#Air header manifold

Explore tagged Tumblr posts

Text

A complete Guide to Air Header

Air headers are crucial components in many industrial applications where multiple pneumatic instruments need to be supplied with air from a central location. An air header uses to distribute compressed air or gas from a single source to multiple instruments or devices, allowing for easier control and regulation of the flow of air.

In this blog post, we will provide a complete guide to air headers, including what they are, how they work, and the different types available in the market.

What is an Air Header?

An air header, also known as an air distribution manifold, is a vital component used to distribute compressed air or gas to various pneumatic instruments or devices. It is typically installed close to the source of compressed air, and its primary function is to provide a central distribution point for multiple instruments or devices.

Air headers consist of a series of inlet and outlet ports, which are connected to the compressed air supply and the pneumatic instruments, respectively.

How do an Air Headers Work?

The operation of an air header is relatively simple. Compressed air is supplied to the inlet port of the header, which is then distributed to the outlet ports via a series of internal passageways. The outlet ports are connected to the pneumatic instruments, allowing them to receive a regulated flow of compressed air or gas.

The header also includes various components, such as valves and pressure regulators, which are used to control the flow of air to each instrument.

Types of Air Headers

Several types of air headers are available in the market, including manifold air headers and instrument air headers, each with unique features and advantages.

Here are some of the most common types:

Standard Air Headers:

These headers are the most basic and commonly used type of air headers. They are typically made of stainless steel or brass and can accommodate a wide range of pneumatic instruments. As an air header supplier, Instrumxx Industries offers a variety of standard air headers to suit different applications.

Modular Air Headers:

Modular air headers consist of several independent blocks that can be connected together to form a larger header. This type of header is ideal for applications where expansion is expected, as additional blocks can be added as needed. Instrumxx Industries offers modular air headers as a flexible solution for our customers.

Instrument Air Headers:

Instrument air headers are designed specifically for use with critical pneumatic instruments that require a high level of accuracy and precision. They are typically made of stainless steel and incorporate advanced features such as pressure gauges and filters. As an instrument air header manufacturer in India, Instrumxx Industries provides instrument air headers that meet the strictest industry standards for precision and reliability.

Specialty Air Headers:

Specialty air headers are designed for specific applications, such as those involving corrosive or hazardous gases. They are made of specialized materials that can withstand the harsh conditions of these applications. As a leading air header manufacturer, Instrumxx Industries offers specialty air headers that are engineered to meet the unique needs of our customers.

Advantages of Air Headers

Here are some of the advantages of using air headers:

Centralized Air Supply:

Air headers allow for a centralized air supply, which simplifies the distribution of compressed air or gas to multiple pneumatic instruments. This makes it easier to control and regulate the flow of air and ensures that each instrument receives a consistent supply of air headers.

Improved Efficiency:

By using air headers, you can reduce the number of airlines required, which can help to minimize pressure drop and improve overall system efficiency. This can result in lower energy costs and improved productivity.

Easy Maintenance:

Air headers are designed for easy maintenance and repair. They can be easily disassembled, cleaned, and reassembled, allowing for quick and efficient servicing of the system.

Customizable:

Air headers can be customized to meet the specific needs of your application. This includes the number of ports, the size of the ports, and the type of valves and regulators used. This ensures that the system is optimized for your specific requirements.

Increased Safety:

Air headers can improve safety in industrial applications by reducing the number of airlines required. This can minimize the risk of leaks, which can be a safety hazard in some applications. Additionally, air headers can be equipped with safety features, such as pressure relief valves and filters, to further enhance safety.

Applications of Air Headers

Here are some of the common applications of air headers:

Pneumatic Instrumentation:

Air headers are commonly used in industrial applications to supply compressed air or gas to multiple pneumatic instruments, such as control valves, actuators, and pressure transmitters. This allows for centralized control and regulation of the flow of air, which can improve efficiency and accuracy.

Process Control:

Air headers are often used in process control applications to regulate the flow of air or gas in a system. This can be important for maintaining consistent process conditions and ensuring product quality.

Chemical Processing:

Air headers are commonly used in chemical processing applications to supply air or gas to process equipment, such as reactors, mixers, and filters. This allows for precise control of process conditions and can improve safety by minimizing the risk of leaks.

Oil and Gas:

Air headers are often used in the oil and gas industry to supply compressed air or gas to control valves, actuators, and other equipment. This is critical for controlling the flow of fluids and gases in the production and refining processes.

Water Treatment:

Air headers are used in water treatment applications to supply air or gas to diffusers, which are used to aerate and mix water in treatment tanks. This can improve the efficiency of the treatment process and help to ensure that water quality standards are met.

Final Thoughts.

Air headers are an essential component in many industrial applications, providing a centralized distribution point for compressed air or gas. Understanding the different types of air headers available in the market, including air header manifold and instrument air header, is crucial to selecting the right header for your application. As a reputable air header manufacturer and supplier in India, Instrumxx Industries provides high-quality air headers that meet the diverse needs of our customers.

Explore high-quality Air headers for your next project with us today!

0 notes

Text

Air Header Manifold in Belgium - Baxcell

Looking for high-quality air header manifolds in Belgium? Baxcell offers premium air header manifolds designed to distribute compressed air to various instruments in industrial applications. Our air header manifolds are manufactured from robust materials, ensuring exceptional durability, corrosion resistance, and reliable performance in demanding environments such as petrochemical, oil and gas, and power plants.

0 notes

Text

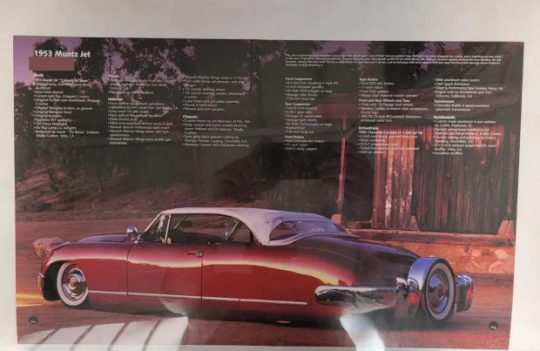

Custom 1953 Muntz Jet Convertible

This 1953 Muntz Jet convertible underwent a three-year custom build under previous ownership, and it was purchased by the seller in 2021. The car is powered by a fuel-injected 5.7-liter LT1 V8 engine paired with a four-speed automatic transmission and a Ford 9″ rear end, and it is finished in Apple Pearl with a white Carson-style removable top over gray snakeskin-style Naugahyde upholstery. Features include custom bodywork, an Art Morrison frame, power-assisted steering, four-wheel disc brakes, airbag suspension, Painless Performance wiring, and more modified and fabricated details. This custom-built Muntz is now offered with a copy of Rodder’s Journal magazine featuring a story on the build and a clean California title in the name of the seller’s business.

