aluminum and Glass,

W.61.5 in; H.29 in; D.86.5 in (W.156.21 cm; H.73.66 cm; D.219.71 cm)

Courtesy: Studio Van Den Akker

#art#design#sculpture#furniture#table#dining table#cast aluminium#glass#forms#gerard mannoni#1970#studio van den akker

9 notes

·

View notes

Photo

Jasper Johns, “Numbers 2007″,

Aluminum, 107⅝ × 83 × 2¼ inches; 273 × 211 × 6 cm,

Courtesy: Matthew Mark Gallery

56 notes

·

View notes

Text

Aluminium Cast Band Heaters

Are you looking Aluminium Cast Band Heaters in Uttar Pradesh, India? Hindon Electricals is well known in this industry. We have years of experience and expertise. We ensure that the quality matches the client's requirements. If you want to buy or know more about aluminum cast band heaters, you can contact us.

Add : A-1/274 Swadeshi Compound Kavi Nagar Industrial Area Ghaziabad -201001

Email : [email protected]

Ph : +91-9811098334, +91-7292031858

https://www.hindonheater.com/aluminium-cast-band-heaters/

2 notes

·

View notes

Photo

A sculpture titled 'Female Torso No. 1 (Nude marble Garden sculpture)' by sculptor Mitchell House. In a medium of Reconstituted marble/Cold cast bronze,iron,, aluminium.

#artist#sculpture#sculptor#art#fineart#Mitchell House#Cast#Marble#stone#Bronze#metal#Iron#Aluminium#limited edition

6 notes

·

View notes

Text

What is the difference between steel alloy and cast iron?

To begin with, steel alloy and cast iron are both types of metal alloys that are widely used in various industries. Although they share some similarities, there are significant differences that set them apart. Steel alloy is made by combining iron with other elements such as carbon, manganese, and chromium. Steel typically contains less carbon than cast iron, making it more ductile and malleable. Its tensile strength is higher, and it's more resistant to corrosion, making it ideal for use in building structures, machinery, and automobiles.

Cast iron, on the other hand, is formed by melting iron and adding carbon, silicon, and other elements. Cast iron contains a higher percentage of carbon, making it harder and more brittle. It is generally used in applications where high compressive strength is required, such as in the production of engine blocks, cookware, and pipes. Cast iron is also more prone to cracking under pressure or impact than steel alloy.

In conclusion, the differences between steel alloy and cast iron are based on their composition and properties. Both materials have distinct advantages and disadvantages, and their suitability depends on the specific application. By the way, after talking about it, only one company name comes to my mind that is Datre Corporation Ltd, is a leading manufacturer of high-quality steel casting products that meet the highest industry standards in Eastern India. So you can confidently utilise their products for your industrial needs.

Company name: Datre Corporation

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#stainless steel#cast iron#steel alloy#carbon#steel casting manufacturer#manufacturing industry#manufacturing company#aluminium manufacturer#manufacturer

3 notes

·

View notes

Photo

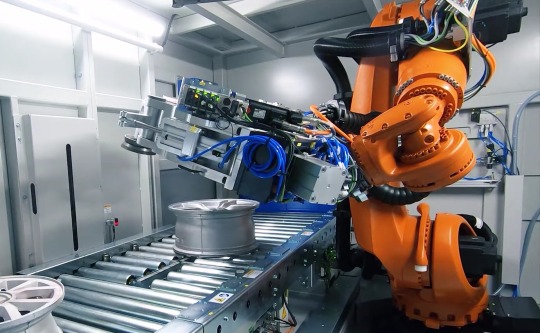

🦾 A006R - Robotic X-ray Inspection of Cast Aluminium Automotive Wheels

Robot Arm 6-axis with special gripper - BarCode inline recognition

ISAR image evaluation software - XEye detector X-ray inspection...

via HeiDetect HEITEC PTS and MetrologyNews

▸ TAEVision Engineering on Pinterest

Data A006R - Apr 12, 2023

#automation#robot#robotics#X-ray Inspection#cast aluminium automotive wheels#robot arm 6-axis#special gripper#BarCode inline recognition#ISAR image evaluation software#XEye detector#HeiDetect#HEITEC PTS#MetrologyNews

2 notes

·

View notes

Text

#urs fischer#The Grass Munchers#2007#Cast aluminium#pigments#pins#wax and hair#wax sculpture#ephemeral art

3 notes

·

View notes

Text

Top Aluminium Die Casting Manufacturer & Supplier in India | BQMP

BQMP is a top aluminum die casting manufacturer and supplier in India, offering high-quality die cast components and custom solutions for diverse industries. Explore our premium Aluminum casting services to meet your specific needs.

0 notes

Text

Aluminium corrugated sheet manufacturer

Aluminium corrugated sheet manufacturer. High-quality, durable sheets for roofing, siding, and industrial applications. Custom sizes and finishes available.

#roof replacement#roofing contractor#roofing repair#roofing services#color coated#roofing sheets#roofing company#aluminium windows and doors#aluminium foil#aluminium die casting#aluminium sheets

0 notes

Text

Astro Amp - Astrotone Fuzz

"made by Universal Amplifier Corp. of New York. This is from 1967"

cred: reverb.com/Sean's Funkadelic Gear Parlor

#astro amp#astrotone#astrotone fuzz#umiversal amplifier corp.#favs#sam ash fuzzz boxx#sand cast aluminium#sand cast#enclosures

31 notes

·

View notes

Text

Aluminiuim Die casting products

Die-casting products are preferred in the automotive industry

The automotive industry needs lightweight, high-precision, sturdy products. Aluminum die-casting offers multiple advantages to automotive manufacturers. Die-cast product manufacturers like Rockman have been using state-of-the-art facilities in India for manufacturing automotive parts in bulk.