Custom 1953 Muntz Jet Convertible

The steel, aluminum, and fiberglass body is mounted on an Art Morrison ladder frame that was boxed and finished in semi-gloss black, and the floor was raised 3″. The exterior was repainted in a Sherwin Williams two-stage Apple Pearl mixed by the late Stan Betz. Features include a chopped Duvall-style windshield, 1950 Chevrolet headlights, dual Appleton spotlights, 1951 Ford Victoria side windows, and a white removable Carson-style top fabricated to match the height of the chopped windshield. Additional equipment includes color-matched rear fender skirts and chrome bumpers. Wear from fitting the top is noted on the rear deck.

Custom 1953 Muntz Jet Convertible

Steel wheels sourced from a 1976 Dodge measure 15″ and are mounted with Cadillac Sombrero-style covers and whitewall tires. A matching spare fitted with a BFGoodrich Silvertown tire is mounted within a rear-mounted Continental-style chrome carrier. A Mustang II front end accommodates power rack-and-pinion steering , and the car rides on an electronically-adjustable Air Ride Technologies airbag suspension system along with 2” lowered front spindles, Strange Engineering tube shocks, a rear Panhard bar, and front and rear sway bars. The seller reports that the front control arm bushings were recently replaced.

Custom 1953 Muntz Jet Convertible

Custom 1953 Muntz Jet Convertible

Braking is handled by GM G-body-sourced calipers matched with Ford Granada discs up front and Ford SVO-specification calipers and discs at the rear.

Custom 1953 Muntz Jet Convertible

The cabin was customized by Jim’s Auto Trim of San Diego, California, and features Glide bucket seats and a rear bench trimmed in gray snakeskin-style Naugahyde upholstery, along with matching treatments for the dash trim, headliner, and door panels. Additional equipment includes a 1952 Lincoln steering wheel mounted to a shortened Lincoln steering column, gray cut-pile carpet, and a Pioneer stereo housed within a custom center cubby.

The engine-turned “Hollywood” instrument cluster houses Stewart Warner gauges consisting of an 8k-rpm tachometer, a 160-mph speedometer, and auxiliary readings for fuel level, battery charge, oil pressure, and water temperature. The five-digit odometer displays 25k miles, though total chassis mileage is unknown. A Lokar pedal assembly was fitted during the build.

Custom 1953 Muntz Jet Convertible

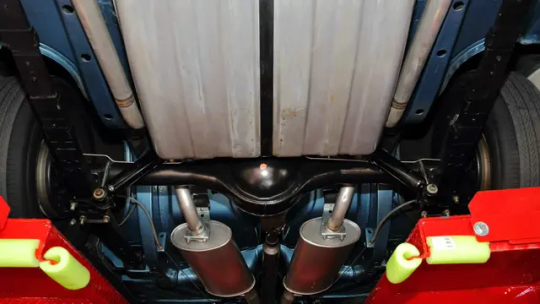

The Corvette-sourced 5.7-liter LT1 V8 features a polished fuel intake manifold along with billet aluminum valve covers, and additional features include an Opti-Spark distributor, a Griffin aluminum radiator, and a wiring loom sourced from Painless Performance Wiring. A set of long-tube headers are connected to a 2.5″ exhaust system equipped with dual Dynaflow mufflers. The seller reports that the oil was recently changed.

Custom 1953 Muntz Jet Convertible

Power is routed to the rear wheels via a four-speed 4L60E automatic transmission and a Ford 9″ rear end with with 3.55:1 gears and Strange Engineering 31-spline axles. Additional photos of the underside, drivetrain, and suspension components are presented in the gallery below.

Custom 1953 Muntz Jet Convertible

The car was featured in issue #36 of Rodders Journal magazine

#Custom 1953 Muntz Jet Convertible#Custom 1953 Muntz Jet#Muntz Jet Convertible#Custom Muntz Jet Convertible#Muntz Jet#Convertible#car#cars#muscle car#american muscle

110 notes

·

View notes

Photo

Winning recipe. The team at Vengeance Racing equipped this 2023 Chevrolet C8 Corvette Stingray with just the right combination of upgrades to make a big impact. On the power side of the equation, they combined a Halltech Systems Hornet cold air intake, CNC ported throttle body, Late Model Engines CNC LT2 cylinder heads, Jet-Hot coated Fabspeed HK long-tube headers & high-flow catalytic converters, and FabSpeed HK catback exhaust to add 50HP. On the style side, they added ACS Composite carbon fiber splitter & side skirts and Vengeance Racing CNC Raised Letter valve covers that are color-matched to a Late Model Engines CNC Billet LT2/C8 intake manifold. And for grip, they lowered the static ride height on factory suspension and installed Carbotech brake pads, Michelin Pilot Sport 4S tires, and 20x9/21x12 Forgeline one piece forged monoblock VX1R wheels finished in Transparent Smoke! See more at: https://forgeline.com/customer-gallery/vengeance-racing-customer

#forgeline#forgelinewheels#forgedwheels#customwheels#forgedmonoblock#VX1R#forgelinevx1r#notjustanotherprettywheel#doyourhomework#madeinUSA#chevrolet#corvette#c8#c8corvette#c8stingray#c8corvettestingray#vengeanceracing

45 notes

·

View notes

Text

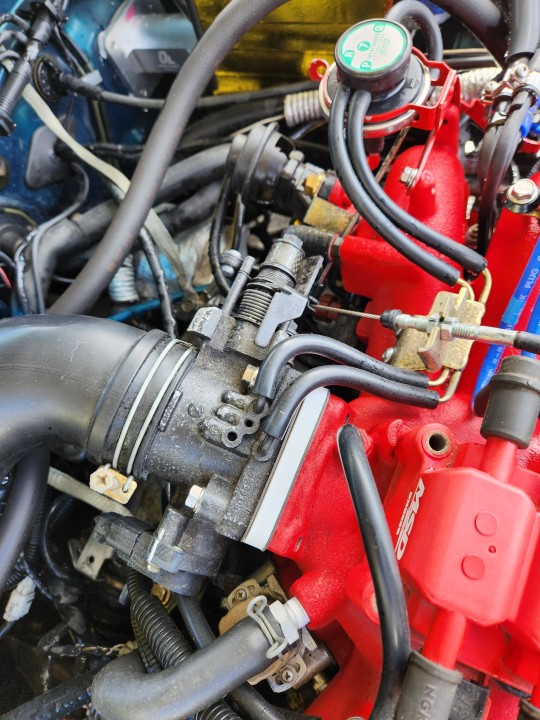

Since there has been some interest in my current intake, here is it broke down. I have tried numerous setups but this custom OEM+ version is the best and passes stupid SMOG visual check.