Aluminium die-cast is the solution

In the automotive industry, in fact, many other industries like ship and aircraft builders need lightweight corrosion resistant, long-lasting parts. Aluminium die-cast parts solve this issue. Aluminium die casting products are corrosion-resistant and appropriate in any weather condition.

Cost-effective method

Compared to other methods of manufacturing automotive products or parts, die-casting is much more cost-effective for automotive manufacturers. Die-cast product manufacturers like Rockman are capable of supplying automotive parts in bulk without compromising the quality.

Find a reputed die-cast manufacturer

When you need die-cast parts in bulk for manufacturing automotive engines or automotive units, ensure you choose the right business partner in India.

For more information of die cast products visit https://www.rockman.in/

0 notes

Photo

Arthur Court, Rare folding screen, USA, c. 1960,

Polished cast aluminum,

62 h × 57 w × 1 d in (157 × 145 × 3 cm)

Courtesy: Wright20

#art#design#sculpture#screen#aluminium#arthur court#1960#floral#organic#cast aluminium#wright20#flowers

7 notes

·

View notes

Text

China Automotive Parts Aluminium Die Casting Industry: Key Trends and Market Outlook

The China automotive parts aluminium die casting industry is undergoing significant growth as demand for lightweight, durable, and high-performance materials continues to rise in the automotive sector. Aluminium die casting is a crucial manufacturing process used to produce complex automotive components, offering key benefits such as reduced weight, high strength, and cost efficiency. The China Automotive Parts Aluminum Die Casting Market Size is projected to be valued at USD 10.41 billion in 2024 and is expected to grow to USD 15.49 billion by 2029, with a compound annual growth rate (CAGR) of 8.26% over the forecast period (2024-2029).

Market Overview

The market for automotive parts aluminium die casting in China is growing at a rapid pace. The shift towards electric vehicles (EVs) and the increasing production of lightweight vehicles to meet regulatory emission standards are driving demand. As of 2024, the market is estimated to be worth billions, with significant growth expected through 2029 due to rising investments in advanced die casting technologies and the expansion of China's automotive industry.

Key Trends Shaping the Industry

Growing Demand for Lightweight Vehicles

In response to strict environmental regulations, the automotive industry is increasingly focusing on lightweight materials to reduce vehicle emissions and improve fuel efficiency. Aluminium die casting offers an effective solution, providing lightweight components without compromising strength and durability. The demand for aluminium parts, such as engine blocks, transmission cases, and structural components, continues to rise in China.

Electric Vehicle (EV) Boom

China’s rapid adoption of electric vehicles is a major driver for the aluminium die casting market. As EVs require lightweight components to extend driving range and improve energy efficiency, aluminium die casting is becoming a preferred process for producing parts like battery enclosures and motor housings. With China being the world’s largest EV market, the demand for aluminium die cast parts is expected to soar.

Technological Advancements

Advanced die casting technologies, such as high-pressure die casting (HPDC), are gaining traction in China’s automotive industry. These technologies enable the production of more complex and precise components with reduced lead times and lower costs. The integration of Industry 4.0 technologies, including automation and robotics, is further improving the efficiency and quality of aluminium die casting processes.

Expansion of the Automotive Industry

China remains one of the world’s largest automotive markets, with continuous growth in vehicle production and sales. This expansion is fueling demand for automotive parts, including aluminium die cast components. Additionally, many global automotive manufacturers are establishing partnerships and production facilities in China, further driving market growth.

Sustainability and Recycling Initiatives

Aluminium is highly recyclable, and the automotive industry in China is increasingly prioritizing sustainability. Aluminium die casting plays a key role in reducing the environmental footprint of vehicle manufacturing, as it allows for the reuse of aluminium scrap in production. This trend is expected to support the long-term growth of the aluminium die casting market.

Challenges Facing the Industry

Despite the strong growth outlook, the aluminium die casting industry faces challenges, such as fluctuating raw material prices and the need for substantial capital investment in advanced machinery and technology. Additionally, competition from other lightweight materials, like magnesium alloys, could impact the market dynamics in the future.

Conclusion

The China automotive parts aluminium die casting industry is poised for substantial growth, driven by the increasing demand for lightweight materials, the rapid adoption of electric vehicles, and technological advancements. As China continues to strengthen its position as a global automotive manufacturing hub, the aluminium die casting sector is expected to play a pivotal role in shaping the future of vehicle production.

For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence https://www.mordorintelligence.com/industry-reports/china-automotive-parts-aluminium-die-casting-market

#china automotive parts aluminium die casting market#china automotive parts aluminium die casting market size#china automotive parts aluminium die casting market share#china automotive parts aluminium die casting market trends#china automotive parts aluminium die casting market forecast

0 notes

Photo

A sculpture titled 'Water Dance 1 (Shiny aluminium Water Creation sculpture)' by sculptor Nando Alvarez. In a medium of Cast in Aluminium and in an edition of 3/7.

2 notes

·

View notes