I also intensely studied the 2.5RS forums and looked at dyno charts showing that this IS the best when combined with a 2.25" cat back exhaust and equal length headers. Trust me!

This was a lot work as well as trial and error and willingness to start over again and redo it again several times. I think this was also the lightest combo if you trying to reduce weight.

One of a kind custom intake for the naturally aspirated Subaru EJ25D....

First up is you need the intake tract/duct and hoses from an earlier model Subaru Impreza or any Subaru that has this intake tube vs the stock version with the "torque box" behind the throttle body. Junkyard is your best buddy.

I had expensive high performance mandrel bent blah blah blah intakes which I constantly struggled with keeping the metal tubing cool (I used a laser temp gauge). This plastic is basically the same but rarely gets too hot to touch. So, actually a cold air intake if you keep reading.

Since the entire manifold needed to come out, I painted it wrinkle red and polished the runners and throttle inlet.

The reason I removed the manifold was to install stainless studs to make installing the 10mm thick teflon spacers and 2 sets of gaskets easier. Similar to 8mm Grimmspeed phenolic (previously installed) but thicker. This mod makes a big difference, the entire manifold now stays cool. No more engine block heat soak, only ambient engine bay heat.

"For every 5 degree reduction in temperature, increases power by 1%"

You have to extend the EGR tube and possibly grind your ignition coil pack mounts lower. Because the entire manifold assembly will be sitting ~12mm higher.

I was fortunate enough to work with the gasket maker. So he made 10mm teflon intake manifold spacers and a matching prototype 10mm throttle body spacer! Again 2 gaskets to ensure no leaks. Not sure if these were ever made available afterwards since I was the first car.

This spacer combo increased plenum volume as well as helped to keep heat transfer drastically reduced.

Using my custom ported, polished and knife edged throttle body that I did myself with the coolant hose permanently bypassed and the cruise control bits removed. Keep in mind you will need longer bolts if you use a spacer here. Definitely improved throttle response after just the throttle body swap.

I scored this GC8 v3 factory resonator/cold air intake inlet from the UK. It's what goes with those fender plugs. Grabs cold air from inside the fender behind the corner light up high, so no chance of sucking up water. FWIW, You really shouldn't just delete the "snorkus", seriously, it's just gonna mess up your MAF sensor.

I was also able to make the resonator from a SVX work in the 04 Outback with some persuasion. It too takes air from the same location but the box was hard to cram in the fender.

The intake tract will work with whatever air filter box but in order to use the EUDM WRX intake inlet/resonator you will need the matching filter housing box from an earlier model or have to drill a new mounting hole. You will need both halves!

BEST panel filter on the market IS made by Grimmspeed! Don't waste your money on any other filter! I also added a Filter Wears waterproof inlet cover/pre-filter to the resonator just incase of water spray. The factory option fender plug fills that hole.

And I'm not sure if this was an upgrade or not but here is the JDM JECS MAF I am also using. Used DEI gold heat reflective tape to keep it cool and extend the life. Possibly more consistent/accurate readings?

The only other things installed are a Weapon R catch can to the PVC, which DOES keep some crap out of the intake tract and off the throttle body but probably no real performance advantage. Plus a heat/flame resistant "sock", same as around my fluid reservoirs, over the bendy/flexible bit of the intake tract just after the MAF. That area is prone to splitting/cracking with heat and age!

Now for treasure at the end of the rainbow! I am actually gonna give you nerds the mother fucking part numbers! These can be life savers when searching for parts.

*You might have to make or reuse your PVC, crankcase, IAC valve hoses. So grab whatever is attached if your at the junkyard or hit up the auto parts store.

•Subaru PN's:

Intake duct/tract (EJ22): 14457AA111

Air filter housing/box: A53FA02 (upper) & A53FA01 (lower)

Fender resonator/snorkus (UK WRX): A21FA03 or A32FA01 or A21FA00

Fender plug: 46059FA000

•Grimmspeed PN's:

Dry-Con Air Filter: 060092

Intake manifold spacers (8mm phenolic): 015001

#subaru#custom#intake#mods#how to#diy#fyi#upgrades#naturally aspirated#ej25d#90s japanese cars#impreza#legacy gt#forester#my car#mecha gt#cold air intake#car parts#part numbers#oem+#the more you know#knowledge#tutorial#hp gains#boxer engine#subie#subienation#modified cars#2nd gen#bk6

19 notes

·

View notes

Text

Top Air Headers Manufacturer, Supplier, and Exporter in India - Mcneil Instruments

Mcneil Instruments is a leading manufacturer, supplier, and exporter of high-quality air headers in India, specializing in air header distribution manifolds for reliable air pressure control across industrial applications. Our air headers are available in a range of configurations, from 4-way to 16-way, with customized inlet, outlet, and drain connections, including ball and needle valves. Made primarily from durable SS316 and SS304, we offer various sizes, such as 2", 3", and 4" schedules 40, 80, and 160, to meet diverse specifications. Tested for quality and conforming to PED standards, Mcneil air headers are valued for their sturdy construction, attrition resistance, and centralized air distribution, making them ideal for gas and fluid systems across industries

0 notes

Text

How Exhaust Works for Car Speed?

Exhaust systems play a crucial role in enhancing a car's performance, including its speed and acceleration. Many car enthusiasts and performance tuners focus on upgrading exhaust systems to improve their vehicle's speed potential. In this article, we will dive into how exhaust systems impact car speed, breaking down each component and the science behind it.

The Role of the Exhaust System in Car Performance

An exhaust system's primary purpose is to remove harmful gases from the engine while reducing noise. However, the design and efficiency of an exhaust system can significantly influence the performance of your car, particularly in terms of speed and power output. A well-optimized exhaust system ensures the engine operates efficiently, leading to better combustion, higher horsepower, and faster acceleration.

1. Exhaust Flow and Engine Efficiency

The exhaust flow plays a pivotal role in how efficiently an engine performs. When the engine burns fuel, it produces gases that need to be expelled from the cylinders quickly and smoothly. The easier it is for the engine to expel these gases, the more efficient the combustion process will be. This directly impacts the car's speed because better engine efficiency means more power is available for acceleration.

2. Backpressure and Its Impact on Speed

One of the key factors in exhaust system performance is backpressure. Backpressure refers to the resistance the exhaust gases face as they exit the engine. While some backpressure is necessary for optimal engine performance, excessive backpressure can hinder engine efficiency. It prevents exhaust gases from leaving the cylinders quickly, which reduces the amount of fresh air that can enter the engine for combustion.

Reduced backpressure allows the engine to "breathe" better, improving the combustion process and, subsequently, the car's speed. Upgraded exhaust systems, such as free-flowing exhausts, are designed to minimize backpressure and maximize engine output.

3. The Relationship Between Horsepower and Exhaust Systems

Increasing the horsepower of a car is one of the primary ways to boost its speed, and the exhaust system plays a significant role in this process. By upgrading the exhaust, you allow the engine to generate more power by improving airflow and reducing resistance. A high-performance exhaust system, such as a cat-back or turbo-back exhaust, increases the horsepower of a car by optimizing the flow of gases.

For example, performance exhausts often include wider pipes or mandrel-bent tubing, which reduce restrictions and enhance the engine's ability to expel exhaust gases quickly. More horsepower means faster acceleration and a higher top speed.

4. The Importance of Exhaust Headers and Manifolds

Exhaust headers or manifolds are critical in determining how quickly the exhaust gases can escape the engine. Performance headers are designed to reduce backpressure and optimize the engine's airflow. By having equal-length headers, the exhaust gases from each cylinder reach the collector simultaneously, which eliminates bottlenecks and improves engine efficiency.

High-quality headers can significantly boost engine power, leading to faster acceleration and increased speed. These headers are often made from materials such as stainless steel, which are more durable and heat-resistant than the standard materials used in factory exhaust systems.

5. Mufflers and Speed: The Balance Between Performance and Sound

Mufflers are essential for reducing noise, but they can also impact performance. A performance-oriented muffler, such as a straight-through design, reduces backpressure and allows for a smoother exit of gases, improving overall engine performance. However, too much sound dampening can restrict airflow, which is why performance mufflers are designed to strike a balance between noise reduction and exhaust flow.

While factory-installed mufflers prioritize quietness, aftermarket performance mufflers focus on minimizing restrictions to ensure optimal power output. By allowing gases to escape more freely, these mufflers can contribute to faster speeds without sacrificing too much noise control.

6. Catalytic Converters and Their Role in Performance

While catalytic converters are primarily designed to reduce harmful emissions, they also play a role in the car's overall performance. A high-flow catalytic converter improves the exhaust system's efficiency by allowing exhaust gases to pass through more easily. This reduces backpressure and enhances the engine's ability to produce power.

By using a performance-oriented catalytic converter, you can maintain emissions standards while still improving engine efficiency and car speed.

7. Turbochargers and Exhaust Efficiency

For turbocharged vehicles, the exhaust system becomes even more critical. The turbocharger uses exhaust gases to spool up and increase the amount of air going into the engine, which boosts power. An efficient exhaust system allows the turbo to spin faster and with less resistance, improving both power output and speed.

Upgrading the downpipe (the part of the exhaust system that connects the turbo to the rest of the exhaust) is a popular modification for turbocharged cars. A larger, smoother downpipe reduces the restrictions on exhaust gases, allowing the turbo to operate more efficiently and improving the car's acceleration and top speed.

8. Exhaust Tips and Aesthetics: Do They Affect Speed?

Exhaust tips are often seen as purely aesthetic components, but their design can have a minor effect on performance. Larger exhaust tips can slightly improve exhaust flow by providing a wider outlet for gases to escape. However, this impact is minimal compared to other components like headers, mufflers, and catalytic converters. While exhaust tips may not drastically affect speed, they can still enhance the overall efficiency of the exhaust system when used in conjunction with other performance upgrades.

Optimizing Exhaust Systems for Maximum Speed

To achieve maximum speed from your vehicle, the entire exhaust system must be optimized for efficiency. This includes:

Reducing backpressure with performance headers and high-flow catalytic converters.

Enhancing exhaust flow with larger, mandrel-bent piping and free-flowing mufflers.

Upgrading turbochargers and downpipes to improve power output in turbocharged engines.

Balancing performance and noise control by choosing the right mufflers and exhaust tips.

These optimizations will allow your engine to generate more power, resulting in faster acceleration and a higher top speed. By upgrading your exhaust system, you can unlock the full potential of your car's engine, leading to significant performance gains on the road or track.

1 note

·

View note

Text

AIR HEADER Manufacturing in Gujarat: Leading the Way in Quality and Innovation

Introduction

In the realm of industrial applications, the importance of efficient air distribution cannot be overstated. This is where air headers come into play. As a crucial component in pneumatic systems, air headers ensure optimal airflow and pressure regulation. At Pedlock Valve, we are proud to be one of the leading manufacturers of air headers in Gujarat, known for our commitment to quality and innovation.

What is an Air Header?

An air header is a pipe or manifold that collects compressed air from multiple sources and distributes it to various outlets or machines. These headers are essential in industries such as manufacturing, automotive, and food processing, where consistent air supply is vital for operations.

Why Choose Pedlock Valve for Your Air Header Needs?

Quality Manufacturing At Pedlock Valve, we adhere to the highest standards of quality in our manufacturing processes. Our air headers are crafted from durable materials, ensuring longevity and reliability even in demanding environments.

Custom Solutions We understand that each industry has unique requirements. That’s why we offer customized air headers tailored to meet specific operational needs. Whether you need different sizes, materials, or configurations, we��ve got you covered.

Expertise and Experience With years of experience in the industry, our skilled team is well-equipped to handle complex projects. We leverage the latest technology and engineering practices to design and manufacture air headers that exceed expectations.

Timely Delivery We recognize the importance of time in industrial operations. Our streamlined production processes ensure that your orders are completed and delivered on schedule, minimizing downtime for your business.

Competitive Pricing Quality doesn’t have to come at a high cost. We strive to provide our clients with competitive pricing without compromising on the quality of our products. Our transparent pricing policy means no hidden costs or surprises.

Applications of Air Headers

Air headers are versatile and can be used across various sectors:

Manufacturing: Ensuring consistent airflow to pneumatic tools and machines.

Automotive: Used in assembly lines for air-powered equipment.

Food Processing: Maintaining hygiene and efficiency in production lines.

Construction: Powering tools and machinery on-site.

Conclusion

When it comes to air header manufacturing in Gujarat, Pedlock Valve stands out as a trusted partner. Our dedication to quality, custom solutions, and timely service ensures that your air distribution needs are met with precision. Explore our range of air headers and discover how we can support your business’s success.

For more information about our products and services, visit Pedlock Valve or contact us today!

0 notes

Text

The Leading Air Header Valve Manufacturer in India

Pedlock is one of the leading Air Header valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India. Our firms offered air headers are intended to lessen the number of potential break ways as opposed to creating Instrumentation associations with tubing.

Air header valves are employed in different trades to control or check the air pressure in transmission tubes. We offer Instrument Air Header valves in various dimensions and designs at competitive prices. Air header valves have the ability to replace numerous unit valve fabrications that generally operate from one source. They can be aptly used with a range of outlet take off valves. In this arrangement, the connection of the inlet can be screw able or flange. It is also possible to create a drain valve at the air distribution manifold outlet. For wall mounting use, a ‘U’ shaped clamp will be supplied.

What is an Air Header Valve?

An air header valve is a crucial component in pneumatic systems, primarily used in industries where compressed air or gas distribution is essential. These valves help distribute air from a central source to multiple outlets, ensuring smooth and controlled operation of various equipment and machinery Air Header valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India are widely used in oil and gas, petrochemical, chemical, pharmaceutical, and other industries requiring precise air or gas flow control.

Why Choose Pedlock as Your Air Header Valve Manufacturer?

Unmatched Quality and Durability

Pedlock prides itself on manufacturing Air Header valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India that are built to last. Each valve is crafted with high-grade materials and undergoes rigorous quality checks to ensure it meets international standards. This commitment to quality ensures that Pedlock's valves provide reliable performance even in the most demanding environments.

Innovative Design and Technology

At Pedlock, innovation is at the core of product development. The company's team of experienced engineers continuously works on designing air header valves that are not only efficient but also easy to install and maintain. By integrating the latest technology and design techniques, Pedlock ensures that its products remain at the forefront of the industry.

Customizable Solutions

Understanding that every industry and application has unique requirements, Pedlock offers customizable air header valve solutions. Whether you need a specific size, material, or configuration, Pedlock can tailor its products to meet your exact needs, providing a perfect fit for your system.

Competitive Pricing

Pedlock believes in offering high-quality products at competitive prices. The company's efficient manufacturing processes and strategic sourcing allow it to provide top-tier air header valves at prices that offer great value for money. This makes Pedlock an ideal partner for businesses looking to optimize their costs without compromising on quality.

Comprehensive After-Sales Support

Pedlock's relationship with its customers doesn't end with the sale. The company offers comprehensive after-sales support, including installation guidance, maintenance tips, and prompt customer service. This ensures that customers can rely on Pedlock for continued support long after their purchase.

Applications of Air Header Valves

Pedlock's air header valves are versatile and find applications in various industries:

Oil and Gas: For safe and efficient distribution of air in refineries and petrochemical plants.

Pharmaceutical: In clean room environments where precise air control is essential.

Manufacturing: For automation and control of pneumatic tools and equipment.

Automotive: In assembly lines and painting booths where air distribution needs to be regulated accurately.

Pedlock: A Trusted Name in Air Header Valve Manufacturing

With years of experience and a proven track record, Pedlock has established itself as a trusted name in Air Header valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India. The company's dedication to quality, innovation, and customer satisfaction has helped it build a strong reputation in the market.

Why Quality Matters in Air Header Valves

The quality of air header valves directly impacts the efficiency, safety, and reliability of the entire pneumatic system. Inferior quality valves can lead to leaks, pressure drops, and even system failures, causing costly downtime and potential safety hazards. By choosing Pedlock as your air header valve manufacturer in India, you can rest assured that you are getting products that are built to last and perform under the most demanding conditions.

Conclusion

As a leading Air Header valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India, Pedlock is committed to providing reliable, innovative, and sustainable solutions to meet your industrial requirements. Our dedication to quality, customer service, and continuous improvement makes us the preferred choice for businesses across various sectors.

#Air Header valve manufacturer in mumbai#Air Header valve manufacturers in Delhi#Air Header valve manufacturers in chennai#Air Header valve manufacturer in Bangalore#Air Header valve manufacturers in Rajasthan#Air Header valve manufacturer in ghaziabad#Air Header valve manufacturer in Gujarat#Air Header valve manufacturer in Vadodara#Air Header valve manufacturer in ahmedabad#High pressure Ball valve manufacturer in mumbai#High pressure Ball valve manufacturer in Delhi#High pressure Ball valve manufacturers in chennai#High pressure Ball valve manufacturer in Bangalore#High pressure Ball valve manufacturer in Rajasthan#High pressure Ball valve manufacturer in Ghaziabad#High pressure Ball valve manufacturer in Gujarat#High pressure Ball valve manufacturers in Vadodara#High pressure Ball valve manufacturer in Ahmedabad#Hydraulic Ball valve manufacturer in mumbai#Hydraulic Ball valve manufacturer in Delhi#Hydraulic Ball valve manufacturer in Chennai#Hydraulic Ball valve manufacturer in Bangalore#Hydraulic Ball valve manufacturer in Rajasthan#Hydraulic Ball valve manufacturer in ghaziabad#Hydraulic Ball valve manufacturer in Gujarat#SS Ball valve manufacturer in Mumbai#SS Ball valve manufacturer in Delhi#SS Ball valve manufacturer in chennai#SS Ball valve manufacturer in Bangalore#SS Ball valve manufacturer in Rajasthan

1 note

·

View note

Text

Air Headers valve manufacturer in India

We at Ped-lock valves and fitting provide high-quality valves for diverse applications and are one of the leading Air Headers manufacturers in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India. Our firms offered air headers are intended to lessen the number of potential break ways as opposed to creating Instrumentation associations with tubing.

Air headers are employed in different trades to control or check the air pressure in transmission tubes. We offer Instrument Air Headers in various dimensions and designs at competitive prices. Air headers have the ability to replace numerous unit valve fabrications that generally operate from one source. They can be aptly used with a range of outlet take-off valves. In this arrangement, the connection of the inlet can be screwable or flange. It is also possible to create a drain valve at the air distribution manifold outlet. For wall mounting use, a ‘U’ shaped clamp will be supplied.

0 notes

Text

Top Air Header Manufacturer in India - Arcellor Controls India

When it comes to precision engineering and top-tier quality in air header systems, Arcellor Controls India stands as the unrivaled leader in the industry. We specialize in crafting instrument air header solutions, and our commitment to excellence has earned us the reputation of being the foremost Air Header Manufacturer in India. Offering an extensive range of air headers in various sizes, specifications, standards, materials, grades, and types, we cater to diverse project needs, ensuring the highest standards for instrument air. Our global presence as an Air Header Exporter further sets us apart in the international market, making us your go-to source for superior quality and reliability in header air solutions.

Air Header

An air header refers to a component in industrial processes that is responsible for distributing compressed air to various pneumatic devices within a system. It typically consists of a manifold or a pipe system that collects and regulates the flow of compressed air from a centralized source, such as a compressor. The instrument air header ensures uniform pressure distribution and controls the direction of airflow to different branches or lines connected to it. This centralized distribution system facilitates efficient operation and control of pneumatic tools, valves, and other devices in industrial settings, contributing to the overall functionality and reliability of pneumatic systems.

Diverse Range of Air Headers:

At Arcellor Controls India, we understand that one size does not fit all. Hence, we bring forth a comprehensive range of Air Headers in various sizes, specifications, standards, materials, grades, and types. Our product line includes:

4-Way Air Header: Designed for efficiency and precision, our 4-Way Air Header is ideal for applications requiring controlled air distribution.

5-Way Air Header: With an extra outlet for enhanced versatility, our 5-Way Air Header ensures optimal performance in diverse industrial settings.

Air Header Distributor: Offering seamless distribution of air in your systems, our Air Header Distributor is a testament to reliability and durability.

12-Way Air Header With Stand: Engineered for projects demanding multiple outlets, our 12-Way Air Header with Stand provides a robust solution with added stability.

Pressure Air Header: Built to withstand varying pressure conditions, our Pressure Air Header ensures consistent performance under challenging environments.

Materials and Grades We offer - Air Header

With us, we construct the air header in various materials and grades including the following

Materials

Grades

Stainless Steel ASME B16.5

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel ASME

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel ASME B16.5

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60

Low-Temperature Carbon Steel

ASTM A350, LF2, LF3

Alloy Steel ASME 16.5

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel ASME B16.5

ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30)

Nickel Alloy ASME B16.5

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201),

Monel

Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500)

Inconel

Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600)

Hastelloy

Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

We also offer Instrument Air Header Made from other materials like aluminum, MS (Mild Steel Grades), and more, to our customers all across the globe!

Applications of Air Header

Air Header Plays a crucial role in maintaining proper pressure and flow control within the system. Here are some applications of air headers:

Instrumentation and Control Systems

Process Control

Pneumatic Tools

Safety Systems

HVAC Systems

Laboratory Equipment

Pneumatic Conveying Systems

Automated Manufacturing

Aerospace Industry

Clean Room Environments

Other Applications

Final Words!

Selecting the optimal Air Header is paramount for the triumph of your industrial ventures, and Arcellor Controls India stands out as the premier choice for astute customers. Boasting a diverse array of top-notch Air Headers, a global presence, and an unwavering dedication to customer contentment, we consistently lead the industry. We transcend the confines of the Indian market; we have positioned ourselves as a prominent Air Header Exporter on the global stage. Our products span the globe, reaching countries including Oman, Qatar, the USA, Germany, the UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. We take immense pride in delivering quality solutions adhering to international standards, ensuring that industries worldwide benefit from our expertise in instrument air and header air manufacturing. Connect with us today at [email protected] to encounter excellence in Air Header production and exportation. Your success is our paramount concern!

0 notes

Text

Air Header type and function application in instrument system

In the elaborate global of industrial automation, countless components paintings together to orchestrate complex approaches. While excessive-tech machinery and sophisticated control systems often take center stage, a much less glamorous but equally essential element perforan a important role – the air header. As a leading air header manufacturer and supplier we understand the importance of these unsung heroes. Today, we delve into the sector of air headers, exploring their kinds, functions, and programs in tool systems.

Demystifying the Air Header:

An air header, also known as an instrument air manifold, is basically a vital distribution factor for compressed air inside a device device. Imagine a sequence of pipes related collectively, with inlets for receiving compressed air and stores for channeling it to diverse contraptions and devices. This reputedly simple design offers a mess of benefits:

Centralized Control: The air header affords a single point of right of entry for controlling and regulating the compressed air supply. This simplifies device management and preservation for our clients.

Efficient Distribution: By putting off the need for personal air strains jogging to each tool, air headers ensure a green and uniform distribution of compressed air at some stage in the system. This translates to price savings and a streamlined design in your tool system.

Reduced Cost and Complexity: Air headers minimize the amount of piping required, leading to decrease set up and protection expenses. They also streamline the general system layout, an advantage we strive to deliver.

Safety Enhancement: Air headers can be prepared with safety capabilities like pressure remedy valves, supporting to shield the gadget from capability overpressure situations, presenting an extra layer of protection on your device gadget.

Types of Air Headers: Tailored Solutions from Instrumxx

We understand that a one-size-fits-all technique does not work. That's why we provide diverse air header configurations to cater to unique application necessities. Here's a breakdown of some not unusual types:

Simple Air Headers: These basic headers characterize a single inlet and a couple of outlets, supplying a trustworthy solution for distributing air to a limited number of instruments. Ideal for smaller structures.

Sectional Air Headers: These modular headers include interconnected sections, taking into consideration enlargement and customization as needed. This is ideal for structures with varying air needs or ability destiny increase, presenting flexibility for our customers.

Filtered Air Headers: These headers comprise filtration elements to get rid of contaminants from the compressed air circulation, protecting touchy devices from damage. Perfect for applications requiring easy air.

Regulated Air Headers: These state-of-the-art headers integrate strain regulators at each outlet, allowing unique management of the air pressure brought to individual instruments. Ideal for structures where instruments require varying stress degrees.

The Power of Application: Where Instrumxx Air Headers Shine

The air headers find software in an extensive range of tool systems throughout numerous industries. Here are a few distinguished examples:

Process Control Systems: In chemical processing plants, refineries, and other centers, the air headers supply compressed air to pneumatic actuators that function valves, dampers, and different control factors.

Instrumentation and Control Panels: Our air headers offer a dependable source of air for powering pressure gauges, transmitters, and other gadgets used for method monitoring and manipulation.

Pneumatic Tool Systems: Our air headers deliver compressed air for various pneumatic tools utilized in manufacturing, meeting strains, and protection programs.

Power Generation Plants: Our air headers play a function in powering managed structures and pneumatic instruments within energy plant life.

Choosing the Right Air Header: Expert Guidance from Us

Selecting the top-rated air header in your tool device requires careful consideration, we're here to assist. Here are a few factors to don't forget:

Flow Rate Requirements: Identify the full compressed air call for your devices to make sure the selected header has sufficient capability. Our crew can assist you with this calculation.

Operating Pressure: Match the air header's strain rating to the strain wishes of your instruments. We provide air headers for various strain tiers.

Number of Outlets: Choose a header with sufficient retailers to accommodate all of your units. We have an extensive range of options to fit your wishes.

Material Compatibility: Select an air header supplier appropriate for the kind of compressed air being used and the environment it'll function in. Our crew can advise on the most appropriate material.

Safety Features: Consider the need for pressure remedy valves or different safety features relying on your software. We offer air headers with diverse safety functions.

Conclusion: Instrumxx - Your Trusted Partner for Air Headers

By expertise in the types, features, and programs of air headers, you could admire their massive role in ensuring the smooth operation of your tool systems.

0 notes

Text

Air Header Manifold in Belgium - Baxcell

Looking for high-quality air header manifolds in Belgium? Baxcell offers premium air header manifolds designed to distribute compressed air to various instruments in industrial applications. Our air header manifolds are manufactured from robust materials, ensuring exceptional durability, corrosion resistance, and reliable performance in demanding environments such as petrochemical, oil and gas, and power plants.

0 notes

Text

1962 Plymouth Savoy Max Wedge: Unleashing the Power of Muscle

1962 Plymouth Savoy Max Wedge

In 1962, a new era of muscle cars emerged, radiating brilliance and power. Chrysler led the way with their groundbreaking Max Wedge lineup, introducing the world to the fusion of unitized-body construction and the high-performance ram-tuned dual-carbureted 413 CI engine. Among these legends was the Plymouth Savoy Max Wedge, a remarkable vehicle that holds a significant place in automotive history.

1962 Plymouth Savoy Max Wedge

1962 Plymouth Savoy Max Wedge

The First Super Stock Max Wedge with Manual Transmission According to the esteemed Chrysler Registry and the meticulous documentation by Darrell Davis, this specific Plymouth Savoy Max Wedge holds a groundbreaking distinction—it was the first Super Stock model equipped with a manual transmission. The car’s odometer displays a mere 6,593 miles and has undergone a meticulous restoration process to return it to its original specifications. Notably, the engine has been upgraded, boasting a dyno-proven power output exceeding 500 HP.

1962 Plymouth Savoy Max Wedge

Unleashing the Power of the 413 CI V-8 Engine The 1962 Plymouth Savoy Max Wedge was powered by the formidable 413 CI V-8 engine. This was the first iteration of Chrysler’s renowned ram induction system, featuring a cross-ram intake manifold meticulously designed to optimize engine efficiency. The engine’s performance was further enhanced by the utilization of cast-iron header-style manifolds, which were rarely preserved but featured in this exceptional vehicle. Dale Reed of California refreshed the engine around 300 miles ago, ensuring its optimal performance. The correct Carter AFB carburetors reside beneath dual black air cleaners, accentuated by carefully placed decals.

1962 Plymouth Savoy Max Wedge

1962 Plymouth Savoy Max Wedge

A Unique Manual Transmission Experience One of the distinctive aspects of this Plymouth Savoy Max Wedge is its manual transmission. Unlike its automatic counterparts, this car delivers a unique driving experience through its floor-mounted shifter, allowing the driver to truly feel the power at their fingertips. Paired with a full aftermarket exhaust equipped with cutouts and the robust 8 ¾ Chrysler differential, this Max Wedge offers an exhilarating ride for those who crave the thrill of the open road.

1962 Plymouth Savoy Max Wedge

Captivating Style and Authenticity The exterior of this Plymouth Savoy Max Wedge embodies the spirit of the era. Finished in captivating light blue paint, it exudes a timeless charm. The interior features a complementary blue cloth-and-vinyl combination, while the white-and-blue two-tone trim adds an elegant touch. The front and rear bench seats provide comfort, and the radio delete plate pays homage to the car’s performance-focused nature. Notably, it features a knee-knocker S-W column-mounted tachometer and a beautifully presented trio of rubber pedals. The car’s attention to detail is evident throughout, with the inclusion of circa-1962 chrome fonts, single-lens tail lamps, and OEM steel wheels adorned with poverty-type hubcaps.

1962 Plymouth Savoy Max Wedge

1962 Plymouth Savoy Max Wedge

Provenance and Documentation Accompanying this Plymouth Savoy Max Wedge is a wealth of provenance and documentation that adds to its allure. It includes the original OEM IBM punch card and build sheet, which serve as a testament to its authenticity. Additionally, the window sticker provides insight into its original specifications, while the dyno sheet confirms its impressive horsepower rating. Vintage photos capture the car’s early years when it was part of a famous drag car collection, showcasing its illustrious past.

1962 Plymouth Savoy Max Wedge

1962 Plymouth Savoy Max Wedge

Conclusion The 1962 Plymouth Savoy Max Wedge stands as a testament to the golden age of muscle cars. With its groundbreaking manual transmission configuration, powerful 413 CI V-8 engine, and captivating style, it represents the pinnacle of Mopar’s storied performance heritage. Meticulously restored to its original glory, this Max Wedge allows enthusiasts to experience a bygone era’s raw power and timeless charm.

FAQs: How many miles does the 1962 Plymouth Savoy Max Wedge have? The odometer of the 1962 Plymouth Savoy Max Wedge reads 6,593 miles. Who documented the Chrysler Registry for this particular car? The meticulous documentation of the Chrysler Registry for this car was done by Darrell Davis. Has the engine of the 1962 Plymouth Savoy Max Wedge been upgraded? Yes, the engine of this Plymouth Savoy Max Wedge has been upgraded to a dyno-proven 500-plus HP. What is the significance of the 413 CI V-8 engine in this car? The 413 CI V-8 engine in this car was the first to receive Chrysler’s shortened version of ram induction, known as the cross-ram intake. It maximizes engine efficiency and pairs it with rarely preserved cast-iron header-style manifolds. What documentation and provenance come with this Plymouth Savoy Max Wedge? This Plymouth Savoy Max Wedge comes with various documentation, including the OEM IBM punch card, build sheet, window sticker, dyno sheet confirming horsepower rating, and vintage photos of its early years as part of a famous drag car collection.

#Plymouth Savoy Max Wedge#Plymouth Savoy#plymouth#Max Wedge#car#cars#muscle car#american muscle#mopar#moparperformance#moparnation#moparworld

95 notes

·

View notes

Text

How Air Header are used in multiple industries

Air header, also known as air manifolds, play a vital role in multiple industries. The versatility of air header makes them indispensable in ensuring reliable and precise air distribution across various industrial sectors.

They are used to control and distribute compressed air or gases to various points within a system.

For more information visit our site: https://fidicondevices.com/how-air-header-are-used-in-multiple-industries/

0 notes

Text

Mike Savage New Canaan Top Five Classic Muscle Cars

Today the term muscle car refers for all sorts of cars with large engines and great performance. However, "back in the day" it described mid-sized automobiles that had big engines stuffed between the fender wells. Corvettes, Camaros, and Mustangs were not considered muscle cars by the purists. Even today many gear heads only consider the mid sized cars from the 1960's as true muscle cars. Everything else is a sports car, pony car or just a plain old car.

So what was the most important of these original muscle cars? We have chosen five of the most popular cars for a retro comparison to determine the king of the hill. The selectees are the 1961 Chevy Impala SS, the 1964 Pontiac GTO, the 1964 Ford Fairlane, the 1966 Dodge Charger and the 1968 Plymouth Road Runner. Let the showdown begin.

1961 Chevy Impala SS

Many consider this the first true muscle car. A 409 cubic inch motor was dropped into the Chevy Impala and a legend was made. With the help of the Beach Boys and their song about the car ('She's so fine, my four-oh-nine') it became an icon for the baby boomers. Chevy's marketing for the car described it as designed "for young men on the move...(who) won't settle for less than REAL driving excitement."

Mike Savage New Canaan

Performance was very good for the era with Motor Trend driving one from zero to sixty on seven seconds and completing the quarter mile in 14 seconds at 98 mph. The car became a legend.

1964 Pontiac GTO

The GTO was another marketing success for General Motors. Although the car was not the fastest car on the market it quickly became successful as an all a round muscle car. It was relatively affordable, relatively fast and relatively handsome. Many consider it the first modern muscle car. Although that is debatable, it is definitely the first successful muscle car in terms of sales.

Performance was very good with Car Life and Motor Trend both measuring zero to sixty times of less than seven seconds and quarter mile times of around 14 seconds.

1964 Ford Fairlane

In 1964 the Fairlane was redesigned and the tail fins were removed. Other improvements included upgrades to the suspension in order to improve ride-quality. Interior enhancements included full carpeting for the floors and turn signals that turned themselves off after the steering wheel was turned. However, the big news for 1964 was the Thunderbolt. The Thunderbolt was one of fastest dragsters ever produced by a manufacturer. Ford stuffed a heavily modified 427 cubic inch engine with two four-barrel carburetors mounted on a high-riser manifold into the relatively light weight Fairlane. The car had a ram-air induction system with air vents mounted in openings in the grill left by deleting the inboard headlights.

Other modifications included: equal-length headers, a trunk-mounted battery, fiberglass hood, doors, fenders and front bumper, Plexiglass windows, and other lightweight options included deleting the rear door window winders, carpeting, radio, sealant, sun visors, armrests, jack, lug wrench, heater, soundproofing, and passenger side windshield wiper. Performance was amazing. Gas Ronda dominated NHRA's 1964 World Championship by running his Thunderbolt through the quarter mile in 11.6 seconds at 124 mph. Later, the NHRA changed the rules to require 500 models of a car to be manufactured for Super Stock competition, and Ford, which had been losing $1500 to $2000 on each Thunderbolt sold at the sticker price of $3900, gave up. In the end, it was the NHRA and its ability to change the rules that stopped the Ford from dominating the drag strips for many years.

Although the Fairlane faded form Ford's performance spotlight as the Mustang took off. It came back in 1966 and 67 as a very nice looking car. Large engines 'encouraged' great performance numbers also.

1966 Dodge Charger

Although it resembled a Coronet with a fastback, the production Charger carried design cues from the Charger II concept car. Both maintained the swoopy fastback that was very popular during the mid-sixties. The electric shaver grill used fully rotating headlights that when opened or closed made the grill look like one-piece. Inside, the Charger used four individual bucket seats with a full length console from front to rear. The rear seats and console pad also folded down which allowed for more cargo room inside. In the rear the full length taillights carried the Charger name.

The car was radically different than anything else on the road and when fitted with a street Hemi it was one of the fastest cars on the road. A Hemi equipped car could do zero to sixty in less than seven seconds and the quarter mile in about 14 seconds. It was a big and radically designed car. And best of al, it was fast.

1968 Plymouth Road Runner

By 1968, muscle cars had become fast, luxurious and expensive. The young people that consisted of the primary market for these types of transportation had been priced out of the market. Plymouth recognized this and exploited to its fullest potential. First, the stripped down a Belvedere to its most basic form and then gave it a large motor. Then the marketing department found a simple way to change the image of the car from that of a bare bones racer to a unique automobile. A popular cartoon character and a unique horn was all that was need to bring this car to the masses.

The Road runner was an instant success. The combination of affordability plus outstanding performance had won the day again. Performance was remarkable with 13 second times for the Hemi and 15 second times for the base engine in the quarter mile.

The Winner

All five of these muscle cars were trend setters in their day. But the one that appeals to this author as the greatest of the early muscle cars is the 1966 Dodge Charger. It was a radical departure from the past with its fast back design and the four passenger bucket seats. It just looked like a muscle car. Performance was strong and the price was reasonable. The 1961 Chevy Impala Super Sport is a close second and if more had been made it may have actually won this little compression.

0 notes